Vibration Analysis of Variable-Thickness Multi-Layered Graphene Sheets

Abstract

1. Introduction

2. Methodology

- 1-

- 2-

- Simulation Software and Interatomic Potential: All MD simulations were performed using LAMMPS, a well-established and robust simulation package. For modeling the interatomic carbon interactions, we selected the AIREBO potential.

- 3-

- Boundary and Initial Conditions: To simulate a realistic scenario, clamped boundary conditions were applied by fixing the atoms on all four edges of the graphene sheets. To initiate the vibration, the system was not subjected to random thermal noise alone. Instead, an initial velocity profile, defined by Equation (1), was applied to the atoms to specifically excite a mode shape approximating the fundamental resonance mode. This is a crucial step to ensure that the fundamental frequency is prominently captured in the subsequent analysis.

- 4-

- Simulation Protocol and System Evolution: The simulation was conducted in two main phases. An initial phase using the NVT (canonical) ensemble was employed to equilibrate the system at the target temperature (e.g., 300 K) and apply the initial driven vibration. Following this, the system was allowed to evolve under the NVE (microcanonical) ensemble, simulating an unconstrained, energy-conserving vibration. The integration of the equations of motion was performed using the velocity-Verlet algorithm with a time step of 1 fs to ensure numerical stability and energy conservation.

