Dynamic Load Analysis of Vertical, Pitching, and Lateral Tilt Vibrations of Multi-Axle Vehicles

Abstract

Featured Application

Abstract

1. Introduction

2. Pavement Roughness Excitation Model

2.1. Pavement Roughness Excitation Power Spectral Density

2.2. Time-Domain Pavement Excitation Model Using the Filtered White Noise Technique

- Time-domain model of single-wheel pavement excitation

- 2.

- The coherence function of the left and right wheels

- 3.

- The time-domain relationship of left and right wheel pavement excitation

- 4.

- The time-domain relationship of front and rear wheel pavement excitation

2.3. Simulation of Time-Domain Pavement Excitation for Filtered White Noise

3. Simplified Vibration Model of Vehicle System

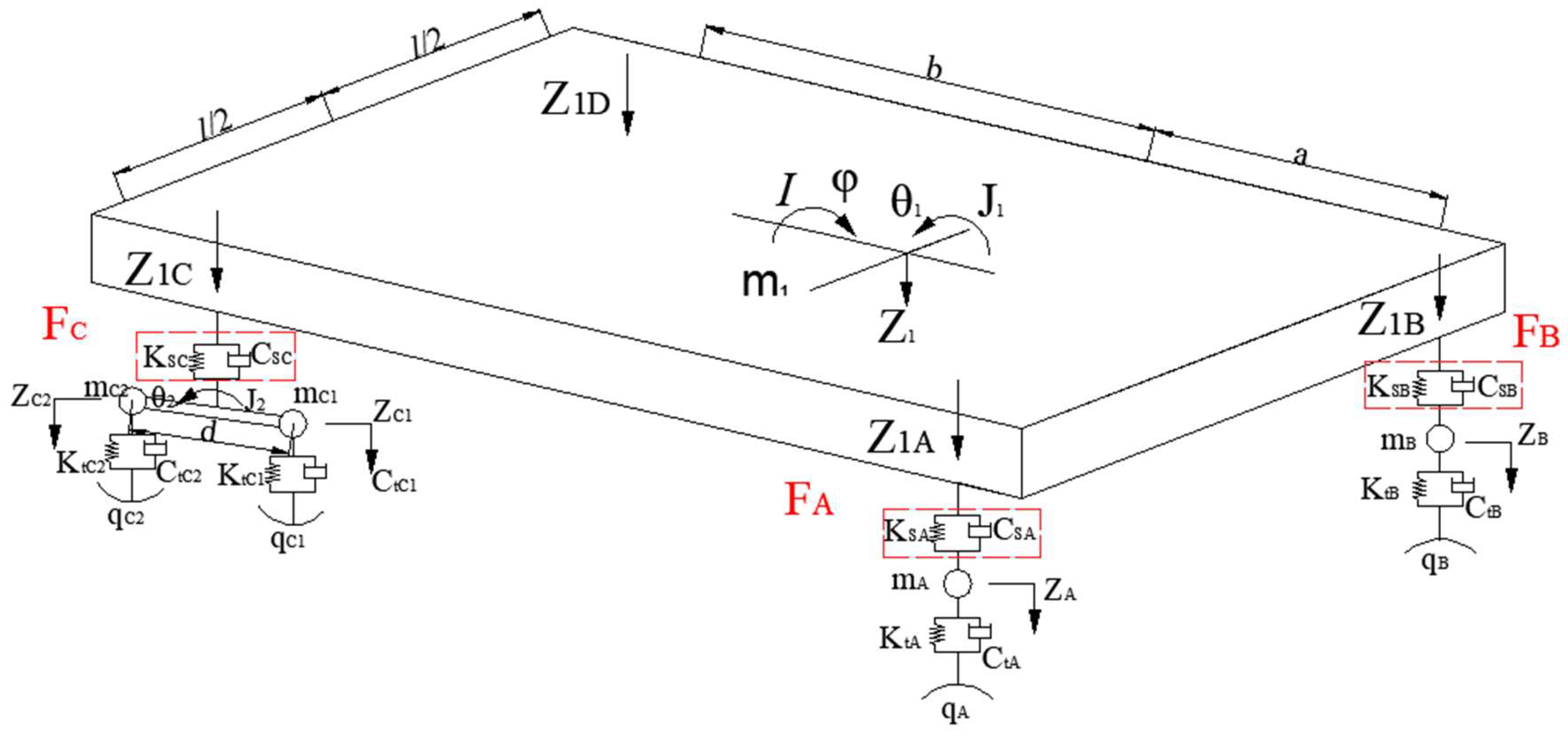

3.1. Whole-Vehicle Model of Three-Axle Vehicle

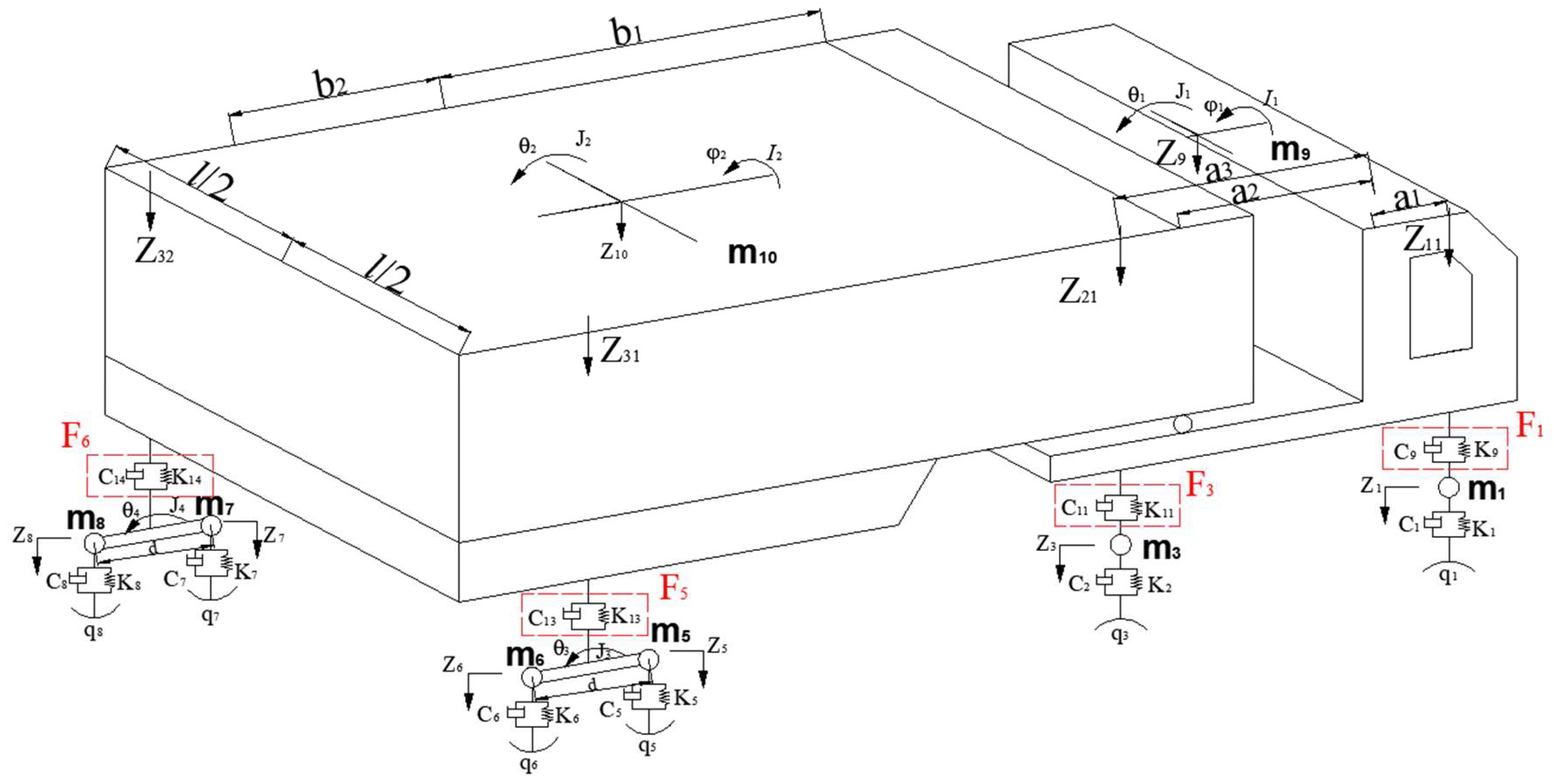

