Review and Experimental Update on Manufacturing of Hybrid Carbon Fiber Composites for Space Use

Abstract

1. Introduction

2. Composite Laminates with Hybrid Reinforcement

| Hybridization | Year | Reference | |

|---|---|---|---|

| Micro-reinforcement hybridization | CFs/GFs | 2020 | [20] |

| 2018 | [9,18] | ||

| 2013 | [19] | ||

| CFs/Kevlar fibers | 2025 | [21] | |

| 2018 | [9] | ||

| CFs/TP fibers | 2020 | [27,28] | |

| 2015 | [24] | ||

| 2006 | [26] | ||

| 2002 | [25] | ||

| Nano-reinforcement hybridization | CFs/CNFs | 2025 | [11] |

| CFs/CNTs | 2025 | [11] | |

| 2021 | [14] | ||

| 2019 | [12,13] | ||

| CFs/GNPs | 2024 | [15,16] | |

| CFs/CNTs/GNPs | 2024 | [17] | |

3. Hybrid Matrix Composites

4. Manufacturing of CFR Epoxy/PEEK Hybrid Composite Laminates

4.1. Hybrid Composites Manufacturing and Testing

4.1.1. Supplied Materials

4.1.2. Laminates Manufacturing

4.1.3. Hybrid Composite Testing

4.2. Results

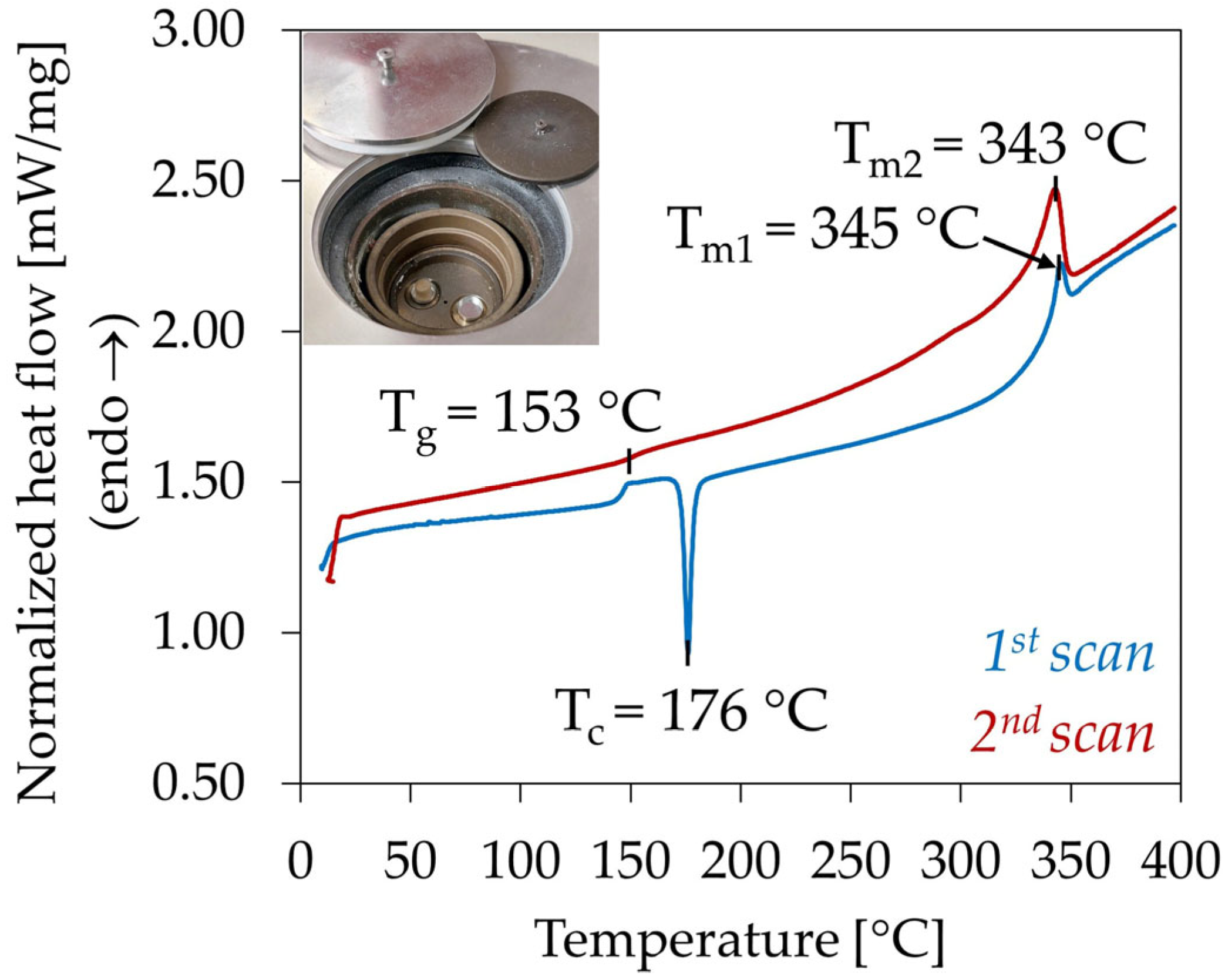

4.2.1. Thermal Analysis

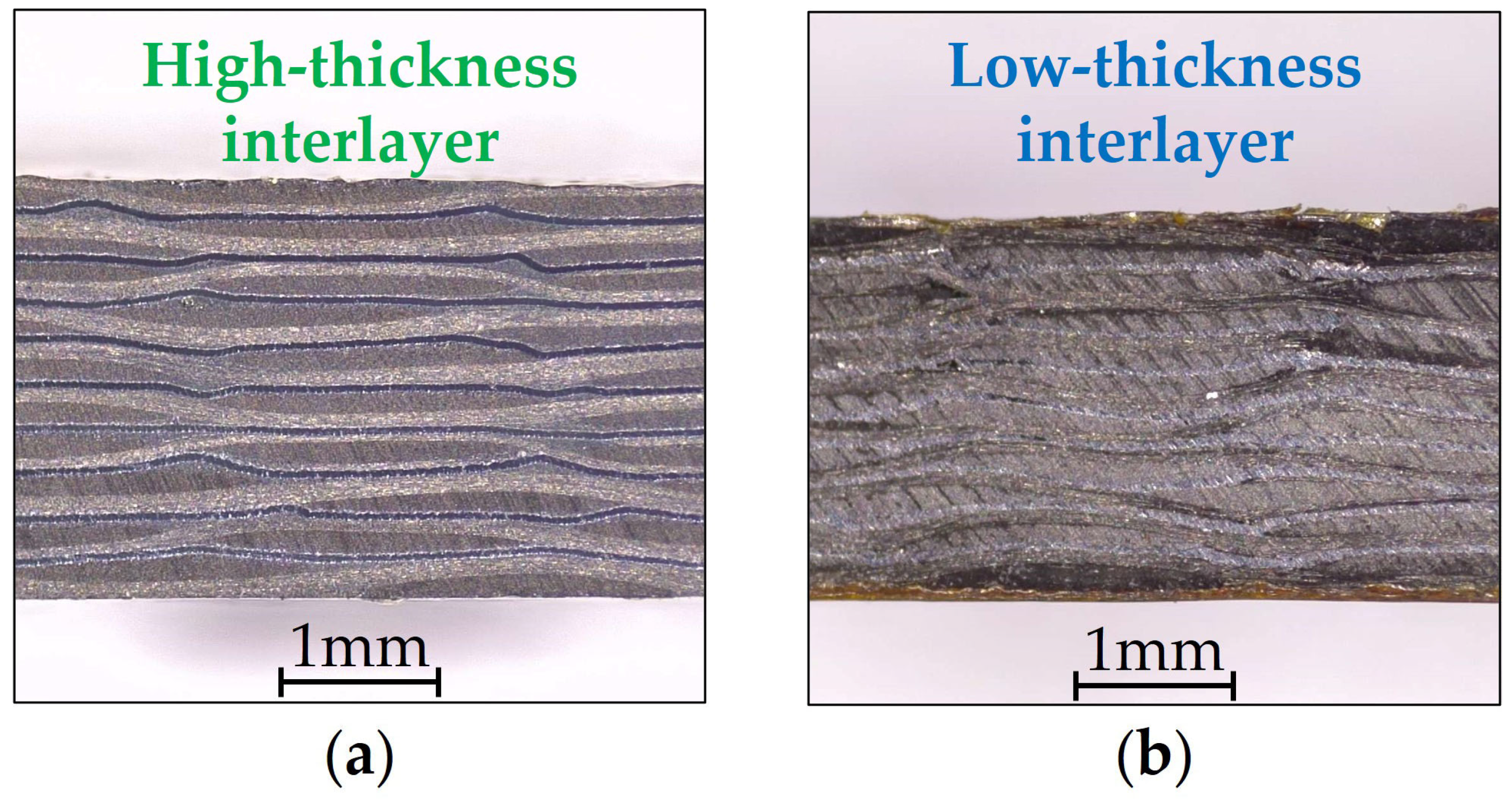

4.2.2. Morphology

4.2.3. Mechanical Testing

4.3. Discussions

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CFs | carbon fibers |

| CNFs | carbon nanofiber |

| CNTs | carbon nanotubes |

| FEP | fluorinated ethylene propylene |

| FRPs | fiber-reinforced polymers |

| FTIR | Fourier-transform infrared spectroscopy |

| GFs | glass fibers |

| GNPs | graphene nanoplatelets |

| PA | polyamide |

| PAEK | poly aryl ether ketone |

| PEEK | poly ether ether ketone |

| PEI | polyetherimide |

| Sa | arithmetical mean height |

| SEM | scanning electron microscope |

| Sz | maximum height |

