Influence of the Process-Related Surface Structure of L-PBF Manufactured Components on Residual Stress Measurement Using the Incremental Hole Drilling Method

Abstract

1. Introduction

- -

- Type I (macro residual stresses):Macroscopic stresses that can lead to distortion.

- -

- Type II (micro residual stresses):Stresses between microstructural areas, e.g., grains.

- -

- Type III (micro residual stresses):Local stresses within the crystal structure.

2. Materials and Methods

2.1. Material and Sample Production

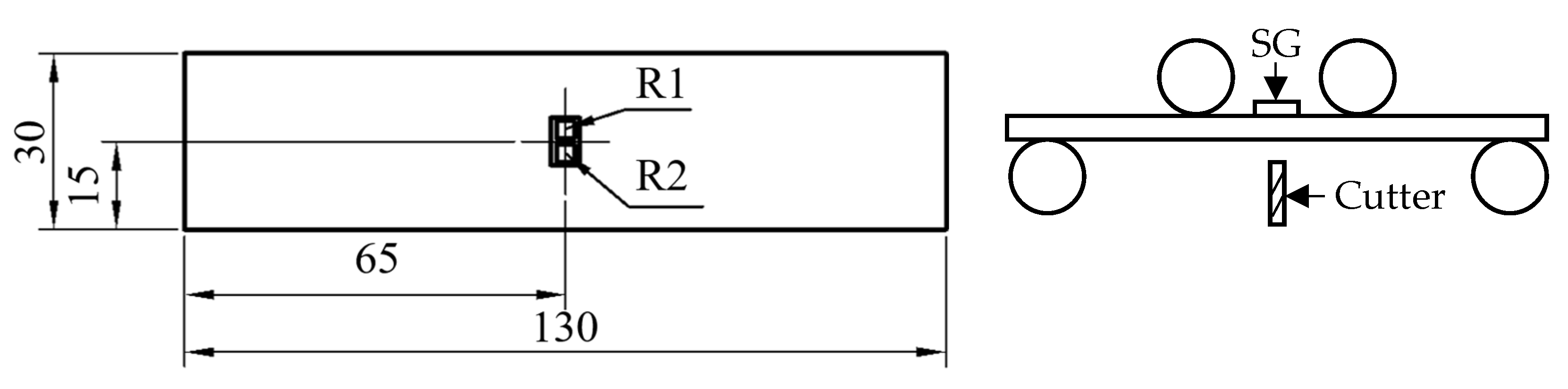

2.2. Sample Preparation

- -

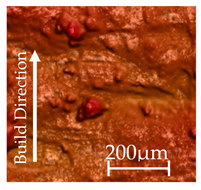

- Side-skin surface:Coarse, sand casting-like structure with fused metal particles and metallic rough sheen.

- -

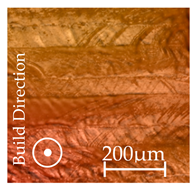

- Up-skin surface:Fine line structure whose line width roughly corresponds to the scan width of the manufacturing process, with a metallic sheen.

- -

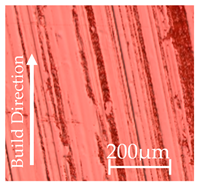

- CNC-milled reference surface:Smooth, even surface with a clear, shiny metallic appearance.

