Research on the Possibilities of Reusing Mixed Reclaimed Asphalt Materials with a Focus on the Circular Economy

Abstract

1. Introduction

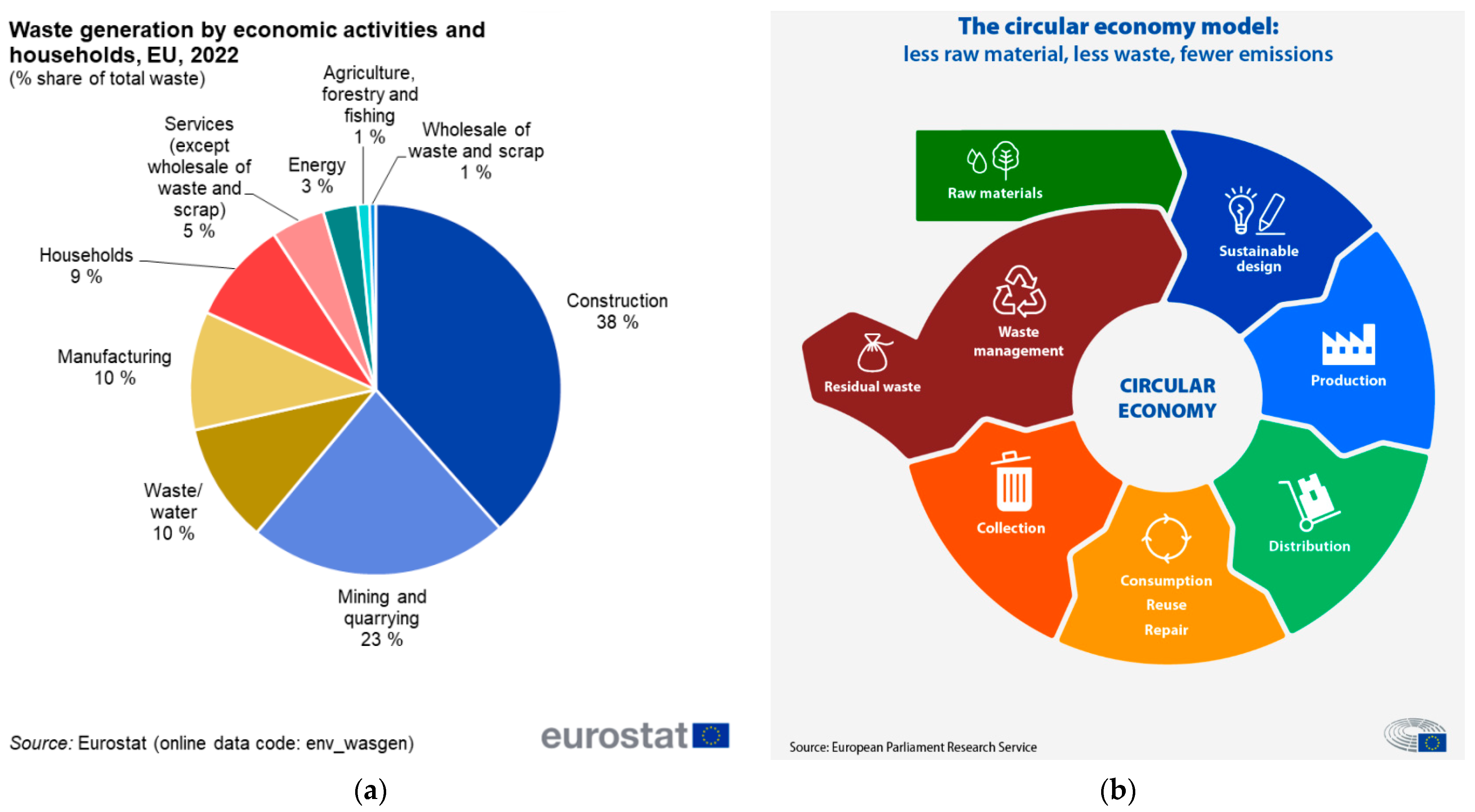

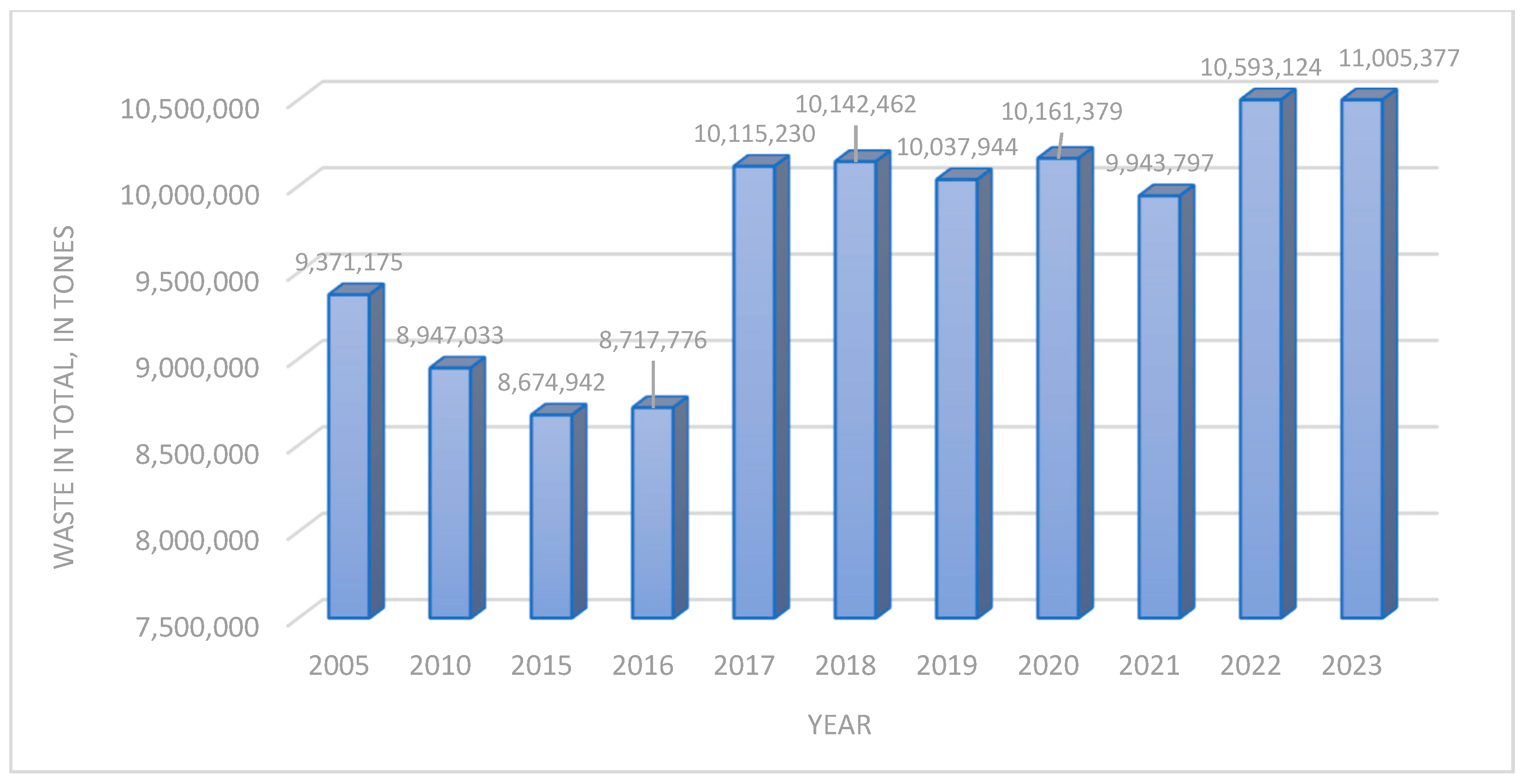

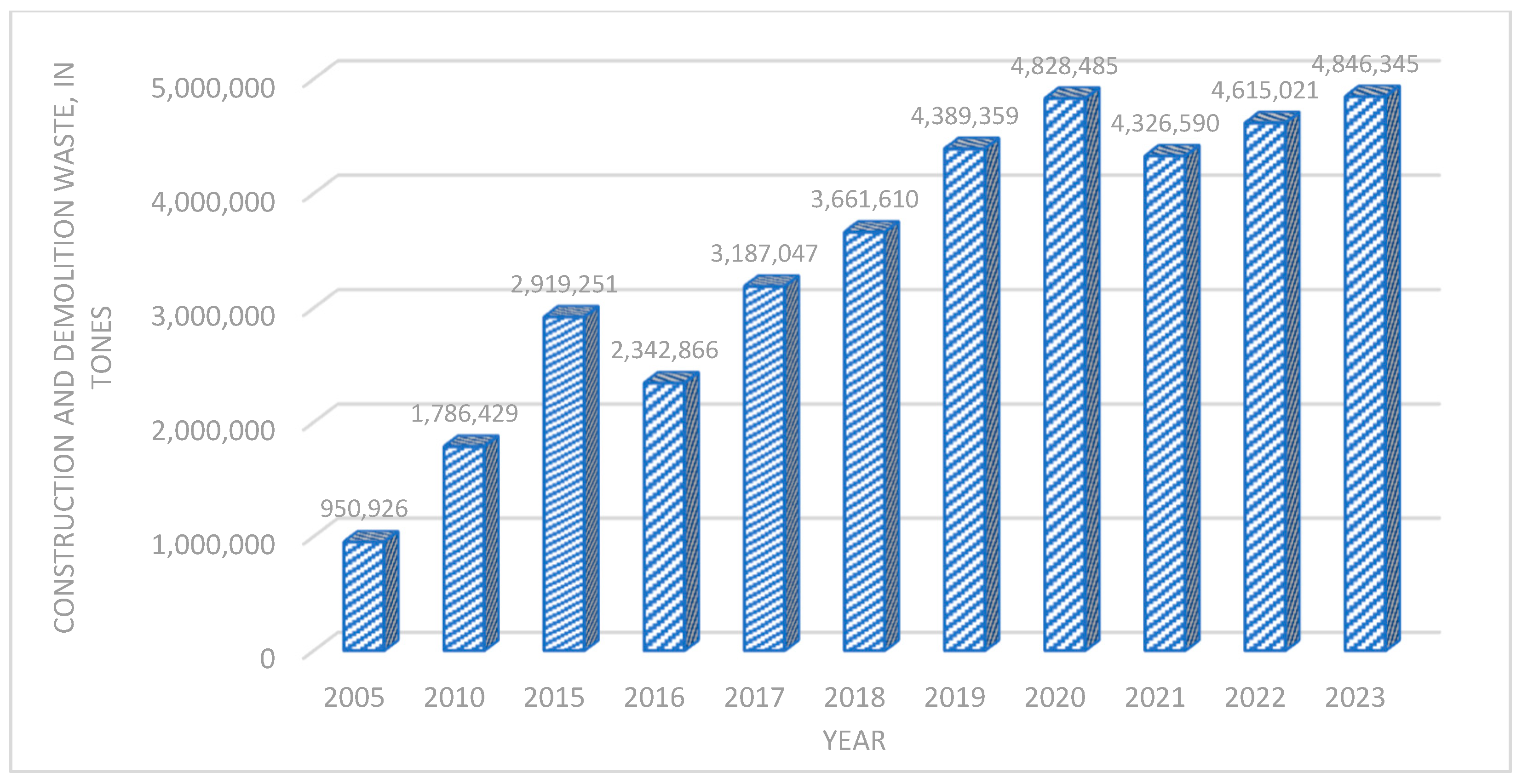

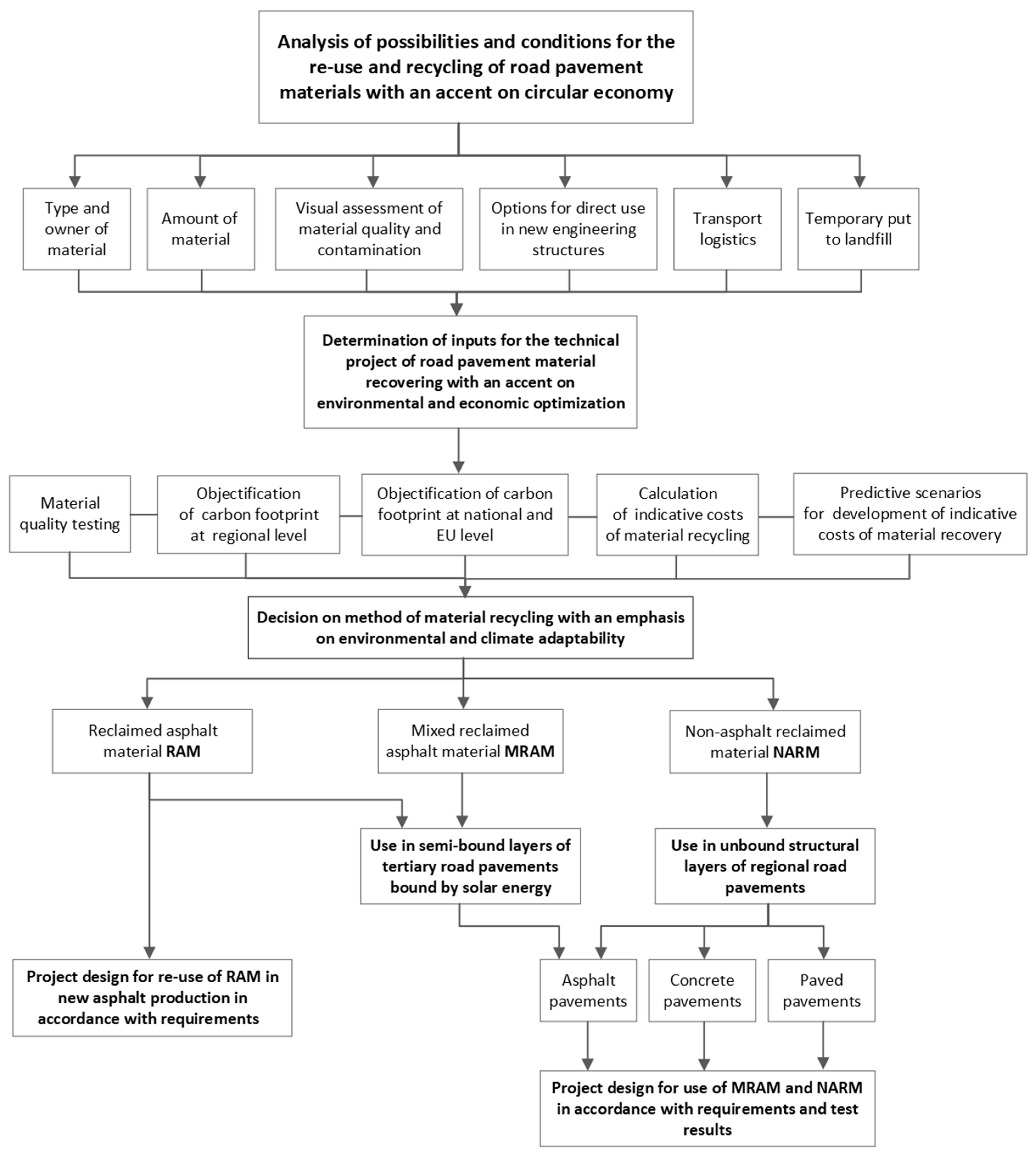

2. Circular Economy in the Slovak Construction Industry

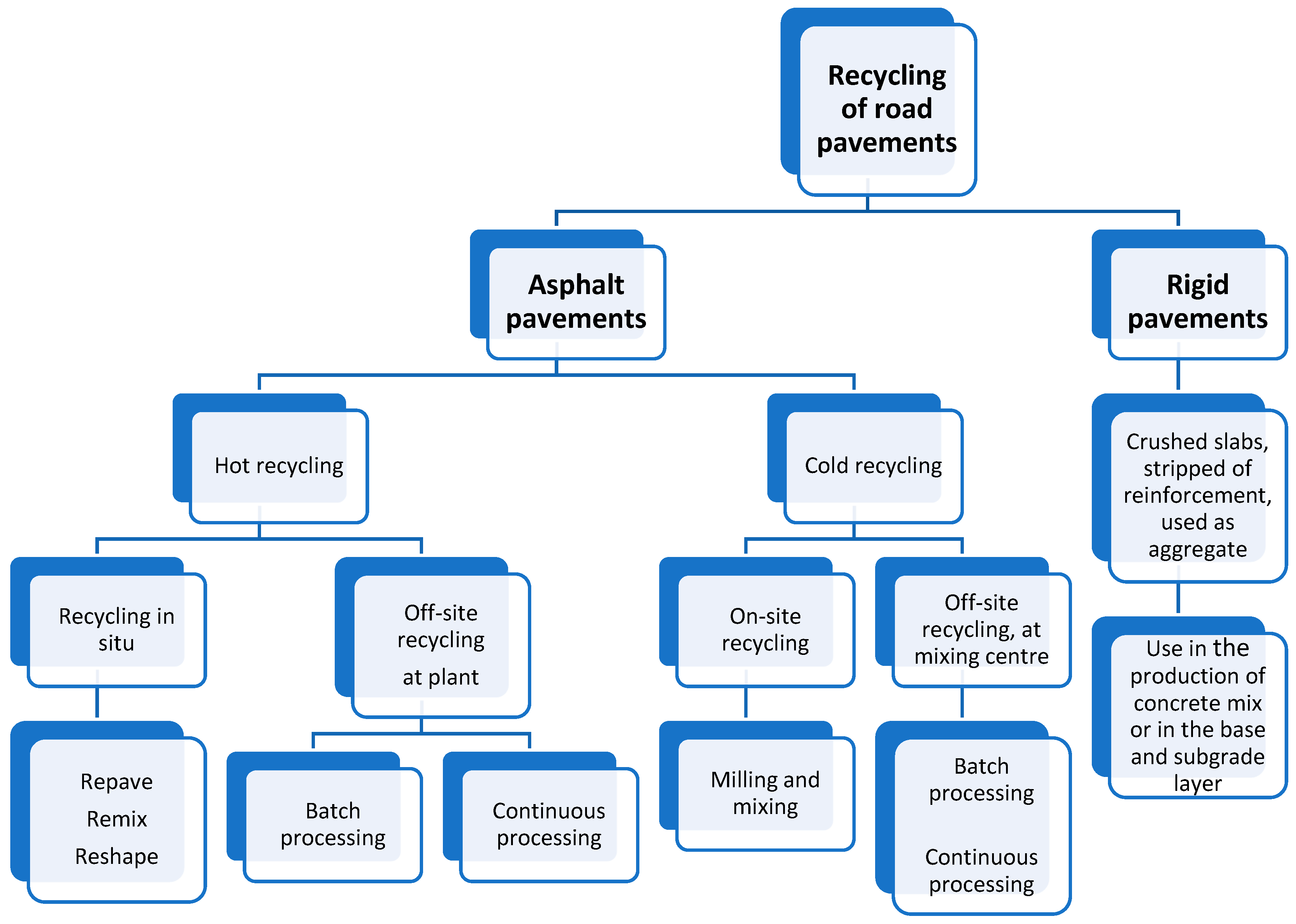

3. Recycling of Road Pavements

- Asphalt disposal or landfilling: In most cases, it is environmentally and economically irresponsible and is prohibited in some countries;

- Base courses: Friendly to raw material resources, economic recovery, and feasible to use relatively simple technologies;

- Pavement surface construction: Friendly to raw material resources, economic recovery, technically demanding technologies, and the highest added value.

4. Research on Properties and Applicability of MRAM in Pavement Construction Layers—Materials and Methods

