Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data

Abstract

1. Introduction

- (a)

- Higher-strength materials exhibit lower ultimate strain,

- (b)

- Confinement can increase strain capacity;

- (c)

- Higher concrete strength reduces the compression zone at both yielding and failure.

- (a)

- Flexure-critical;

- (b)

- Flexure–shear-critical;

- (c)

- Shear-critical.

- If no shear damage was reported, the column was categorized as flexure critical.

- If shear damage (diagonal cracks) was noted, the absolute maximum effective force (Feff)—the highest measured force in the experimental response—was compared to the calculated “ideal” force (F0.004), corresponding to a maximum axial compressive strain of 0.004 (the strain at which unconfined concrete spalls). The failure displacement ductility (μfail) was defined as the displacement ductility at 80% of the maximum effective force (Feff). If or if , the column was classified as shear-critical. Otherwise, the column was categorized as flexure–shear-critical. All columns in the database were further grouped by cross-sectional shape (rectangular or circular).

- According to the authors’ knowledge, the PEER structural performance database is employed for the first time in order to detect the failure mode of RC columns based on the traditional methods which employ engineering mechanics solutions applied to the whole database.

- The above results are thoroughly compared to the performance of ANNs for the entire database, both for rectangular and circular RC columns.

- Finally, all the performance metrics necessary for the evaluation of the ML methodology in detecting the failure mode of RC columns are provided too.

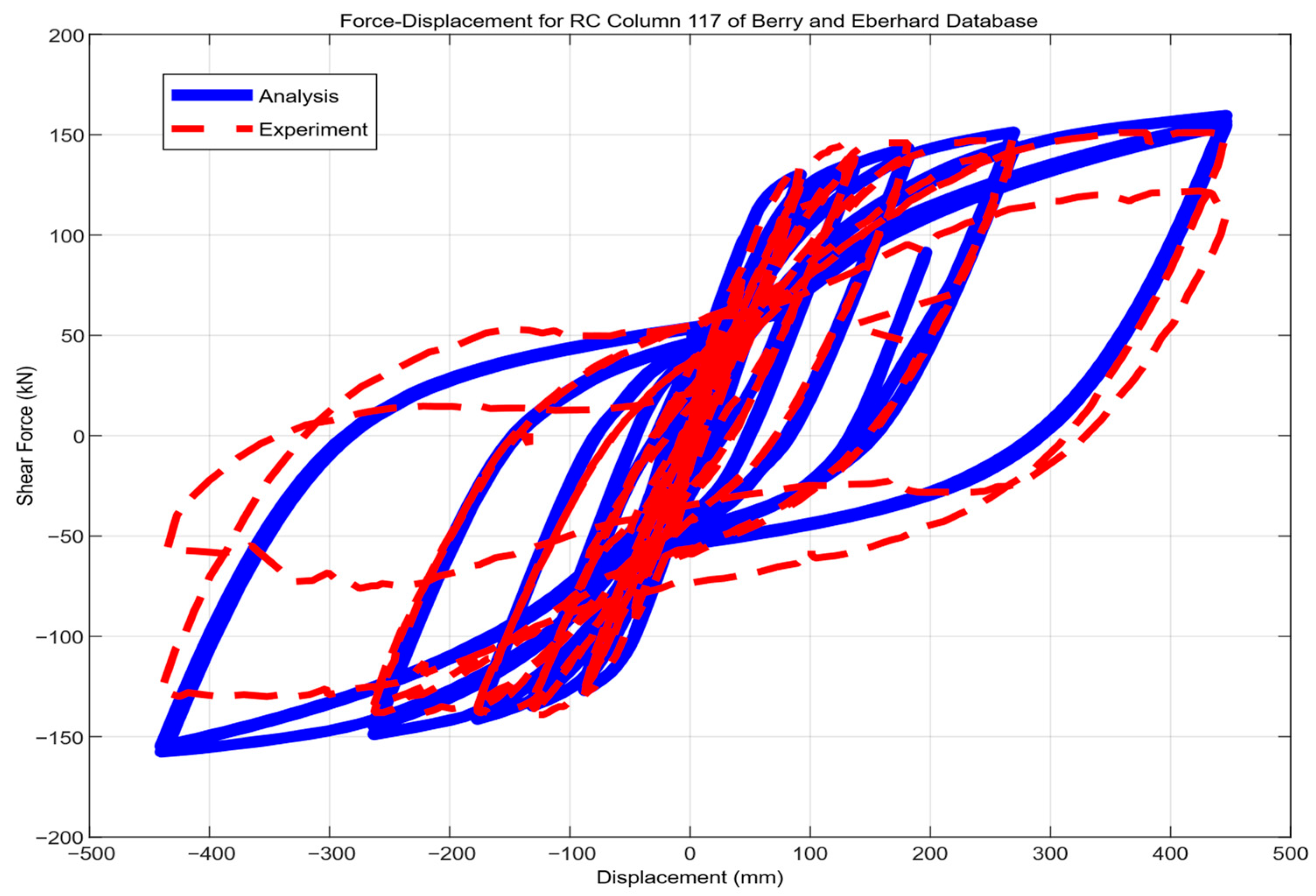

2. Materials and Methods

2.1. Flexural Capacity

2.2. Shear Capacity

2.3. Failure Mode Prediction

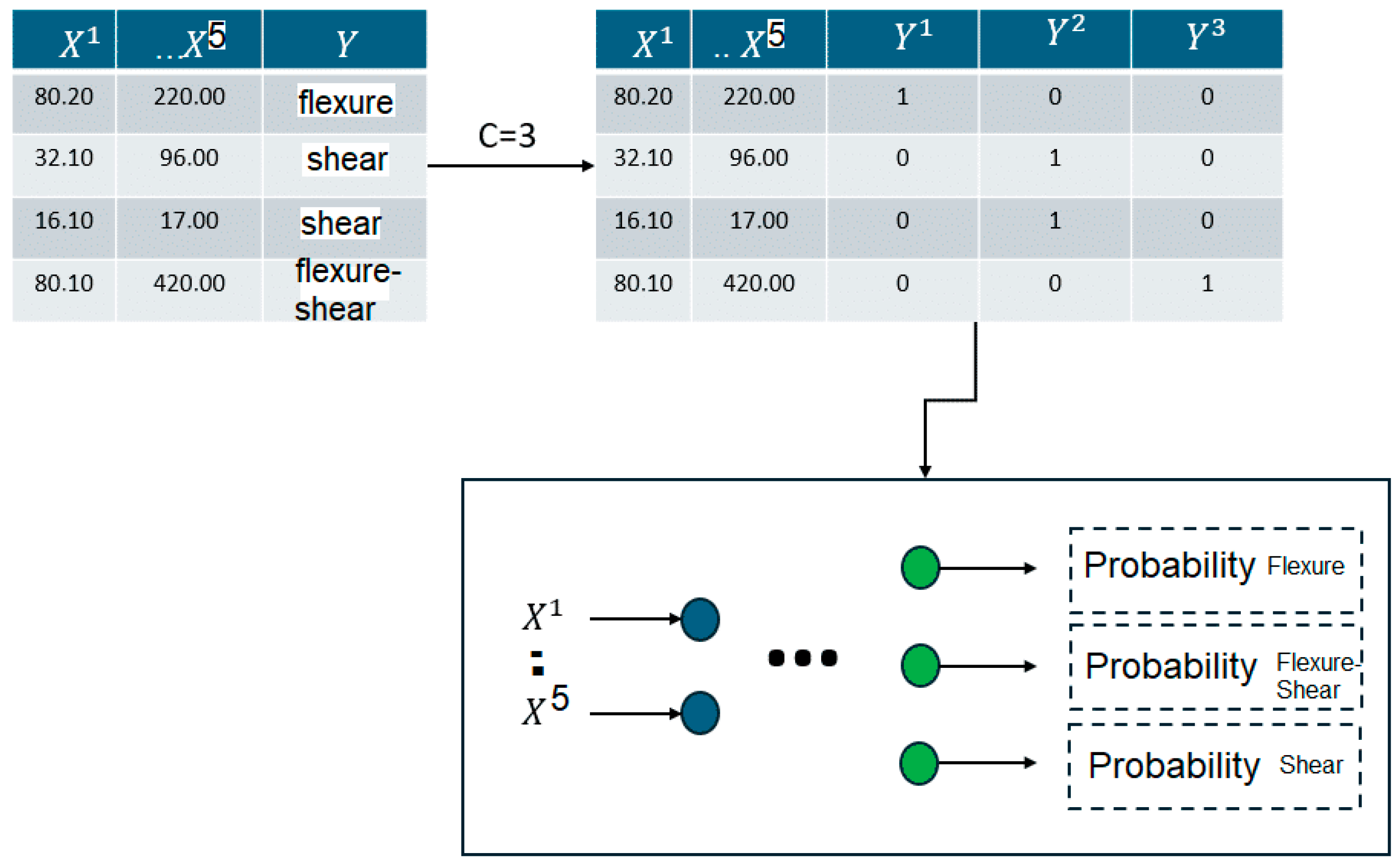

2.4. Artificial Neural Networks with Python

- Define the problem and determine the necessary data.

