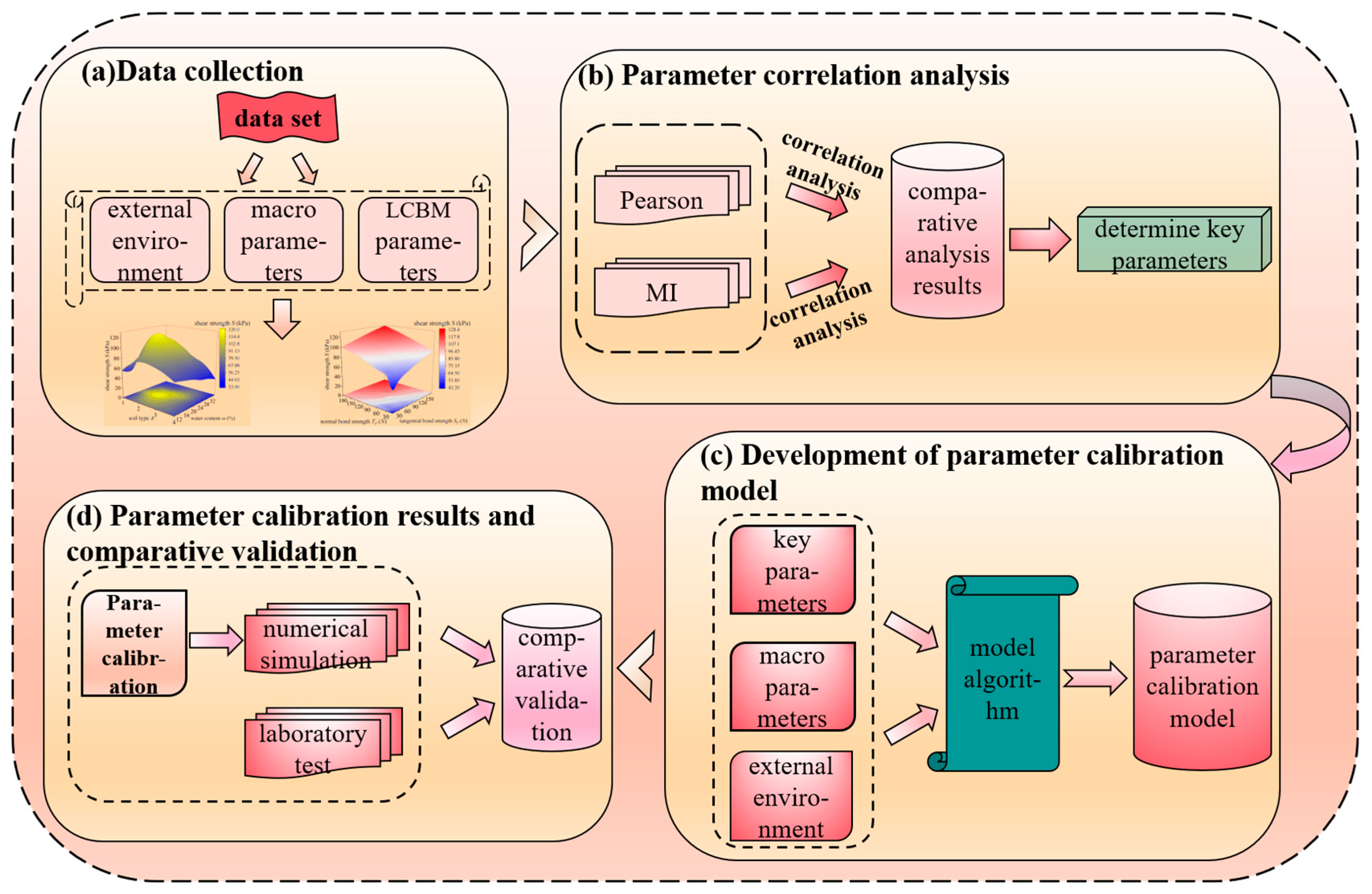

3.2.1. Project Overview

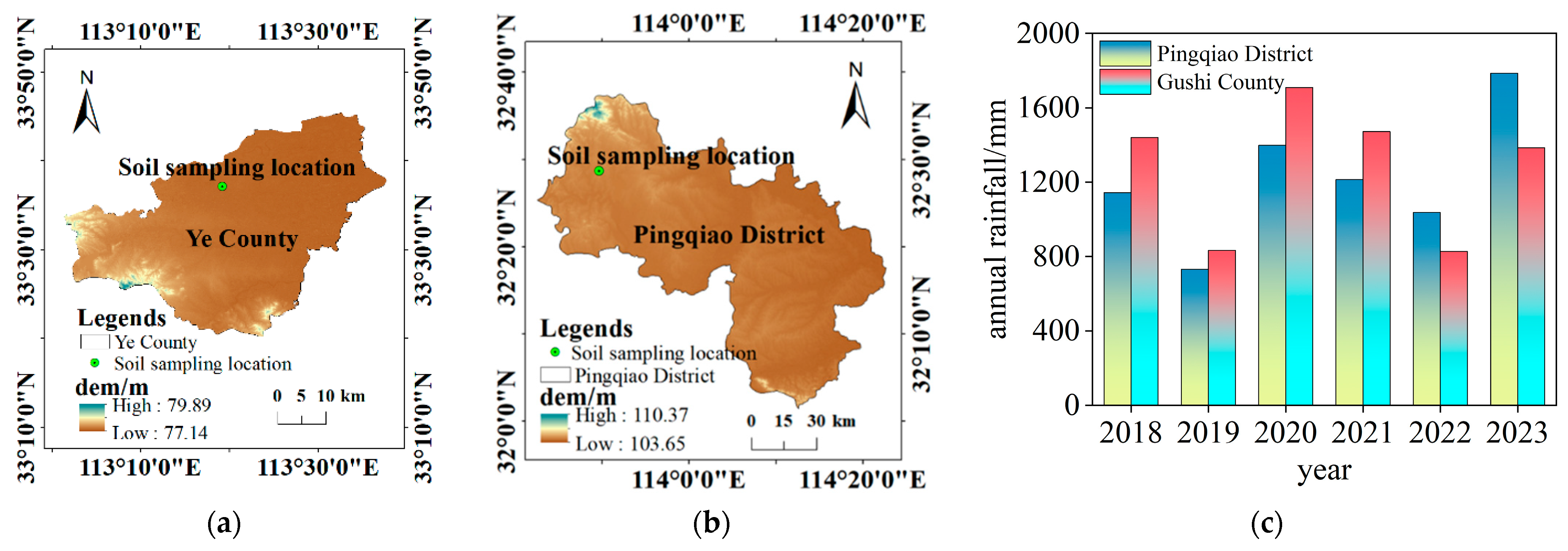

The sampling locations for silty clay, clay, and silt are Ye County (Pingdingshan City, Henan Province), Pingqiao District (Xinyang City, Henan Province), and Gushi County (Xinyang City, Henan Province), respectively. All sampling locations are geotechnical engineering structures, as shown in