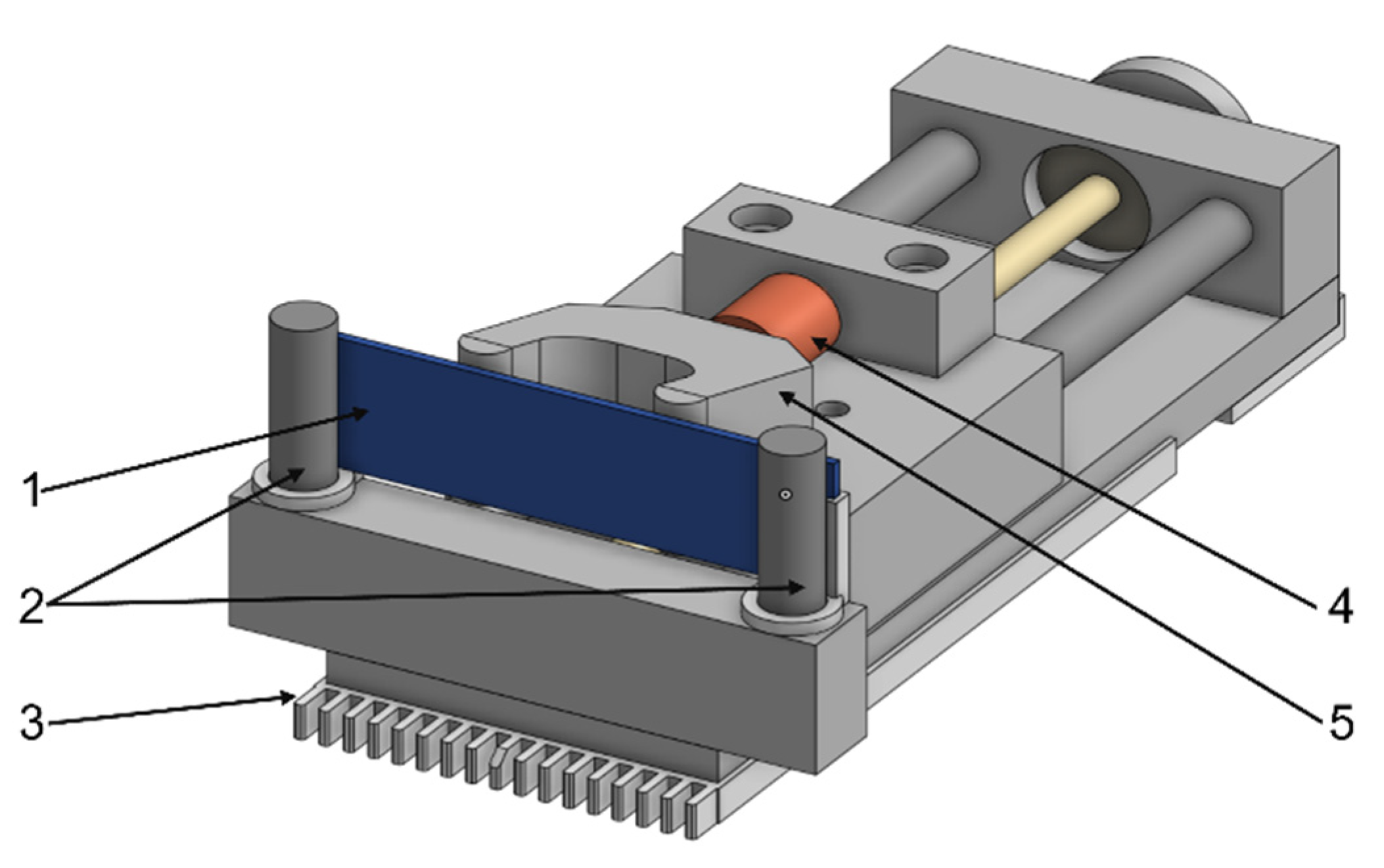

2.3. Test Setup and Verification

- -

- Test samples (position 1): Central element of the load test.

- -

- Counter bearing (position 2): Fixes and supports the sample.

- -

- Grid system (position 3): Manual grid with a horizontal step width of 2.5 mm and height adjustment in 2.5 mm steps to ensure a close-meshed measuring point grid system with a maximum deviation of 0.1 mm.

- -

- Force measuring sensor (position 4): Type ME-Systems KM16z 2 kN (ME-Systeme GmbH, Hennigsdorf, Germany), for real-time monitoring of the applied forces.

- -

- Load fork (position 5): Manual adjustment to avoid control errors due to servo or stepper motors.