- Reclaimed asphalt (RA material)—processed asphalt material obtained from a construction site (pavement) and, after testing, assessment, and classification according to the EN 13108-8 standard [53], usable as an input material for an asphalt mixture. Processing may include one or more of the following methods: milling, crushing, sorting, mixing, etc.

- Mixed reclaimed asphalt material (MRAM)—material obtained by breaking up materials from road structures bound to various types of binder, together with unbounded layers; the content of bitumen-bound grains in the material ranges from (20 to 80) %, and the bituminous binder content is (0.7 to 4.0) % by weight of the mixture.

- Non-asphalt reclaimed material (NARM)—material obtained by breaking up materials from road layers; the content of asphalt grains in the mixture is less than 20% by weight, and the bitumen binder content is less than 0.7% by weight.

- Experimental field for research of unbound pavement construction layers (EFRUPCL), unbound MRAM: Verification of the mechanical efficiency of MRAM that was cold-laid at an air temperature of 10 °C, without the use of compaction equipment (Figure 5).

- Scientific Research Workplace of the Faculty of Civil Engineering of the University of Žilina (SRW of FCE UNIZA): A compacted unbound MRAM layer was cold-laid at a temperature of 20 °C using a compaction plate (Figure 6). This verifies the hypothesis that MRAM, after compaction with a light vibrating plate in combination with solar heating, will demonstrate significantly higher deformation characteristics than when laid without compaction. Measurements were performed at different temperatures (e.g., 6 °C, −4 °C, and 18 °C).

- Rehabilitation of the local road pavement: Application of a 20 cm thick, semi-bound MRAM layer (Figure 7) at an air temperature of 30 °C and compaction with a heavy 10-ton roller. Subsequently, surface condition monitoring was carried out from 2017 to 2025.

