A New Mathematical Model for the Features of Bubble Collapse in Steam Cavitation Processes

Abstract

1. Introduction

2. Mathematical Model and Methodology

2.1. Governing Equations

2.2. Modelling of Phase Transitions and Boundary Conditions

3. Results

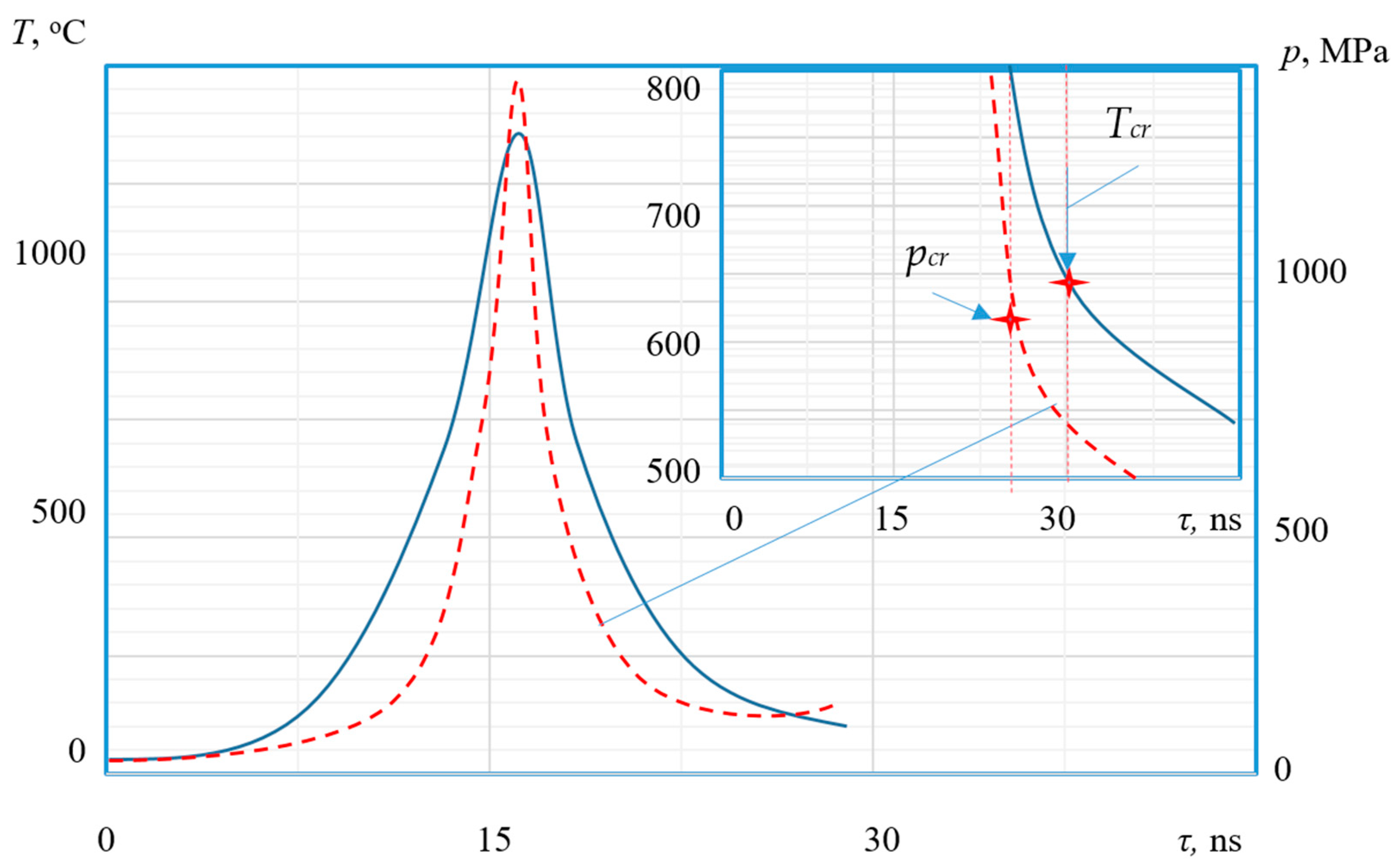

3.1. Theoretical Analysis of Bubble Collapse Conditions

3.2. Comparison with Experimental Data for Hydrodynamic Cavitation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| p | pressure, Pa |

