Manufacturing Management Processes Integration Framework

Abstract

1. Introduction

2. Literature Review

2.1. General Overview

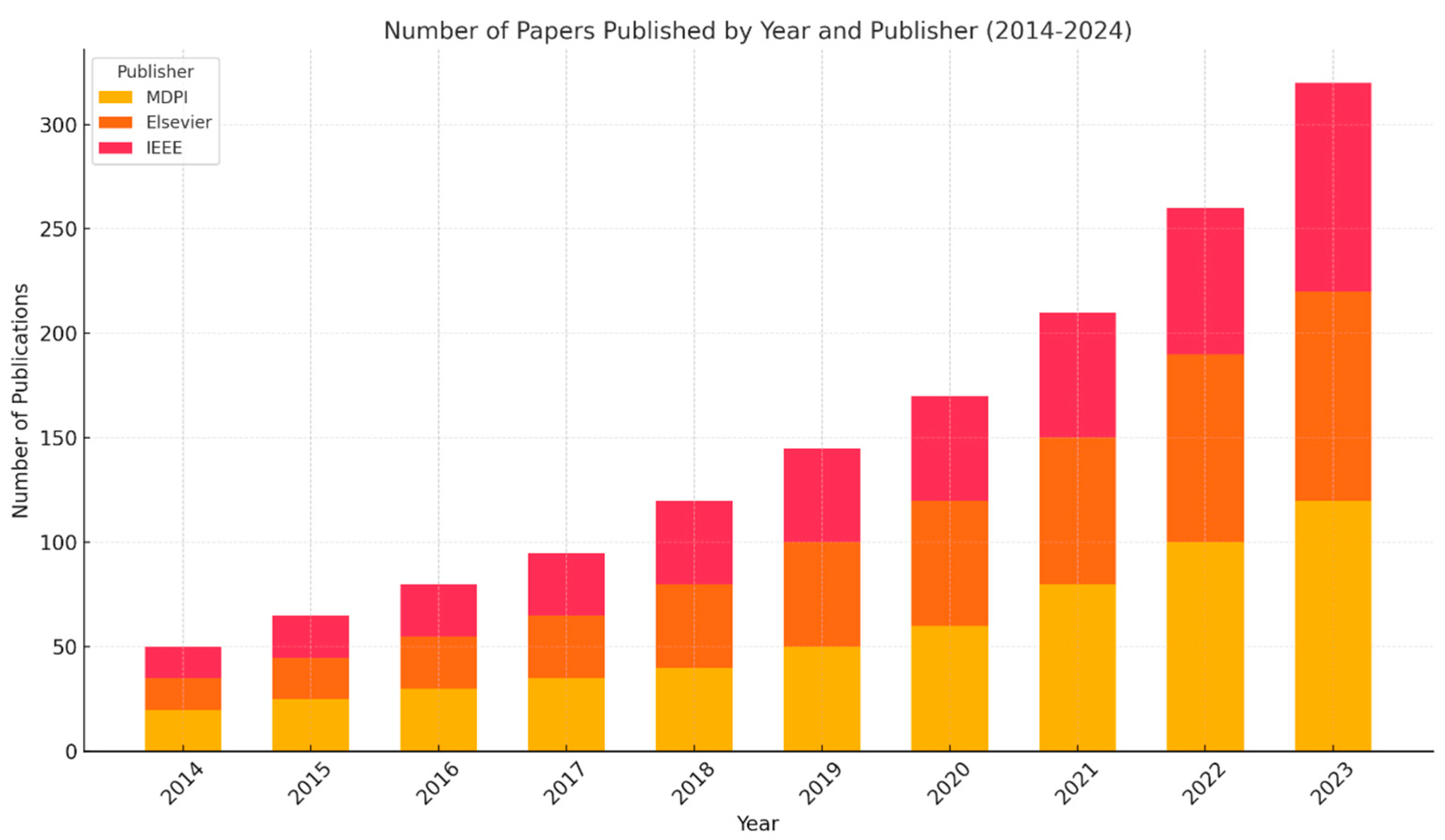

2.2. Systematic Literature Review Methodology

2.3. Analysis and Discussion of Key Contributions from the Literature

2.4. Classification of Enabling Technologies, Applications and Integration Gaps

2.4.1. Technology Classification

2.4.2. Implementation Contexts

2.4.3. Identified Limitations

2.4.4. Comparative Positioning with Reference Frameworks

2.5. Implications

2.6. Implications

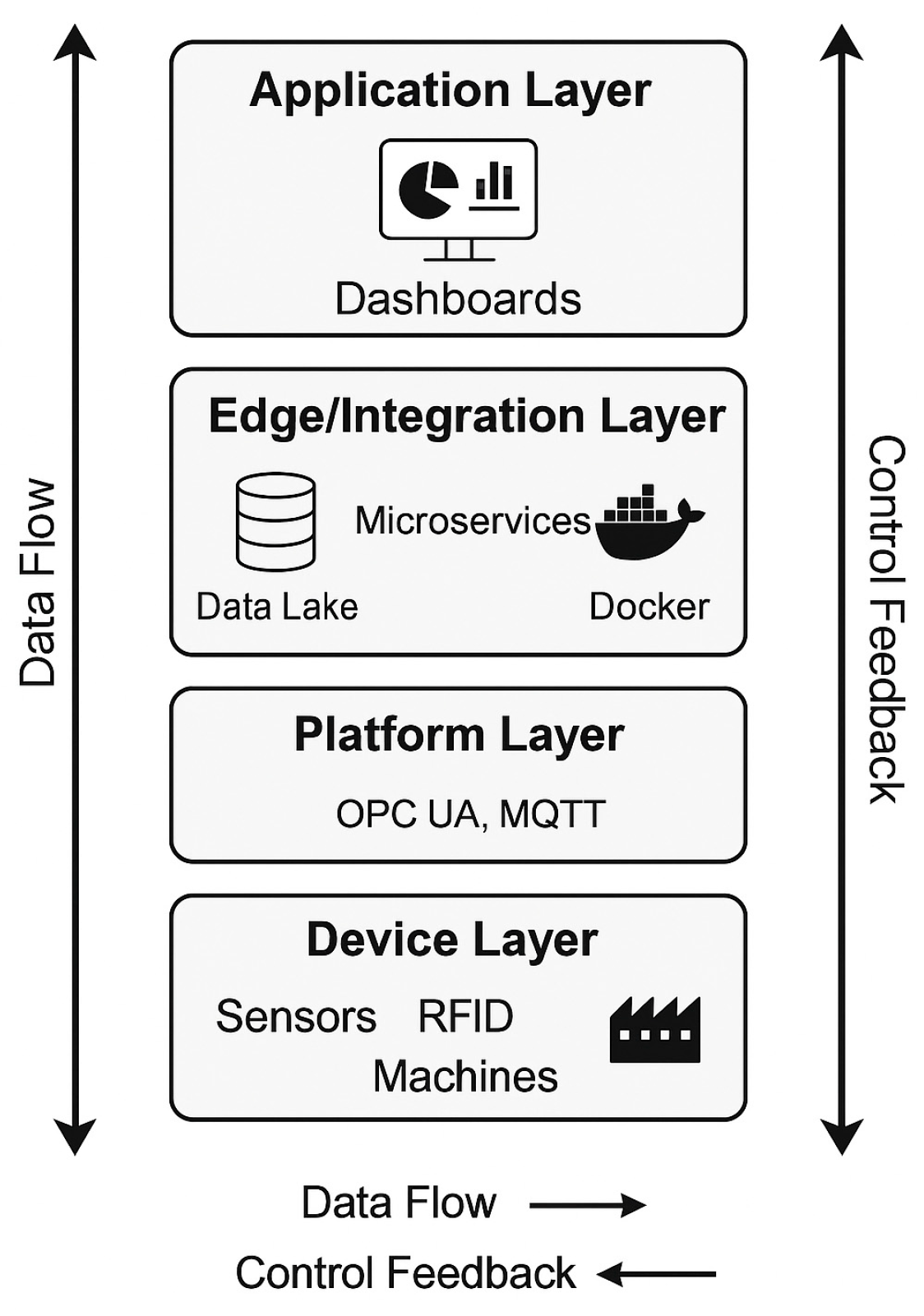

3. Framework for Manufacturing Management Integration

- Device Layer: Includes physical assets (sensors, RFID readers, machines) responsible for data generation at the shop floor level;

- Edge/Integration Layer: Manages local data processing, filtering, and protocol conversion (e.g., OPC-UA, MQTT), ensuring semantic consistency and low-latency responsiveness;

- Platform Layer: Provides core functionalities such as data storage (data lake), analytics, and microservices orchestration, deployed via containerized environments;

- Application Layer: Delivers dashboards, alerts, and decision-support tools, ensuring secure and human-centric interactions.

3.1. Framework Requirements and Design Rationale

- Integration Complexity: Coordination across internal departments and external stakeholders requires a unified data and decision-making backbone;

- Real-Time Coordination: Operational decisions must react to events in real time, therefore, the system must process and act upon data with minimal delay;

- Interoperability: Seamless interaction between legacy systems (e.g., ERP, MES) and modern digital tools is essential;

