A Streamlined Polynomial Regression-Based Modeling of Speed-Driven Hermetic-Reciprocating Compressors

Abstract

1. Introduction

2. Methodology

2.1. Analytical Procedures

2.2. Mathematical Model

3. Results

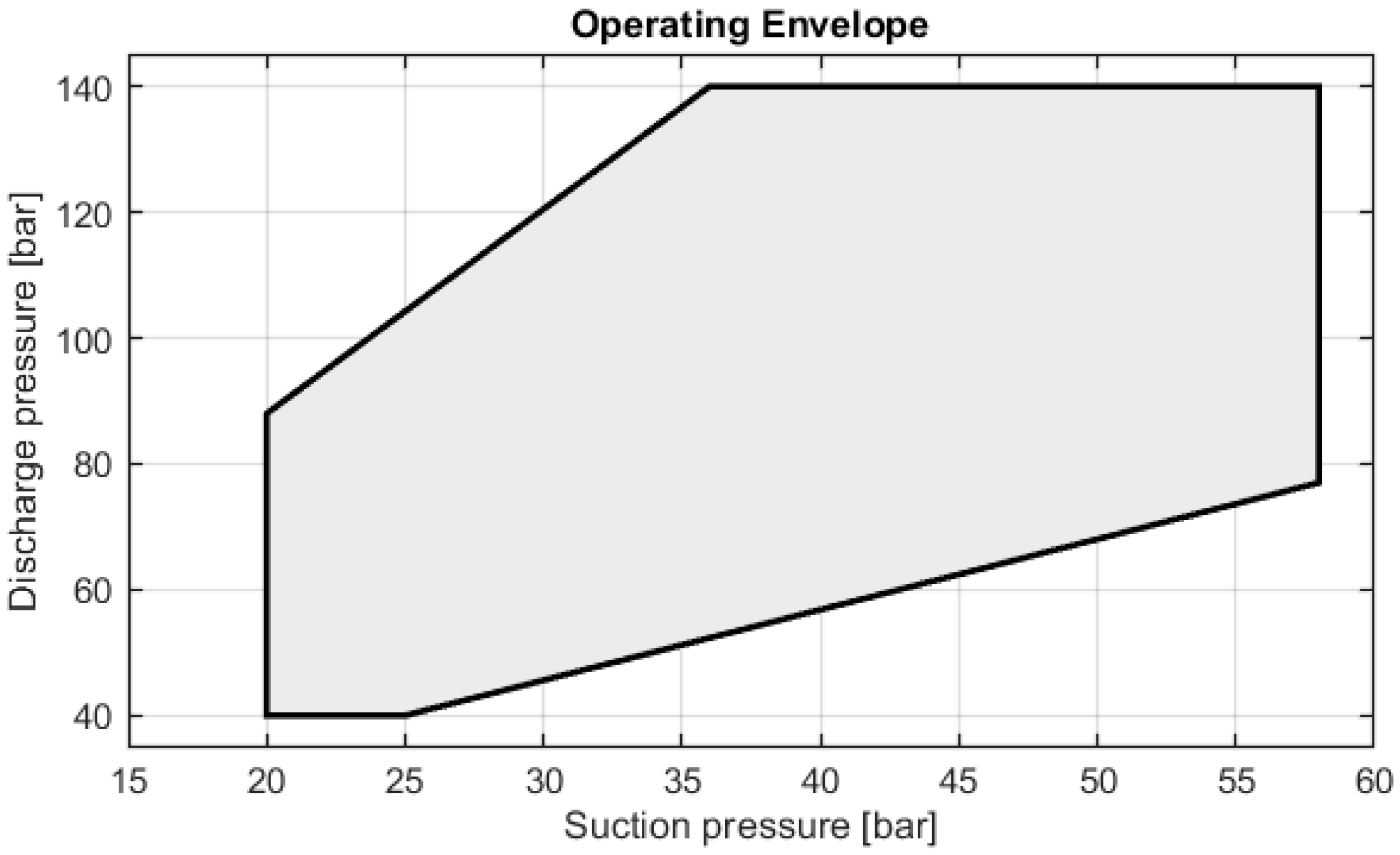

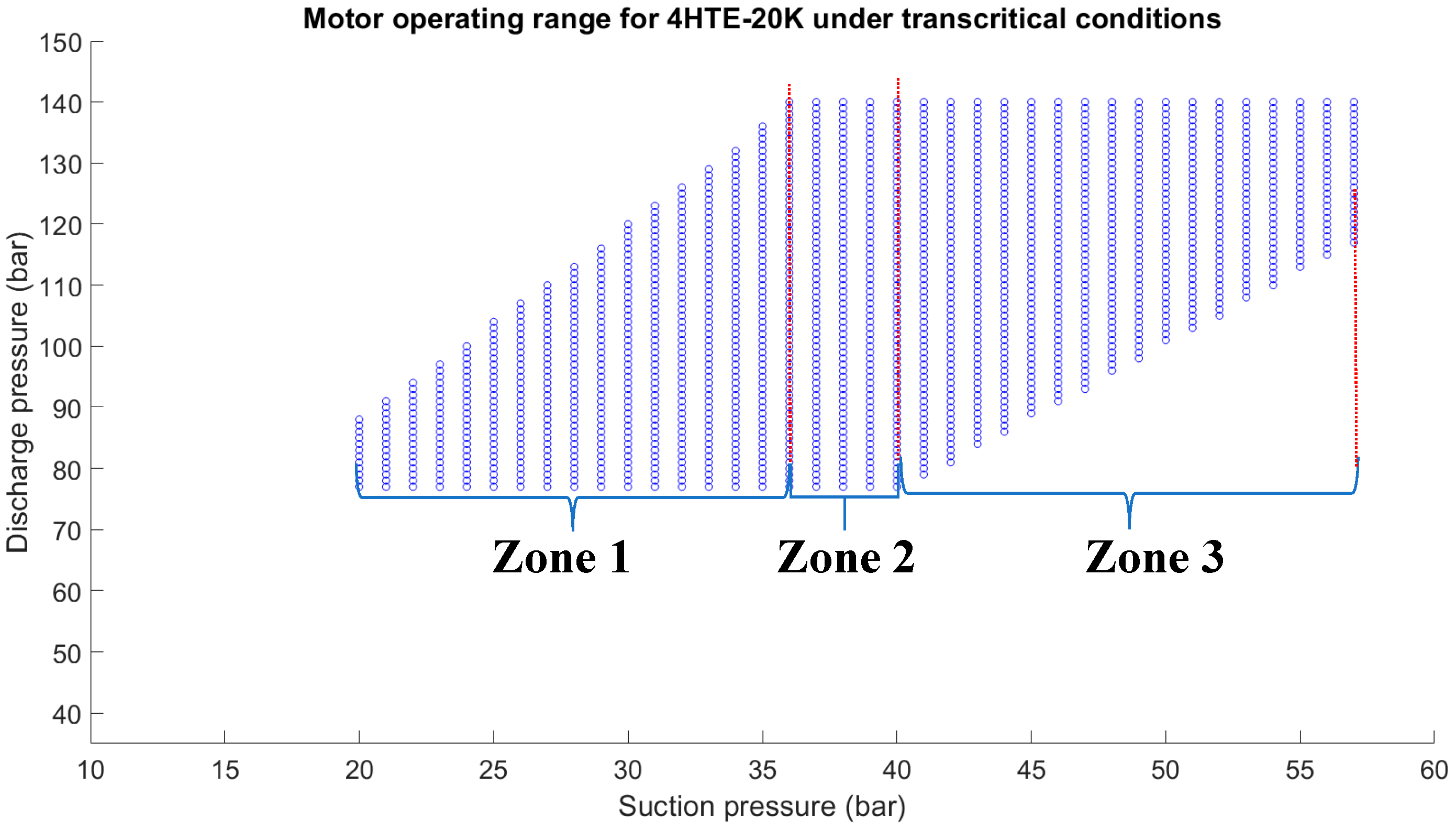

