Study of Electrical Contact in a System for High Power Transmission Through Well Piping

Abstract

Featured Application

Abstract

1. Introduction

- High-voltage effects on the system:

- ○

- Arcing effects;

- ○

- Electric etching;

- ○

- Contact welding;

- ○

- Heating at current transfer interfaces.

- Mechanical and chemical failure mechanisms in the system:

- ○

- Fatigue;

- ○

- Corrosion;

- ○

- Surface treatment and roughness.

2. Materials and Methods

2.1. High-Voltage Effects

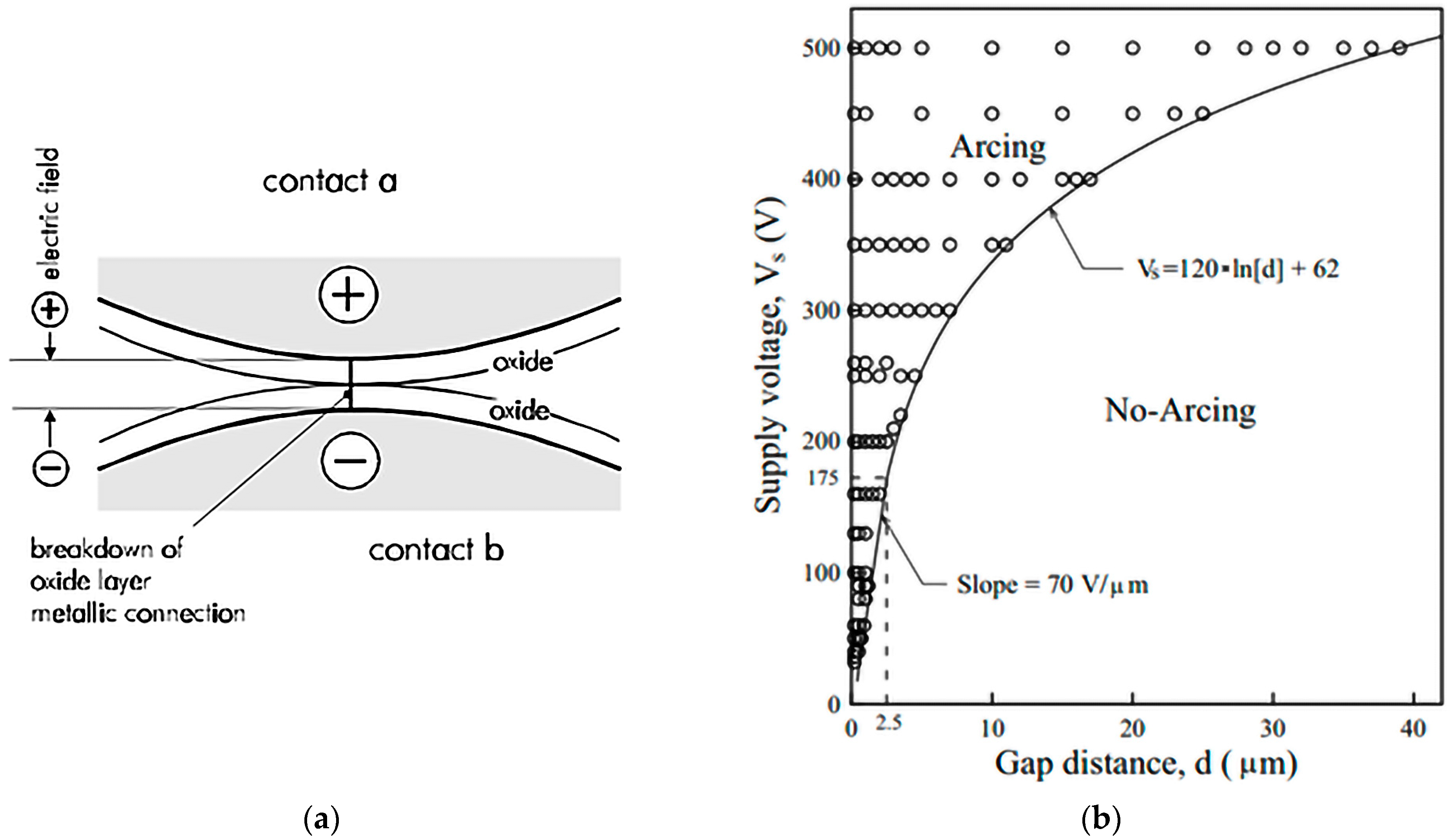

2.1.1. Arcing Effects

- A reliable contact between packer slip teeth and the casing surface must be provided to avoid contact fritting;

- Current switching should be performed when the packer slip is closed.

2.1.2. Electric Etching

- k—units-related coefficient (k = 0.1 when units are µm, V, and nF);

- U—voltage, V;

- C—capacitance, nF.

2.1.3. Electric Arcing and Etching Summary

2.1.4. Contact Welding

- The first option is by electric arc in the contact area. It is unlikely for this option to occur due to the following circumstances: the absence of switching (on or off) under voltage, and relatively high pressure (30 MPa) during current flow. For a micro-arc to ignite during current flow through a closed contact, it is necessary for the voltage across the connection to exceed the ionization potential of the medium. Since the drop in contact resistance is not expected to exceed 0.1V, the occurrence of this mechanism is unlikely.

- The second option involves the possibility of cold pressure welding occurrence in the contact system. This option, however, is not applicable in steel, where temperatures (up to 100 °C ÷ 150 °C) are insufficient to conduct effective diffusion processes in the joining area.

- The third option is the formation of a compound through increased welding resistance (resistance flash welding is not applicable). This requires volumetric flow of plastic deformation in the joining area and an increase in temperature to a value close to the solidus temperature (typically 0.8 of the melting temperature expressed in Kelvin degrees). For this process to happen, the current density should be in the range of 15 to 30 A/mm2, but in some instances the welding current density reaches 3000 A/mm2. Based on the material properties and the initial conditions, it can be argued that such a compound cannot be formed. However, heating of the system components should be analyzed to confirm that the probability of forming individual welded sections is very low.