Figure 2a,b. The sampling location in Ye County has an elevation ranging from 77.14 m to 79.89 m. The soil stratum exhibits a brownish-yellow color, containing iron and manganese oxides. The sampling location in Pingqiao District has an elevation ranging from 103.65 m to 110.37 m. The soil stratum, primarily grayish-brown, exhibits uneven quality with locally high sand particle content and abundant gravel. The sampling locations experience abundant rainfall, with average annual totals of 1218.9 mm and 1277.9 mm, respectively, as shown in

Figure 2c. Intense rainfall can induce a range of engineering problems, such as landslides [

22,

23], ground collapse [

24,

25], and significant deformation of foundation pits [

26,

27]. These problems cause substantial damage and pose severe risks, so it is necessary to investigate the patterns of rock–soil strength degradation under rainfall influence.

3.2.2. Macroscopic Analysis of Rock–Soil Strength Degradation Based on Direct Shear Test

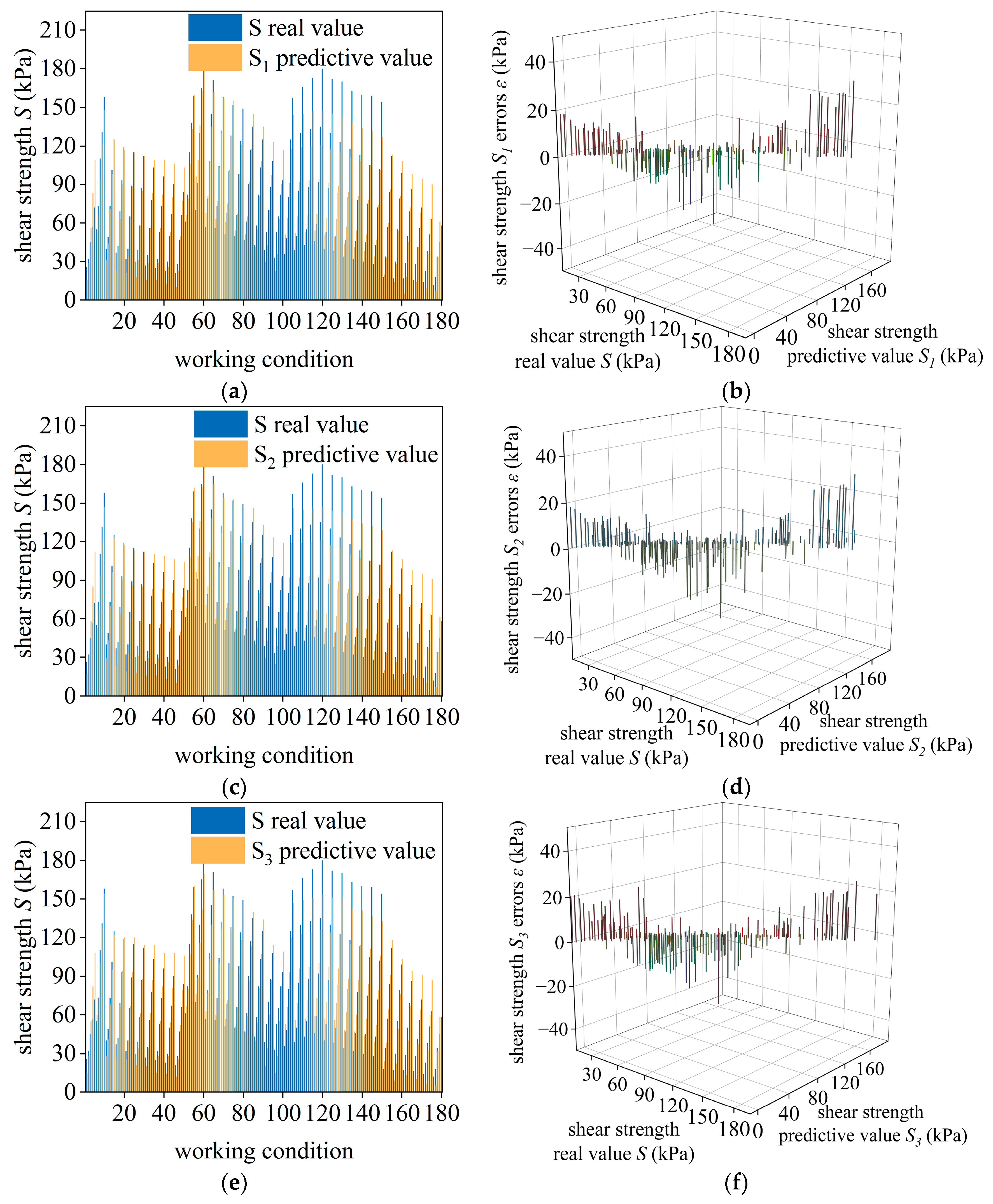

This study employs a strain-controlled direct shear apparatus. To investigate the variation patterns of shear strength under different water contents and soil types, the test soils are divided into three groups of silty clay, clay, and silt, with 10 samples of distinct water contents in each group. Each sample underwent direct shear tests under five vertical pressures (50, 100, 200, 300, and 400 kPa). The quick shear test method is applied with a shear rate of 0.8 mm/min, and testing is terminated when the shear displacement reaches 6 mm. Stress–strain curves are plotted to derive the soil’s shear strength.