- 5-

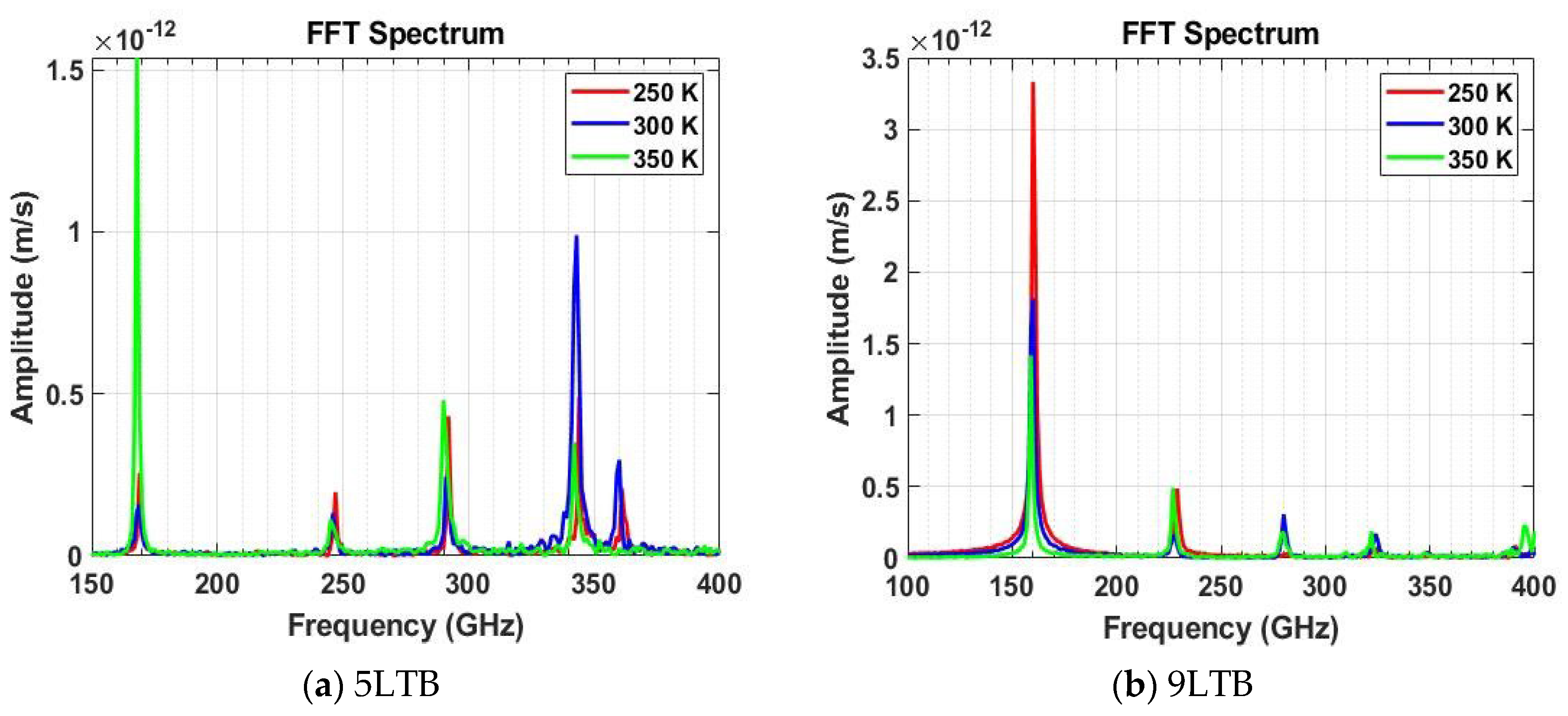

- Data Acquisition and Analysis: During the NVE phase, VACF was recorded over a duration of approximately 1 ns. The natural frequencies of the structure were then extracted from this time-domain data by applying the FFT method, which converts the VACF into a VDOS spectrum. The peaks in this spectrum directly correspond to the natural frequencies of the system.

- 6-

- Parametric Temperature Study: To investigate the influence of thermal effects, the entire simulation procedure described above was systematically repeated for three distinct temperatures: 250 K, 300 K, and 350 K.

3. Results and Discussion

4. Conclusions

- The inverse relationship between the number of graphene layers and the natural frequency is a direct consequence of the increased mass. As the number of layers increases, the total mass of the nanostructure rises, while the stiffness—primarily determined by in-plane covalent bonds—does not increase proportionally. This alters the mass-to-stiffness ratio, resulting in a lower natural frequency. As described by fundamental vibration theory, a system’s natural frequency is proportional to the square root of its stiffness (k) over its mass (m). While adding layers increases both mass and stiffness (due to van der Waals forces), the increase in mass is the dominant factor, leading to a decrease in the overall natural frequency. This relationship is crucial for designing nanoresonators, as it enables precise frequency tuning by simply controlling the number of layers.

- It has been established that the vibrational response is significantly influenced by temperature. For all models, an increase in simulation temperature from 250 K to 350 K resulted in a relative decrease in the fundamental natural frequencies. This behavior is attributed to a reduction in the structure’s overall rigidity, which is a direct consequence of increased thermal motion causing atoms to deviate more from their equilibrium positions. This phenomenon is known as thermal softening. The rise in temperature increases the kinetic energy of the atoms, leading to larger-amplitude thermal vibrations. These increased vibrations alter the average bond lengths and angles between atoms, thereby reducing the material’s macroscopic elastic properties. As the temperature increases, the thermal motion of the atoms intensifies, which in turn reduces the material’s rigidity. Since the mass remains constant, the dominant effect on the frequency is the drop in rigidity, which ultimately lowers the natural frequency. This phenomenon highlights the potential for nanoresonators to be used as temperature sensors, where the frequency shift can serve as a highly sensitive measure of temperature.

- The frequency peaks were also observed to broaden at higher temperatures. It indicates an enhanced vibrational damping effect due to more frequent interatomic interactions.

- Simulation studies at varying temperatures showed no single trend for damping ratios; their behavior is highly dependent on the model’s structure. For example, while the damping ratio of the uniform 1L model steadily increased with rising temperature, it decreased in the 3LTB model and followed a more complex pattern of initial increase then decrease in the 5LTB model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VTGSs | Variable-Thickness Graphene Sheets |

| MD | Molecular Dynamics |

| LAMMPS | Large-Scale Atomic/Molecular Massively Parallel Simulator |

| FFT | Fast Fourier Transform |

| VACF | Velocity Autocorrelation Function |

| CNTs | Carbon Nanotubes |

| FEM | Finite Element Modeling |

| SWNTs | Single-Walled Carbon Nanotubes |

| SWCNCs | Single-Walled Carbon Nanocones |

| SLGSs | Single-Layered Graphene Sheets |

| DLGSs | Double-Layered Graphene Sheets |

| MWCNTs | Multi-Walled Carbon Nanotubes |

| vdW | Van Der Waals |

| VMD | Visual Molecular Dynamics |

| ζ | Damping Ratio |

| ωn | Natural Frequency |

References

- Casiraghi, C.; Pisana, S.; Novoselov, K.S.; Geim, A.K.; Ferrari, A.C. Raman Fingerprint of Charged Impurities in Graphene. Appl. Phys. Lett. 2007, 91, 233108. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Cui, Y.S.; Wang, Y.Q.; Pan, H.G. Vibration Characteristics of Graphene Nanoplatelet Reinforced Disk-Shaft Rotor with Eccentric Mass. Mech. Adv. Mater. Struct. 2022, 29, 3485–3498. [Google Scholar] [CrossRef]