3.1. Operating Range

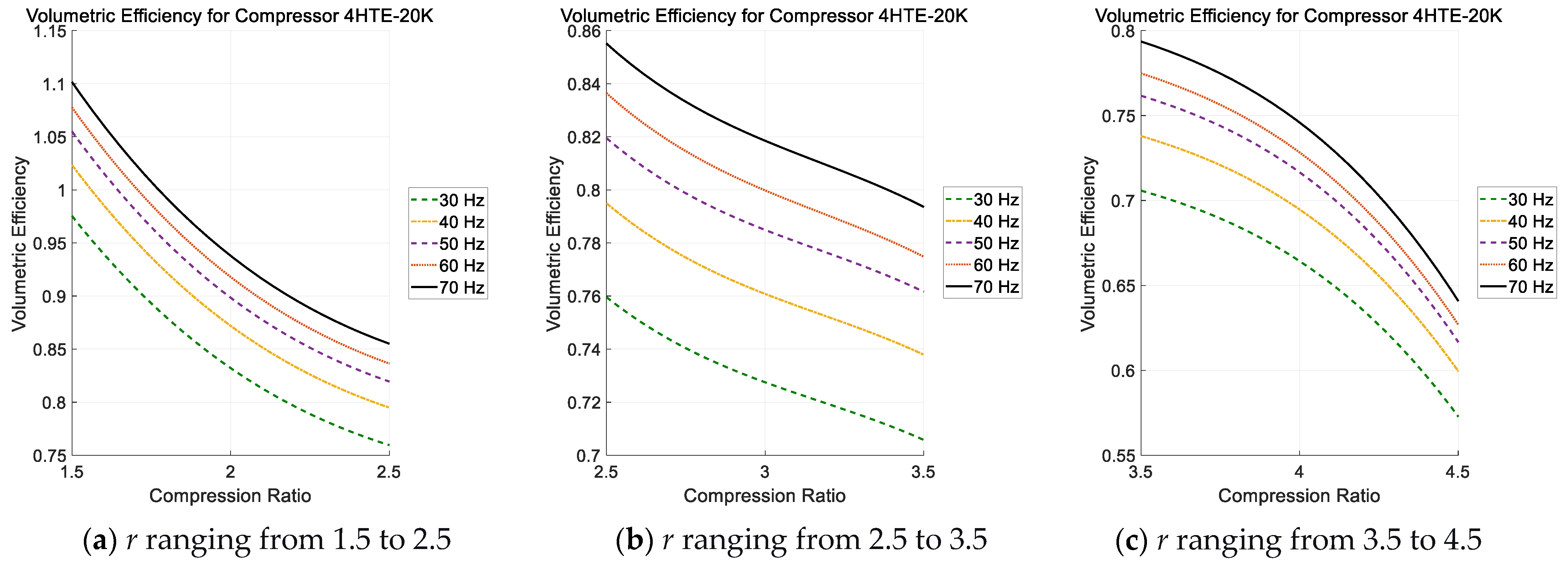

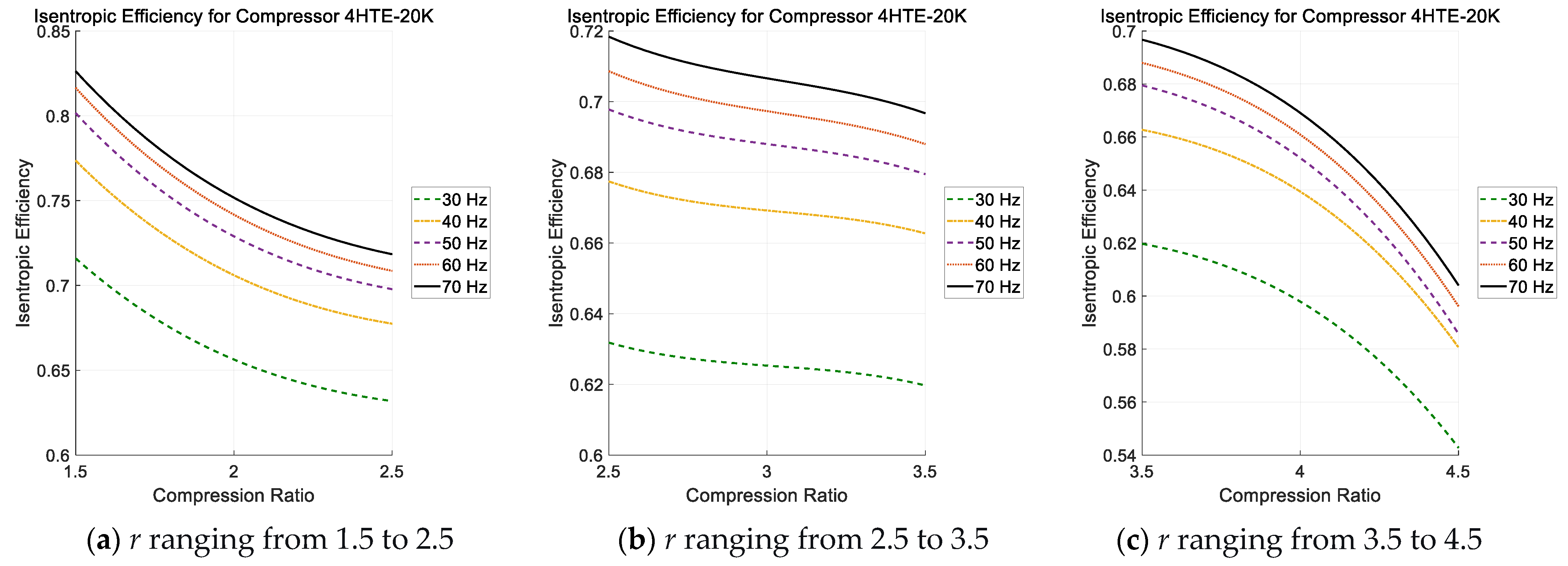

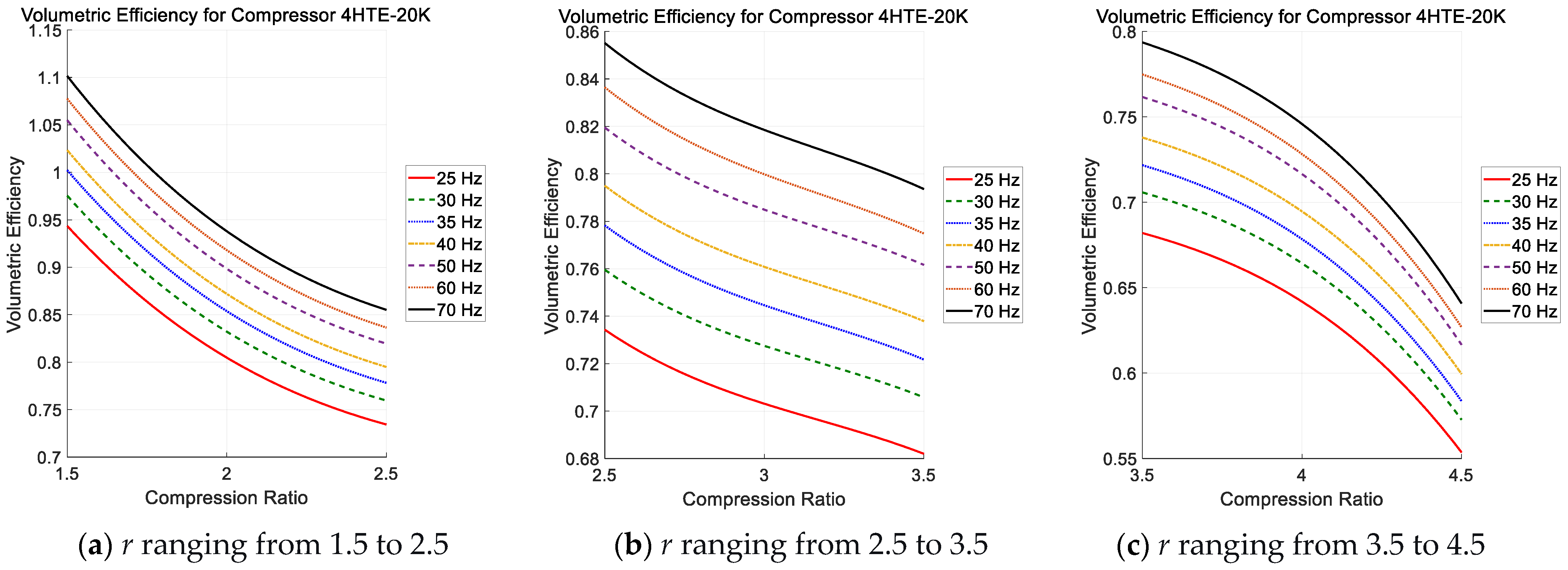