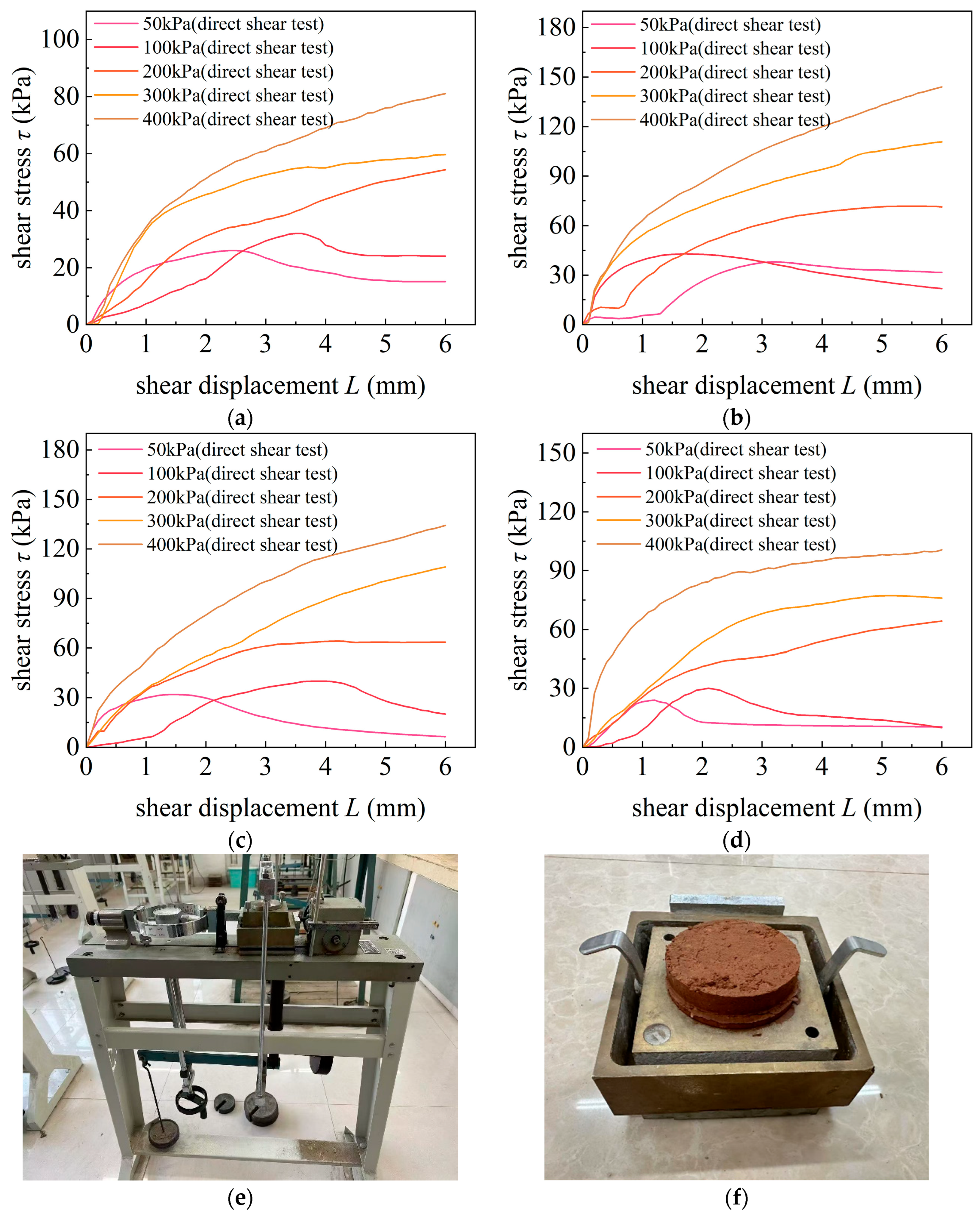

Taking silty clay as an example, the stress–strain curve and laboratory test images are shown in

Figure 3. The results in

Figure 3a–d indicate that, under a constant water content condition, as the vertical pressure increases, the shear stress on the stress–strain curve correspondingly increases. Analysis of the stress–strain curves under the same vertical pressure across different water contents found that the shear strength first increases and then decreases with increasing water content. This phenomenon is attributed to the increase in shear strength as the water content approaches the optimum water content, followed by a gradual reduction as it exceeds this optimum water content, consistent with the findings of Wang et al. [

28]. Based on the comparative analysis of a part of the shear strength values for silty clay and clay in

Table 1, the two soils exhibit similar variation patterns of the shear strength. The comparative analysis above indicates that, before reaching the optimum water content, increased water content inhibits the degradation of rock–soil strength. In contrast, beyond this optimum, further increases in water content promote such degradation.

3.2.3. Mesoscopic Analysis of Rock–Soil Strength Degradation Based on PFC

The direct shear test model and boundary conditions for silty clay are shown in

Figure 4e. To facilitate comparison with laboratory tests, the sample dimensions (61.8 mm in length × 20 mm in height) are consistent with the actual dimensions. The discrete element model is developed using PFC2D version 6.0 and consists of 17,889 circular particles. During shearing, the lower shear box remains fixed, while the upper shear box moves at a constant velocity. At the same time, a constant vertical pressure is applied to the top of the upper shear box. Excessively high shear speeds can cause significant fluctuations in the stress–strain curve, while excessively low speeds may lead to high time consumption. Hence, considering both laboratory direct shear test requirements and computational efficiency, the shear speeds during the shearing process are set to 0.005 mm/s. To validate the accuracy of the model, four groups of water content levels of 16.1%, 21.8%, 22.2%, and 24.9% are chosen as comparative work conditions for silty clay. The parameters for DEM simulation are shown in

Table 2.

Figure 4a–d show a comparison of curve results between laboratory direct shear tests and PFC simulations. Although minor discrepancies exist between the simulated and test curves, the shear strengths obtained from both methods are close, and most curves exhibit similarity. This confirms that the mesoscopic parameters obtained from the simulation are effective. The model is calibrated primarily against the peak shear strength, and as a result, it does not fully capture other critical aspects of the stress–strain response. The key limitations include its inability to accurately replicate the contraction and dilation behavior throughout shearing, the shape of the pre- and post-peak stress–strain curve, and the precise post-peak softening or hardening behavior.

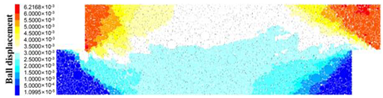

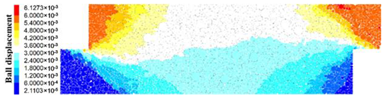

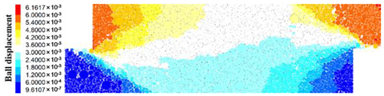

Table 3 presents the particle motion of silty clay and clay under a vertical pressure of 200 kPa. As shown in the table, during shearing, particles in the upper shear box move with the shear box and exhibit significant displacement, while those in the lower shear box undergo minor displacement due to particle misalignment during the shearing process. Overall, the upper shear box exhibited the largest displacement at both ends, whereas the lower shear box displayed the smallest displacement. Analysis revealed that the particle motion of both soil types adhered to this pattern, confirming the accuracy of this pattern.

