1. Introduction

Accidents occurring within utility tunnels and standalone tunnels can be caused by various factors, significantly impacting facility operations and safety. In particular, complex facilities like utility tunnels pose a risk of rapid incident escalation, as their interconnected structure allows a single accident to spread easily to other facilities. Due to these characteristics, there is a high likelihood of various issues arising, such as fire, flooding, condensation, and external intrusion. Therefore, it is crucial to anticipate these issues in advance and establish systematic response measures.

If such measures are not established, minor issues or hazard events can escalate into major accidents, potentially causing casualties and property damage within the facility. For example, if a fire occurs in a utility tunnel and the initial response is delayed, the fire can spread rapidly, affecting the entire structure. Similarly, if flooding is not properly managed in its early stages, there is a risk of damage to critical equipment and electrical systems, which could lead to operational shutdowns or large-scale losses. To prevent such incidents, a systematic management and response plan for each potential issue must be implemented in advance.

However, despite the growing number of incidents and the complexity of facilities, there is still no standardized framework for systematically classifying hazard events and defining response levels in utility tunnels. Existing studies mainly focused on individual hazards, such as fire or flooding, without integrating them into a unified management system.

The motivation for this study arises from recent large-scale fire and flooding incidents in urban utility tunnels in Korea, which revealed significant limitations in existing management systems. The absence of clear hazard classification and stage-based response procedures has often resulted in delayed actions and inconsistent decisions among facility managers.

Most accidents that occur in utility tunnels and standalone tunnels follow predictable patterns. Therefore, it is essential to analyze these patterns and establish management and response strategies tailored to each situation. To achieve this, the first step is to define various hazard events that may arise within utility tunnels and set criteria for determining when these conditions become problematic. Additionally, a step-by-step analysis of risk factors for each hazard event should be conducted, followed by the development of appropriate management methods. This will enable facility managers to respond effectively and appropriately to potential incidents.

In particular, data collection on hazard events that may occur within utility tunnels is a crucial aspect of establishing a response system. Identifying and appropriately defining these hazard events is the first step in developing effective management measures. While potential issues may vary depending on the structure and characteristics of each facility, defining and categorizing them based on common criteria can help facility managers respond more consistently and promptly. For example, in the case of a fire, the initial stage may involve monitoring risk factors during the attention phase, followed by escalation to caution, warning, and critical stages, with appropriate responses at each level. By systematically establishing such a step-by-step response plan, confusion during actual incidents can be minimized, enabling a faster and more effective response.

Additionally, issues such as condensation and external intrusion can occur more frequently depending on the structural characteristics of the facility and external environmental factors. In such cases, a management system that allows real-time monitoring and immediate implementation of appropriate countermeasures when hazard events arise is essential for the efficient and safe operation of utility tunnels. Condensation can result from humidity and temperature differences within the facility, potentially damaging equipment and structures. Therefore, preventive management strategies should be established to mitigate condensation issues before they occur. Furthermore, if condensation does arise, a step-by-step response plan must be in place to minimize damage. For external intrusion, enhancing the facility’s security system is crucial. It is also important to integrate the security system with the response framework to ensure a rapid and appropriate reaction when an intrusion is detected.

As such, the management and response system for various potential issues within utility tunnels is of critical importance. Therefore, this study aims to systematically analyze accident risks, define these issues as hazard events, and develop a structured framework that outlines risk levels, management measures, and response strategies for each stage. To achieve this, major accident cases in both utility tunnels and standalone tunnels will be investigated. Based on the findings, detailed response scenarios will be developed to ensure that facility managers can take appropriate actions at each stage. Specifically, this study aims to define representative hazard types that can occur in utility tunnels, establish response stages for each hazard, and propose corresponding detection methods and management measures suitable for real-world application. The primary goal of this study is to establish a systematic management framework that enhances response capabilities. Through this research, we expect to improve facility management efficiency, strengthen safety within utility tunnels, and contribute to accident prevention. In summary, this study addresses the urgent need for a standardized and integrated response framework for hazard events in utility tunnels. By analyzing representative hazard cases and defining stage-based response procedures, this research provides a foundation for improving practical safety management and policy implementation in underground infrastructure systems.

2. Case Study

Hazard events that can occur in utility tunnels include fire, flooding, condensation, structural damage, and external intrusion. These situations pose serious threats to facility safety, and if an incident occurs, it can lead to significant human casualties and economic losses. For example, in the event of a fire, smoke can spread rapidly, making evacuation difficult, while flooding or condensation can cause electrical system failures, potentially paralyzing the entire infrastructure. Therefore, it is crucial to quickly detect hazard events in utility tunnels and implement appropriate response measures.

This study investigated cases of hazard events in utility tunnels and standalone tunnels based on references [

1,

2]. Among the recorded incidents, fire accounted for the highest proportion (

Figure 1). The scale of damage ranged from 50 million KRW to over 15 billion KRW. In addition to direct property losses, secondary damages were also identified, including the destruction of communication cables, telephone outages affecting over 3000 households, power outages for approximately 200 households, and disruptions in communication networks and computing systems. The primary causes of fire were identified as electrical fires, with contributing factors including insulation failures leading to short circuits, electrical faults, lightning strikes, welding mishaps during maintenance, and unidentified causes. Apart from fire, flooding was another frequently occurring incident. The main causes of flooding in utility tunnels were identified as leakage due to pipe damage and stormwater inflow caused by heavy rainfall.

