Seismic Performance of Multi-Floor Grain Warehouse Under Various Storage Conditions

Abstract

1. Introduction

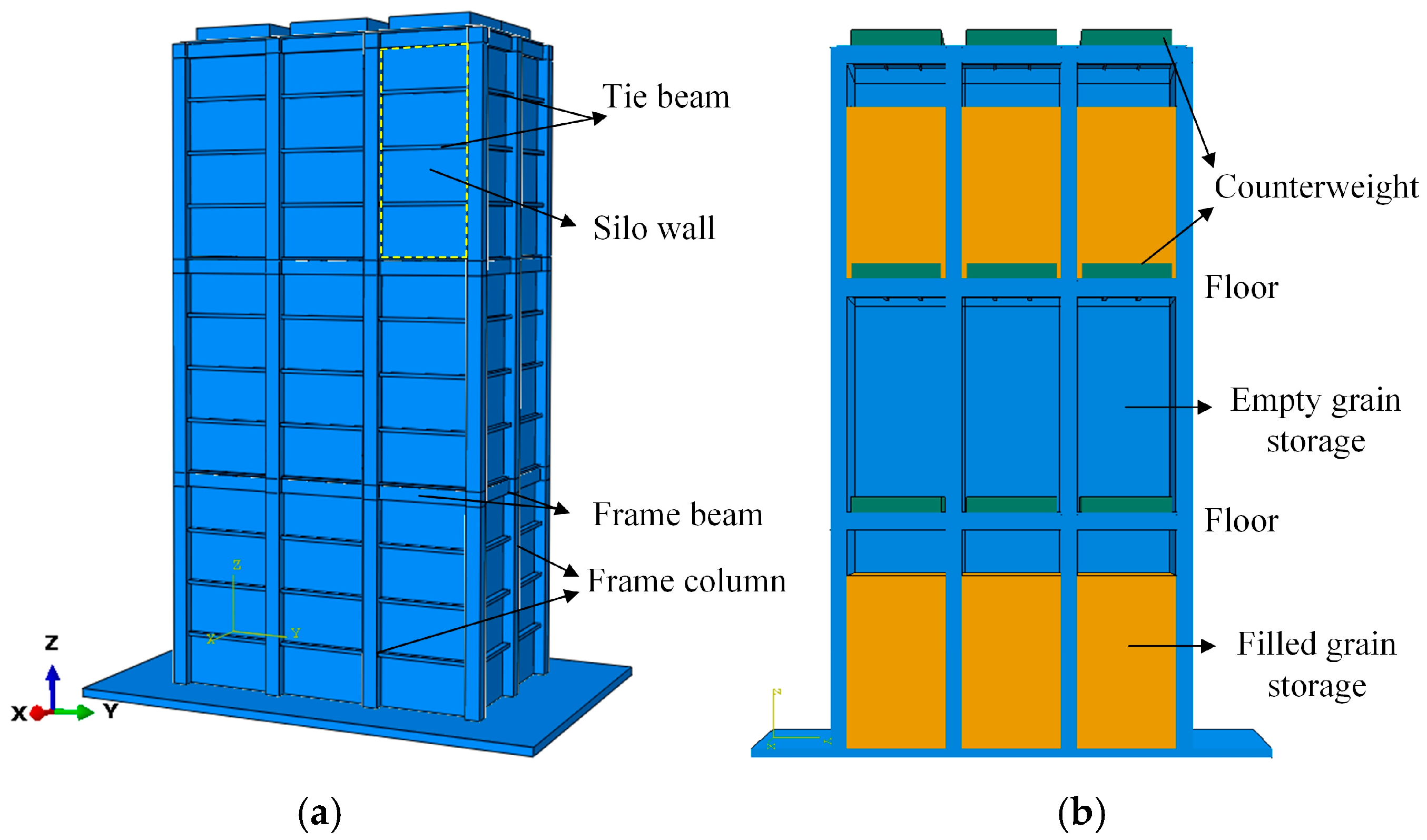

2. Numerical Model of Multi-Floor Grain Warehouse

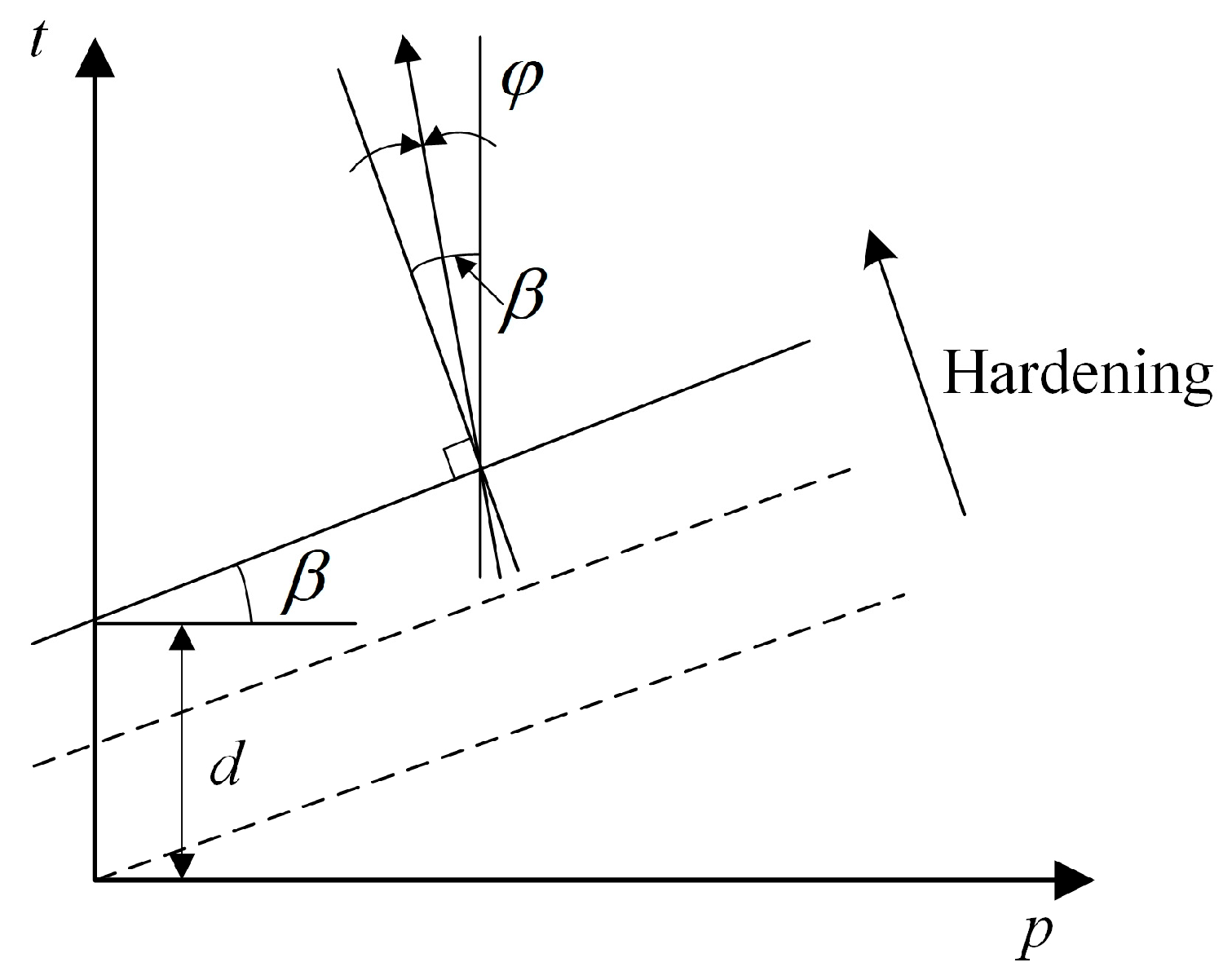

2.1. Constitutive Model of Storage Material

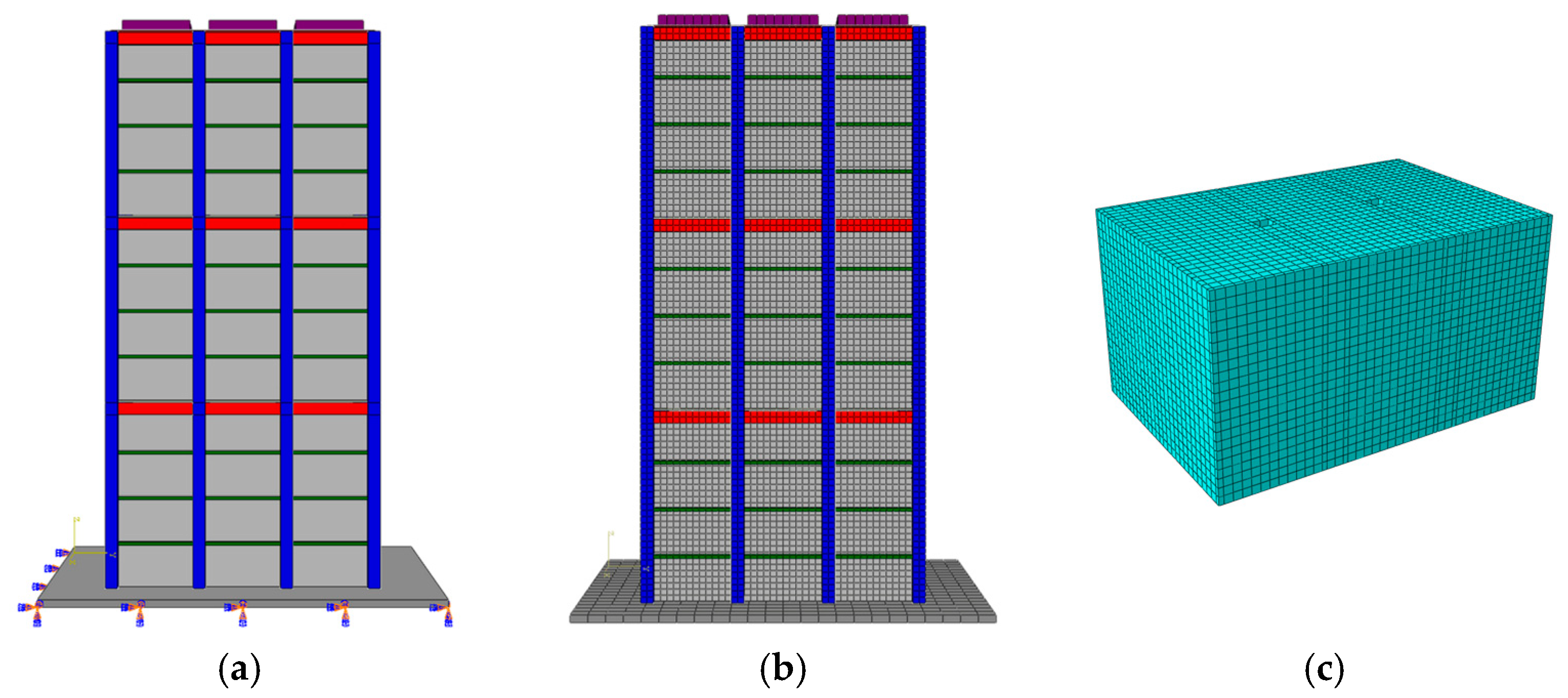

2.2. Boundary Conditions and Mesh Division

3. Validation of Numerical Model of Multi-Floor Grain Warehouse Model by Shaking Table

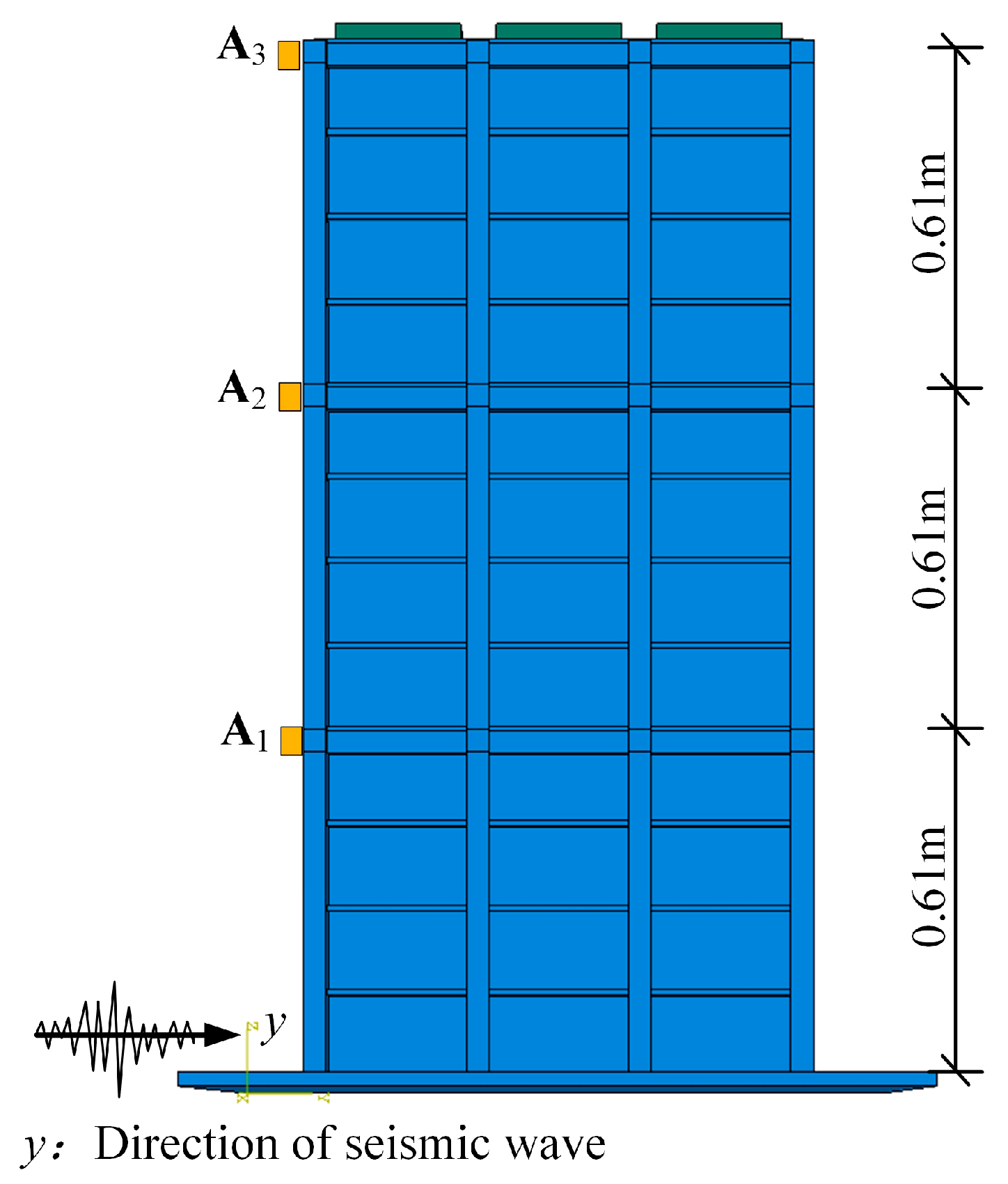

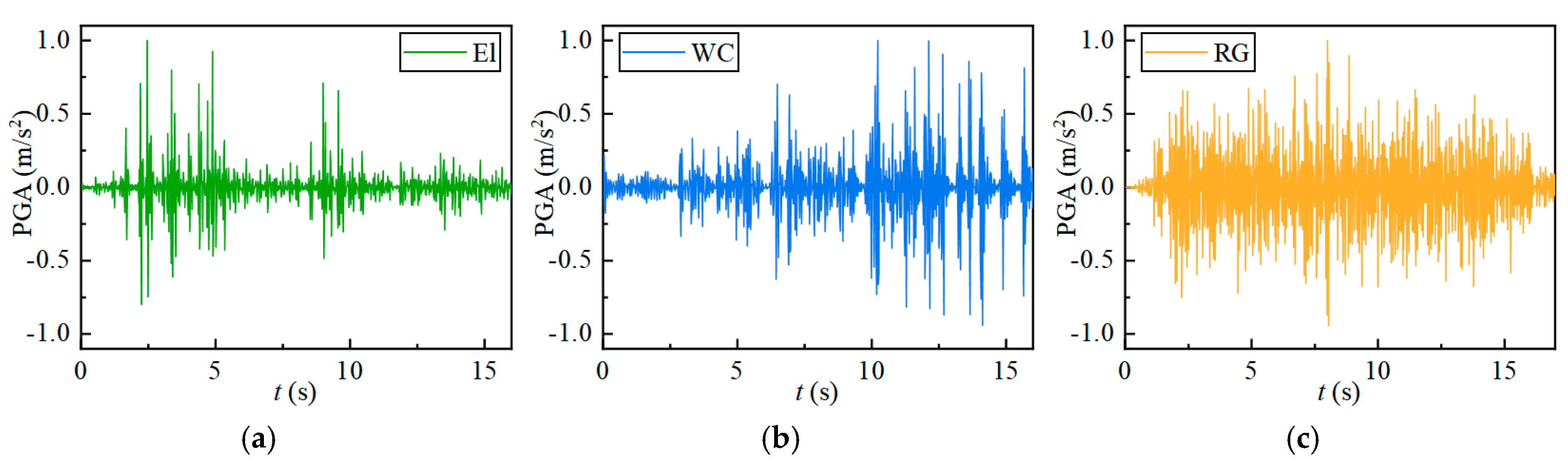

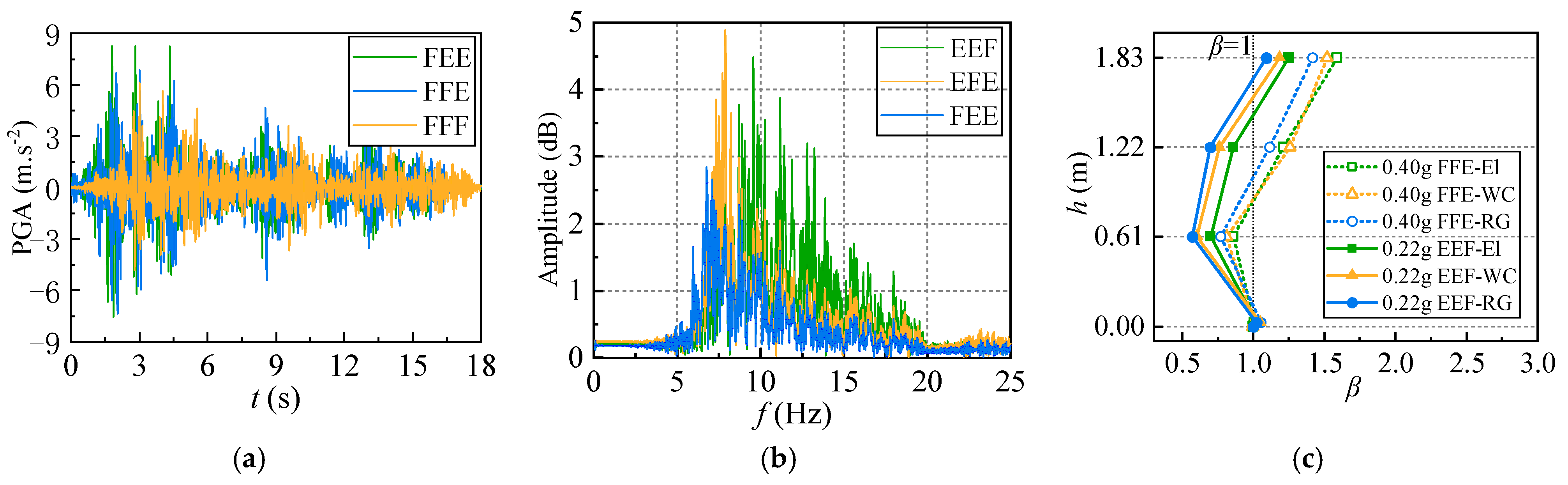

3.1. Introduction to the Shaking Table Test

3.2. Comparison of Dynamic Characteristics

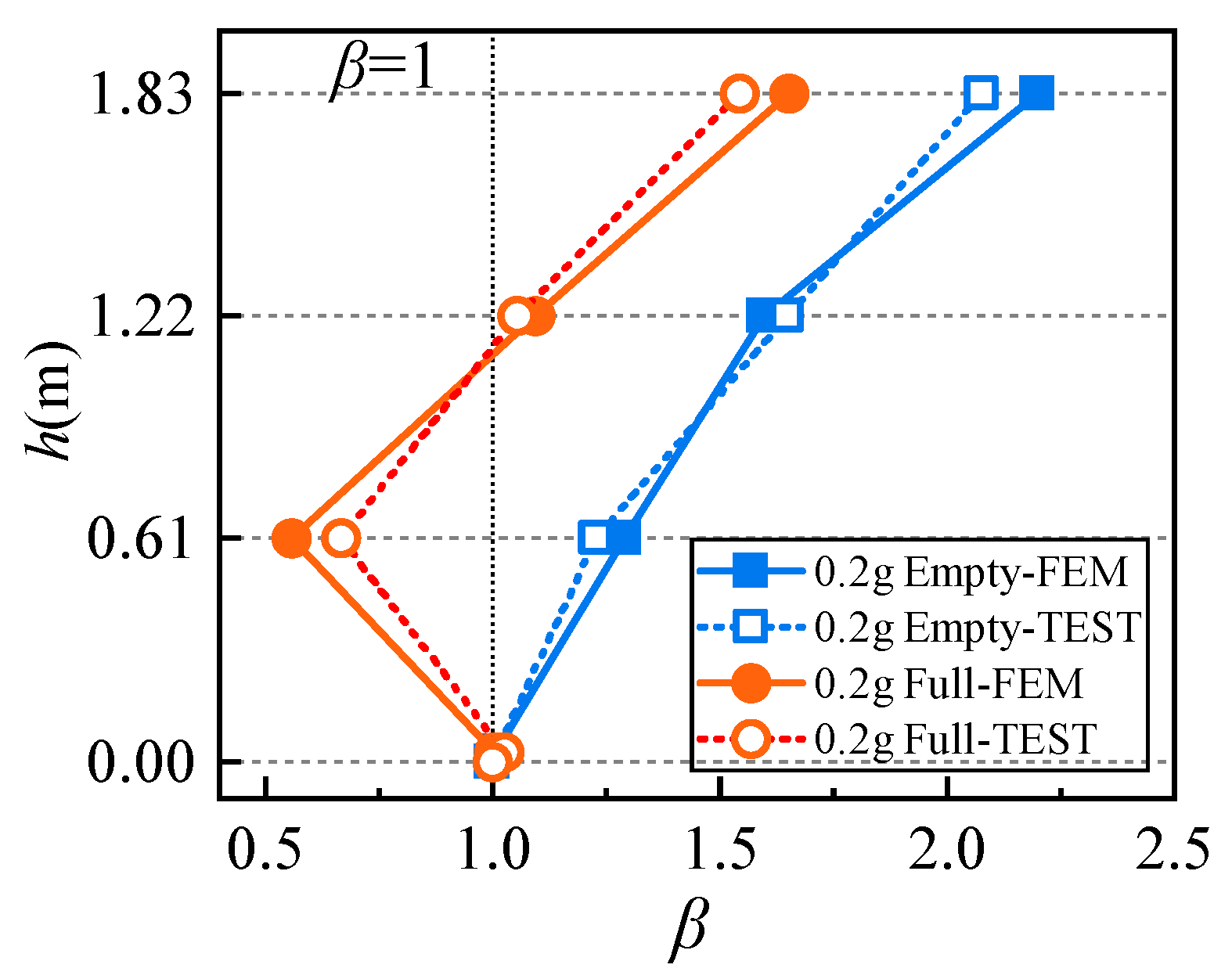

3.3. Comparison of Acceleration Response

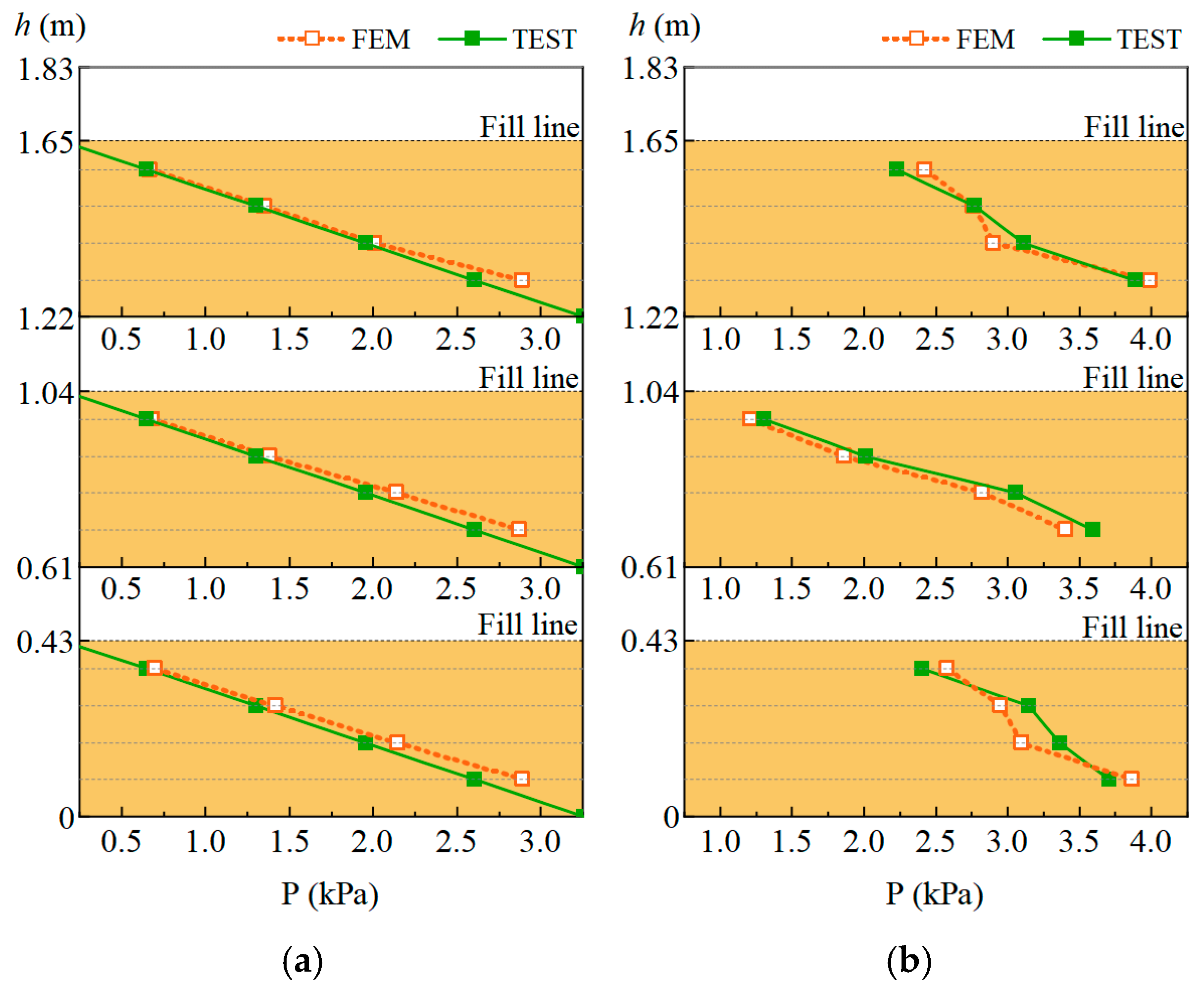

3.4. Comparative Analysis of Pressure on Silo Walls

4. Effects of Storage Conditions on Seismic Response of Multi-Floor Grain Warehouses

4.1. Comparison of Pressure on Silo Walls