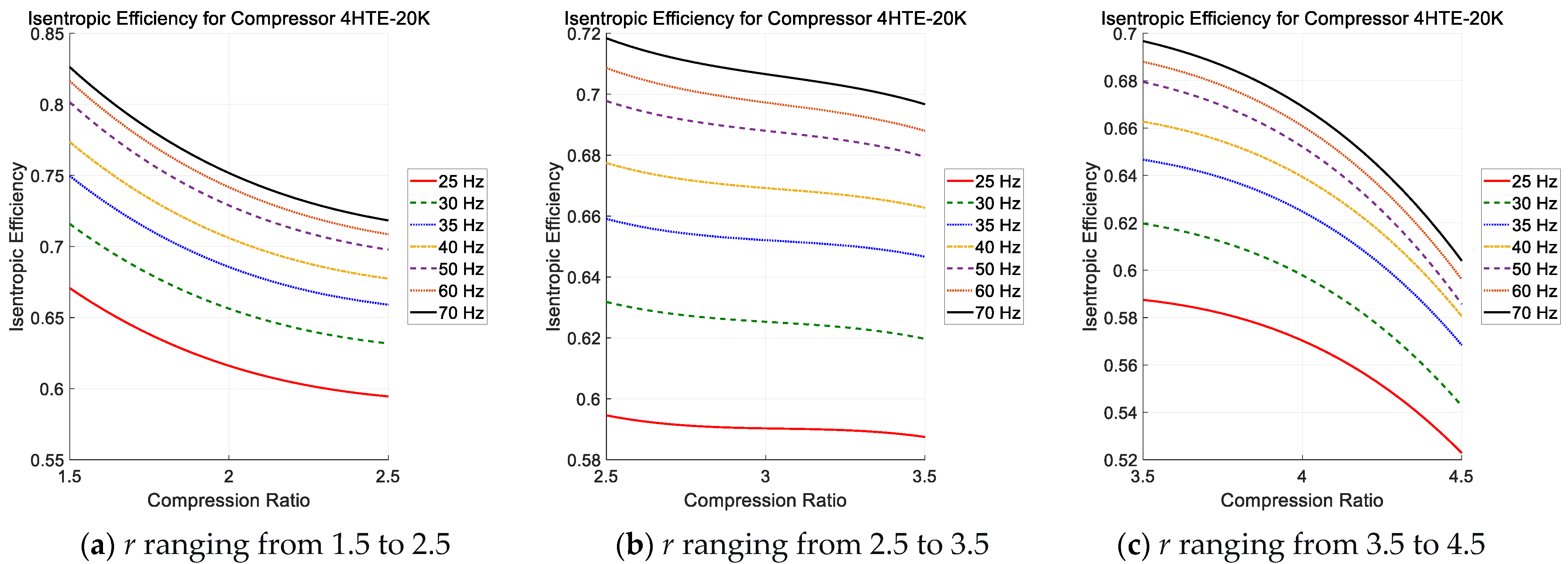

3.2. One-Dimensional Polynomial Regression

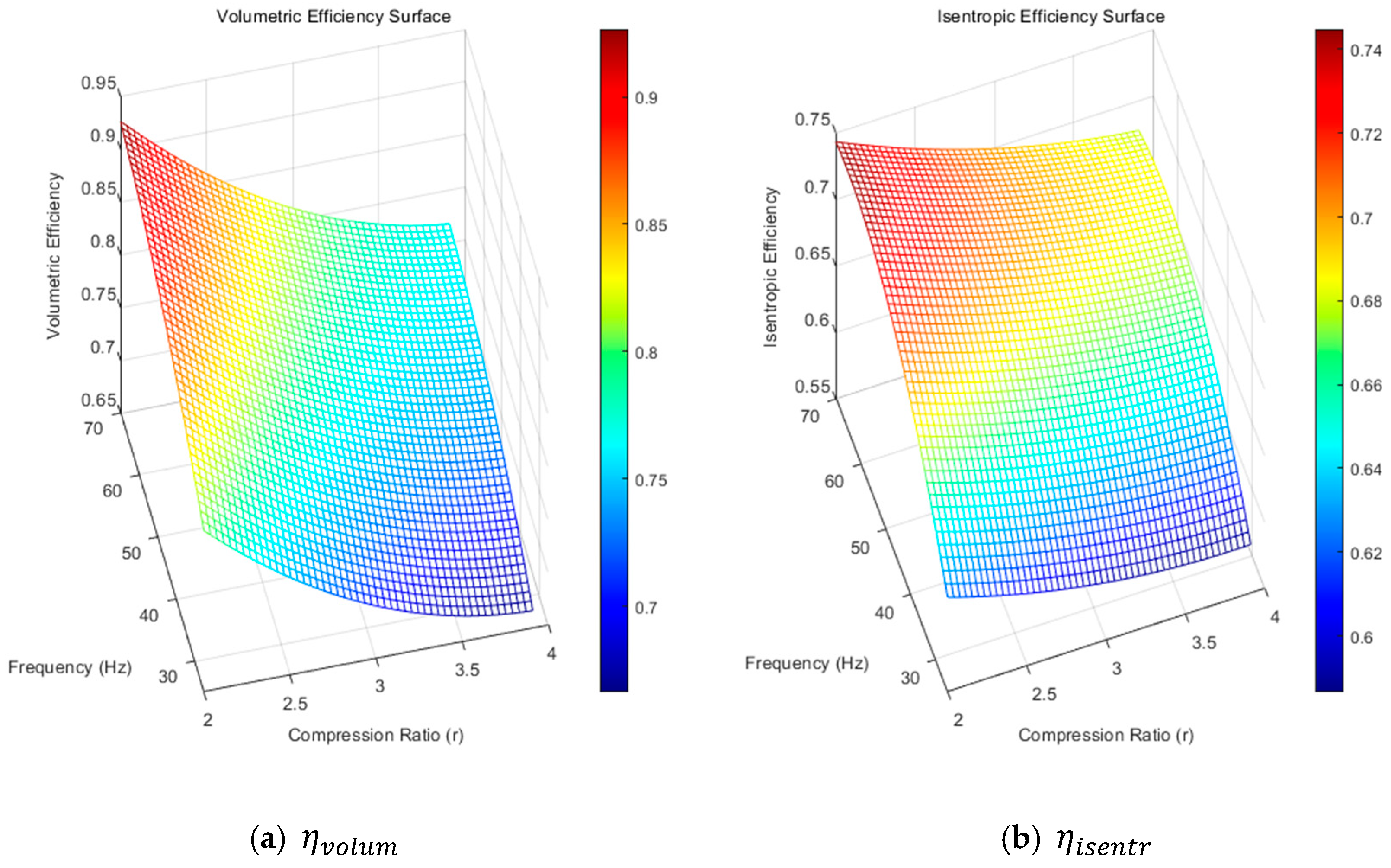