Table 1 presents the recorded cases of hazard events in utility tunnels and standalone tunnels.

3. Summary of Hazard Events in Utility Tunnels

Utility tunnels are critical facilities that integrate key infrastructure such as electricity, telecommunications, gas, and water supply. The safety of these facilities directly impacts the national economy and the daily lives of citizens. Therefore, it is essential to proactively assess and prepare for various potential hazards. In this study, in addition to fire and flooding, which have been identified as major safety concerns due to past incidents in utility and standalone tunnels, we aim to explore additional factors that could pose safety risks within these facilities.

Ref. [

3] conducted a survey involving a total of 15 managers working in six different utility tunnel sites. According to the study “Research on Risk Factors and Control Levels through a Survey of Utility Tunnel Personnel,” 10 respondents identified surface condensation prevention as the most critical aspect of utility tunnel maintenance and management. Surface condensation is a critical factor that must be identified and managed, as it can serve as a precursor to flooding, increase the risk of electrical fires due to leakage currents, and accelerate pipeline corrosion, among other potential hazards.

The intrusion of wild animals and unauthorized individuals, pipeline corrosion and pressure fluctuations, and damage caused by nearby underground construction are also critical risk factors that can lead to serious issues. Therefore, this study includes these factors in the list of hazard events requiring management within utility and standalone tunnels, ensuring a comprehensive approach to risk assessment and mitigation.

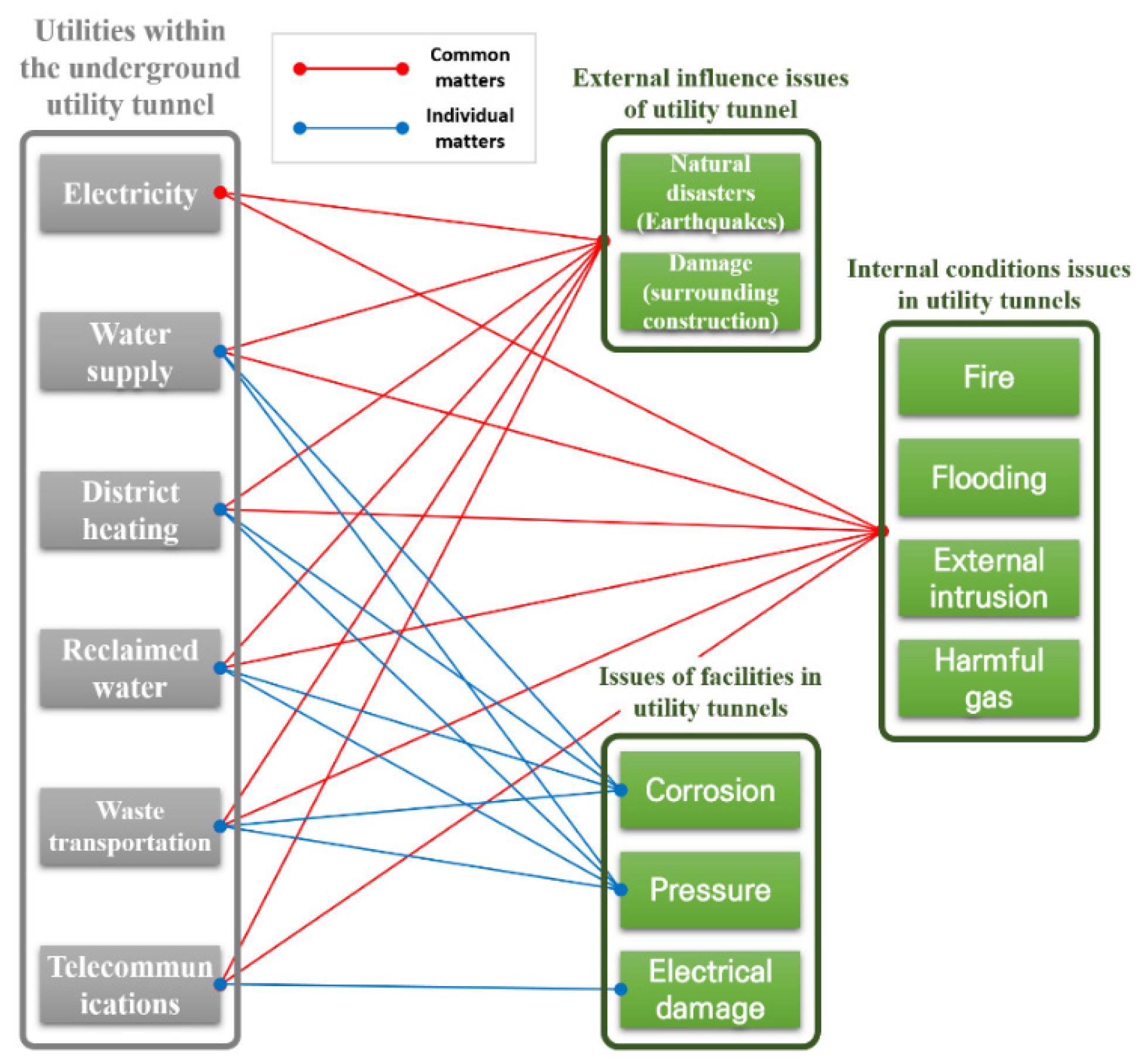

As a result, the hazard events that may occur in individual pipelines within utility and standalone tunnels can be categorized into three main groups: issues caused by external influences, internal conditions issues in the utility tunnel, and issues of facilities in the utility tunnel. These classifications are summarized in

Figure 2.

