Mission Schedule Control for an Aviation Cluster Based on the Critical Path Transition Tree

Abstract

1. Introduction

- Mission constraints: Critical task nodes must be executed on time, which is the core objective of the mission.

- Sequential constraints: These manifest as sequential logical dependencies between the initiation and completion of subtasks. Due to airport runway capacity management, a subsequent UAV can only begin to taxi after the preceding one has taken off. The strike mission can only be executed after the reconnaissance UAV has completed its survey and the strike UAV has arrived at its designated strike position.

- Resource constraints: Each UAV has a limited amount of fuel to complete its respective subtasks. The duration of a UAV’s subtask is related to its flight speed; higher speeds result in greater fuel consumption.

- Flight performance constraints: The real-time flight speed of a UAV must comply with its flight performance capabilities, with an upper limit on flight speed.

- The task controllability constraint: Due to the specific circumstances of each task, it is not necessarily possible to compress the planned duration of all tasks. Additionally, whether a task is controllable depends on its current state.Tasks that are already completed are obviously uncontrollable. For tasks that are currently in progress, since their execution requires certain resources and once a task starts, it means those resources may have already been put into use, we no longer make ad hoc adjustments to tasks that are in progress. This approach also serves to reduce the cognitive load on the executor. Only tasks that have not yet started at the current time are controllable.

- 1.

- We established a real-time control system for aviation cluster mission plans operating under practical resource constraints, with the objective of ensuring the on-time execution of critical task nodes.

- 2.

- We propose a precise control method based on a Critical Path Transform Tree. This method solves the difficult reverse mapping problem for dynamically changing network plan recursion formulas. We have validated this approach through simulations, demonstrating its ability to achieve precise control.

2. Model

2.1. Problem Description

- 1.

- On-time Execution of Critical Nodes: The primary and most critical objective of the control system is to ensure that critical task nodes are executed punctually.

- 2.

- Sequential Constraints: Precedence constraints exist among the various subtasks of different UAVs. This creates interdependencies where the start time of one subtask is dependent on the completion time of others.

- 3.

- Disturbance Management: The plan is subject to disturbances during execution, which can cause delays and jeopardize the on-time start of critical nodes. This necessitates a control mechanism for the schedule, but one that avoids frequent or excessive plan revisions (i.e., schedule instability).

- 4.

- Fuel Sufficiency: Each UAV must have enough fuel to complete all of its assigned tasks.

- 5.

- Time-Resource Trade-off: The duration of a UAV’s subtask is correlated with its flight speed; higher speeds reduce flight time but lead to greater fuel consumption.

- 6.

- Performance Limits: The real-time flight speed of each UAV must remain within its specified performance limits.

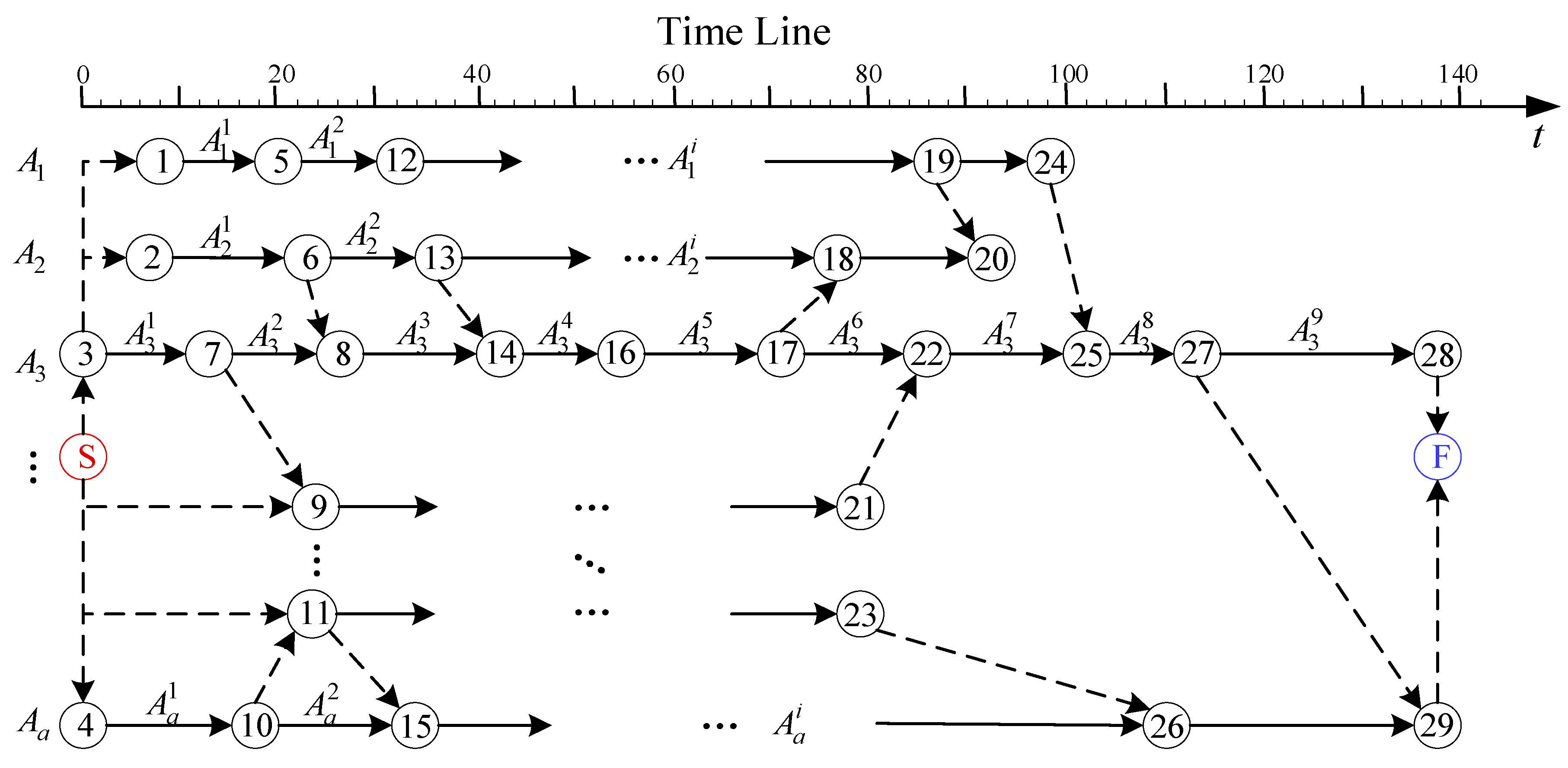

2.2. Control System Modeling

- 1.