3.2. Vehicle Model of a Heavy-Duty Four-Axle Vehicle

3.3. Vehicle Model of Cornering

3.4. Parameters of Vehicle Model

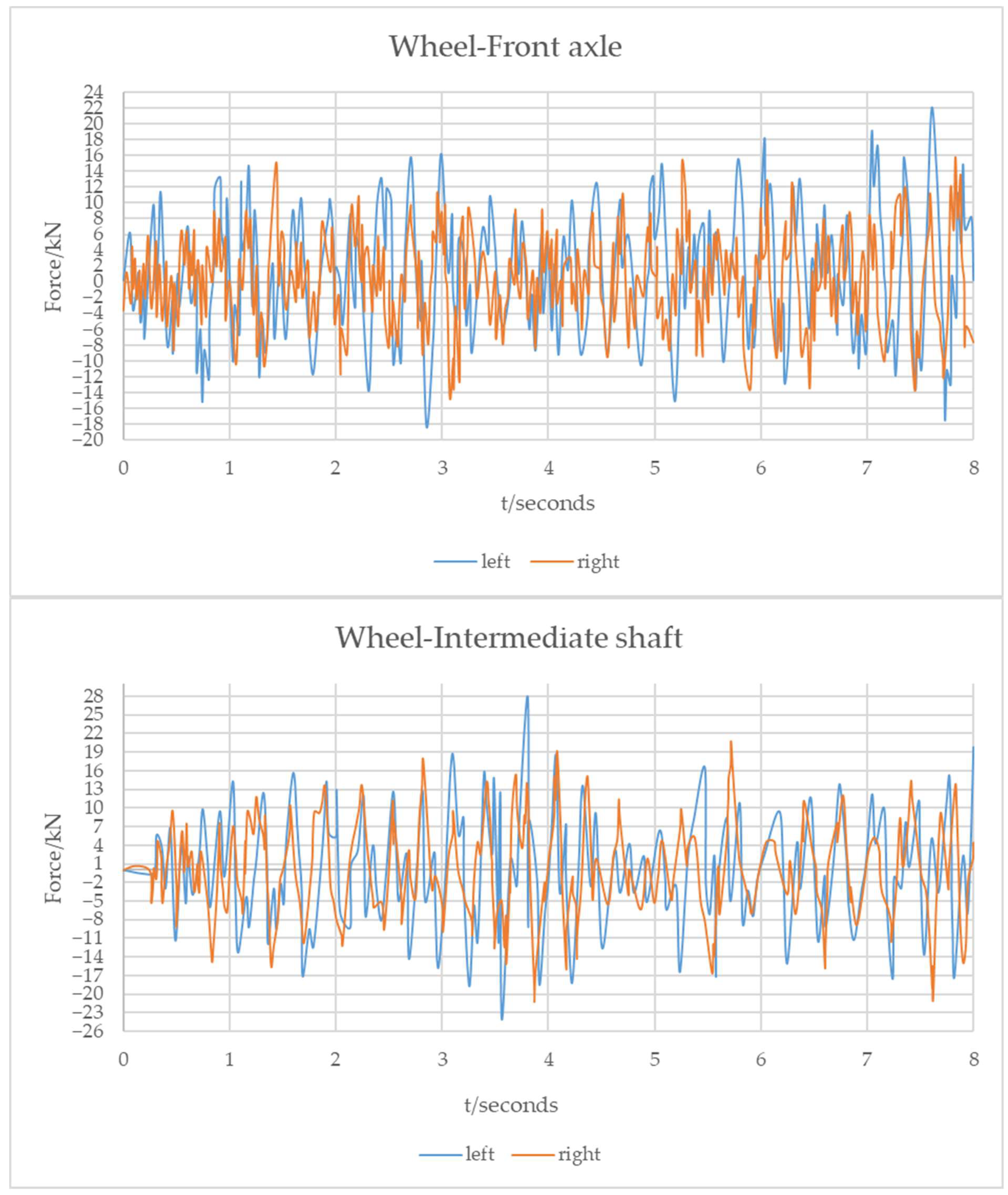

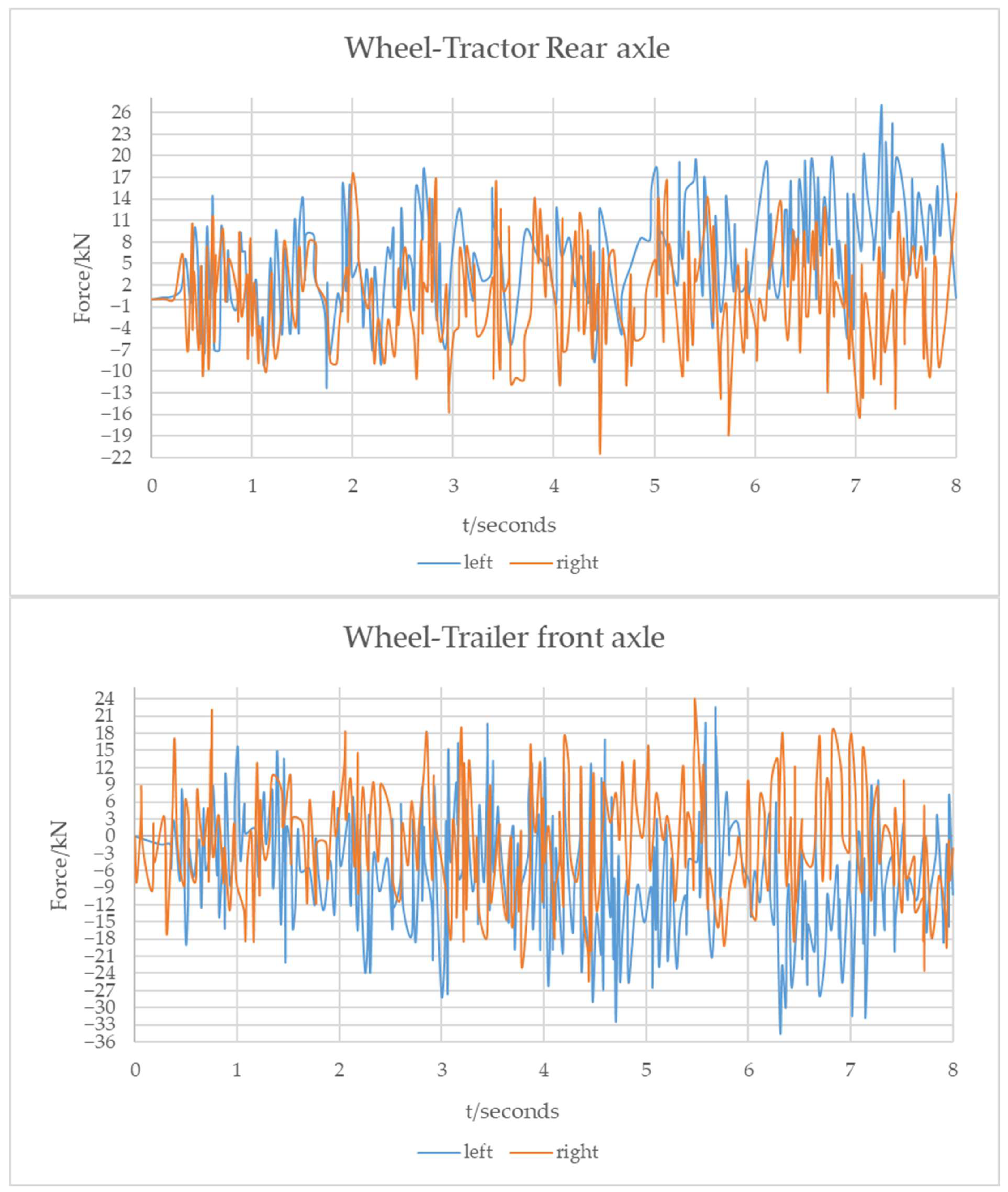

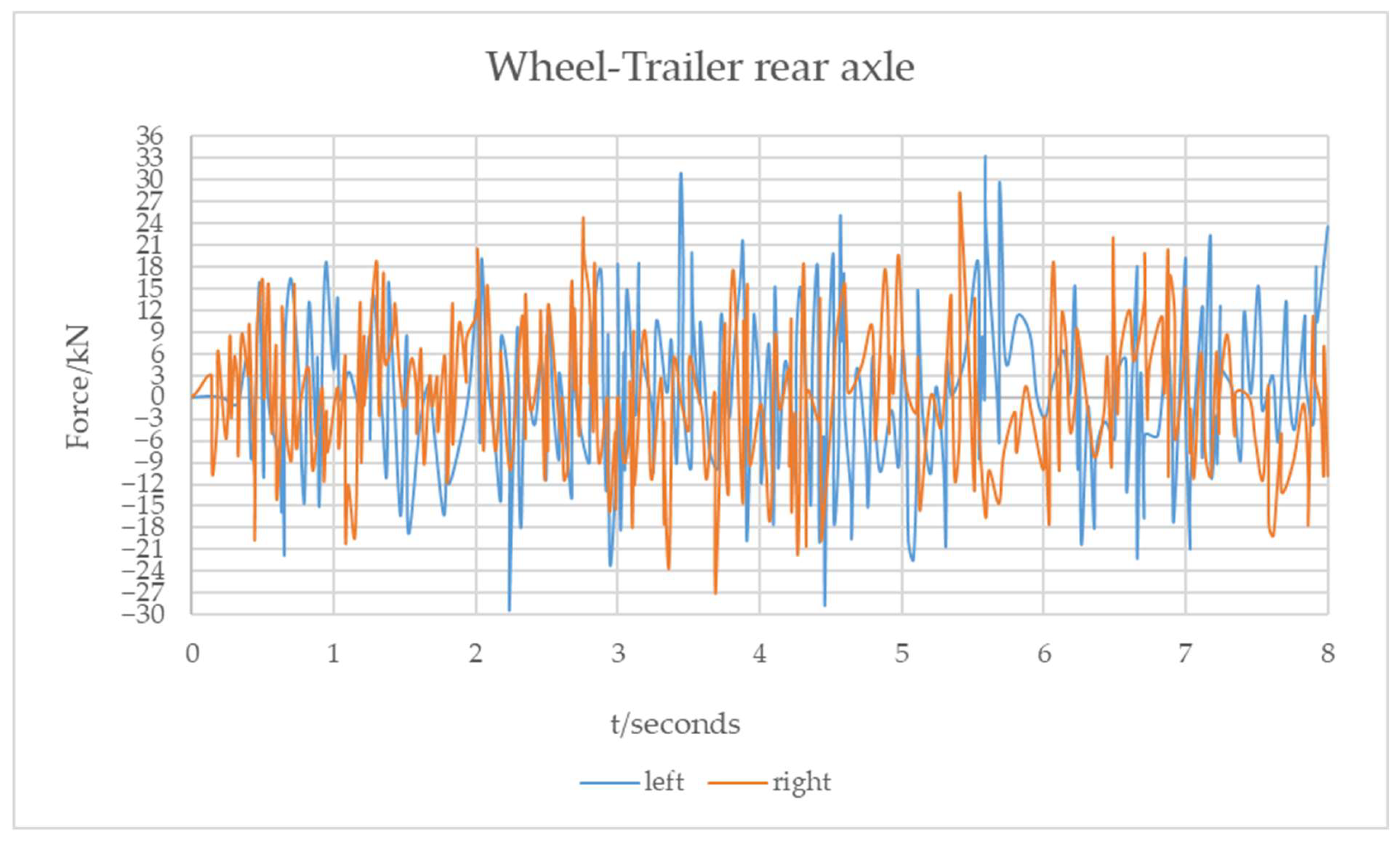

3.5. Numerical Simulation of Vehicle Model

4. Simulation and Analysis of Heavy-Duty Whole Vehicles

- Root-mean-square values of the dynamic load

- 2.

- Dynamic load coefficient

- ①

- Three-axle vehicle

- ②

- Four-axle vehicle

- Table 1’s four grades—A, B, C, and D—are chosen to represent four different pavement roughness coefficients;

- The load is selected from four situations: no-load, standard load, full load, and 0.2-times overload;

- The vehicle speeds are 6 m/s, 14 m/s, and 25 m/s;

- The cornering radii are 71 m, 36 m, and 24 m, and the corresponding front wheel turning angles are 5°, 10°, and 15°, respectively.