While Chung et al. [

4] developed complex-disaster scenarios linking fire, flood, and seismic events for digital-twin simulations, the present study integrates such multihazard interactions into a unified response framework that can be directly applied to real-time hazard management within utility tunnels.

4. Design of Response Stages for Hazard Events

This study aims to design response stages and scenarios for ten types of hazard events: natural disasters, structural damage, fire, flooding, condensation, external intrusion, hazardous gases, pipeline corrosion, pipeline pressure fluctuations, and electrical damage/interference. However, since these hazard events are categorized based on their causes, some may be managed using the same response procedures or may be addressed concurrently during the resolution of other hazard events. Having separate response stages and scenarios for each event could increase procedural complexity rather than improving efficiency. Therefore, it is necessary to simplify the number of scenarios by analyzing the event flow and interrelationships among the different hazard events.

Fire can be classified into arson-induced fires and fires caused by electrical faults, such as leakage currents and short circuits. Arson-induced fires are caused by external intruders, so they can be addressed in the external intrusion scenario. Fires caused by electrical faults can be included in the fire response stages and scenarios by monitoring heat generation due to electrical damage and interference. If the fire spreads due to failure in early intervention during the heat generation phase, high oxygen consumption and carbon dioxide production will occur. Additionally, the combustion of insulation materials and other coverings may release various hazardous gases. Therefore, monitoring hazardous gas emissions must be included in the fire response scenario, and hazardous gas-related scenarios should also be integrated into the fire response stages and scenarios.

Similarly, pipeline corrosion can be managed in advance through condensation prevention, so it should be included in the condensation prevention response stages and scenarios. Likewise, sudden pressure fluctuations in pipelines can act as an initial stage of leakage and flooding, so they should be addressed within the flooding response stages and scenarios.

Therefore, by reorganizing the original 10 hazard events from a response and management perspective, five key hazard events will be defined for response stage development and scenario design: damage due to external impact, fire, flooding, condensation, and intrusion. Additionally, for critical hazard events that require emergency measures and external intervention, the four-stage crisis alert system (Attention, Caution, Warning, and Critical) outlined by the Ministry of Land, Infrastructure and Transport (2019) [

5] will be applied as a principle. The division of response phases was established with reference to the standards and guidelines provided by the National Fire Agency (2023) [

6], the Ministry of Employment and Labor (2024) [

7], and the Ministry of Land, Infrastructure and Transport (2023) [

8]. However, post-disaster recovery and restoration stages will be excluded, and the study will focus solely on identifying early warning signs and establishing response strategies.

4.1. Fire Response Stage Development and Scenario Design

While Seo et al. [

9] developed a construction-phase fire-risk scenario using cause–consequence analysis to predict potential hazards, their scope was limited to fire events and did not address multi-hazard response or operational-phase decision making. In contrast, this study establishes a standardized four-stage framework applicable to various hazard types—including fire, flooding, and condensation—within operational utility tunnels, thereby providing an integrated basis for multi-hazard response management. Following the quantitative risk-evaluation concepts of Niu et al. [

10], the threshold levels in each stage were derived to ensure consistency between hazard severity and managerial response.

Based on the Ministry of Land, Infrastructure and Transport (2019) [

5], the risk levels and severity of warning signs at each stage have been summarized. The Attention Stage refers to a phase where no actual hazard events, disasters, or accidents have occurred yet, but the risk of occurrence is high due to noncompliance with relevant safety regulations. At this stage, the focus is on establishing safety standards and monitoring systems to prevent human-related disasters in advance. The Caution Stage is an early risk phase where elements leading to hazard events have actually occurred, but the situation has not yet escalated into a full-scale disaster or emergency. In the case of fire, this stage includes overheating, overload, and sparks or heat generation due to leakage current. At this point, a rapid initial response by nearby personnel can prevent the situation from developing into a disaster or emergency. The Warning Stage is the phase just before the outbreak of visible flames, where additional risk factors such as cable melting due to heat generation and the release of hazardous gases begin to emerge. At this stage, rapid preparation for disaster response and the evacuation of workers are required. The Critical Stage is a high-risk phase where fire and high concentrations of smoke are actively present, posing a serious threat to human life. At this stage, fire response is no longer manageable by onsite workers or facility managers alone; instead, a broader response from governmental and emergency agencies is required for large-scale intervention. In practice, the response-system optimization model developed by Cai et al. [

11] illustrates how the proposed stage-based framework can be operationalized for gas-leakage emergencies through adaptive coordination of ventilation rates and shut-down valve actuation. Next, based on the four-stage classification, the factors that can be detected and identified at each stage are defined. Additionally, the response measures for nearby workers and facility managers within the utility tunnel at each stage are outlined. These details are summarized in

Table 2. Also, the response scenario for facility managers is as

Figure 3.