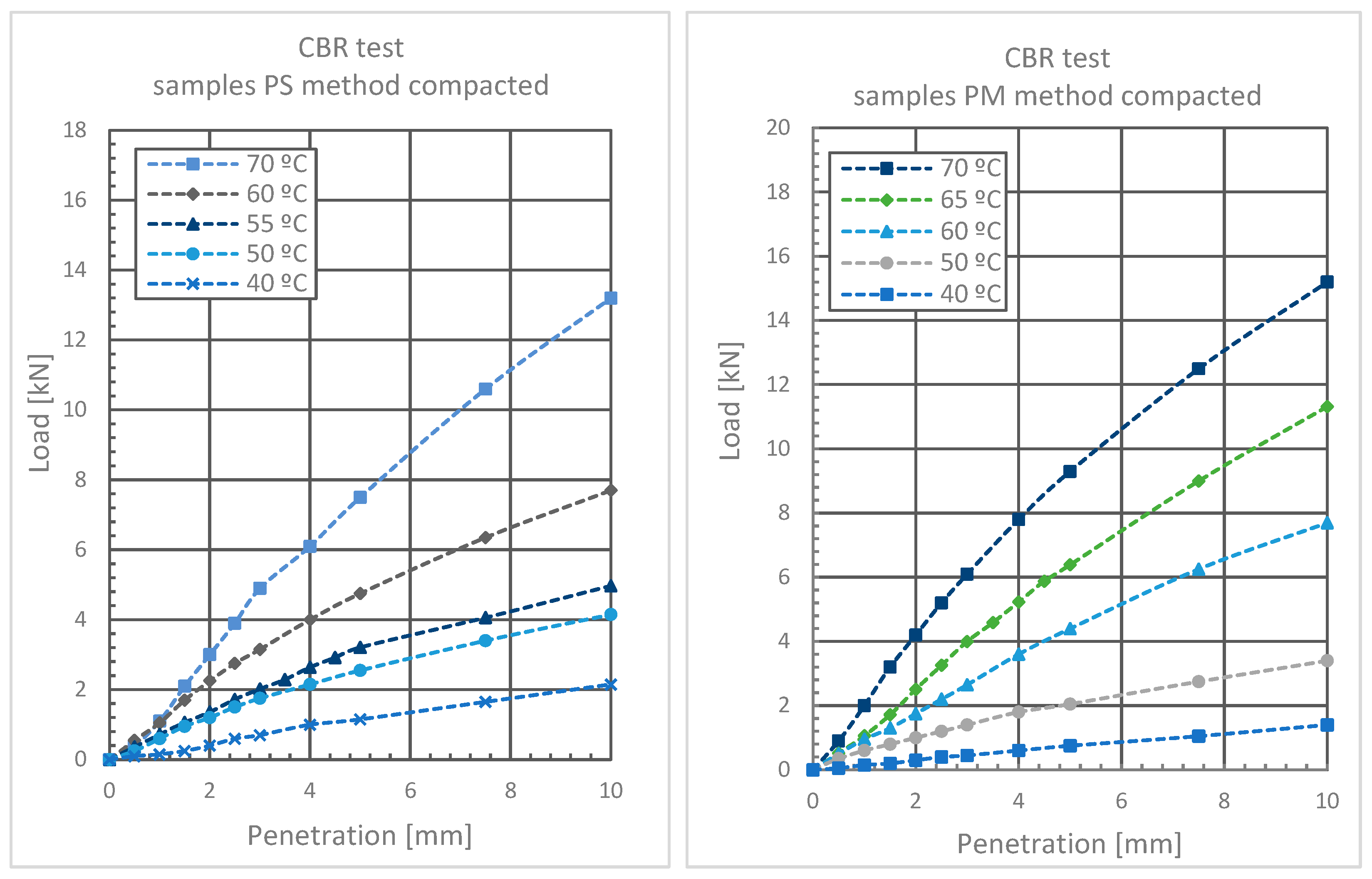

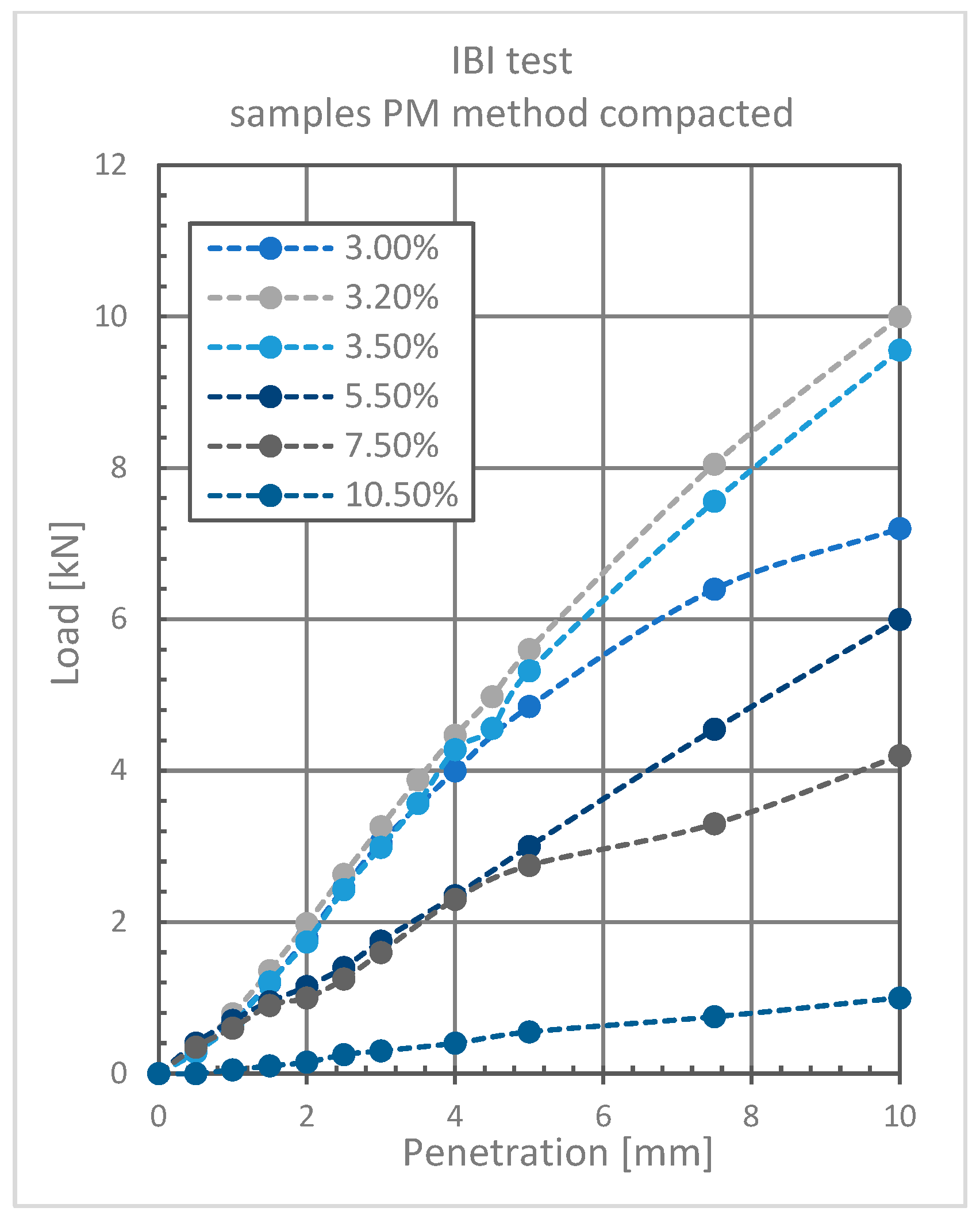

- Laboratory determination of MRAM properties: The California Bearing Ratio (CBR) and Immediate Bearing Index (IBI) tests of mixed recycled asphalt were performed at temperatures from 20 to 70 °C (Figure 8).

- Static plate load test (SPTL) according to [58]; test performed with circular plates of various dimensions for load distribution.

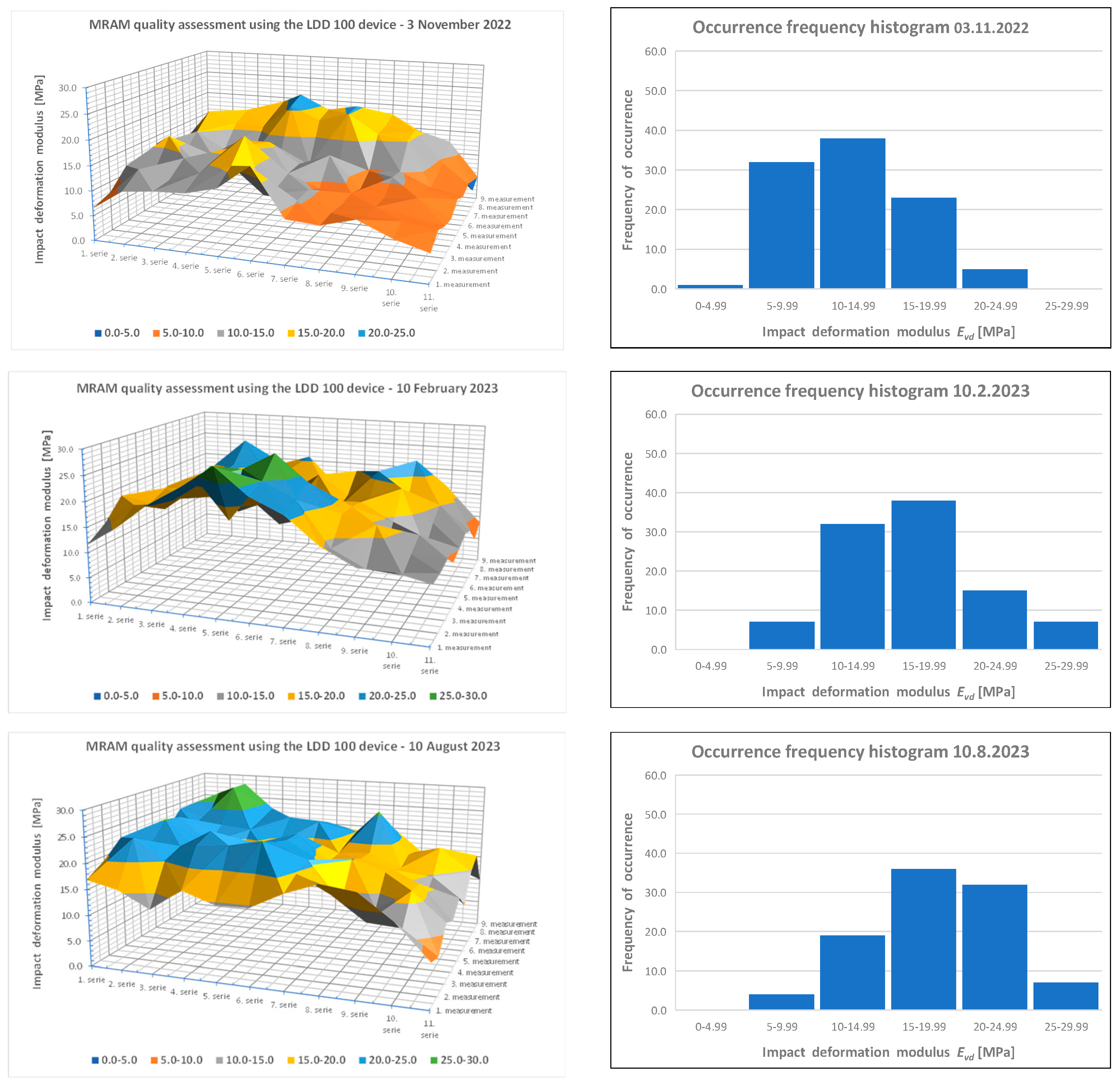

- Impact deformation modulus test using the LDD 100 device (ECM, Brno, Czech Republic); 11 series of 9 measurements evenly distributed over the area of the MRAM layer and performed during the years 2022 to 2023.