- Gather the data in a usable format.

- Identify and address any data gaps or uncertainties.

- Prepare the data for input into the machine learning model.

- Train the model using the training dataset.

- Apply the trained model to make predictions on the test dataset.

- Evaluate the predictions against known test outcomes and calculate performance metrics.

- If results are unsatisfactory, improve the model, collect more data, or investigate alternative modeling methods.

- The records of the entire training set pass through the neural network, and for each one, the network generates a prediction of the variable to be predicted.

- The above predictions are used to calculate the value of the cost function, which quantifies the “error” made by the ANN in attempting to predict the value to be predicted. A very common choice is the mean squared error (MSE) function.

- Forward propagation, described in steps 1 and 2, is followed by backward propagation, during which the parameter values used in the neural network in steps 1 and 2 to generate predictions from the ANN are revised and renewed in such a way as to contribute to reducing the value of the cost function calculated above. This process is called backward propagation because the revision–renewal of the parameter values starts from the output layer and reaches the input layer of the ANN.

- The process described in steps 1 to 3, where the records of the training set are forward propagated to calculate a value of the cost function and then backward propagated with the aim of updating the values of the parameters used in order to reduce the value of the cost function calculated, is referred to in the literature as an epoch.

- The next epoch begins, using the revised values of the parameters determined during the backward propagation of the previous epoch. The training process stops at the last epoch selected, and the ANN parameter values obtained in the backward propagation of the last epoch are the final ones for the ANN.