| Tc | crystallization temperature |

| Tg | glass transition temperature |

| Tm | melting temperature |

| TP | thermoplastic |

| TS | thermosetting |

| UHMWPE | ultrahigh-molecular-weight polyethylene |

References

- Tserpes, K.; Sioutis, I. Advances in Composite Materials for Space Applications: A Comprehensive Literature Review. Aerospace 2025, 12, 215. [Google Scholar] [CrossRef]

- Vickers, J.H.; Tate, L.C.; Gaddis, S.W.; Neal, R.E. Composites Materials and Manufacturing Technologies for Space Applications. In Proceedings of the NASA-Sponsored Technical Interchange Conference, New Orleans, LA, USA, 6–7 May 2015. [Google Scholar]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Boudjemai, A.; Amri, R.; Mankour, A.; Salem, H.; Bouanane, M.H.; Boutchicha, D. Modal Analysis and Testing of Hexagonal Honeycomb Plates Used for Satellite Structural Design. Mater. Des. 2012, 35, 266–275. [Google Scholar] [CrossRef]

- Yang, Y.-Z.; Yang, J.-L.; Fang, D.-N. Research Progress on Thermal Protection Materials and Structures of Hypersonic Vehicles. Appl. Math. Mech. 2008, 29, 51–60. [Google Scholar] [CrossRef]

- Voevodin, A.; Zabinski, J. Nanocomposite and Nanostructured Tribological Materials for Space Applications. Compos. Sci. Technol. 2005, 65, 741–748. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Recent Advances in Fibre-Hybrid Composites: Materials Selection, Opportunities and Applications. Int. Mater. Rev. 2019, 64, 181–215. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact Behaviour of Hybrid Composites for Structural Applications: A Review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Liu, J.; Wei, X. Enhancing the Impact Performance of Reinforced Composites through Fiber Hybridization—A Hybrid Dynamic Shear-Lag Model. Extreme Mech. Lett. 2021, 47, 101352. [Google Scholar] [CrossRef]