| R, r | radius, mm |

| T | temperature, °C |

| τ | time, s |

| B | universal gas constant |

| Mg, Mst | relative molecular masses of neutral gas and vapour, respectively |

| ag, bg | Van der Waals constants for gas |

| ast, bst | Van der Waals constants for vapour |

| mg | mass of the gas mixture |

| ust, ug | molecular kinetic velocities of vapour and gas molecules, respectively |

| c | specific heat capacity |

| j | mass flux |

| L | latent heat of evaporation (condensation) |

| M | molecular mass |

| m | mass |

| p | pressure |

| pst | partial pressure |

| Q | heat flow |

| q | specific heat flow |

| R | radius |

| r | radial coordinate |

| T | temperature |

| Tf | liquid phase temperature |

| u, v | velocity |

| w, wr | radial velocity |

| δ | boundary layer thickness |

| λ | thermal conductivity coefficient |

| µ | dynamic viscosity coefficient; chemical potential |

| ρ | density |

| σ | interfacial tension coefficient |

| τ | time |

| Subscripts | |

| 0 | initial value |

| boil | boiling |

| cr | critical |

| f | liquid |

| s | surface |

| st | vapour |

References

- Zhao, Y.; Jiang, S.; Wang, X.; Guo, W.; Zhao, G.; Zhao, F.; Xu, W. Study on the collapse process of double cavitation bubble based on coarse-grained force field. J. Mol. Liq. 2025, 429, 127517. [Google Scholar] [CrossRef]

- Świetlicki, A.; Szala, M.; Walczak, M. Effects of Shot Peening and Cavitation Peening on Properties of Surface Layer of Metallic Materials-A Short Review. Materials 2022, 15, 2476. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Yu, J.; Zhang, X.P.; Hao, Y.; Chen, J.-P.; Xu, Y.-Q. Study on dynamic characteristics of cavitation in underwater explosion with large charge. Sci. Rep. 2024, 14, 8580. [Google Scholar] [CrossRef]

- Pandit, A.V.; Sarvothaman, V.P.; Ranade, V.V. Estimation of chemical and physical effects of cavitation by analysis of cavitating single bubble dynamics. Ultrason. Sonochem. 2021, 77, 105677. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Trushliakov, E.; Pavlenko, A.; Radchenko, R. Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria. Energies 2023, 16, 1381. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, J.; Ye, J.; Gao, Z. Numerical Study on the Dynamics and Thermal Effects of Bubble Stable Cavitation in Focused Ultrasound Fields. Processes 2025, 13, 951. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Intensification of Gas Hydrate Formation Processes by Renewal of Interfacial Area between Phases. Energies 2021, 14, 5912. [Google Scholar] [CrossRef]

- Pavlenko, A.; Koshlak, H.; Usenko, B. The processes of heat and mass exchange in the vortex devices. Metall. Min. Ind. 2014, 6, 55–59. [Google Scholar]

- Hao Geng, Tairan Chen, Jiacheng Chen, Biao Huang, Guoyu Wang, Temperature effects on single cavitation bubble dynamics under the free field condition: Experimental and theoretical investigations on water. Ultrason. Sonochem. 2025, 120, 107520. [CrossRef] [PubMed]

- Yu, L.; Cheng, L.; Sheng, W.; Lei, S.; Xu, W.; Shen, J. Research on the energy characteristics of the turning region in the cavitation performance curve of an axial flow pump based on energy flow density and entropy production. Eng. Appl. Comput. Fluid Mech. 2025, 19, 2499132. [Google Scholar] [CrossRef]

- Zheng, H.; Zheng, Y.; Zhu, J. Recent Developments in Hydrodynamic Cavitation Reactors: Cavitation Mechanism, Reactor Design, and Applications. Engineering 2022, 19, 180–198. [Google Scholar] [CrossRef]

- Tiong, T.J.; Chu, J.K.; Tan, K.W. Advancements in Acoustic Cavitation Modelling: Progress, Challenges, and Future Directions in Sonochemical Reactor Design. Ultrason. Sonochem. 2025, 112, 107163. [Google Scholar] [CrossRef] [PubMed]