4.2. Flood Response Stage Establishment and Scenario Design

According to Lee et al. [

12], the causes of flooding in underground utility tunnels can generally be categorized into two main types: flooding due to poor drainage in low-lying underground facilities and flooding caused by the detachment or damage of water conduits. Therefore, this study considers both external inflows and internally generated water as factors contributing to flooding and as key elements in developing response measures. However, as the aforementioned study does not specify distinct emergency response stages for flooding incidents, this study adapts the crisis alert levels proposed by the Ministry of Land, Infrastructure, and Transport (2019) [

5] for fire-related incidents to better suit flooding scenarios.

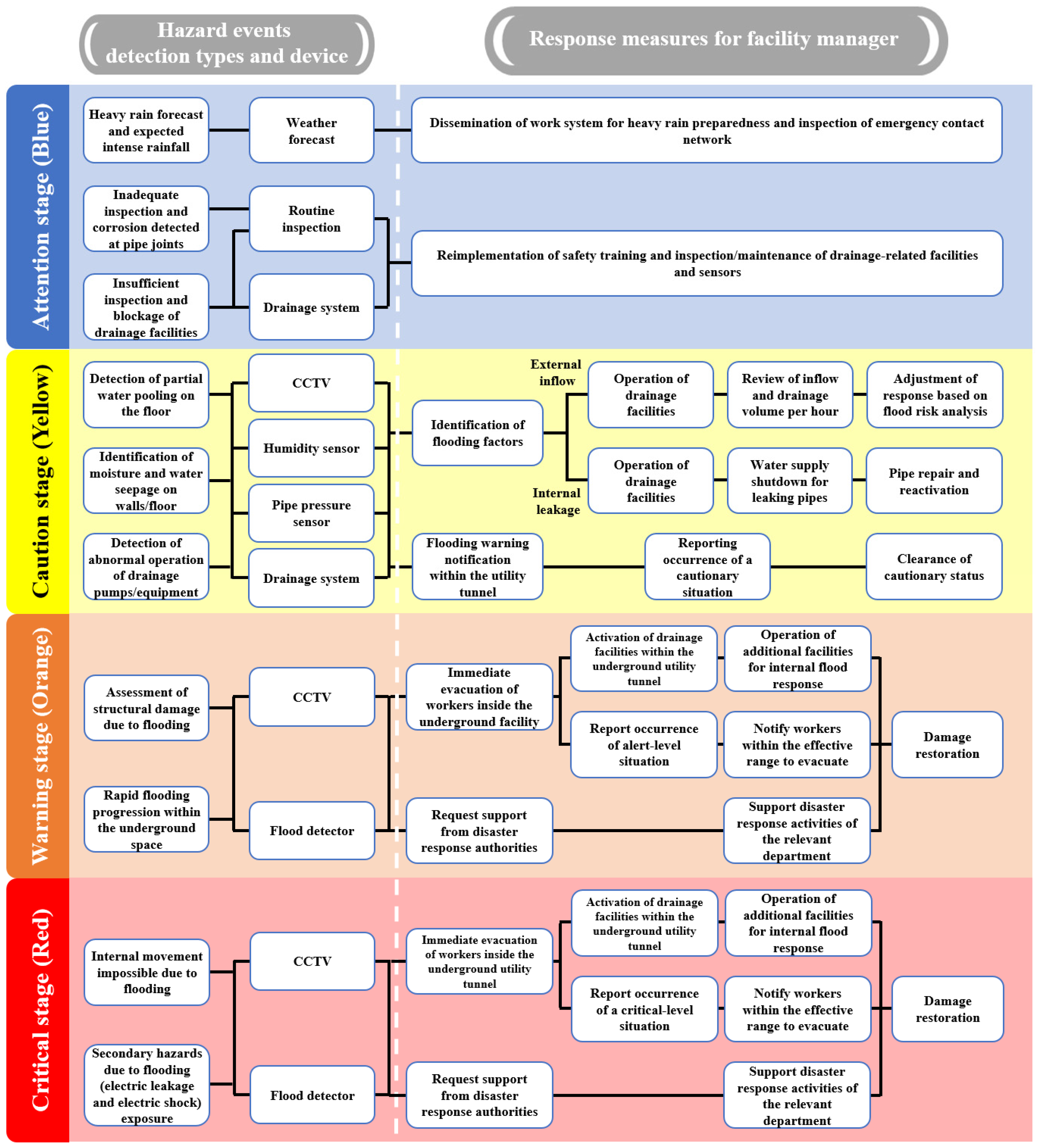

Table 3 presents the scenario for flooding, and its visualization is shown in

Figure 4.