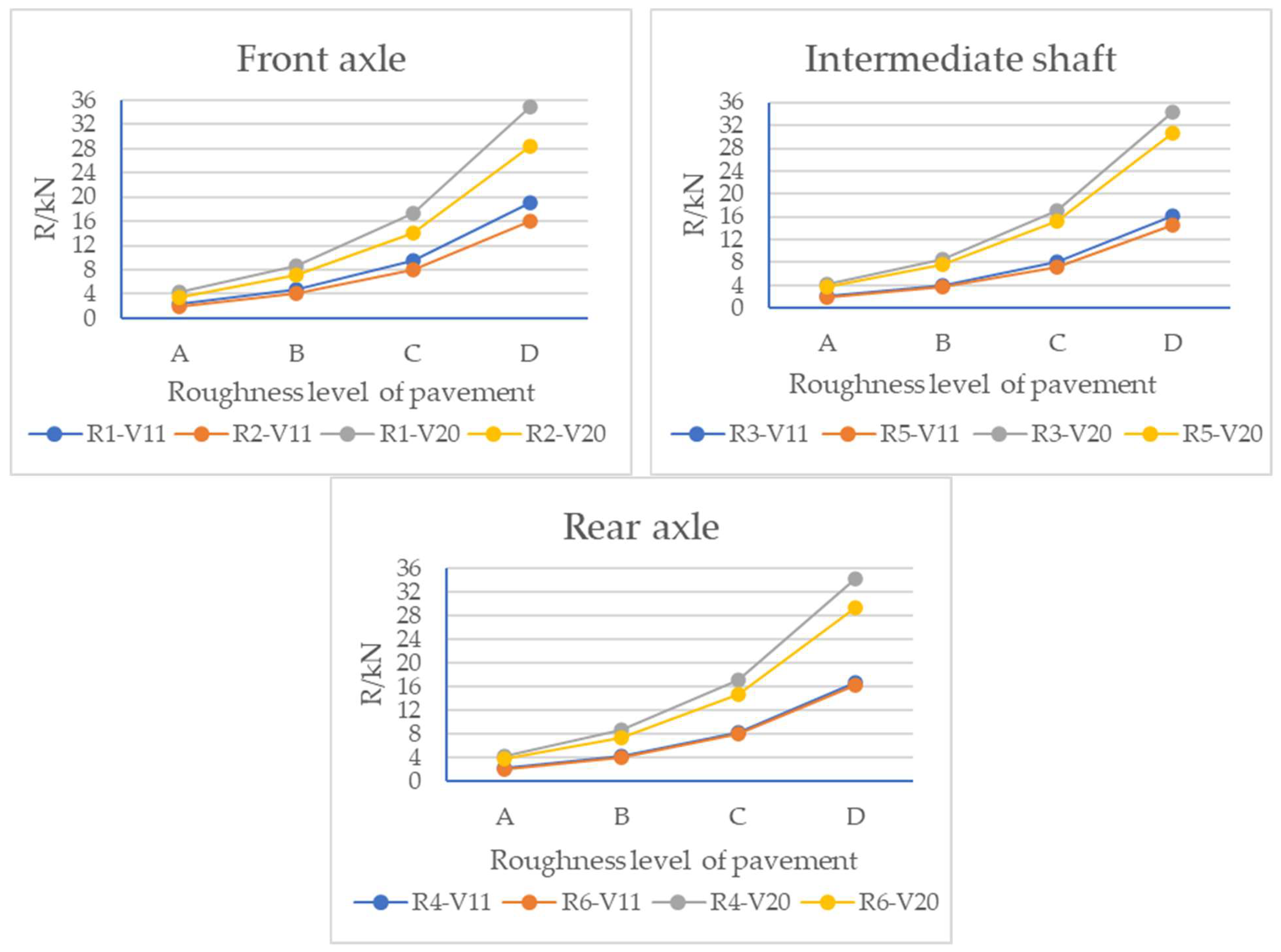

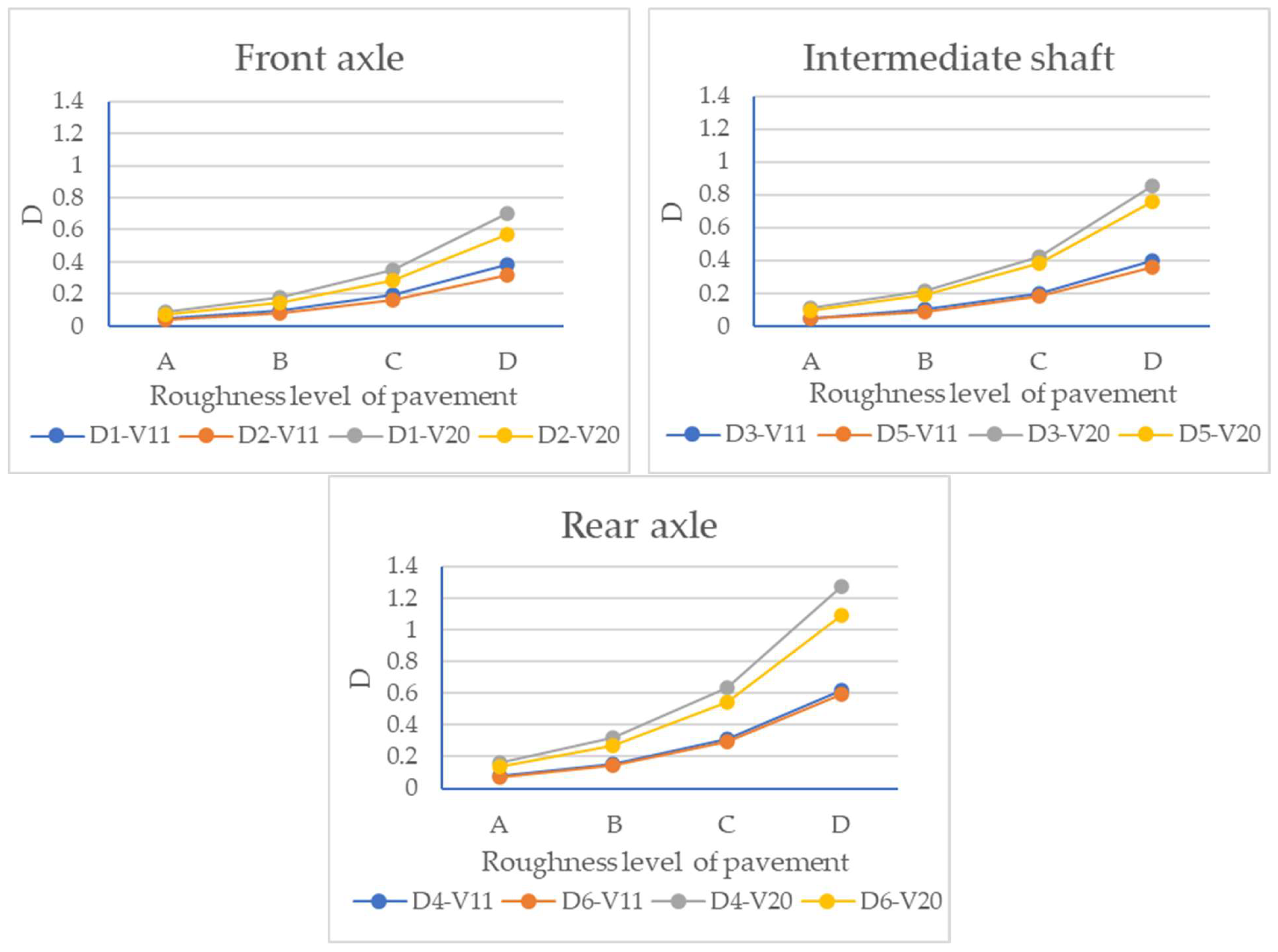

4.1. Effect of Roughness Coefficient on Dynamic Load

- With the deterioration in the pavement roughness grade from grade A to grade D, the root-mean-square value and dynamic load coefficient of each wheel of the three-axle vehicle gradually increase rapidly with a nonlinear trend. This shows that the greater the fluctuation in the longitudinal section of the pavement surface, the more intense the vibration generated by the wheels.

- The root-mean-square value and dynamic load coefficient of the wheel forces are more significantly impacted by the pavement surface roughness as the vehicle speed increases.

- Under the same pavement surface roughness level and the same speed, the average dynamic load index of the rear axle wheel is larger than that of the front axle and the intermediate shaft.

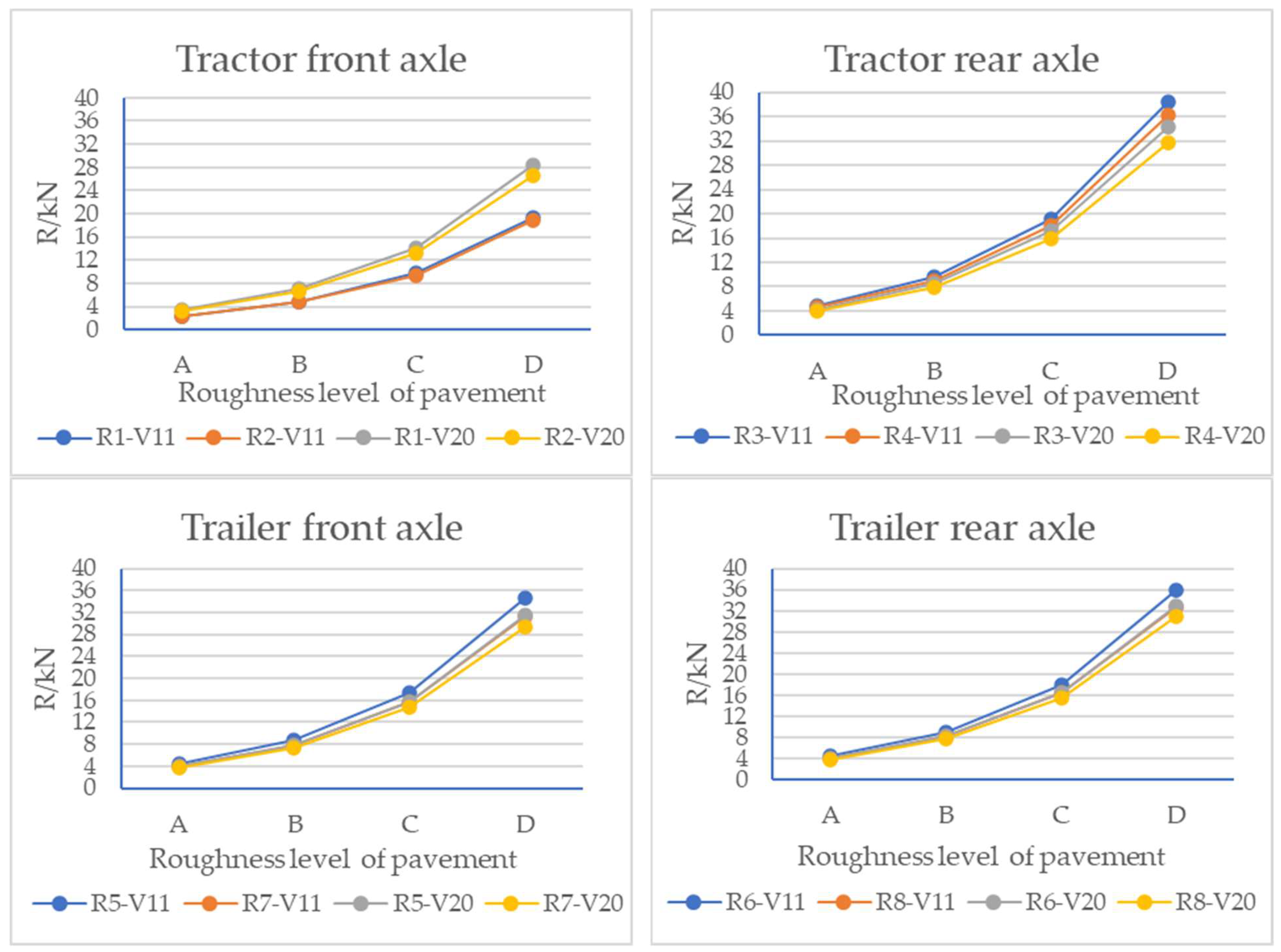

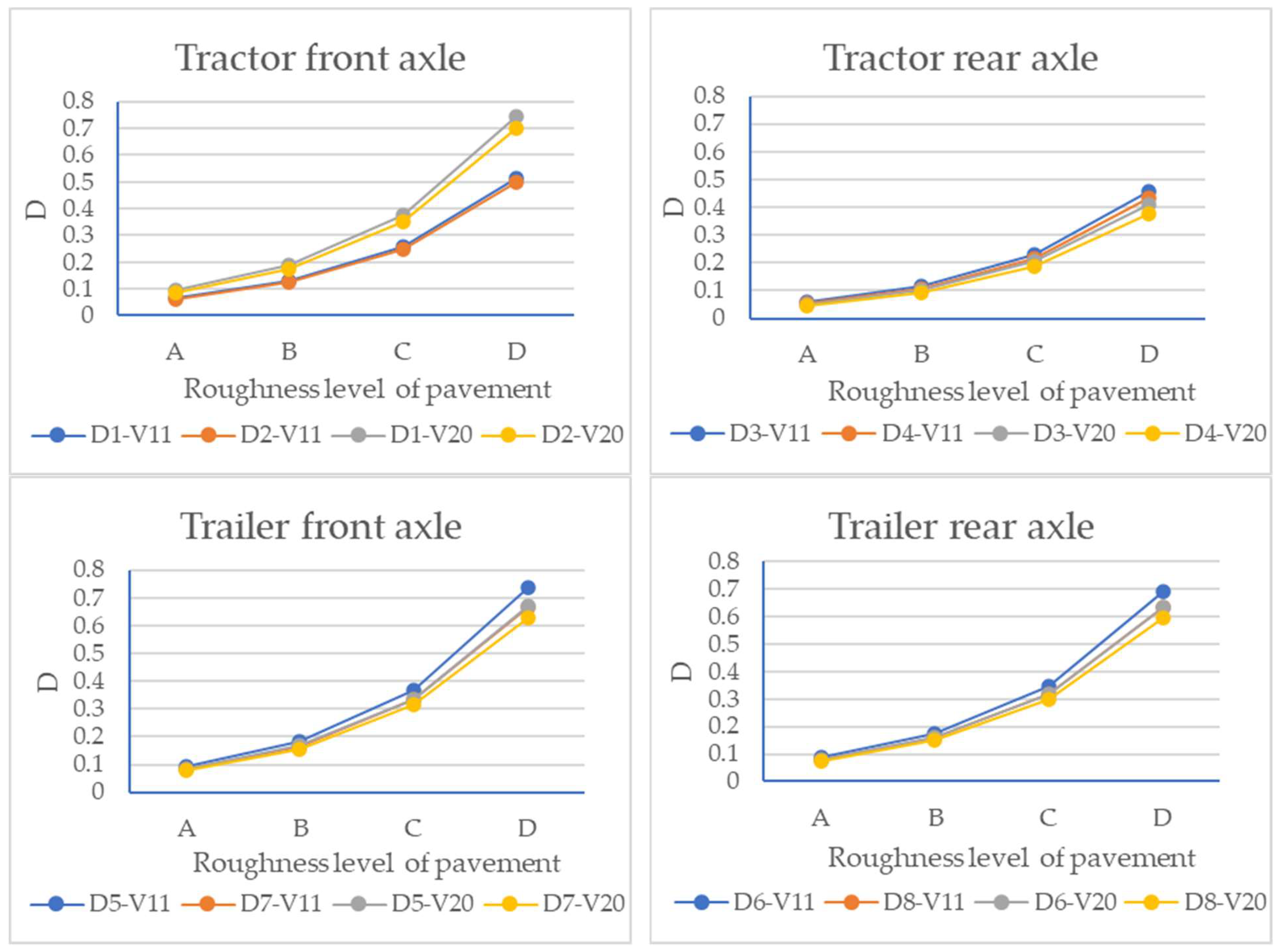

- The variation law of the root-mean-square value and dynamic load coefficient of the dynamic load of the four-axle vehicle is similar to that of the three-axle vehicle, and with a deterioration in roughness, the root-mean-square value of the dynamic load and the dynamic load coefficient of each wheel increase nonlinearly. The higher the vehicle speed, the greater the influence of the pavement surface roughness on the root-mean-square value and dynamic load coefficient of the dynamic load.