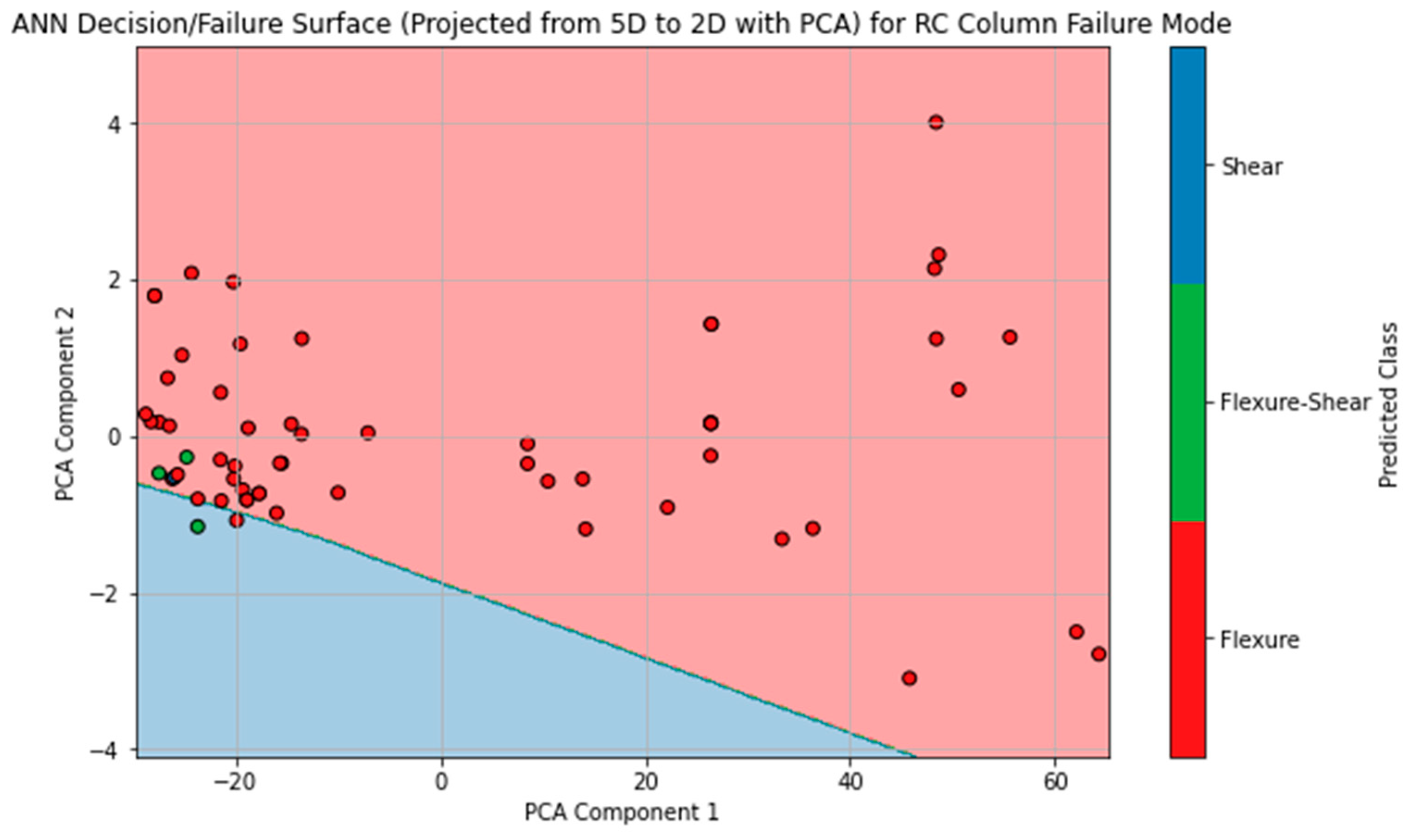

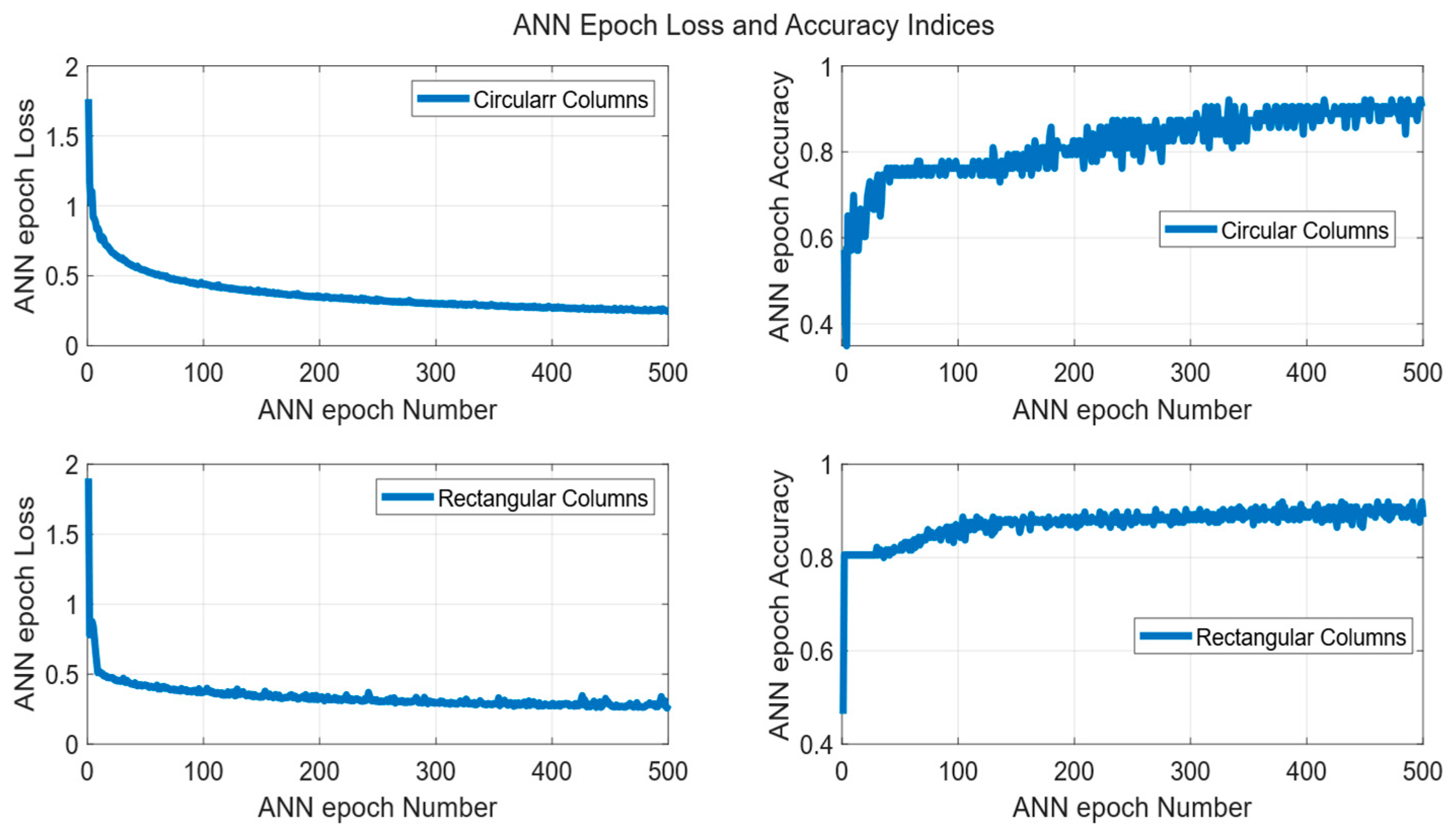

3. Results

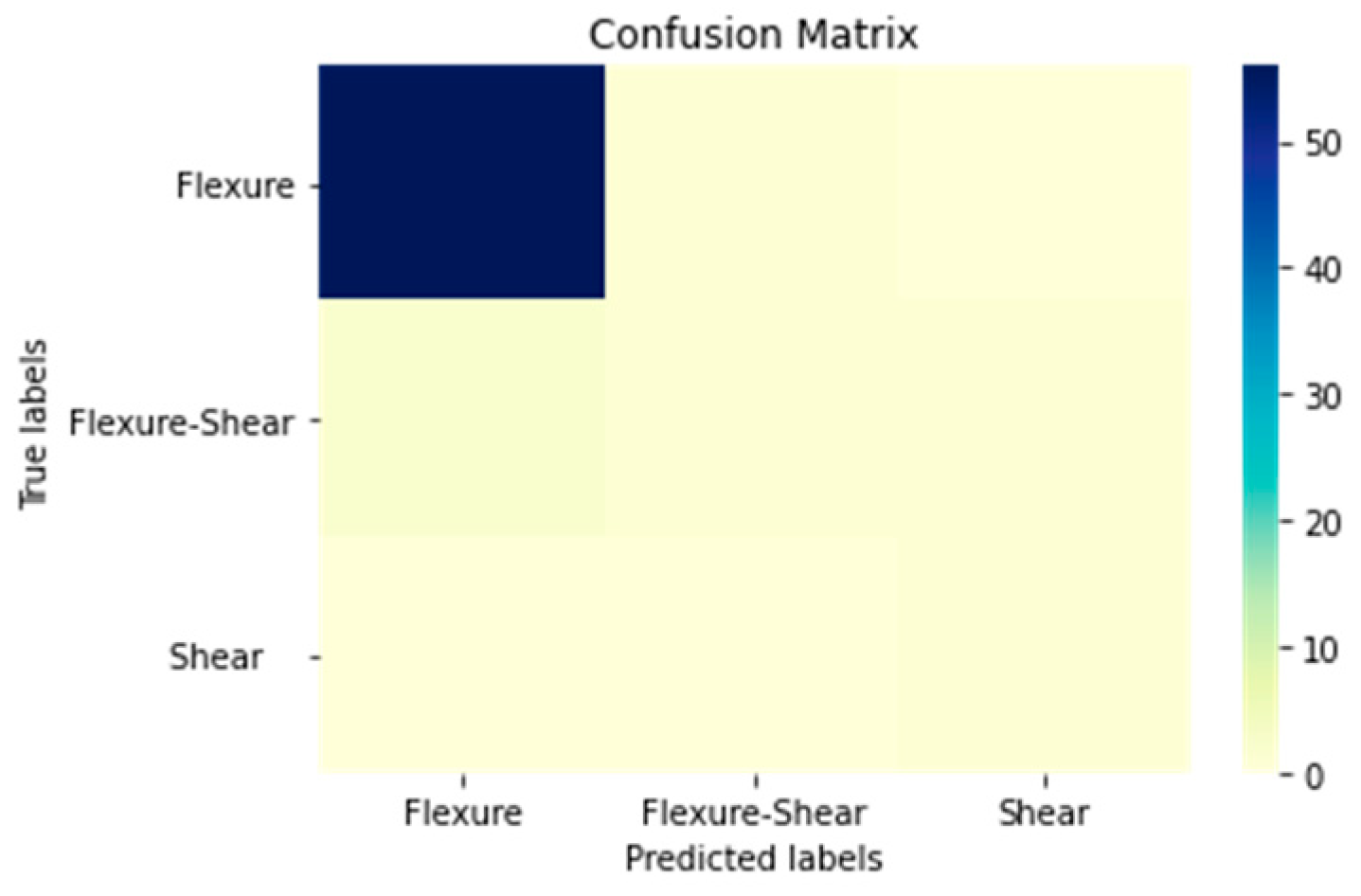

3.1. Rectangular RC Columns

- The receiver operating characteristic (ROC) curve demonstrates the balance between True acceptance rate (TAR) along the y-axis and false acceptance rate (FAR) along the x-axis. The upper left corner of the contour represents the ideal point where TAR equals one and FAR equals zero.

- The area under the curve (AUC) is used to quantify the quality of the authentication model as an alternative to accuracy. The value of AUC ranges from 0.0 to 1.0.

3.2. Circular RC Columns

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ML | Machine Learning |

| ANNs | Artificial Neural Networks |

| TP | True Positive |

| TN | True Negative |

| FP | False Positive |

| FN | False Negative |

| TAR | True Acceptance Rate |

| FAR | False Acceptance Rate |

| ROC | Receiver Operating Characteristic |

| AUC | Area Under Curve |

| PEER | Pacific Earthquake Engineering Research Center |

| RC | Reinforced Concrete |

Appendix A

| Feature Values | True Label Values (0 = Flexure, 1 = Flexure–Shear, 2 = Shear) | ||||