- The Proctor test is used to determine the maximum dry density and optimum moisture content by compacting it with a standardized amount of energy;

- The California Bearing Ratio (CBR) test is used to characterize compactability and strength at different loads (Proctor standard PS and Proctor modified PM methods) and temperature conditions (standard laboratory temperature conditions, ±20 °C, and a temperature range of 40 to 70 °C);

- The Immediate Bearing Index (IBI) is used to determine the strength characteristics of compacted samples without surcharge at different moisture values of the material.

5. Results and Discussion of Practical Applications and Experimental Measurements

5.1. Properties of MRAM as an Unbound Pavement Layer Without Compaction

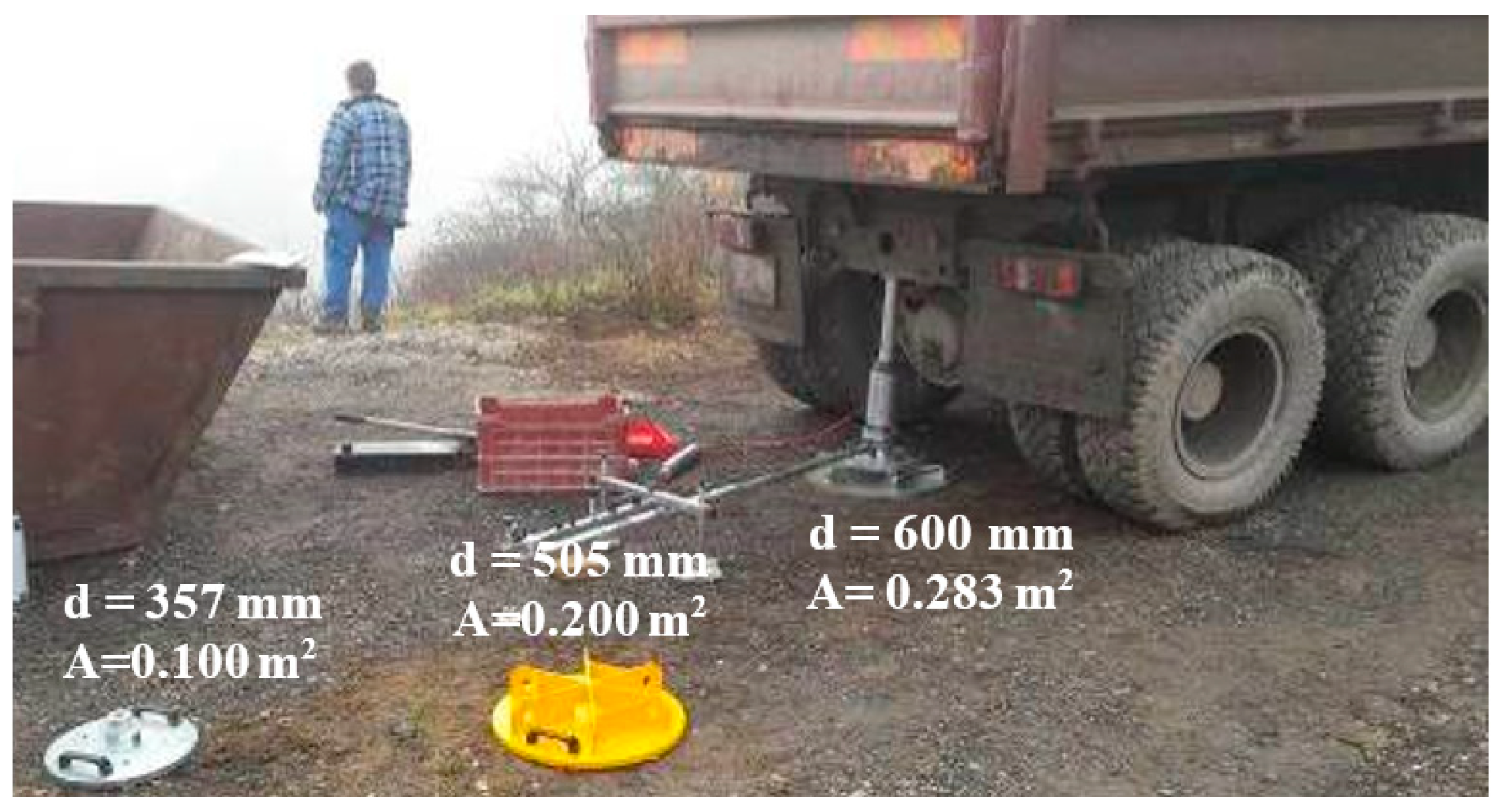

- Small plate with an area of 0.100 m2 (diameter d = 357 mm, radius r = 178.5 mm);

- Middle plate with an area of 0.200 m2 (d = 505 mm, r = 252.5 mm);

- Middle plate with an area of 0.283 m2 (d = 600 mm, r = 300 mm);

- Large plate with an area of 0.500 m2 (d = 798 mm, r = 399 mm).