- Data Security and Privacy: As data cross organizational boundaries, secure communication (e.g., encrypted APIs, blockchain integrity) is required;

- Scalability and Adaptability: The architecture must be modular and scalable across different sites and adaptable to new industrial contexts.

- IoT and Edge Components: For real-time sensing and local decision-making;

- Integration Middleware: To bridge legacy systems with modern services;

- Machine learning and Digital Twins: For predictive analytics and intelligent monitoring;

- Blockchain-based Security Mechanisms: To ensure traceability and trust in data transactions across multiple stakeholders;

- User Interfaces and Dashboards: Designed for intuitive decision support, promoting human-in-the-loop collaboration in line with Industry 5.0 principles.

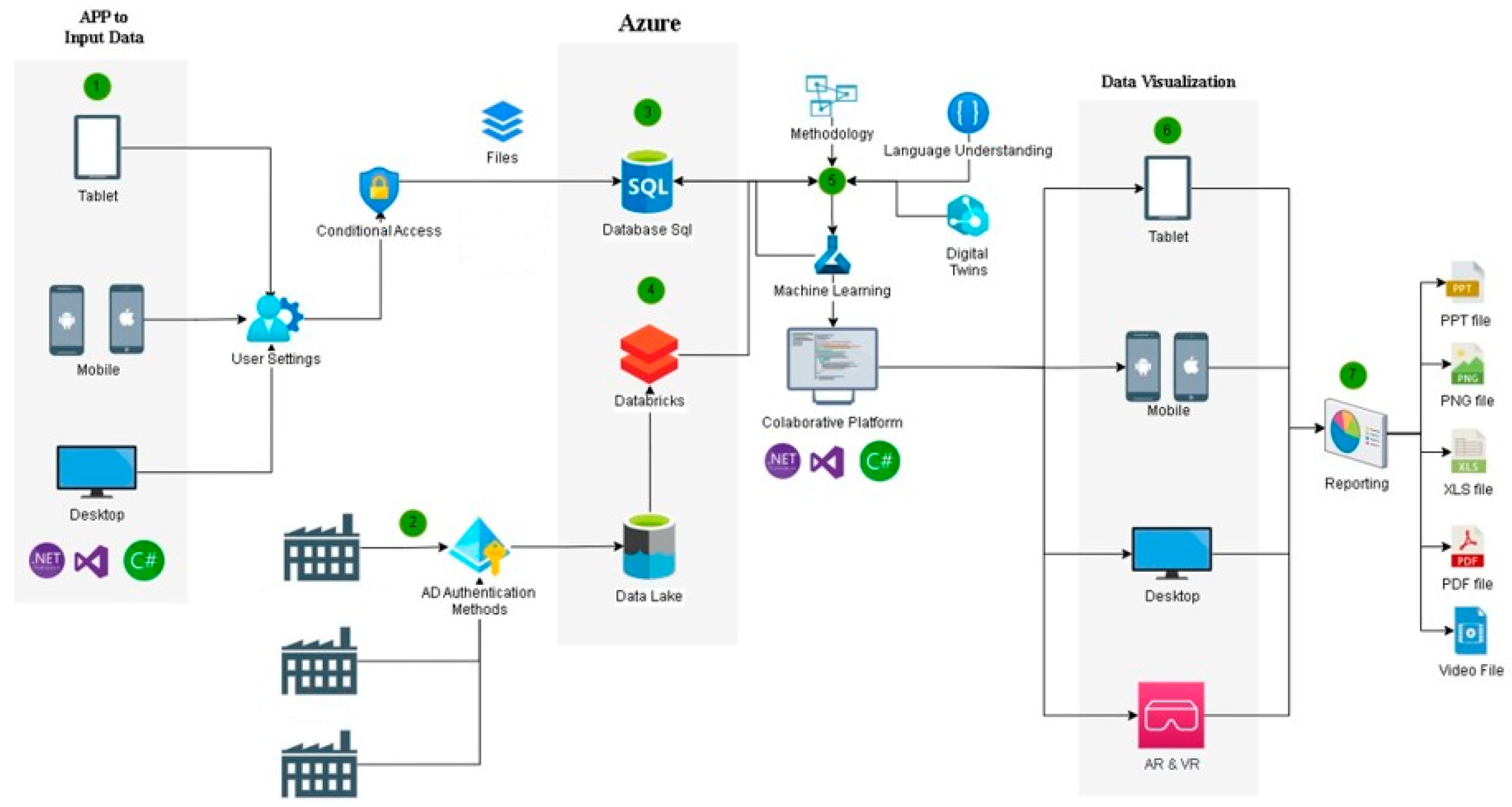

3.2. Technological Components and Tools

- IoT Integration: Utilized MQTT protocol and Node-RED for data orchestration, along with microcontroller platforms (e.g., Arduino, ESP32) for sensor-based input;

- Backend Logic: Developed using Python (Version 3.11) and Node.js (Version 20.x) to ensure flexibility and easy API integration;

- Data Storage and Streaming: PostgreSQL and Apache Kafka support high-volume data management and real-time processing;

- AI/ML Analytics: Implemented using Scikit-learn and TensorFlow for predictive modelling and adaptive learning;

- Dashboards and Interfaces: ReactJS and Grafana were used to create rich visualization environments for decision support;

- Cloud Infrastructure: Hosted on Microsoft Azure to ensure scalability and secure access across factories;

- Security and Privacy: JWT-based authentication and a blockchain pilot layer provide traceability and protection of sensitive data.