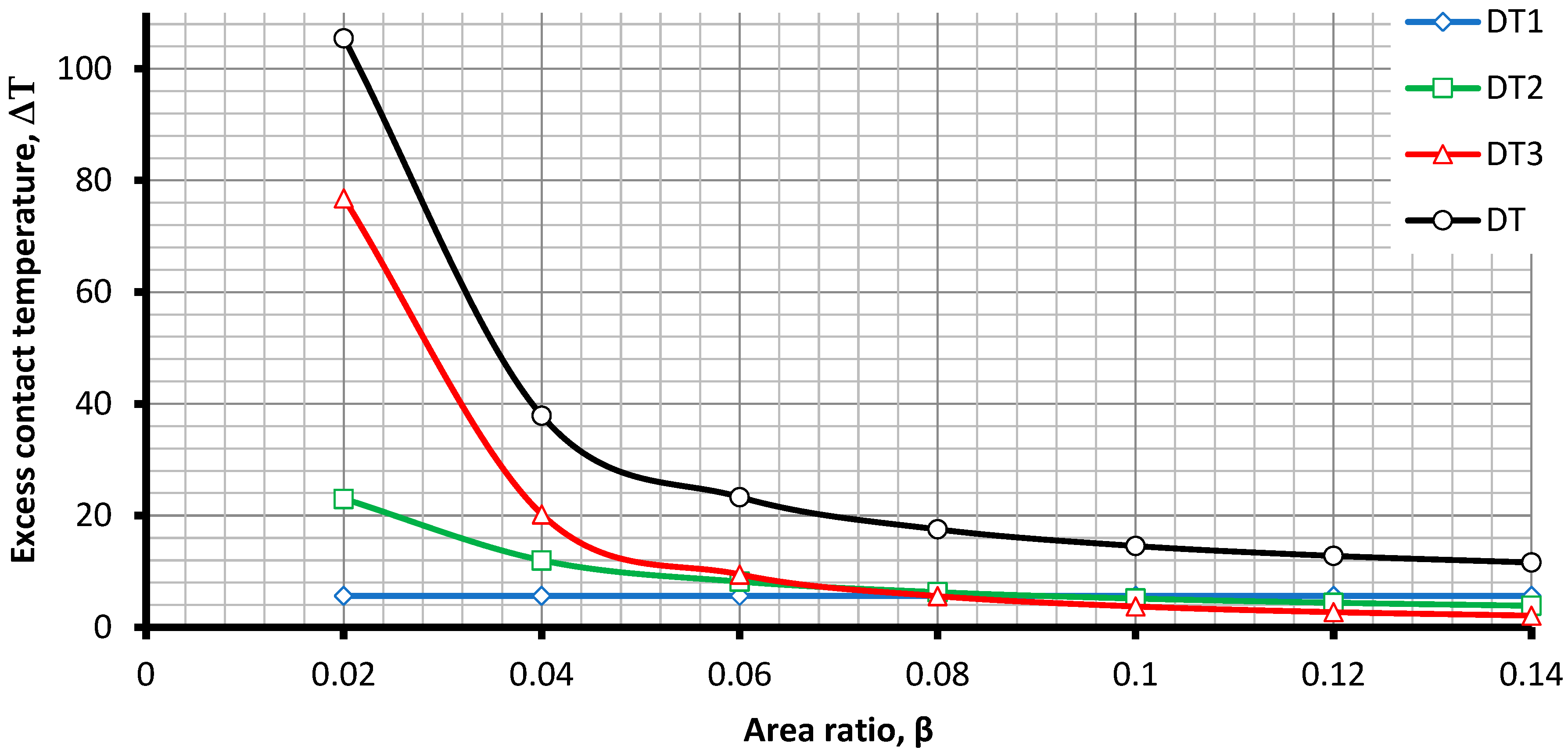

- ΔT1 is the excess temperature of the contact parts forming the contact system over the ambient temperature. This excess is determined by the heat generated by the current through the contact parts and heat removal. The highest value occurs in the tubing and is used;

- ΔT2 is the excess temperature of the contacting zone over the temperature of the contact parts;

- ΔT3 is the excess temperature of the effective area of the contact parts over the temperature of the conditioned area of the contact parts.

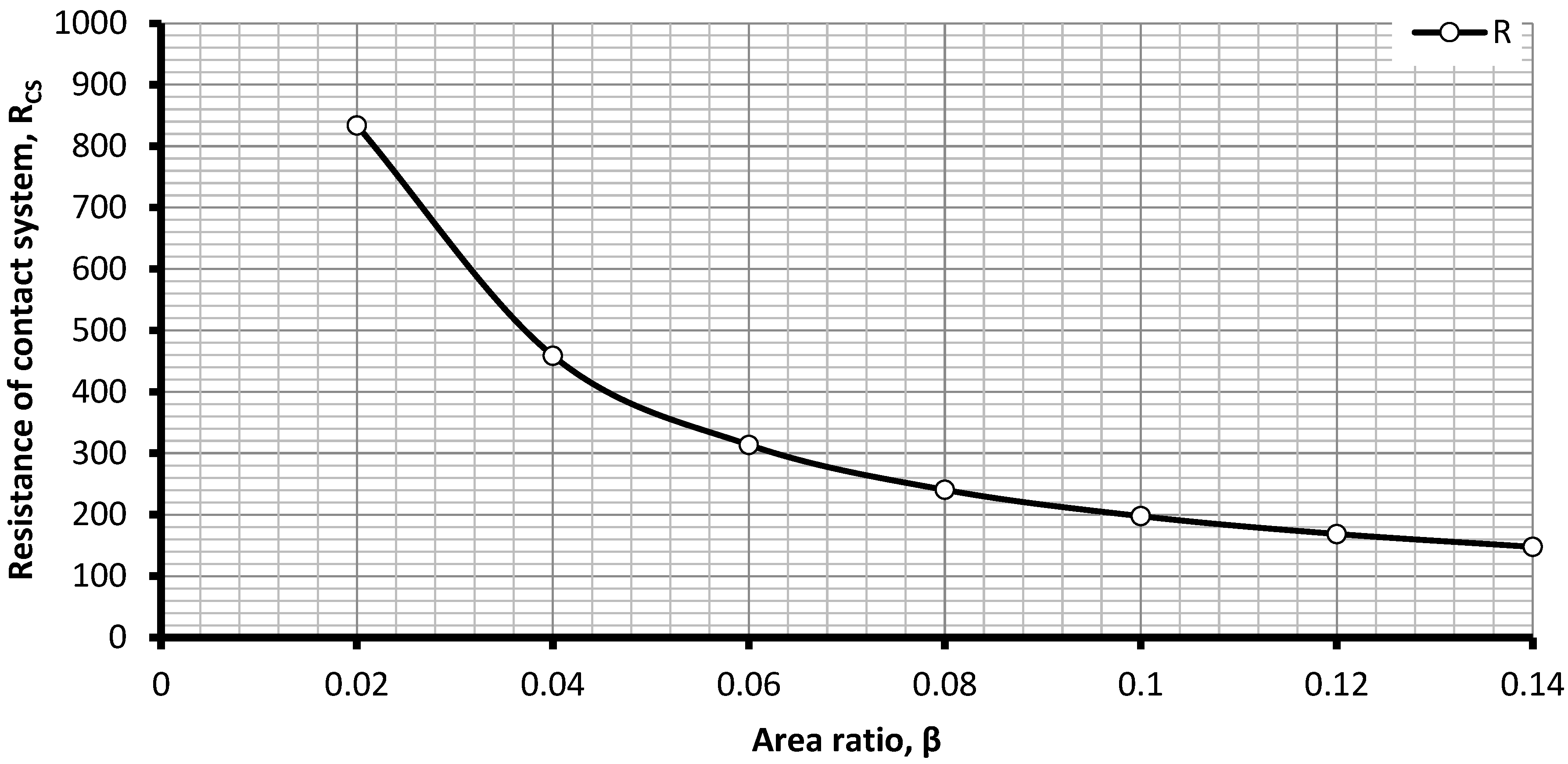

Determination of the Temperature Increase in the Tube from the Current Flow

Determination of the Excess Temperature at the Area of Contact over the Temperature of the Contact Parts

Determination of the Excess Temperature of the Effective Area of the Contact over the Temperature of Conditioned Area of the Contact

2.1.5. High-Voltage Effects—Summary

Several Assumptions Can Be Made Based on the Performed Research Regarding High-Voltage Effects (Arcing, Etching, Welding, and Heating)

