Development of Soft Type Metering Device for Garlic Planter and Performance Analysis in Accordance with Design Parameters

Abstract

1. Introduction

2. Materials and Methods

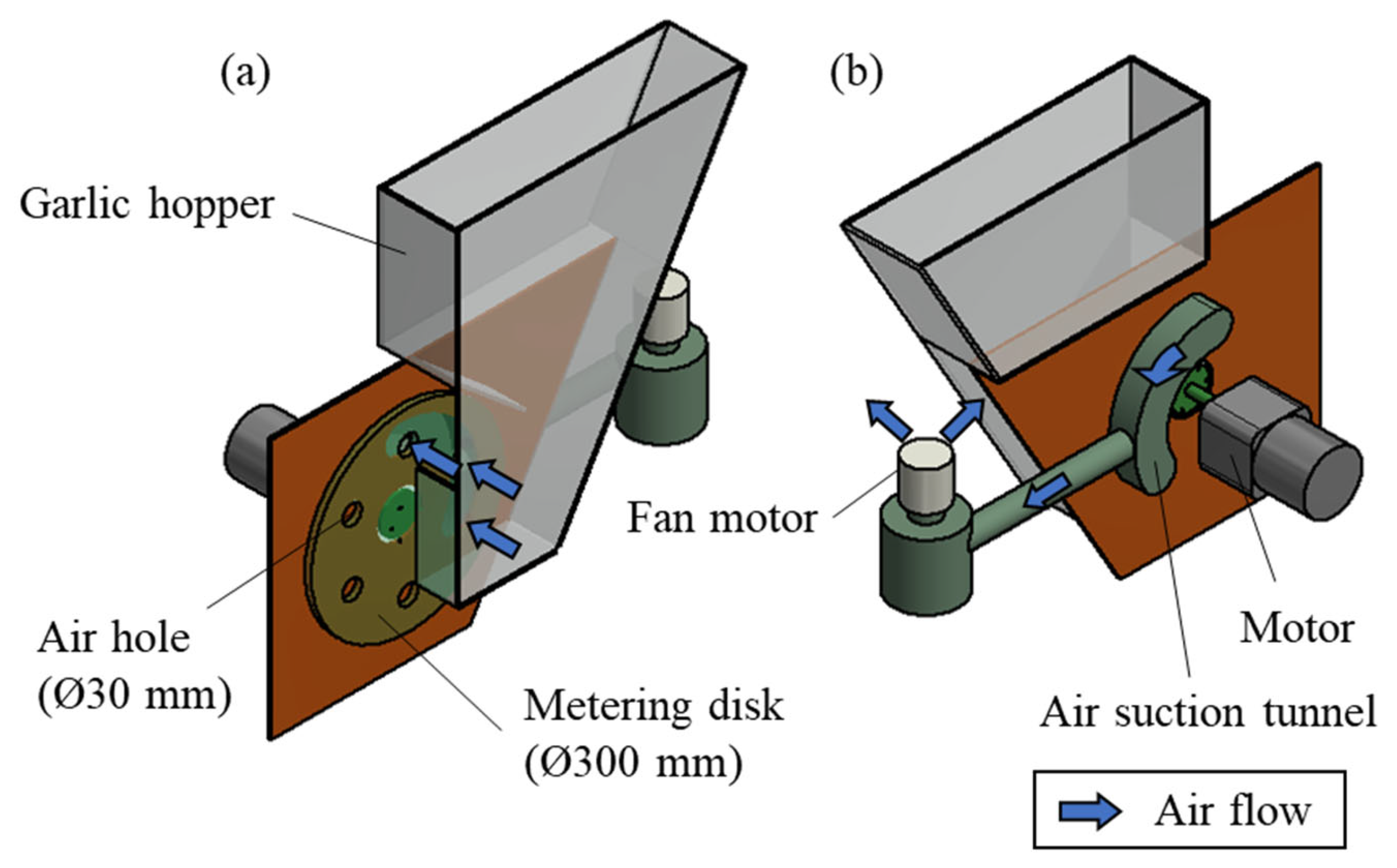

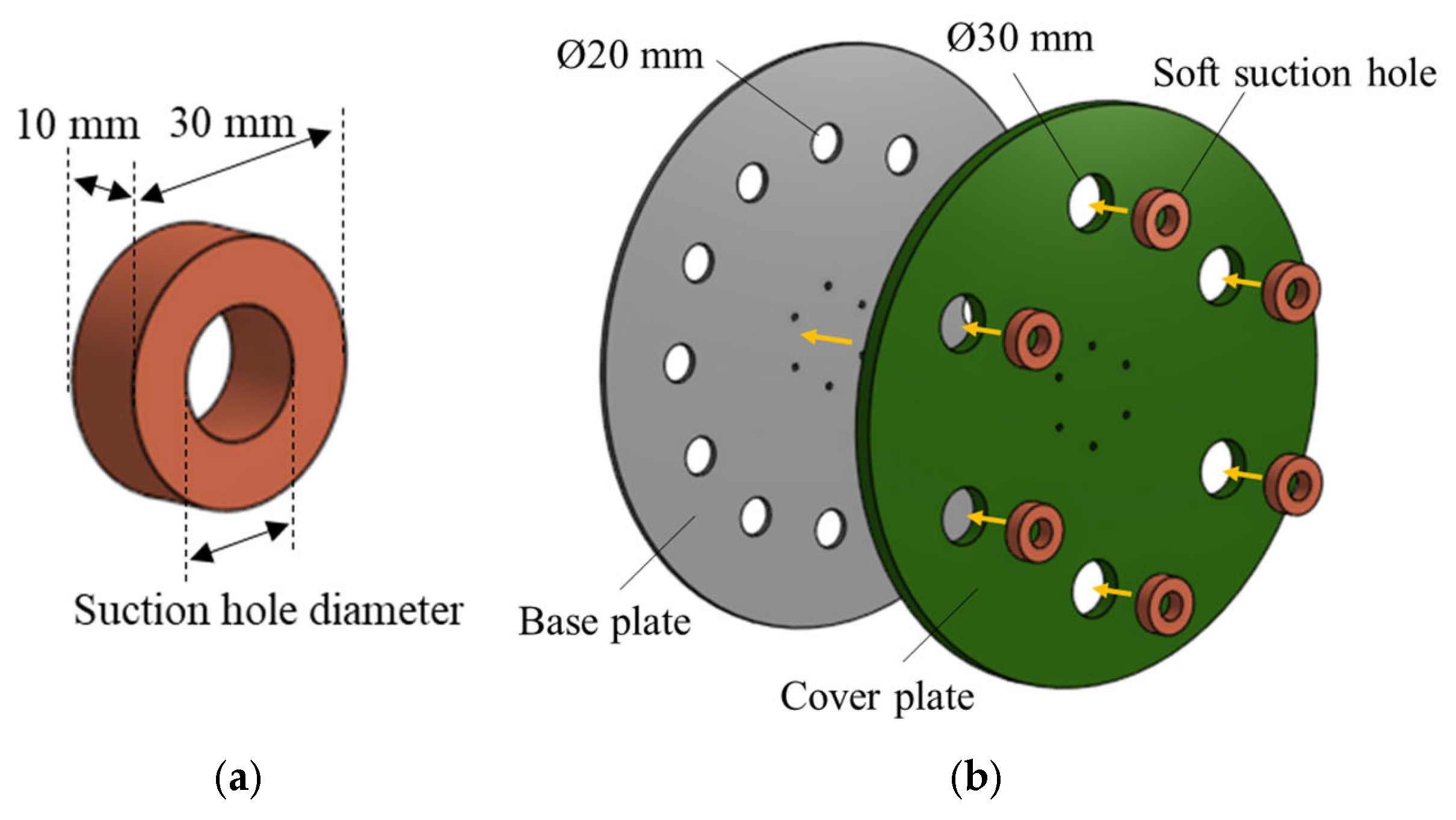

2.1. Design of the Air-Suction Soft-Metering Device

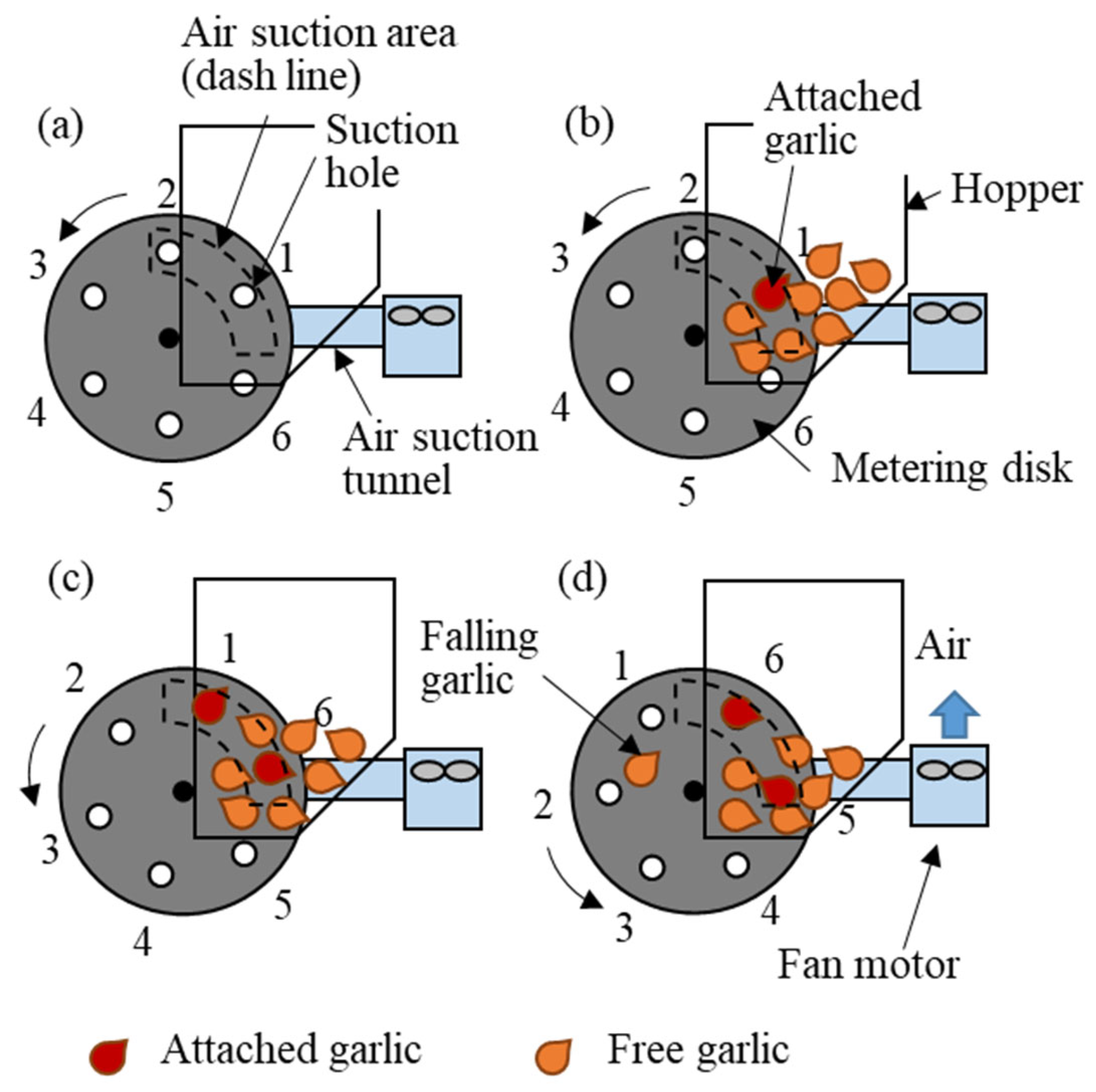