- State Variable

- 2.

- Output Variable

- 3.

- Control Variable

- 4.

- System Equation

| Algorithm 1: Output equation of the control system |

| Input: State variable Mission vector Set of predecessor tasks and set of successor tasks Planned time of the critical task node |

| Output: Real-time deviation of critical task node |

| 1. Initialization: Create a directed task set , and a first-in-first-out queue ; 2. for in : 3. Obtain the number of elements in the set of predecessor tasks of the task ; 4. Add the task to , if 5. 6. end for 7. while : 8. Take out the first task in the queue and add to ; 9. for in : 10. ; 11. Add the task to , if 12. end for 13. end while 14. for in : 15. for in : 16. if : 17. 18. 19. return |

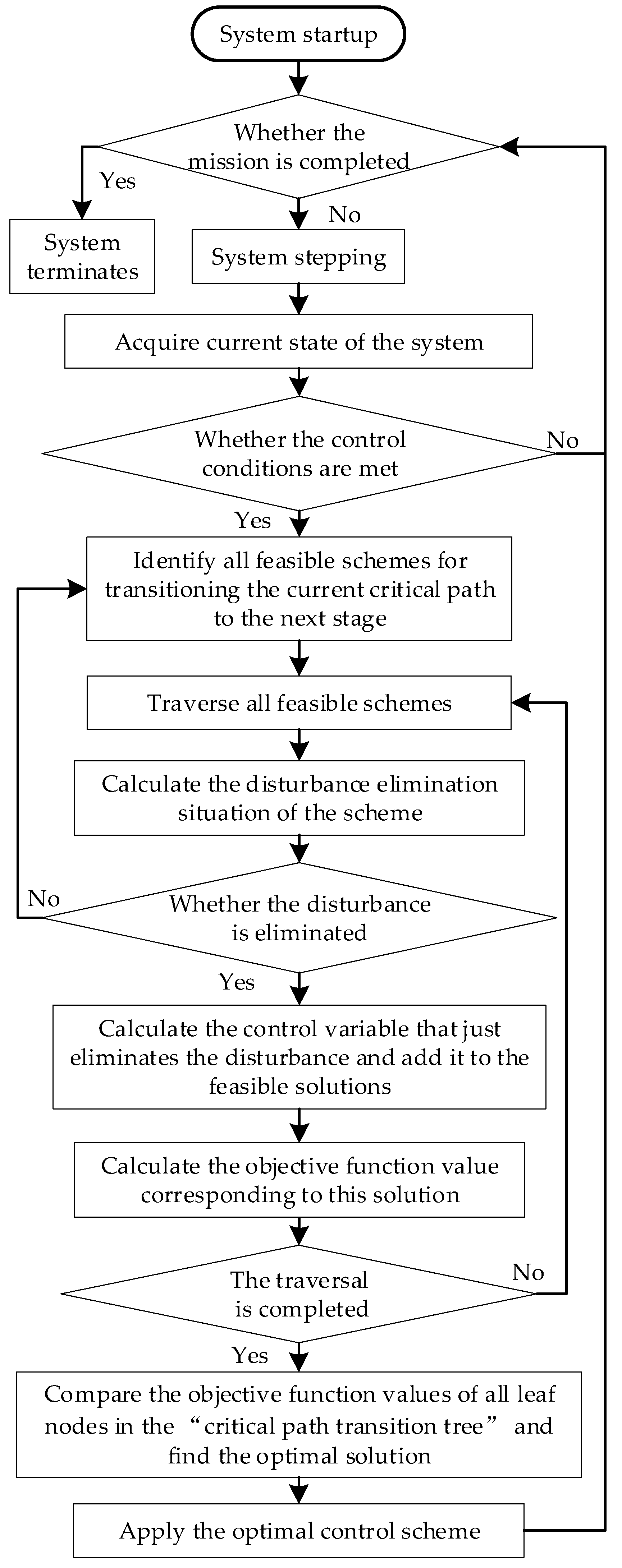

2.3. Control Policy Optimization

- 1.

- Control Objective

- 2.

- Control Constraints

- 3.

- Control Timing

- (1)

- There must be a non-zero disturbance in the system output; if the disturbance is zero, no control is necessary.

- (2)

- All tasks that have been delayed up to the current moment must have fully completed.

- (3)

- The current moment must be precisely when one of the delayed tasks has just finished.

- 4.

- Control Strategy

- (1)

- Effectiveness of Controllable Tasks

| Algorithm 2: Breadth-First Search algorithm for critical path identifying |

| Function: Breadth-First Search (task ) Input: Global start node S, ends at the global end node F The set of tasks with zero slack time Set of successor tasks |

| Output: Set of critical path |

| 1. Initialization: Create a critical path set and a critical path queue ; 2. Breadth-First Search (task S): 3. Add to critical path queue ; 4. if current task == F: 5. return ; 6. for : 7. if : 8. Breadth-First Search (task ); 9. Add to ; 10. return |

