Hybrid AI-Driven Computer-Aided Engineering Optimization: Large Language Models Versus Regression-Based Models Validated Through Finite-Element Analysis

Abstract

1. Introduction

2. Literature Review

2.1. Applications and Comparisons of Various Optimization Approaches

2.2. Applications of Artificial Intelligence Tools in Engineering Domains

2.3. Prompt Engineering Strategies and Developments

3. Methodology

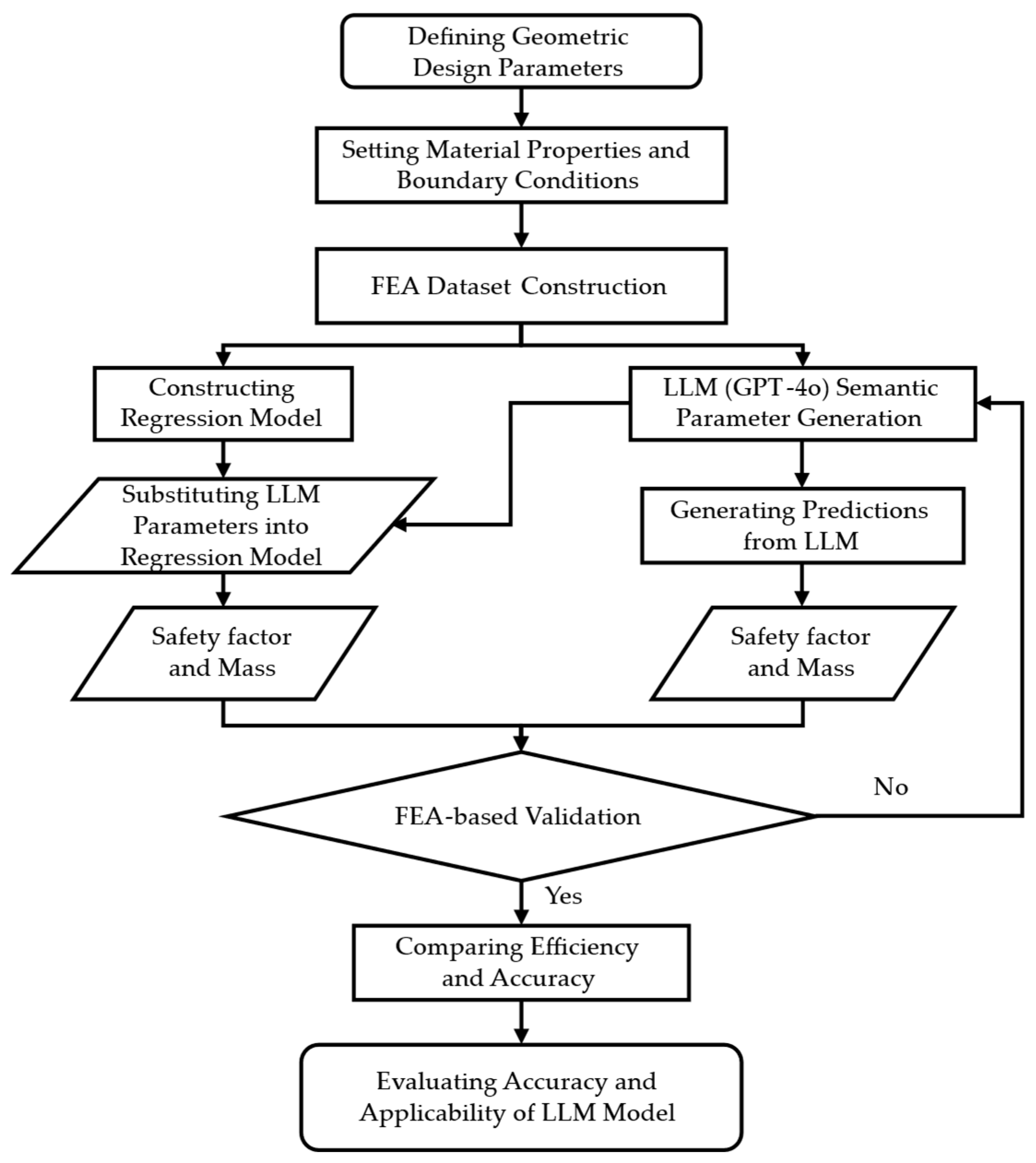

3.1. Research Workflow

3.2. Geometric Dimensioning Parameter Definition

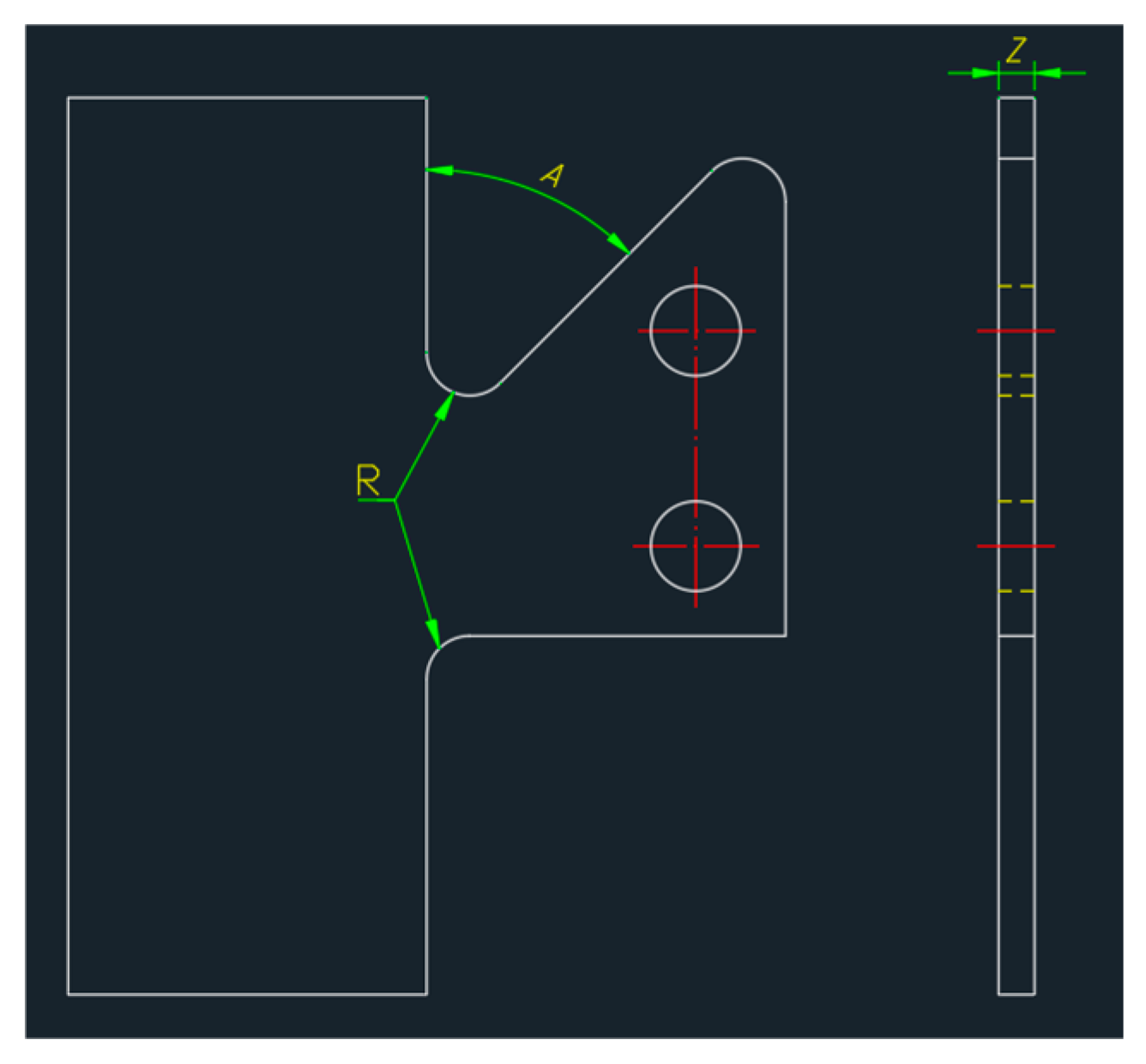

- Thickness (Z, mm): Represents the plate thickness of the bracket body, serving as a key factor influencing load-carrying capacity and global stiffness. An increase in thickness generally improves structural strength and the safety factor but also results in greater mass, thereby creating a trade-off between strength and weight.

- Inner Fillet Radius (R, mm): Located at the junction between the bracket body and the reinforcement rib, this parameter affects stress concentration and distribution. A smaller radius may lead to sharp-corner effects and fatigue risks, while an excessively large radius can compromise geometric compactness and interfere with design constraints.

- Rib Angle (A, degrees): Defined as the angle between the reinforcement rib and the bracket body, this parameter determines the alignment of the rib relative to the primary load path. An appropriate rib angle contributes to directional stiffness, reduces bending moment eccentricity, and improves local load-transfer efficiency.