- Ramachandrarao, M.; Khan, S.H.; Abdullah, K. Carbon Nanotubes and Nanofibers—Reinforcement to Carbon Fiber Composites—Synthesis, Characterizations and Applications: A Review. Compos. Part C Open Access 2025, 16, 100551. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Md Akil, H.; Abdul Kudus, M.H.; Ullah, F.; Javed, F.; Nosbi, N. Hybrid Carbon Fiber-Carbon Nanotubes Reinforced Polymer Composites: A Review. Compos. Part B Eng. 2019, 176, 107313. [Google Scholar] [CrossRef]

- Malekimoghadam, R.; Icardi, U. Prediction of Mechanical Properties of Carbon Nanotube–carbon Fiber Reinforced Hybrid Composites Using Multi-Scale Finite Element Modelling. Compos. Part B Eng. 2019, 177, 107405. [Google Scholar] [CrossRef]

- Kim, J.J.; Brown, A.D.; Bakis, C.E.; Smith, E.C. Hybrid Carbon Nanotube—Carbon Fiber Composites for High Damping. Compos. Sci. Technol. 2021, 207, 108712. [Google Scholar] [CrossRef]

- Bilgi, C.; Demir, B.; Aydın, H.; Üstün, B.; Kurtan, Ü. Effect of Functionalized Graphene Nanoplatelet Dispersion on Thermal and Electrical Properties of Hybrid Carbon Fiber Reinforced Aviation Epoxy Laminated Composite. Mater. Chem. Phys. 2024, 325, 129702. [Google Scholar] [CrossRef]

- Koutroumanis, N.; Manikas, A.C.; Pappas, P.N.; Anagnostopoulos, G.; Galiotis, C. Interfacial Properties and Mechanical Performance of Hybrid Graphene/Carbon Fibre Composites. Mater. Today Commun. 2024, 41, 110458. [Google Scholar] [CrossRef]