|---|---|---|---|---|---|

| Aspect Ratio | Axial Load Ratio | ρs (%) | fc (MPa) | vmax/√fc | Failure |

| 2.00 | 0.00 | 0.51 | 37.5 | 0.42 | 1 |

| 2.00 | 0.00 | 0.51 | 37.2 | 0.29 | 1 |

| 2.50 | 0.00 | 0.51 | 36 | 0.37 | 1 |

| 2.00 | 0.00 | 0.51 | 30.6 | 0.42 | 2 |

| 2.00 | 0.00 | 0.76 | 31.1 | 0.47 | 1 |

| 1.50 | 0.00 | 0.51 | 30.1 | 0.57 | 2 |

| 2.00 | 0.00 | 0.38 | 29.5 | 0.41 | 2 |

| 2.00 | 0.20 | 1.02 | 28.7 | 0.69 | 1 |

| 2.00 | 0.20 | 1.02 | 31.2 | 0.64 | 1 |

| 2.00 | 0.20 | 0.51 | 29.9 | 0.59 | 1 |

| 1.50 | 0.10 | 1.02 | 28.6 | 0.78 | 1 |

| 2.00 | 0.10 | 1.02 | 36.2 | 0.58 | 1 |

| 2.00 | 0.00 | 0.51 | 33.7 | 0.43 | 1 |

| 2.00 | 0.00 | 0.51 | 34.8 | 0.31 | 1 |

| 2.00 | 0.10 | 0.51 | 33.4 | 0.51 | 2 |

| 2.50 | 0.10 | 0.51 | 34.3 | 0.44 | 1 |

| 1.50 | 0.10 | 0.51 | 35 | 0.68 | 2 |

| 1.50 | 0.10 | 0.38 | 34.4 | 0.59 | 2 |

| 1.75 | 0.17 | 0.38 | 36.7 | 0.64 | 2 |

| 2.00 | 0.00 | 0.38 | 33.2 | 0.37 | 2 |

| 2.00 | 0.00 | 0.39 | 30.9 | 0.41 | 2 |

| 2.00 | 0.00 | 0.76 | 32.3 | 0.47 | 1 |

| 2.00 | 0.00 | 0.77 | 33.1 | 0.47 | 1 |

| 2.00 | 0.19 | 1.42 | 38 | 0.60 | 0 |

| 2.00 | 0.39 | 0.47 | 37 | 0.64 | 1 |

| 2.00 | 0.39 | 1.42 | 37 | 0.76 | 0 |

| 6.22 | 0.05 | 0.63 | 38.8 | 0.07 | 0 |

| 6.22 | 0.09 | 0.63 | 36.2 | 0.08 | 0 |

| 2.93 | 0.05 | 0.63 | 35.9 | 0.19 | 1 |

| 2.92 | 0.10 | 0.63 | 34.4 | 0.21 | 1 |

| 7.50 | 0.24 | 1.45 | 34.5 | 0.18 | 0 |

| 3.75 | 0.24 | 1.45 | 34.5 | 0.39 | 0 |

| 3.75 | 0.35 | 1.45 | 34.5 | 0.40 | 0 |

| 6.01 | 0.07 | 0.63 | 35.8 | 0.12 | 0 |

| 3.01 | 0.07 | 1.49 | 34.3 | 0.31 | 0 |

| 3.00 | 0.10 | 1.41 | 24.1 | 0.27 | 0 |

| 3.00 | 0.21 | 1.41 | 23.1 | 0.31 | 0 |

| 6.00 | 0.10 | 0.68 | 25.4 | 0.13 | 0 |

| 3.00 | 0.10 | 1.41 | 24.4 | 0.26 | 0 |

| 3.00 | 0.20 | 1.41 | 24.3 | 0.32 | 0 |

| 6.00 | 0.11 | 0.68 | 23.3 | 0.13 | 0 |

| 4.50 | 0.09 | 0.94 | 29 | 0.19 | 0 |

| 4.50 | 0.09 | 0.94 | 29 | 0.19 | 0 |

| 4.50 | 0.09 | 0.94 | 35.5 | 0.17 | 0 |

| 4.50 | 0.09 | 0.94 | 35.5 | 0.21 | 0 |

| 4.50 | 0.09 | 0.94 | 35.5 | 0.18 | 0 |

| 4.50 | 0.09 | 0.94 | 32.8 | 0.19 | 0 |

| 4.50 | 0.09 | 0.94 | 32.8 | 0.17 | 0 |

| 4.50 | 0.09 | 0.94 | 32.5 | 0.18 | 0 |

| 4.50 | 0.10 | 0.94 | 27 | 0.20 | 0 |

| 4.50 | 0.10 | 0.94 | 27 | 0.19 | 0 |

| 4.50 | 0.10 | 0.94 | 27 | 0.19 | 0 |

| 1.50 | 0.06 | 0.28 | 30 | 0.26 | 1 |

| 1.50 | 0.06 | 0.17 | 30 | 0.37 | 1 |

| 6.00 | 0.15 | 0.89 | 41.1 | 0.19 | 0 |

| 1.99 | 0.31 | 1.14 | 38.3 | 0.61 | 0 |

| 1.99 | −0.10 | 1.14 | 39.2 | 0.28 | 1 |

| 1.99 | 0.15 | 1.14 | 39.4 | 0.54 | 0 |

| 1.99 | 0.15 | 2.70 | 35 | 1.02 | 1 |

| 1.99 | −0.08 | 0.85 | 35.2 | 0.41 | 1 |

| 1.99 | 0.33 | 3.04 | 35 | 1.14 | 0 |

| 8.00 | 0.30 | 0.92 | 36.6 | 0.19 | 0 |

| 8.00 | 0.27 | 1.38 | 40 | 0.17 | 0 |

| 8.00 | 0.28 | 0.92 | 38.6 | 0.19 | 0 |

| 4.00 | 0.07 | 0.70 | 31 | 0.18 | 0 |

| 8.00 | 0.07 | 0.70 | 31 | 0.09 | 0 |

| 10.00 | 0.07 | 0.70 | 31 | 0.06 | 0 |

| 4.00 | 0.07 | 0.70 | 31 | 0.11 | 0 |

| 4.00 | 0.07 | 0.70 | 31 | 0.30 | 0 |

| 3.00 | 0.09 | 0.89 | 34.5 | 0.32 | 0 |

| 8.00 | 0.09 | 0.89 | 34.5 | 0.12 | 0 |

| 10.00 | 0.09 | 0.89 | 34.5 | 0.11 | 0 |

| 3.00 | 0.04 | 0.54 | 34.6 | 0.26 | 0 |

| 3.00 | 0.04 | 0.81 | 33 | 0.28 | 0 |

| 6.58 | 0.31 | 1.54 | 65 | 0.18 | 0 |

| 6.58 | 0.31 | 3.49 | 65 | 0.17 | 0 |

| 6.58 | 0.42 | 1.74 | 90 | 0.17 | 0 |

| 6.58 | 0.21 | 1.54 | 90 | 0.16 | 0 |

| 6.58 | 0.42 | 1.54 | 90 | 0.17 | 0 |

| 2.58 | 0.00 | 0.10 | 34.7 | 0.19 | 1 |

| 2.58 | 0.00 | 0.26 | 35.4 | 0.23 | 1 |

| 2.00 | 0.00 | 0.13 | 29.8 | 0.25 | 2 |

| 2.00 | 0.00 | 0.13 | 26.8 | 0.22 | 2 |

| 2.00 | 0.00 | 0.13 | 31.2 | 0.20 | 2 |

| Feature Values | True Label Values (0 = Flexure, 1 = Flexure–Shear, 2 = Shear) | ||||