3.3. Finite-Element Analysis Setup

3.3.1. Linear Static Finite-Element Analysis: Theory and Assumptions

- (1)

- The material is homogeneous, isotropic, and linearly elastic according to Hooke’s law.

- (2)

- Structural deformations remain within the small strain regime.

- (3)

- Geometric and contact nonlinearities are not considered.

- (4)

- All applied loads are static, with no inertial or time-dependent effects included.

3.3.2. FFE Plus Solver: Implementation and Applicability

3.3.3. Material Properties

- AISI 1020 medium carbon steel is a heat-treatable material with high yield strength and stiffness. Representing traditional structural steels, it serves as a high-strength, high-density reference case for assessing performance under more demanding mechanical requirements.

- 6061-T6 aluminum alloy is a widely used lightweight material with high specific strength and excellent machinability. It is extensively applied in the transportation and consumer product industries. In this study, it represents a low-density material suitable for evaluating the trade-off between weight and strength.

- AISI 304 stainless steel offers moderate strength and good ductility. As a commonly used general-purpose structural material that does not require heat treatment, it provides a practical baseline for analyzing structural stiffness and SF behavior, particularly under mid-range density and stiffness conditions.

3.3.4. Boundary Conditions and Load Application

3.3.5. Mesh Generation and Convergence Analysis

3.3.6. Output Parameters and Data Acquisition

3.4. Regression Model Construction and Validation

3.4.1. Rationale for Using Second-Order Polynomial Regression

3.4.2. Design of Training Samples and Data Generation

3.4.3. Formulation of Regression Equations

3.4.4. Evaluation of Regression Model Accuracy

3.5. Prompt Engineering for GPT-4o

3.5.1. GPT-4o Framework and Application Assumptions

3.5.2. LLM-Based Parameter Recommendation and Screening

3.5.3. Training Examples Provided to the LLM

- (1)

- Material Property Declaration:

- (2)

- Boundary Conditions and Load Application:

- (3)

- Initial Optimization Request (Wide Design Space):

- (4)

- Search Space Refinement and Convergence:

- (5)

- Material Substitution for Cross-Material Validation:

3.5.4. Limitations of the LLM-Based Approach

3.6. Computational Setup

4. Results

4.1. Regression Model Derivation Results

4.1.1. Regression Model Derivation Results for AISI 1020

4.1.2. Regression Model Derivation Results for 6061-T6

4.1.3. Regression Model Derivation Results for AISI 304

4.2. LLM-Based Design Recommendations

4.2.1. LLM-Based Design Recommendations for AISI 1020

4.2.2. LLM-Based Design Recommendations for 6061-T6

4.2.3. LLM-Based Design Recommendations for AISI 304

4.3. Comparison of Mass and Safety Factor Prediction Errors

4.3.1. Error Comparison for AISI 1020

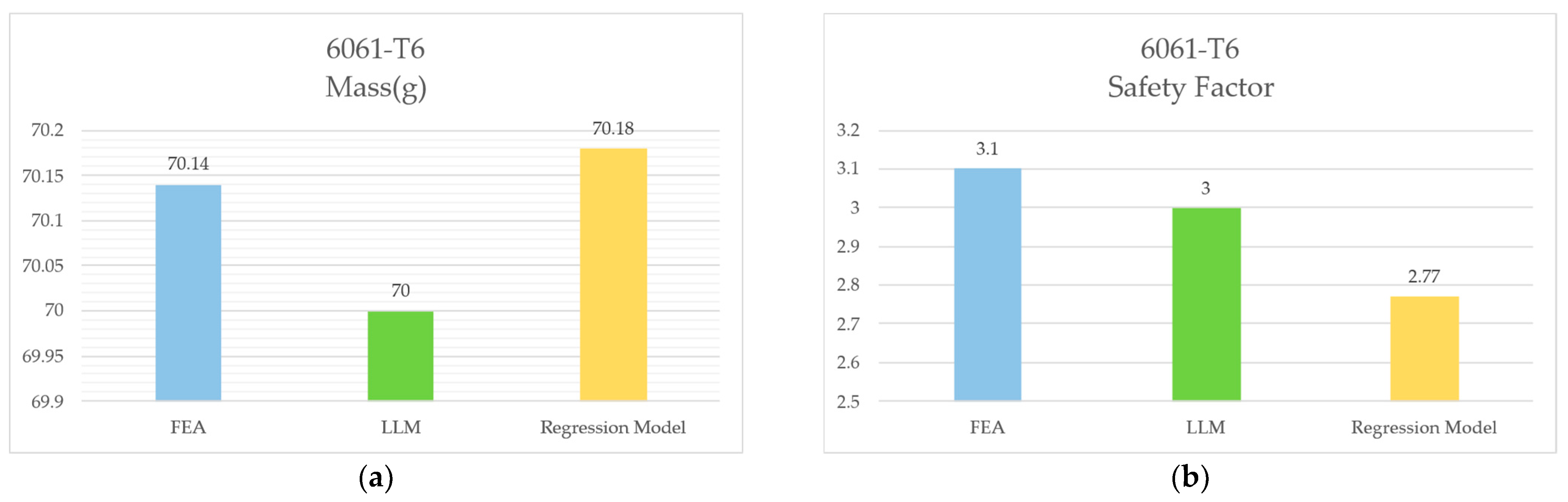

4.3.2. Error Comparison for 6061-T6

4.3.3. Error Comparison for AISI 304

5. Discussion

5.1. Time Efficiency and Process Challenges of Modeling Approaches

5.2. Design Safety in AI-Driven Optimization

6. Conclusions

- Prediction Accuracy: Both the regression model and GPT-4o demonstrated the ability to generate parameter suggestions that approached the target SF and Mass constraints. However, the regression model failed to meet the safety factor threshold (SF > 3) for the 6061-T6 material. In contrast, GPT-4o, although initially less accurate, showed improving performance attained through prompt refinement and iterative simulation. This adaptive behavior highlights its potential as a design assistant during early-stage exploration.

- Data Efficiency: The regression model required a substantial dataset (252 samples per material) to build reliable polynomial equations. In comparison, GPT-4o generated near-optimal suggestions using only 18 initial reference samples, supplemented by a few rounds of prompt engineering and simulation validation. This demonstrates its advantage in data-scarce environments. Overall, the LLM-based workflow required only about 27 FEA simulations for all three materials, compared with 756 for the regression models, thereby quantitatively demonstrating its substantial advantage in data efficiency, particularly in data-scarce environments.

- Generalization Capability: The regression model’s applicability to new materials was constrained by the coverage of its training dataset. Without retraining, its predictive power diminished for unseen materials. Conversely, GPT-4o maintained consistent performance across different materials—6061-T6 aluminum alloy, AISI 304 stainless steel, and AISI 1020 medium carbon steel—and exhibited reduced iteration requirements as more prompts were refined, showcasing strong semantic reasoning and cross-material adaptability.

- Process Complexity and Interpretability: While the LLM-based workflow significantly reduced sample requirements, it relied heavily on manual prompt iterations and FEA verification to suppress hallucinations. This process involved prompt adjustment, parameter translation, and simulation coordination, contributing to workflow complexity. The regression-based approach, despite requiring extensive simulations, followed a relatively straightforward and repetitive process, demanded lower domain expertise, and yielded interpretable mathematical models that facilitated design traceability.

- Numerical Function Construction: Unlike regression or surrogate models that rely on explicitly constructed numerical functions, LLMs offer a fundamentally different approach by generating design suggestions through semantic interpretation rather than direct numerical prediction. However, post-hoc FEA simulations remain essential to validate the physical feasibility of these suggestions. This workflow does not eliminate the need for numerical analysis altogether, but rather shifts it to the verification stage. In other words, an LLM does not predict SF or Mass values directly via learned equations, but proposes parameter combinations that are then evaluated through FEA validation. This distinction highlights the model’s semantic reasoning capabilities while acknowledging the continued importance of physical verification in engineering workflows.

7. Future Perspectives

7.1. Toward LLM–CAE Workflow Automation

7.2. Statistical Benchmarking and Future Research Directions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| LLM | Large Language Model |

| FEA | Finite-Element Analysis |

| CAE | Computer-Aided Engineering |

| SF | Safety Factor |

| API | Application Programming Interfaces |

| Material Yield Strength | |

| Maximum Equivalent Stress | |

| Z | Thickness (mm) |

| R | Inner Fillet Radius (mm) |

| A | Rib Angle (°) |

Appendix A

Appendix A.1. Material Property Declaration Prompt

Appendix A.2. Boundary Conditions and Load Application Prompt

Appendix A.3. Initial Optimization Request Prompt (Wide Design Space)

Appendix A.4. Search Space Refinement and Convergence Prompt

Appendix A.5. Material Substitution for Cross-Material Validation Prompt

References

- Nah, F.F.-H.; Zheng, R.; Cai, J.; Siau, K.; Chen, L. Generative AI and ChatGPT: Applications, challenges, and AI-human collaboration. J. Inf. Technol. Case Appl. Res. 2023, 25, 277–304. [Google Scholar] [CrossRef]

- Luckin, R.; Holmes, W.L. Intelligence Unleashed: An Argument for AI in Education; Pearson: London, UK, 2016. [Google Scholar]