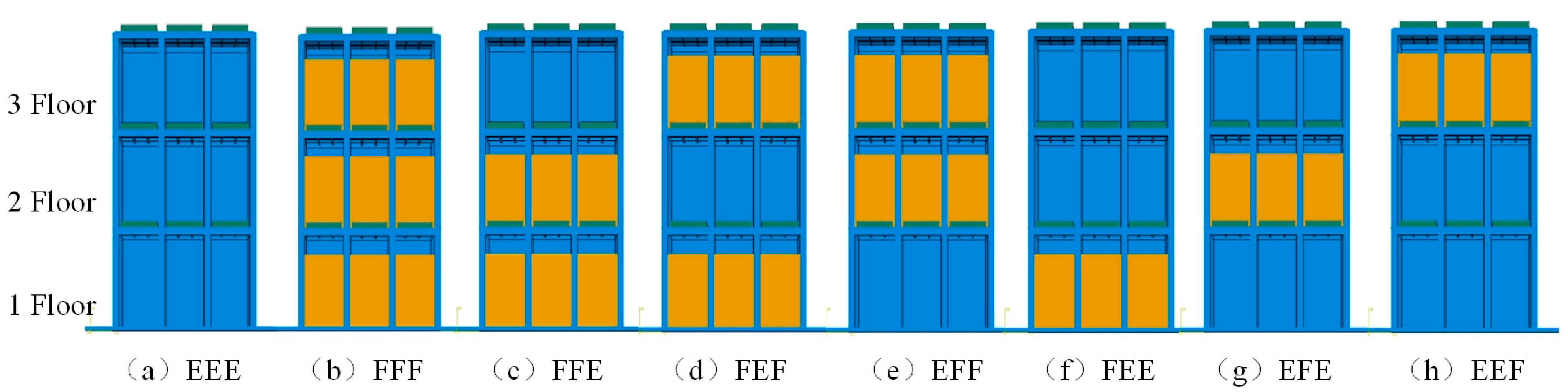

4.2. Definition of Storage Conditions in a Multi-Floor Grain Warehouse

4.3. Natural Frequency

4.4. Acceleration Response of the Structure

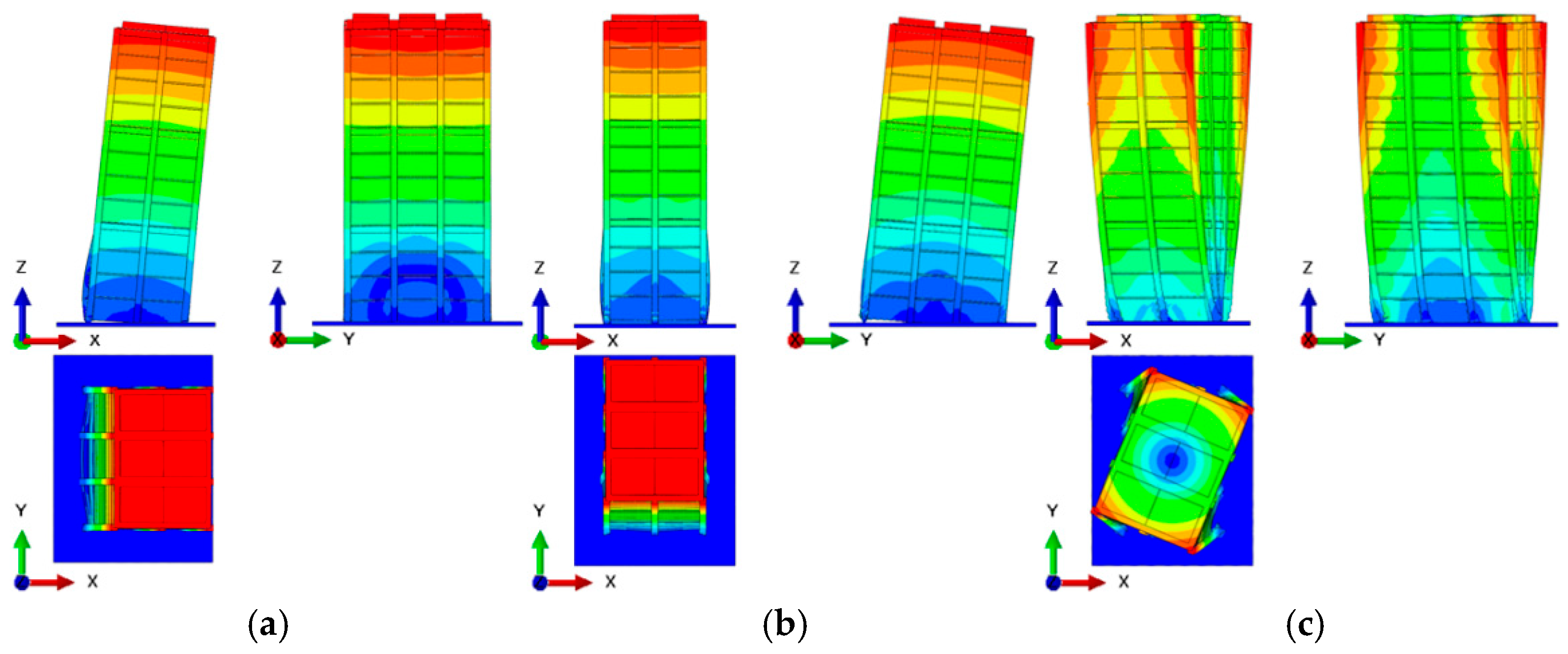

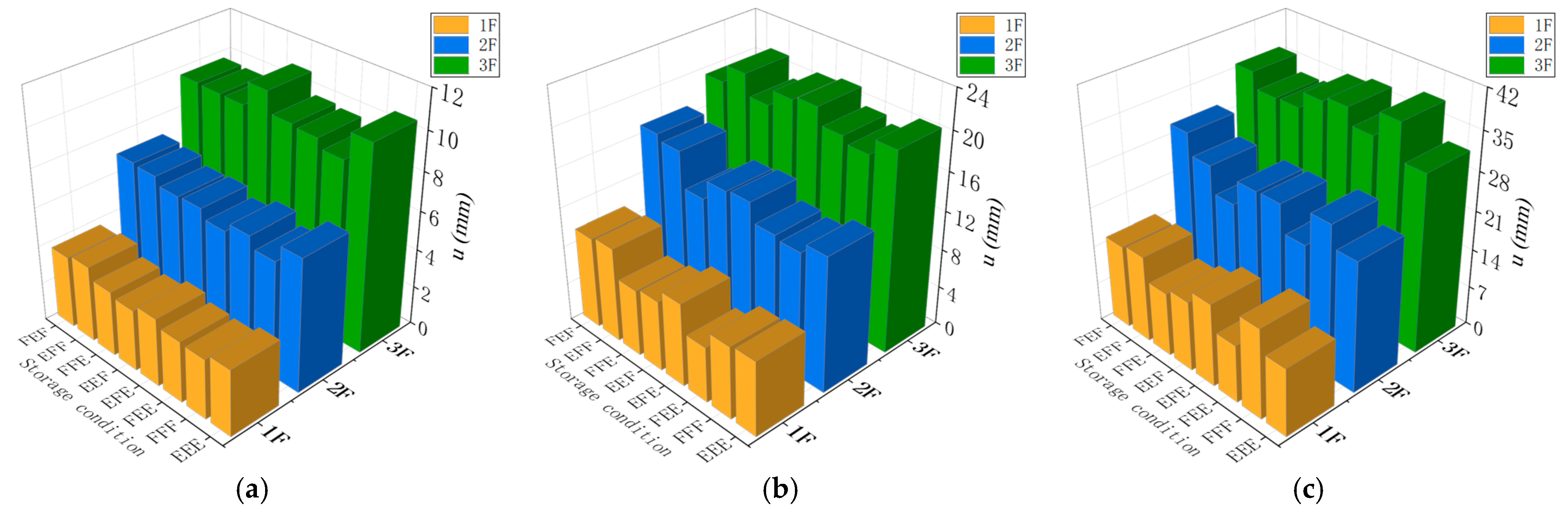

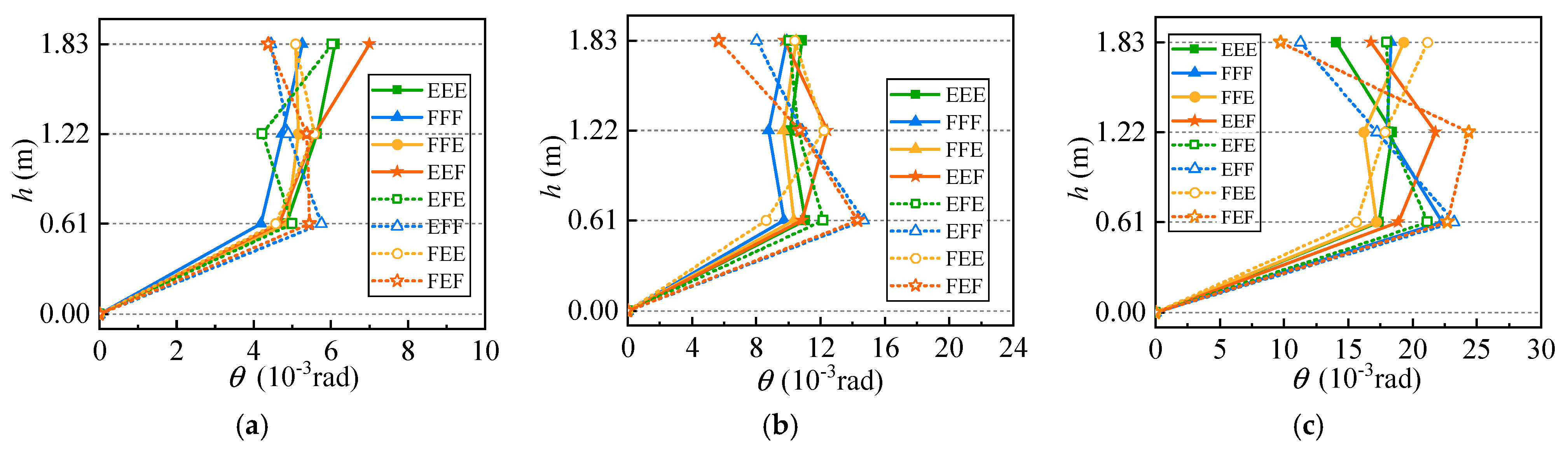

4.5. Displacement Response of the Structure

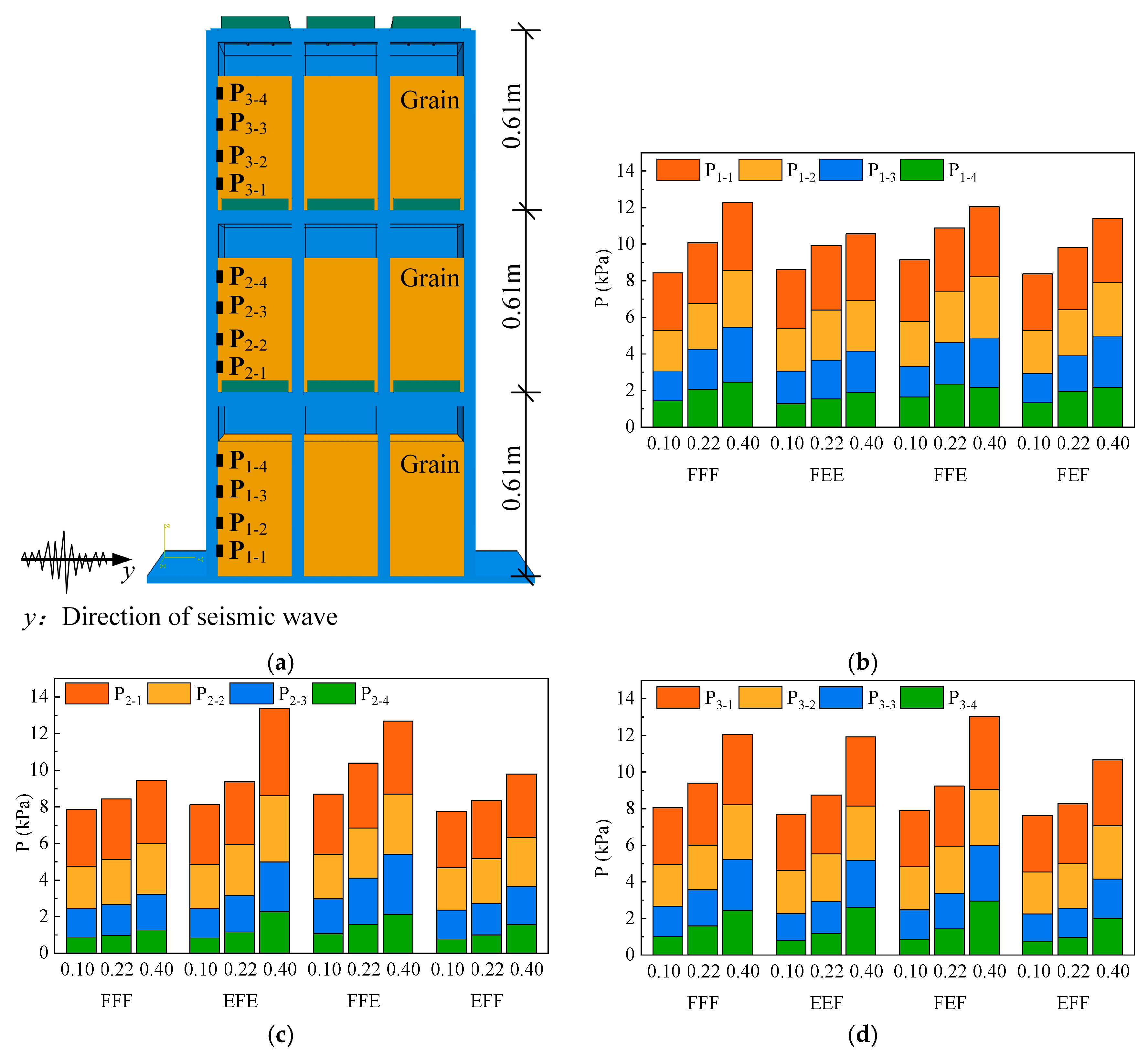

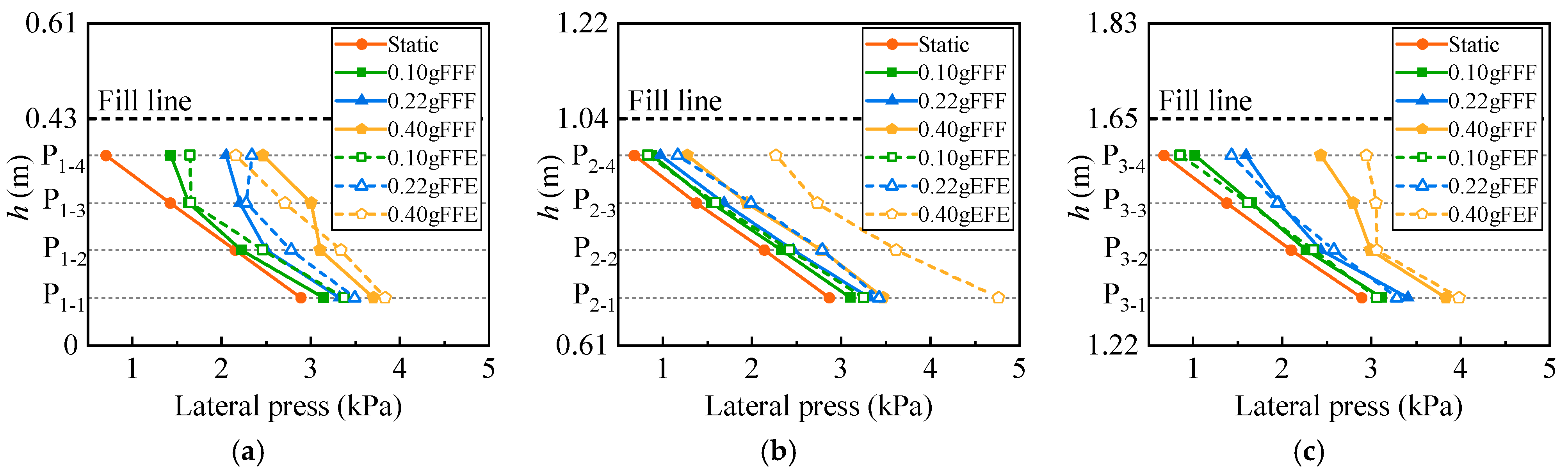

4.6. Pressure on Silo Walls of the Structure

5. Conclusions

- (1)

- An increase in the mass of the storage materials leads to a decrease in the natural frequency. The first-order natural frequencies of the FEE, FFE, and FFF storage conditions are reduced by 29%, 30%, and 36%, respectively, compared with EEE. A higher storage position results in a large damping ratio of the structural model, indicating a more pronounced contribution of storage material movement to overall structural damping.

- (2)