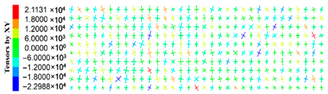

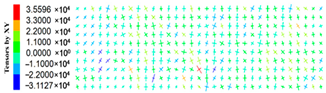

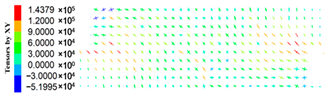

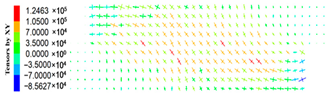

Table 4 shows the evolution of the force chain network and stress field of silty clay and clay under a vertical pressure of 200 kPa. A force chain represents the propagation path of contact forces between particles, with its thickness reflecting the magnitude of these contact forces. Larger contact forces accumulate to form strong force chains, whereas smaller contact forces give rise to weak force chains. The external load is primarily borne through the strong force chains. At a shear displacement of 0 mm, the strong force chain appears vertically, consistent with the direction of the external load. As displacement increases, there is a concentration of strong force chains in the upper-left and lower-right corners, whereas weak force chains develop in the upper-right and lower-left corners. The stress field is monitored using measurement circles arranged within the model. The stress field is monitored using measurement circles arranged within the model. During shearing, the principal stress direction is shifted. Near the shear plane, the direction of the major principal stress aligns with that of the strong force chains. Overall, the stress field distribution shows that the area between the upper-left and lower-right corners exhibits stronger stress, while the area between the upper-right and lower-left corners shows relatively lower stress.

To characterize the evolution of anisotropy during the shearing process, the equation proposed by R.J. Bathurst et al. [

29] is employed for fitting analysis, as shown in Equations (5)–(7).

where

a,

an, and

at are the anisotropy coefficients of the contact normal, normal contact force, and tangential contact force, respectively.

θa,

θn, and

θt are the principal directions of the contact normal, normal contact force, and tangential contact force, respectively. And

f0 is the average normal contact force across all contacts.

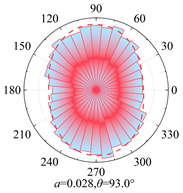

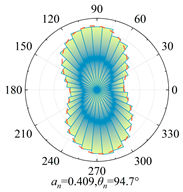

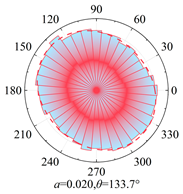

Silty clay is taken as an example to show the anisotropy during shearing and the results are shown in

Table 5. The analysis shows that, at zero shear displacement, the principal directions of contact normal, normal contact force, and tangential contact force are all 90°. With increasing shear displacement, the principal directions of anisotropy gradually rotate counterclockwise. The contact normal gradually evolves into an elliptical morphology. The normal contact force exhibits a peanut-shaped distribution, where the maximum contact forces are concentrated in the principal direction. The tangential contact force exhibits a four-leaf clover shape, with its principal directions positioned between two leaves. By comparing the anisotropy coefficients of the two soil types, it is found that

a and

at are significantly smaller than

an. The findings indicate that the load is primarily borne by the normal contact force during shearing and that it also contributes most to the shear strength.

3.2.4. Analysis of Meso–Mechanical Characteristics Under Different Water Contents

To investigate the intrinsic connection between the water content variations caused by external rainfall and mesoscopic mechanical characteristics of rock–soil structures, an analysis of mesoscopic mechanical characteristics under different water contents is performed based on particle displacement evolution pattern, the particle bond failure rate, and the anisotropy coefficient evolution pattern.

Four groups of clay with water contents of 16.1%, 23.8%, 26.7%, and 28% are chosen. The post-shear simulation samples under a vertical pressure of 200 kPa are selected as working conditions to investigate the evolution of particle displacement. The results are shown in

Table 6. An analysis of

Table 6 found that the average displacement of central particles decreases initially and then increases with rising water content, which is opposite to the trend in the shear strength. During shearing, lower shear box particles are driven to move by upper shear box particles due to interparticle friction and compression, resulting in particle movement and reorganization. The difficulty of reorganization is indicated through the displacement magnitude, where the smaller the displacement, the greater the reorganization difficulty and the higher the shear strength.