3.2.1. Software

- Integration with IoT:

- For connecting devices, sensors and systems, creating a data network that operates in real time;

- The software facilitates communication between machines (M2M) and between machines and human systems, enabling a seamless and transparent workflow;

- Application example: Remote monitoring of machines, real-time production control and predictive maintenance.

- Intelligent Automation:

- The developed platform enables to automate repetitive and complex processes, ensuring precision, speed and error reduction;

- Automation is supported by advanced algorithms that adjust processes based on real-time and historical data;

- Application example: optimization of assembly lines and integrated inventory management.

- Artificial Intelligence and Machine Learning:

- The platform implements AI for predictive analysis, pattern identification and resource optimization;

- The underlying platform’s software uses machine learning to continually improve processes, learning from historical data and adapting to changes in the operational environment;

- Application example: equipment failure prediction and dynamic production planning.

- Integrated Management Systems:

- The platform enables to connect all areas of a company—production, logistics, sales and maintenance—into a single integrated ecosystem;

- This guarantees full visibility of processes and allows for informed and agile decisions;

- Application example: interactive dashboards with KPIs (key performance indicators) updated in real time.

- Advanced Data Analysis and Big Data:

- The platform’s software collects and analyzes large volumes of data, transforming it into actionable information;

- It uses data visualization techniques to present insights in a clear and intuitive way, facilitating strategic decision-making;

- Application example: energy efficiency analysis and identification of bottlenecks in the production process.

- Connectivity with Industry 5.0:

- The developed platform places humans at the center of the operation, promoting collaboration between machines and operators;

- It prioritizes personalization, sustainability and an intuitive and fluid user experience;

- Application example: human–machine interface (HMI) systems with virtual assistants for technical and operational support.

3.2.2. Prototypes

- Real-Time Monitoring and Control: Devices equipped with advanced IoT sensors to track operational conditions, production and performance in real time;

- Automation and M2M Communication: Prototypes that enable direct communication between machines, optimizing operations and reducing time-consuming human intervention;

- Personalization and Sustainability: Equipment designed to customize operations according to specific needs and promote energy and environmental efficiency.

- Modularity and Scalability:The solutions can be customized to meet each client’s specific needs, with the possibility of expansion as operations grow;

- Compliance with Global Standards:The developed platform is aligned with the highest industrial standards, ensuring compatibility with equipment and systems from different suppliers;

- Security and Robustness:The platform implements advanced cybersecurity protocols to protect critical data and operations from attacks or failures based on blockchain technology;

- Interoperability:The platform integrates different technology, including legacy systems and new technologies, ensuring that everything works harmoniously and in real time.

3.2.3. Impacts of the Software on the Industrial Environment

- Increase Productivity: Automating tasks and optimizing processes, reducing waste and downtime;

- Reduce Operating Costs: By improving energy efficiency, predicting failures and optimizing resource use;

- Improve Product Quality: With greater control over processes and real-time adjustments;

- Promote Sustainability: With analysis and optimization of resources, promoting a greener and more economical operation;

- Increase Competitiveness and interoperation: By adopting cutting-edge technologies that place the company at the forefront of the sector, enabling interoperation between different technology and further collaboration among the company’s interacting factories and other external stakeholders, including suppliers, business partners and clients;

- These impacts demonstrate how traditional Industry 4.0 technologies can be reconfigured to serve broader objectives beyond productivity, including environmental efficiency, system robustness, and collaborative human–machine interaction. This reinforces the alignment of the proposed platform with the paradigm of Industry 5.0, where technology plays a supporting role in more adaptive, inclusive, and sustainable manufacturing ecosystems.

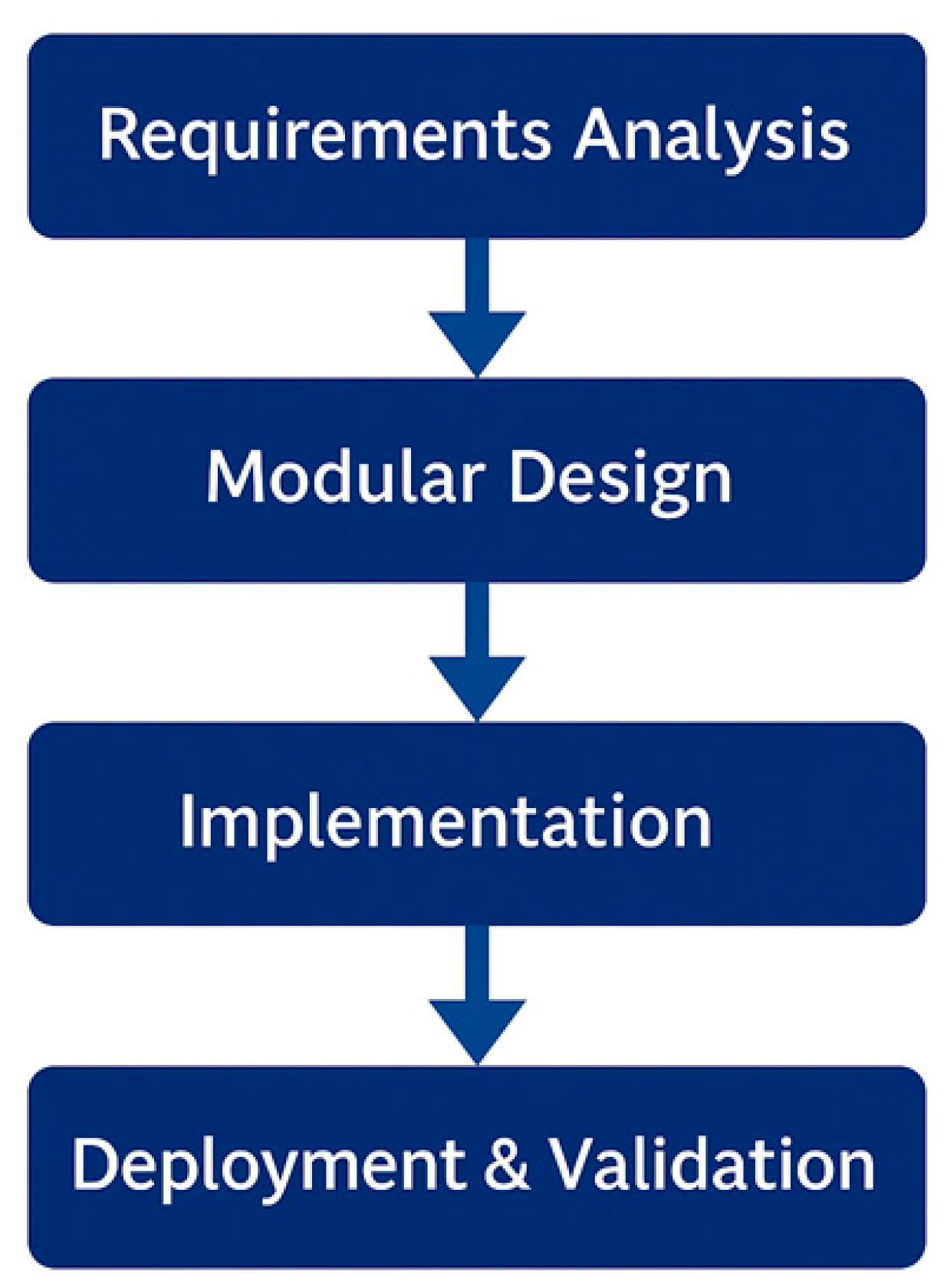

3.3. Platform Development Methodology and Lifecycle

- Requirements Analysis: Functional and non-functional requirements were gathered through direct interaction with company stakeholders (e.g., production managers, IT staff, and operators). These included real-time monitoring capabilities, user-friendly dashboards, modular system architecture, integration with legacy ERP/MES systems, and security compliance;