- Wang, K.D.; Burkholder, E.; Wieman, C.; Salehi, S.; Haber, N. Examining the potential and pitfalls of ChatGPT in science and engineering problem-solving. Front. Educ. 2024, 8, 1330486. [Google Scholar] [CrossRef]

- Makatura, L.; Foshey, M.; Wang, B.; HähnLein, F.; Ma, P.; Deng, B.; Tjandrasuwita, M.; Spielberg, A.; Owens, C.E.; Chen, P.Y.; et al. How can large language models help humans in design and manufacturing? arXiv 2023, arXiv:2307.14377. [Google Scholar] [CrossRef]

- Liu, S.; Chen, C.; Qu, X.; Tang, K.; Ong, Y.-S. Large Language Models as Evolutionary Optimizers. Presented at the 2024 IEEE Congress on Evolutionary Computation (CEC), Yokohama, Japan, 30 June–5 July 2024. [Google Scholar] [CrossRef]

- Pan, X.; Li, X.; Li, Q.; Hu, Z.; Bao, J. Evolving to multi-modal knowledge graphs for engineering design: State-of-the-art and future challenges. J. Eng. Des. 2024, 36, 1156–1195. [Google Scholar] [CrossRef]

- White, J.; Fu, Q.; Hays, S.; Sandborn, M.; Olea, C.; Gilbert, H.; Elnashar, A.; Spencer-Smith, J.; Schmidt, D.C. A prompt pattern catalog to enhance prompt engineering with chatgpt. arXiv 2023, arXiv:2302.11382. [Google Scholar] [CrossRef]

- Giray, L. Prompt Engineering with ChatGPT: A Guide for Academic Writers. Ann. Biomed. Eng. 2023, 51, 2629–2633. [Google Scholar] [CrossRef] [PubMed]

- Royston, P.; Sauerbrei, W. Multivariable Modeling with Cubic Regression Splines: A Principled Approach. Stata J. 2007, 7, 45–70. [Google Scholar] [CrossRef]

- Luedeke, T.; Bonertz, R.; Vielhaber, M. Weight Optimization Approach for Conceptual Design-Requirements, Functions, Working Principles. In Proceedings of the NordDesign 2014, Espoo, Finland, 27–29 August 2014. [Google Scholar]

- Simpson, T.W.; Poplinski, J.D.; Koch, P.N.; Allen, J.K. Metamodels for Computer-based Engineering Design: Survey and recommendations. Eng. Comput. 2001, 17, 129–150. [Google Scholar] [CrossRef]

- Akande, T.O.; Alabi, O.O.; Ajagbe, S.A. A Deep Learning-Based CAE Approach for Simulating 3D Vehicle Wheels Under Real-World Conditions. Artif. Intell. Appl. 2024, 1–5. [Google Scholar] [CrossRef]

- Shahriari, B.; Swersky, K.; Wang, Z.; Adams, R.P.; de Freitas, N. Taking the Human Out of the Loop: A Review of Bayesian Optimization. Proc. IEEE 2016, 104, 148–175. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Jin, R.; Chen, W.; Simpson, T. Comparative studies of metamodelling techniques under multiple modelling criteria. Struct. Multidiscip. Optim. 2001, 23, 1–13. [Google Scholar] [CrossRef]

- Liao, X.; Li, Q.; Yang, X.; Zhang, W.; Li, W. Multiobjective optimization for crash safety design of vehicles using stepwise regression model. Struct. Multidiscip. Optim. 2008, 35, 561–569. [Google Scholar] [CrossRef]

- Moustapha, M.; Sudret, B. Surrogate-assisted reliability-based design optimization: A survey and a unified modular framework. Struct. Multidiscip. Optim. 2019, 60, 2157–2176. [Google Scholar] [CrossRef]

- Fang, H.; Rais-Rohani, M.; Liu, Z.; Horstemeyer, M. A comparative study of metamodeling methods for multiobjective crashworthiness optimization. Comput. Struct. 2005, 83, 2121–2136. [Google Scholar] [CrossRef]

- Deshpande, S.; Szefer, J. Analyzing ChatGPT’s Aptitude in an Introductory Computer Engineering Course. Paper Presented at the 2023 Congress in Computer Science, Computer Engineering, & Applied Computing (CSCE), Las Vegas, NV, USA, 24–27 July 2023. [Google Scholar] [CrossRef]

- Aluga, M. Application of CHATGPT in civil engineering. East Afr. J. Eng. 2023, 6, 104–112. [Google Scholar] [CrossRef]