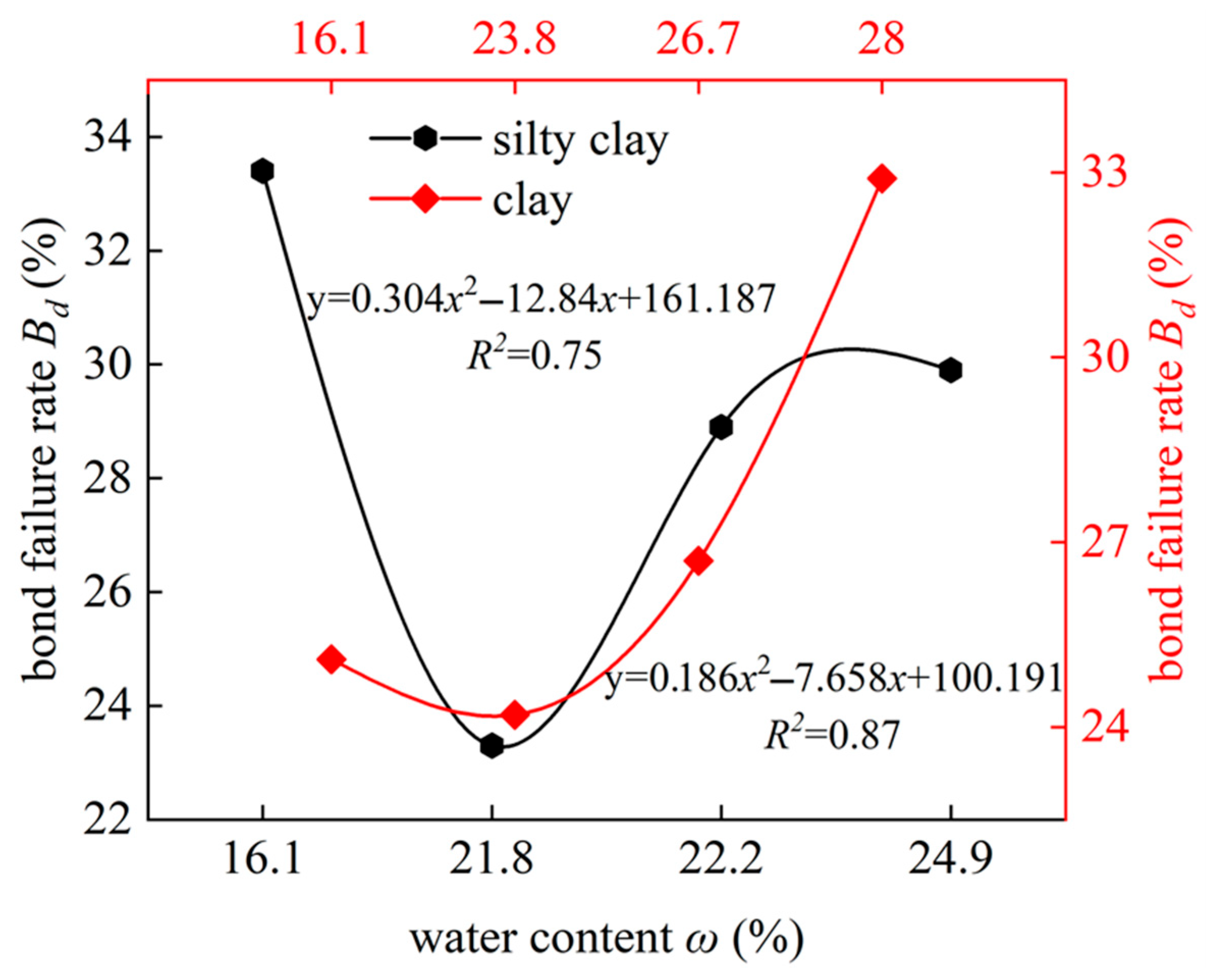

Four groups of silty clay with water contents of 16.1%, 21.8%, 22.2%, and 24.9%, along with another four groups of clay with water contents of 16.1%, 23.8%, 26.7%, and 28%, are chosen. The post-shear simulation samples under a vertical pressure of 200 kPa are used as working conditions to investigate the evolution of the particle bond failure rate.

Within the linear contact bond model, when the shear force acting on the interparticle bond exceeds its limit strength, bond failure occurs, after which interparticle interactions degrade to a linear contact relationship. The intrinsic mechanisms governing the mesoscopic mechanical characteristics of soils can be performed through the analysis of the bond failure behavior in different water contents. To quantify the degree of bond failure, the bond failure rate is employed as a quantitative indicator, as shown in Equation (8).

where

Bd is the bond failure rate,

Ni is the number of linear contacts under different conditions, and

N is the total number of contacts.

Figure 5 shows the change in the bond failure rate of silty clay and clay samples with water content and the quantitative relationships between the water content and the bond failure rate. The results indicate that the relationship between the bond failure rate and the water content follows an upward-opening parabolic curve. When the water content is below the optimum level, the bond failure rate decreases with increasing water content. Conversely, when the water content exceeds the optimum level, the bond failure rate increases accordingly. Notably, the trend in bond failure rate with varying water content opposes that of the shear strength. This comparison indicates that there is a significant negative correlation between the macroscopic shear strength of soil and the interparticle bond failure rate, consistent with the findings reported by Zhang et al. [

30].

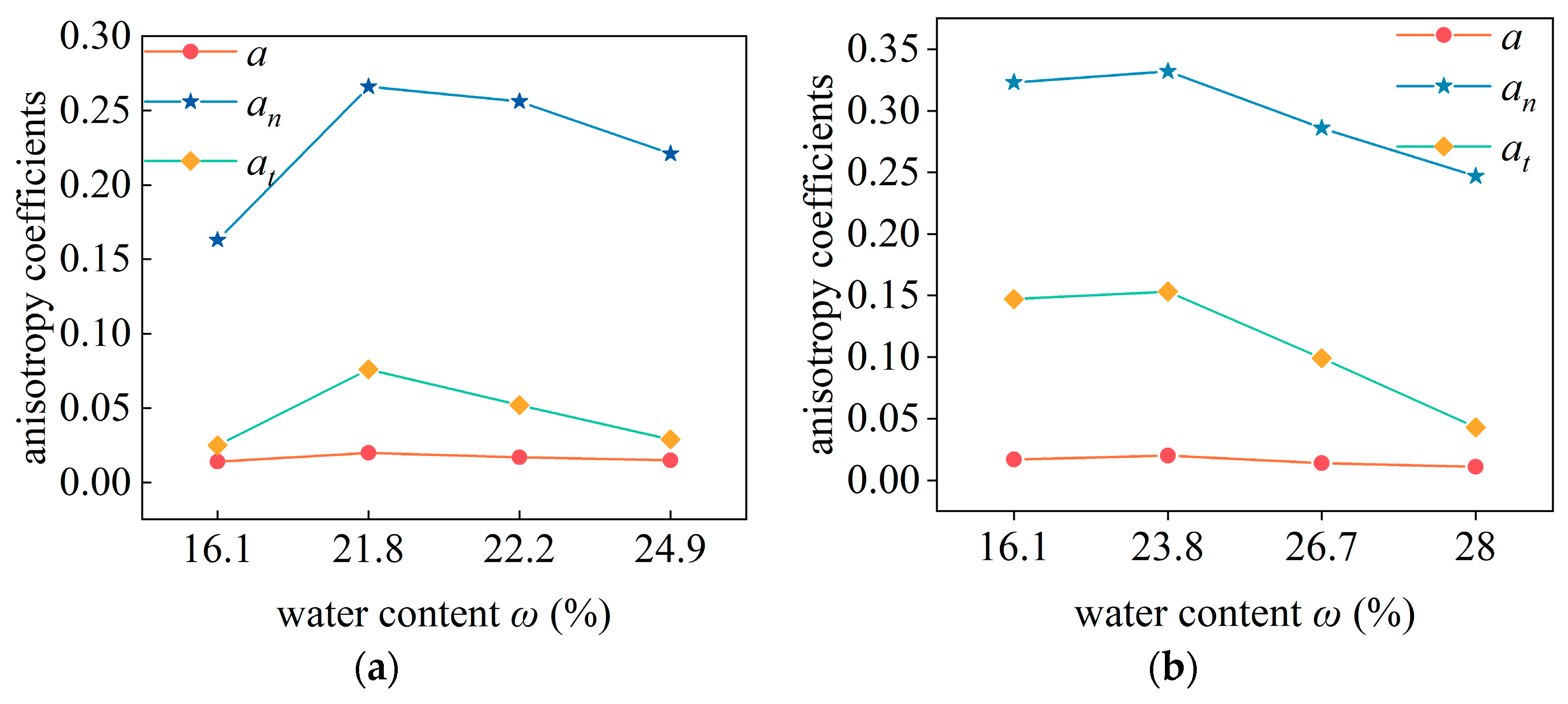

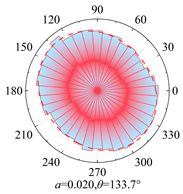

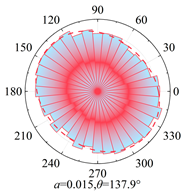

The post-shear samples of silty clay (water content 16.1%, 21.8%, 22.2%, 24.9%) and clay (water content 16.1%, 23.8%, 26.7%, 28%) under a vertical pressure of 200 kPa are chosen as the research conditions. Using Equations (5) and (6) to fit the samples, the anisotropy evolution results are shown in

Figure 6 and

Table 7. Analysis shows that, with increasing water content, the anisotropy coefficients

a,

an, and

at all exhibit a nonlinear trend of initial increase followed by a subsequent decrease.