- Modular System Design: The architecture was modelled using a microservices-based approach. Each functional component (e.g., IoT connectivity, AI analytics, dashboard generation) was designed as an independent module to enhance maintainability and scalability. The system design was documented using UML diagrams and process workflows;

- Implementation: The platform was implemented using open-source technologies and widely adopted industrial platforms. Python and Node.js were used for core logic and API handling, while MQTT protocols handled IoT communication. For data handling and analytics, PostgreSQL and Apache Kafka were used. Cloud infrastructure was deployed using Microsoft Azure, supporting elastic scalability;

- Testing and Integration: A test-driven development (TDD) approach was adopted. Unit, integration, and system-level tests were performed to validate the functionality and robustness of each module. System simulations using historical and synthetic datasets were conducted to assess performance under various operational loads;

- Deployment and Maintenance: The platform was deployed in a real industrial environment—a Portuguese manufacturing group comprising three factories. Post-deployment support included performance monitoring, user feedback integration, and regular patching based on stakeholder suggestions.

- Reduction in machine downtime (measured through MTTR—Mean Time to Repair);

- Increase in production throughput per shift;

- Improved detection and response time to operational anomalies;

- Overall system uptime and reduction in integration-related errors.

Observed Implementation Limitations and Practical Implications

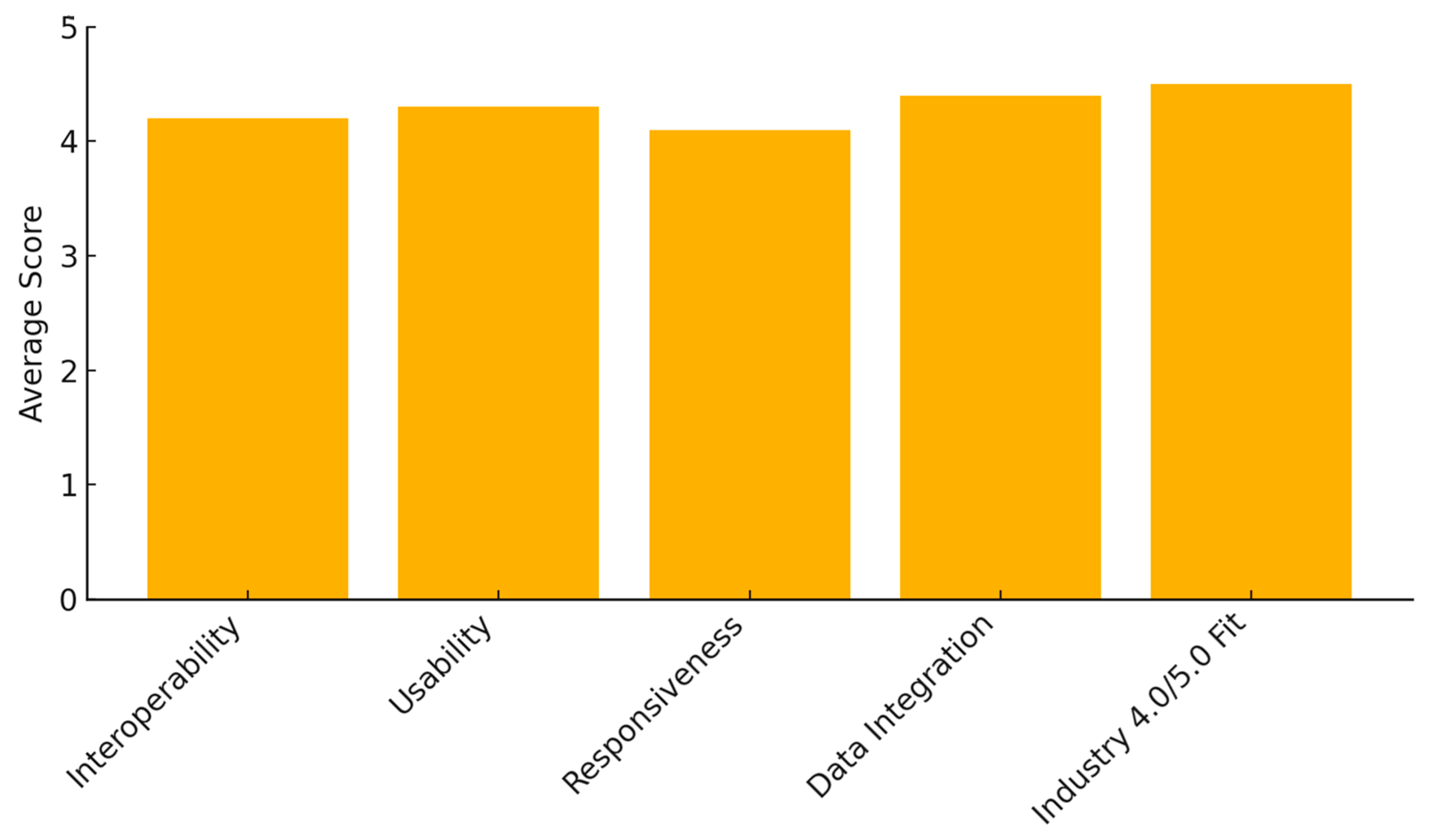

4. Framework Implementation Validation

- Interoperability;

- Usability;

- Responsiveness;

- Data integration;

- Alignment with Industry 4.0/5.0 principles.

- “To what extent does the platform enable real-time monitoring of key manufacturing indicators?”

- “How effective is the framework in supporting collaborative decision-making across departments or factories?”

- “Does the system improve integration with external stakeholders (e.g., suppliers, partners)?”

- This demonstrates that your questions were well-designed and aligned with framework objectives.

5. Discussion

- Vertical integration: Connecting different levels of the manufacturing hierarchy, from shop floor devices to enterprise-level systems;

- Horizontal integration: Linking different companies within the supply chain, enabling collaborative planning and execution;

- End-to-end integration: Connecting all stages of the product lifecycle, from design and engineering to manufacturing and after-sales service.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Ten years of Industrie 4.0. Sci 2022, 4, 26. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021.