- Ashokkumar, M. The characterization of acoustic cavitation bubbles—An overview. Ultrason. Sonochem. 2011, 18, 864–872. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Das, R.S.; Bhavya, M.L.; Garcia-Vaquero, M.; Tiwari, B.K. Acoustic cavitation for agri-food applications: Mechanism of action, design of new systems, challenges and strategies for scale-up. Ultrason. Sonochem. 2024, 105, 106850. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; You, W.; Xuan, X.; Ji, L.; Xu, X.; Wang, G.; Zhao, S.; Boczkaj, G.; Yoon, J.Y.; Chen, S. Effect of the cavitation generation unit structure on the performance of an advanced hydrodynamic cavitation reactor for process intensifications. Chem. Eng. J. 2021, 412, 128600. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Application of Thermal and Cavitation Effects for Heat and Mass Transfer Process Intensification in Multicomponent Liquid Media. Energies 2021, 14, 7996. [Google Scholar] [CrossRef]

- Gevari, M.T.; Abbasiasl, T.; Niazi, S.; Ghorbani, M.; Koşar, A. Direct and indirect thermal applications of hydrodynamic and acoustic cavitation: A review. Appl. Therm. Eng. 2020, 171, 115065. [Google Scholar] [CrossRef]

- Ge, M.; Petkovšek, M.; Zhang, G.; Jacobs, D.; Coutier-Delgosha, O. Cavitation dynamics and thermodynamic effects at elevated temperatures in a small Venturi channel. Int. J. Heat Mass Transf. 2021, 170, 120970. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Trushliakov, E.; Koshlak, H.; Radchenko, R. Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast Onsite Operation—Part 2: Phenomenological Simulation to Recoup Refrigeration Energy. Energies 2023, 16, 1922. [Google Scholar] [CrossRef]

- Galloni, M.G.; Fabbrizio, V.; Giannantonio, R.; Falletta, E.; Bianchi, C.L. Applications and applicability of the cavitation technology. Curr. Opin. Chem. Eng. 2025, 48, 101129. [Google Scholar] [CrossRef]

- Falletta, E.; Donnadio, A.; Mila, N.; Haghshenas, N.; Fabbrizio, V.; Vivani, R.; Giordana, A.; Perna, G.; Cottone, F.; Di Michele, A.; et al. Ultrasound-assisted synthesis of strontium-bismuth titanate and its application in environmental remediation. Ultrason. Sonochem. 2025, 118, 107380. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Xu, H.; Xuan, X.; Manickam, S.; Boczkaj, G.; Wang, B. Assessing the industrialization progress of hydrodynamic cavitation process intensification technology: A review. Curr. Opin. Chem. Eng. 2024, 45, 101037. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Z.; Yang, B.; Liu, L. Insights into cavitation enhancement: Numerical simulation and spectrum analysis of a novel dual-frequency octagonal ultrasonic reactor. Ultrason. Sonochem. 2025, 112, 107197. [Google Scholar] [CrossRef]

- Hattori, K.D.; Yamamoto, T. Stability analysis of the effect of harmonic waves on the shape stability of acoustic cavitation bubbles. Ultrason. Sonochem. 2025, 120, 107444. [Google Scholar] [CrossRef]

- Yamamoto, T. Linear stability analysis for bubble shape of acoustic cavitation with different ultrasonic frequencies. Phys. Fluids 2024, 36, 112127. [Google Scholar] [CrossRef]

- Yamamoto, T. Bubble shape instability of acoustic cavitation in molten metal used in ultrasonic casting. Ultrason. Sonochem. 2024, 111, 107064. [Google Scholar] [CrossRef] [PubMed]

- Klapcsik, K. GPU accelerated numerical investigation of the spherical stability of an acoustic cavitation bubble excited by dual-frequency. Ultrason. Sonochem. 2021, 77, 105684. [Google Scholar] [CrossRef]

- Vogel, A.; Lauterborn, W.; Timm, R. Optical and acoustic investigations of the dynamics of laser-produced cavitation bubbles near a solid boundary. J. Fluid Mech. 1989, 206, 299–338. [Google Scholar] [CrossRef]

- Pavlenko, A.; Koshlak, H. Study of the Dynamics of a Single Bubble. Energies 2024, 17, 4236. [Google Scholar] [CrossRef]