The anisotropy coefficient

a characterizes the degree of anisotropy in the contact normal distribution among particles [

29]. During shearing, the particle system dynamically adjusts its contact direction to optimize the force transmission pathways and adapt to stress variations. Soils with different water contents exhibit varying resistance to shear deformation, leading to distinct distributions of particle contact directions post-shear. When the soil is close to its optimal water content, the contact force chains become more concentrated along the principal direction. And there is an increase in the anisotropy coefficient

a, at the same time macroscopically showing as an increase in the shear strength of the soil. After exceeding the optimum water content, the concentration of the contact force chain in the principal direction decreases. And the anisotropy coefficient

a gradually decreases, and at the same time the soil’s shear strength weakens.

The anisotropy coefficient

an characterizes the degree of difference in the magnitude of normal contact force across different directions. The normal contact force is the main contributor to the shear strength, which can reflect the normal load-bearing capacity of the force chain [

31]. Prior to optimum water content, the anisotropy coefficient

an increases with increasing water content, enhancing force chain load-bearing capacity, and at the same time, the shear strength is improved. Conversely, beyond the optimum water content, these trends are reversed.

The anisotropy coefficient

at characterizes the degree of difference in the magnitudes of tangential normal forces across different directions. The tangential contact force is provided by the tangential bond strength and friction resistance [

32,

33]. Below the optimum water content, soil interparticle bond strength is enhanced through capillary action. This strengthened bonding increases the force required for interparticle relative sliding, and at the same time the tangential anisotropy coefficient

at shows an increase. However, beyond the optimum water content, interparticle water lubrication becomes dominant, with tangential bond strength and interparticle frictional resistance being reduced, and at the same time the tangential anisotropy coefficient

at decreases. This trend is consistent with the pattern of the shear strength changes.