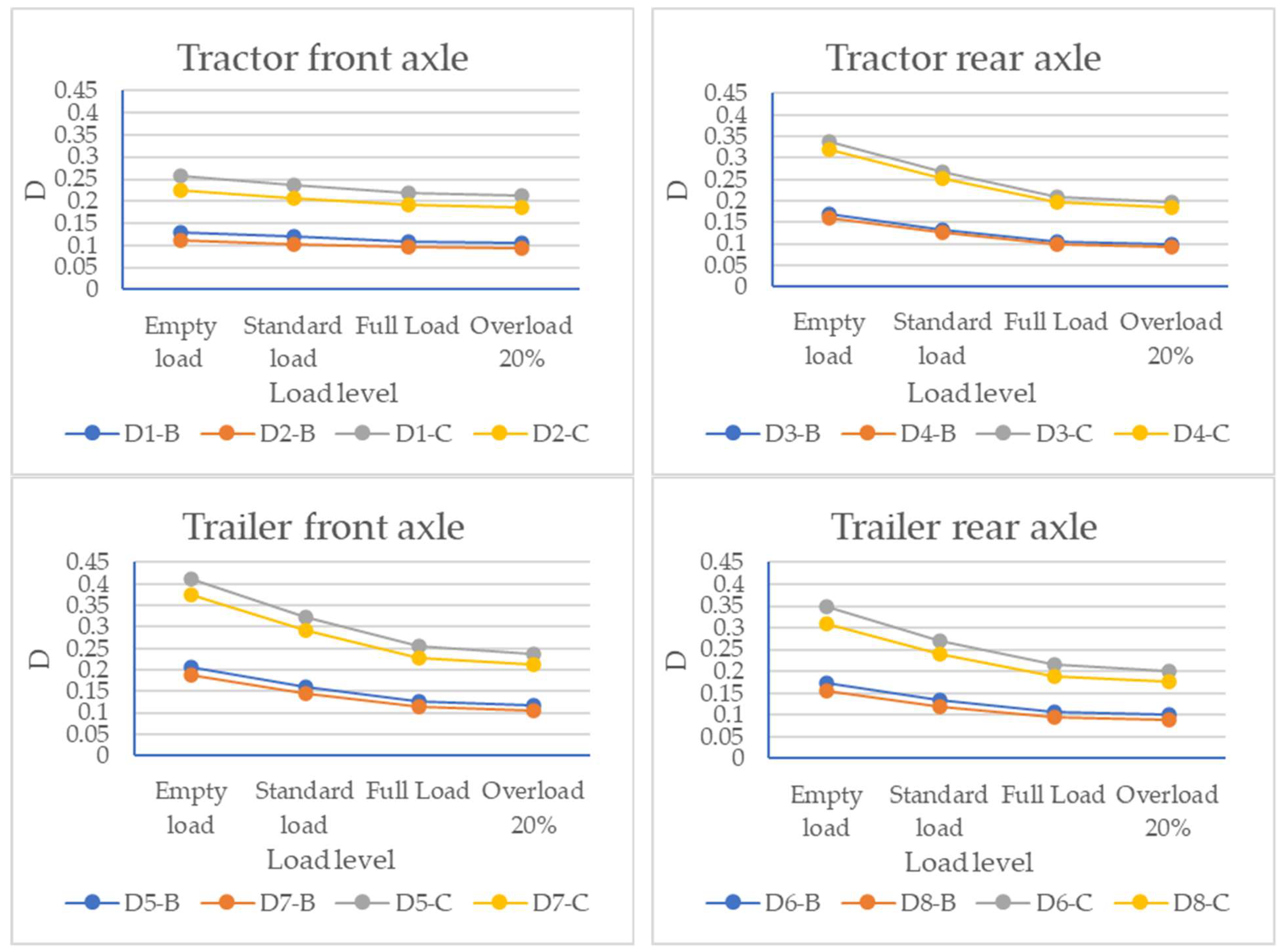

- The variation in the dynamic load coefficient of the trailer is greater than that of the tractor, indicating that the roughness has a greater impact on the trailer of the four-axle vehicle.

4.2. Effect of Load on Dynamic Load

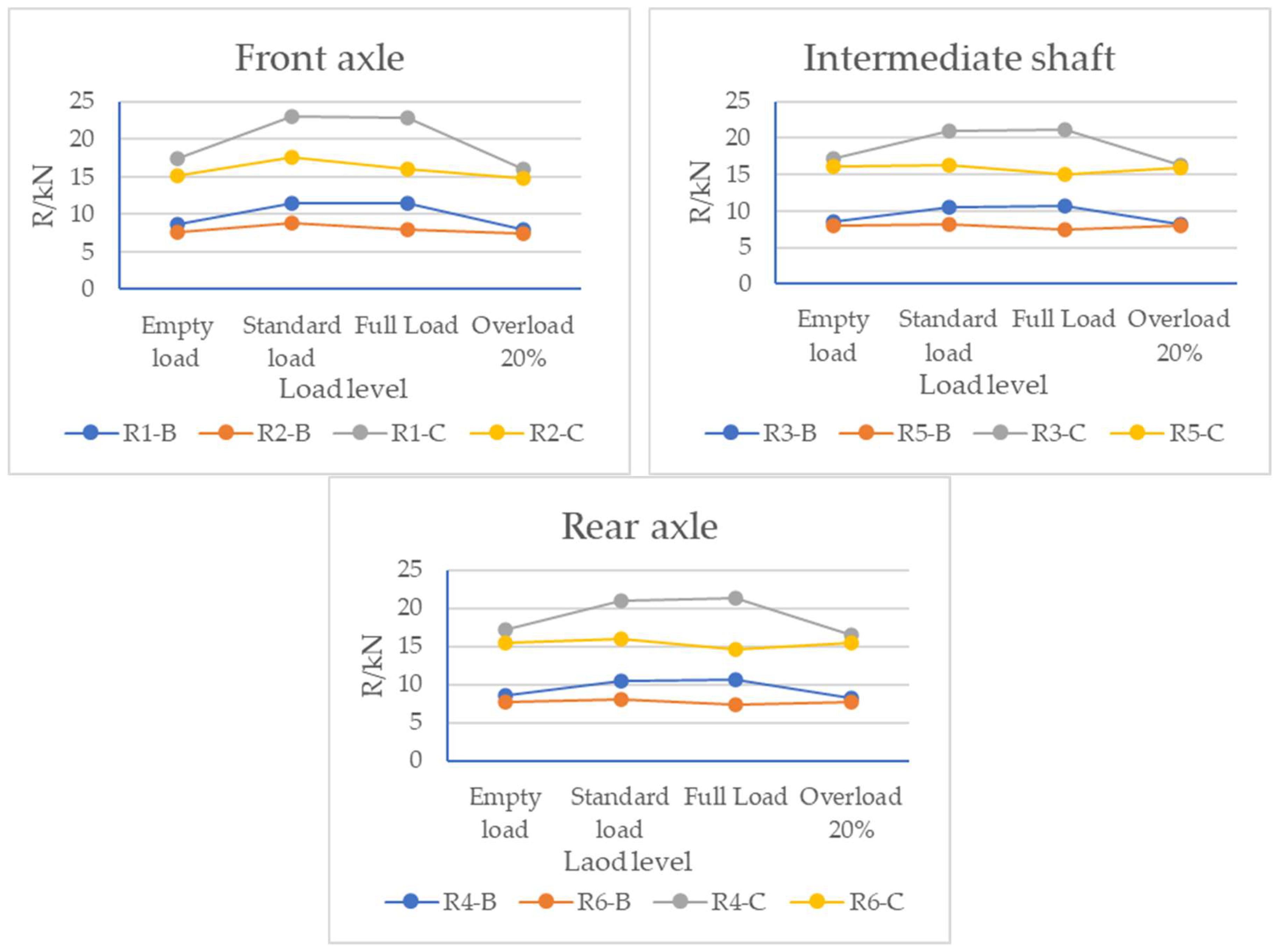

- The root-mean-square value of the dynamic load of each wheel of the three-axle vehicle increases slowly with an increase in load, and its impact becomes greater as the roughness of the pavement surface. At the same time, the R value of each wheel decreases from full load to overload, indicating that a higher load contributes to preventing the vehicle from vibrating.