- Lee, J.E.; Ahn, G.; Shim, J.; Lee, Y.S.; Ryu, S. Optical Separation of Mechanical Strain from Charge Doping in Graphene. Nat. Commun. 2012, 3, 1024. [Google Scholar] [CrossRef] [PubMed]

- Del Corro, E.; Kavan, L.; Kalbac, M.; Frank, O. Strain Assessment in Graphene Through the Raman 2D′ Mode. J. Phys. Chem. C 2015, 119, 22651–22656. [Google Scholar] [CrossRef]

- Huang, X.; Zeng, Z.; Fan, Z.; Liu, J.; Zhang, H. Graphene-Based Electrodes. Adv. Mater. 2012, 24, 5979–6004. [Google Scholar] [CrossRef]

- Gibson, R.F.; Ayorinde, E.O.; Wen, Y.F. Vibrations of Carbon Nanotubes and Their Composites: A Review. Compos. Sci. Technol. 2007, 67, 1–28. [Google Scholar] [CrossRef]

- Qian, D.; Wagner, G.J.; Liu, W.K.; Yu, M.F.; Ruoff, R.S. Mechanics of Carbon Nanotubes. Appl. Mech. Rev. 2002, 55, 495–533. [Google Scholar] [CrossRef]

- Gao, G.; Çaǧin, T.; Goddard, W.A. Energetics, Structure, Mechanical and Vibrational Properties of Single-Walled Carbon Nanotubes. Nanotechnology 1998, 9, 184. [Google Scholar] [CrossRef]

- Zheng, Z.; Deng, F.; Su, Z.; Zhan, H.; Wang, L. Analysis of the Vibrational Characteristics of Diamane Nanosheet Based on the Kirchhoff Plate Model and Atomistic Simulations. Discov. Nano 2023, 18, 108. [Google Scholar] [CrossRef]

- Ansari, R.; Momen, A.; Rouhi, S.; Ajori, S. On the Vibration of Single-Walled Carbon Nanocones: Molecular Mechanics Approach versus Molecular Dynamics Simulations. Shock. Vib. 2014, 2014, 410783. [Google Scholar] [CrossRef]

- Arash, B.; Wang, Q. Vibration of Single- and Double-Layered Graphene Sheets. J. Nanotechnol. Eng. Med. 2011, 2, 011012. [Google Scholar] [CrossRef]

- Yoon, J.; Ru, C.Q.; Mioduchowski, A. Vibration of an Embedded Multiwall Carbon Nanotube. Compos. Sci. Technol. 2003, 63, 1533–1542. [Google Scholar] [CrossRef]

- Jalali, S.K.; Jomehzadeh, E.; Pugno, N.M. Influence of Out-of-Plane Defects on Vibration Analysis of Graphene: Molecular Dynamics and Non-Local Elasticity Approaches. Superlattices Microstruct. 2016, 91, 331–344. [Google Scholar] [CrossRef]

- Seifoori, S.; Khoshgoftar, M.J. Impact and Vibration Response of Multi-Layered Graphene Sheets under Different Striker Based on the Analytical Model and Molecular Dynamics. Superlattices Microstruct. 2019, 135, 106249. [Google Scholar] [CrossRef]

- Bedi, D.; Sharma, S.; Tiwari, S.K.; Ajori, S. Effect of Defects and Boundary Conditions on the Vibrational Behavior of Carbon Nanotube and Graphene: A Molecular Dynamics Perspective. Diam. Relat. Mater. 2022, 126, 109052. [Google Scholar] [CrossRef]

- Jiang, K.; Wang, J.; Yuan, J.; Wang, Q. Investigating Vacancy-Defect Effects on the Vibration Characteristics of Graphene Resonators with Molecular Dynamics Simulation. Comput. Mater. Sci. 2025, 252, 113794. [Google Scholar] [CrossRef]

- Mao, J.J.; Liu, S.; Li, L.; Chen, J. Molecular Dynamic Simulation of Defective Graphene Nanoribbons for Tension and Vibration. Nanomaterials 2022, 12, 2407. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Wang, J. Effect of Vacancy Defects on the Vibration Frequency of Graphene Nanoribbons. Nanomaterials 2022, 12, 764. [Google Scholar] [CrossRef]