- Tian, J.; Hou, J.; Wu, Z.; Shu, P.; Liu, Z.; Xiang, Y.; Gu, B.; Filla, N.; Li, Y.; Liu, N.; et al. Assessing large language models in mechanical engineering education: A study on mechanics-focused conceptual understanding. arXiv 2024, arXiv:2401.12983. [Google Scholar] [CrossRef]

- Cao, Y.; Li, S.; Liu, Y.; Yan, Z.; Dai, Y.; Yu, P.S.; Sun, L. A comprehensive survey of ai-generated content (aigc): A history of generative ai from gan to chatgpt. arXiv 2023, arXiv:2303.04226. [Google Scholar] [CrossRef]

- Jadhav, Y.; Farimani, A.B. Large language model agent as a mechanical designer. arXiv 2024, arXiv:2404.17525. [Google Scholar] [CrossRef]

- Li, H.; Hao, Y.; Zhai, Y.; Qian, Z. Assisting Static Analysis with Large Language Models: A Chatgpt Experiment. In Proceedings of the 31st ACM Joint European Software Engineering Conference and Symposium on the Foundations of Software Engineering, San Francisco, CA, USA, 3–9 December 2023. [Google Scholar] [CrossRef]

- Lange, R.; Tian, Y.; Tang, Y. Large Language Models as Evolution Strategies. In Proceedings of the Genetic and Evolutionary Computation Conference Companion, Melbourne, Australia, 14–18 July 2024. [Google Scholar] [CrossRef]

- Wang, X.; Anwer, N.; Dai, Y.; Liu, A. ChatGPT for design, manufacturing, and education. Procedia CIRP 2023, 119, 7–14. [Google Scholar] [CrossRef]

- Berenguer, A.; Morejón, A.; Tomás, D.; Mazón, J.-N. Leveraging Large Language Models for Sensor Data Retrieval. Appl. Sci. 2024, 14, 2506. [Google Scholar] [CrossRef]

- Han, Z.; Wang, J.; Yan, X.; Jiang, Z.; Zhang, Y.; Liu, S.; Gong, Q.; Song, C. CoReaAgents: A Collaboration and Reasoning Framework Based on LLM-Powered Agents for Complex Reasoning Tasks. Appl. Sci. 2025, 15, 5663. [Google Scholar] [CrossRef]

- Federiakin, D.; Molerov, D.; Zlatkin-Troitschanskaia, O.; Maur, A. Prompt engineering as a new 21st century skill. Front. Educ. 2024, 9, 1366434. [Google Scholar] [CrossRef]

- Gu, J.; Han, Z.; Chen, S.; Beirami, A.; He, B.; Zhang, G.; Liao, R.; Qin, Y.; Tresp, V.; Torr, P. A systematic survey of prompt engineering on vision-language foundation models. arXiv 2023, arXiv:2307.12980. [Google Scholar] [CrossRef]

- Zhou, Y.; Muresanu, A.I.; Han, Z.; Paster, K.; Pitis, S.; Chan, H.; Ba, J. Large Language Models are Human-Level Prompt Engineers. arXiv 2023. [Google Scholar] [CrossRef]

- Wang, L.; Chen, X.; Deng, X.; Wen, H.; You, M.; Liu, W.; Li, Q.; Li, J. Prompt engineering in consistency and reliability with the evidence-based guideline for LLMs. NPJ Digit. Med. 2024, 7, 41. [Google Scholar] [CrossRef] [PubMed]

- Bansal, P. Prompt engineering importance and applicability with generative AI. J. Comput. Commun. 2024, 12, 14–23. [Google Scholar] [CrossRef]

- Schmidt, D.C.; Spencer-Smith, J.; Fu, Q.; White, J. Cataloging Prompt Patterns to Enhance the Discipline of Prompt Engineering. Available online: https://www.dre.vanderbilt.edu/~schmidt/PDF/ADA_Europe_Position_Paper.pdf (accessed on 25 September 2023).

- Dai, J.; Pan, X.; Sun, R.; Ji, J.; Xu, X.; Liu, M.; Wang, Y.; Yang, Y. Safe rlhf: Safe reinforcement learning from human feedback. arXiv 2023, arXiv:2310.12773. [Google Scholar] [CrossRef] [PubMed]

- Ji, Z.; Yu, T.; Xu, Y.; Lee, N.; Ishii, E.; Fung, P. Towards Mitigating LLM Hallucination via Self Reflection. Paper Presented at the Findings of the Association for Computational Linguistics: EMNLP 2023, Singapore, 6–10 December 2023. [Google Scholar] [CrossRef]