|---|---|---|---|---|---|

| Aspect Ratio | Axial Load Ratio | ρs (%) | fc (MPa) | vmax/√fc | Failure |

| 2.18 | 0.26 | 1.50 | 23.1 | 0.48 | 0 |

| 2.18 | 0.21 | 2.30 | 41.4 | 0.42 | 0 |

| 2.18 | 0.42 | 2.00 | 21.4 | 0.48 | 0 |

| 2.18 | 0.60 | 3.50 | 23.5 | 0.47 | 0 |

| 4.00 | 0.38 | 2.83 | 23.6 | 0.25 | 0 |

| 4.00 | 0.21 | 2.22 | 25 | 0.21 | 0 |

| 4.00 | 0.10 | 0.86 | 46.5 | 0.18 | 0 |

| 4.00 | 0.30 | 1.22 | 44 | 0.26 | 0 |

| 4.00 | 0.30 | 0.80 | 44 | 0.26 | 0 |

| 4.00 | 0.30 | 0.57 | 40 | 0.26 | 0 |

| 4.00 | 0.22 | 1.56 | 28.3 | 0.25 | 0 |

| 4.00 | 0.39 | 1.99 | 40.1 | 0.27 | 0 |

| 4.00 | 0.50 | 0.66 | 41 | 0.29 | 0 |

| 4.00 | 0.50 | 0.32 | 40 | 0.29 | 0 |

| 4.00 | 0.70 | 1.26 | 42 | 0.29 | 0 |

| 4.00 | 0.70 | 0.70 | 39 | 0.30 | 0 |

| 4.00 | 0.70 | 2.33 | 40 | 0.31 | 0 |

| 4.00 | 0.20 | 2.55 | 25.6 | 0.21 | 0 |

| 4.00 | 0.20 | 2.55 | 25.6 | 0.21 | 0 |

| 4.00 | 0.20 | 2.55 | 25.6 | 0.22 | 0 |

| 4.00 | 0.20 | 2.55 | 25.6 | 0.21 | 0 |

| 3.00 | 0.10 | 1.70 | 32 | 0.23 | 0 |

| 3.00 | 0.10 | 1.70 | 32 | 0.24 | 0 |

| 3.00 | 0.30 | 2.08 | 32.1 | 0.36 | 0 |

| 3.00 | 0.30 | 2.08 | 32.1 | 0.36 | 0 |

| 2.97 | 0.10 | 2.17 | 26.9 | 0.32 | 0 |

| 1.50 | 0.33 | 1.18 | 20.6 | 0.57 | 0 |

| 1.50 | 0.17 | 0.81 | 21.6 | 0.47 | 2 |

| 1.50 | 0.35 | 1.39 | 21 | 0.61 | 1 |

| 4.00 | 0.03 | 0.32 | 24.8 | 0.15 | 0 |

| 4.00 | 0.03 | 0.32 | 24.8 | 0.14 | 0 |

| 4.00 | 0.03 | 0.32 | 24.8 | 0.14 | 0 |

| 2.00 | 0.14 | 0.57 | 32 | 0.45 | 1 |

| 2.00 | 0.15 | 0.57 | 29.9 | 0.51 | 1 |

| 1.65 | 0.05 | 0.36 | 27.1 | 0.45 | 2 |

| 2.00 | 0.80 | 0.73 | 21.1 | 0.58 | 1 |

| 2.00 | 0.80 | 0.73 | 21.1 | 0.61 | 0 |

| 2.00 | 0.90 | 1.75 | 21.1 | 0.57 | 1 |

| 3.00 | 0.70 | 0.73 | 28.8 | 0.41 | 1 |

| 3.00 | 0.70 | 0.73 | 28.8 | 0.40 | 1 |

| 3.00 | 0.70 | 1.75 | 28.8 | 0.38 | 1 |

| 3.00 | 0.11 | 0.38 | 27.9 | 0.25 | 0 |

| 3.00 | 0.11 | 0.38 | 27.9 | 0.24 | 0 |

| 3.00 | 0.11 | 0.38 | 27.9 | 0.25 | 0 |

| 3.00 | 0.12 | 0.38 | 24.8 | 0.27 | 0 |

| 3.00 | 0.11 | 0.38 | 27.9 | 0.25 | 0 |

| 3.00 | 0.11 | 0.38 | 27.9 | 0.23 | 0 |

| 1.25 | 0.18 | 0.21 | 31.8 | 0.71 | 2 |

| 1.25 | 0.45 | 0.21 | 33 | 0.72 | 2 |

| 2.50 | 0.40 | 1.61 | 85.7 | 0.66 | 0 |

| 2.50 | 0.63 | 1.61 | 85.7 | 0.65 | 0 |

| 2.50 | 0.63 | 1.61 | 85.7 | 0.67 | 0 |

| 2.50 | 0.25 | 1.61 | 115.8 | 0.59 | 0 |

| 2.50 | 0.25 | 1.61 | 115.8 | 0.59 | 0 |

| 2.50 | 0.42 | 1.61 | 115.8 | 0.67 | 0 |

| 2.50 | 0.42 | 1.61 | 115.8 | 0.67 | 0 |

| 1.50 | 0.26 | 0.91 | 25.8 | 0.64 | 1 |

| 1.50 | 0.62 | 0.91 | 25.8 | 0.67 | 1 |

| 2.00 | 0.35 | 0.50 | 99.5 | 0.66 | 0 |

| 2.00 | 0.35 | 0.75 | 99.5 | 0.66 | 0 |

| 2.00 | 0.35 | 0.61 | 99.5 | 0.69 | 0 |

| 2.00 | 0.35 | 0.50 | 99.5 | 0.65 | 0 |

| 2.00 | 0.35 | 0.50 | 99.5 | 0.65 | 0 |

| 2.00 | 0.35 | 0.50 | 99.5 | 0.67 | 0 |

| 2.00 | 0.35 | 0.50 | 99.5 | 0.65 | 0 |

| 1.16 | 0.74 | 0.89 | 46.3 | 0.98 | 1 |

| 2.88 | 0.12 | 0.33 | 34.7 | 0.36 | 1 |

| 2.88 | 0.12 | 0.33 | 34.7 | 0.37 | 0 |

| 2.88 | 0.15 | 0.48 | 26.1 | 0.44 | 1 |

| 2.88 | 0.15 | 0.48 | 26.1 | 0.41 | 0 |

| 2.88 | 0.11 | 0.33 | 33.6 | 0.35 | 1 |

| 2.88 | 0.11 | 0.33 | 33.6 | 0.39 | 0 |

| 2.88 | 0.07 | 0.33 | 33.6 | 0.33 | 2 |

| 2.88 | 0.07 | 0.33 | 33.6 | 0.35 | 0 |

| 2.88 | 0.11 | 0.67 | 33.4 | 0.38 | 1 |

| 2.88 | 0.11 | 0.67 | 33.4 | 0.37 | 0 |

| 2.88 | 0.11 | 1.47 | 33.5 | 0.45 | 1 |

| 2.88 | 0.11 | 1.47 | 33.5 | 0.45 | 0 |

| 2.88 | 0.11 | 0.92 | 33.5 | 0.45 | 1 |

| 2.88 | 0.11 | 0.92 | 33.5 | 0.45 | 0 |

| 5.50 | 0.10 | 1.54 | 29.1 | 0.12 | 0 |

| 5.50 | 0.09 | 0.93 | 30.7 | 0.12 | 0 |

| 5.50 | 0.10 | 1.54 | 29.2 | 0.12 | 0 |

| 5.50 | 0.10 | 0.93 | 27.6 | 0.15 | 0 |

| 5.50 | 0.20 | 1.54 | 29.4 | 0.15 | 0 |

| 5.50 | 0.18 | 0.93 | 31.8 | 0.14 | 0 |

| 5.50 | 0.26 | 1.54 | 33.3 | 0.15 | 0 |

| 5.50 | 0.27 | 0.93 | 32.4 | 0.15 | 0 |

| 5.50 | 0.28 | 1.54 | 31 | 0.16 | 0 |

| 5.50 | 0.27 | 0.93 | 31.8 | 0.15 | 0 |

| 1.11 | 0.16 | 0.28 | 34.9 | 0.58 | 2 |

| 1.98 | 0.16 | 0.31 | 34.9 | 0.47 | 2 |

| 1.11 | 0.27 | 0.28 | 42 | 0.67 | 2 |

| 1.50 | 0.10 | 0.26 | 29.9 | 0.42 | 2 |

| 3.00 | 0.21 | 2.19 | 39.3 | 0.36 | 0 |

| 3.00 | 0.31 | 1.26 | 39.8 | 0.37 | 0 |

| 2.86 | 0.00 | 0.85 | 43.6 | 0.34 | 0 |

| 2.86 | 0.14 | 1.69 | 34.8 | 0.38 | 0 |

| 2.86 | 0.15 | 2.54 | 32 | 0.47 | 0 |

| 2.86 | 0.13 | 1.95 | 37.3 | 0.46 | 0 |

| 2.86 | 0.13 | 1.95 | 39 | 0.45 | 0 |

| 4.56 | 0.30 | 1.22 | 80 | 0.23 | 0 |

| 4.56 | 0.30 | 1.22 | 80 | 0.22 | 0 |

| 4.56 | 0.20 | 1.22 | 80 | 0.18 | 0 |

| 4.56 | 0.20 | 1.22 | 80 | 0.25 | 0 |

| 4.56 | 0.20 | 1.83 | 80 | 0.25 | 0 |

| 4.56 | 0.30 | 1.83 | 80 | 0.23 | 0 |

| 4.56 | 0.30 | 1.83 | 80 | 0.23 | 0 |

| 4.56 | 0.20 | 1.83 | 80 | 0.20 | 0 |

| 4.56 | 0.20 | 3.66 | 80 | 0.18 | 0 |

| 4.56 | 0.30 | 3.66 | 80 | 0.23 | 0 |

| 4.56 | 0.20 | 3.66 | 80 | 0.24 | 0 |

| 4.56 | 0.30 | 3.66 | 80 | 0.24 | 0 |

| 4.56 | 0.20 | 1.22 | 80 | 0.31 | 0 |

| 4.56 | 0.30 | 1.22 | 80 | 0.30 | 0 |

| 4.56 | 0.30 | 1.22 | 80 | 0.31 | 0 |

| 4.56 | 0.20 | 1.22 | 80 | 0.37 | 0 |

| 4.56 | 0.20 | 1.83 | 80 | 0.29 | 0 |

| 4.56 | 0.20 | 1.83 | 80 | 0.35 | 0 |

| 4.56 | 0.30 | 1.83 | 80 | 0.31 | 0 |

| 4.56 | 0.30 | 1.83 | 80 | 0.31 | 0 |

| 4.56 | 0.20 | 3.66 | 80 | 0.31 | 0 |

| 4.56 | 0.20 | 3.66 | 80 | 0.31 | 0 |

| 4.56 | 0.30 | 3.66 | 80 | 0.30 | 0 |

| 4.56 | 0.30 | 3.66 | 80 | 0.32 | 0 |

| 3.83 | 0.10 | 0.37 | 27.2 | 0.30 | 0 |

| 3.83 | 0.24 | 0.37 | 27.2 | 0.33 | 0 |

| 3.83 | 0.09 | 0.48 | 28.1 | 0.31 | 0 |

| 3.83 | 0.23 | 0.48 | 28.1 | 0.35 | 0 |

| 3.22 | 0.09 | 0.08 | 26.9 | 0.26 | 2 |

| 3.22 | 0.07 | 0.08 | 33.1 | 0.20 | 1 |

| 3.22 | 0.28 | 0.08 | 25.5 | 0.29 | 1 |

| 3.22 | 0.26 | 0.08 | 27.6 | 0.30 | 2 |

| 3.22 | 0.26 | 0.25 | 27.6 | 0.32 | 2 |

| 3.22 | 0.09 | 0.08 | 26.9 | 0.25 | 2 |

| 3.22 | 0.07 | 0.08 | 33.1 | 0.19 | 1 |

| 3.22 | 0.28 | 0.25 | 25.5 | 0.35 | 1 |

| 2.00 | 0.10 | 3.67 | 76 | 0.58 | 0 |

| 2.00 | 0.20 | 3.67 | 76 | 0.67 | 0 |

| 2.00 | 0.10 | 3.67 | 86 | 0.46 | 0 |

| 2.00 | 0.19 | 3.67 | 86 | 0.53 | 0 |

| 2.00 | 0.10 | 1.63 | 86 | 0.45 | 1 |

| 2.00 | 0.19 | 1.63 | 86 | 0.54 | 1 |

| 2.00 | 0.60 | 0.90 | 118 | 0.61 | 0 |

| 2.00 | 0.60 | 1.41 | 118 | 0.66 | 0 |