- Schonberger, R.J. Japanese Manufacturing Techniques: Nine Hidden Secrets of Success; The Free Press: Washington, DC, USA, 1982. [Google Scholar]

- Davenport, T.H. Putting the enterprise into enterprise systems. Harv. Bus. Rev. 1998, 76, 121–131. [Google Scholar] [PubMed]

- Lee, J.; Bagheri, B.; Kao, H.-A. A cyber-physical systems architecture for industry 4.0 manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Varela, M.L.R.; Alves, C.F.V.; Santos, A.S.; Vieira, G.G.; Lopes, N.; Putnik, G.D. Analysis of a Collaborative Scheduling Model Applied in a Job Shop Manufacturing Environment. Machines 2022, 10, 1138. [Google Scholar] [CrossRef]

- Varela, M.L.R.; Trojanowska, J.; Cruz-Cunha, M.M.; Pereira, M.A.; Putnik, G.D.; Machado, J. Global Resources Management: A Systematic Review and Framework Proposal for Collaborative Management of CPPS. Appl. Sci. 2023, 13, 750. [Google Scholar] [CrossRef]

- Gil-Vilda, F.; Yaguee-Fabra, J.A.; Sunyer, A. From lean production to lean 4.0: A systematic literature review, including classification of studies by technology type, application context, results, and limitations with a historical perspective. Appl. Sci. 2021, 11, 10318. [Google Scholar] [CrossRef]

- Oliveira, M.; Chauhan, S.; Pereira, F.; Felgueiras, C.; Carvalho, D. Blockchain Protocols and Edge Computing Targeting Industry 5.0 Needs. Sensors 2023, 23, 9174. [Google Scholar] [CrossRef]

- Varela, M.L.R.; Putnik, G.D.; Romero, F. Collaborative Manufacturing and Management contextualization in the Industry 4.0 based on a Systematic Literature Review. Int. J. Manag. Sci. Eng. Manag. 2023, 19, 78–95. [Google Scholar] [CrossRef]

- Ramakurthi, V.; Manupati, V.K.; Machado, J.; Varela, L.; Babu, S. An innovative approach for resource sharing and scheduling in a sustainable distributed manufacturing system. Adv. Eng. Inform. 2022, 52, 101620. [Google Scholar] [CrossRef]

- Roeck, D. The Foundation of Distributed Ledger Technology for Supply Chain Management. In Proceedings of the 53rd Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020; pp. 1–10. [Google Scholar]

- Koulamas, C.; Lazarescu, M.T. Real-time sensor networks and systems for the industrial iot: What next? Sensors 2020, 20, 5023. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, X.; Liang, W.; Zeng, Z.; Shimizu, S.; Yang, L.T.; Jin, Q. Intelligent small object detection for digital twin in smart manufacturing with industrial cyber-physical systems. IEEE Trans. Ind. Inform. 2021, 18, 1377–1386. [Google Scholar] [CrossRef]

- Simion, C.; Popescu, T.; Popescu, M.; Militaru, A. Research on the Use of Integrated Management Systems. Adv. Sci. Technol. 2021, 110, 31–36. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of digital twin across industries: A review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Flores-García, E.; Jeong, Y.; Liu, S.; Wiktorsson, M.; Wang, L. Enabling industrial internet of things-based digital servitization in smart production logistics. Int. J. Prod. Res. 2023, 61, 3884–3909. [Google Scholar] [CrossRef]

- Wang, H.; Yan, Q.; Wang, J. Blockchain-secured multi-factory production with collaborative maintenance using Q learning-based optimisation approach. Int. J. Prod. Res. 2023, 61, 3685–3702. [Google Scholar] [CrossRef]

- Grieves, M. Intelligent digital twins and the development and management of complex systems. Digit. Twin 2024, 1, 8. [Google Scholar]

- Li, X.; He, B.; Wang, Z.; Zhou, Y.; Li, G.; Zhu, Z. A digital twin system for Task-Replanning and Human-Robot control of robot manipulation. Adv. Eng. Inform. 2024, 62, 102570. [Google Scholar] [CrossRef]

- Zheng, W.; Lu, H.; Zhang, M.; Wu, Q.; Hou, Y.; Zhu, J. Distributed Energy Management of Multi-Entity Integrated Electricity and Heat Systems: A Review of Architectures, Optimization Algorithms, and Prospects. IEEE Trans. Smart Grid 2024, 15, 1544–1561. [Google Scholar] [CrossRef]

- Ghuge, S.; Akarte, M.; Raut, R. Decision-making frameworks in additive manufacturing management: Mapping present landscape and establishing future research avenues. Benchmarking Int. J. 2024, 33. [Google Scholar] [CrossRef]

- Khan, W.; Islam, M.S.; Ullah Ibne Hossain, N.; Fazio, S. Measuring economic resilience of manufacturing organization leveraging integrated data envelopment analysis (DEA)-machine learning approach. Int. J. Manag. Sci. Eng. Manag. 2024, 19, 228–238. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Chung, W.; Adams, D.; Lee, J.H. Techno-economic analysis for design and management of international green hydrogen supply chain under uncertainty: An integrated temporal planning approach. Energy Convers. Manag. 2024, 301, 118010. [Google Scholar] [CrossRef]

- Hammad, M.; Islam, M.S.; Salam, M.A.; Jafry, A.T.; Ali, I.; Khan, W.A. Framework for the Implementation of Smart Manufacturing Systems: A Case in Point. Processes 2023, 11, 1436. [Google Scholar] [CrossRef]

- Vacchi, M.; Siligardi, C.; Settembre-Blundo, D. Driving Manufacturing Companies toward Industry 5.0: A Strategic Framework for Process Technological Sustainability Assessment (P-TSA). Sustainability 2024, 16, 695. [Google Scholar] [CrossRef]

- Martín-Gómez, A.M.; Agote-Garrido, A.; Lama-Ruiz, J.R. A Framework for Sustainable Manufacturing: Integrating Industry 4.0 Technologies with Industry 5.0 Values. Sustainability 2024, 16, 1364. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, Z.; Huang, T.; Shi, J.; Lu, F.; Xu, Z. An Intelligent Manufacturing Management System for Enhancing Production in Small-Scale Industries. Electronics 2024, 13, 2633. [Google Scholar] [CrossRef]

- Raddi-Mira, L.H.; Pecora Junior, J.E.; Deschamps, F. Framework for Implementing Industry 4.0 Projects. Sustainability 2024, 16, 2387. [Google Scholar] [CrossRef]

- Lyngdorf, N.E.R.; Jiang, D.; Du, X. Frameworks and Models for Digital Transformation in Engineering Education: A Literature Review Using a Systematic Approach. Educ. Sci. 2024, 14, 519. [Google Scholar] [CrossRef]

- Bastos, T.; Guimarães, C.; Teixeira, L. Framework of Best Practices to Drive the Digital Transition: Towards a 4.0 Paradigm Based on Evidence from Case Studies. Future Internet 2025, 17, 82. [Google Scholar] [CrossRef]

- Latino, M.E. A maturity model for assessing the implementation of Industry 5.0 in manufacturing SMEs: Learning from theory and practice. Technol. Forecast. Soc. Change 2025, 214, 124045. [Google Scholar] [CrossRef]

- Dehghan, S.; Sattarpanah Karganroudi, S.; Echchakoui, S.; Barka, N. The Integration of Additive Manufacturing into Industry 4.0 and Industry 5.0: A Bibliometric Analysis (Trends, Opportunities, and Challenges). Machines 2025, 13, 62. [Google Scholar] [CrossRef]

- Islam, M.T.; Sepanloo, K.; Woo, S.; Woo, S.H.; Son, Y.-J. A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines 2025, 13, 267. [Google Scholar] [CrossRef]

- Talapatra, S.; Santos, G.; Uddin, K.; Carvalho, F. Main Benefits of Integrated Management Systems through Literature Review. Int. J. Qual. Res. 2019, 13, 1037. [Google Scholar] [CrossRef]

- Rolofs, G.; Wilking, F.; Goetz, S.; Wartzack, S. Integrating Digital Twins and Cyber-Physical Systems for Flexible Energy Management in Manufacturing Facilities: A Conceptual Framework. Electronics 2024, 13, 4964. [Google Scholar] [CrossRef]

- Siemens AG. Siemens Partners with Singapore to Establish Its First Fully-Integrated Digitalization Hub. Siemens Press Release Report Munich PR2017070365COEN. 2017. Available online: https://assets.new.siemens.com/siemens/assets/api/uuid:7f1bbdd2-aaa0-4186-b8e8-454a796a7014/pr-idcc-digi-hub-singapore-20170711.pdf (accessed on 6 March 2025).