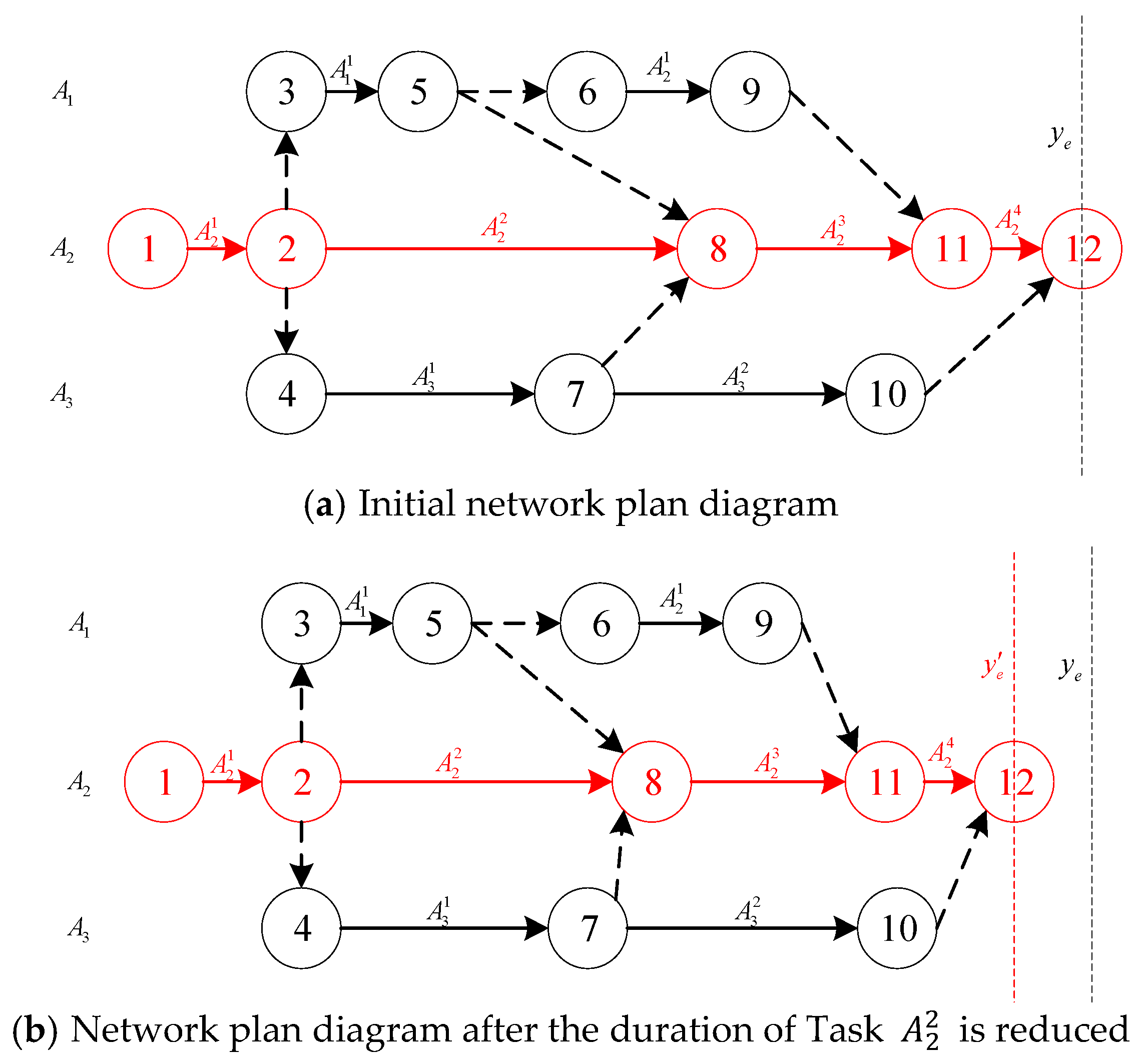

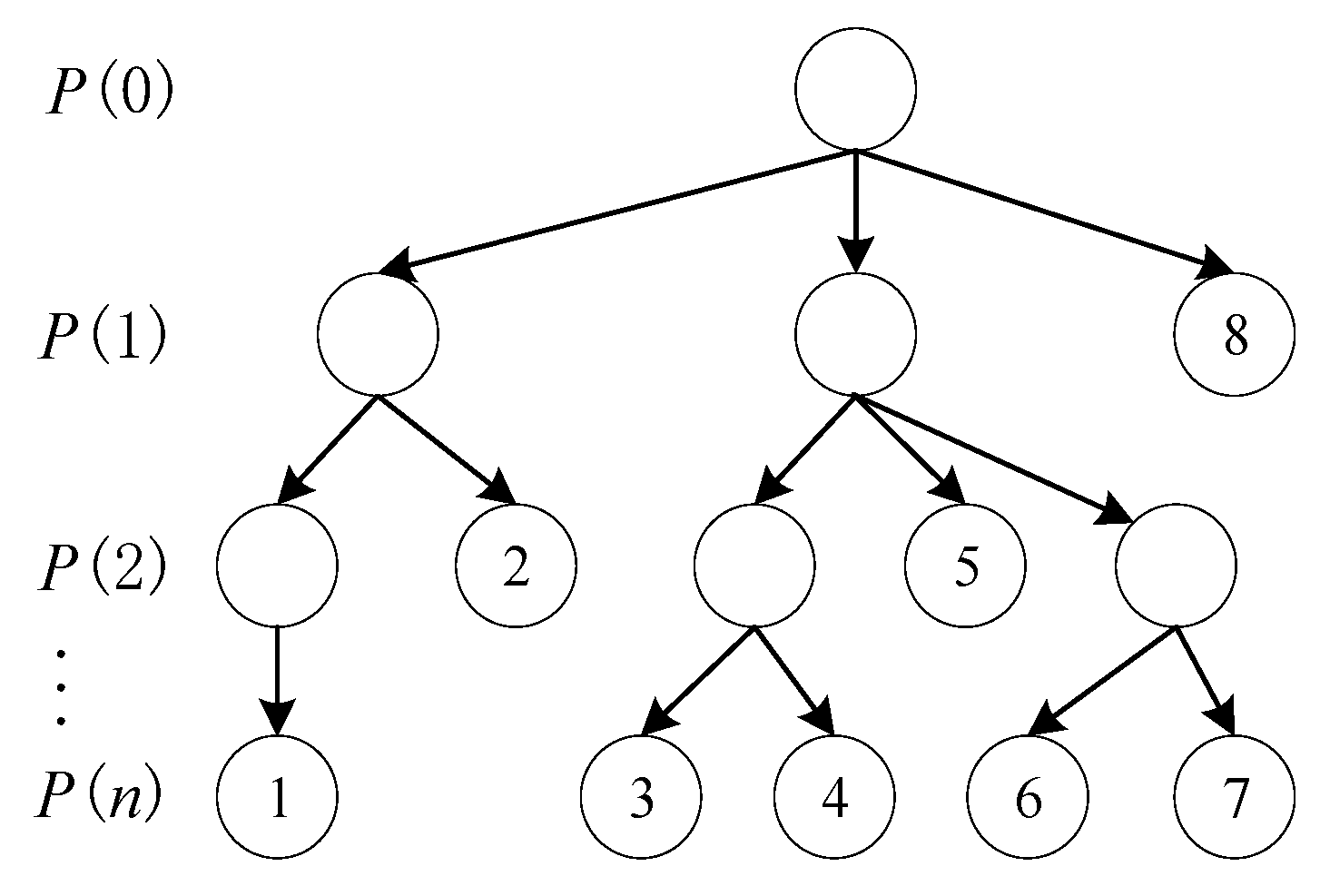

- (2)

- Critical Path Transition Tree

- 1.