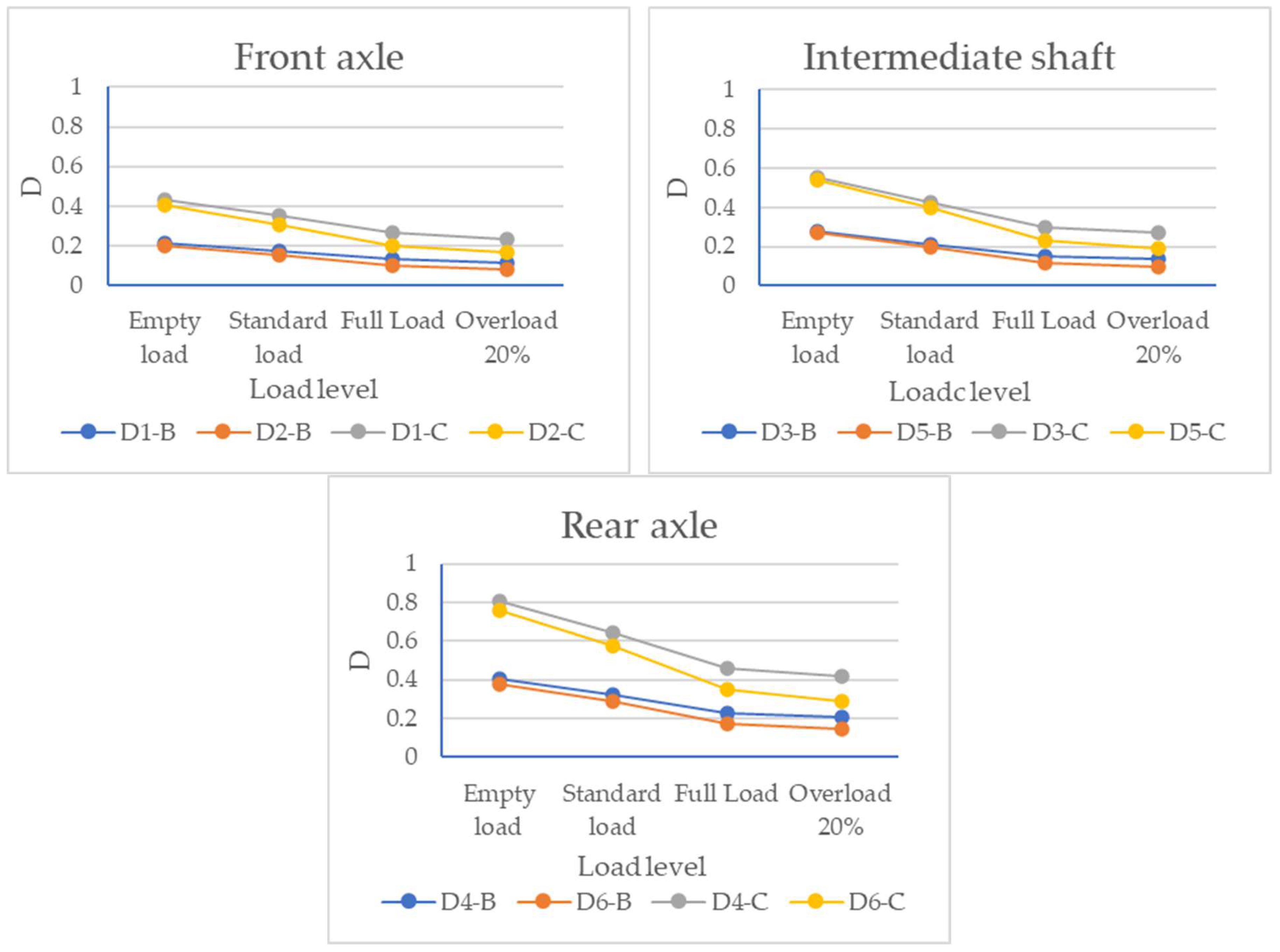

- The dynamic load coefficient of each wheel shows a downward trend with an increase in load, and this downward trend gradually slows down as the load increases. The results show that an increase in vehicle load inhibits the vibration of the vehicle, while the slowdown in the downward trend indicates that the influence of the dynamic load coefficient is greater when the vehicle is lightly loaded.

- The dynamic load coefficient of the rear axle wheel of the three-axle vehicle is greater than that of the front wheel, and the smaller the vehicle load, the greater the difference. This is mainly because the load weight of three-axle vehicles is concentrated in the rear compartment of the vehicle.

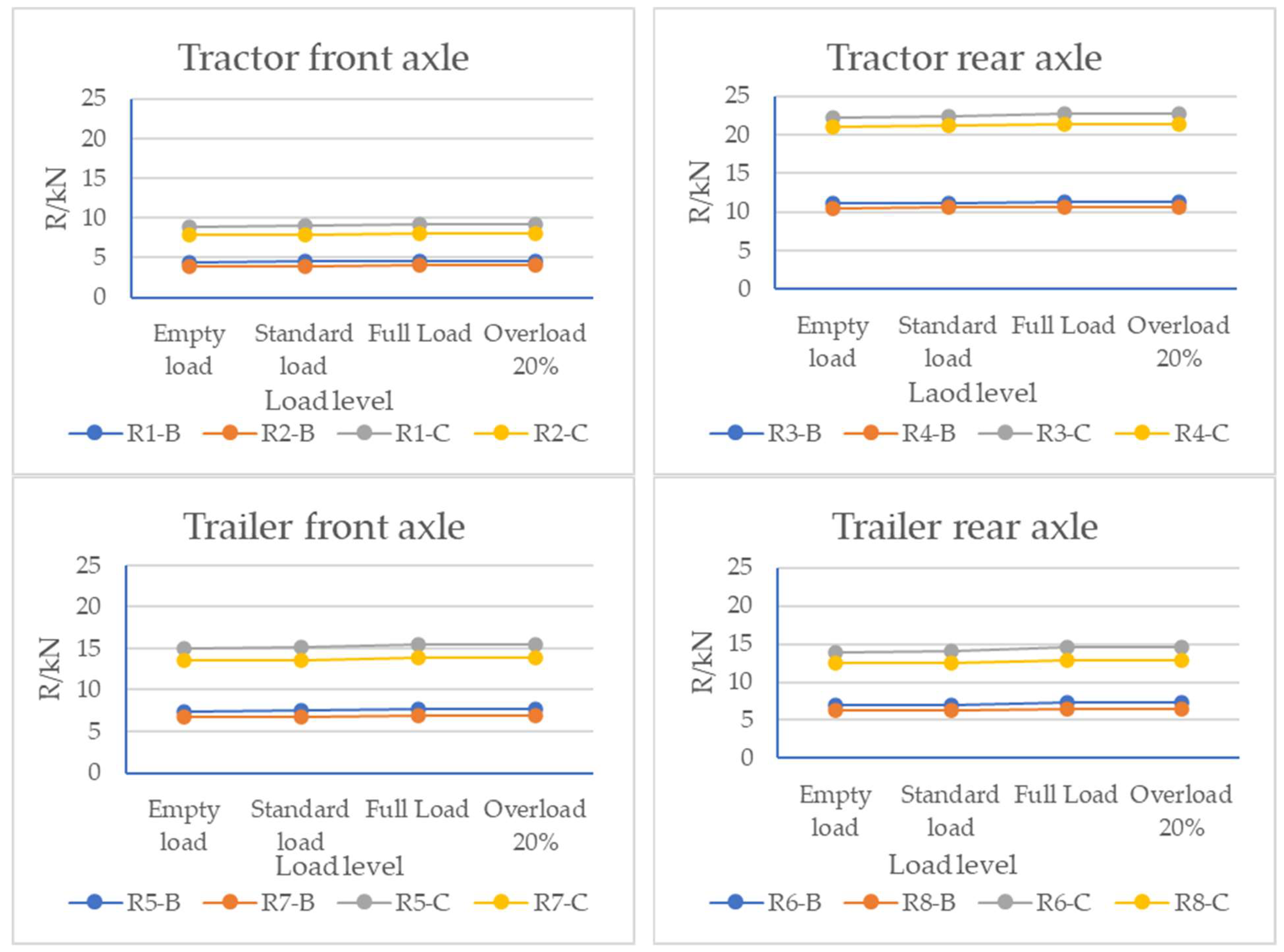

- The root-mean-square value of the dynamic load of each wheel does not change much in different load states, showing a trend of increasing slowly.

- The dynamic load coefficient for each wheel likewise decreases as the load increases. The dynamic load coefficient of the tractor wheel is larger than that of the trailer, and the smaller the vehicle load, the greater the difference between the two. This indicates that the increase in the vehicle load has a higher effect on the four-axle vehicle tractor’s dynamic load.

4.3. Effect of Vehicle Speed on Dynamic Load

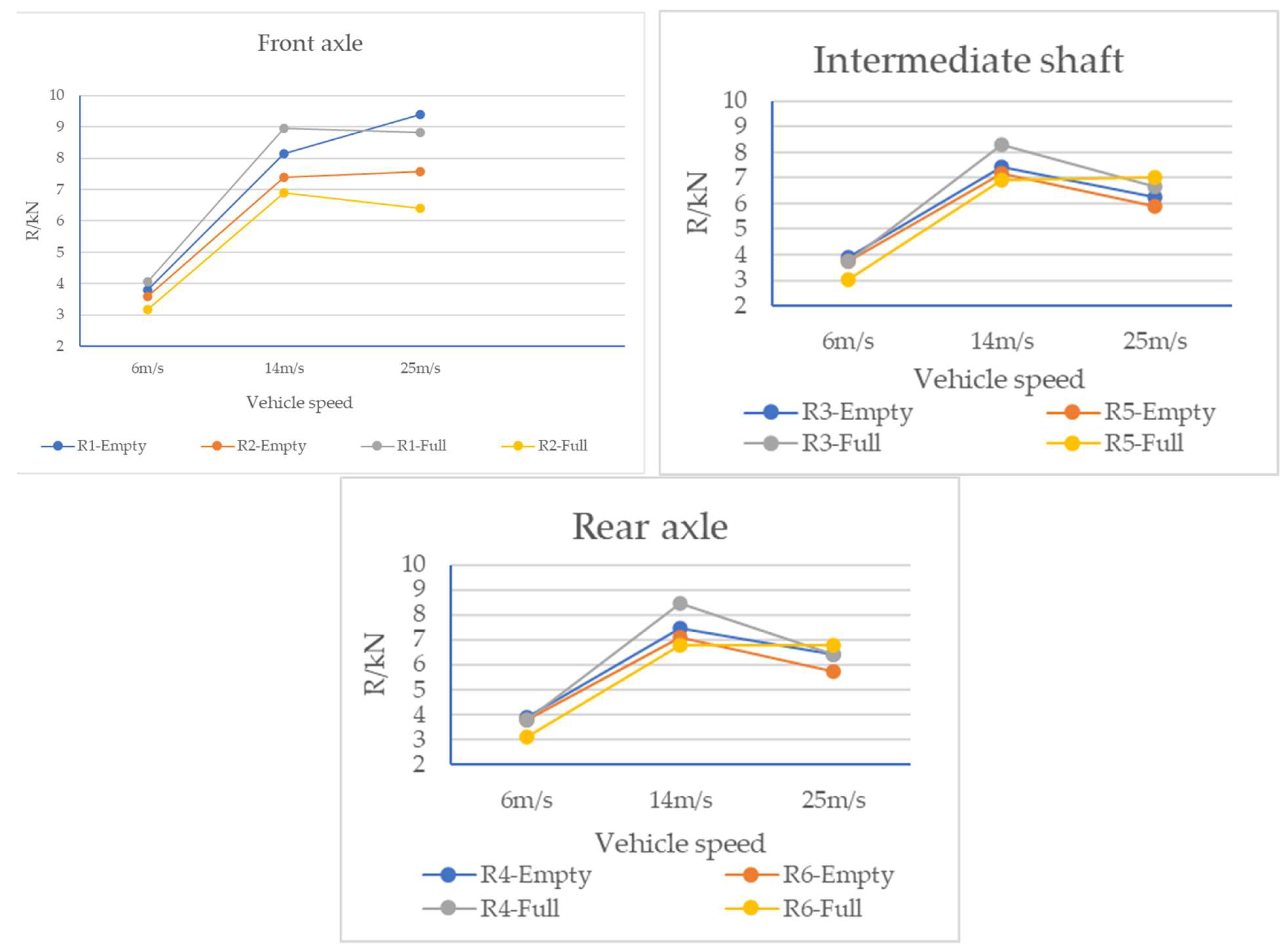

- As speed increases, the root-mean-square value of the dynamic load for each wheel of a three-axle vehicle increases first and then tends to flatten or decrease. The dynamic load coefficient of the front axle gradually increases, while those of the intermediate shaft and rear axle increase first and then decrease. This is mainly because, as the speed changes, the wheel vibration frequency also changes; when the wheel vibration frequency is close to or equal to pavement excitation frequency, the wheel and pavement surface resonate, resulting in an increase in the degree of wheel vibration, and the corresponding dynamic load index also increases. When the vehicle speed continues to increase, the dynamic load index exhibits a declining trend, the wheel’s vibration frequency is far from the pavement surface’s excitation frequency, and the resonance between the wheel and pavement surface vanishes.

- At different speeds, the dynamic load of the vehicle without a load is greater than that of the vehicle with a full load, which also shows that an increase in vehicle load plays a certain role in inhibiting the vibration of the wheel.