- Putnik, G.D.; Pabba, S.K.; Manupati, V.K.; Varela, M.L.R.; Ferreira, F. Semi-Double-loop machine learning based CPS approach for predictive maintenance in manufacturing system based on machine status indications. CIRP Ann.-Manuf. Technol. 2021, 70, 365–368. [Google Scholar] [CrossRef]

- Katuu, S. Enterprise resource planning: Past, present, and future. New Rev. Inf. Netw. 2020, 25, 37–46. [Google Scholar] [CrossRef]

- Wang, L. From intelligence science to intelligent manufacturing. Engineering 2019, 5, 615–618. [Google Scholar] [CrossRef]

- Arrais-Castro, A.; Varela, M.L.R.; Putnik, G.D.; Ribeiro, R.A.; Machado, J.; Ferreira, L. Collaborative framework for virtual organisation synthesis based on a dynamic multi-criteria decision model. Int. J. Comput. Integr. Manuf. 2018, 31, 857–868. [Google Scholar] [CrossRef]

- Silveira, M.; Adriano, S.; Filipe, P.; António, R.; José, M. 3D Vision Object Identification Using YOLOv8. Int. J. Mechatron. Appl. Mechanics 2024, 17, 7–15. [Google Scholar] [CrossRef]

- Santos, A.A.; Schreurs, C.; da Silva, A.F.; Pereira, F.; Felgueiras, C.; Lopes, A.M.; Machado, J. Integration of Artificial Vision and Image Processing into a Pick and Place Collaborative Robotic System. J. Intell. Robot. Syst. 2024, 110, 159. [Google Scholar] [CrossRef]

- Santos, A.A.; Pereira, F.; Felgueiras, C. Optimization and improving of the production capacity of a flexible tyre painting cell. Int. J. Adv. Manuf. Technol. 2025, 136, 3957–3969. [Google Scholar] [CrossRef]

- Yin, S.; Rodriguez-Andina, J.J.; Jiang, Y. Real-time monitoring and control of industrial cyberphysical systems: With integrated plant-wide monitoring and control framework. IEEE Ind. Electron. Mag. 2019, 13, 38–47. [Google Scholar] [CrossRef]

- Freitas, L.; Pereira, F.; Lopes, H.; Avram, C.; Leal, N.; Morgado, T.; Machado, J. OPC-UA vs. MQTT (UNS): Evaluating Alignment with RAMI4.0 Through Literature Review. In Innovations in Mechatronics Engineering IV; Machado, J., Trojanowska, J., Soares, F., Rea, P., Butdee, S., Gramescu, B., Eds.; Icieng 2025; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2025. [Google Scholar] [CrossRef]

- Terras, N.; Pereira, F.; Ramos Silva, A.; Santos, A.A.; Lopes, A.M.; Silva, A.F.d.; Cartal, L.A.; Apostolescu, T.C.; Badea, F.; Machado, J. Integration of Deep Learning Vision Systems in Collaborative Robotics for Real-Time Applications. Appl. Sci. 2025, 15, 1336. [Google Scholar] [CrossRef]

- Patrício, L.; Varela, L.; Silveira, Z.; Felgueiras, C.; Pereira, F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Appl. Sci. 2025, 15, 7402. [Google Scholar] [CrossRef]

- Pereira, F.; Pinto, L.; Soares, F.; Vasconcelos, R.; Machado, J.; Carvalho, V. Online yarn hairiness–Loop & protruding fibers dataset. Data Brief 2024, 54, 110355. [Google Scholar] [CrossRef]

- Pinto, R.; Pereira, F.; Carvalho, V.; Soares, F.; Vasconcelos, R. Yarn linear mass determination using image processing: First insights. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 198–203. [Google Scholar] [CrossRef]

- Pereira, F.; Lopes, H.; Pinto, L.; Soares, F.; Vasconcelos, R.; Machado, J.; Carvalho, V. Yarn quality analysis by using computer vision and deep learning techniques. Text. Res. J. 2025. [Google Scholar] [CrossRef]

- Pereira, F.; Lopes, H.; Pinto, L.; Soares, F.; Vasconcelos, R.; Machado, J.; Carvalho, V. A Novel Deep Learning Approach for Yarn Hairiness Characterization Using an Improved YOLOv5 Algorithm. Appl. Sci. 2025, 15, 149. [Google Scholar] [CrossRef]

- Pereira, F.; Oliveira, E.L.; Ferreira, G.G.; Sousa, F.; Caldas, P. Textile Yarn Winding and Unwinding System. In Innovations in Mechanical Engineering; Machado, J., Soares, F., Trojanowska, J., Ottaviano, E., Eds.; Icieng 2021; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Wu, X.; Yu, C.; Zhang, L.; Zhang, H.; Dai, W. Cloud-Based Data-Driven Behavior Model Recovery for Distributed Automation Systems. EAI Endorsed Transactions on Digital Transformation of Industrial Processes. Available online: https://publications.eai.eu/index.php/dtip/article/view/8591 (accessed on 7 March 2025).

- Trunzer, E.; Calà, A.; Leitão, P.; Gepp, M.; Kinghorst, J.; Lüder, A.; Schauerte, H.; Reifferscheid, M.; Vogel-Heuser, B. System architectures for Industrie 4.0 applications. Prod. Eng. Res. Devel. 2019, 13, 247–257. [Google Scholar] [CrossRef]

- Santos, A.; Lima, C.; Pinto, T.; Reis, A.; Barroso, J. Context-Aware Systems Architecture in Industry 4.0: A Systematic Literature Review. Appl. Sci. 2025, 15, 5863. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.-J.; Zhou, Y.; Wen, S.; Dou, K.-Q.; Li, Q. Study on the Reference Architecture and Assessment Framework of Industrial Internet Platform. IEEE Access 2020, 8, 164950–164971. [Google Scholar] [CrossRef]

- Kaiser, J.; McFarlane, D.; Hawkridge, G.; André, P.; Leitão, P. A review of reference architectures for digital manufacturing: Classification, applicability and open issues. Comput. Ind. 2023, 149, 103923. [Google Scholar] [CrossRef]