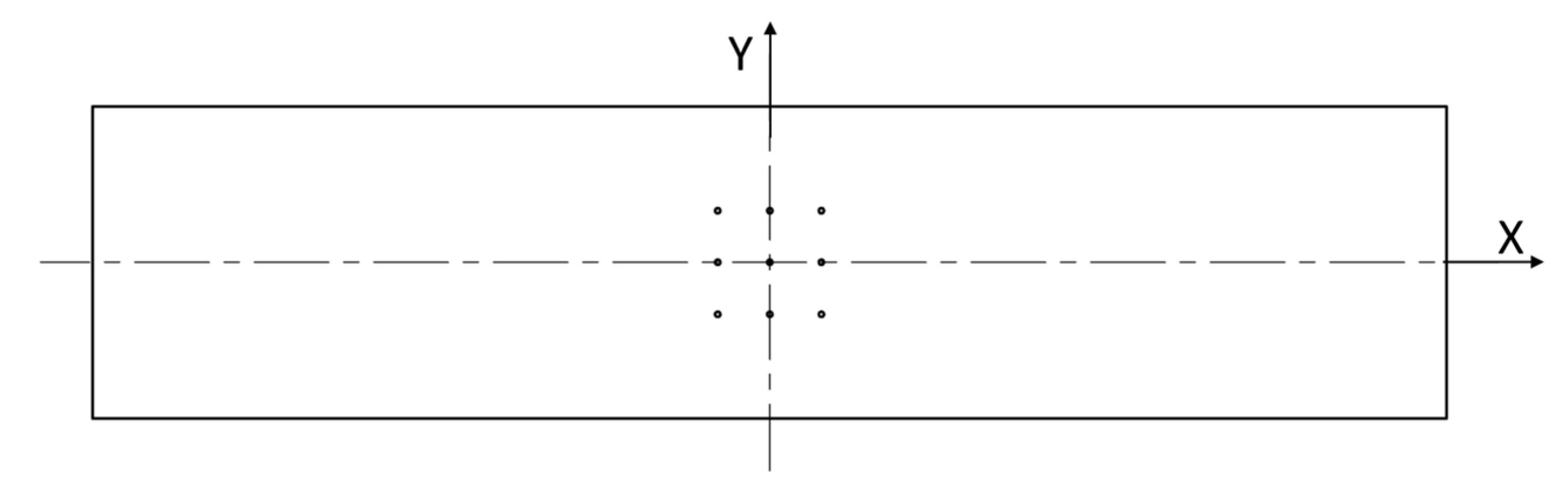

2.4. Test Procedure

- -

- 10MPa: This preload was used to fix the sample and to check that the residual stresses caused by the manufacturing process were significantly reduced by the heat treatment.

- -

- 70MPa: This value represents typical residual stresses that occur in L-PBF-manufactured components of AlSi10Mg [35].

- -

- 140MPa: Chosen to assess the IHD–ESPI method near its upper recommended range (see Section 2.1 for yield strength and guideline limit).