- When the early start time of task is exactly equal to , task mn will just change the critical path;

- 2.

- When the early start time of task is less than , but the task itself changes the critical path;

- 3.

- When the early start time of task is greater than , since the critical path has already changed when the early start time equals , any further advancement will be meaningless. According to Theorem 1, this task will no longer be an effectively controllable task.

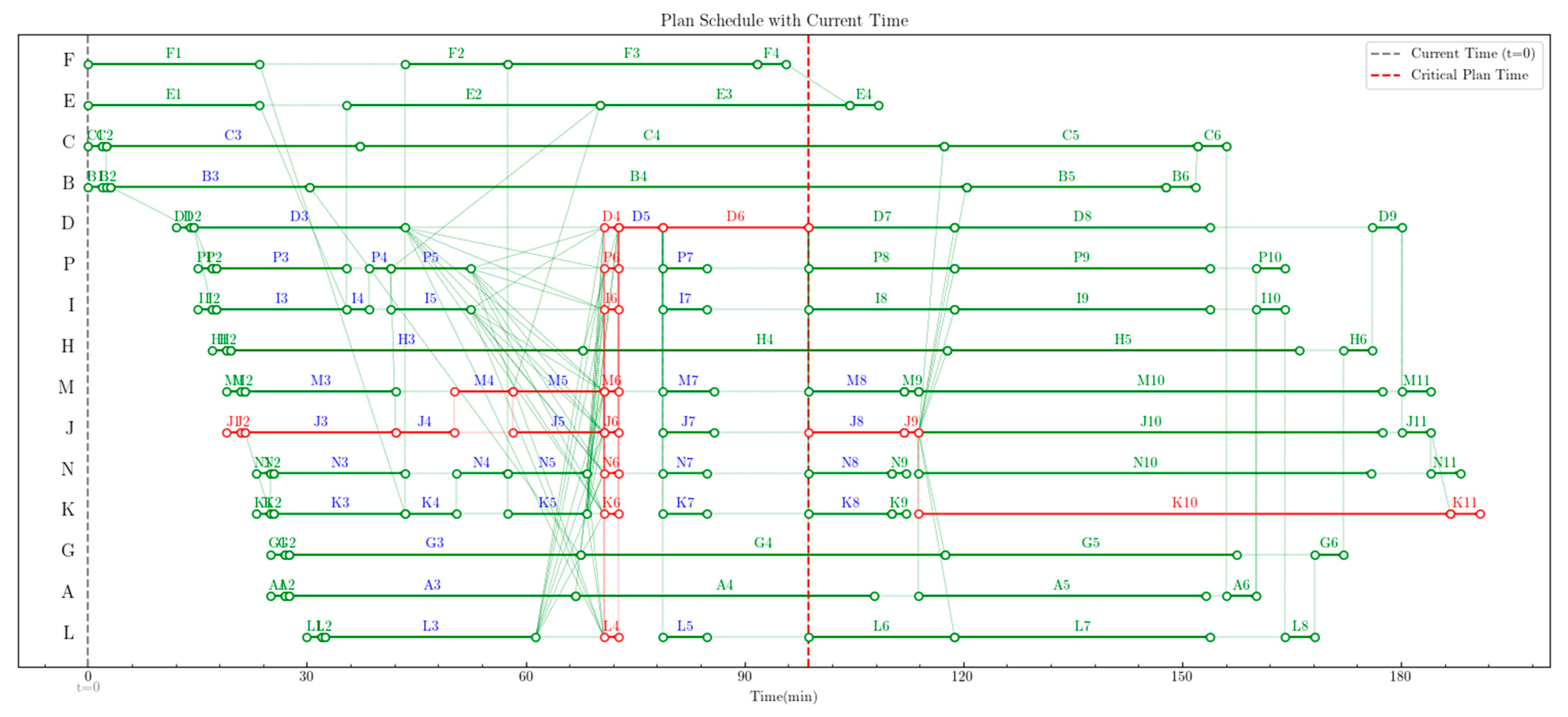

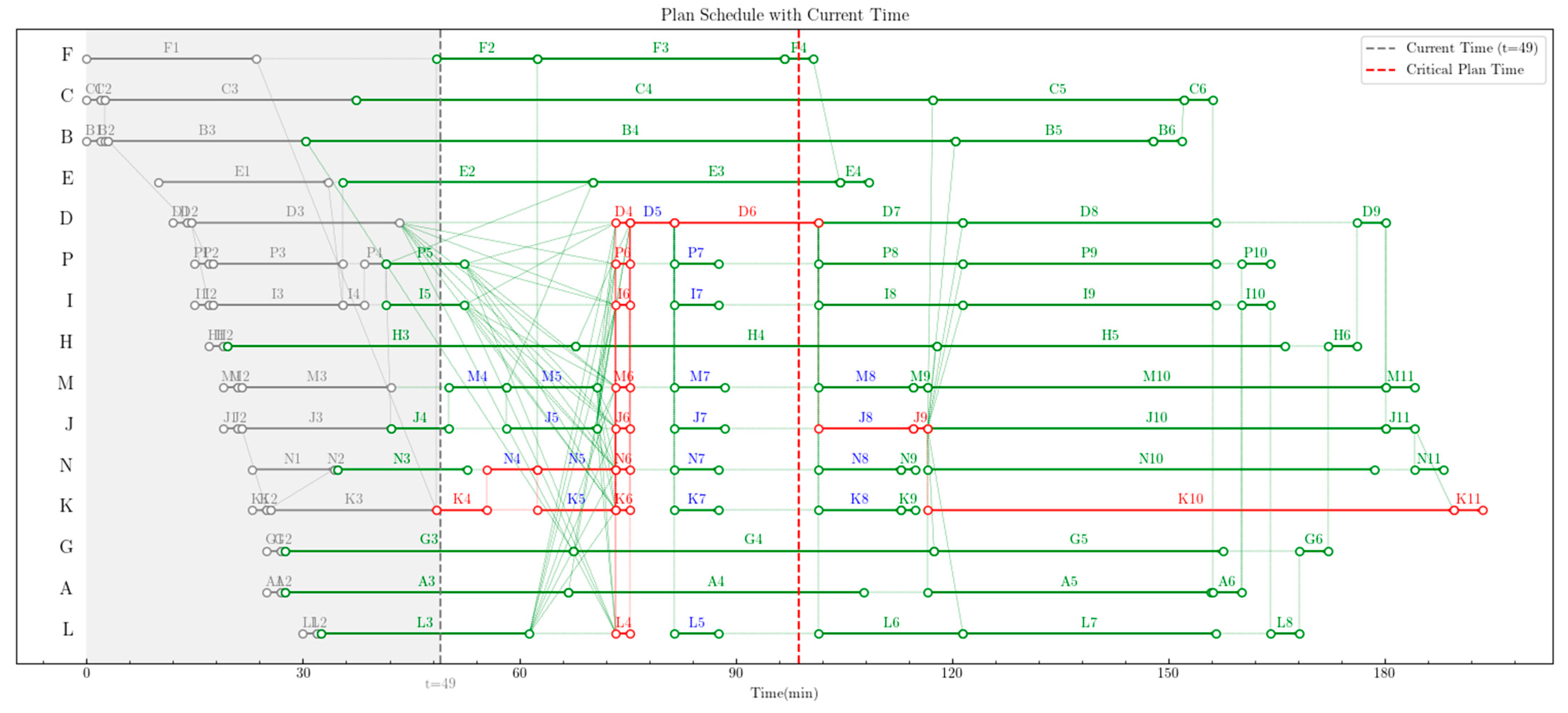

3. Results

- There is a disturbance at the current moment;

- All delayed tasks have been completed by the current moment;

- A delayed task is exactly completed at the current moment.

4. Conclusions

- (1)

- Overly strict control conditions. The control system established in this paper intervenes in control only when three conditions are simultaneously satisfied, and control can only be implemented when all currently delayed tasks are completed. When the task scale is larger (with hundreds of UAVs) and multiple disturbances occur simultaneously, it may become difficult for the system to meet the control timing requirements, resulting in delays in control intervention. Future research can draw on the EVM, set multiple checkpoints for key tasks, and establish a disturbance prediction model to achieve proactive prediction of potential disturbances. This would enable estimating the disturbance magnitude as soon as a disturbance emerges and conducting more timely control interventions.

- (2)

- Limited control measures. The control measure proposed in this paper focuses on regulating task durations (essentially, the amount of fuel refueled also controls the refueling duration). However, in practical applications, more diverse control measures may be adopted to further eliminate delay disturbances, such as simplifying task processes (by removing subtasks) and dynamically modifying the dependency relationships among subtasks. Therefore, future research can explore incorporating such more diverse control variables into the scheduling framework.

- (3)

- A single type of disturbance variable. This paper only considers time disturbances and does not account for disturbances in the number of UAVs (e.g., a UAV being forced to land due to a malfunction after takeoff). In practical missions, changes in the number of UAVs may lead to dynamic modifications of strike targets, the formulation of entirely new tasks, or even the cancellation of tasks. This requires constructing a UAV quantity-target mapping model, which falls within the scope of dynamic task planning.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Task Code | Planned Task Duration/min | Duration Variance | Predecessor Task | Planned Start Time/min | Planned Finish Time/min |