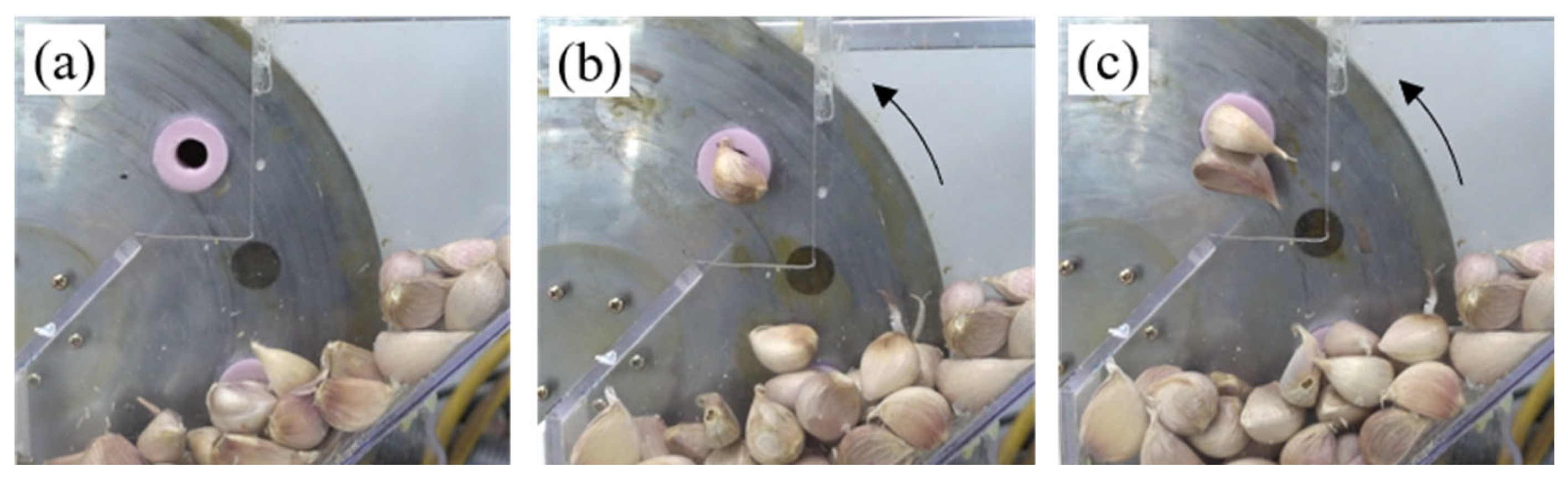

2.2. Operation Principle

2.3. Design Elements and Experimental Methods

2.4. Statistical Methods for Performance Analysis