- El Aoud, B.; Althobaiti, S.; Aljohani, A.F.; Selim, M.M.; Boujelbene, M.; Mohamed, S.M.Y.; Mahariq, I. Micromechanical Modeling of Thermal Conductivities of Unidirectional Carbon Fiber/Epoxy Composites Containing Carbon Nanotube/Graphene Hybrids. Int. Commun. Heat Mass Transf. 2024, 157, 107726. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials 2018, 11, 1105. [Google Scholar] [CrossRef] [PubMed]

- Pandya, K.S.; Pothnis, J.R.; Ravikumar, G.; Naik, N.K. Ballistic Impact Behavior of Hybrid Composites. Mater. Des. 2013, 44, 128–135. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, L.; Ying, Z.; Ke, J.; Hu, X. Low-Velocity Impact Performance of Hybrid 3D Carbon/Glass Woven Orthogonal Composite: Experiment and Simulation. Compos. Part B Eng. 2020, 196, 108098. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, Z.; Bai, Y.; Fang, S.; Ma, D.; Zhang, C. Intralaminar Hybrid Configurations on the Impact Resistance of Carbon/Kevlar Plain-Woven Composite Plates. Thin-Walled Struct. 2025, 209, 112895. [Google Scholar] [CrossRef]

- Hazell, P.J.; Appleby-Thomas, G. A Study on the Energy Dissipation of Several Different CFRP-Based Targets Completely Penetrated by a High Velocity Projectile. Compos. Struct. 2009, 91, 103–109. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Liu, Z.; Ren, Y.; Jiang, H. Hybrid Effects and Failure Mechanisms of Carbon/Kevlar Fiber Composite Laminates under the Bending-after-Impact Loading. Eng. Struct. 2024, 299, 117101. [Google Scholar] [CrossRef]

- Swolfs, Y.; Meerten, Y.; Hine, P.; Ward, I.; Verpoest, I.; Gorbatikh, L. Introducing Ductility in Hybrid Carbon Fibre/Self-Reinforced Composites through Control of the Damage Mechanisms. Compos. Struct. 2015, 131, 259–265. [Google Scholar] [CrossRef]

- Larsson, F.; Svensson, L. Carbon, Polyethylene and PBO Hybrid Fibre Composites for Structural Lightweight Armour. Compos. Part A Appl. Sci. Manuf. 2002, 33, 221–231. [Google Scholar] [CrossRef]

- Lu, S.; Liang, G.; Zhou, Z.; Li, F. Structure and Properties of UHMWPE Fiber/Carbon Fiber Hybrid Composites. J. Appl. Polym. Sci. 2006, 101, 1880–1884. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, M.; Tan, H.X.; Ridha, M.; Tay, T.E. Hybrid Woven Carbon-Dyneema Composites under Drop-Weight and Steel Ball Impact. Compos. Struct. 2020, 236, 111811. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, Y.; Liu, D.; Guo, J.; Zhang, J.; Chen, Z. Damage Tolerance of 2-Dimentional UHMWPE/CF Hybrid Woven Laminates Subjected to Low-Velocity Impact. Mater. Des. 2020, 191, 108604. [Google Scholar] [CrossRef]

- Xue, Y.; Li, Z.; Luo, J.; Yang, X.; Yang, Z.; Shi, Y.; Liu, Y.; Ma, Y.; Zhang, H.; Yu, J. Simultaneous Toughening and Strengthening of CF/EP Composites through Bi-Component Thermoplastics with Hybrid Phases between Composite Layers. Compos. Part B Eng. 2024, 274, 111286. [Google Scholar] [CrossRef]

- Karakaya, N.; Papila, M.; Özkoç, G. Overmolded Hybrid Composites of Polyamide-6 on Continuous Carbon and Glass Fiber/Epoxy Composites: ‘An Assessment of the Interface’. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105771. [Google Scholar] [CrossRef]

- Proietti, A.; Quadrini, F.; Gallo, N.; Santo, L. Thermo-Formable Hybrid Carbon Fibre Laminates by Composite Recycling. Int. J. Adv. Manuf. Technol. 2023, 127, 2989–3001. [Google Scholar] [CrossRef]

- Proietti, A.; Quadrini, F.; Santo, L. Repairing of Recycled Hybrid Carbon Fiber Laminates. Polym. Compos. 2024, 45, 16752–16763. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, N.; Dong, X.; Gao, J. Flexible Carboxylated CNT/PA66 Nanofibrous Mat Interleaved Carbon Fiber/Epoxy Laminates with Improved Interlaminar Fracture Toughness and Flexural Properties. Ind. Eng. Chem. Res. 2020, 59, 1151–1158. [Google Scholar] [CrossRef]