- Pavlenko, A.M. Change of emulsion structure during heating and boiling. Int. J. Energy Clean Environ. 2019, 20, 291–302. [Google Scholar] [CrossRef]

- Pavlenko, A. Numerical Modeling of the Behavior of Bubble Clusters in Cavitation Processes. Energies 2024, 17, 1741. [Google Scholar] [CrossRef]

- Zhang, A.-M.; Li, S.-M.; Cui, P.; Li, S.; Liu, Y.-L. A unified theory for bubble dynamics. Phys. Fluids 2023, 35, 033323. [Google Scholar] [CrossRef]

- Deike, L. Mass transfer at the ocean-atmosphere interface: The role of wave breaking, droplets, and bubbles. Annu. Rev. Fluid Mech. 2022, 54, 191–224. [Google Scholar] [CrossRef]

- Yan, S.-L.; Wang, X.-Q.; Zhu, L.-T.; Zhang, X.-B.; Luo, Z.-H. Mechanisms and modeling of bubble dynamic behaviors and mass transfer under gravity: A review. Chem. Eng. Sci. 2023, 277, 118854. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, P.; Ren, Z.; Yu, L.; Zuo, Z.; Liu, S. Dynamics of cavitation bubbles in viscous liquids in a tube during a transient process. Ultrason. Sonochem. 2024, 104, 106840. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, P.; Zuo, Z.; Liu, S. Effect of liquid elasticity on transient cavitation bubbles in the tube. Phys. Fluids 2024, 36, 081702. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, Y.; Yin, J.; Lv, L.; Zhang, J.; Zhu, J. Investigation on heat and mass transfer characteristics of a near-wall multi-cycle cavitation bubble and its thermal effects on the wall using an improved compressible multiphase model. Ocean Eng. 2024, 298, 117118. [Google Scholar] [CrossRef]

- Choi, K.; Kim, S.; Kim, H.; Kim, C. Computational investigation on the non-isothermal phase change during cavitation bubble pulsations. Ocean Eng. 2023, 285 Pt 2, 115414. [Google Scholar] [CrossRef]

- Yamamoto, T. Mass transfer of chemical specie in acoustic cavitation bubble. Chem. Eng. Sci. 2024, 287, 119739. [Google Scholar] [CrossRef]

- Phan, T.-H.; Nguyen, V.-T.; Duy, T.-N.; Kim, D.-H.; Park, W.-G. Influence of phase-change on the collapse and rebound stages of a single spark-generated cavitation bubble. Int. J. Heat Mass Transf. 2022, 184, 122270. [Google Scholar] [CrossRef]

- Phan, T.-H.; Kadivar, E.; Nguyen, V.-T.; el Moctar, O.; Park, W.-G. Thermodynamic effects on single cavitation bubble dynamics under various ambient temperature conditions. Phys. Fluids 2022, 34, 023318. [Google Scholar] [CrossRef]

- Qin, D.; Lei, S.; Chen, B.; Li, Z.; Wang, W.; Ji, X. Numerical investigation on acoustic cavitation characteristics of an air-vapor bubble: Effect of equation of state for interior gases. Ultrason. Sonochem. 2023, 97, 106456. [Google Scholar] [CrossRef]

- Wang, T.; Chen, L. Thermodynamic Behavior and Energy Transformation Mechanism of the Multi-Period Evolution of Cavitation Bubbles Collapsing near a Rigid Wall: A Numerical Study. Energies 2023, 16, 1048. [Google Scholar] [CrossRef]

- Phan, T.-H.; Nguyen, V.-T.; Duy, T.-N.; Kim, D.-H.; Park, W.-G. Numerical study on simultaneous thermodynamic and hydrodynamic mechanisms of underwater explosion. Int. J. Heat Mass Transf. 2021, 178, 121581. [Google Scholar] [CrossRef]

- Qu, T.; Luo, J.; Xu, W.; Li, J.; Fu, G.; Ma, Y.; Zhao, Z. Experimental study on the collapse behavior of cavitation bubbles under low ambient pressure conditions. Ultrason. Sonochem. 2025, 114, 107255. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Avila, S.R.; Denner, F.; Ohl, C.-D. The acoustic pressure generated by the cavitation bubble expansion and collapse near a rigid wall. Phys. Fluids 2021, 33, 032118. [Google Scholar] [CrossRef]