- The intensity of earthquake action is negatively correlated with the acceleration response of the structure. Under the FFF condition, when the PGA is 0.4 g, the acceleration amplification coefficient at the top of the structure is 69.7% of the corresponding parameter when PGA is 0.10 g. The higher the storage floor of the material, the more significant the reduction in structural acceleration. Under 0.40 g earthquake action, the acceleration amplification factors of two layers of material under EFF and one layer of material under EEF are 52.0% and 58.8% of those under the EEE condition, respectively.

- (3)

- The discontinuity of the storage space within the structure increases the possibility of higher-order vibration modes, resulting in a torsional effect on the structure. When the PGA is 0.22 g, the peak drift ratio of the first floor in the EFF condition is 1.7 times that of the FEE, while under a PGA of 0.40 g, the peak drift ratio of the second floor in the FEF condition is 1.5 times that in the FFE condition.

- (4)

- The distribution of silo wall pressure at varying burial depths under seismic excitation exhibits a pronounced nonlinear trend, and the overpressure coefficient at the same burial depth of the warehouse wall is directly proportional to the PGA of the earthquake. Under 0.1 g, 0.22 g, and 0.40 g seismic action, the maximum overpressure coefficients at the Pi-1 position at the bottom of the warehouse wall on different floors are 1.13, 1.21, and 1.66, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China News Service. Shenzhen Longgang Xikeng to Build the Nation’s “Tallest” Granary; China News Service: Beijing, China, 2024. [Google Scholar]

- GB50320-2014; Code for Design of Grain Storehouse. China Planning Press: Beijing, China, 2014.

- Xu, J.; Lv, J.; Bai, C.; Tang, P.A.; Guo, C.; Zhang, L.L. Advances in Research and Application of Modified Atmosphere in the Control of Stored Grain Pests. J. Chin. Cereals Oils Assoc. 2017, 38, 21–28, (In Chinese with English Abstract). [Google Scholar]