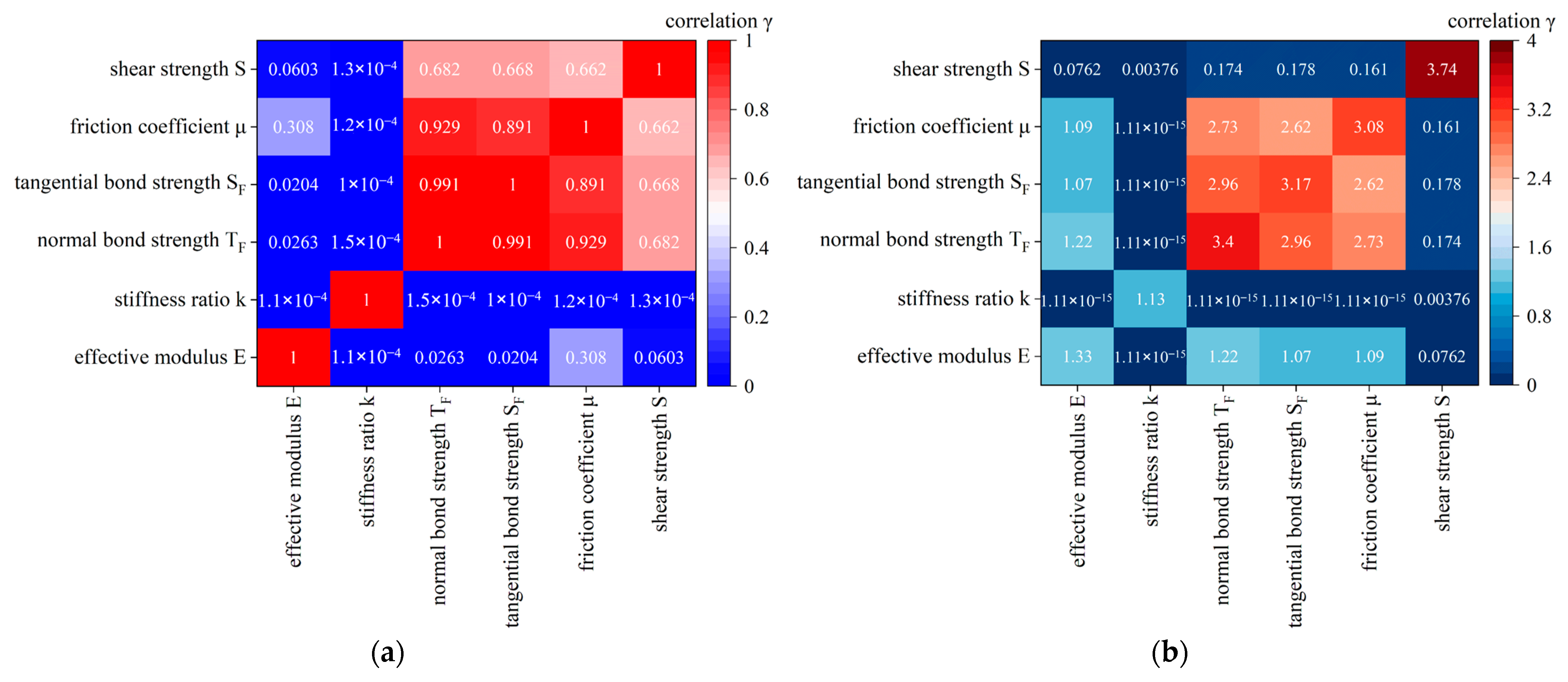

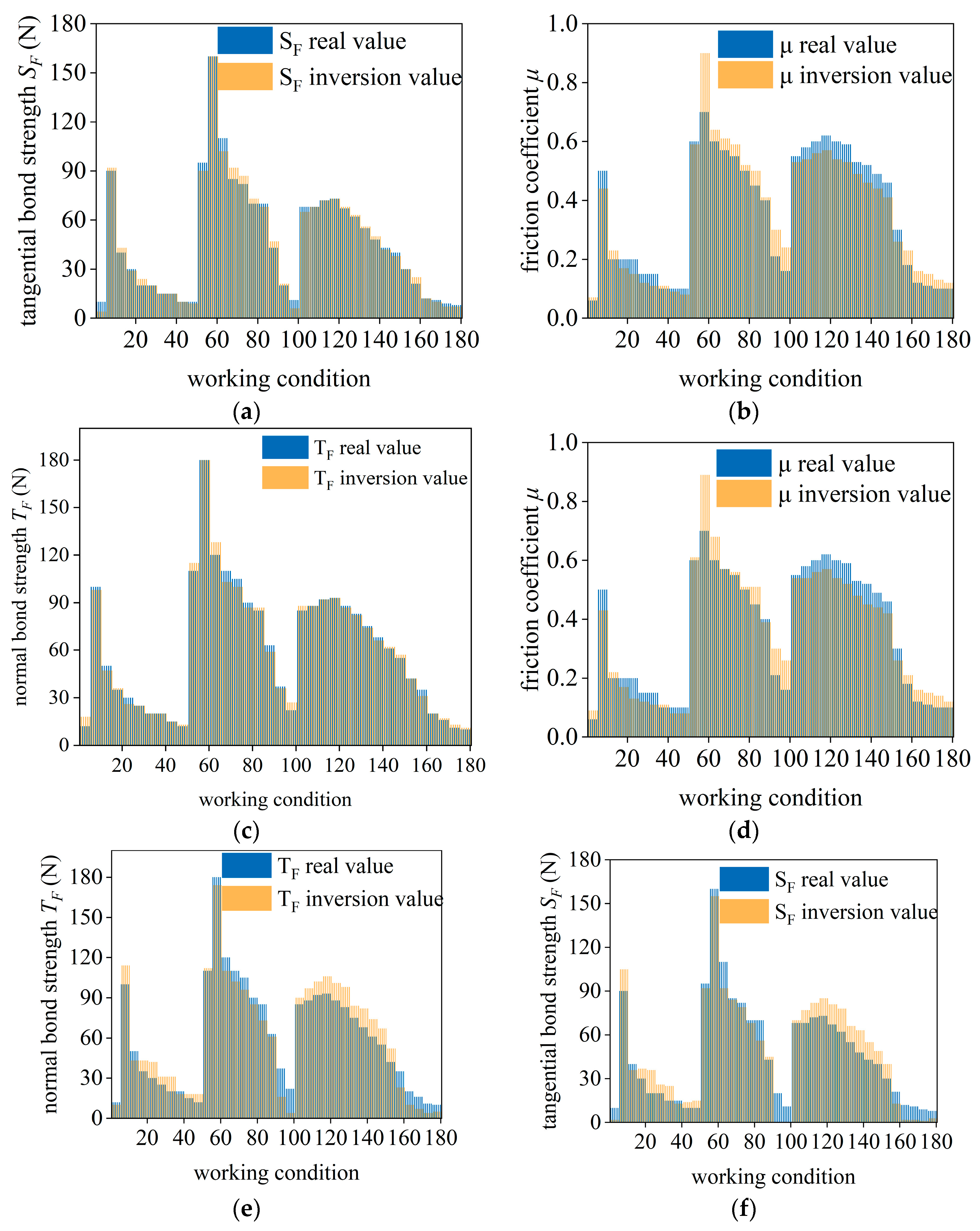

3.2.5. Macro–Mesoscopic Synergistic Analysis of Rock–Soil Strength Degradation

To explore the macro–mesoscopic intrinsic mechanisms of rock–soil strength degradation, a synergistic macro–mesoscopic analysis is performed based on the relationships among the water content, the shear strength, and the mesoscopic parameters. This analysis further provides a foundation for parameter calibration. The linear contact bond model is employed to simulate the mechanical characteristics of rock–soil, with mesoscopic parameters continuously adjusted to ensure numerical simulation results gradually tend toward laboratory test data. When the two are substantially consistent, this group of parameters is deemed capable of effectively characterizing the soil’s macroscopic mechanical characteristics. It is shown that the normal bond strength, the tangential bond strength, and the friction coefficient are found to be the primary parameters affecting the shear strength of soil under different water contents [

34].