3.3. Two-Dimensional Polynomial Regression

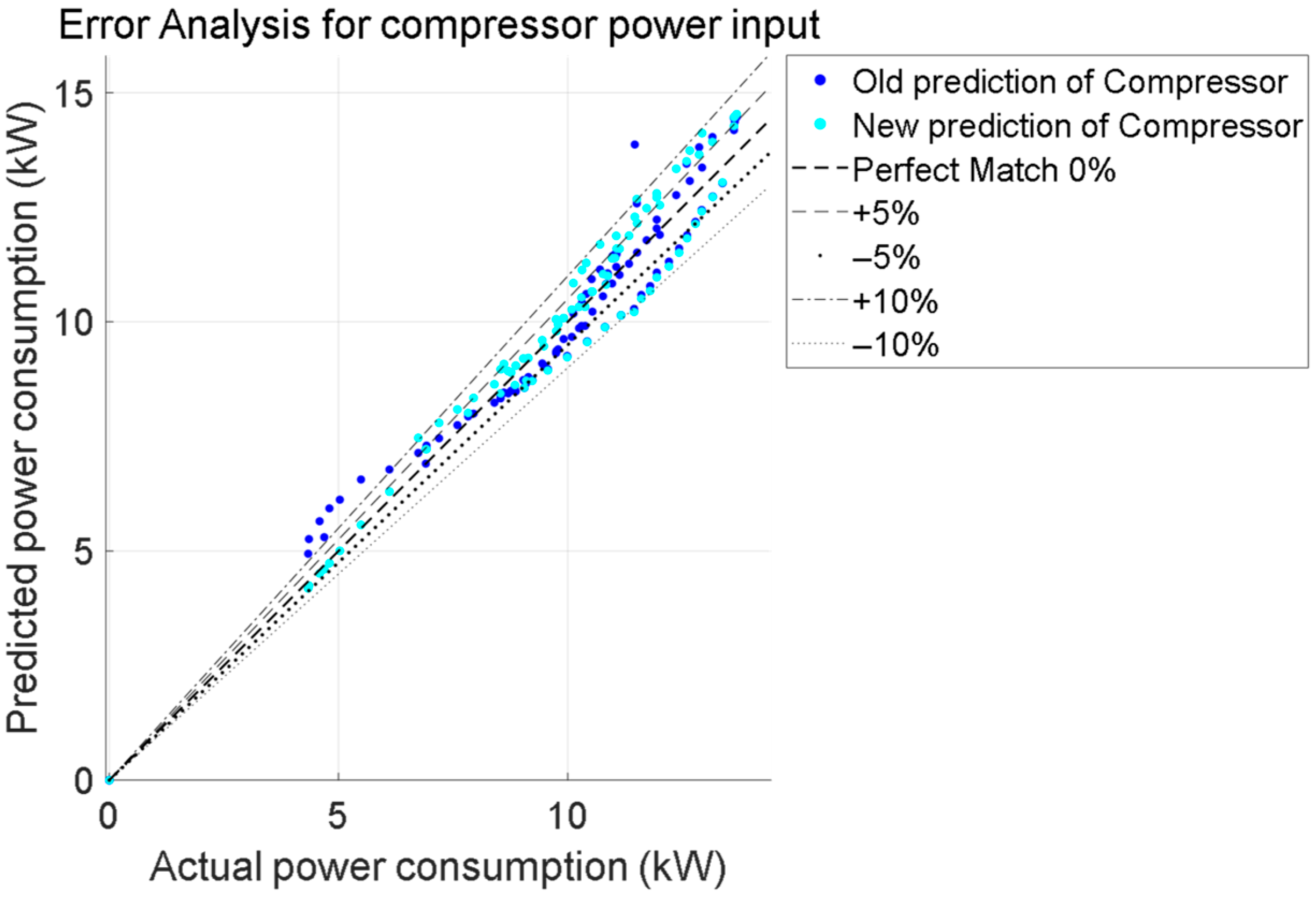

4. Validation and Comparison

5. Conclusions

- (1)

- A systematic and detailed methodology for determining and of the reciprocating compressor has been thoroughly elaborated and implemented.