- Wang, J.; Pozegic, T.R.; Xu, Z.; Nigmatullin, R.; Harniman, R.L.; Eichhorn, S.J. Cellulose Nanocrystal-Polyetherimide Hybrid Nanofibrous Interleaves for Enhanced Interlaminar Fracture Toughness of Carbon Fibre/Epoxy Composites. Compos. Sci. Technol. 2019, 182, 107744. [Google Scholar] [CrossRef]

- Korycki, A.; Carassus, F.; Tramis, O.; Garnier, C.; Djilali, T.; Chabert, F. Polyaryletherketone Based Blends: A Review. Polymers 2023, 15, 3943. [Google Scholar] [CrossRef]

- Yan, M.; Tian, X.; Yao, R. Processability and Reusability of CF/PEEK Mixture for Powder Bed Fusion of High Strength Composites. Compos. Commun. 2022, 35, 101318. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, X.; Li, D.; Du, J.; Wang, B.; Li, T. Mechanical Properties of Solution-Blended Graphene Nanoplatelets/Polyether-Ether-Ketone Nanocomposites. J. Phys. Chem. B 2021, 125, 10597–10609. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Varadarajan, K.M.; Koo, J.H.; Hart, A.J.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Rehman, M.M.; Shaker, K.; Nawab, Y. Influence of Polyether Ether Ketone Particles on Thermal Characteristics of Carbon/Epoxy Composite. J. Therm. Anal. Calorim. 2023, 148, 6003–6011. [Google Scholar] [CrossRef]

- Quan, D.; Wang, G.; Zhao, G.; Alderliesten, R. On the Interlayer Toughening of Carbon Fibre/Epoxy Composites Using Surface-Activated Ultra-Thin PEEK Films. Compos. Struct. 2023, 303, 116309. [Google Scholar] [CrossRef]

- Quan, D.; Ma, Y.; Yue, D.; Liu, J.; Xing, J.; Zhang, M.; Alderliesten, R.; Zhao, G. On the application of strong thermoplastic–thermoset interactions for developing advanced aerospace-composite joints. Thin-Walled Struct. 2023, 186, 110671. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kumar, S.; Li, X.; Kim, S.Y.; Shin, D.H. Temperature-dependent mechanical properties and material modifications of carbon fiber composites for optimized structures in high-end industrial applications. Compos. Part B Eng. 2025, 303, 112602. [Google Scholar] [CrossRef]

- Proietti, A.; Gallo, N.; Bellisario, D.; Quadrini, F.; Santo, L. Damping Behavior of Hybrid Composite Structures by Aeronautical Technologies. Appl. Sci. 2022, 12, 7932. [Google Scholar] [CrossRef]

- Quadrini, F.; Proietti, A.; Santo, L. Manufacturing of thermoformable hybrid carbon fiber laminates. J. Thermoplast. Compos. Mater. 2025, 08927057251344263. [Google Scholar] [CrossRef]

| Specimens | Stiffness [N/mm] | Load Max [N] | Stress Max [MPa] | Elastic Modulus [GPa] |

|---|---|---|---|---|

| High-thickness interlayer | 190 | 348 | 340 | 50 |

| Low-thickness interlayer | 110 | 135 | 140 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Proietti, A.; Noqra, D.; Quadrini, F.; Santo, L. Review and Experimental Update on Manufacturing of Hybrid Carbon Fiber Composites for Space Use. Appl. Sci. 2025, 15, 9863. https://doi.org/10.3390/app15189863

Proietti A, Noqra D, Quadrini F, Santo L. Review and Experimental Update on Manufacturing of Hybrid Carbon Fiber Composites for Space Use. Applied Sciences. 2025; 15(18):9863. https://doi.org/10.3390/app15189863

Chicago/Turabian StyleProietti, Alice, Dounia Noqra, Fabrizio Quadrini, and Loredana Santo. 2025. "Review and Experimental Update on Manufacturing of Hybrid Carbon Fiber Composites for Space Use" Applied Sciences 15, no. 18: 9863. https://doi.org/10.3390/app15189863

APA StyleProietti, A., Noqra, D., Quadrini, F., & Santo, L. (2025). Review and Experimental Update on Manufacturing of Hybrid Carbon Fiber Composites for Space Use. Applied Sciences, 15(18), 9863. https://doi.org/10.3390/app15189863