3. Results and Discussion

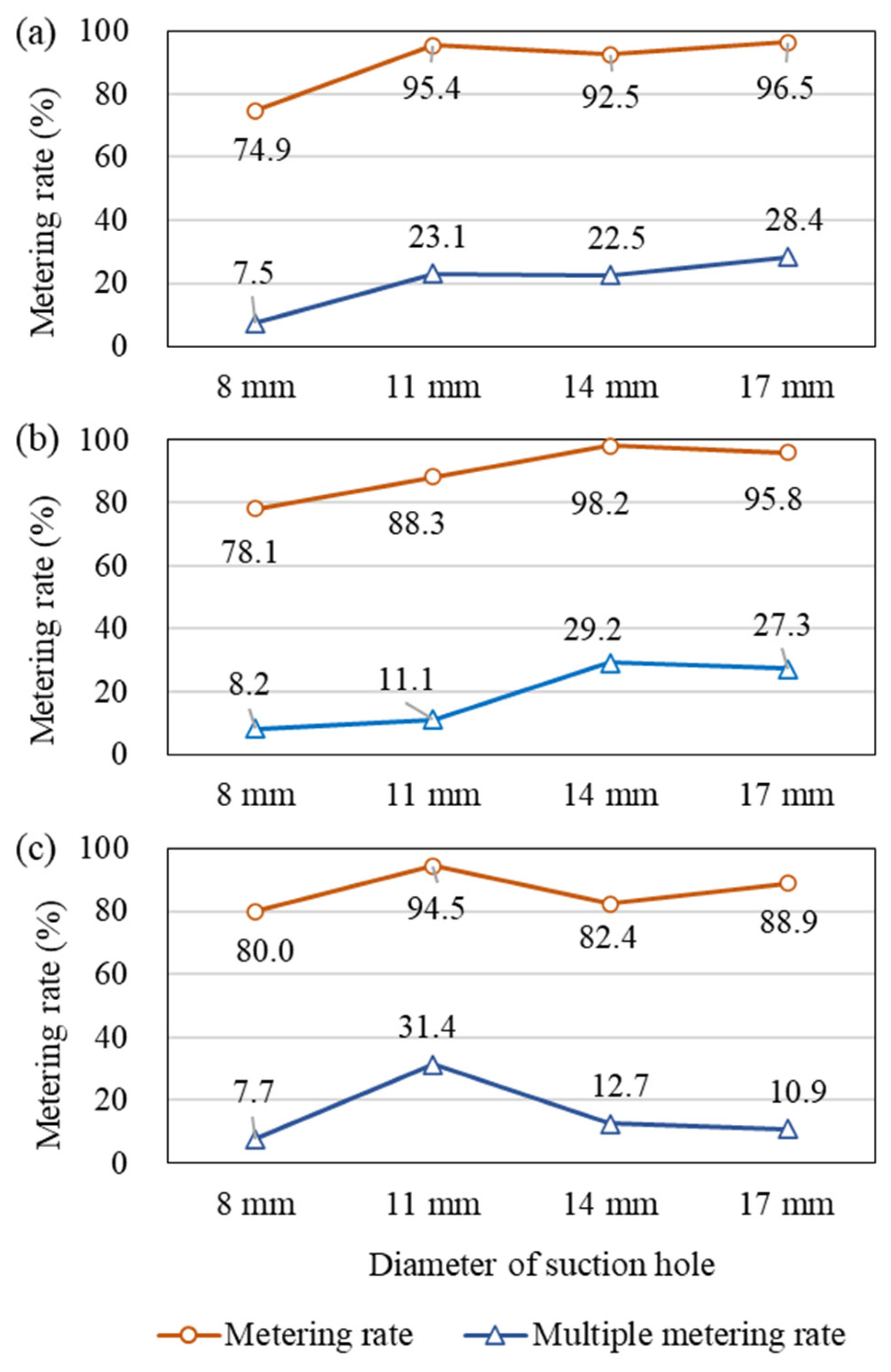

3.1. Analysis of Metering Rate Depending on Suction Hole Diameter

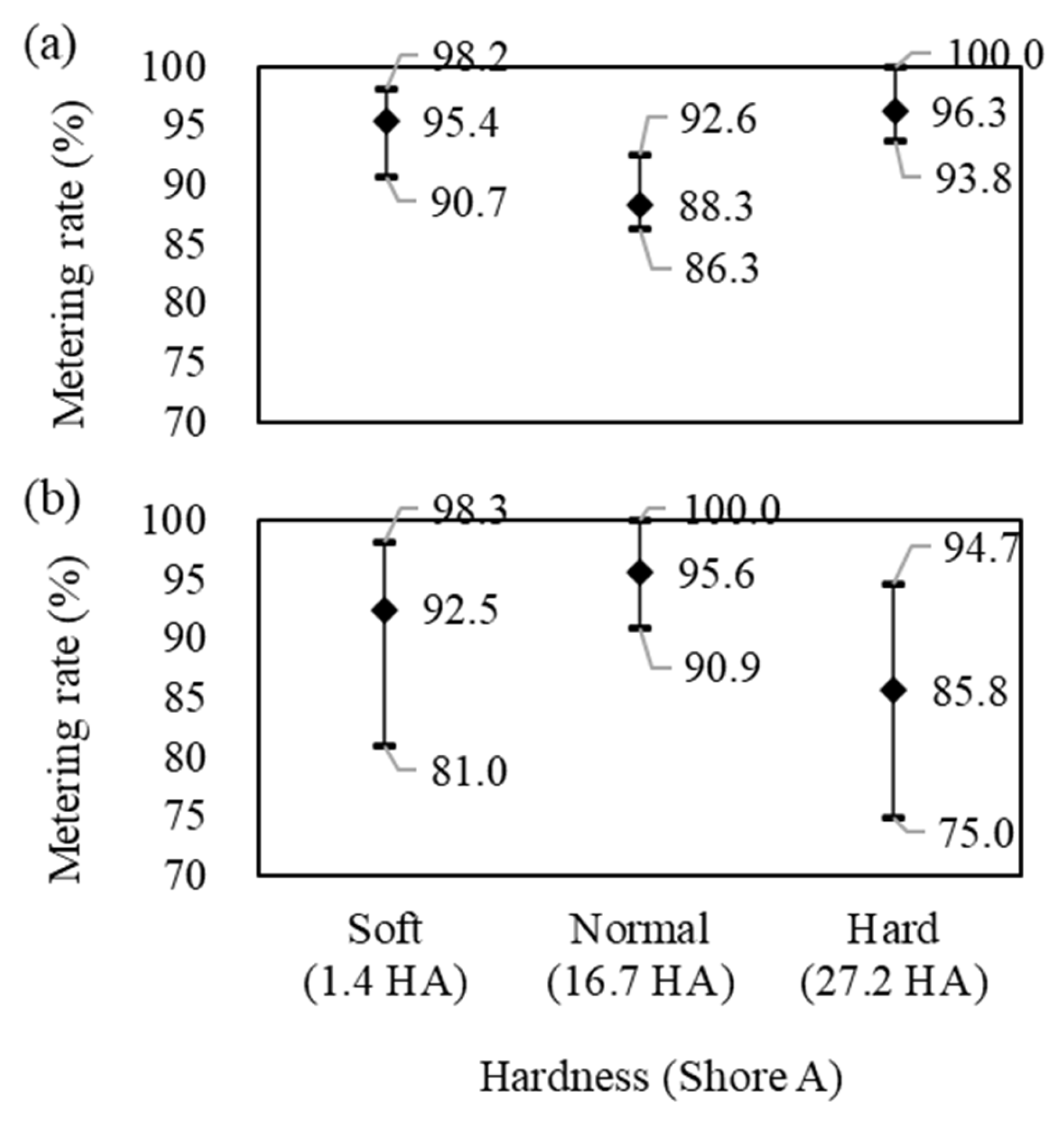