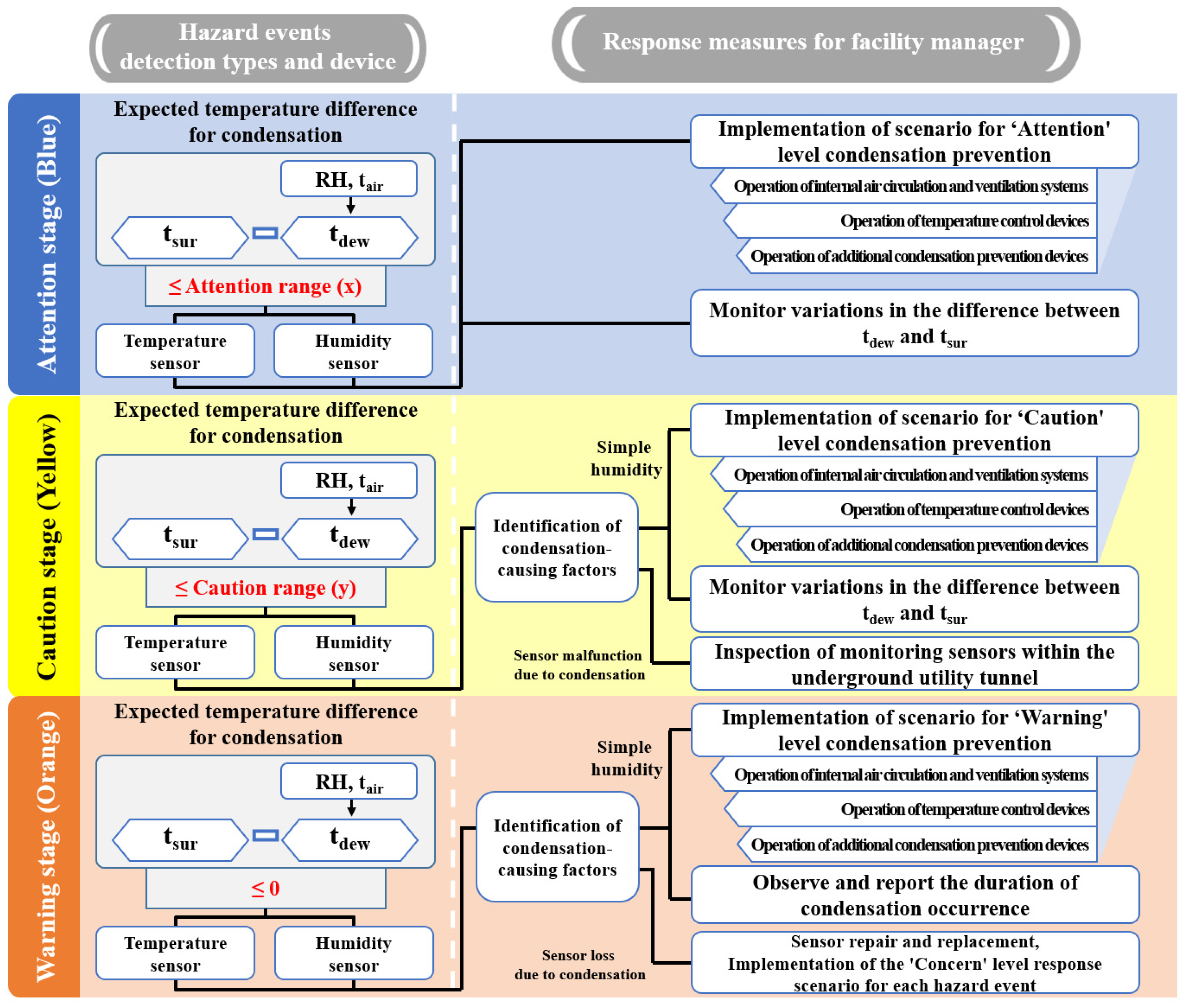

4.3. Condensation Response Stage Establishment and Scenario Design

Condensation is not hazard event that rapidly develops into a major hazard, causing significant casualties, like fire or flooding. However, prolonged exposure can lead to secondary damage, such as leaks and flooding due to pipe corrosion, or electric shock and short circuits from moisture affecting power lines. Therefore, condensation requires continuous condition monitoring and management to prevent such secondary hazards (

Table 4). Research on preventing condensation continues to be actively conducted [

13,

14,

15]. In this study, the primary objective is to maintain an efficient environment that prevents condensation. However, if condensation occurs due to external or internal factors, the response stages are designed to ensure its removal as quickly as possible to maintain a safe and comfortable environment within the utility tunnel. Consequently, instead of the four-stage system applied to fire and flooding, a three-stage management approach is proposed, excluding the critical stage. Unlike other hazard events, condensation is managed with three stages because its progression beyond the warning stage typically leads to secondary hazards such as fire, flooding, or intrusion caused by sensor or control device failures. In other words, the critical stage of condensation corresponds to the onset of these subsequent hazard events.

Before defining the hazard event factors for each stage of condensation, it is essential to conduct a preliminary assessment of the potential for condensation. This assessment should determine whether there are any risk factors that could lead to condensation in the future based on the current conditions, how much preparation time is available if condensation becomes likely, and what procedures should be implemented to prevent condensation. To achieve this, obtaining precise data on these factors is necessary. Therefore, this study follows Murray [

16] in deriving the dew point temperature (the temperature at which moist air cools and water vapor condenses into dew, leading to condensation) based on the dry-bulb temperature (the current temperature measured by an exposed external sensor) and relative humidity. By analyzing the difference between the surface temperature and the dew point temperature under the current humidity conditions, the study aims to adjust the condensation risk level accordingly. The formula for deriving the dew point temperature using dry-bulb temperature and relative humidity is as follows. According to Murray [

16], the difference between empirical formulas for saturation vapor pressure is less than 0.5% within the meteorological temperature range. Therefore, this formula provides sufficient accuracy for estimating the dew point temperature under typical environmental conditions in utility tunnels.

where e

s = saturation vapor pressure (P

a); t

air = dry-bulb temperature (°C).

where e

a = actual vapor pressure (P

a); RH = relative humidity.

where t

dew = dew point temperature (°C).