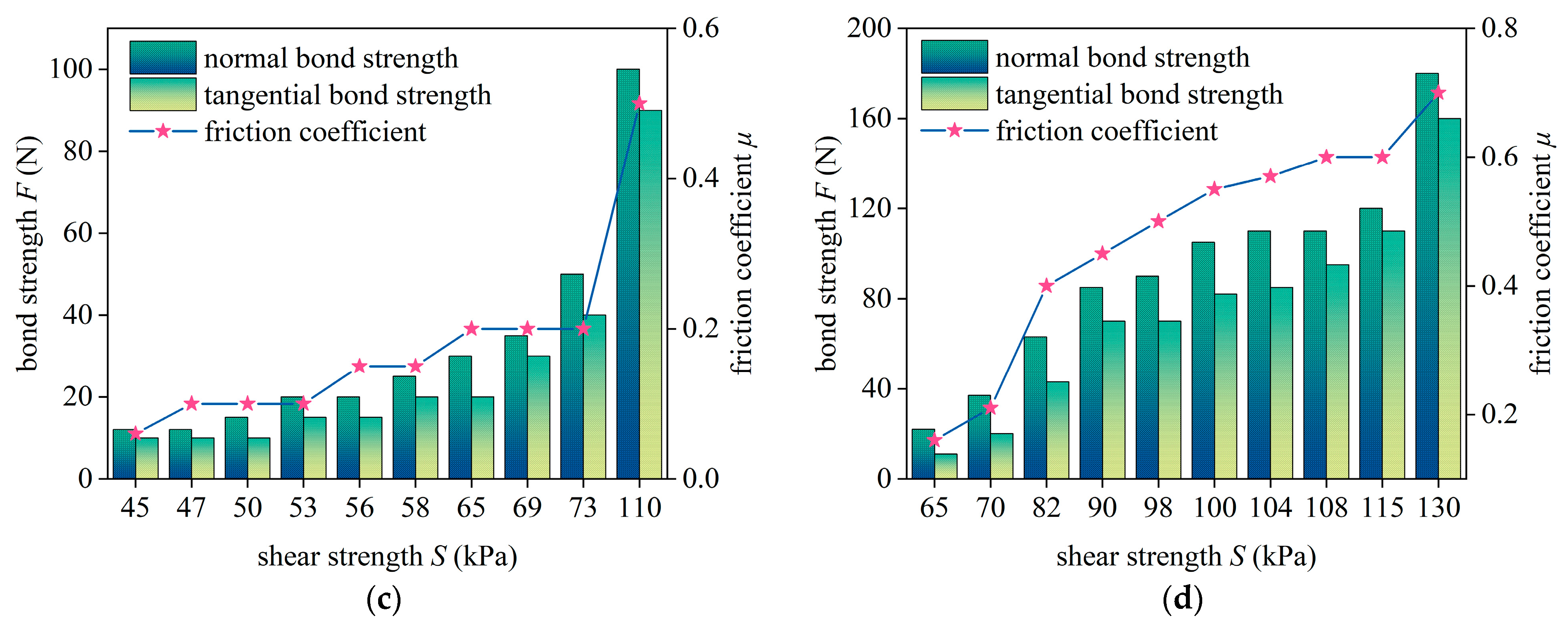

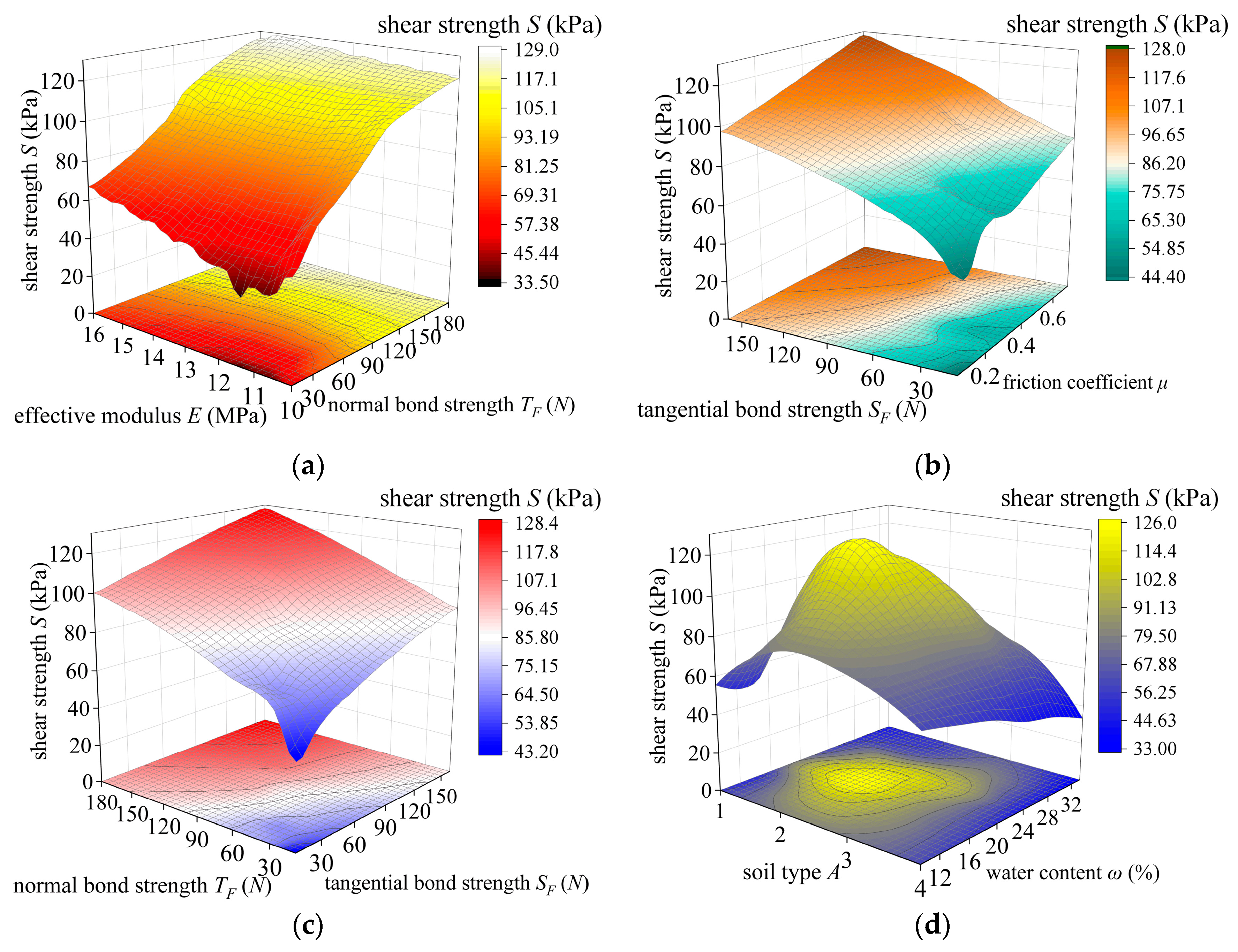

To investigate the intrinsic relationships among the water content, the shear strength, and the mesoscopic parameters, working conditions are designed under a vertical pressure of 200 kPa based on different water contents. A total of 20 working conditions are employed, including 10 groups of silty clay and 10 groups of clay. The relationships between mesoscopic parameters and water content are shown in

Figure 7a,b. The results indicate that both the bond strength and the friction coefficient initially increase and then decrease with increasing water content. As the water content approaches the optimum, it enhances interparticle bonding, bringing particles into closer contact and gradually increasing bond strength and the friction coefficient. When exceeding the optimum water content, water acts as a lubricant between particles, reducing interparticle bond strength and the friction coefficient. This reduction leads to a decrease in the macroscopic shear strength and exhibits rock–soil strength degradation [

35,

36].

Figure 7c,d show that the bond strength and the friction coefficient exhibit a positive correlation with the shear strength. As the bond strength increases, the shear force required to break the bond also increases, with the shear strength hence being enhanced. Meanwhile, the friction coefficient reflects the interparticle resistance. It is indicated by the increase in its value that particles face greater difficulty sliding past each other, requiring a higher shear force for movement and hence enhancing the shear strength [

37]. Comparative analysis of

Figure 7 reveals that the water content of rock–soil gradually approaches the optimum under rainfall, increasing interparticle bond strength and hence enhancing the shear strength. The water content in rock–soil is driven beyond the optimum by continuous rainfall, leading to reduced bond strength and friction coefficient, which in turn leads to degradation of rock–soil strength.