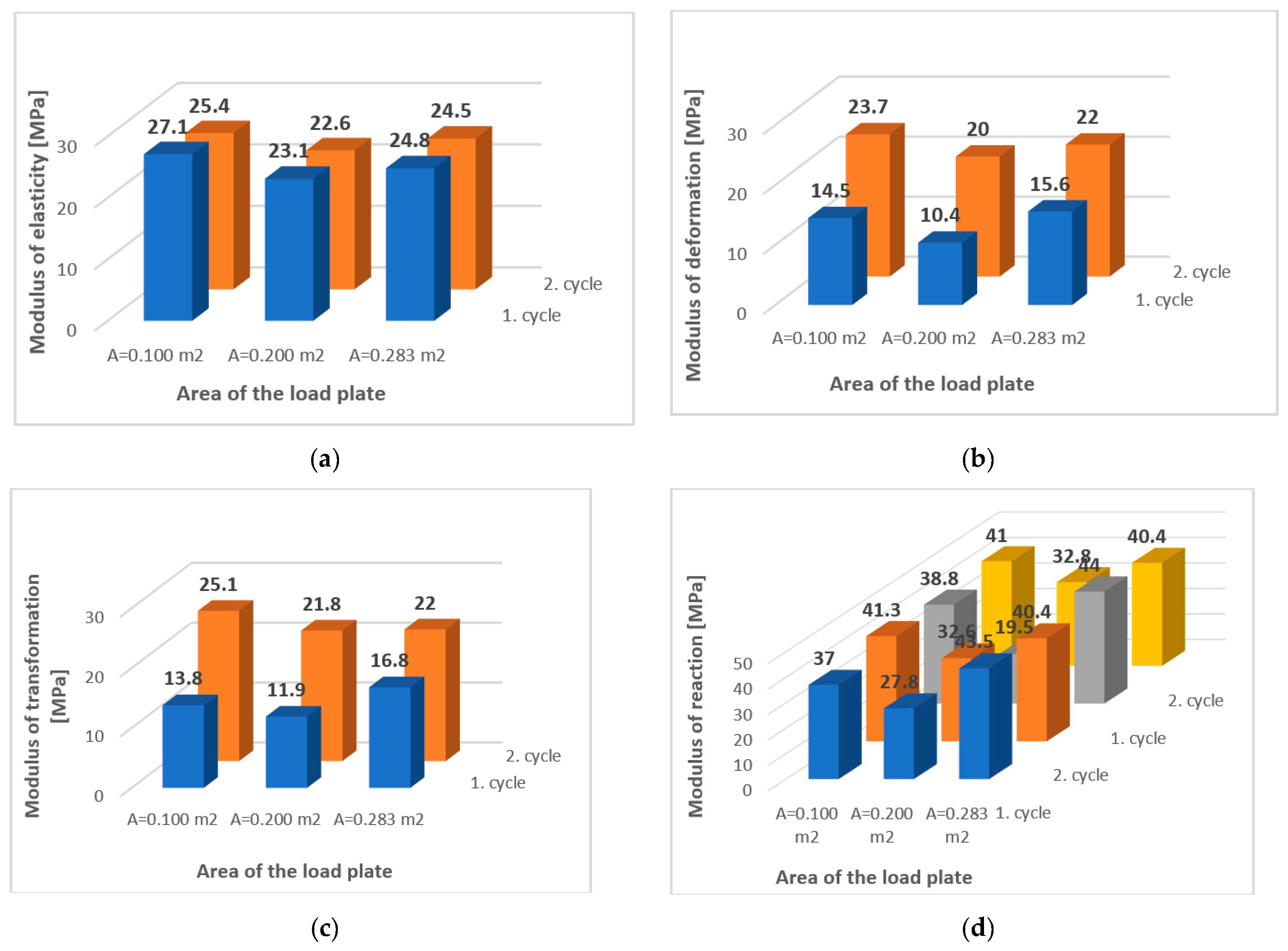

- The static modulus of deformation, E0, in MPa, is determined by a static load test performed with a small or middle plate so that at the last loading stage, the plate pressure exerted is greater than that used for calculating the modulus according to Equation (1):

- The static modulus of elasticity, E, in MPa, is determined in the same way as the deformation modulus, E0, and is calculated according to Equation (2), in which fe is the average elastic deformation of the material in m:

- The reaction modulus, k, in MN/m3 is determined according to [58] using a static load test with a large plate, performed so that the total average plate deformation is 1.27 mm, calculated according to Equation (3):

5.2. Properties of MRAM on the SRW of FCE UNIZA as an Unbound Pavement Layer Without Compaction

5.3. Rehabilitation of the Local Road Pavement, Semi-Bound Layer

5.4. Laboratory Determination of Mixed Reclaimed Asphalt Properties

5.5. Summary of Results

6. Conclusions

- Using isomorphic models and test sections of rehabilitated roadways using MRAM, it was found that when using MRAM without heating and compaction, it is not possible to achieve the required characteristics (specified by relevant standards and technical regulations). The achieved low values of the static modulus of deformation from the second loading cycle in the range of 20.0 to 23.7 MPa indicate the necessity of intervention.

- The influence of the size of the load plate on the load distribution was not evident. The deformation characteristics (modulus of elasticity, modulus of deformation, and modulus of reaction) were approximately the same, confirming the assumption of a homogeneous elastic half-space.

- A comparison of the deformation modules of the MRAM layer on the SRW of the FCE UNIZA, measured by an LDD 100 device during the years 2022 and 2023, shows only a slight improvement in the stiffness of the MRAM (an increase in the impact deformation modulus from 12.1 MPa to 18.5 MPa), which, after excluding mechanical effects on the layer, was caused by the consolidation under effect of solar energy. However, the hypothesis of a significant increase in deformation characteristics meeting the required values due to solar radiation was not confirmed.

- The hypothesis that the long-term effect of solar energy alone would lead to a significant increase in the deformation characteristics of compacted MRAM was not confirmed. Measurements of the non-traffic-loaded test section (SRW FCE UNIZA) showed only a slight improvement in stiffness over time, increasing the impact deformation modulus from an average of 12.1 MPa to 18.5 MPa due to consolidation under the effect of solar energy. This indicates that solar heating without traffic loading is insufficient to activate the required bearing capacity.

- Laboratory tests demonstrated that temperature is the critical factor for enhancing MRAM bearing capacity. On isomorphic MRAM models, the CBR test showed a 4-, 5-, and 14-times increase in CBR values when the temperature was increased from 20 °C to 40, 50, and 70 °C. At the highest tested compaction temperature, it is possible to reach a CBR value of 45 MPa. Conversely, increasing moisture reduces the immediate bearing capacity of the MRAM, expressed by the IBI value.

- The laboratory results were confirmed by monitoring the surface conditions of a rehabilitated local road between 2017 and 2025 using MRAM, where some sections showed the properties of semi-bound layers after eight years.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Commission on Environment and Development. Our Common Future; Oxford University Press: Oxford, UK, 1987.

- Sneddon, C.; Howarth, R.B.; Norgaard, R.B. Sustainable development in a post-Brundtland world. Ecol. Econ. 2006, 57, 253–268. [Google Scholar] [CrossRef]

- Mallick, R.B.; El-Korchi, T. Pavement Engineering: Principles and Practise, 3rd ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2018; 747p. [Google Scholar] [CrossRef]

- Kibert, C.J. Establishing principles and a model for sustainable construction. In Proceedings of the First International Conference of CIB TG 16, Tampa, FL, USA, 6–9 November 1994. [Google Scholar]

- Vanegas, J.A.; Pearce, A.R. Drivers for change: An organizational perspective on sustainable construction. In Proceedings of the Construction Congress VI: Building Together for a Better Tomorrow in an Increasingly Complex World, Orlando, FL, USA, 20–22 February 2000; pp. 406–415. [Google Scholar] [CrossRef]

- Pulaski, M.H. The Alignment of Sustainability and Constructability: A Continuous Value Enhancement Process. Ph.D. Dissertation, The Pennsylvania State University, University Park, PA, USA, 2005. [Google Scholar]

- Ghosh, S.K.; Ghosh, S.K.; Mohapatra, B.G.; Mersky, R.L. (Eds.) Circular Economy in the Construction Industry; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2021. [Google Scholar] [CrossRef]

- Oo, P.Z.; Prapaspongsa, T.; Strezov, V.; Huda, N.; Oshita, K.; Takaoka, M.; Ren, J.; Halog, A.; Gheewala, S.H. The role of global waste management and circular economy towards carbon neutrality. Sustain. Prod. Consum. 2024, 52, 498–510. [Google Scholar] [CrossRef]

- Kumar, A. United Nations Environment Programme (UNEP). Yearb. Int. Environ. Law 2023, 34, yvae022. [Google Scholar] [CrossRef]

- Matsuoka, T.; Oshita, K.; Takaoka, M. Prediction of greenhouse gas emissions from municipal solid waste incinerators with consideration of utilization of heat and captured CO2 in the Tokyo waterfront area. J. Mater. Cycles Waste Manag. 2023, 25, 1853–1875. [Google Scholar] [CrossRef]

- Paes, M.X.; de Medeiros, G.A.; Mancini, S.D.; Gasol, C.; Pons, J.R.; Durany, X.G. Transition towards eco-efficiency in municipal solid waste management to reduce GHG emissions: The case of Brazil. J. Clean. Prod. 2020, 263, 121370. [Google Scholar] [CrossRef]

- Bruyninckx, H.; Hatfield-Dodds, S.; Hellweg, S.; Schandl, H.; Vidal, B.; Razian, H.; Nohl, R.; Marcos-Martinez, R.; West, J.; Lu, Y.; et al. Global Resources Outlook 2024: Bend the Trend. Pathways to a Liveable Planet as Resource Use Spikes, United Nations Environment Programme 2024. Available online: http://wedocs.unep.org/handle/20.500.11822/44901 (accessed on 3 November 2025).