3. Results

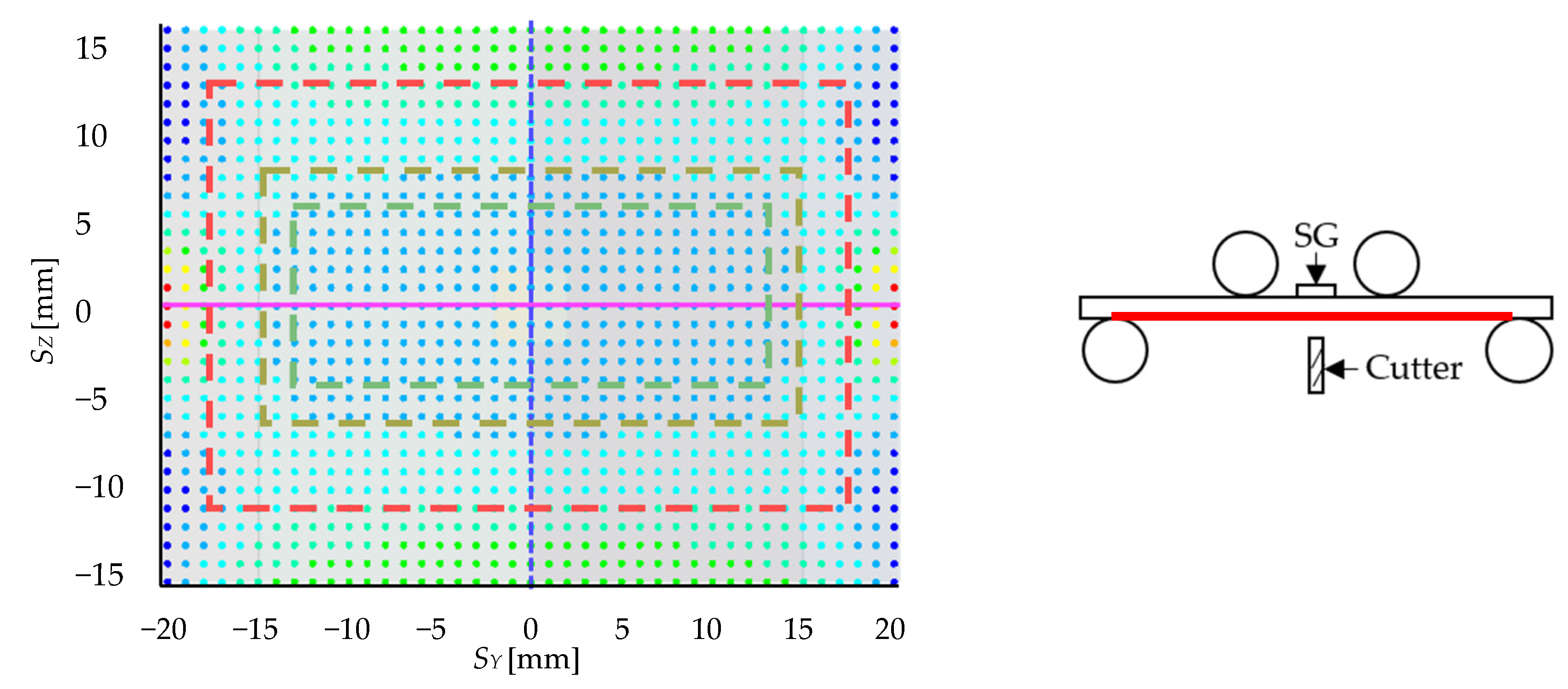

3.1. Numerical Results

- -

- Inside green border: 1% deviation

- -

- Inside yellow border: 2% deviation

- -

- Inside red border: 5% deviation

3.2. Experimental Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AlSi10Mg | Aluminum-Silicon-Magnesium Alloy |

| ASTM | American Society for Testing and Materials |

| CCD | Charge-Coupled Device |

| CNC | Computerized Numerical Control |

| DIC | Digital Image Correlation |

| DIN | Deutsches Institut für Normung (German Institute for Standardization) |

| EN | European Standard |

| ESPI | Electronic Speckle Pattern Interferometry |

| FE | Finite Element |

| HL | High Laser (Machine-Specific Designation, e.g., SLM 280 HL) |

| IHD | Incremental Hole Drilling |

| L-PBF | Laser Powder Bed Fusion |

| MPa | Megapascal |

| NPL | National Physical Laboratory (United Kingdom) |

| Ra/Rz | Roughness Average/Maximum Height of the Roughness Profile |

| SNR | Signal-to-Noise Ratio |

| XRD | X-ray Diffraction |

References

- Elkaseer, A.; Charles, A.; Schneider, S.; Scholz, S.G. Part tailoring in metal-additive manufacturing: A step towards functionally graded customized stainless-steel components using laser powder bed fusion. Appl. Sci. 2022, 12, 6193. [Google Scholar] [CrossRef]

- Staub, A.; Scherer, M.; Zehnder, P.; Spierings, A.B.; Wegener, K. Residual Stresses Measurements in Laser Powder Bed Fusion Using Barkhausen Noise Analysis. Materials 2022, 15, 2676. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Fritsch, T.; Mishurova, T.; Trofimov, A.; Apel, D.; Ulbricht, A.; Kromm, A.; Hesse, R.; Evans, A.; Bruno, G. On the interplay of microstructure and residual stress in LPBF IN718. J. Mater. Sci. 2021, 56, 5845–5867. [Google Scholar] [CrossRef]

- Nielsen, M.A. Analyse von Mikrostruktur und Eigenspannungszuständen in mit Selektivem Laserstrahlschmelzen Gefertigten Materialien Mittels Hochenergetischer Röntgenstrahlung. Ph.D. Thesis, Christian-Albrechts-Universität zu Kiel, Kiel, Germany, 2023. [Google Scholar]

- Kremer, R. Experimentelle und simulative Untersuchung der Kristallstruktur und Eigenspannungen an Selektiv Lasergeschmolzenen Bauteilen aus CuSn10. Master’s Thesis, Fachhochschule Dortmund, Dortmund, Germany, 2022. [Google Scholar]