- (2)

- Both and exhibit significant dependency on variations in motor speed frequency; however, the disparity in observed between 30 Hz and 40 Hz is markedly more pronounced when compared to the differentials identified across other adjacent frequency intervals.

- (3)

- Although 1-D polynomial regression approaches are capable of representing compressor performance under constant-speed or fixed-frequency conditions, they demonstrate considerable limitations and fail to deliver reliable predictions when applied to variable-speed operational scenarios.

- (4)

- The introduction of 2-D regression models, which simultaneously incorporate compression ratio and motor frequency as independent variables, facilitates highly accurate predictions of compressor performance under speed-varying conditions and significantly improves model accuracy at low-frequency operation, where traditional models tend to underperform.

- (5)

- The newly developed CO2 compressor model proposed in this study has been rigorously validated against publicly available experimental datasets, demonstrating satisfactory agreement between simulated and empirical results, with particular emphasis on its enhanced predictive accuracy under low-speed operating regimes.

- (6)

- The proposed framework represents a novel and transparent numerical approach that accounts for frequency-dependent behavior without relying on complex CFD models. This methodological advancement provides a practical foundation for future numerical studies, system-level simulations, and optimization of variable-speed compressor applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| f | motor speed frequency, Hz |

| , , , , | functions of refrigerant property |

| h | enthalpy, kJ/kg |

| mass flow rate, kg/s | |

| P | pressure, bar |

| r | compression ratio |

| T | temperature, °C or K |

| ΔT | temperature difference, °C or K |

| displacement rate of the compressor, m3/h | |

| compression work, kW | |

| efficiency | |

| volum | volumetric efficiency |

| isentr | Isentropic efficiency |

| density, kg/m3 | |

| MAPE | mean absolute percentage error |

| RMSE | root mean square error |

| RPM | Revolution per minute |

| 1-D | One-dimensional |

| 2-D | Two-dimensional |

| comp | compressor |

| dis | discharge |

| evaporation | |

| ref | reference |

| suc | suction |

References

- Mathie, R.; Markides, C.N.; White, A.J. A Framework for the Analysis of Thermal Losses in Reciprocating Compressors and Expanders. Heat Transf. Eng. 2014, 35, 1435–1449. [Google Scholar] [CrossRef]

- Prata, A.T.; Barbosa, J.R., Jr. Role of the Thermodynamics, Heat Transfer, and Fluid Mechanics of Lubricant Oil in Hermetic Reciprocating Compressors. Heat Transf. Eng. 2009, 30, 533–548. [Google Scholar] [CrossRef]

- Barbosa, J.R., Jr.; Ribeiro, G.B.; de Oliveira, P.A. A State-of-the-Art Review of Compact Vapor Compression Refrigeration Systems and Their Applications. Heat Transf. Eng. 2012, 33, 356–374. [Google Scholar] [CrossRef]

- Stouffs, P.; Tazerout, M.; Wauters, P. Thermodynamic analysis of reciprocating compressors. Int. J. Therm. Sci. 2001, 40, 52–66. [Google Scholar] [CrossRef]

- Rigola, J.; Pérez-Segarra, C.; Raush, G.; Oliva, A.; Escriba, M.; Jover, J.; Escanes, F. Experimental studies of hermetic reciprocating compressors with special emphasis on pV diagram. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 16–19 July 2002. [Google Scholar]

- Liu, Z.; Luo, W.; Zhao, Q.; Zhao, W.; Xu, J. Preliminary Design and Model Assessment of a Supercritical CO2 Compressor. Appl. Sci. 2018, 8, 595. [Google Scholar] [CrossRef]

- Ozdemir, A.R.; Oguz, E.; Onbasioglu, S. An investigation of the heat transfer phenomena between the hermetic reciprocating compressor components. In Proceedings of the 8th International Conference on Compressors and their Systems, London, UK, 9–10 September 2013; Woodhead Publishing: Sawston, UK, 2013; pp. 385–395. [Google Scholar] [CrossRef]

- Kroupa, A. Modelling of phase diagrams and thermodynamic properties using Calphad method–Development of thermodynamic databases. Comput. Mater. Sci. 2013, 66, 3–13. [Google Scholar] [CrossRef]