Based on the formula, surface condensation occurs when the dew point temperature (t

dew) is equal to or higher than the surface temperature (t

sur) of structures such as walls or ceilings, as well as pipes within the utility tunnel (t

dew ≥ t

sur). The dew point temperature represents the lowest possible temperature at which the current amount of moisture in the air can be retained. If the surface temperature is equal to or lower than the dew point temperature, the amount of moisture that can be held in the air at the current dry-bulb temperature becomes lower than the actual moisture content in the air. As a result, the excess moisture that cannot be retained in the air reaches saturation and condenses on facility surfaces and walls. To address condensation-related hazard events, a three-stage response system (Attention, Caution, and Warning) is defined. The specific levels of hazard events and corresponding response measures for each stage are summarized in

Table 4.

In the case of condensation, differences in the internal structure of individual utility tunnels and surrounding environmental factors can significantly affect the response speed and the time required for condensation mitigation at each stage (Attention, Caution, and Warning). Therefore, this study does not explicitly define fixed stages for condensation prevention. Instead, it applies a “predefined dew point temperature and surface temperature difference range” set individually at each site as the classification criterion for each stage, allowing for situational adjustments based on onsite conditions. The ultimate goal of this study is to ensure that ventilation and airflow procedures are initiated at the appropriate time to prevent condensation inside utility tunnels. Thus, it is recommended that each site determine an appropriate dew point temperature and surface temperature difference range that allows sufficient response in the Attention and Caution stages to prevent escalation to the Warning stage. This determination should be based on changes in relative humidity due to ventilation and reductions in dry-bulb temperature through airflow at each site. Based on the hazard events detection factors and response measures for each stage of condensation, the response scenario for facility managers is as

Figure 5.