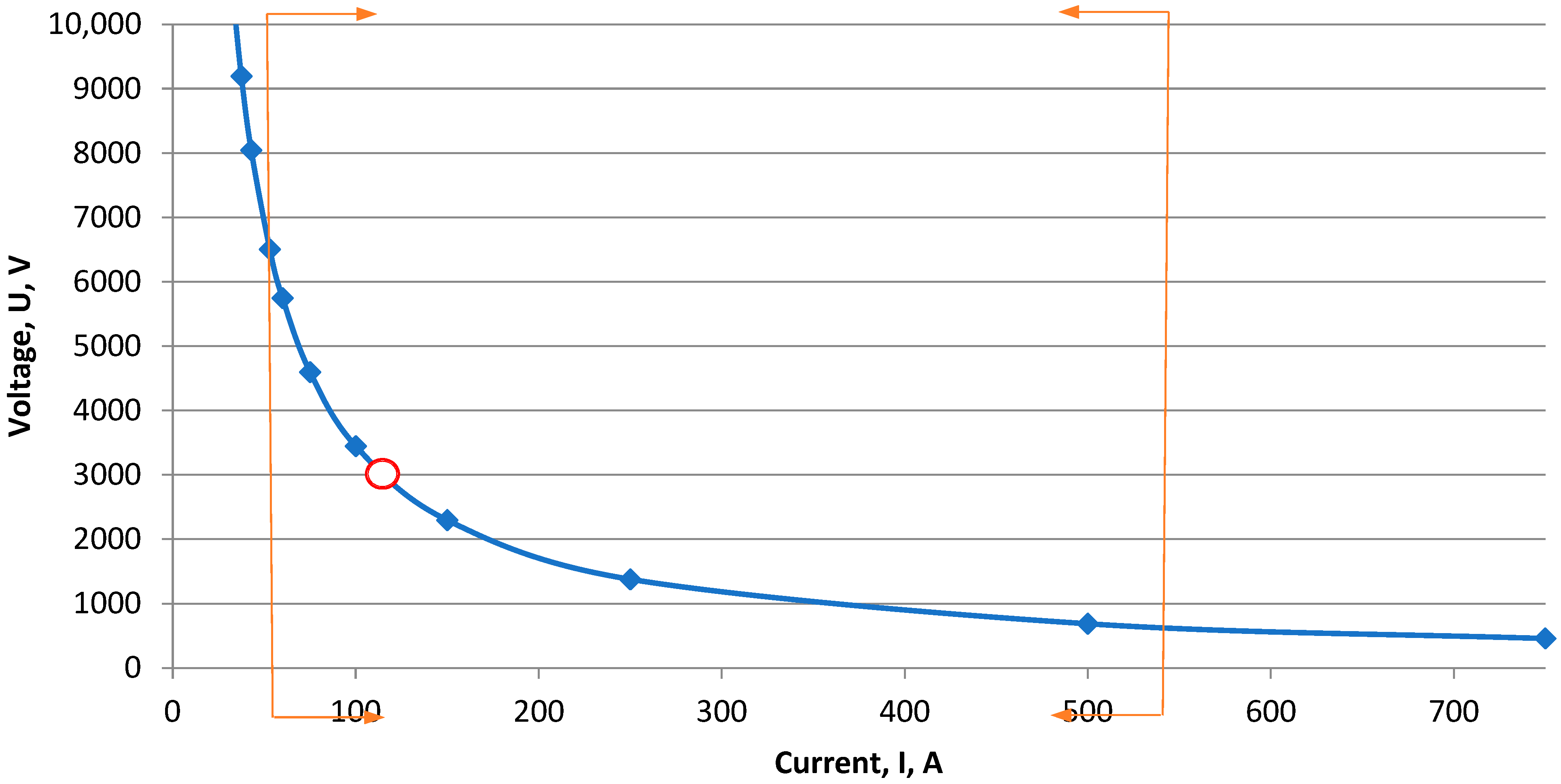

- The main goal here was to determine possible combinations of voltage and current that will result in 300 kW electric power transfer. Thus, the functioncan be used, and it is graphically presented in Figure 6 for cosφ = 0.87.

- Next, current density through the contact pair should be considered as a limitation. This is defined by the study of contact welding process possibilities, where examined values vary from 3 A/cm2 up to 30 A/cm2 (expected maximum possible value). Corresponding current values of 53 A and 530 A are shown as limiting lines in Figure 6.

- The second limitation results from the study of arcing effects. Assuming that the current will be switched on after slip activation, calculations show that it does not influence voltage choice.

- The third limitation is the breakdown voltage between two conducting bodies—the casing and the production tube (the nearest point of the production tube is the connector, about 16 mm away from the casing). Paschen’s law can be applied, simplified by performed tests, as the following formula to determine breakdown voltage through dry air at standard atmosphere pressure [25]:

- The fourth limitation is related to electric etching, specifically the linear etching velocity. The corresponding values for both voltage variants are shown for steel to steel contact as follows:

- ○

- For U = 925 V, the linear etching velocity is 4.5 μm/year;

- ○

- For U = 3 kV, the linear etching velocity is 14.5 μm/year.

- Finally, the approximate power losses (considering only the main conducting bodies—the production tube and the casing, initially excluding the gap-sub joints and all contact resistances) are to be calculated for the two possible voltage variants—925 V and 3 kV. These values correspond to currents of 372.6 A and 115 A. Assuming a tube length of 3700 m, a casing pipe of 5.5”, and production tubing of 2.375”, the corresponding overall power losses can be calculated as follows:

2.2. Mechanical and Chemical Failure Mechanisms

2.2.1. Fatigue

- Steady loads—basically, these are the loads applied by the packer slips when connected to the casing (borehole wall);

- Fluctuating loads—these loads result in thermal stresses in slips and casing near their contact zone, caused by switching power supply.

- Electrolytic Plating: Metallic coatings (plating) with chromium, nickel, or cadmium reduce the fatigue limit by half, making it necessary to eliminate the plating process. Other platings, such as zinc, do not affect the fatigue strength. Light alloys, with anodic oxidation, lead to a nearly 40% reduction in the fatigue limit for bending, but it do not affect torsional fatigue.

- Metal Spraying: This reduces the fatigue limit by about 15% of due to surface imperfections that can initiate cracks.

- Fretting Corrosion: This is caused by small relative displacements in tightly assembled components, such as bolted connections, wheel hubs, etc. The process is also referred to as pitting and leads to eventual failure due to fatigue.

- Low-frequency thermal cycling;

- High-frequency thermal cycling.

- Brittle materials (for instance, cast iron): initiation of cracks in the hot zone of the component (thermal cycling), and probable propagation through the section.

- Ductile iron materials: severe distortion, leading to general failure.

- All materials, when improper materials are selected or with insufficient design stiffness: general cracking through the entire section during the first few cycles, known as low-cycling fatigue.

- Failures caused by problems in production technology: materials with lower mechanical properties because of process variations, leading to the premature failure of components.