- Piat, J.R.; Danjou, C.; Agard, B.; Beauchemin, R. A guideline to implement a CPS architecture in an SME. Prod. Manuf. Res. 2023, 11, 2218910. [Google Scholar] [CrossRef]

- Chavez, Z.; Hauge JB Bellgran, M. Industry 4.0, transition or addition in SMEs? A systematic literature review on digitalization for deviation management. Int. J. Adv. Manuf. Technol. 2022, 119, 57–76. [Google Scholar] [CrossRef]

- Oñate, W.; Sanz, R. Integration of Fog Computing in a Distributed Manufacturing Execution System Under the RAMI 4.0 Framework. Appl. Sci. 2024, 14, 10539. [Google Scholar] [CrossRef]

- Di Modica, G.; Foschini, L. A Survey on the Use of Lightweight Virtualization in I4.0 Manufacturing Environments. J. Netw. Syst. Manag. 2023, 31, 37. [Google Scholar] [CrossRef]

- Quadrini, W.; Cimino, C.; Abdel-Aty, T.A.; Fumagalli, L.; Rovere, D. Asset Administration Shell as an interoperable enabler of Industry 4.0 software architectures: A case study. Procedia Comput. Sci. 2023, 217, 1794–1802. [Google Scholar] [CrossRef]

- Bär, M.A.; Colombo, A.W. Engineering ICPS for Small and Medium Enterprises: A Novel DIN SPEC 91345 Compliant Digitalization Approach. IEEE Trans. Ind. Cyber-Phys. Syst. 2023, 1, 307–321. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef]

- Garcia, A.; Oregui, X.; Arrieta, U.; Valverde, I. Methodology and Tools to Integrate Industry 4.0 CPS into Process Design and Management: ISA-88 Use Case. Information 2022, 13, 226. [Google Scholar] [CrossRef]

- Cindrić, I.; Jurčević, M.; Hadjina, T. Mapping of Industrial IoT to IEC 62443 Standards. Sensors 2025, 25, 728. [Google Scholar] [CrossRef] [PubMed]

- Sufian, A.T.; Abdullah, B.M.; Miller, O.J. Smart Manufacturing Application in Precision Manufacturing. Appl. Sci. 2025, 15, 915. [Google Scholar] [CrossRef]

- Oñate, W.; Sanz, R. Fog Computing Architecture for Load Balancing in Parallel Production with a Distributed MES. Appl. Sci. 2025, 15, 7438. [Google Scholar] [CrossRef]

| Keyword Group | KWG1 | KWG2 | KWG3 |

|---|---|---|---|

| List of keywords | Manufacturing, Management, Maintenance, System, Process, Cyber-physical, Network, Environment, Factory, Company, Enterprise | Dynamic, Distributed, Parallel, Extended, Integrated, Real-Time, Agile, Intelligent | Artificial Intelligence, IoT, Technology, Augmented Reality, Virtual Reality, Mixed Reality, Digital Twins. |

| Publisher | Contribution Trend | Main Characteristics | Key Insight |

|---|---|---|---|

| MDPI | Rapid increase since 2019 | Strong focus on multidisciplinary and applied research; publishes extensively on Industry 4.0 topics | Rapid growth reflects the success of its open-access model and its appeal to fast-evolving research areas |

| Elsevier | Steady over the decade | Established reputation; large portfolio in engineering, manufacturing, and management | Remains a cornerstone for both foundational and applied research in the field |

| IEEE | Steady but smaller increase | Emphasis on technological and engineering innovations; focus on core enabling technologies like CPS and IoT | Plays a key role in technology-centric contributions, though with fewer total publications |

| Authors | Main Contributions | Source (Journal/Editor) |

|---|---|---|

| Roeck, D. (2020) [12] | Refers to the Foundation of Distributed Ledger Technology for Supply-Chain Management | HICSS, ScholarSpace |

| Koulamas, C. and Lazarescu, M.T. (2020) [13] | Study real-time sensor networks and systems for the industrial IoT. | Journal of Manufacturing Science and Engineering, ASME |

| Zhou et al. (2021) [14] | Study intelligent small object detection for digital twin in smart manufacturing with industrial cyber-physical systems. | IEEE Transactions on Industrial Informatics |

| Simion et al. (2021) [15] | Research on the Use of Integrated Management Systems | Advances in Science and Technology |

| Kagermann, H., Wahlster, W. and Helbig, J. (2022) [1] | Discusses the key technologies and concepts driving Industry 4.0 and their impact on manufacturing. | Sci, MDPI |

| Singh et al. (2022) [16] | Focus on the applications of digital twin across industries, based on a literature review. | Applied Sciences, MDPI |

| Flores-García et al. (2023) [17] | A study on enabling digital servitization based on the Industrial Internet of Things (IIoT) in smart production logistics. | International Journal of Production Research, Taylor & Francis |

| Wang, H., Yan, Q. and Wang, J. (2023) [18] | Refer to blockchain-secured multi-factory production with collaborative maintenance using Q learning-based optimization approach. | International Journal of Production Research, Taylor & Francis |

| Grieves (2024) [19] | Intelligent digital twins and the development and management of complex systems | Digital Twin, Taylor & Francis |

| Li et al. (2024) [20] | Refer to a digital twin system for Task-Replanning and Human-Robot control of robot manipulation | Advanced Engineering Informatics, Elsevier. |

| Zheng et al. (2024) [21] | Distributed Energy Management of Multi-Entity Integrated Electricity and Heat Systems: A Review of Architectures, Optimization Algorithms, and Prospects | IEEE Transactions on Smart Grid |

| Ghuge, Akarte and Raut, (2024) [22] | Decision-making frameworks in additive manufacturing management: mapping present landscape and establishing future research avenues | Benchmarking: An International Journal |

| Khan et al. (2024) [23] | Measuring economic resilience of manufacturing organization leveraging integrated data envelopment analysis (DEA)-machine learning approach | International Journal of Management Science and Engineering Management |

| Kim et al. (2024) [24] | Techno-economic analysis for design and management of international green hydrogen supply chain under uncertainty: An integrated temporal planning approach | Energy Conversion and Management |

| Hammad, M. et al. (2023) [25] | Propose a framework using fuzzy DEMATEL to support smart manufacturing implementation in SMEs. | Processes, MDPI |

| Vacchi, M. et al. (2024) [26] | Propose a strategic framework for assessing technological sustainability to support the transition from Industry 4.0 to 5.0. | Sustainability, MDPI |

| Martín-Gómez, A.M. et al. (2024) [27] | Propose a framework integrating Industry 4.0 technologies with Industry 5.0 values for sustainable manufacturing. | Sustainability, MDPI |

| Wang, Y. et al. (2024) [28] | Present an intelligent management system for small-scale industries, integrating IoT and optimization algorithms. | Electronics, MDPI |

| Raddi-Mira, M. et al. (2024) [29] | Assess maturity models for smart factories in the context of Industry 5.0, identifying evaluation gaps and priorities. | Sustainability, MDPI |

| Lyngdorf, A. et al. (2024) [30] | Review and structure smart maintenance within Industry 5.0 using a PRISMA-based systematic literature review. | Education Sciences, MDPI |

| Bastos, F. et al. (2024) [31] | Present a knowledge-based model to evaluate a framework of the best practices to drive the digital transition in industry’s | Future Internet, MDPI |