- Friedlingstein, P.; O’sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Landschützer, P.; Le Quéré, C.; Li, H.; Luijkx, I.T.; Olsen, A.; et al. Global carbon budget 2024. Earth Syst. Sci. Data 2024, 17, 965–1039. [Google Scholar] [CrossRef]

- Shi, S.; Hu, Y.H. 2024, A Landmark Year for Climate Change and Global Carbon Capture, Utilization, and Storage: Annual Progress Review. Energy Sci. Eng. 2025, 13, 3448–3458. [Google Scholar] [CrossRef]

- Miller, T.; Bahia, H. Sustainable Asphalt Pavements Technologies, Knowledge Gaps and Opportunities; Modified Asphalt Research Center, University of Wisconsin Madison: Madison, MI, USA, 2009. [Google Scholar]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Cho, G.C. Global CO2 emission-related geotechnical engineering hazards and the mission for sustainable geotechnical engineering. Energies 2019, 12, 2567. [Google Scholar] [CrossRef]

- López, L.C.S.; Ramos, J.C.L.; de la Rosa, Y.E.N.; Bruschi, G.J.; Baldovino, J.D.J.A. Stabilization of Clay Soils Using a Lime Derived from Seashell. Materials 2025, 18, 2723. [Google Scholar] [CrossRef]

- da Silva, T.R.; de Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of plastic wastes in construction materials: A review using the concept of life-cycle assessment in the context of recent research for future perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef]

- Barakat, B.; Jaoude, A.A.R.; Mantalovas, K.; Dunn, I.P.; Acuto, F.; Yazoghli-Marzouk, O.; Di Mino, G.; Srour, I.M. Examining the critical factors that influence the success of construction and demolition waste reverse logistics operations. Int. J. Environ. Impacts Manag. Mitig. Recovery 2022, 5, 236–248. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Tan, S.K.; Gersberg, R.M. Municipal solid waste management in China: Status, problems and challenges. J. Environ. Manag. 2010, 91, 1623–1633. [Google Scholar] [CrossRef]

- Sharholy, M.; Ahmad, K.; Mahmood, G.; Trivedi, R.C. Municipal solid waste management in Indian cities—A review. Waste Manag. 2008, 28, 459–467. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Santero, N.J.; Masanet, E.; Horvath, A. Life-cycle assessment of pavements. Part I: Critical review. Resour. Conserv. Recycl. 2011, 55, 801–809. [Google Scholar] [CrossRef]

- Santero, N.J.; Masanet, E.; Horvath, A. Life-cycle assessment of pavements Part II: Filling the research gaps. Resour. Conserv. Recycl. 2011, 55, 810–818. [Google Scholar] [CrossRef]

- Aryan, Y.; Dikshit, A.K.; Shinde, A.M. A critical review of the life cycle assessment studies on road pavements and road infrastructures. J. Environ. Manag. 2023, 336, 117697. [Google Scholar] [CrossRef]

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Farina, A.; Kutay, M.E.; Anctil, A. Environmental assessment of asphalt mixtures modified with polymer coated rubber from scrap tires. J. Clean. Prod. 2023, 418, 138090. [Google Scholar] [CrossRef]

- Ferreira, V.J.; Vilaplana, A.S.D.G.; García-Armingol, T.; Aranda-Usón, A.; Lausín-González, C.; López-Sabirón, A.M.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2016, 130, 175–186. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Penabaena-Niebles, R.; Giustozzi, F.; Martinez-Arguelles, G. Eco-friendly design of Warm mix asphalt (WMA) with recycled concrete aggregate (RCA): A case study from a developing country. Constr. Build. Mater. 2022, 326, 126890. [Google Scholar] [CrossRef]

- Komačka, J.; Remišová, E.; Schlosser, F. Asphalt mixtures using reclaimed asphalt containing polymer modified binder. Deliverable Nr 4.1 Report of RECYPMA Project initiated by ERA-NET ROAD. 2013. Available online: https://www.cedr.eu/download/other_public_files/research_programme/eranet_road/call_2011/design/recympma/RECYPMA-D-4-1-final-version.pdf (accessed on 3 July 2025).

- Almusawi, A.; Jaleel, M.M.; Shoman, S.; Lupanov, A.P. Enhancing waste asphalt durability through cold recycling and additive integration. Funct. Compos. Mater. 2024, 5, 10. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, C.; Chen, H.; Kang, A.H.; Guan, Y. Research on Macro and Micro Performance Degradation of Hot In-Place Recycled Asphalt Mixtures with High RAP Contents. Case Stud. Constr. Mater. 2025, 22, e04825. [Google Scholar] [CrossRef]

- Circular Economy: Definition, Importance and Benefits. The Circular Economy: Find Out What It Means, How It Benefits You, the Environment and Our Economy. Published: 24-05-2023. Available online: https://www.europarl.europa.eu/topics/en/article/20151201STO05603/circular-economy-definition-importance-and-benefits (accessed on 19 September 2025).

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics,29.9.2025 (accessed on 19 September 2025).

- Madajova, Z.; Belicova, P.; Males, I. Circular Economy in Slovakia. Institute of Circular Economy, oz, pp. 17. 2018. Available online: https://www.incien.sk/wp-content/uploads/2019/01/Bro%C5%BE%C3%BAra-o-cirkul%C3%A1rnej-ekonomike-na-Slovensku-v-roku-2018-Cyan.pdf (accessed on 3 July 2025). (In Slovak).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- OECD. Farm Management Practices to Foster Green Growth; OECD: Paris, France, 2016. [CrossRef]

- MacArthur, E. Towards the circular economy. Ellen MacArthur Found. Rethink. Future 2013, 2, 111. [Google Scholar]

- Ernst & Young. Are You Ready for the Circular Economy? The Necessity of an Integrated Approach; EY: London, UK, 2015. [Google Scholar]

- Píry, M.; Škorvagová, E.; Decký, M. Green Infrastructure: Legislative and behavioral approaches in the context of urban engineering. Civ. Environ. Eng. 2023, 19, 748–757. [Google Scholar] [CrossRef]

- Samek, M. A Holistic Approach to the Recovery of Industrial Wastes in Pavement Constructions. Ph.D. Dissertation, University of Zilina, Zilina, Slovakia, 2025. [Google Scholar]

- Miyatake, Y. Technology development and sustainable construction. J. Manag. Eng. 1996, 12, 23–27. [Google Scholar] [CrossRef]

- Pulaski, M.H.; Horman, M.; Riley, D.; Dahl, P.; Hickey, A.; Lapinski, A.; Vittori, G. Field Guide for Sustainable Construction; Pentagon Renovation and Construction Program Office Safety Sustainability and Environment IPT and Washington Headquarters Services Defense; The Pennsylvania State University: University Park, PA, USA, 2004. [Google Scholar]

- Juhás, M. Balance of Waste Generation in the Slovak Republic in 2005 and 2020. Ph. D. Dissertation, University of Zilina, Zilina, Slovakia, 2023. [Google Scholar]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste management in a sustainable circular economy as a part of design of construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Mandičák, T.; Spišáková, M.; Mésároš, P. Sustainable design and building information modeling of construction project management towards a circular economy. Sustainability 2024, 16, 4376. [Google Scholar] [CrossRef]

- Remišová, E.; Decký, M.; Papán, D. Sustainable Materials and Technologies for Design and Construction of Pavements; Pearson: Harlow Essex England, 2025; p. 120. [Google Scholar]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; ICE Publishing: London, UK, 2015; p. 761. [Google Scholar]

- EN 13108-8:2016; Bituminous Mixtures. Material Specifications. Part 8: Reclaimed Asphalt. CEN: Brussel, Belgium, 2016.

- EAPA. Asphalt in Figures. 2023. Available online: https://eapa.org/asphalt-in-figures-2023/ (accessed on 2 July 2025).

- Šrámek, J.; Decký, M.; Zgútová, K.; Kozel, M.; Remek, Ľ. Management of R-material. Analytical task, Ministry of Transport and Construction of the Slovak Republic, Bratislava, Slovakia. 2022. Available online: https://www.ssc.sk/files/documents/technicke-predpisy/rozborove_ulohy/ru_2022_hospodarenie_r_materialom.pdf (accessed on 17 June 2025). (In Slovak)

- STN 72 1016; Laboratory Determination of the California Bearing Ratio of Soils. UNMS: Bratislava, Slovakia, 1992. (In Slovak)

- EN 13286-47: 2022; Unbound and Hydraulically Bound Mixtures. Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. CEN: Brussel, Belgium, 2022.