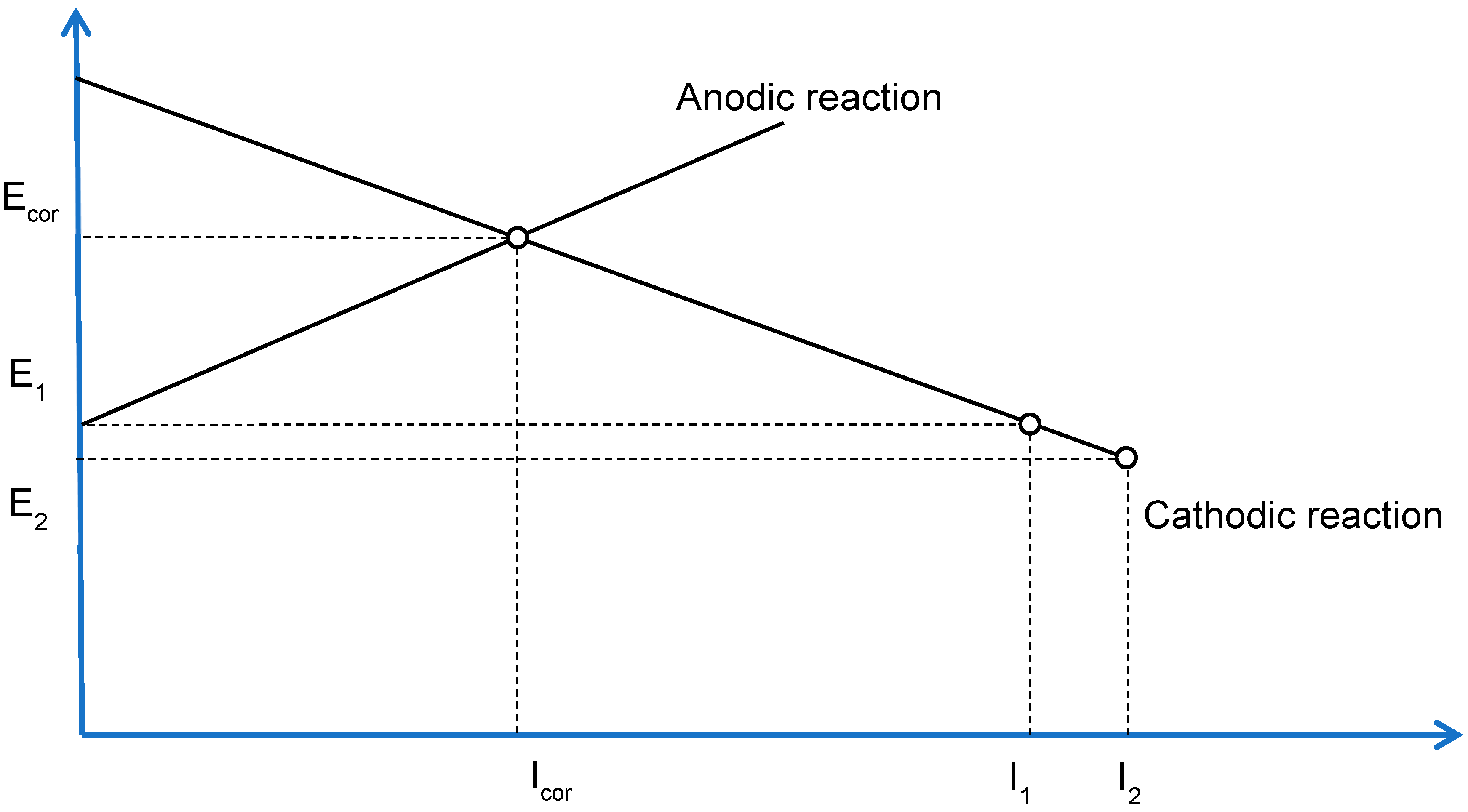

2.2.2. Electrochemical Corrosion and Corrosion Protection

2.2.3. Surface Treatment and Roughness

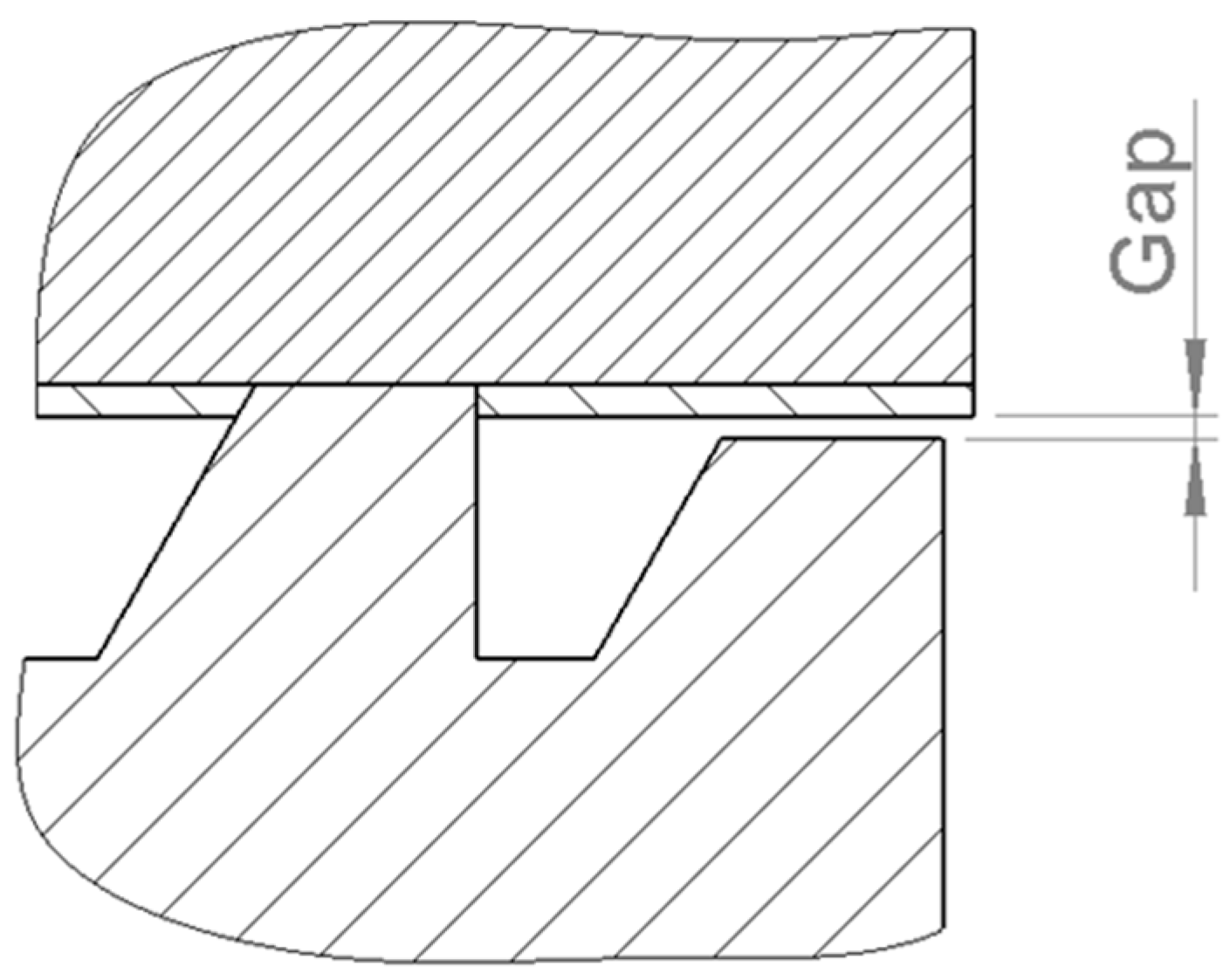

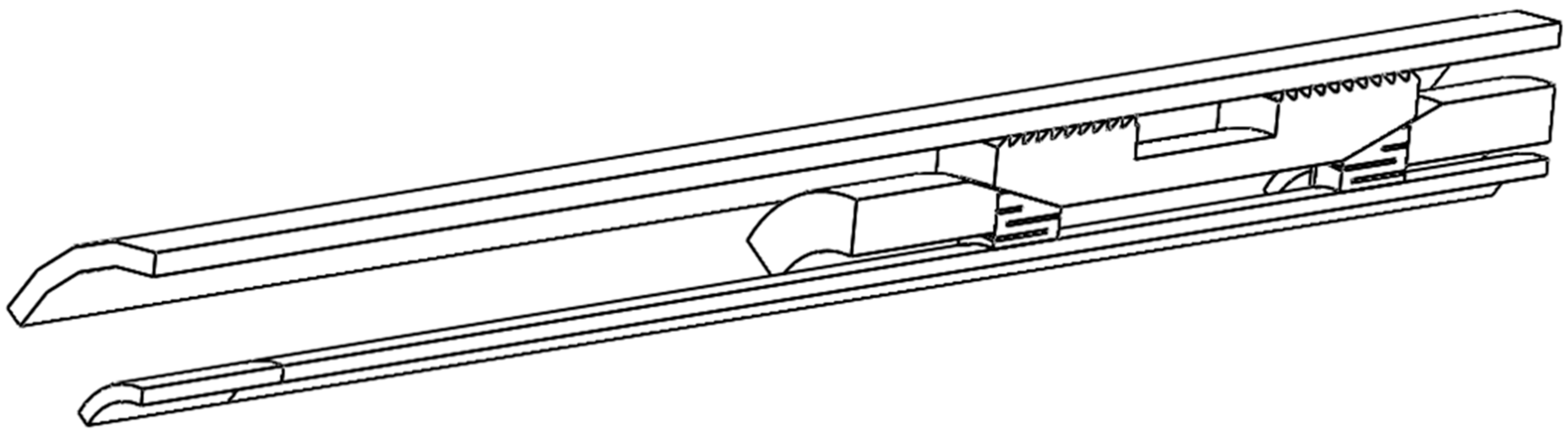

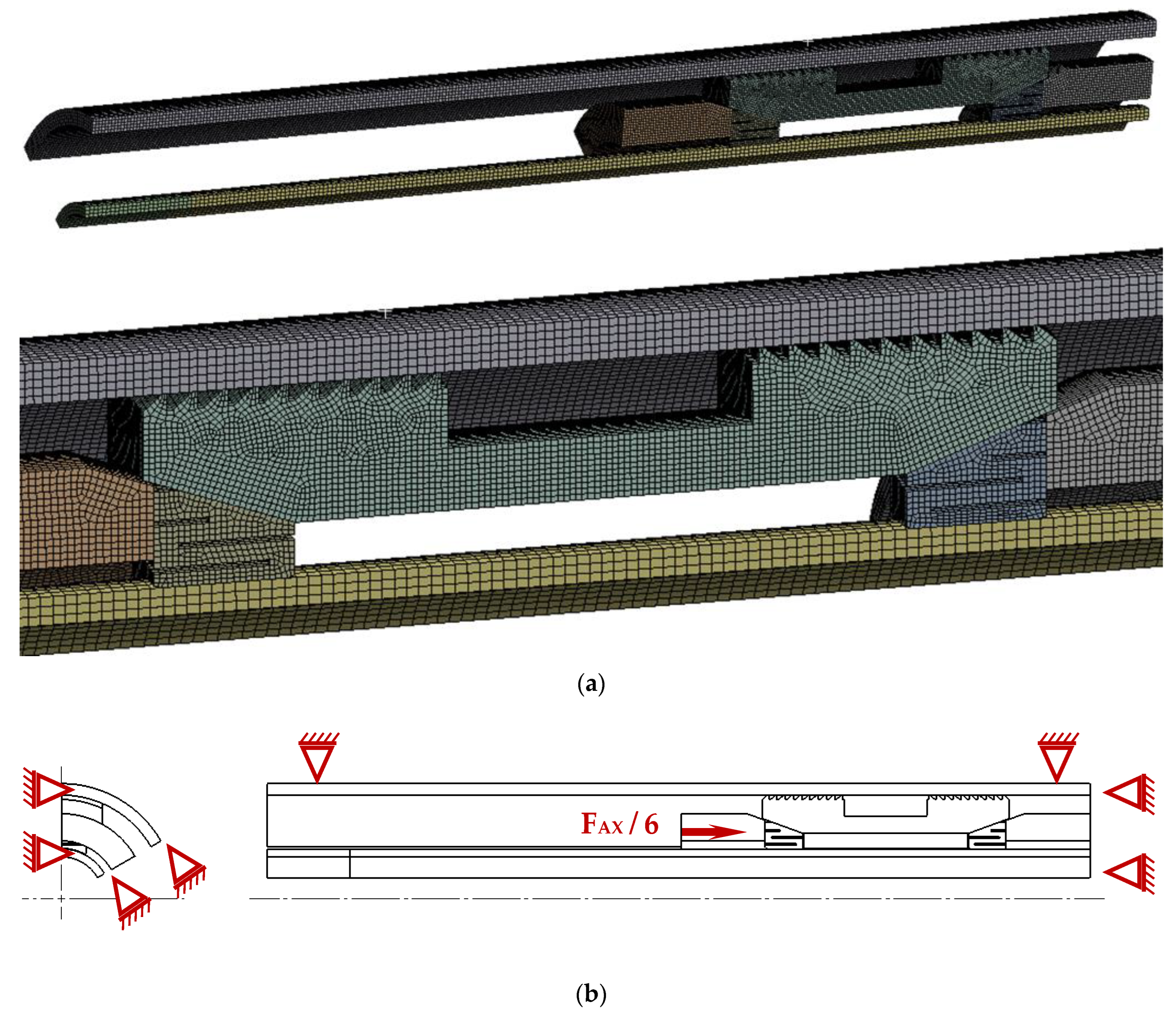

2.3. Study of Mechanical Contact Behavior

- Contact pressure for three interfaces: To review the geometry, identify design modifications to improve and guarantee sufficient contact pressure values, and to provide good electrical contact:

- ○

- Casing (steel AISI 4340)–slip (steel AISI 4340);

- ○

- Slip–caliper (copper alloy ASTM B36);

- ○

- Caliper–mandrel (steel AISI 4340);

- Equivalent (von Mises) stress distributions: To examine whether critical zones exist and to make possible changes.