- Denner, F.; Evrard, F.; van Wachem, B. Modeling Acoustic Cavitation Using a Pressure-Based Algorithm for Polytropic Fluids. Fluids 2020, 5, 69. [Google Scholar] [CrossRef]

- Sun, X.; Liu, S.; Zhang, X.; Tao, Y.; Boczkaj, G.; Yoon, J.Y.; Xuan, X. Recent advances in hydrodynamic cavitation-based pretreatments of lignocellulosic biomass for valorization. Bioresour. Technol. 2022, 345, 126251. [Google Scholar] [CrossRef]

- Panda, D.; Saharan, V.K.; Manickam, S. Controlled Hydrodynamic Cavitation: A Review of Recent Advances and Perspectives for Greener Processing. Processes 2020, 8, 220. [Google Scholar] [CrossRef]

- Hamidi, R.; Damizia, M.; De Filippis, P.; Patrizi, D.; Verdone, N.; Vilardi, G.; de Caprariis, B. Recent developments and future outlooks of hydrodynamic cavitation as an intensification technology for renewable biofuels production. J. Environ. Chem. Eng. 2023, 11, 110819. [Google Scholar] [CrossRef]

- Ge, M.; Sun, C.; Zhang, G.; Coutier-Delgosha, O.; Fan, D. Combined suppression effects on hydrodynamic cavitation performance in Venturi-type reactor for process intensification. Ultrason. Sonochem. 2022, 86, 106035. [Google Scholar] [CrossRef] [PubMed]

- Soyama, H.; Liang, X.; Yashiro, W.; Kajiwara, K.; Asimakopoulou, E.M.; Bellucci, V.; Birnsteinova, S.; Giovanetti, G.; Kim, C.; Kirkwood, H.J.; et al. Revealing the origins of vortex cavitation in a Venturi tube by high speed X-ray imaging. Ultrason. Sonochem. 2023, 101, 106715. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, H.; Wang, Z.; Zhang, J.; Wang, J. Analysis of the Effects of Nozzle Geometry on the Cavitation Water Jet Flow Field Using Orthogonal Decomposition. Iran. J. Sci. Technol. Trans. Mech. Eng. 2024, 48, 119–132. [Google Scholar] [CrossRef]

- Soyama, H.; Hiromori, K.; Shibasaki-Kitakawa, N. Simultaneous extraction of caffeic acid and production of cellulose microfibrils from coffee grounds using hydrodynamic cavitation in a Venturi tube. Ultrason. Sonochem. 2025, 118, 107370. [Google Scholar] [CrossRef]

- Apte, D.; Ge, M.; Zhang, G.; Coutier-Delgosha, O. Numerical investigation of three-dimensional effects of hydrodynamic cavitation in a Venturi tube. Ultrason. Sonochem. 2024, 111, 107122. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Karri, R.R.; Koduru, J.R.; Manickam, S.; Tyagi, I.; Mubarak, N.M.; Suhas. Recent trends in the applications of sonochemical reactors as an advanced oxidation process for the remediation of microbial hazards associated with water and wastewater: A critical review. Ultrason. Sonochem. 2023, 94, 106302. [Google Scholar] [CrossRef] [PubMed]

- Petkovšek, M.; Dular, M. IR measurements of the thermodynamic effects in cavitating flow. Int. J. Heat Fluid Flow 2013, 44, 756–763. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koshlak, H.; Pavlenko, A. A New Mathematical Model for the Features of Bubble Collapse in Steam Cavitation Processes. Appl. Sci. 2025, 15, 9948. https://doi.org/10.3390/app15189948

Koshlak H, Pavlenko A. A New Mathematical Model for the Features of Bubble Collapse in Steam Cavitation Processes. Applied Sciences. 2025; 15(18):9948. https://doi.org/10.3390/app15189948

Chicago/Turabian StyleKoshlak, Hanna, and Anatoliy Pavlenko. 2025. "A New Mathematical Model for the Features of Bubble Collapse in Steam Cavitation Processes" Applied Sciences 15, no. 18: 9948. https://doi.org/10.3390/app15189948

APA StyleKoshlak, H., & Pavlenko, A. (2025). A New Mathematical Model for the Features of Bubble Collapse in Steam Cavitation Processes. Applied Sciences, 15(18), 9948. https://doi.org/10.3390/app15189948