| Maria, H. et al. (2025) [32] | Integrated approach for evaluating maturity models in smart factories, aligning with Industry 5.0 values. | Technological Forecasting and Social Change, Elsevier |

| Dehghan, S. et al. (2025) [33] | Provide a bibliometric analysis of the integration of additive manufacturing into Industry 4.0 and 5.0 paradigms. | Machines, MDPI |

| Md Tariqul Islam et al. (2025) [34] | Identify key challenges and enabling technologies for Smart Manufacturing transition through a systematic literature review. | Machines, MDPI |

| Framework | Focus | Real-Time | Edge/AI Integration | Human-Centric | Implementation Level |

|---|---|---|---|---|---|

| ISA-95 | Enterprise Control Levels | X | X | X | Conceptual |

| RAMI 4.0 | Asset Lifecycle and Layers | ◒ | ◒ | X | Reference |

| IIRA | Domains and Functional View | ◒ | ◒ | X | Reference |

| Proposed | Integrated Execution Model | ✓ | ✓ | ✓ | Practical, Deployable |

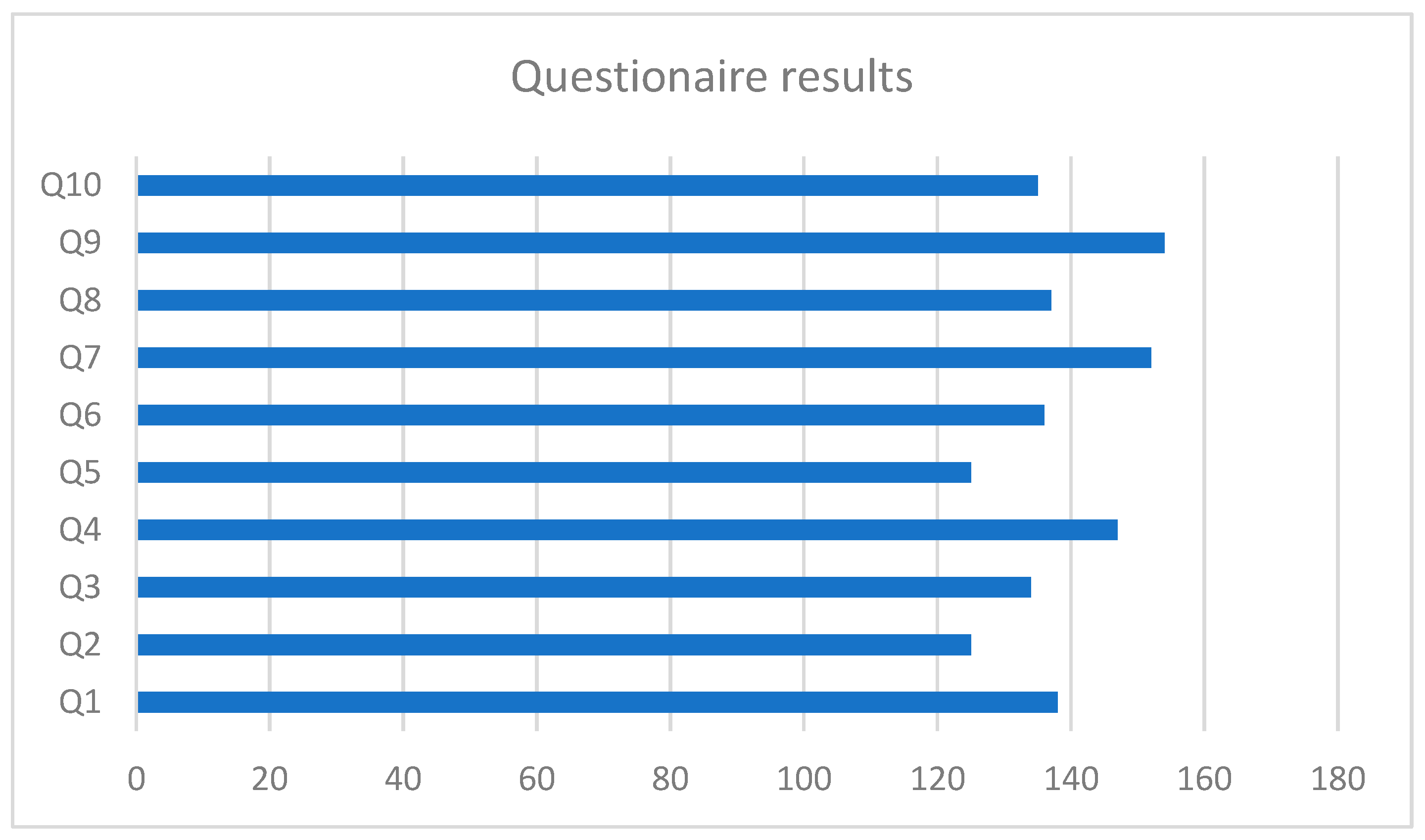

| Question | Management Paradigm (Technology/Tool) | Number of Points (Assessment Order) |

|---|---|---|

| Q1 | Dynamic | 138 (4) |

| Q2 | Augmented/virtual/mixed reality | 125 (9) |

| Q3 | Cloud computing | 134 (8) |

| Q4 | Real time based | 147 (3) |

| Q5 | Cyber physical systems | 125 (9) |

| Q6 | Digital twins | 136 (6) |

| Q7 | Distributed/Parallel | 152 (2) |

| Q8 | Agile | 137 (5) |

| Q9 | Integrated | 154 (1) |

| Q10 | Intelligent | 135 (7) |

| Evaluation Dimension | Assessment Method |

|---|---|

| Real-time integration | Questionnaire (Q4, Q9) |

| Decision-making support | Questionnaire + Interview |

| Usability and user satisfaction | Open-ended feedback |

| External interoperability | Questionnaire (Q6, Q10) |

| System flexibility and agility | Questionnaire (Q1, Q7, Q8) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, M.Â.; Vieira, G.; Varela, L.; Putnik, G.; Cruz-Cunha, M.; Santos, A.; Dieguez, T.; Pereira, F.; Leal, N.; Machado, J. Manufacturing Management Processes Integration Framework. Appl. Sci. 2025, 15, 9165. https://doi.org/10.3390/app15169165

Pereira MÂ, Vieira G, Varela L, Putnik G, Cruz-Cunha M, Santos A, Dieguez T, Pereira F, Leal N, Machado J. Manufacturing Management Processes Integration Framework. Applied Sciences. 2025; 15(16):9165. https://doi.org/10.3390/app15169165

Chicago/Turabian StylePereira, Miguel Ângelo, Gaspar Vieira, Leonilde Varela, Goran Putnik, Manuela Cruz-Cunha, André Santos, Teresa Dieguez, Filipe Pereira, Nuno Leal, and José Machado. 2025. "Manufacturing Management Processes Integration Framework" Applied Sciences 15, no. 16: 9165. https://doi.org/10.3390/app15169165

APA StylePereira, M. Â., Vieira, G., Varela, L., Putnik, G., Cruz-Cunha, M., Santos, A., Dieguez, T., Pereira, F., Leal, N., & Machado, J. (2025). Manufacturing Management Processes Integration Framework. Applied Sciences, 15(16), 9165. https://doi.org/10.3390/app15169165