- Martino, A.; Iannelli, M.; Truong, C. Knowledge Injection to Counter Large Language Model (LLM) Hallucination. Paper Presented at the European Semantic Web Conference, Crete, Greece, 28 April–1 May 2023. [Google Scholar] [CrossRef]

- Friel, R.; Sanyal, A. Chainpoll: A high efficacy method for LLM hallucination detection. arXiv 2023, arXiv:2310.18344. [Google Scholar] [CrossRef]

- McDonald, D.; Papadopoulos, R.; Benningfield, L. Reducing LLM hallucination using knowledge distillation: A case study with mistral large and mmlu benchmark. techRxiv 2024. [Google Scholar] [CrossRef]

- Varshney, K.R. Engineering Safety in Machine Learning. Paper Presented at the 2016 Information Theory and Applications Workshop (ITA), La Jolla, CA, USA, 31 January–5 February 2016. [Google Scholar] [CrossRef]

- Bach, T.A.; Kristiansen, J.K.; Babic, A.; Jacovi, A. Unpacking human-AI interaction in safety-critical industries: A systematic literature review. IEEE Access 2024, 12, 106385–106414. [Google Scholar] [CrossRef]

- Rueß, H.; Burton, S. Safe AI—How is this Possible? arXiv 2022, arXiv:2201.10436. [Google Scholar] [CrossRef]

- Geissler, F.; Roscher, K.; Trapp, M. Concept-Guided LLM Agents for Human-AI Safety Codesign. In Proceedings of the AAAI Symposium Series, Stanford, CA, USA, 25–27 March 2024. [Google Scholar] [CrossRef]

- Liu, H.; Liao, J.; Feng, D.; Xu, K.; Wang, H. Autofeedback: An llm-based framework for efficient and accurate api request generation. arXiv 2024, arXiv:2410.06943. [Google Scholar] [CrossRef]

- Li, M.; Zhao, Y.; Yu, B.; Song, F.; Li, H.; Yu, H.; Li, Z.; Huang, F.; Li, Y. Api-bank: A comprehensive benchmark for tool-augmented llms. arXiv 2023, arXiv:2304.08244. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.; Yao, Z.; Zhang, J.; Xie, Y.; Tu, S.; Fu, Y.; Feng, Y.; Zhang, J.; Zhang, J.; et al. A solution-based LLM API-using methodology for academic information seeking. arXiv 2024, arXiv:2405.15165. [Google Scholar] [CrossRef]

| Material | Young’s Modulus (GPa) | Yield Strength (MPa) | Density (kg/m3) |

|---|---|---|---|

| AISI 1020 | 210 | 350 | 7870 |

| 6061-T6 | 69 | 275 | 2700 |

| AISI 304 | 190 | 207 | 8000 |

| Stage | Prompt Summary | Key Inputs | Output Purpose |

|---|---|---|---|

| 1 | Declare materials + parameter ranges | Material Properties, Z/R/A ranges | Establish LLM context |

| 2 | Provide boundary and load conditions | Fx, Fy, fixed constraints | Add physics to context |

| 3 | Request initial optimization | Wide range, SF > 3 | First design suggestion |

| 4 | Restrict search space | Z/R/A refined | Force focused convergence |

| 5 | Cross-material prediction prompts | New material properties (e.g., 6061, 304), same constraints | Evaluate generalization with material substitution |

| Sample Number | Thickness (mm) | Fillet Radius (mm) | Rib Angle (°) | Mass (g) | Safety Factor |

|---|---|---|---|---|---|

| C01 | 3 | 5 | 45 | 201.69 | 2.721 |

| C02 | 3 | 5 | 60 | 214.21 | 5.779 |

| C03 | 3 | 5 | 75 | 223.37 | 9.134 |

| C04 | 3 | 10 | 45 | 204.26 | 4.663 |

| C05 | 3 | 10 | 60 | 215.81 | 8.528 |

| C06 | 3 | 10 | 75 | 224.44 | 9.658 |

| C07 | 5 | 5 | 45 | 336.14 | 4.45 |

| C08 | 5 | 5 | 60 | 357.01 | 9.417 |

| C09 | 5 | 5 | 75 | 372.29 | 14.98 |

| C10 | 5 | 10 | 45 | 340.44 | 7.755 |

| C11 | 5 | 10 | 60 | 359.68 | 14.12 |

| C12 | 5 | 10 | 75 | 374.07 | 16.16 |

| C13 | 7 | 5 | 45 | 470.6 | 6.243 |

| C14 | 7 | 5 | 60 | 499.81 | 13.29 |

| C15 | 7 | 5 | 75 | 521.2 | 20.9 |

| C16 | 7 | 10 | 45 | 476.62 | 10.83 |

| C17 | 7 | 10 | 60 | 503.55 | 19.77 |

| C18 | 7 | 10 | 75 | 523.7 | 22.9 |

| Sample Number | Thickness (mm) | Fillet Radius (mm) | Rib Angle (°) | Mass (g) | Safety Factor |