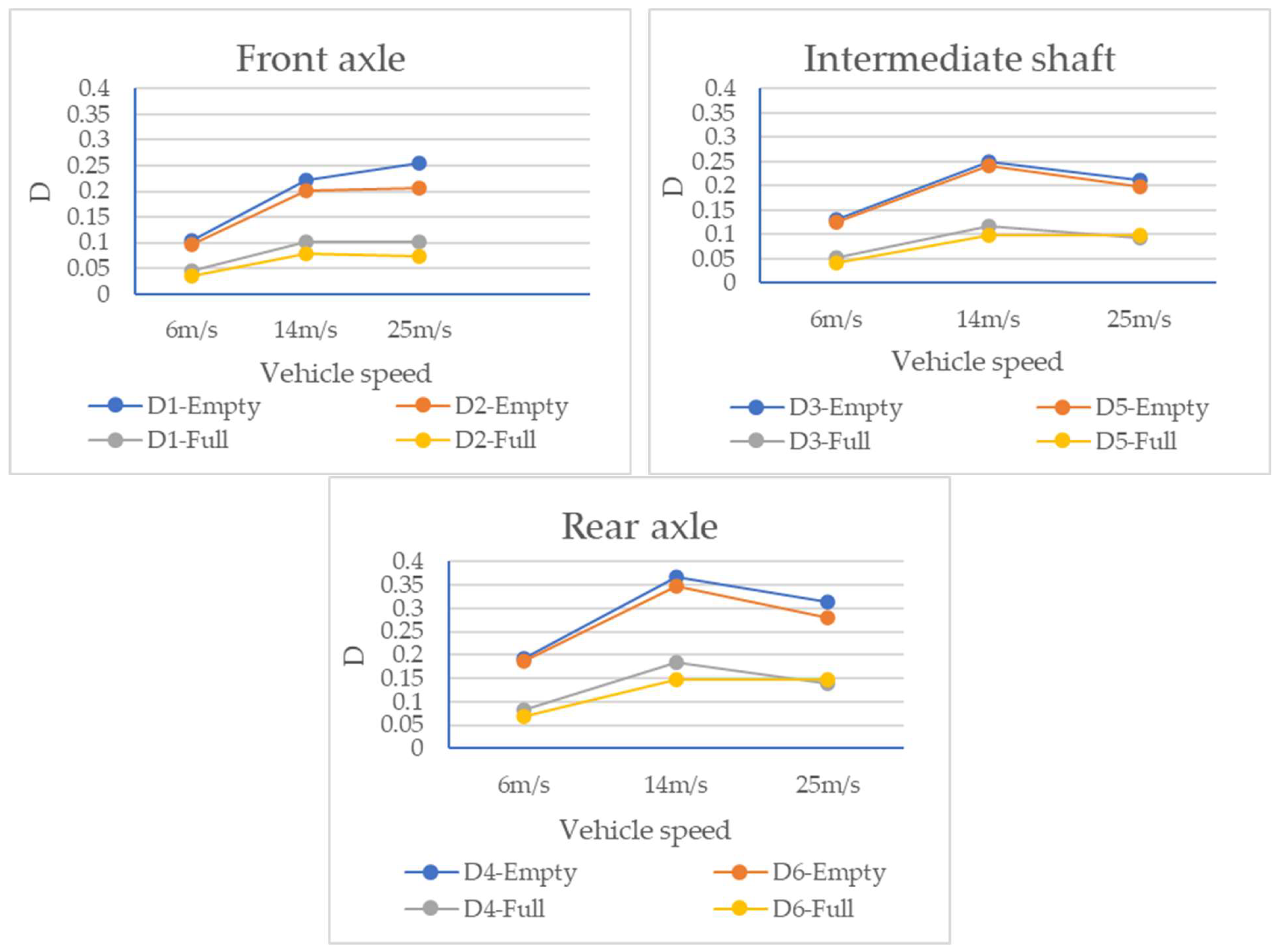

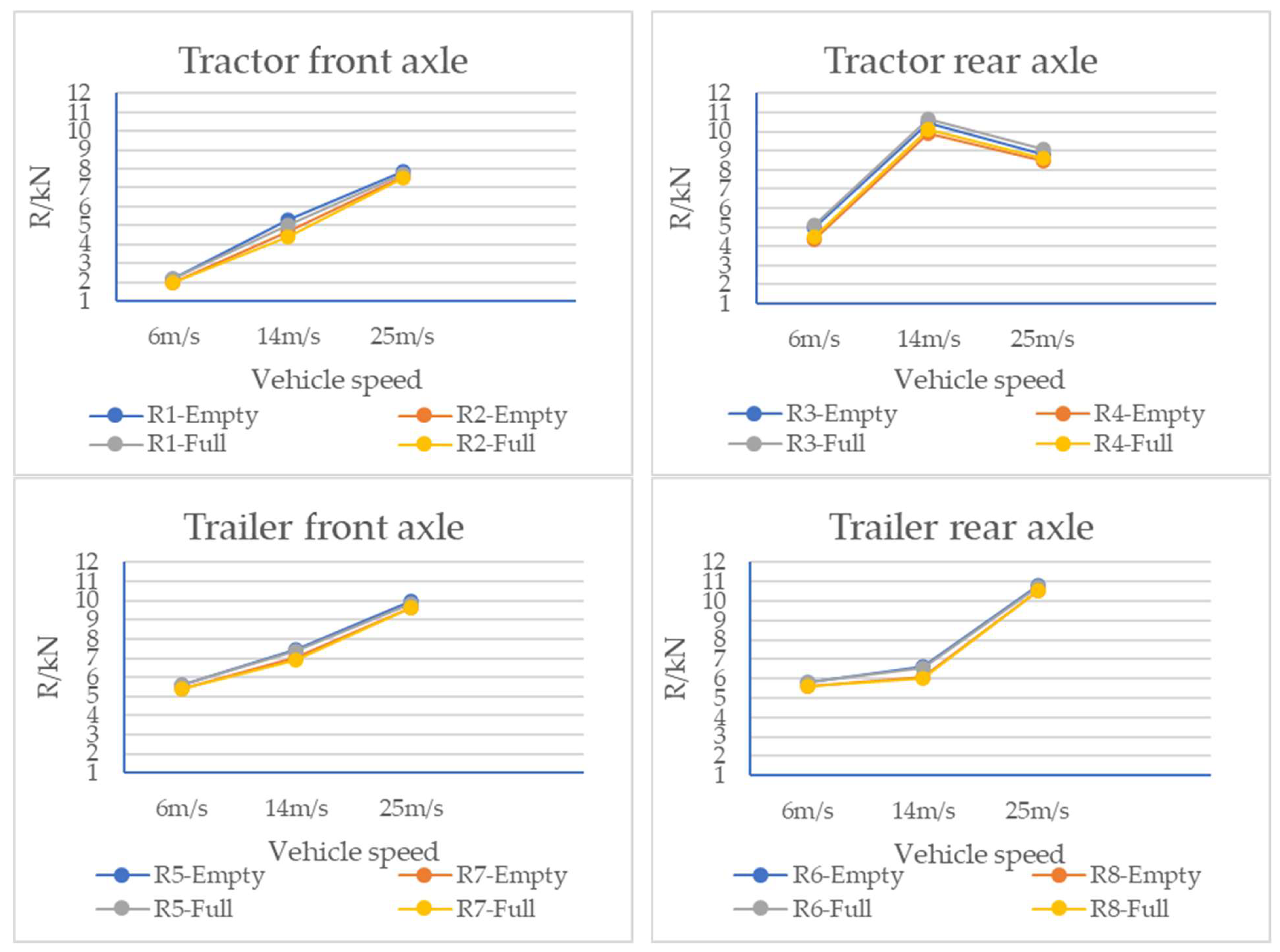

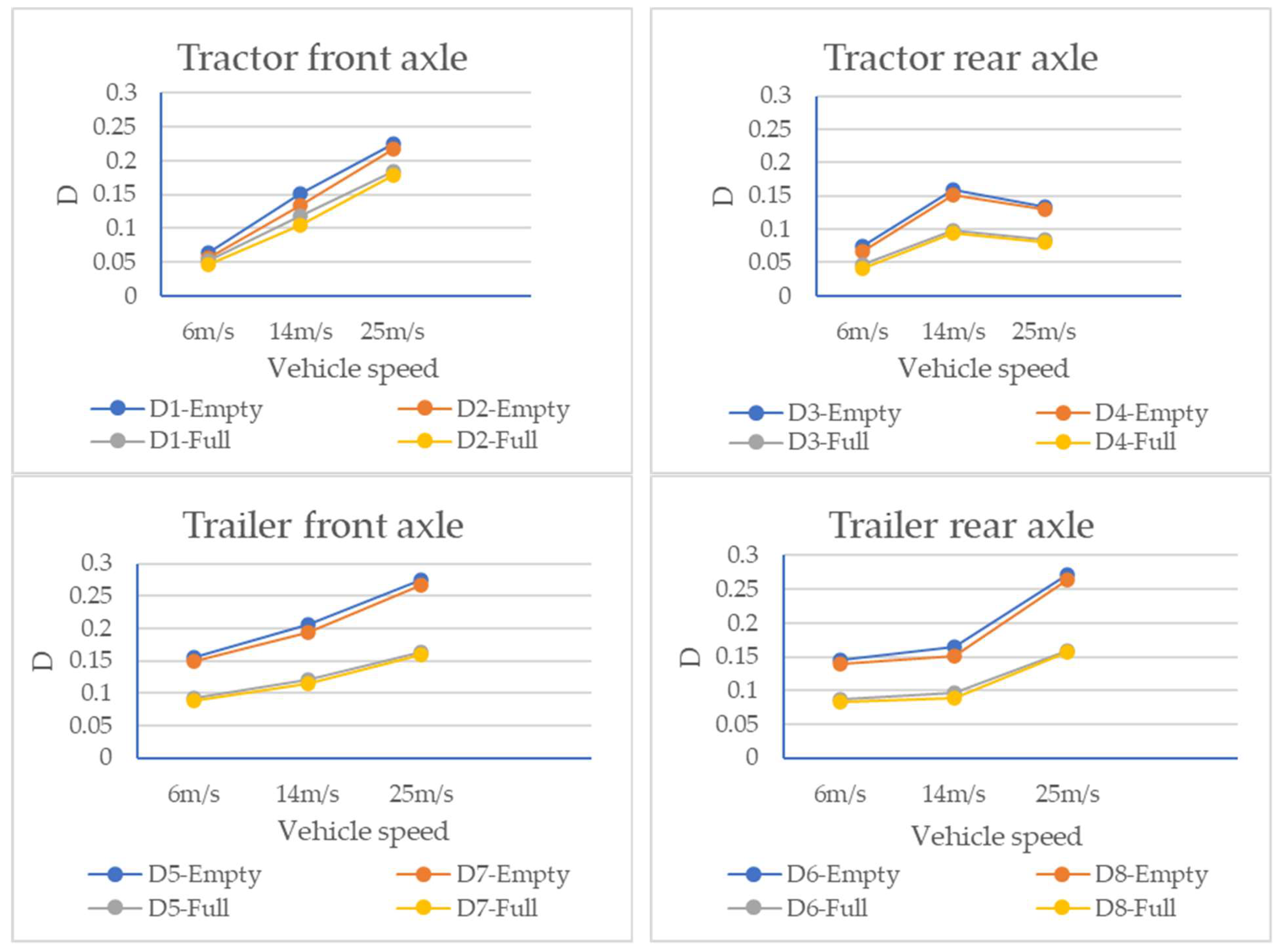

- With an increase in speed, the dynamic load index, the front axle of the four-axle vehicle tractor, and those of the front and rear axle wheels of the trailer all show an increasing trend, while those of the rear axle wheels of the tractor show a decreasing trend. This is also due to the interaction between the vibration frequency of the rear wheel of the tractor and the frequency of the pavement surface excitation.

- For the four-axle vehicle, whether it is at the no-load or full load has little influence on its dynamic load index.