| 2.00 | 0.60 | 1.82 | 118 | 0.74 | 0 |

| 2.00 | 0.35 | 1.41 | 118 | 0.67 | 0 |

| 2.00 | 0.35 | 1.82 | 118 | 0.67 | 0 |

| 7.64 | 0.34 | 0.12 | 40.6 | 0.13 | 0 |

| 6.04 | 0.50 | 3.15 | 72.1 | 0.19 | 0 |

| 6.04 | 0.36 | 2.84 | 71.7 | 0.19 | 0 |

| 6.04 | 0.50 | 2.84 | 71.8 | 0.19 | 0 |

| 6.04 | 0.50 | 5.12 | 71.9 | 0.19 | 0 |

| 6.04 | 0.45 | 4.02 | 101.8 | 0.21 | 0 |

| 6.04 | 0.46 | 6.74 | 101.9 | 0.21 | 0 |

| 6.04 | 0.45 | 2.72 | 102 | 0.18 | 0 |

| 6.04 | 0.47 | 4.29 | 102.2 | 0.19 | 0 |

| 4.70 | 0.43 | 1.00 | 34 | 0.27 | 0 |

| 4.70 | 0.43 | 2.00 | 34 | 0.27 | 0 |

| 4.70 | 0.20 | 2.00 | 34 | 0.23 | 0 |

| 4.70 | 0.46 | 1.33 | 34 | 0.29 | 0 |

| 4.70 | 0.46 | 2.66 | 34 | 0.33 | 0 |

| 4.70 | 0.46 | 2.66 | 34 | 0.31 | 0 |

| 4.70 | 0.46 | 1.26 | 34 | 0.30 | 0 |

| 4.70 | 0.23 | 1.26 | 34 | 0.28 | 0 |

| 4.70 | 0.46 | 1.26 | 34 | 0.31 | 0 |

| 4.70 | 0.46 | 2.66 | 34 | 0.33 | 0 |

| 3.00 | 0.05 | 1.00 | 69.6 | 0.20 | 0 |

| 3.00 | 0.05 | 1.00 | 69.6 | 0.20 | 0 |

| 3.00 | 0.10 | 1.00 | 67.8 | 0.28 | 0 |

| 3.00 | 0.10 | 1.00 | 67.8 | 0.28 | 0 |

| 3.00 | 0.21 | 1.00 | 65.5 | 0.32 | 0 |

| 3.00 | 0.21 | 1.00 | 65.5 | 0.31 | 0 |

| 3.00 | 0.00 | 1.00 | 37.9 | 0.23 | 0 |

| 3.00 | 0.00 | 1.00 | 37.9 | 0.23 | 0 |

| 3.00 | 0.14 | 1.00 | 48.3 | 0.25 | 0 |

| 3.00 | 0.14 | 1.00 | 48.3 | 0.25 | 0 |

| 3.00 | 0.36 | 1.00 | 38.1 | 0.33 | 0 |

| 3.00 | 0.36 | 1.00 | 38.1 | 0.33 | 0 |

| 3.50 | 0.11 | 0.76 | 24.9 | 0.31 | 0 |

| 3.50 | 0.16 | 0.76 | 26.7 | 0.32 | 0 |

| 3.50 | 0.22 | 0.76 | 26.1 | 0.37 | 0 |

| 3.50 | 0.11 | 0.73 | 25.3 | 0.31 | 0 |

| 3.50 | 0.16 | 0.73 | 27.1 | 0.34 | 0 |

| 3.50 | 0.21 | 0.73 | 26.8 | 0.37 | 0 |

| 3.50 | 0.11 | 0.71 | 26.38 | 0.31 | 0 |

| 3.50 | 0.15 | 0.71 | 27.48 | 0.34 | 0 |

| 3.50 | 0.21 | 0.71 | 26.9 | 0.36 | 0 |

| 2.67 | 0.00 | 0.04 | 21.9 | 0.23 | 2 |

| 1.33 | 0.00 | 0.09 | 16 | 0.38 | 2 |

| 3.92 | 0.00 | 0.96 | 102.7 | 0.20 | 0 |

| 3.92 | 0.20 | 0.96 | 86.3 | 0.34 | 0 |

| 3.92 | 0.00 | 0.96 | 87.5 | 0.19 | 0 |

| 3.92 | 0.10 | 0.96 | 83.4 | 0.26 | 0 |

| 3.92 | 0.20 | 0.96 | 90 | 0.30 | 0 |

| 3.92 | 0.00 | 0.96 | 67.5 | 0.21 | 0 |

| 3.92 | 0.10 | 0.96 | 74.6 | 0.26 | 0 |

| 3.92 | 0.20 | 0.96 | 81.8 | 0.27 | 0 |

| 3.92 | 0.20 | 0.77 | 75.8 | 0.28 | 0 |

| 3.92 | 0.20 | 0.64 | 87 | 0.29 | 0 |

| 3.92 | 0.20 | 0.54 | 71.2 | 0.27 | 0 |

| 3.22 | 0.15 | 0.25 | 21.1 | 0.33 | 1 |

| 3.22 | 0.61 | 0.25 | 21.1 | 0.37 | 1 |

| 3.22 | 0.15 | 0.25 | 21.8 | 0.30 | 1 |

| 6.56 | 0.14 | 2.50 | 92.4 | 0.14 | 0 |

| 6.56 | 0.28 | 2.50 | 93.3 | 0.18 | 0 |

| 6.56 | 0.39 | 2.50 | 98.2 | 0.21 | 0 |

| 6.56 | 0.14 | 1.16 | 94.8 | 0.12 | 0 |

| 6.56 | 0.26 | 1.16 | 97.7 | 0.18 | 0 |

| 6.56 | 0.37 | 1.16 | 104.3 | 0.19 | 0 |

| 6.56 | 0.40 | 2.50 | 78.7 | 0.21 | 0 |

| 6.56 | 0.41 | 2.50 | 109.2 | 0.22 | 0 |

| 6.56 | 0.35 | 1.93 | 109.5 | 0.20 | 0 |

| 6.56 | 0.37 | 1.33 | 104.2 | 0.21 | 0 |

| 6.56 | 0.53 | 1.93 | 104.5 | 0.21 | 0 |

| 6.56 | 0.51 | 2.50 | 109.4 | 0.22 | 0 |

| 2.25 | 0.08 | 0.57 | 33.7 | 0.42 | 0 |

| 2.25 | 0.08 | 0.57 | 33.7 | 0.42 | 0 |

| 2.25 | 0.09 | 1.64 | 32.1 | 0.44 | 0 |

| 2.25 | 0.09 | 1.64 | 32.1 | 0.44 | 0 |

| 2.25 | 0.10 | 0.82 | 29.9 | 0.45 | 0 |

| 2.25 | 0.10 | 0.82 | 29.9 | 0.45 | 0 |

| 2.25 | 0.10 | 1.09 | 27.4 | 0.47 | 0 |

| 2.25 | 0.10 | 1.09 | 27.4 | 0.47 | 0 |

| 2.25 | 0.16 | 0.82 | 36.4 | 0.47 | 0 |

| 2.25 | 0.16 | 0.82 | 36.4 | 0.47 | 0 |

| 2.25 | 0.08 | 1.09 | 34.9 | 0.42 | 0 |

| 2.25 | 0.08 | 1.09 | 34.9 | 0.42 | 0 |

| 2.25 | 0.08 | 1.09 | 36.5 | 0.42 | 0 |

| 2.25 | 0.08 | 1.09 | 36.5 | 0.42 | 0 |

| 2.50 | 0.30 | 0.59 | 37.6 | 0.52 | 0 |

| 2.50 | 0.60 | 0.59 | 37.6 | 0.49 | 0 |

| 2.00 | 0.57 | 0.99 | 39.2 | 0.55 | 0 |

| 2.00 | 0.57 | 0.99 | 39.2 | 0.59 | 0 |

| 2.14 | 0.59 | 0.99 | 32.2 | 0.67 | 0 |

| 3.11 | 0.03 | 0.23 | 35.9 | 0.16 | 0 |

| 3.11 | 0.03 | 0.23 | 35.7 | 0.15 | 0 |

| 3.11 | 0.03 | 0.23 | 34.3 | 0.16 | 0 |

| 3.11 | 0.03 | 0.23 | 33.2 | 0.17 | 0 |

| 3.11 | 0.03 | 0.23 | 36.8 | 0.16 | 0 |

| 3.11 | 0.03 | 0.23 | 35.9 | 0.18 | 0 |

| 3.49 | 0.20 | 1.85 | 64.1 | 0.35 | 0 |

| 3.49 | 0.33 | 1.85 | 62.1 | 0.40 | 0 |

| 3.49 | 0.22 | 1.48 | 62.1 | 0.36 | 0 |

| 3.49 | 0.32 | 1.48 | 62.1 | 0.40 | 0 |

| 3.49 | 0.20 | 1.23 | 64.1 | 0.34 | 0 |

| 3.49 | 0.20 | 1.23 | 64.1 | 0.34 | 0 |

References

- Megalooikonomou, K.G. Modeling the Behavior of Shear-Critical Reinforced Concrete Columns Under Lateral Loads. Ph.D. Thesis, Department of Civil and Environmental Engineering, Faculty of Engineering, University of Cyprus, Nicosia, Cyprus, December 2019. [Google Scholar] [CrossRef]

- Megalooikonomou, K.G. Seismic Assessment and Retrofit of Reinforced Concrete Columns, 1st ed.; Cambridge Scholars Publishing: Newcastle upon Tyne, UK, 2024; p. 387. [Google Scholar]

- Mangalathu, S.; Jeon, J.-S. Machine Learning-Based Failure Mode Recognition of Circular Reinforced Concrete Bridge Columns: Comparative Study. ASCE J. Struct. Eng. 2019, 145, 04019104. [Google Scholar] [CrossRef]

- Xie, Y.; Sichani, M.E.; Padgett, J.E.; DesRoches, R. The promise of implementing machine learning in earthquake engineering: A state-of-the-art review. Earthq. Spectra 2020, 36, 1769–1801. [Google Scholar] [CrossRef]

- Ghosh, J.; Padgett, J.E.; Dueñas-Osorio, L. Surrogate modeling and failure surface visualization for efficient seismic vulnerability assessment of highway bridges. Probab. Eng. Mech. 2013, 34, 189–199. [Google Scholar] [CrossRef]

- Jeon, J.-S.; Shafieezadeh, A.; DesRoches, R. Statistical models for shear strength of RC beam-column joints using machine-learning techniques. Earthq. Eng. Struct. Dyn. 2014, 43, 2075–2095. [Google Scholar] [CrossRef]

- Krishnan, N.; Mangalathu, S.; Smedskjaer, M.M.; Tandia, A.; Burton, H.; Bauchy, M. Predicting the dissolution kinetics of silicate glasses using machine learning. J. Non-Cryst. Solids 2017, 487, 37–45. [Google Scholar] [CrossRef]

- Mangalathu, S.; Heo, G.; Jeon, J.-S. Artificial neural network based multi-dimensional fragility development of skewed concrete bridge classes. Eng. Struct. 2018, 162, 166–176. [Google Scholar] [CrossRef]