- Wang, S.X.; Fu, P.C.; Liu, S.Q.; Ye, Z.H.; Zeng, L.P.; Jiang, Z.X. Current Situation and Prospect of Application and Development of Low-Temperature Grain Storage Technology in China. J. Chin. Cereals Oils Assoc. 2023, 38, 215–224. [Google Scholar]

- Li, Z.; Ding, Y.; Zhao, J.; Guo, C.; Xu, Z.; Xu, Q.; Ren, G.; Liu, H. Experimental study on spatial joint of prefabricated steel reinforced concrete multi-floored grain warehouse. J. Build. Eng. 2025, 103, 112001. [Google Scholar] [CrossRef]

- Wang, L.; Xu, Q.; Liu, Y. Simple analysis of the current status and development of bulk grain building warehouses. Grain Distrib. Technol. 2013, 4, 9–11, (In Chinese with English Abstract). [Google Scholar]

- Zhang, Q.; Qiu, X.; Wang, Z. Column space analysis of multi-storied warehouse with bulk grain based on economy. J. Henan Univ. Technol. 2016, 37, 107–113, (In Chinese with English Abstract). [Google Scholar]

- Zhang, Q.; Qiu, X.; Wang, Z. Mechanical characteristics and structure type selection of multi-storied warehouse with bulk grain. J. Henan Univ. Technol. 2016, 37, 111–115, (In Chinese with English Abstract). [Google Scholar]

- Durmuş, A.; Livaoglu, R. A simplified 3 DOF model of A FEM model for seismic analysis of a silo containing elastic material accounting for soil–structure interaction. Soil Dyn. Earthq. Eng. 2015, 77, 1–14. [Google Scholar] [CrossRef]

- Tremblay, R.; Mitchell, D.; Tinawi, R. Damage to industrial structures due to the 27 February 2010 Chile earthquake. Can. J. Civ. Eng. 2013, 40, 735–749. [Google Scholar] [CrossRef]

- Gu, Z.; Liu, C. Vulnerability analysis of the grain multi-storied warehouse under earthquake load. J. Water Resour. Archit. Eng. 2022, 20, 209–215, (In Chinese with English Abstract). [Google Scholar]

- Xu, Q.; Shi, Z.; Liu, Q.; Ding, Y.; Ren, G. Dynamic characteristics of granular grain building warehouse under different storage conditions. Trans. Chin. Soc. Agric. Eng. 2023, 39, 272–278, (In Chinese with English Abstract). [Google Scholar]

- Xu, Q.; Zhang, R.; Liu, Q.; Cao, L.; Ding, Y.; Wang, H. Dynamic lateral pressure analysis of granular grain building warehouse walls under seismic effects. Trans. Chin. Soc. Agric. Eng. 2024, 40, 49–58, (In Chinese with English Abstract). [Google Scholar]

- Sun, W.; Qi, F.; Yuan, J.; Cao, Y.; Wang, L.; Zhou, L.; Wu, Y.; Feng, J. Structural behavior of stiffened steel silos subject to eccentric discharge pressures. Stored Prod. Res. 2025, 114, 102741. [Google Scholar] [CrossRef]

- Xu, Y.; Quan, C.; Li, R.; Wang, W.; Hua, Y.; Yang, H. Measurement of static and dynamic normal stress of granular materials in silos. Measurement 2025, 252, 117335. [Google Scholar] [CrossRef]

- Pinilla, A.; Fuentes, J.M.; Ayuga, F.; Gallego, E. Experimental Measurements in a Model Silo with Eccentric Hoppers. Powder Technol. 2025, 467, 121514. [Google Scholar] [CrossRef]