- Madani, S.H.; Sabour, M.H.; Fadaee, M. Molecular Dynamics Simulation of Vibrational Behavior of Annular Graphene Sheet: Identification of Nonlocal Parameter. J. Mol. Graph. Model. 2018, 79, 264–272. [Google Scholar] [CrossRef]

- Huang, C.; Xu, F.; Sun, Y. Effects of Morphology, Tension and Vibration on Wettability of Graphene: A Molecular Dynamics Study. Comput. Mater. Sci. 2017, 139, 216–224. [Google Scholar] [CrossRef]

- Rahman, R.; Foster, J.T. A Molecular Dynamics Based Investigation of Thermally Vibrating Graphene under Different Boundary Conditions. Phys. E Low-Dimens. Syst. Nanostructures 2015, 72, 25–47. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhu, P.; Li, R. The Influence of Vertical Vibration on Nanoscale Friction: A Molecular Dynamics Simulation Study. Crystals 2018, 8, 129. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A Reactive Potential for Hydrocarbons with Intermolecular Interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef]

- Yang, X.; Qiao, F.; Zhu, X.; Zhang, P.; Chen, D.; To, A.C. Coalescence of Parallel Finite Length Single-Walled Carbon Nanotubes by Heat Treatment. J. Phys. Chem. Solids 2013, 74, 436–440. [Google Scholar] [CrossRef]

- Meng, F.Y.; Shi, S.Q.; Xu, D.S.; Yang, R. Size Effect of X-Shaped Carbon Nanotube Junctions. Carbon 2006, 44, 1263–1266. [Google Scholar] [CrossRef]

- Lennard-Jones, J.E. Cohesion. Proc. Phys. Soc. 1931, 43, 461–482. [Google Scholar] [CrossRef]

- William, H.; Andrew, D.; Klaus, S. VMD—Visual Molecular Dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar]

- Taylor, R.L.; Govindjee, S. Solution of Clamped Rectangular Plate Problems. Commun. Numer. Methods Eng. 2004, 20, 757–765. [Google Scholar] [CrossRef]

- Treszkai, M.F.; Vehovszky, B.; Feszty, D. Damping determination by the half power bandwidth method for a rectangular flat plate with bitumen damping layer application. J. Vibroeng. 2021, 23, 1267–1277. [Google Scholar] [CrossRef]

| Model Name | Fundamental Frequency [GHz] | ||

|---|---|---|---|

| 250 K | 300 K | 350 K | |

| 1L | 201 | 200 [11] | 199 |

| 3LT | 178 | 177 | 177 |

| 3LTB | 173 | 172 | 172 |

| 5LT | 169 | 168 | 167 |

| 5LTB | 169 | 168 | 168 |

| 9LTB | 160 | 160 | 159 |

| Model Name | Damping Ratio [%] | ||

|---|---|---|---|

| 250 K | 300 K | 350 K | |

| 1L | 0.0016 | 0.0017 | 0.0024 |

| 3LT | 0.0021 | 0.0042 | 0.0022 |

| 3LTB | 0.0049 | 0.0027 | 0.0027 |

| 5LT | 0.0049 | 0.0027 | 0.0027 |

| 5LTB | 0.0024 | 0.0053 | 0.0024 |

| 9LTB | 0.0047 | 0.0061 | 0.0031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yildiz, Y.O.; Sen, M.; Yigid, O.; Huseyinoglu, M.; Kara, S.E. Vibration Analysis of Variable-Thickness Multi-Layered Graphene Sheets. Appl. Sci. 2025, 15, 9200. https://doi.org/10.3390/app15169200

Yildiz YO, Sen M, Yigid O, Huseyinoglu M, Kara SE. Vibration Analysis of Variable-Thickness Multi-Layered Graphene Sheets. Applied Sciences. 2025; 15(16):9200. https://doi.org/10.3390/app15169200

Chicago/Turabian StyleYildiz, Yunus Onur, Murat Sen, Osman Yigid, Mesut Huseyinoglu, and Sertac Emre Kara. 2025. "Vibration Analysis of Variable-Thickness Multi-Layered Graphene Sheets" Applied Sciences 15, no. 16: 9200. https://doi.org/10.3390/app15169200

APA StyleYildiz, Y. O., Sen, M., Yigid, O., Huseyinoglu, M., & Kara, S. E. (2025). Vibration Analysis of Variable-Thickness Multi-Layered Graphene Sheets. Applied Sciences, 15(16), 9200. https://doi.org/10.3390/app15169200