- Töppel, T.; Müller, B.; Hoeren, K.P.; Witt, G. Eigenspannungen und Verzug bei der additiven Fertigung durch Laserstrahlschmelzen. Schweißen Und Schneid. 2016, 4, 176–187. [Google Scholar]

- Kaess, M.; Werz, M.; Weihe, S. Residual Stress Formation Mechanisms in Laser Powder Bed Fusion—A Numerical Evaluation. Materials 2023, 16, 2321. [Google Scholar] [CrossRef] [PubMed]

- Sobolevski, E.G.; Scholtes, B. Residual Stress Analysis of Components with Real Geometries Using the Incremental Hole-Drilling Technique and a Differential Evaluation Method; Kassel University Press GmbH: Kassel, Germany, 2007; pp. 14–39. ISBN 978-3-89958-343-4. [Google Scholar]

- Macherauch, E.; Kloos, K.H. Origin, Measurement and Evaluation of Residual Stresses. In Residual Stresses in Science and Technology; DGM-Informationsgesellschaft: Oberursel, Germany, 1987; pp. 3–26. [Google Scholar]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual Stress Part 1-Measurement Techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Clyne, T.W.; Gill, S.C. Residual stresses in thermal spray coatings and their effect on interfacial adhesion: A review of recent work. J. Therm. Spray Technol. 1996, 5, 401–418. [Google Scholar] [CrossRef]

- Molina-Ballinas, A.; Urriolagoitia-Sosa, G.; Urriolagoitia-Calderón, G.; Hernández-Gómez, L.H.; Verduzco-Cedeño, V.F.; Torres-Franco, D.; Torres-San Miguel, C.R.; Romero-Ángeles, B. Determination of Residual Stresses Originated in a Die Process Using the Crack Compliance Method. In Proceedings of the World Congress on Engineering 2011, London, UK, 6–8 July 2011; Volume III, pp. 1–5, ISSN 2078-0966. [Google Scholar]

- Urriolagoitia-Sosa, G.; Urriolagoitia-Calderon, G.; Romero-Ángeles, B.; Torres-Franco, D.; Hernández-Gómez, L.H.; Molina-Ballinas, A.; Torres-San Miguel, C.R.; Campos-López, J.P. Using fracture mechanics for determining residual stress fields in diverse geometries. Ing. Investig. 2012, 32, 19–26. [Google Scholar] [CrossRef]

- Valentini, E.; Bertelli, L.; Benincasa, A. Improvements in the hole-drilling test method for determining residual stresses in polymeric materials. Mater. Perform. Charact. 2018, 7, 446–464. [Google Scholar] [CrossRef]

- ASTM International. E837–20 Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Schajer, G.S.; Whitehead, P.S. Measurement Good Practice Guide No. 53-Issue 2: The Measurement of Residual Stresses by Incremental Hole Drilling Technique; Vishay Precision Group: Malvern, PA, USA, 2009; pp. 47–68. [Google Scholar]

- Kim, J.H.; Baek, C.H.; Lee, S.K.; Kang, J.H.; Park, J.H.; Ko, D.C. Effect of a multiple reduction die on the residual stress of drawn wires. Materials 2021, 14, 1358. [Google Scholar] [CrossRef]

- Rahimi, S.; Violatos, I. Comparison Between Surface and Near-Surface Residual Stress Measurement Techniques Using a Standard Four-Point-Bend Specimen. Exp. Mech. 2022, 62, 223–236. [Google Scholar] [CrossRef]

- Kaufmann, G.H.; Albertazzi, A., Jr. Speckle interferometry for the measurement of residual stresses. In New Direction in Holography and Speckle; Caulfield, H.J., Vikram, C.S., Eds.; American Scientific Publishers: Valencia, CA, USA, 2008; pp. 1–22. [Google Scholar]

- Schajer, G.S.; Steinzig, M. Full-field calculation of hole drilling residual stresses from electronic speckle pattern interferometry data. Exp. Mech. 2005, 45, 526–532. [Google Scholar] [CrossRef]

- Prabhathan, P.; Song, C.; Haridas, A.; Prasad, G.; Chan, K.; Murukeshan, V.M. Experimental investigations and parametric studies of surface roughness measurements using spectrally correlated speckle images. In Proceedings of SPIE-Fifth International Conference on Optical and Photonics Engineering, Singapore, 4–7 April 2017; Volume 10449, p. 1044913. [Google Scholar] [CrossRef]