4.4. Effect of Vehicle Lateral Tilt on Dynamic Load

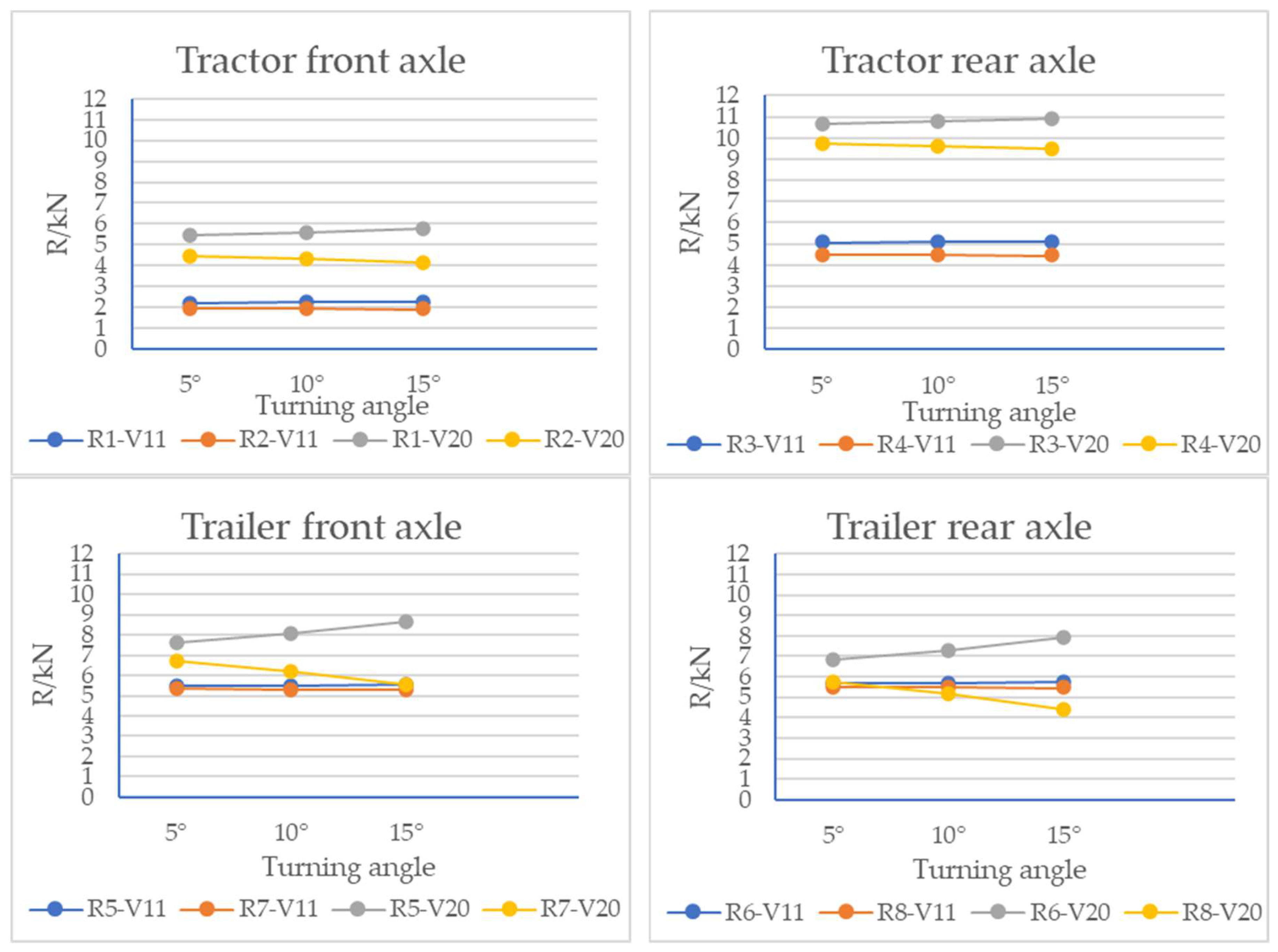

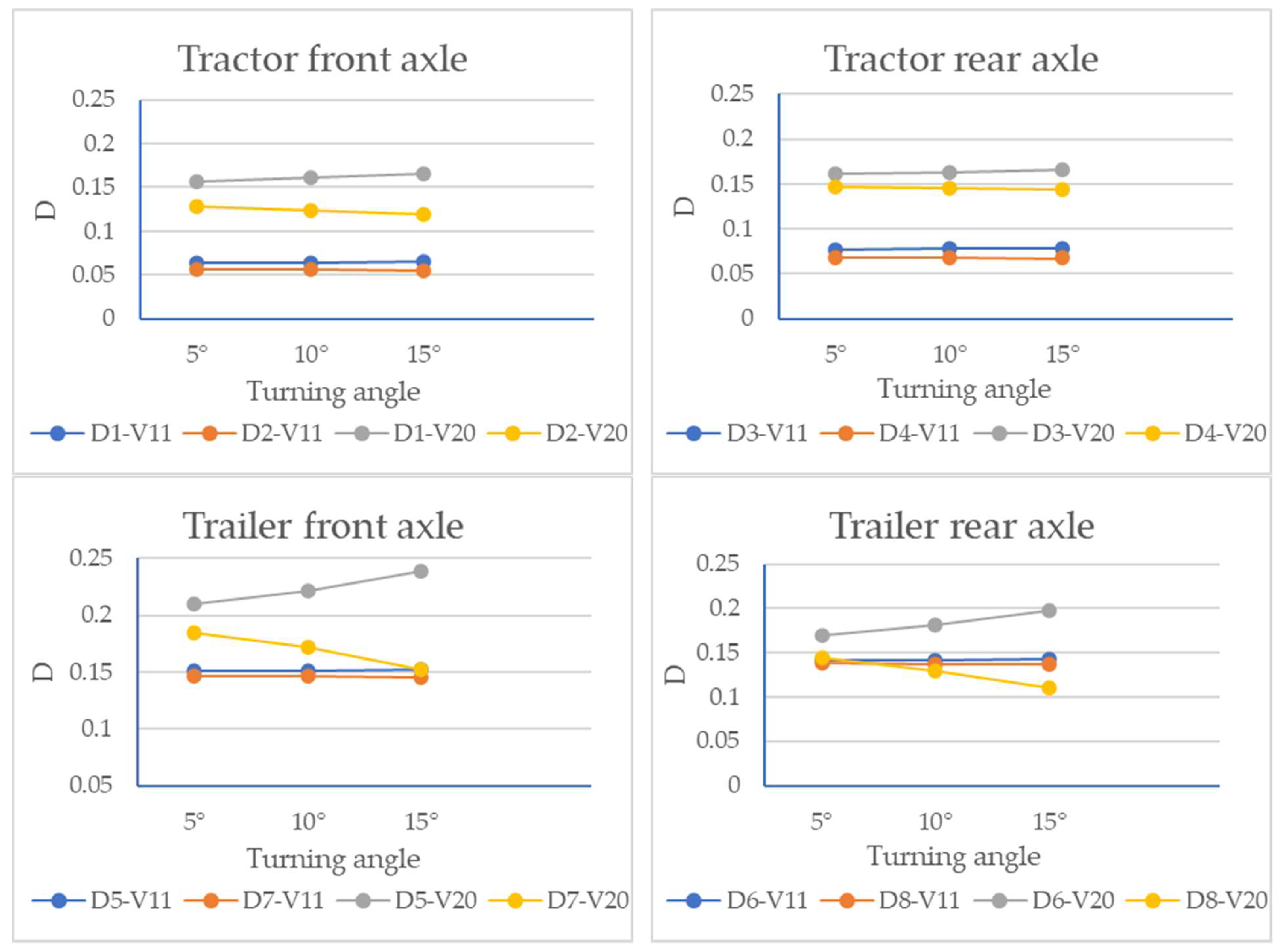

- The turning radius has little influence on the dynamic load index of each wheel, and the faster the vehicle’s speed, the greater its dynamic load index.

- When the vehicle is cornering, the dynamic load indices of the left and right wheels are not the same, while those of the wheels on both sides of the front axle are very close at lower speeds, and the dynamic load index of the left wheel of the front axle is greater than that of the right wheel at higher speeds. At both speeds, the dynamic load index of the left wheel of the intermediate shaft and rear axle is larger than that of the right wheel. At the same time, the dynamic load index of the left wheel increases slowly with an increase in cornering angle, and that of the right wheel decreases slowly with an increase in cornering angle. This is mainly due to the lateral tilt caused by the cornering of the vehicle, which is affected by centrifugal force, resulting in a larger dynamic load index of the left wheel than that of the right wheel.

- Similar to the situation of the three-axle vehicle, the faster the speed, the greater the dynamic load index of the vehicle.

- In cornering, the dynamic load indices of the left wheels of the tractor and the trailer are greater than those of the right wheel, and the dynamic load index of the left wheel gradually increases with an increase in cornering angle, while that of the right wheel steadily declines. The increase and decrease ranges are greater than those of the three-axle vehicle.

5. Conclusions

- With a deterioration in the pavement roughness from grade A to grade D, the dynamic load of each wheel of the three-axle and four-axle vehicle increased nonlinearly, indicating that the greater the fluctuation in the longitudinal section of the pavement, the more intense the vibration generated by the wheel. Specifically, the average dynamic load increased by 95.3% when the roughness rose from grade A to grade D. Under 20% overload conditions, the peak dynamic load increased by 23.7% compared to under a standard load. Moreover, the higher the vehicle speed, the greater the influence of the pavement surface roughness on the dynamic load. At the same time, the dynamic load of the rear axle wheels of the three-axle vehicle was greater than that of the front axle and the intermediate shaft, and the dynamic load of the tractor of the four-axle vehicle was greater than that of the trailer.

- With the progression from no-load to overload, the root-mean-square value of the dynamic load of the three-axle vehicle first increased slowly and then gradually decreased with an increase in load, and the dynamic load coefficient showed a downward trend with an increase in load; similar characteristics were observed for the four-axle vehicle. This shows that an increase in load inhibited the vibration of the vehicle. At the same time, the dynamic load coefficient of the rear axle wheel of the three-axle vehicle was greater than that of the front wheel, and the dynamic load coefficient of the trailer wheel of the four-axle vehicle was greater than that of the tractor, which was related to the fact that the load weight was mainly concentrated in the rear compartment of the vehicle.

- As the vehicle speed increased from 6 m/s to 25 m/s, the dynamic load on the intermediate axle rose from 3894 N to 6261 N (a 60.8% increase), whereas the front axle load increased from 3807 N to 9396 N (a 146.8% increase), revealing significant differences in sensitivity to speed among different axle positions. The root-mean-square value of the dynamic load of the wheel of the three-axle vehicle increased first and then tended to become flat or decreased, and the dynamic load coefficient gradually increased for the front axle, while it first increased and then decreased for the intermediate shaft and the rear axle. The front axle of the tractor and the front and rear axle wheels of the trailer of the four-axle vehicle showed an increasing trend, while the rear axle wheels of the trailer showed a decreasing trend. Notably, when the vehicle’s vibration frequency (1.2–1.8 Hz) approached the dominant pavement excitation frequency (1.5 Hz), the dynamic load increased by up to 37.5%. This reflects the interaction between the vibration frequency of the vehicle and the excitation frequency of the pavement surface, and the negative influence on the pavement structure should be given great attention when the vehicle is driving at low speed.