3.2. Analysis of Metering Rate Depending on Suction Hole Hardness

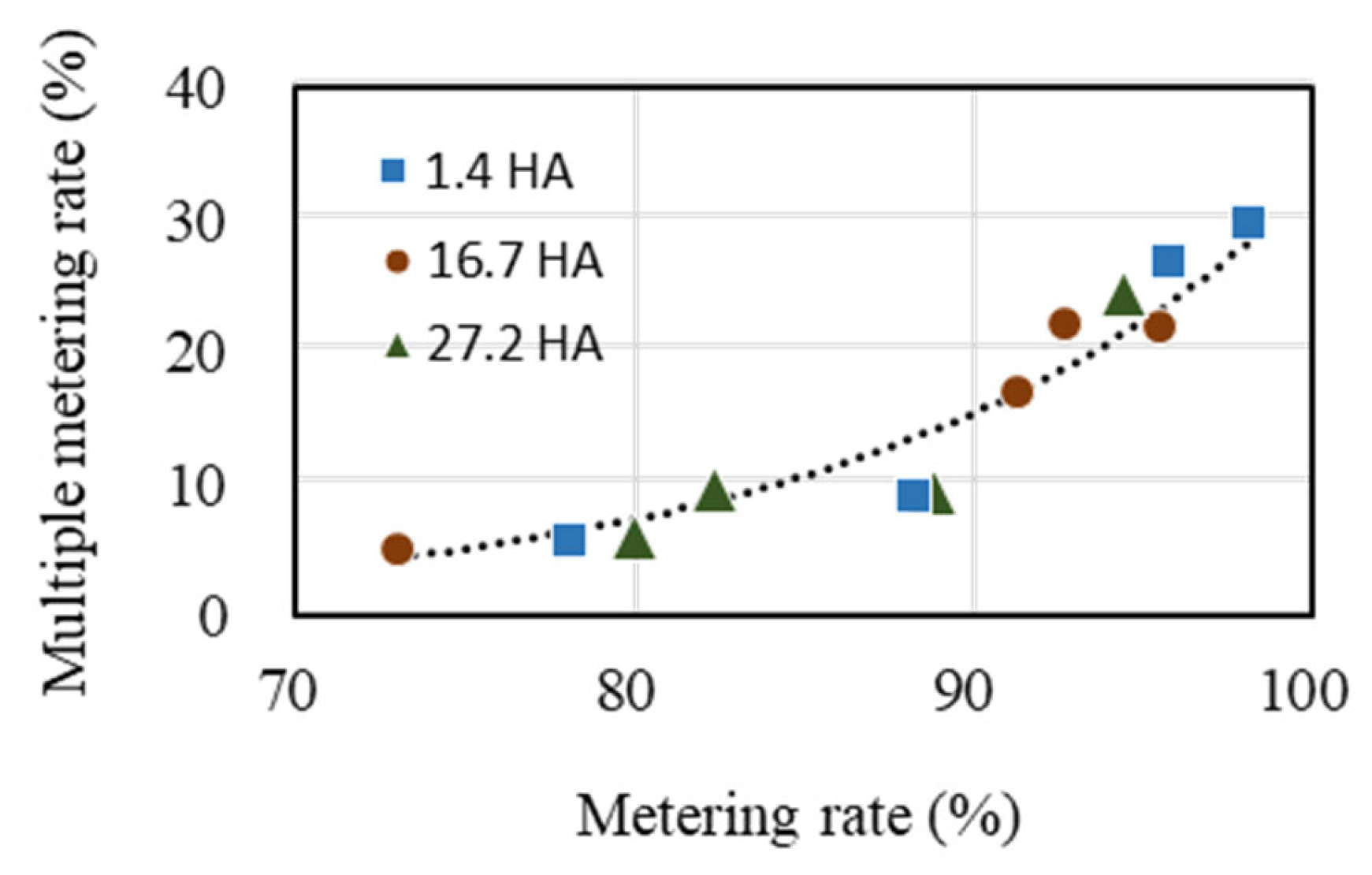

3.3. Analysis of the Relationship Between Metering Rate and Multiple-Metering Rate

3.4. Performance Indexes and Optimization

3.5. Future Work and Application

- Garlic planting implements for conventional agricultural tractors;