- Nicklawy, M.; Hassan, A.F.; Bahrawi, M.; Farid, N.; Sanjid, A.M. Characterizing surface roughness by speckle pattern analysis. J. Sci. Ind. Res. 2009, 68, 118–121. [Google Scholar]

- Lim, C.H. Novel heat treatment methodology for residual stress relieve of AlSi10Mg without compromise of mechanical strength. Mater. Perform. Charact. 2022, 70, 45–49. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia Cirp 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Cao, Q.; Bai, Y.; Zheng, Z.; Zhang, J.; Fuh, J.Y.H.; Wang, H. Support Removal on Thin-Walled Parts Produced by Laser Powder Bed Fusion. 3D Print. Addit. Manuf. 2023, 10, 762–775. Available online: https://pmc.ncbi.nlm.nih.gov/articles/PMC10440680/ (accessed on 10 August 2025). [CrossRef]

- DIN EN 1706:2020-12; Aluminium and Aluminium Alloys—Castings—Chemical Composition and Mechanical Properties. Beuth: Berlin, Germany, 2020.

- ASTM F3318-18; Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion. ASTM International: West Conshohocken, PA, USA, 2018.

- SLM Solutions Group AG. Material Data Sheet-AlSi10Mg (Version 2024-04.1). Available online: https://nikon-slm-solutions.com/wp-content/uploads/2025/02/mds5123.pdf (accessed on 17 April 2025).

- Meyer, P.; Risse, J.; Tjiong, M.; Wieder, P.; Becker, N.; Müssigbrodt, L. Test Methods for the Mechanical Characterization of Variable Cross-Section Flexure Hinges. Exp. Mech. 2023, 64, 753–766. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019.

- Görres, F.; Widuch, A.; Löwisch, G.; Brenner, S.; Nedeljkovic-Groha, V. Wärmebehandlung additiv gefertigter Teile aus Al-Si10Mg. In Proceedings of the 4th Meeting of the Working Group on Additively Manufactured Components and Structures, Berlin, Germany, 6–7 November 2019; pp. 1–6, DVM—Deutscher Verband für Materialforschung und-prüfung e.V.. ISSN 2509-8772. [Google Scholar]

- Lim, C.H.; Li, H.; Krishnan, M.; Chen, K.; Li, J. Investigation of the transition heat treatment temperature of AlSi10Mg manufactured by selective laser melting and the effect on the compressive strength. Mater. Today Proc. 2022, 70, 45–49. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 2230 Part 1: Systematic Calculation of High Duty Bolted Joints—Joints with One Cylindrical Bolt; VDI: Düsseldorf, Germany, 2015. [Google Scholar]

- Bobzin, K.; Wietheger, W.; Knoch, M.A.; Schacht, A.; Reisgen, U.; Sharma, R.; Oster, L. Comparison of Residual Stress Measurements Conducted by X-ray Stress Analysis and Incremental Hole Drilling Method. J. Therm. Spray Technol. 2020, 29, 1218–1228. [Google Scholar] [CrossRef]

- Gersch, S.; Schulz, C.; Bagdahn, J. Impact of Hatching Strategy on Mechanical Properties and Residual Stresses in Additively Manufactured AlSi10Mg Components. In TMS 2025 154th Annual Meeting & Exhibition Supplemental Proceedings, ser. The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Hack, T. Residual stress measurement by ESPI hole drilling and XRD. In Proceedings of the 13th International Conference on Shot Peening, Montreal, QC, Canada, 18–21 September 2017; pp. 181–186. Available online: https://www.shotpeener.com/library/pdf/2017044.pdf (accessed on 10 August 2025).

- Pruss, L.S. Field Guide to Displacement Measuring Interferometry; SPIE Press: Bellingham, WA, USA, 2012; Available online: https://www.spiedigitallibrary.org/ebooks/FG/Field-Guide-to-Displacement-Measuring-Interferometry/eISBN-9780819498007/10.1117/3.1002328 (accessed on 10 August 2025).

- Pooser, R.C.; Lawrie, B.J. Ultrasensitive Measurement of Microcantilever Displacement Below the Shot-Noise Limit. Science.gov. 2015. Available online: https://www.science.gov/topicpages/s/sensitive+displacement+measurement (accessed on 10 August 2025).