|---|---|---|---|---|---|

| C19 | 3 | 5 | 55 | 210.57 | 4.7 |

| C20 | 3 | 7 | 45 | 202.51 | 3.5 |

| C21 | 3 | 6 | 60 | 214.44 | 6.3 |

| C22 | 3 | 7 | 52 | 208.82 | 5 |

| C23 | 3 | 7.5 | 58 | 213.51 | 6.6 |

| C24 | 3 | 8 | 60 | 215.04 | 7.5 |

| C25 | 3 | 7 | 65 | 217.94 | 8.1 |

| Sample Number | Thickness (mm) | Fillet Radius (mm) | Rib Angle (°) | Mass (g) | Safety Factor |

|---|---|---|---|---|---|

| C26 (Result of LLM generation) | 3 | 6.8 | 54 | 210 (0.1%) | 3.2 (40%) |

| C26 (Result of FEA) | 3 | 6.8 | 54 | 210.33 | 5.4 |

| C27 (Result of LLM generation) | 3 | 6.6 | 50 | 205 (0.9%) | 3.2 (27%) |

| C27 (Result of FEA) | 3 | 6.6 | 50 | 206.99 | 4.4 |

| C28 (Result of LLM generation) | 3 | 6.6 | 46 | 204.5 (−0.58%) | 3.2 (8.6%) |

| C28 (Result of FEA) | 3 | 6.6 | 46 | 203.32 | 3.5 |

| Sample Number | Thickness (mm) | Fillet Radius (mm) | Rib Angle (°) | Mass (g) | Safety Factor |

|---|---|---|---|---|---|

| C30 (Result of LLM generation) | 3 | 7 | 45 | 200 (−65%) | 3.2 (15%) |

| C30 (Result of FEA) | 3 | 7 | 45 | 69.21 | 2.7 |

| C31 (Result of LLM generation) | 3 | 6.6 | 50 | 70.5 (0.3%) | 3.2 (6%) |

| C31 (Result of FEA) | 3 | 6.6 | 50 | 70.74 | 3.4 |

| C32 (Result of LLM generation) | 3 | 6.6 | 46 | 70.5 (−1.4%) | 3.0 (6%) |

| C32 (Result of FEA) | 3 | 6.6 | 46 | 69.49 | 2.8 |

| C33 (Result of LLM generation) | 3 | 6.6 | 48 | 70 (0.2%) | 3.0 (3%) |

| C33 (Result of FEA) | 3 | 6.6 | 48 | 70.14 | 3.1 |

| Sample Number | Thickness (mm) | Fillet Radius (mm) | Rib Angle (°) | Mass (g) | Safety Factor |

|---|---|---|---|---|---|

| C34 (Result of LLM generation) | 3 | 7 | 60 | 210 (−1%) | 3.0 (23%) |

| C34 (Result of FEA) | 3 | 7 | 60 | 207.81 | 2.3 |

| C35 (Result of LLM generation) | 4 | 7 | 60 | 275 (0.7%) | 3.2 (−3%) |

| C35 (Result of FEA) | 4 | 7 | 60 | 277.08 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chien, C.T.; Chien, C.H. Hybrid AI-Driven Computer-Aided Engineering Optimization: Large Language Models Versus Regression-Based Models Validated Through Finite-Element Analysis. Appl. Sci. 2025, 15, 10123. https://doi.org/10.3390/app151810123

Chien CT, Chien CH. Hybrid AI-Driven Computer-Aided Engineering Optimization: Large Language Models Versus Regression-Based Models Validated Through Finite-Element Analysis. Applied Sciences. 2025; 15(18):10123. https://doi.org/10.3390/app151810123

Chicago/Turabian StyleChien, Che Ting, and Chao Heng Chien. 2025. "Hybrid AI-Driven Computer-Aided Engineering Optimization: Large Language Models Versus Regression-Based Models Validated Through Finite-Element Analysis" Applied Sciences 15, no. 18: 10123. https://doi.org/10.3390/app151810123

APA StyleChien, C. T., & Chien, C. H. (2025). Hybrid AI-Driven Computer-Aided Engineering Optimization: Large Language Models Versus Regression-Based Models Validated Through Finite-Element Analysis. Applied Sciences, 15(18), 10123. https://doi.org/10.3390/app151810123