- Electric control garlic planters for autonomous or unmanned agricultural vehicles;

- Automatic garlic planting devices for conveyor planting systems in nurseries;

- Planting machines for shallots, tulips, etc., which have a shape like a garlic clove.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 10 May 2025).

- Lee, M.H.; Kang, Y.K.; Cheon, C.U.; Park, S.H. Development and Performance Verification of Line Sowing Type Garlic Planter. J. Korea Acad. Ind. Coop. 2023, 24, 598–604. (In Korean) [Google Scholar]

- Ahmadi, E.; Ghassemzadeh, H.R.; Moghaddam, M.; Kim, K.U. Development of a precision seed drill for oilseed rape. Turk. J. Agric. For. 2008, 32, 451–458. [Google Scholar]

- Wang, H.; Sun, X.; Li, H.; Fu, J.; Zeng, X.; Xu, Y.; Wang, Y.; Liu, H.; Lü, Z. Design and parameter optimization of a finger clip plate garlic seed-metering device based on EDEM. Agronomy 2022, 12, 1543. [Google Scholar] [CrossRef]

- Lüling, N.; Straub, J.; Stana, A.; Brodbeck, M.; Reiser, D.; Berner, P.; Griepentrog, H.W. Development and evaluation of a self-adaptable planting unit for an autonomous planting process of field vegetables. Smart Agric. Technol. 2024, 9, 100578. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Zheng, W.; Lv, Z.; Zhang, W. Design of a sweet potato transplanter based on a robot arm. Appl. Sci. 2021, 11, 9349. [Google Scholar] [CrossRef]

- Calleja-Huerta, A.; Lamandé, M.; Green, O.; Munkholm, L.J. Vertical and horizontal stresses from a lightweight autonomous field robot during repeated wheeling. Soil Tillage Res. 2023, 233, 105790. [Google Scholar] [CrossRef]

- Shaikh, T.A.; Rasool, T.; Lone, F.R. Towards leveraging the role of machine learning and artificial intelligence in precision agriculture and smart farming. Comput. Electron. Agric. 2022, 198, 107119. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, D.; Yang, L.; Cui, T.; Li, K.; Yin, X. Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM. Trans. Chin. Soc. Agric. Eng. 2015, 31, 62–69. [Google Scholar]

- Guo, H.; Cao, Y.; Song, W.; Zhang, J.; Wang, C.; Wang, C.; Zhu, L. Design and simulation of a garlic seed metering mechanism. Agriculture 2021, 11, 1239. [Google Scholar] [CrossRef]

- Im, D.; Kim, J.H.; Moon, D.J.; Moon, T.I.; Yu, S.H.; Park, Y.J. Optimization of bucket size of garlic metering device using multibody dynamics simulation. J. Biosyst. Eng. 2022, 47, 480–488. [Google Scholar] [CrossRef]

- Choi, D.K.; Park, S.H.; Kang, T.G.; Kwak, T.Y.; Lee, C.S.; Cho, S.C.; Kim, Y.J. Development of a garlic clove planter attached to power tiller. J. Biosyst. Eng. 2009, 34, 140–146. [Google Scholar] [CrossRef]

- Choi, D.K.; Cho, S.C.; Lee, C.S.; Park, S.H.; Kim, H.J.; Kang, T.K.; Kim, C.K.; Kwak, T.Y. Development of a metering device for the garlic planter. J. Korea Soc. Agric. Mach. 2001, 26, 525–534. [Google Scholar]

- Kang, T.G.; Lee, S.H.; Kim, J.G.; Kim, Y.K.; Choi, Y.; Choi, I.S.; Kwon, Y.S.; Lim, J. A factor analysis of garlic metering device for development of a garlic planter. J. Agric. Sci. 2018, 52, 143–151. [Google Scholar]

- Park, W.Y.; Lee, S.S. Development of rope-type seeding system for the garlic planter. Proc. Korean Soc. Agric. Mach. Conf. 2013, 18, 153–154. [Google Scholar]