- When the vehicle was in lateral tilt, the turning radius had a greater influence on the dynamic load index of the left and right wheels, and generally, the dynamic load index of the left wheel was greater than that of the right wheel, which was mainly caused by the centrifugal force of the vehicle’s cornering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.F.; Jiang, J.Q.; Mao, G.H. Analysis of Dynamic Vehicle Load Caused by Pavement Roughness. China Munic. Eng. 2002, 4. [Google Scholar] [CrossRef]

- Dodds, C.J.; Robson, J.D. The description of road surface roughness. J. Sound Vib. 1973, 312, 175–183. [Google Scholar] [CrossRef]

- Cebon, D. Theoretical road damage due to dynamic tyre forces of heavy vehicles part 1: Dynamic analysis of vehicles and road surfaces. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1988, 202, 103–108. [Google Scholar] [CrossRef]

- Watts, G.R. The generation and propagation of vibration in various soils produced by the dynamic loading of road pavements. J. Sound Vib. 1992, 156, 191–206. [Google Scholar] [CrossRef]

- Deng, X. Study on dynamics of vehicle-ground pavement structure system. J. Southeast Univ. (Nat. Sci. Ed.) 2002, 32, 474–479. [Google Scholar] [CrossRef]

- Naraghi, M.; Zadeh, E.N. Effect of Heavy Vehicle Suspension Designs on Dynamic Road Loading—A Comparative Study. SAE Int. Truck. Bus Meet. Expo. 2002, 110, 363–369. [Google Scholar]

- Mitschke, M. Influence of Road and Vehicle Dimensions on the Amplitude of Body Motions and Dynamic Vehicle Loads. SAE Tech. Pap. 1962, 70, 434–446. [Google Scholar] [CrossRef]

- Jing, C. Basic Research on the Interaction Between Vehicle and Pavement. Doctoral Dissertation, Jilin University, Changchun, China, 2002. (In Chinese). [Google Scholar]

- Sun, L.; Luo, F. Nonstationary Dynamic Pavement Loads Generated by Vehicles Traveling at Varying Speed. J. Transp. Eng. 2007, 133, 252–263. [Google Scholar] [CrossRef]

- Sayers, M.W.; Gillespie, T.D.; Queiroz, C.A.V. The International Road Roughness Experiment: Establishing Correlation and Standard for Measurements. In World Bank Technical Paper; The World Bank: Washington, DC, USA, 1986; Available online: http://documents.worldbank.org/curated/en/326081468740204115 (accessed on 1 July 2010).

- Zhong, Y.; Wang, Z.R.; Zhang, X.N. Random Dynamic Pressure of Moving Vehicle on Rough Pavement. China J. Highw. Transp. 1992, 5, 40–43. (In Chinese) [Google Scholar]

- Tao, X.; Hang, X. Analysis and calculation of frequency domain simulations of dynamic load. J. Huazhong Univ. Sci. Technol. Urban Sci. Ed. 2003, 20, 47–50. [Google Scholar]

- Tan, R.H.; Chen, Y.; Lu, Y.X. The mathematical models in time domain for the road disterbances and the simulation. China J. Highw. Transp. 1998, 11, 96–102. [Google Scholar]

- Ruichen, J. Simulation of the road irregularity and study of nonlinear random vibration of the automobile. J. Tsinghua Univ. 1999, 39, 76–79. [Google Scholar]

- Hao, X.; Jun, X.; Xu, T. Influence analysis of driving dynamic load of multi-axle heavy-duty vehicles based on pavement roughness. J. Transp. Sci. Eng. 2023, 39, 26–37. (In Chinese) [Google Scholar]

- Beskou, N.D.; Hatzigeorgiou, G.D.; Theodorakopoulos, D.D. Dynamic inelastic analysis of 3-d flexible pavements under moving vehicles: A unified fem treatment. Soil Dyn. Earthq. Eng. 2016, 90, 420–431. [Google Scholar] [CrossRef]

- Si, L.T. Random Vibration Analysis of Linear Continuous Systems Under Moving Random Loads. Ph.D. Dissertation, Dalian University of Technology, Dalian, China, 2017. [Google Scholar]

- Lv, Y.; Ying, B.; Zou, L. Stress-strain analysis of asphalt pavement under random loading. Highw. Eng. 2018, 43, 94–101. [Google Scholar]

- Mamlouk, M.S. General outlook of pavement and vehicle dynamics. J. Transp. Eng. 1997, 123, 515–517. [Google Scholar] [CrossRef]

- Fryba, L. Dynamic interaction of vehicles with tracks and roads. Veh. Syst. Dyn. 1987, 16, 129–138. [Google Scholar] [CrossRef]

- Liang, B.; Su, S.Y.; Luo, H. Coupled dynamic analysis of vehicle-road system under roughness conditions. Eng. Mech. 2009, 26, 189–194. [Google Scholar]

- Li, H.Y.; Yang, S.P.; Qi, Y.Q.; Xu, B.Q. Dynamics of asphalt pavement under moving stochastic loads and parameter analysis. Eng. Mech. 2011, 28, 159–165. [Google Scholar] [CrossRef]

- Zhao, M.J.; Yin, T.; Fu, S.J. Dynamic response analysis and crack location of cracked beams considering the randomness of moving loads. Chin. J. Civ. Eng. Manag. 2016, 33, 102–108. [Google Scholar]

- Dong, Z.; Ma, X. Analytical solutions of asphalt pavement responses under moving loads with arbitrary non-uniform tire contact pressure and irregular tire imprint. Road Mater. Pavement Des. 2018, 19, 1887–1903. [Google Scholar] [CrossRef]

- Zeng, F.; Chen, F.; Eghbal, S. Vibroacoustic analysis of asphalt pavement responses to moving loads and attached mass-spring-damper systems. Soil Dyn. Earthq. Eng. 2024, 185, 13. [Google Scholar] [CrossRef]

- Mo, C.L. Analysis of dynamic response of asphalt pavement structure and vehicle comfort. West. Transp. Technol. 2023, 7, 44–47. [Google Scholar] [CrossRef]

- Luo, R.K.; Gabbitas, B.L.; Brickle, B.V. Fatigue Life Evaluation of a Railway Vehicle Bogie Using an Integrated Dynamic Simulation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 1994, 208, 123–132. [Google Scholar] [CrossRef]

- Cascino, A.; Meli, E.; Rindi, A. Comparative Analysis and Dynamic Size Optimization of Aluminum and Carbon Fiber Thin-Walled Structures of a Railway Vehicle Car Body. Materials 2025, 18, 1501. [Google Scholar] [CrossRef] [PubMed]

- Xiandong, L. Research on the method of simulating road roughness numerically. J. Beijing Univ. Aeronaut. Astronaut. 2003, 29, 843–846. [Google Scholar] [CrossRef]

- Yu, Z.S. Automobile Theory, 3rd ed.; China Machine Press: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Robson, J.D. Road surface description and vehicle response. Int. J. Veh. Des. 1979, 1, 25–35. [Google Scholar] [CrossRef]

- Zhang, G.; Fang, Z.; Chen, S.; Song, Y. White Noise Simulation for Road Roughness Based on Power Function. Automot. Eng. 2008, 30, 44–47. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.Z.; Zheng, K.F. Simulation research on time domain model of road roughness with time-space correlation. J. Vib. Shock. 2013, 32, 70–74. [Google Scholar]

- Lu, F.; Chen, S.Z. Modeling and simulation of road surface excitation on vehicle in time domain. Automot. Eng. 2015, 37, 549–553. [Google Scholar]

- Zhou, C.; Sun, B.; Sun, Q.; Chen, N.; Ma, Z.; Li, S.; Wang, H. Modeling and simulation of harshness of an articulated tipper. Automob. Technol. 2004, 9, 15–18. [Google Scholar] [CrossRef]

- Cole, D.J.; Cebon, D. Modification of a heavy vehicle suspension to reduce road damage. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1995, 209, 183–194. [Google Scholar] [CrossRef]

| Pavement Grade | |||

|---|---|---|---|

| Lower Limit | Geometric Mean | Upper Limit | |

| A | 8 | 16 | 32 |

| B | 32 | 64 | 128 |

| C | 128 | 256 | 512 |

| D | 512 | 1024 | 2048 |

| E | 2048 | 4096 | 8192 |

| F | 8192 | 16,384 | 32,768 |

| G | 32,768 | 65,536 | 131,072 |

| H | 131,072 | 262,144 | 524,288 |

| Body mass, m1 (kg) | 8130 | Unsprung mass of intermediate shaft, mC1; mC2 (kg) | 523.6 |

| Unsprung mass of front axle, mA; mB (kg) | 634.8 | Unsprung mass of rear axle, mD1; mD2 (kg) | 523.6 |

| Stiffness of front axle suspension spring, KSA; KSB (N/m) | 7,658,000 | Damping coefficient of front suspension, CSA; CSB (Ns/m) | 5073 |

| Stiffness of rear axle suspension sping, KSC; KSD (N/m) | 19,835,000 | Damping coefficient of rear suspension, CSC; CSD (Ns/m) | 70,396 |

| Front tire stiffness, KtA; KtB (N/m) | 1,200,000 | Front tire damping coefficient, CtA; CtB (Ns/m) | 4200 |

| Intermediate tire stiffness, KtC1; KtD1 (N/m) | 1,200,000 | Intermediate tire damping coefficient, CtC1; CtD1 (Ns/m) | 4200 |

| Rear tire stiffness, KtC2; KtD2 (N/m) | 1,200,000 | Rear tire damping coefficient, CtC2; CtD2 (Ns/m) | 4200 |

| Pitching moment of inertia of body, J1(N·m2) | 61,230 | Moment of inertia of rear balance suspension, J2; J3(N·m2) | 43.5 |

| Lateral tilt moment of inertia of the body, I (N·m2) | 47,630 |

| Sprung mass of the tractor, m9 (kg) | 2730 | Sprung mass of the trailer, m10(kg) | 13,750 |

| Unsprung mass of the tractor front wheel, m1; m2 (kg) | 530 | Unsprung mass of the trailer front wheel, m5; m7 (kg) | 457 |

| Unsprung mass of the tractor rear wheel, m3; m4 (kg) | 530 | Unsprung mass of the trailer rear wheel, m6; m8 (kg) | 457 |

| Tire stiffness of tractor front wheel, K1; K2 (N/m) | 1,250,000 | Tire damping coefficient of tractor front wheel, C1; C2 (Ns/m) | 4320 |

| Tire stiffness of tractor rear wheel, K3; K4 (N/m) | 2,470,000 | Tire damping coefficient of tractor rear wheel, C3; C4 (Ns/m) | 4320 |

| Tire stiffness of trailer front wheel, K5; K7 (N/m) | 2,760,000 | Tire damping coefficient of trailer front wheel, C5; C7 (Ns/m) | 4320 |

| Tire stiffness of trailer rear wheel, K6; K8 (N/m) | 2,760,000 | Tire damping coefficient of trailer rear wheel, C6; C8 (Ns/m) | 4320 |

| Stiffness of tractor front axle suspension spring, K9; K10 (N/m) | 763,000 | Damping coefficient of suspension of tractor front axle, C9; C10 (Ns/m) | 3918 |

| Stiffness of tractor rear axle suspension spring, K11; K12 (N/m) | 820,000 | Damping coefficient of suspension of tractor rear axle, C11; C12 (Ns/m) | 11,700 |

| Stiffness of rear balance suspension axle, K13; K14 (N/m) | 1,880,000 | Damping coefficient of suspension of rear balance suspension axle, C13; C14 (Ns/m) | 23,600 |

| Pitching moment of inertia of tractor, J1(N·m2) | 62,500 | Pitching moment of inertia of trailer, J2(N·m2) | 979,300 |

| Pitching moment of rear balance suspension, J3; J4(N·m2) | 27.3 | Lateral tilt moment of inertia of trailer, I1(N·m2) | 386,070 |

| Lateral tilt moment of inertia of tractor, I2(N·m2) | 604,900 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Yan, S.; Feng, C. Dynamic Load Analysis of Vertical, Pitching, and Lateral Tilt Vibrations of Multi-Axle Vehicles. Appl. Sci. 2025, 15, 9906. https://doi.org/10.3390/app15189906

Xie J, Yan S, Feng C. Dynamic Load Analysis of Vertical, Pitching, and Lateral Tilt Vibrations of Multi-Axle Vehicles. Applied Sciences. 2025; 15(18):9906. https://doi.org/10.3390/app15189906

Chicago/Turabian StyleXie, Jun, Sibin Yan, and Chenglin Feng. 2025. "Dynamic Load Analysis of Vertical, Pitching, and Lateral Tilt Vibrations of Multi-Axle Vehicles" Applied Sciences 15, no. 18: 9906. https://doi.org/10.3390/app15189906

APA StyleXie, J., Yan, S., & Feng, C. (2025). Dynamic Load Analysis of Vertical, Pitching, and Lateral Tilt Vibrations of Multi-Axle Vehicles. Applied Sciences, 15(18), 9906. https://doi.org/10.3390/app15189906