- Mangalathu, S.; Jeon, J.-S. Classification of failure mode and prediction of shear strength for reinforced concrete beam-column joints using machine learning techniques. Eng. Struct. 2018, 160, 85–94. [Google Scholar] [CrossRef]

- Wang, Z.; Pedroni, N.; Zentner, I.; Zio, E. Seismic fragility analysis with artificial neural networks: Application to nuclear power plant equipment. Eng. Struct. 2018, 162, 213–225. [Google Scholar] [CrossRef]

- Zhang, Y.; Burton, H.V.; Sun, H.; Shokrabadi, M. A machine learning framework for assessing post-earthquake structural safety. Struct. Saf. 2018, 72, 1–16. [Google Scholar] [CrossRef]

- Mitra, N.; Mitra, S.; Lowes, L.N. Probabilistic model for failure initiation of reinforced concrete interior beam-column connections subjected to seismic loading. Eng. Struct. 2011, 33, 154–162. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Afan, H.A.; Tran, M.T. Beam-column joint shear prediction using hybridized deep learning neural network with genetic algorithm. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 012025. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, Y.; Wu, D.; Liu, Z.; Zhang, H.; Zhu, M.; Chen, Z.; Sun, J.; Wang, X. An experimental investigation and machine learning-based prediction for seismic performance of steel tubular column filled with recycled aggregate concrete. Rev. Adv. Mater. Sci. 2022, 61, 849–872. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, Y.; Wu, D.; Chen, M.; Pang, L.; Sun, J.; Feng, W.; Wang, X. Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis. Rev. Adv. Mater. Sci. 2023, 62, 20230347. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Mirzazadeh, A.; Weber, G.-W.; Pasandideh, S.H.R. A robust fuzzy approach for constrained multi-product economic production quantity with imperfect items and rework process. Optimization 2020, 69, 63–90. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Khalilpourazary, S. SCWOA: An efficient hybrid algorithm for parameter optimization of multi-pass milling process. J. Ind. Prod. Eng. 2018, 35, 135–147. [Google Scholar] [CrossRef]

- Çiftçioglu, A.Ӧ. RAGN-L: A Stacked Ensemble Learning Technique for Classification of Fire-Resistant Columns. Expert Syst. Appl. 2024, 240, 122491. [Google Scholar] [CrossRef]

- Naderpour, H.; Mirrashid, M.; Parsa, P. Failure mode prediction of reinforced concrete columns using machine learning methods. Eng. Struct. 2021, 248, 113263. [Google Scholar] [CrossRef]

- Carbas, S. Design optimization of steel frames using an enhanced firefly algorithm. Eng. Optim. 2016, 48, 2007–2025. [Google Scholar] [CrossRef]

- Grzywinski, M.; Dede, T.; Ozdemír, Y.I. Optimization of the braced dome structures by using Jaya algorithm with frequency constraints. Steel Compos. Struct. 2019, 30, 47–55. [Google Scholar]

- Shehab, B.A.; Ekmekyapar, T. Connection behaviour of through reinforced concrete beam to concrete-filled steel tube column after exposed to heating. Fire Saf. J. 2022, 133, 103666. [Google Scholar] [CrossRef]

- Ozturk, B.; Cetin, H.; Aydin, E. Optimum vertical location and design of multiple tuned mass dampers under seismic excitations. Structures 2022, 41, 1141–1163. [Google Scholar] [CrossRef]

- Ciftcioglu, A.Ӧ.; Ustuner, B.; Dogan, E.; Arafat, S.; Hussain, A. Taguchi-enhanced Grey Wolf Optimizer for robust design of cellular beams. Mech. Based Des. Struct. Mach. 2024, 52, 5739–5768. [Google Scholar] [CrossRef]

- Yang, S.; Chen, H.; Feng, Z.; Qin, Y.; Zhang, J.; Cao, Y.; Liu, Y. Intelligent multiobjective optimization for high-performance concrete mix proportion design: A hybrid machine learning approach. Eng. Appl. Artif. Intell. 2023, 126, 106868. [Google Scholar] [CrossRef]

- Marani, A.; Zhang, L.; Nehdi, M.L. Design of concrete incorporating microencapsulated phase change materials for clean energy: A ternary machine learning approach based on generative adversarial networks. Eng. Appl. Artif. Intell. 2023, 118, 105652. [Google Scholar] [CrossRef]

- Ghoreishi, M.; Mirzazadeh, A.; Weber, G.-W. Optimal pricing and ordering policy for non-instantaneous deteriorating items under inflation and customer returns. Optimization 2014, 63, 1785–1804. [Google Scholar] [CrossRef]

- Çiftçioglu, A.Ӧ.; Naser, M.Z. Fire resistance evaluation through synthetic fire tests and generative adversarial networks. Front. Struct. Civ. Eng. 2024, 18, 587–614. [Google Scholar] [CrossRef]

- Üstüner, B.; Aydogdu, I.; Ozyürek, C.; Dogan, E. A comparative analysis of metaheuristic algorithms for optimizing curved roof structures. Structures 2024, 70, 107722. [Google Scholar] [CrossRef]

- Zhou, X.-Q.; Huang, B.-G.; Wang, X.-Y.; Xia, Y. Deep learning-based prediction of structural responses of RC slabs subjected to blast loading. Eng. Struct. 2024, 311, 118184. [Google Scholar] [CrossRef]

- Yan, H.; Xie, N.; Shen, D. Hybrid Optimized Algorithms for Predicting Punching Shear Strength in Flat Slabs Considering Failure modes. KSCE J. Civ. Eng. 2025, 29, 100079. [Google Scholar] [CrossRef]

- Shen, Y.; Wu, L.; Liang, S. Explainable machine learning-based model for failure mode identification of RC flat slabs without transverse reinforcement. Eng. Fail. Anal. 2022, 141, 106647. [Google Scholar] [CrossRef]

- Zhao, C.; Zhu, Y.; Zhou, Z. Machine learning-based approaches for predicting the dynamic response of RC slabs under blast loads. Eng. Struct. 2022, 273, 115104. [Google Scholar] [CrossRef]

- Albostami, A.S.; Mohamad, S.A.; Alzabeebee, S.; Al-Hamd, R.K.S.; Al-Bander, B. Optimized punching shear design in steel fiber-reinforced slabs: Machine learning vs. evolutionary prediction models. Eng. Struct. 2025, 322, 119150. [Google Scholar] [CrossRef]

- Çiftçioğlu, A.Ӧ. Exploring failure mechanisms in reinforced concrete slab-column joints: Machine learning and causal analysis. Eng. Fail. Anal. 2025, 174, 109549. [Google Scholar] [CrossRef]

- Megalooikonomou, K.G.; Beligiannis, G.N. Random Forests Machine Learning Applied to PEER Structural Performance Experimental Columns Database. Appl. Sci. 2023, 13, 12821. [Google Scholar] [CrossRef]

- Berry, M.P.; Parrish, M.; Eberhard, M.O. PEER Structural Performance Database User’s Manual, Version 1.0; Pacific Earthquake Engineering Research Center (PEER) Report; University of California: Berkeley, CA, USA, 2004; Available online: http://nisee.berkeley.edu/spd/ (accessed on 30 July 2025).

- EN 1998-3; Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- ASCE/SEI 41; Seismic Rehabilitation of Existing Buildings. American Society of Civil Engineers: Reston, VA, USA, 2007.

- Filippou, F.C.; Constantinides, M. FEDEAS Lab—Getting Started Guide and Simulation Examples, NEESgrid Report 2004-22 and SEMM Report 2004-05. 2004. Available online: https://fedeas.net/ (accessed on 1 August 2025).

- Filippou, F.C.; Fenves, G.L. Methods of analysis for earthquake-resistant structures. In Earthquake Engineering: From Engineering Seismology to Performance-Based Engineering; Bozorgnia, Y., Bertero, V.V., Eds.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- MATLAB: User’s Guide, Version R2024b; Mathworks Inc.: Natick, MA, USA, 2024.

- The FEMA 440 Report. Improvement of Nonlinear Static Seismic Analysis Procedures; Federal Emergency Management Agency (FEMA): Washington, DC, USA, 2005; p. 392.

- Scott, B.D.; Park, R.; Priestley, M.J.N. Stress-strain behavior of concrete confined by overlapping hoops at low and high strain rates. Am. Concr. Inst. J. 1982, 79, 13–27. [Google Scholar]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. ASCE 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Menegotto, M.; Pinto, E. Method of Analysis for Cyclically Loaded Reinforced Concrete Plane Frames Including Changes in Geometry and Nonelastic Behavior of Elements under Combined Normal Force and Bending. In Proceedings of the IABSE Symposium on Resistance and Ultimate Deformability of Structures Acted on by Well-Defined Repeated Loads, Final Report, Lisbon, Portugal, 13–14 September 1973. [Google Scholar]

- Megalooikonomou, K.G. Random Forests Machine Learning Applied to PEER Structural Performance Experimental Columns Database. Master’s Thesis, School of Science and Technology, Hellenic Open University, Patras, Greece, 2025. in press. [Google Scholar]

- Burkov, A. The Hundred-Page Machine Learning Book; Andriy Burkov: Quebec City, QC, Canada, 2019; pp. 3–11. Available online: https://themlbook.com/ (accessed on 20 July 2025).