|---|---|---|---|---|---|

| A1 | 2.0 | 0.1 | START | 25.0 | 27.0 |

| A2 | 0.5 | 0.1 | A1 | 27.0 | 27.5 |

| A3 | 39.3 | 4.0 | A2 | 27.5 | 66.8 |

| A4 | 50.0 | 10.0 | A3 | 66.8 | 107.8 |

| A5 | 39.3 | 5.0 | A4/J9 | 113.9 | 153.2 |

| A6 | 4.0 | 0.10 | A5/C6 | 156.1 | 160.1 |

| B1 | 2.0 | 0.1 | START | 0 | 2.0 |

| B2 | 0.5 | 0.05 | B1/C2 | 2.5 | 3.0 |

| B3 | 27.4 | 3.0 | B2 | 3.0 | 30.4 |

| B4 | 90.0 | 10.0 | B3 | 30.4 | 120.4 |

| B5 | 27.4 | 5.0 | B4/J9 | 120.4 | 147.8 |

| B6 | 4.0 | 0.1 | B5 | 147.8 | 151.8 |

| C1 | 2.0 | 0.1 | START | 0 | 2.0 |

| C2 | 0.5 | 0.1 | C1 | 2.0 | 2.5 |

| C3 | 34.8 | 4.0 | C2 | 2.5 | 37.3 |

| C4 | 90.0 | 10.0 | C3 | 37.3 | 117.3 |

| C5 | 34.8 | 5.0 | C4/J9 | 117.3 | 152.1 |

| C6 | 4.0 | 0.1 | C5/B6 | 152.1 | 156.1 |

| D1 | 2.0 | 0.1 | START | 12.0 | 14.0 |

| D2 | 0.5 | 0.1 | D1/B2 | 14.0 | 14.5 |

| D3 | 28.9 | 6.0 | D2 | 14.5 | 43.4 |

| D4 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 70.7 | 72.7 |

| D5 | 6.1 | 0.1 | D4/I6/J6/K6/L4/A3/G3/H3 | 72.7 | 78.8 |

| D6 | 20.0 | 2.0 | D5 | 78.8 | 98.8 |

| D7 | 20.0 | 3.0 | D6 | 98.8 | 118.8 |

| D8 | 55.0 | 7.0 | D7/J9 | 118.8 | 153.8 |

| D9 | 4.0 | 0.1 | D8/H6 | 176.1 | 180.1 |

| E1 | 23.5 | 5.0 | START | 0 | 23.5 |

| E2 | 50.0 | 2.0 | E1/I3 | 35.5 | 70.2 |

| E3 | 34.2 | 5.0 | E2/I4/J4 | 70.2 | 104.4 |

| E4 | 4.0 | 0.1 | E3/F4 | 104.4 | 108.4 |

| F1 | 23.5 | 0 | START | 0 | 23.5 |

| F2 | 50.0 | 2.0 | F1/K3 | 43.5 | 57.5 |

| F3 | 34.2 | 2.0 | F2/K4 | 57.5 | 91.7 |

| F4 | 4.0 | 0.1 | F3 | 91.7 | 95.7 |

| G1 | 2.0 | 0.1 | START | 25.0 | 27.0 |

| G2 | 0.5 | 0.1 | G1 | 27.0 | 27.5 |

| G3 | 40.0 | 5.0 | G2 | 27.5 | 67.5 |

| G4 | 50.0 | 5.0 | G3/B3 | 67.5 | 117.5 |

| G5 | 40.0 | 3.0 | G4/J9 | 117.5 | 157.5 |

| G6 | 4.0 | 0.1 | G5/L8 | 168.1 | 172.1 |

| H1 | 2.0 | 0.1 | START | 17.0 | 19.0 |

| H2 | 0.5 | 0.1 | H1 | 19.0 | 19.5 |

| H3 | 48.3 | 5.0 | H2 | 19.5 | 67.8 |

| H4 | 50.0 | 5.0 | H3 | 67.8 | 117.8 |

| H5 | 48.3 | 3.0 | H4/J9 | 117.8 | 166.1 |

| H6 | 4.0 | 0.1 | H5/G6 | 172.1 | 176.1 |

| I1 | 2.0 | 0.1 | START | 15.0 | 17.0 |

| I2 | 0.5 | 0.1 | I1/D2 | 160.1 | 164.1 |

| I3 | 18.0 | 2.0 | I2 | 17.0 | 17.5 |

| I4 | 9.0 | 0.5 | I3/E1 | 17.5 | 35.5 |

| I5 | 10.9 | 0.5 | I4 | 35.5 | 38.5 |

| I6 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 41.5 | 52.4 |

| I7 | 6.1 | 0.2 | I6/D5 | 70.7 | 72.7 |

| I8 | 20.0 | 1.2 | I7/D6 | 78.8 | 84.9 |

| I9 | 35.0 | 3.5 | I8/J9 | 98.8 | 118.8 |

| I10 | 4.0 | 0.1 | I9/A6 | 118.8 | 153.8 |

| J1 | 2.0 | 0.1 | START | 19.0 | 21.0 |

| J2 | 0.5 | 0.1 | J1 | 113.9 | 177.4 |

| J3 | 20.7 | 0.8 | J2 | 180.1 | 184.1 |

| J4 | 8.0 | 1.0 | J3/P4 | 21.0 | 21.5 |

| J5 | 12.5 | 0.8 | J4 | 21.5 | 42.2 |

| J6 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 42.2 | 50.2 |

| J7 | 7.0 | 1.0 | J6/D5 | 58.2 | 70.7 |

| J8 | 13.1 | 1.2 | J7/D6 | 70.7 | 72.7 |

| J9 | 2.0 | 0.5 | J8 | 78.8 | 85.8 |

| J10 | 63.5 | 10.0 | J9 | 98.8 | 111.9 |

| J11 | 4.0 | 0.1 | J10/D9 | 111.9 | 113.9 |

| K1 | 2.0 | 0.1 | START | 23.0 | 25.0 |

| K2 | 0.5 | 0.1 | K1/J2 | 113.9 | 186.8 |

| K3 | 18.0 | 4.1 | K2 | 186.8 | 190.8 |

| K4 | 7.0 | 1.0 | K3/F1 | 25.0 | 25.5 |

| K5 | 10.9 | 0.6 | K4 | 25.5 | 43.5 |

| K6 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 43.5 | 50.5 |

| K7 | 6.1 | 0.8 | K6/D5 | 57.5 | 68.4 |

| K8 | 11.4 | 1.0 | K7/D6 | 70.7 | 72.7 |

| K9 | 2.0 | 0.3 | K8 | 78.8 | 84.9 |

| K10 | 62.0 | 6.0 | K9/J9 | 98.8 | 110.2 |

| K11 | 4.0 | 0.1 | K10/J11 | 110.2 | 112.2 |

| L1 | 2.0 | 0.1 | START | 30.0 | 32.0 |

| L2 | 0.5 | 0.1 | L1 | 32.0 | 32.5 |

| L3 | 28.9 | 5.2 | L2 | 32.5 | 61.4 |

| L4 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 70.7 | 72.7 |

| L5 | 6.1 | 0.2 | L4/D5 | 78.8 | 84.9 |

| L6 | 20.0 | 2.0 | L5/D6 | 98.8 | 118.8 |

| L7 | 35.0 | 1.0 | L6/J9 | 118.8 | 153.8 |

| L8 | 4.0 | 0.10 | L7/I10 | 164.1 | 168.1 |

| M1 | 2.0 | 0.1 | START | 19.0 | 21.0 |

| M2 | 0.5 | 0.1 | M1 | 113.9 | 177.4 |

| M3 | 20.7 | 2.0 | M2 | 180.1 | 184.1 |

| M4 | 8.0 | 1.00 | M3/J4 | 21.0 | 21.5 |

| M5 | 12.5 | 0.5 | M4 | 21.5 | 42.2 |

| M6 | 2.0 | 0.1 | D3/I5/J5/K5/L3 | 50.2 | 58.2 |

| M7 | 7.0 | 0.3 | M6/D5 | 58.2 | 70.7 |

| M8 | 13.1 | 0.9 | M7/D6 | 70.7 | 72.7 |

| M9 | 2.0 | 0.2 | M8 | 78.8 | 85.8 |

| M10 | 63.5 | 5.0 | M9 | 98.8 | 111.9 |

| M11 | 4.0 | 0.1 | M10/D9 | 111.9 | 113.9 |

| N1 | 2.0 | 0.1 | START | 23.0 | 25.0 |

| N2 | 0.5 | 0.1 | N1/J2 | 113.9 | 175.9 |

| N3 | 18.0 | 0.6 | N2 | 184.1 | 188.1 |

| N4 | 7.0 | 1.0 | N3/K4 | 25.0 | 25.5 |

| N5 | 10.9 | 0.5 | N4 | 25.5 | 43.5 |

| N6 | 2.0 | 0.1 | D3/I5/J5/N5/L3 | 50.5 | 57.5 |