4.4. Damage Response Stage Establishment and Scenario Design

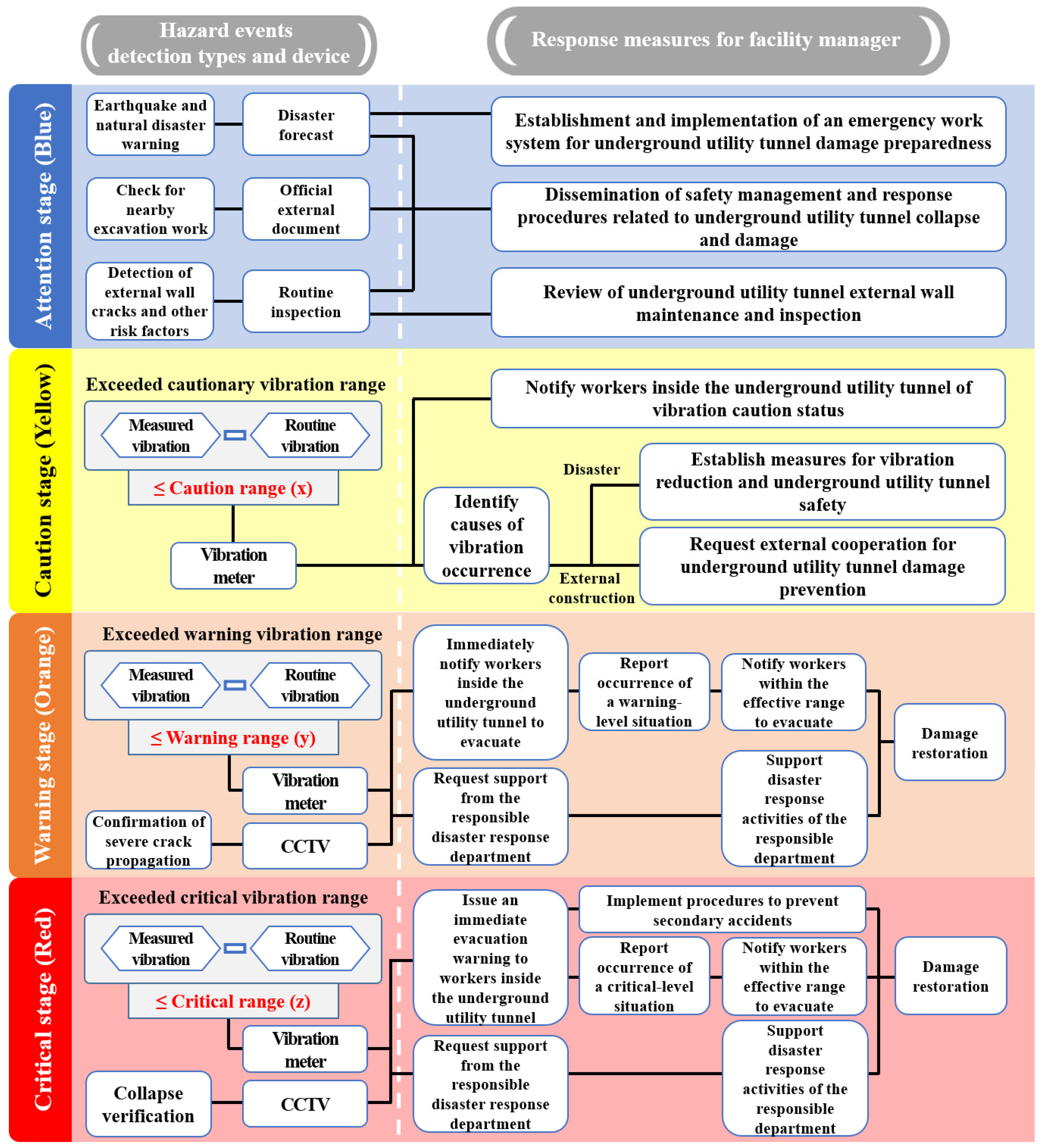

Natural disasters such as earthquakes and external construction involving underground excavation do not directly impact the pipelines within the utility tunnel. However, they can cause damage to the outer walls of the tunnel, leading to the infiltration of groundwater, rainwater, and soil, which may result in operational paralysis and risks such as tunnel collapse. Therefore, continuous monitoring of various factors affecting the structural integrity of the tunnel walls, including impact, load, and vibration, as well as a rapid response to related hazard events, is essential.

As with flooding, damage caused by external factors has not been explicitly classified into separate response stages for collapse risk. Therefore, this study adapts and applies the crisis alert levels for fire incidents proposed by the Ministry of Land, Infrastructure, and Transport (2019) [

5] to damage caused by external factors. Based on a four-stage system, this study defines the factors that can be detected and identified at each hazard event stage and organizes the response measures for nearby workers and facility managers within the utility tunnel at each stage. These details are summarized in

Table 5, and the hazard event response scenario for damage is illustrated in

Figure 6.

In the case of utility tunnel damage risks caused by external impacts, differences in the internal structure of individual tunnels and surrounding environmental factors can significantly affect the response speed and critical elements at each stage (Attention, Caution, Warning, and Critical). Therefore, this study does not explicitly define fixed response stages for damage caused by external impacts. Instead, it applies a “predefined abnormal vibration range that exceeds the normal measurement range at each site” as the classification criterion for each stage, allowing for situational adjustments based on on-site conditions. For example, the Attention stage can be defined as up to a 25% increase in vibration from the normal measurement range, the Caution stage as a 25~50% increase, the Warning stage as a 50~100% increase, and the Critical stage as an increase exceeding 100%. However, it is recommended that each site determine an appropriate threshold based on local environmental factors to ensure an effective response system.