3. Results

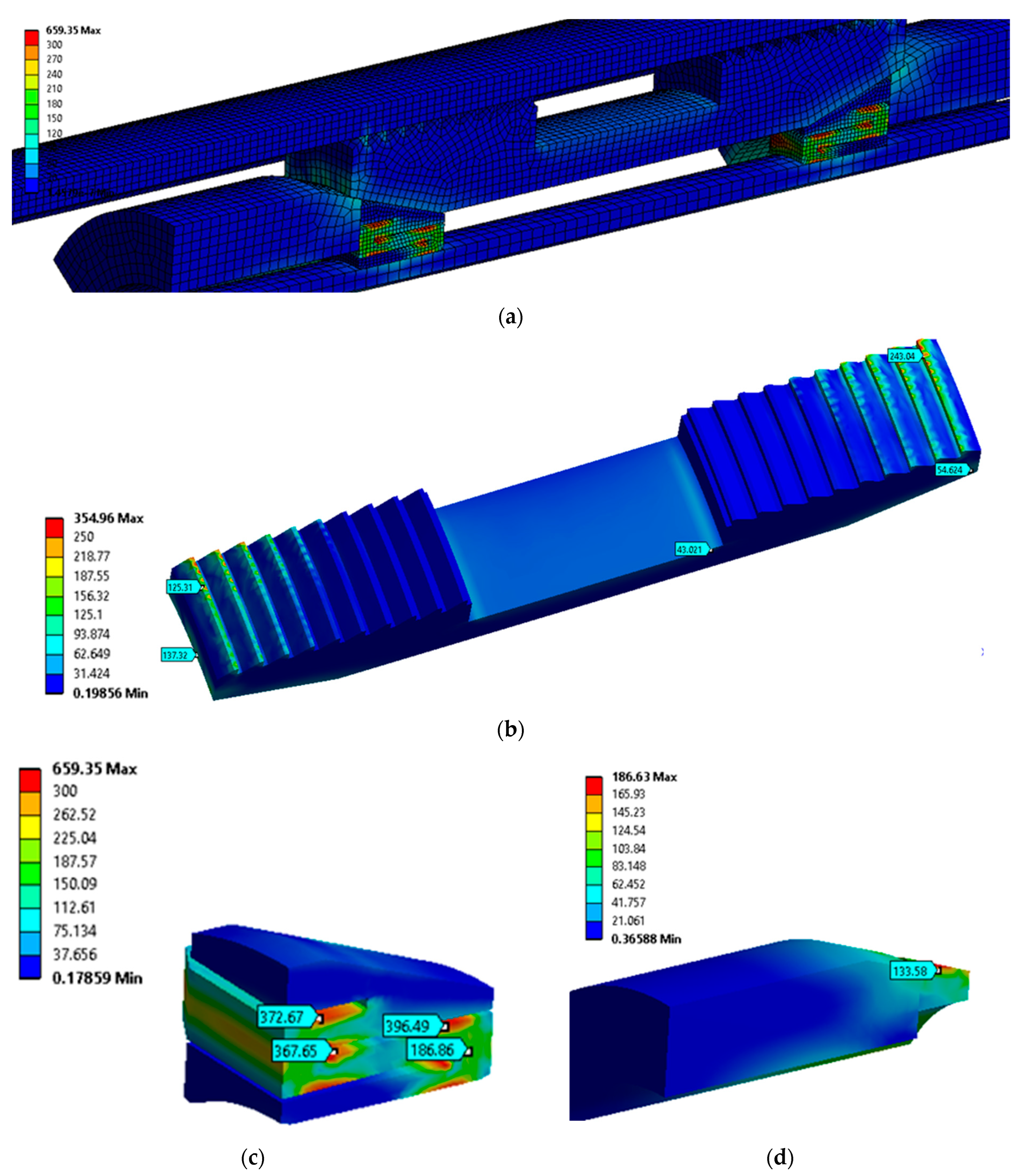

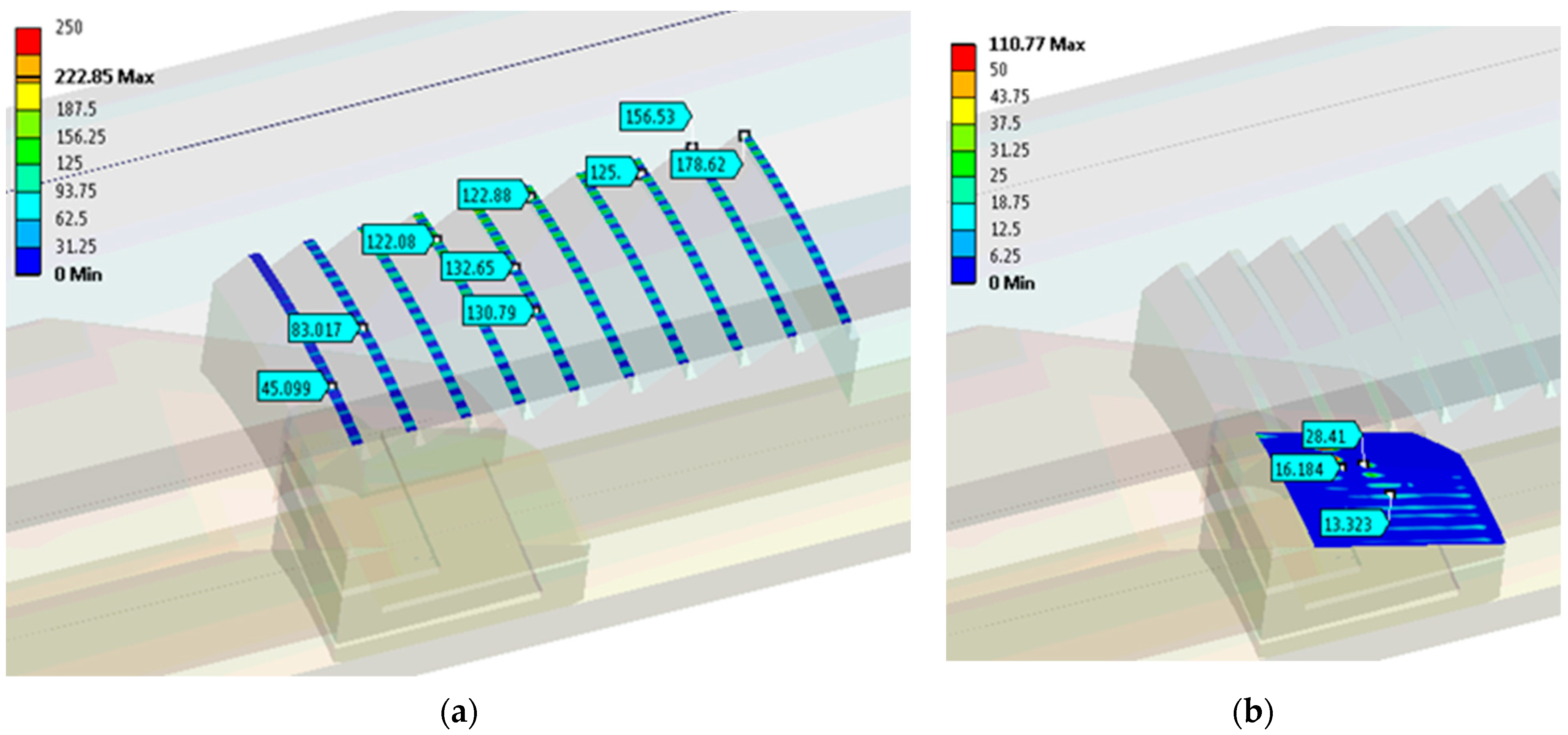

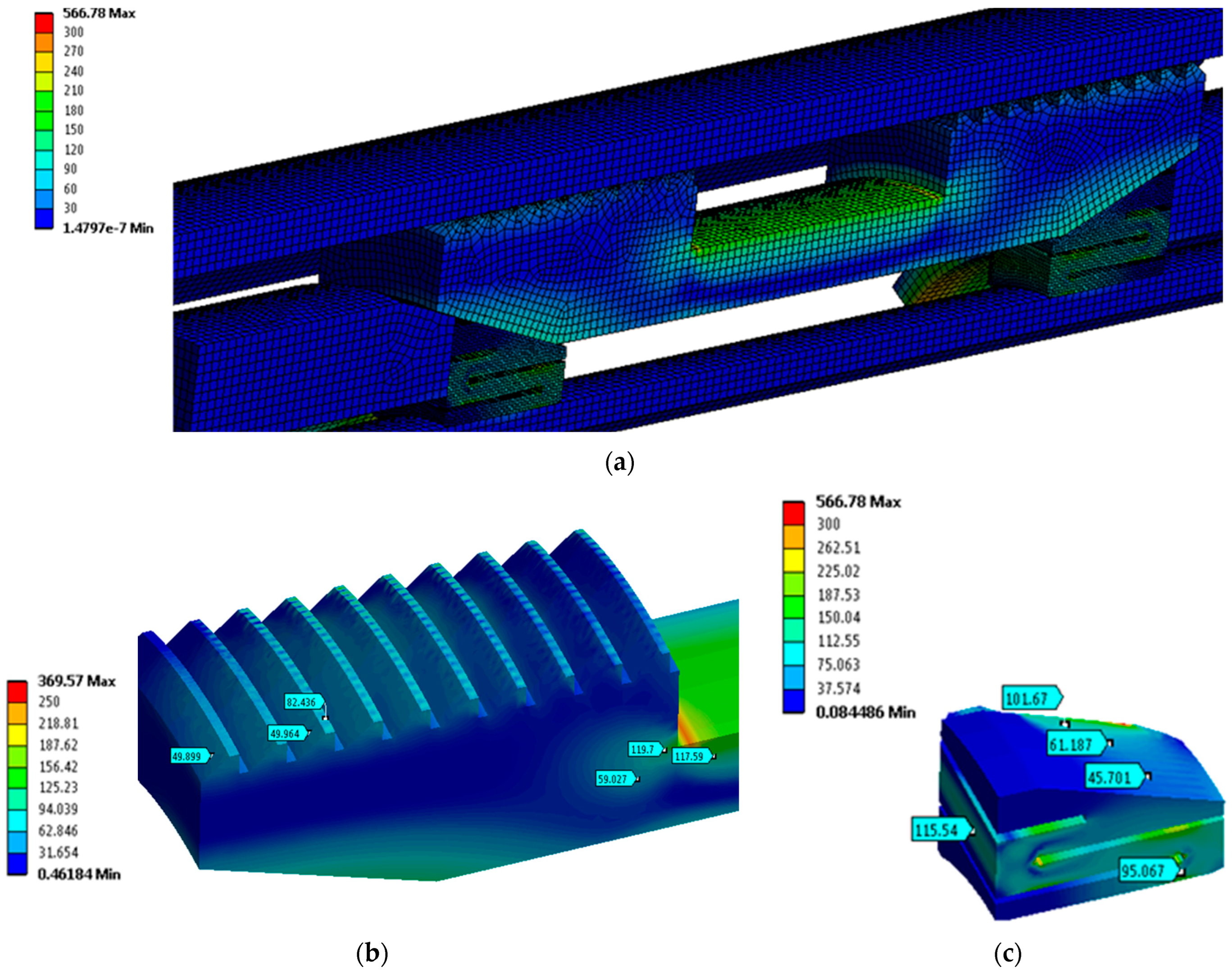

3.1. Simulation Results for Contact Pressure

3.2. Simulation Results for Equivalent Stress

3.3. Results Analysis

- Caliper design (refer to Figure 12):

- ○

- High stresses were found in the calipers, exceeding the allowable stresses for electrical copper alloy;

- ○

- Certain caliper behavior improvement can be achieved by tuning its deflection by adjusting the dimension “Δ”. This will be included in the final detailed design that will be used in the prototype.

- Slip (refer to Figure 12):

- ○

- The contact of the slip teeth to casing also needs improvement. It varies from about 250 MPa to 0 MPa (no contact), increasing the local contact resistivity;

- ○

- Contacting teeth surfaces form an elliptical area, which is defined by the direction of the cone’s acting force vector and by the slip’s stiffness;

- ○

- Two directions for improvement are proposed (as shown in the figure below):

- ○

- Conical external teeth surfaces at the optimal angle α would improve the contact pressure homogeneous distribution;

- ○

- Decreasing the slip’s slot between the teeth with dimensions “g” and “t” would improve the slip’s stiffness and equalize the teeth contact pressure.

3.4. Improved Mechanical Behavior of the Contact System

4. Discussion

- Electrical effects, such as arcing effects, electric etching, contact welding, heating at current transfer interfaces, contact conductivity, etc., for the following specific areas:

- ○

- Electrical contact between slip teeth and casing;

- ○

- Electrical contact between slips and cones.

- Mechanical effects (strength and force-deflection behavior):

- ○

- Mechanical stiffness and resulting force of connector caliper;

- ○

- Holding capacity of the button-type hold-down device for slips and back cone;

- ○

- Locking and unlocking at the sub to back cone assembly interface;

- Environmental effects, such as corrosion and contamination.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manfroni, M.; Bukkens, S.G.; Giampietro, M. The declining performance of the oil sector: Implications for global climate change mitigation. Appl. Energy 2021, 298, 117210. [Google Scholar] [CrossRef]

- Wiatros-Motyka, M.; Fulghum, N.; Jones, D. Global Electricity Review 2024; Ember: London, UK, 2024. [Google Scholar]

- Patel, D.; Thakar, V.; Pandian, S.; Shah, M.; Sircar, A. A review on casing while drilling technology for oil and gas production with well control model and economical analysis. Petroleum 2019, 5, 1–12. [Google Scholar] [CrossRef]