| N7 | 6.1 | 0.3 | N6/D5 | 57.5 | 68.4 |

| N8 | 11.4 | 0 | N7/D6 | 70.7 | 72.7 |

| N9 | 2.0 | 0.3 | N8 | 78.8 | 84.9 |

| N10 | 62.0 | 8.2 | N9/J9 | 98.8 | 110.2 |

| N11 | 4.0 | 0.1 | N10/J11 | 110.2 | 112.2 |

| P1 | 2.0 | 0 | START | 15.0 | 17.0 |

| P2 | 0.5 | 0 | P1/D2 | 160.1 | 164.1 |

| P3 | 18.0 | 2.0 | P2 | 17.0 | 17.5 |

| P4 | 9.0 | 0.2 | P3/I4 | 17.5 | 35.5 |

| P5 | 10.9 | 0.5 | P4 | 38.5 | 41.5 |

| P6 | 2.0 | 0.1 | D3/P5/J5/K5/L3 | 41.5 | 52.4 |

| P7 | 6.1 | 1.0 | P6/D5 | 70.7 | 72.7 |

| P8 | 20.0 | 3.0 | P7/D6 | 78.8 | 84.9 |

| P9 | 35.0 | 2.3 | P8/J9 | 98.8 | 118.8 |

| P10 | 4.0 | 0.10 | P9/A6 | 118.8 | 153.8 |

References

- Chen, F.; Wang, Z.; Tian, X.L. A production schedule evaluation method based on program evaluation and review technique. J. Ordnance Equip. Eng. 2016, 37, 177–180. [Google Scholar]

- Ma, G.F.; Chen, Q. Study on project scheduling management. Shanghai Manag. Sci. 2006, 28, 70–74. [Google Scholar]

- Sadri, S.; Ghomi, S.M.T.F.; Deghghanian, A. Analysis of a time-cost trade-off in a resource-constrained GERT project scheduling problem using the Markov decision process. Ann. Oper. Res. 2024, 338, 535–568. [Google Scholar] [CrossRef]

- Wang, L.; Liu, H.; Xia, M.; Wang, Y.; Li, M. A machine learning based EMA-DCPM algorithm for production scheduling. Sci. Rep. 2024, 14, 20810. [Google Scholar] [CrossRef] [PubMed]

- Davis, E.W. Project scheduling under resource constraints: Historical review and categorization of procedures. AIIE Trans. 1973, 5, 297–313. [Google Scholar] [CrossRef]

- Levchuk, G.M.; Levchuk, Y.N.; Luo, J.; Pattipati, K.R.; Kleinman, D.L. Normative design of organizations. I. mission planning. IEEE Trans. Syst. Man Cybern.–Part A Syst. Hum. 2002, 32, 346–359. [Google Scholar] [CrossRef]

- Machado Lf Paternina, C.D.; Velez, J. An adaptative bacterial foraging optimization algorithm for solving the MRCPSP with discounted cash flows. Top 2022, 30, 221–248. [Google Scholar] [CrossRef]

- Hu, M.; Zhou, M.; Zhang, Z.; Zhang, L.; Li, Y. A novel disjunctive-graph-based meta-heuristic approach for multi-objective resource-constrained project scheduling problem with multi-skilled staff. Swarm Evol. Comput. 2025, 95, 101939. [Google Scholar] [CrossRef]

- Peng, W.L.; Lin, X.J.; Li, H.T. Critical chain based Proactive-Reactive scheduling for Resource-Constrained project scheduling under uncertainty. Expert Syst. Appl. 2023, 214, 119188. [Google Scholar] [CrossRef]

- Passlanneau, A.; Bendotti, P.; Brunodindrigo, L. Exact and heuristic methods for Anchor-Robust and Adjustable-Robust RCPSP. Ann. Oper. Res. 2024, 337, 649–682. [Google Scholar] [CrossRef]

- Peng, W.L.; Lin, X.J. A Dynamic Reactive Scheduling Method for the Resource Constrained Project Scheduling Problem. Chin. J. Manag. Sci. 2025, 33, 200–209. [Google Scholar]

- Guo, W.K.; Vanhoucks, M.; Coelho, J. Comparison of two problem transformation-based methods in detecting the best performing branch-and-bound procedures for the RCPSP. Expert Syst. Appl. 2025, 281, 127383. [Google Scholar] [CrossRef]

- Melo, L.V.; Queiroz, T.A. Integer Linear Programming Formulations for the RCPSP considering Multi-Skill, Multi-Mode, and Minimum and Maximum Time Lags. IEEE Lat. Am. Trans. 2021, 19, 5–16. [Google Scholar] [CrossRef]

- Carvin, B.; Bellenguez, O.; Massonnet, G. Tabu search for a multi-mode RCPSP with generalized precedence sequence-dependent setup time. Comput. Ind. Eng 2025, 111142. [Google Scholar] [CrossRef]

- Cai, H.X.; Bian, Y.Q.; Liu, L.L. Deep reinforcement learning for solving resource constrained project scheduling problems with resource disruptions. Robot. Comput.-Integr. Manuf. 2024, 85, 102628. [Google Scholar] [CrossRef]

- Xue, W.R. Research on Project Schedule Management Oriented to Collaborative Construction. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2015; pp. 1–45. [Google Scholar]

- Guan, Y.; Du, X.L. Research on production planning management in supply chain management environment. Mod. Ind. Econ. Informationization 2023, 13, 236–238. [Google Scholar]

- Yang, X.J. Research on Production Schedule Control of Aerospace Products Based on Multi-Level Earned Value Method. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2015; pp. 1–38. [Google Scholar]

- Zhang, Y. Application of improved earned value method in cost control of road construction projects. Eng. Cost Manag. 2024, 69–75. [Google Scholar] [CrossRef]

- Li, S.M.; Hu, J.B.; Xu, S.Y.; Sun, D.J.; Wei, Z.H. Evaluation of flight plan robustness based on flight redistribution. J. Nanjing Univ. Aeronaut. Astronaut. 2023, 55, 1044–1054. [Google Scholar] [CrossRef]