- Pérez-Segarra, C.D.; Rigola, J.; Sòria, M.; Oliva, A. Detailed thermodynamic characterization of hermetic reciprocating compressors. Int. J. Refrig. 2005, 28, 579–593. [Google Scholar] [CrossRef]

- Wang, J.; Belusko, M.; Evans, M.; Liu, M.; Zhao, C.; Bruno, F. A comprehensive review and analysis on CO2 heat pump water heaters. Energy Convers. Manag. X 2022, 15, 100277. [Google Scholar] [CrossRef]

- Shariatzadeh, O.J.; Abolhassani, S.; Rahmani, M.; Nejad, M.Z. Comparison of transcritical CO2 refrigeration cycle with expander and throttling valve including/excluding internal heat exchanger: Exergy and energy points of view. Appl. Therm. Eng. 2016, 93, 779–787. [Google Scholar] [CrossRef]

- Wang, J.; Belusko, M.; Semsarilar, H.; Evans, M.; Liu, M.; Bruno, F. An optimisation study on a real-world transcritical CO2 heat pump system with a flash gas bypass. Energy Convers. Manag. 2022, 251, 114995. [Google Scholar] [CrossRef]

- Dutra, T.; Deschamps, C.J. A simulation approach for hermetic reciprocating compressors including electrical motor modeling. Int. J. Refrig. 2015, 59, 168–181. [Google Scholar] [CrossRef]

- Rafiee, S.E. Experimental and thermo-dynamical analysis of fully turbulent gas flows in vortex tube-fluid, temperature and power separations, isentropic efficiency, coefficient of performance (COP). Int. Commun. Heat Mass Transf. 2022, 138, 106296. [Google Scholar] [CrossRef]

- Wang, J.; Belusko, M.; Liu, M.; Semsarilar, H.; Liddle, R.; Alemu, A.; Evans, M.; Zhao, C.; Hudson, J.; Bruno, F. A comprehensive study on a novel transcritical CO2 heat pump for simultaneous space heating and cooling—Concepts and initial performance. Energy Convers. Manag. 2021, 243, 114397. [Google Scholar] [CrossRef]

- Bitzer. ECOLINE Series (Transcritical CO2). Available online: https://www.bitzer.de/gb/en/reciprocating-compressors/ecoline-transcritical/ (accessed on 11 July 2025).

- Sandberg, M.R. Equation Of State Influences On Compressor Performance Determination; Texas A&M University: College Station, TX, USA, 2005. [Google Scholar]

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and pseudo-pure fluid thermophysical property evaluation and the open-source thermophysical property library CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508. [Google Scholar] [CrossRef] [PubMed]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST reference fluid thermodynamic and transport properties—REFPROP. NIST Stand. Ref. Database 2002, 23, v7. [Google Scholar]

- Bitzer. Bitzer Software Version 7.0.5. Available online: https://www.bitzer.de/websoftware/calculate/HHK/?tab=results (accessed on 11 July 2025).

- Hazem, Z.B.; Saidi, F.; Guler, N.; Altaif, A.H. Reinforcement learning-based intelligent trajectory tracking for a 5-DOF Mitsubishi robotic arm: Comparative evaluation of DDPG, LC-DDPG, and TD3-ADX. Int. J. Intell. Robot. Appl. 2025. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| f (Hz) | 25 | (kg/h) | 490 |

| fref (Hz) | 50 | suc (kg/m3) | 102.39 |

| Pdis (bar) | 80 | (m3/h) | 12 |

| Psuc (bar) | 40 | 0.7975 | |

| r | 2 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Pdis (bar) | 80 | Δ | 35.22 |

| Psuc (bar) | 40 | (kW) | 7.8 |

| r | 2 | 0.6146 | |

| (kg/s) | 0.136 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Lu, W. A Streamlined Polynomial Regression-Based Modeling of Speed-Driven Hermetic-Reciprocating Compressors. Appl. Sci. 2025, 15, 12016. https://doi.org/10.3390/app152212016

Wang J, Lu W. A Streamlined Polynomial Regression-Based Modeling of Speed-Driven Hermetic-Reciprocating Compressors. Applied Sciences. 2025; 15(22):12016. https://doi.org/10.3390/app152212016

Chicago/Turabian StyleWang, Jay, and Wei Lu. 2025. "A Streamlined Polynomial Regression-Based Modeling of Speed-Driven Hermetic-Reciprocating Compressors" Applied Sciences 15, no. 22: 12016. https://doi.org/10.3390/app152212016

APA StyleWang, J., & Lu, W. (2025). A Streamlined Polynomial Regression-Based Modeling of Speed-Driven Hermetic-Reciprocating Compressors. Applied Sciences, 15(22), 12016. https://doi.org/10.3390/app152212016