- Nouman, D.; Ullah, M.F.; Haider, S.H.; Keyani, M.B.K. An Overview of Downhole Electrical Machines and their Benefits. In Proceedings of the 1st International Conference on Contemporary Academic Research, Konya, Turkey, 17–19 May 2023. [Google Scholar]

- Shentu, L.; Yiming, M.; Jin, W.; Jia, Z.; Libing, Z.; Kun, Q. Design and Analysis of a Direct-Drive Permanent Magnet Vernier Motor for Electric Drilling Applications. In Proceedings of the IEEE: 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2018. [Google Scholar]

- Epelle, E.I.; Gerogiorgis, D.I. A review of technological advances and open challenges for oil and gas drilling systems engineering. AIChE J. 2020, 66, e16842. [Google Scholar] [CrossRef]

- Alghamdi, A.S. Encapsulated ESP System: An Innovative Solution for Extended Run Life in High H2S Environments. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 1–3 March 2023. [Google Scholar]

- Mubarak, G.; Verma, C.; Barsoum, I.; Alfantazi, A. Internal corrosion in oil and gas wells during casings and tubing: Challenges and opportunities of corrosion inhibitors. J. Taiw. Inst. Chem. Eng. 2023, 150, 105027. [Google Scholar] [CrossRef]

- Liu, S. Study on the cause of casing damage and the feasibility of comprehensive prevention. In Proceedings of the E3S Web of Conferences 375, 01027, ESAT 2023, Yichang, China, 10–12 March 2023. [Google Scholar]

- Wang, J.; Li, D.; Du, X.; Li, H.; Yang, S. Development of a Design Method for Casing and Tubing Strings under Complex Alternating Loads. Processes 2023, 11, 2582. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, J.; Zhou, M.; Li, G.; Xiao, X. Casing failure mechanism and slip anchoring optimization of the compression packer in the oil and gas well. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 238, 2759–2769. [Google Scholar] [CrossRef]

- Dou, Y.; Pan, H.; Tong, S.; Cao, Y.; Gao, W. Study on the Interaction Mechanism of Packer Slips and Thick Wall Casing. Op Mech. Eng. J. 2014, 8, 230–233. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Q.; Zheng, F. Contact Analysis between Packer Slips and Casing Based on Abaqus. Adv. Mat. R. 2014, 850–851, 262–265. [Google Scholar] [CrossRef]

- Sun, X.; Dou, Y.; Song, H.; Wang, X.; Cao, Y. Analysis of the Interaction between Casing and Completion Packer Slip in HPHT Wells. In Proceedings of the Conference: 2015 2nd International Conference on Machinery, Materials Engineering, Chemical Engineering and Biotechnology, Phuket, Thailand, 27–28 December 2015. [Google Scholar]