- Kim, S.; Hwang, H.; Oh, K.; Shin, J. A Machine-Learning-Based Failure Mode Classification Model for Reinforced Concrete Columns Using Simple Structural Information. Appl. Sci. 2024, 14, 1243. [Google Scholar] [CrossRef]

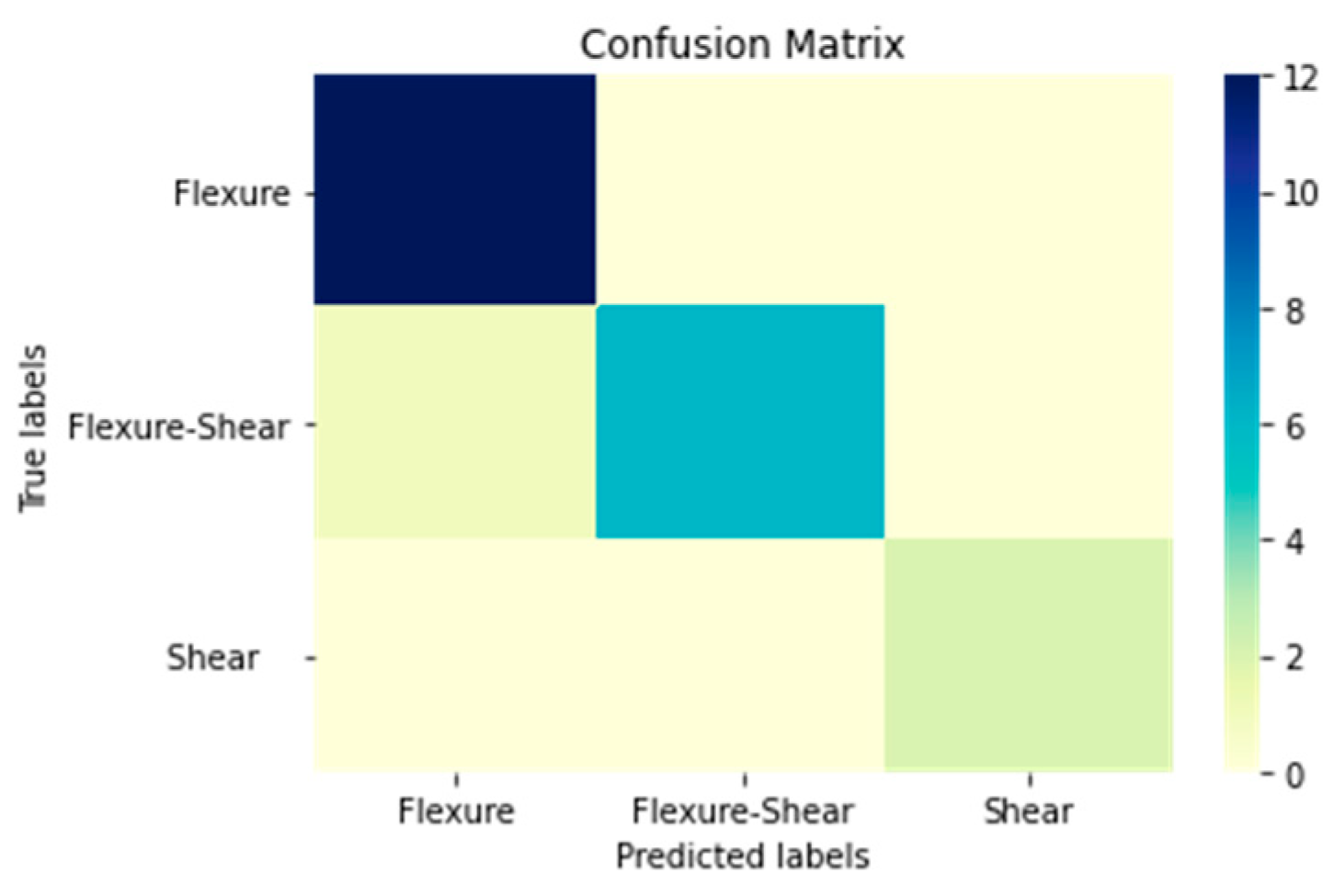

| Confusion Matrix in Numbers | ||||

|---|---|---|---|---|

| True Values | Flexure | 12 | 0 | 0 |

| Flexure–Shear | 2 | 5 | 0 | |

| Shear | 0 | 2 | 0 | |

| Flexure | Flexure–Shear | Shear | ||

| Predicted Values | ||||

| Confusion Matrix in Numbers | ||||

|---|---|---|---|---|

| True Values | Flexure | 57 | 0 | 0 |

| Flexure–Shear | 1 | 3 | 0 | |

| Shear | 1 | 0 | 0 | |

| Flexure | Flexure–Shear | Shear | ||

| Predicted Values | ||||

| Activation Function | Equation | Application |

|---|---|---|

| ReLu | F(x) = max(0, x) | Classification Problems with many hidden layers |

| Softmax | Non-binary classification problems and applied to the output layer |

| Cost Function | Equation | Application |

|---|---|---|

| Multiclass Cross Entropy (MCE) | Non-binary classification problems |

| Confusion Matrix in Numbers * | ||||

|---|---|---|---|---|

| True Values | Flexure | 56 | 1 | 0 |

| Flexure–Shear | 2 | 1 | 1 | |

| Shear | 0 | 0 | 1 | |

| Flexure | Flexure–Shear | Shear | ||

| Predicted Values | ||||

| Performance Metrics * | |||||||

|---|---|---|---|---|---|---|---|

| True Positive | True Negative | False Positive | False Negative | Accuracy | Precision | Recall | |

| Flexure | 56 | 1 + 1 + 1 + 0 = 3 | 2 + 0 = 2 | 1 + 0 = 1 | (56 + 3)/(56 + 3 + 2 + 1) = 59/62 = 95% | (56)/(56 + 2) = 56/58 = 97% | (56)/(56 + 1) = 56/57 = 98% |

| Flexure–Shear | 1 | 56 + 0 + 0 + 1= 57 | 1 + 0 =1 | 2 + 1 = 3 | (1 + 57)/(1 + 57 + 1 + 3) = 58/62 = 94% | (1)/(1 + 1) = 1/2 = 50% | (1)/(1 + 3) = 1/4 = 25% |

| Shear | 1 | 56 +1 + 2 + 1 = 60 | 1 + 0 = 1 | 0 + 0 = 0 | (1 + 60)/(1 + 60 + 1 + 0) = 61/62 = 98% | (1)/(1 + 1) = 1/2 = 50% | (1)/(1 + 0) = 1/1 = 100% |

| Confusion Matrix in Numbers * | ||||

|---|---|---|---|---|

| True Values | Flexure | 12 | 0 | 0 |

| Flexure–Shear | 1 | 6 | 0 | |

| Shear | 0 | 0 | 2 | |

| Flexure | Flexure–Shear | Shear | ||

| Predicted Values | ||||

| Performance Metrics * | |||||||

|---|---|---|---|---|---|---|---|

| True Positive | True Negative | False Positive | False Negative | Accuracy | Precision | Recall | |

| Flexure | 12 | 6 + 0 + 0 + 2 = 8 | 1 + 0 = 1 | 0 + 0 = 0 | (12 + 8)/(12 + 8 + 1 + 0) = 20/21 = 95% | (12)/(12 + 1) = 12/13 = 92% | (12)/(12 + 0) = 12/12 = 100% |

| Flexure–Shear | 6 | 12 + 0 + 0 + 2 = 14 | 0 + 0 = 0 | 1 + 0 = 1 | (6 + 14)/(6 + 14 + 0 + 1) = 20/21 = 95% | (6)/(6 + 0) = 6/6 = 100% | (6)/(6 + 1) = 6/7 = 86% |

| Shear | 2 | 12 +0 + 1 + 6 = 19 | 0 + 0 = 0 | 0 + 0 = 0 | (2 + 19)/(2 + 19 + 0 + 0) = 21/21 = 100% | (2)/(2 + 0) = 2/2 = 100% | (2)/(2 + 0) = 2/2 = 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Megalooikonomou, K.G.; Beligiannis, G.N. Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data. Appl. Sci. 2025, 15, 10175. https://doi.org/10.3390/app151810175

Megalooikonomou KG, Beligiannis GN. Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data. Applied Sciences. 2025; 15(18):10175. https://doi.org/10.3390/app151810175

Chicago/Turabian StyleMegalooikonomou, Konstantinos G., and Grigorios N. Beligiannis. 2025. "Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data" Applied Sciences 15, no. 18: 10175. https://doi.org/10.3390/app151810175

APA StyleMegalooikonomou, K. G., & Beligiannis, G. N. (2025). Application of Supervised Neural Networks to Classify Failure Modes in Reinforced Concrete Columns Using Basic Structural Data. Applied Sciences, 15(18), 10175. https://doi.org/10.3390/app151810175