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C. Remarks on Residual Stress Measurement by Hole-Drilling and Electronic Speckle Pattern Interferometry. Sci. World J. 2014, 2014, 487149. [Google Scholar] [CrossRef]

- Martinez-Celorio, R.A.; Kaufmann, G.H.; Kujawinska, M. Out-of-plane displacement measurement by electronic speckle pattern interferometry in presence of large in-plane displacement. Opt. Commun. 2002, 208, 17–24. [Google Scholar] [CrossRef]

- Marola, S.; Bosia, S.; Veltro, A.; Fiore, G.; Manfredi, D.; Lombardi, M.; Amato, G.; Baricco, M.; Battezzati, L. Residual stresses in additively manufactured AlSi10Mg. Mater. Des. 2021, 202, 109550. Available online: https://www.sciencedirect.com/science/article/pii/S0264127521001039 (accessed on 10 August 2025). [CrossRef]

- Grant, P.V.; Lord, J.D.; Whitehead, P.S. The Measurement of Residual Stresses by the Incremental Hole Drilling Technique; National Physical Laboratory: Teddington, UK, 2006; pp. 21–22. [Google Scholar]

| Side-Skin Surface | Up-Skin Surface | CNC-Milled Surface |

|---|---|---|

|  |  |

| Roughness Ra/Rz Horizontal [µm] | ||

| 9.15/51.02 | 8.79/34.10 | 1.02/9.32 |

| Roughness Ra/Rz Vertical [µm] | ||

| 7.58/50.19 | 15.51/58.4 | 0.71/6.72 |

| Surface | Measured Stress σy Strain Gauges | Deviation FE-Value [%] Between σy Strain Gauges and σy Numerical |

|---|---|---|

| Side-skin | 145.5 MPa | 0.14 |

| Up-skin | 146.2 MPa | 0.62 |

| CNC-milled | 144.6 MPa | 0.48 |

| Applied Bending Stress | X_n [mm] | Y_1_2_3 [mm] |

|---|---|---|

| 10 MPa_1/_2/_3 | −5 | 5/0/−5 |

| 70 MPa_1/_2/_3 | 0 | 5/0/−5 |

| 140 MPa_1/_2/_3 | 5 | 5/0/−5 |

| Surface Condition | Applied Bending Stress [MPa] σy Strain Gauges | Stress Measured by Stresstech IHD ESPI Method [MPa] | Deviation (%) |

|---|---|---|---|

| Side-skin | 10 | 8.16 | 18.4 |

| 70 | 65.77 | 6.04 | |

| 140 | 120.00 | 14.29 | |

| Up-skin | 10 | 7.64 | 23.6 |

| 70 | 67.10 | 4.14 | |

| 140 | 110.47 | 21.09 | |

| CNC-Milled | 10 | 9.86 | 1.40 |

| 70 | 65.63 | 6.24 | |

| 140 | 121.67 | 13.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gersch, S.; Noster, U.; Schulz, C.; Bagdahn, J. Influence of the Process-Related Surface Structure of L-PBF Manufactured Components on Residual Stress Measurement Using the Incremental Hole Drilling Method. Appl. Sci. 2025, 15, 9861. https://doi.org/10.3390/app15189861

Gersch S, Noster U, Schulz C, Bagdahn J. Influence of the Process-Related Surface Structure of L-PBF Manufactured Components on Residual Stress Measurement Using the Incremental Hole Drilling Method. Applied Sciences. 2025; 15(18):9861. https://doi.org/10.3390/app15189861

Chicago/Turabian StyleGersch, Sebastian, Ulf Noster, Carsten Schulz, and Jörg Bagdahn. 2025. "Influence of the Process-Related Surface Structure of L-PBF Manufactured Components on Residual Stress Measurement Using the Incremental Hole Drilling Method" Applied Sciences 15, no. 18: 9861. https://doi.org/10.3390/app15189861

APA StyleGersch, S., Noster, U., Schulz, C., & Bagdahn, J. (2025). Influence of the Process-Related Surface Structure of L-PBF Manufactured Components on Residual Stress Measurement Using the Incremental Hole Drilling Method. Applied Sciences, 15(18), 9861. https://doi.org/10.3390/app15189861