- Tang, Y.; Sun, P.; Wang, G.; Li, W. Analysis of pressure-bearing performance and optimization of structural parameters of the slip in a compression packer. Sci. Prog. 2019, 103, 20–34. [Google Scholar] [CrossRef]

- Yu, X.; Cen, X.; Kan, C.; Hu, Y.; Yang, Y.; Tao, S. Numerical Simulation Analysis of Wellbore Integrity and Casing Damage in High-Temperature Injection and Production of Shale Oil. Processes 2023, 11, 3053. [Google Scholar] [CrossRef]

- Slade, P.G. Electrical Contacts. Principles and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Alabani, A.; Ranjan, P.; Jiang, J.; Chen, L.; Cotton, I.; Peesapati, V. Electrical Characterization and Modeling of High Frequency Arcs for Higher Voltage Aerospace Systems. IEEE Trans. Transp. Electrif. 2023, 9, 4716–4725. [Google Scholar] [CrossRef]

- Lee, R.-T.; Chung, H.-H.; Chiou, Y.C. Arc erosion behaviour of silver electric contacts in a single arc discharge across a static gap. IEEE Proc.—Sci. Meas. Technol. 2001, 148, 8–14. [Google Scholar] [CrossRef]

- Esmaeili, K.; Wang, L.; Harvey, T.; White, N.; Holweger, W. A Study on the Influence of Electrical Discharges on the Formation of White Etching Cracks in Oil-Lubricated Rolling Contacts and Their Detection Using Electrostatic Sensing Technique. Lubricants 2023, 11, 164. [Google Scholar] [CrossRef]

- Steinweg, F.; Mikitisin, A.; Oezel, M.; Schwedt, A.; Janitzky, T.; Hallstedt, B.; Broeckmann, C.; Mayer, J. Formation of White Etching Cracks under electrical current flow—Influence of load, slip and polarity. Wear 2022, 504–505, 204394. [Google Scholar] [CrossRef]

- Holm, R.; Holm, E. Electric Contacts: Theory and Application, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Zhang, X.; Ren, W.; Zheng, Z.; Wang, S. Effect of Electrical Load on Contact Welding Failure of Silver Tin Oxide Material Used in DC Electromechanical Relays. IEEE Acc. 2019, 7, 133079–133089. [Google Scholar] [CrossRef]

- Ksiazkiewicz, A.; Janiszewski, J. Welding tendency for selected contact materials under different switching conditions. Eksploat. Niezawodn. 2019, 21, 237–245. [Google Scholar] [CrossRef]

- Al-Taie, A.; Park, C.; Cheetham, P.; Kim, C.; Graber, L.; Pamidi, S. A New Representation of Paschen’s Law Suitable for Variable Temperature Power Applications. In Proceedings of the 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019. [Google Scholar]

- Qi-Ling, Z.; Lei, H.; Chao, H.; He-Gao, W. Low-cycle fatigue issue of steel spiral cases in pumped-storage power plants under China’s and US’s design philosophies: A comparative numerical case study. Int. J. Press. Vessel. Pip. 2019, 172, 134–144. [Google Scholar]

- Tanaka, S.; Ichikawa, M.; Akita, S. A probabilistic investigation of fatigue life and cumulative cycle ratio. Eng. Fract. Mech. 1984, 20, 501–513. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Zheng, Y. Experimental Study on Corrosion Fatigue Performance of High-Strength Steel Wire with Initial Defect for Bridge Cable. Appl. Sci. 2020, 10, 2293. [Google Scholar] [CrossRef]

- Behvar, A.; Haghshenas, M. A critical review on very high cycle corrosion fatigue: Mechanisms, methods, materials, and models. J. Space Saf. Eng. 2023, 10, 284–323. [Google Scholar] [CrossRef]

- Tateishi, K.; Hanji, T.; Minami, K. A prediction model for extremely low cycle fatigue strength of structural steel. Int. J. Fatig. 2007, 29, 887–896. [Google Scholar] [CrossRef]

- Akpoborie, J.; Fayomi, O.S.I.; Agboola, O.; Samuel, O.; Oreko, B.; Ayoola, A. Electrochemical Corrosion Phenomenon and Prospect of Materials Selection in Curtailing the Challenges. IOP Conf. Ser. Mater. Sci. Eng. 2021, 12, 1107. [Google Scholar] [CrossRef]

- Adamczyk, P.; Zięty, A.; Grygier, D. Evaluation of materials used for coatings of electrical connectors used in the electrical harness of passengers cars. Comb. Eng. 2023, 192, 43–49. [Google Scholar] [CrossRef]

- Song, J.; Wang, L.; Zibart, A.; Koch, C. Corrosion Protection of Electrically Conductive Surfaces. Metals 2012, 2, 450–477. [Google Scholar] [CrossRef]

- Yu, G.-F.; Chiu, Y.; Zheng, X.; Yuan, Z.-L.; Wang, Z.-X. Contact pressure of high-voltage DC power relay change and life prediction and structure optimization. Adv. Mech. Eng. 2021, 13, 2–22. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, G.; Zhao, C.; Qin, H.; Yang, J. Influence of mechanical faults on electrical resistance in high voltage circuit breaker. Int. J. Electr. Power Energy Syst. 2021, 129, 106827. [Google Scholar] [CrossRef]

- Shen, F.; Ke, L.-L. Numerical Study of Coupled Electrical-Thermal-Mechanical-Wear Behavior in Electrical Contacts. Metals 2021, 11, 955. [Google Scholar] [CrossRef]

- Malakov, I.; Zaharinov, V. Optimization of size ranges of technical products. Appl. Mech. Mat. 2016, 859, 194–203. [Google Scholar] [CrossRef]

- Romansky, R.P.; Hinov, N.L. Deterministic and Stochastic Approaches in Computer Modeling and Simulation; IGI Global: Hershey, PA, USA, 2023. [Google Scholar]

- Soares, M.; He, Q.; DePaiva, J.; de Freitas, B.; Soares, P.; Veldhuis, S.; Amorim, F.; Torres, R. Mechanical and Tribological Behavior of Nitrided AISI/SAE 4340 Steel Coated with NiP and AlCrN. Lubricants 2024, 12, 181. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Todorov, G.; Kamberov, K.; Sofronov, Y.; Gavrilov, T.; Miltchev, R. Study of Electrical Contact in a System for High Power Transmission Through Well Piping. Appl. Sci. 2025, 15, 9932. https://doi.org/10.3390/app15189932

Todorov G, Kamberov K, Sofronov Y, Gavrilov T, Miltchev R. Study of Electrical Contact in a System for High Power Transmission Through Well Piping. Applied Sciences. 2025; 15(18):9932. https://doi.org/10.3390/app15189932

Chicago/Turabian StyleTodorov, Georgi, Konstantin Kamberov, Yavor Sofronov, Todor Gavrilov, and Radoslav Miltchev. 2025. "Study of Electrical Contact in a System for High Power Transmission Through Well Piping" Applied Sciences 15, no. 18: 9932. https://doi.org/10.3390/app15189932

APA StyleTodorov, G., Kamberov, K., Sofronov, Y., Gavrilov, T., & Miltchev, R. (2025). Study of Electrical Contact in a System for High Power Transmission Through Well Piping. Applied Sciences, 15(18), 9932. https://doi.org/10.3390/app15189932