- Yazgi, A.; Degirmencioglu, A. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology. Biosyst. Eng. 2007, 97, 347–356. [Google Scholar] [CrossRef]

- Singh, R.C.; Singh, G.; Saraswat, D.C. Optimisation of design and operational parameters of a pneumatic seed metering device for planting cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Ma, C.; Yi, S.; Tao, G.; Li, Y.; Liu, H. Theoretical analysis and experiment of seed-picking mechanism of belt high-speed seed-guiding device for corn. J. Agric. Eng. 2024, 55, 1543. [Google Scholar] [CrossRef]

- St Jack, D.; Hesterman, D.C.; Guzzomi, A.L. Precision metering of Santalum spicatum (Australian Sandalwood) seeds. Biosyst. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Park, D.; Lee, C.G.; Yang, D.; Kim, D.; Kim, J.Y.; Rhee, J.Y. Analysis of Inter-particle Contact Parameters of Garlic Cloves Using Discrete Element Method. J. Biosyst. Eng. 2021, 46, 332–345. [Google Scholar] [CrossRef]

- Song, S.; Drotlef, D.M.; Majidi, C.; Sitti, M. Controllable load sharing for soft adhesive interfaces on three-dimensional surfaces. Proc. Natl. Acad. Sci. USA 2017, 114, E4344–E4353. [Google Scholar] [CrossRef]

- Park, W.K.; Choi, D.K.; Kim, Y.K. Development of a Garlic Clove Planter (I) -Survey for planting condition and physical properties of garlic clove. J. Korea Soc. Agric. Mach. 2001, 26, 495–502. [Google Scholar]

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

- Değirmencioğlu, A.; Çakmak, B.; Yazgi, A. Prototype twin vacuum disk metering unit for improved seed spacing uniformity performance at high forward speeds. Turk. J. Agric. For. 2018, 42, 195–206. [Google Scholar] [CrossRef]

| Hole Diameter | Mean | Standard Deviation | F Value | Multiple Comparisons |

|---|---|---|---|---|

| 8 mm | 74.9% | 0.374% | 20.72 *** | 8 ≠ 11, 14, 17 mm *** |

| 11 mm | 95.4% | 0.084% | ||

| 14 mm | 92.5% | 0.471% | ||

| 17 mm | 96.5% | 0.066% |

| Hole Diameter | Mean | Standard Deviation | F Value | Multiple Comparisons |

|---|---|---|---|---|

| 8 mm | 80.1% | 0.048% | 31.54 *** | 8 ≠ 11 mm ** 8 ≠ 14, 17 mm *** 11 ≠ 14, 17 mm ** |

| 11 mm | 88.3% | 0.072% | ||

| 14 mm | 95.6% | 0.118% | ||

| 17 mm | 95.6% | 0.113% |

| Hole Diameter | Mean | Standard Deviation | F Value | Multiple Comparisons |

|---|---|---|---|---|

| 8 mm | 82.7% | 0.608% | 3.549 * | 8 ≠ 11 mm * |

| 11 mm | 96.3% | 0.073% | ||

| 14 mm | 85.8% | 0.617% | ||

| 17 mm | 89.3% | 0.634% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.-s.; Kim, D.-K.; Son, H.-s.; Yang, S.-H. Development of Soft Type Metering Device for Garlic Planter and Performance Analysis in Accordance with Design Parameters. Appl. Sci. 2025, 15, 9926. https://doi.org/10.3390/app15189926

Yoo J-s, Kim D-K, Son H-s, Yang S-H. Development of Soft Type Metering Device for Garlic Planter and Performance Analysis in Accordance with Design Parameters. Applied Sciences. 2025; 15(18):9926. https://doi.org/10.3390/app15189926

Chicago/Turabian StyleYoo, Jung-sang, Deok-Keun Kim, Hyun-sik Son, and Seung-Hwan Yang. 2025. "Development of Soft Type Metering Device for Garlic Planter and Performance Analysis in Accordance with Design Parameters" Applied Sciences 15, no. 18: 9926. https://doi.org/10.3390/app15189926

APA StyleYoo, J.-s., Kim, D.-K., Son, H.-s., & Yang, S.-H. (2025). Development of Soft Type Metering Device for Garlic Planter and Performance Analysis in Accordance with Design Parameters. Applied Sciences, 15(18), 9926. https://doi.org/10.3390/app15189926