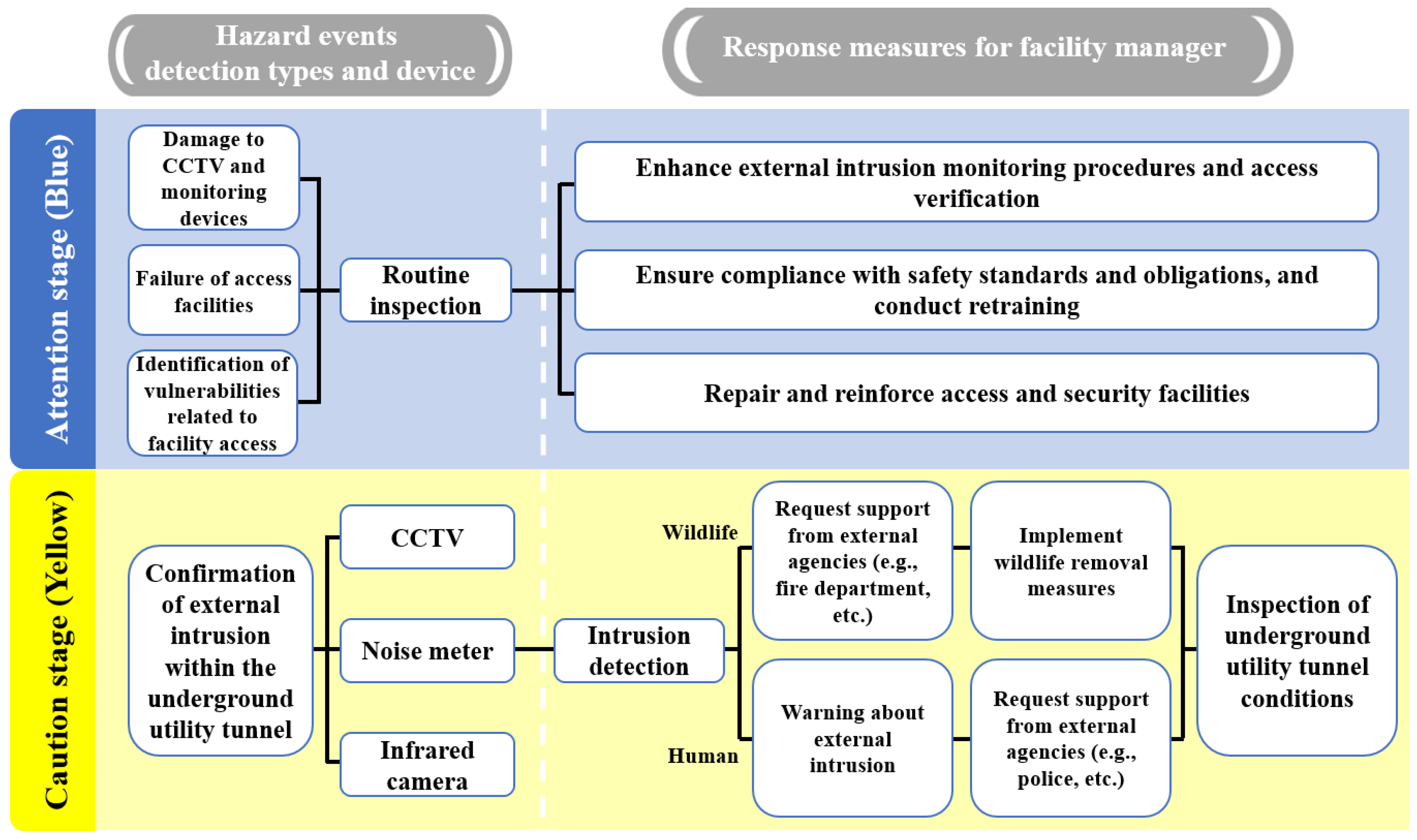

4.5. Intrusion Response Stage Establishment and Scenario Design

The utility tunnel is a facility that, due to its designation as a national critical facility and a national security target facility, restricts access to unauthorized individuals in principle. To fundamentally block disruptions to distribution and supply operations caused by damage and destruction of internal utility pipelines, strict access control and a rapid response to intruders are required. As with damage caused by external factors and flooding, it has been found that no separate hazard event response stages have been defined for external intrusion. Therefore, this study adjusts and applies other response stages to align with the key elements of intrusion response. Since unauthorized access to the utility tunnel is fundamentally impossible, the intrusion response stages proposed in this study are set to two levels: the “Attention” stage, in which vulnerabilities in access and security facilities that may lead to unauthorized entry are identified and require reinforcement measures, and the “Caution” stage, in which an intruder is detected and response actions are performed. These are summarized in

Table 6, and the hazard event response scenario for facility managers is illustrated in

Figure 7.

5. Conclusions

This study aimed to systematically analyze various accident scenarios that may occur in utility tunnels and standalone tunnels in Korea and, based on this analysis, define hazard events and establish step-by-step response measures. Issues such as fire, flooding, condensation, structural damage, and external intrusion can significantly impact the safety and management of facilities, making it crucial to recognize these risks in advance and respond appropriately. In particular, the study focuses on defining risk factors and management strategies for each hazard event by stage and designing response scenarios that enable facility managers to take swift and effective action based on these predefined measures.

The fire scenario is classified into four stages: the Attention stage, where no fire has occurred but there is a violation of safety regulations; the Caution stage, where fire risk factors are present but no fire has yet ignited; the Warning stage, where a fire has occurred; and the Critical stage, where the fire poses a significant threat of severe damage. Similarly, the flooding scenario is also categorized into four stages: Attention, Caution, Warning, and Critical, following the same structure as the fire scenario. Each stage includes detection devices for identifying flooding and corresponding response measures.

Unlike fire and flooding, condensation does not rapidly escalate into a major hazard but can cause secondary damage if exposed for an extended period. Therefore, this study examines the causes of condensation (tdew ≥ tsur) based on existing literature and classifies the response into three stages: Attention, Caution, and Warning. The response stages are designed to eliminate condensation as quickly as possible, ensuring a comfortable and safe environment within the utility tunnel.

In the case of structural damage risk, differences in the internal structure of the utility tunnel and surrounding environmental factors can significantly affect the response speed and key elements at each stage (Attention, Caution, Warning, and Critical). Therefore, this study does not explicitly define fixed response stages for damage caused by external impacts. However, a four-stage scenario (Attention, Caution, Warning, and Critical) is proposed to allow for appropriate threshold settings based on environmental factors at each site. For intrusion, the response scenario is set to two stages: the Attention stage, where vulnerabilities in access and security facilities are identified, and the Caution stage, where an intruder is detected and response actions are taken accordingly.

In complex facilities such as utility tunnels, rapid response in the event of an accident is of utmost importance. To achieve this, it is essential to predict potential incidents in advance and establish a prepared response system. This study aims to provide practically applicable response scenarios by developing a step-by-step response system tailored to each issue. Although the framework was primarily developed for operational decision-making, its structured response stages and detection-response mapping can also serve as reference data during the design phase. Engineers can utilize these elements when planning sensor layouts, establishing alarm thresholds, and integrating automated control systems for hazard prevention. Through this approach, it is expected to enhance facility management efficiency, minimize damage in the event of an incident, and contribute to the creation of a safe operational environment.

Future research will require a refinement process based on feedback from actual field operations, focusing on the types of hazard events, classification of response stages, and response scenarios for each stage. In addition, future work will address the analysis of compound and cascading disasters that were beyond the scope of this study. Specifically, it will focus on (1) compound hazards occurring when two different disaster events take place within the same section, and (2) simultaneous hazards arising in different sections of a utility tunnel. Moreover, cascading disasters, such as electrical leakage and subsequent fire or explosion caused by flooding, will be examined to develop an interconnected and adaptive response framework. Future research may also adopt data-driven approaches such as the interaction-based deep-learning framework proposed by Xue et al. [

17], enabling real-time hazard evaluation and adaptive decision-making within the proposed response framework.