- STN 73 6190; Static Plate Load Test of Building Constructions. UNMS: Bratislava, Slovakia, 2019. (In Slovak)

- STN 73 6133; Road Building. Roads Embankments and Subgrades. UNMS: Bratislava, Slovakia, 2017. (In Slovak)

- STN 72 1015; Laboratory Determination of Earth Compactibility. UNMS: Bratislava, Slovakia, 1988. (In Slovak)

- Plati, C.; Tsakoumaki, M.; Gkyrtis, K. Physical and Mechanical Properties of Reclaimed Asphalt Pavement (RAP) Incorporated into Unbound Pavement Layers. Appl. Sci. 2023, 13, 362. [Google Scholar] [CrossRef]

- Domitrović, J.; Rukavina, T.; Dimter, S. Properties of unbound base course mixes with recycled asphalt. GRAĐEVINAR 2016, 68, 269–277. [Google Scholar] [CrossRef]

- Hodásová, K. Innovative, Climate-Adaptive Constructions of Paved Traffic Surfaces. Ph. D. Dissertation, University of Zilina, Zilina, Slovakia, 2024. [Google Scholar]

- Decky, M.; Hodasova, K.; Papanova, Z.; Remisova, E. Sustainable adaptive cycle pavements using composite foam concrete at high altitudes in central Europe. Sustainability 2022, 14, 9034. [Google Scholar] [CrossRef]

- Iwanski, M.M.; Linek, M.; Nita, P.; Piotrovska, P.; Remišová, E. Assessment of suitability of reclaimed asphalt pavement material for use in cement concrete pavements. Roads Bridges—Drog. I Mosty 2023, 22, 63–80. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable practice in pavement engineering through value-added collective recycling of waste plastic and waste tyre rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Lan, J.; Chen, R.; Jiang, J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J. Clean. Prod. 2022, 336, 130405. [Google Scholar] [CrossRef]

- Zhang, K.; Xiong, J.; Ruiz, C.; Zhang, J. Design and performance assessment of sustainable road pothole patching materials using waste cooking oil, plastic, and reclaimed asphalt pavement. Constr. Build. Mater. 2024, 429, 136426. [Google Scholar] [CrossRef]

- Ji, G.; Wang, X.; Guo, Y.; Zhang, Y.; Yin, Q.; Luo, Y. Study on the Physical, Chemical and Nano-Microstructure Characteristics of Asphalt Mixed with Recycled Eggshell Waste. Sustainability 2021, 13, 11173. [Google Scholar] [CrossRef]

- Aswathi, V.P.; Meera, S.; Maria, C.G.A.; Nidhin, M. Green synthesis of nanoparticles from biodegradable waste extracts and their applications: A critical review. Nanotechnol. Environ. Eng. 2023, 8, 377–397. [Google Scholar] [CrossRef]

- Debnath, J.; Singh, K.L.; Kuity, A. A review study on utilization of waste cooking oil, eggshell, glass, and plastic in bituminous mixtures. Environ. Sci. Pollut. Res. 2025, 32, 1–23. [Google Scholar] [CrossRef]

- Yao, H.; Zeng, J.; Wang, Y.; You, Z. Review of Nanomaterials in Pavement Engineering. ACS Appl. Nano Mater. 2025, 8, 5254–5274. [Google Scholar] [CrossRef]

- Zhang, J.; Sesay, T.; You, Q.; Jing, H. Maximizing the Application of RAP in Asphalt Concrete Pavements and Its Long-Term Performance: A Review. Polymers 2022, 14, 4736. [Google Scholar] [CrossRef] [PubMed]

- Blacktop, R. 6 Benefits of Recycling Asphalt. Richfield Blacktop. 2020. Available online: https://www.richfieldblacktop.com/asphalt-recycling (accessed on 3 November 2025).

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

| Year | Total Amount of Site-Won Asphalt Generated in Year in Million Tons | Amount of RA Available to be Used by the Asphalt Industry in Million Tons | Total Reuse in % | Total Recycling in % | Total Landfill in % |

|---|---|---|---|---|---|

| 2021 | 56.009 | 32.166 | 72.0 | 25.0 | 3.0 |

| 2022 | 45.484 | 40.681 | 71.3 | 22.6 | 3.9 |

| 2023 | 52.755 | 41.441 | 76.0 | 20.0 | 4.0 |

| Sieve size [mm] | 22.4 | 16 | 11.2 | 8 | 4 | 2 | 1 | 0.5 | 0.25 | 0.125 | 0.063 |

| Passing [%] | 100 | 99.6 | 94.1 | 78.2 | 51.3 | 27.9 | 22.1 | 16.3 | 13.1 | 10.9 | 9.3 |

| Date | Assessed Deformation Characteristics | Assessed Deformation Characteristics of SPLT for 1. and 2. Load Cycles (LCs) and the Area of the Load Plate | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A = 0.100 m2 | A = 0.200 m2 | A = 0.283 m2 | ||||||||

| 1. LC | 2. LC | Ratio 2. LC/1. LC | 1. LC | 2. LC | Ratio 2. LC/1. LC | 1. LC | 2. LC | Ratio 2. LC/1. LC | ||

| 23 November 2017 | Static modulus of elasticity, Ei [MPa] | 27.1 | 25.4 | 0.93 | 23.1 | 22.6 | 0.98 | 24.8 | 24.5 | 0.99 |

| Static modulus of deformation, E0,i [MPa] | 14.5 | 23.7 | 1.63 | 10.4 | 20.0 | 1.92 | 15.6 | 22.0 | 1.41 | |

| Modulus of transformation, Edef,i [MPa] | 13.8 | 25.1 | 1.82 | 11.9 | 21.8 | 1.83 | 16.8 | 22.0 | 1.31 | |

| Reaction modulus, kpi,1.27 mm [MN/m3] | 37.0 | 41.3 | 1.12 | 27.8 | 32.6 | 1.52 | 43.5 | 40.4 | 0.93 | |

| Recalculated reaction modulus, kpi,0.07 mm [MN/m3] | 38.8 | 41.0 | 1.06 | 19.5 | 32.8 | 1.68 | 44.0 | 40.4 | 0.92 | |

| Test Date | Air Temperature [°C] | Average Moisture MRAM w [%] |

|---|---|---|

| 3 November 2022 | 6 | 3.78 |

| 10 February 2023 | −4 | 4.17 |

| 10 August 2023 | 18 | 2.42 |

| Parameter CBR | Parameter CBR | ||||

|---|---|---|---|---|---|

| Compaction Method | |||||

| Proctor Standard | Proctor Modified | Proctor Modified | |||

| Temperature [°C] | CBR [%] | Temperature [°C] | CBR [%] | Moisture [%] | IBI [%] |

| 40 | 6 | 40 | 4 | 3.2 | 28 |

| 50 | 13 | 50 | 11 | 3.5 | 27 |

| 55 | 16 | 60 | 22 | 5.5 | 15 |

| 60 | 24 | 65 | 32 | 7.5 | 14 |

| 70 | 38 | 70 | 45 | 10.5 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decký, M.; Remišová, E.; Samek, M. Research on the Possibilities of Reusing Mixed Reclaimed Asphalt Materials with a Focus on the Circular Economy. Appl. Sci. 2025, 15, 12004. https://doi.org/10.3390/app152212004

Decký M, Remišová E, Samek M. Research on the Possibilities of Reusing Mixed Reclaimed Asphalt Materials with a Focus on the Circular Economy. Applied Sciences. 2025; 15(22):12004. https://doi.org/10.3390/app152212004

Chicago/Turabian StyleDecký, Martin, Eva Remišová, and Martin Samek. 2025. "Research on the Possibilities of Reusing Mixed Reclaimed Asphalt Materials with a Focus on the Circular Economy" Applied Sciences 15, no. 22: 12004. https://doi.org/10.3390/app152212004

APA StyleDecký, M., Remišová, E., & Samek, M. (2025). Research on the Possibilities of Reusing Mixed Reclaimed Asphalt Materials with a Focus on the Circular Economy. Applied Sciences, 15(22), 12004. https://doi.org/10.3390/app152212004