- Qu, J.Y.; Wu, S.X.; Zhang, J.J. Flight delay propagation prediction based on deep learning. Mathematics 2023, 11, 494. [Google Scholar] [CrossRef]

- Wei, X.; Li, Y.; Shang, R.; Ruan, C.; Xing, J. Airport cluster delay prediction based on TS-BiLSTM-attention. Aerospace 2023, 10, 580. [Google Scholar] [CrossRef]

- Dong, B.; Peng, Z.C. Irregular flight recovery under resource restriction. Ship Electron. Eng. 2024, 44, 51–56. [Google Scholar]

- Wang, W.H.; Luan, S.C. The crucial technology research of operational plan management. Comput. Knowl. Technol. 2010, 6, 4841–4844. [Google Scholar]

- Zhang, Y.X. Research on Modeling and Optimization Method of Military Mission Plan in Uncertain Environment. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2014; pp. 1–35. [Google Scholar]

- Chen, X.J.; Qi, H.; Yang, D.S. Modeling and solution of joint operational plans with time windows. Syst. Eng-Theory Pract. 2012, 32, 1979–1985. [Google Scholar]

- Sun, P.; Chen, G.Y.; Zhang, J.Y.; Wu, J.S. Dynamic task plan adjustment model and algorithm based on battlefield emergencies. Control Decis. 2020, 35, 1052–1062. [Google Scholar]

- Wu, R.J.; Sun, P.; Sun, Y. Distributed dynamic task plan adjustment model and algorithm. Syst. Eng. Electron. 2017, 39, 322–328. [Google Scholar]

- Yang, X.M.; Yu, J.; Chen, Y.; Gao, Q.F. Design of battle management system based on workflow engine. Command Inf. Syst. Technol. 2024, 15, 21–27. [Google Scholar] [CrossRef]

- Fang, B.; Wang, Z.W.; Chen, A.; Chen, W.X. Technology for intelligent battle management. Command Inf. Syst. Technol. 2023, 14, 18–24. [Google Scholar] [CrossRef]

- Saputra, P.D.; Fansuri, M.H.; Laksmi, A.A. Development of work breakdown structure (WBS) for rapid damage runway repair (RADARR) time planning at military airbases. E3S Web Conf. 2024, 517, 05002. [Google Scholar] [CrossRef]

- Song, Q.; Zuo, J.L.; Wu, A.; Yang, R.N.; Wang, Y.; Li, L.Y. Collaborative mission schedule management method for air battle management. Acta Aeronaut. Et Astronaut. Sin. 2025, 46, 331480. (In Chinese) [Google Scholar] [CrossRef]

| UAV Name | Total Fuel Quantity /kg | Flight Altitude /km | Flight Speed /(km·h−1) | Fuel Consumption Rate /(kg·min−1) | Loitering Flight Speed /(km·h−1) | Consumption Rate /(kg·min−1) |

|---|---|---|---|---|---|---|

| A | 8935 | 25 | 759.32 | 16.66 | 759.32 | 16.66 |

| B/C/D | 13,972 | 7.3~10 | 1018.60 | 107.20 | 648.20 | 49.00 |

| E/F | 28,540 | 7.3~10 | 537.08 | 29.37 | 537.08 | 29.37 |

| G | 73,800 | 7.3~10 | 592.64 | 111.05 | 592.64 | 111.05 |

| H | 28,540 | 7.3~10 | 537.08 | 29.37 | 537.08 | 29.37 |

| I/P | 7060 | 7.3~10 | 1018.60 | 63.50 | 648.20 | 30.40 |

| J/M | 7060 | 7.3~10 | 888.96 | 92.70 | 648.20 | 74.10 |

| K/N | 13,972 | 7.3~10 | 1018.60 | 136.80 | 648.20 | 62.50 |

| L | 15,200 | 7.3~10 | 1018.60 | 81.64 | 648.20 | 39.10 |

| Unmanned Aerial Vehicle Name | Total Fuel Quantity /kg | Fuel Consumption/kg | Fuel Refueling Quantity /kg | Remaining Fuel Quantity/kg |

|---|---|---|---|---|

| B | 13,972 | 7580 | 0.0 | 6392.0 |

| C | 13,972 | 7967.1 | 0.0 | 6004.9 |

| D | 13,972 | 9743.6 | 0.0 | 4228.4 |

| I | 7060 | 5116.95 | 2426.4 | 4369.5 |

| J | 7060 | 11,783.1 | 4800 | 76.9 |

| K | 13,972 | 10,957.8 | 4200 | 7514.2 |

| L | 15,200 | 9857.2 | 0.0 | 5342.8 |

| M | 7060 | 11,783.1 | 4800 | 76.9 |

| N | 13,972 | 10,957.8 | 4200 | 7514.2 |

| P | 7060 | 5116.95 | 2426.4 | 4369.5 |

| Algorithm | Average Accuracy of the Algorithm (min) | Average Running Time of the Algorithm (s) | Mission Success Rate |

|---|---|---|---|

| Critical Path Transition Tree | 0.0 | 2.1 | 0.61 |

| Adaptive Differential Evolution Algorithm | 0.21 | 6.7 | 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Song, Q.; Wang, Y.; Wu, B.; Li, J.; Zhang, J.; Wang, D. Mission Schedule Control for an Aviation Cluster Based on the Critical Path Transition Tree. Appl. Sci. 2025, 15, 10258. https://doi.org/10.3390/app151810258

Sun Y, Song Q, Wang Y, Wu B, Li J, Zhang J, Wang D. Mission Schedule Control for an Aviation Cluster Based on the Critical Path Transition Tree. Applied Sciences. 2025; 15(18):10258. https://doi.org/10.3390/app151810258

Chicago/Turabian StyleSun, Yao, Qi Song, Ying Wang, Bin Wu, Jianfeng Li, Jiafeng Zhang, and Dong Wang. 2025. "Mission Schedule Control for an Aviation Cluster Based on the Critical Path Transition Tree" Applied Sciences 15, no. 18: 10258. https://doi.org/10.3390/app151810258

APA StyleSun, Y., Song, Q., Wang, Y., Wu, B., Li, J., Zhang, J., & Wang, D. (2025). Mission Schedule Control for an Aviation Cluster Based on the Critical Path Transition Tree. Applied Sciences, 15(18), 10258. https://doi.org/10.3390/app151810258