- Dornelas, K.C.; Soares Rodrigues, H.C.; Gandia, R.M.; Gomes, F.C.; Nascimento, J.W.B.D. Pressures Measurements of Maize Grain in Cylindrical Steel Silos and Comparison with Different International Standards. J. Stored Prod. Res. 2024, 108, 102391. [Google Scholar] [CrossRef]

- Ding, Y.; Sun, Q.; Liu, Q.; Xu, Q. Experimental study on dynamic lateral pressure of vertical grain silo during layered unloading. J. Henan Univ. Technol. 2022, 43, 113–120, (In Chinese with English Abstract). [Google Scholar]

- Chen, Y.; Lv, Y.; Wu, K.; Huang, X.; Shi, Y.-D. Special-Shape Similitude Law of a Soil-pile–Structure Model for Centrifuge Shaking Table Tests. Ocean Eng. 2023, 286, 115682. [Google Scholar] [CrossRef]

- Khalil, M.; Ruggieri, S.; Tateo, V.; Butenweg, C.; Nascimbene, R.; Uva, G. Assessment of the seismic overpressure in flat bottom steel silos based on advanced FE modelling approach. Soil Dyn. Earthq. Eng. 2025, 190, 109149. [Google Scholar] [CrossRef]

- Dornelas, K.C.; Rodrigues, H.C.S.; Cheung, A.B.; Junior, C.C.; Nascimento, J.W.B. Pressures in squat steel silo with flat bottom storing maize grain. Stored Prod. Res. 2024, 109, 102424. [Google Scholar] [CrossRef]

- Demir, A.D.; Livaoglu, R. Simplified seismic response model for a bulk solid-silo-embedded foundation/soil system. Soil Dyn. Earthq. Eng. 2023, 165, 107664. [Google Scholar] [CrossRef]

- Jing, H.; He, W.; Yang, J. Test on dynamic interaction of soybean storage and steel silo model. J. Henan Univ. Sci. Technol. 2023, 44, 84–92, (In Chinese with English Abstract). [Google Scholar]

- Demir, A.D.; Livaoglu, R. SSI effects on seismic response of RC flat-bottom circular silos. Structures 2023, 57, 105296. [Google Scholar] [CrossRef]

- GB/T50011-2010 CS; Code for Seismic Design of Buildings. China Building Industry Press: Beijing, China, 2024.

- Goodey, R.J.; Brown, C.J.; Rotter, J.M. Verification of a 3-dimensional model for filling pressures in square thin-walled silos. Eng. Struct. 2003, 25, 1773–1783. [Google Scholar] [CrossRef]

- Furinghetti, M.; Mansour, S.; Marra, M.; Silvestri, S.; Lanese, I.; Weber, F.; Pavese, A. Shaking table tests of a full-scale base-isolated flat-bottom steel silo equipped with curved surface slider bearings. Soil Dyn. Earthq. Eng. 2024, 176, 108321. [Google Scholar] [CrossRef]

- Fullard, L.A.; Godfrey, A.J.R.; Manaf, M.F.; Davies, C.E.; Cliff, A.; Fukuoka, M. Mixing experiments in 3D-printed silos; the role of wall friction and flow correcting inserts. Adv. Powder Technol. 2020, 31, 1915–1923. [Google Scholar] [CrossRef]

- Mehretehran, A.M.; Maleki, S. Axial buckling of imperfect cylindrical steel silos with isotropic walls under stored solids loads: FE analyses versus Eurocode provisions. Eng. Fail. Anal. 2022, 137, 106282. [Google Scholar] [CrossRef]

- Brunesi, E.; Nascimbene, R.; Pagani, M.; Beilic, D. Seismic performance of storage steel tanks during the May 2012 Emilia, Italy, earthquakes. J. Perform. Constr. Facil. 2015, 29, 04014137. [Google Scholar] [CrossRef]

- Nateghi, F.; Yakhchalian, M. Seismic behavior of silos with different height to diameter ratios considering granular material structure interaction. Int. J. Eng. 2012, 25, 27–37. [Google Scholar] [CrossRef]

- Silvestri, S.; Mansour, S.; Marra, M.; Distl, J.; Furinghetti, M.; Lanese, I.; Hernández-Montes, E.; Neri, C.; Palermo, M.; Pavese, A.; et al. Shaking table tests of a full-scale flat-bottom manufactured steel silo filled with wheat: Main results on the fixed-base configuration. Earthq. Eng. Struct. Dyn. 2022, 51, 169–190. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, X.; Hao, H. Overpressure rise rate prediction method for hydrogen-air explosions in vented silos. Gas Sci. Eng. 2025, 136, 205565. [Google Scholar] [CrossRef]

| Mass Density | Modulus of Elasticity | Poisson’s Ratio | Flow Stress Ratio | Damp | Internal Friction Angle | Friction Between CBPs and PMMA |

|---|---|---|---|---|---|---|

| ρ/(kg/m3) | E/MPa | ν | κ | c | φ | μ |

| 1346 | 2 | 0.3 | 0.841 | 0.5 | 15° | 0.27 |

| Vibration Pattern | Empty Silo | Full Silo | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | |

| FEM | 10.85 | 11.69 | 36.06 | 6.86 | 7.44 | 21.55 |

| TEST | 10.31 | - | - | 7.34 | - | - |

| Seismic Intensity | PGA (g = 10 m/s2) | PGA of Actual Input (g) |

|---|---|---|

| 7-degree fortification | 0.10 g | 0.15 g |

| 7-degree rare | 0.22 g | 0.33 g |

| 8-degree rare | 0.40 g | 0.6 g |

| Vibration Mode | Storage Conditions | |||||||

|---|---|---|---|---|---|---|---|---|

| EEE | FEE | FFE | FFF | FEF | EEF | EFF | EFE | |

| 1 | 10.85 | 7.69 | 7.51 | 6.86 | 7.96 | 8.15 | 7.63 | 8.56 |

| 2 | 11.69 | 8.43 | 9.88 | 7.44 | 10.55 | 8.78 | 8.22 | 11.05 |

| 3 | 36.06 | 25.40 | 24.49 | 21.55 | 26.67 | 26.23 | 23.86 | 27.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Ding, Y.; Wang, G.; Xu, Q.; Zhang, Y. Seismic Performance of Multi-Floor Grain Warehouse Under Various Storage Conditions. Appl. Sci. 2025, 15, 9128. https://doi.org/10.3390/app15169128

Wang H, Ding Y, Wang G, Xu Q, Zhang Y. Seismic Performance of Multi-Floor Grain Warehouse Under Various Storage Conditions. Applied Sciences. 2025; 15(16):9128. https://doi.org/10.3390/app15169128

Chicago/Turabian StyleWang, Huifen, Yonggang Ding, Guiling Wang, Qikeng Xu, and Yanan Zhang. 2025. "Seismic Performance of Multi-Floor Grain Warehouse Under Various Storage Conditions" Applied Sciences 15, no. 16: 9128. https://doi.org/10.3390/app15169128

APA StyleWang, H., Ding, Y., Wang, G., Xu, Q., & Zhang, Y. (2025). Seismic Performance of Multi-Floor Grain Warehouse Under Various Storage Conditions. Applied Sciences, 15(16), 9128. https://doi.org/10.3390/app15169128