Featured Application

The proposed 3 m hybrid wind–photovoltaic rotor—with pivoting PV-coated blades and a lightweight rigidising rim—can be deployed as a single-mast micro-generator for remote farms, off-grid cabins, and smart-grid street-lighting poles where roof or ground area is limited. By harvesting wind energy at night and photovoltaic power during the day (or simultaneously in moderate winds), the unit delivers a higher annual energy yield per square metre than separate small wind or rooftop PV systems, while requiring only one foundation and one power electronics package.

Abstract

This paper presents a literature review of low-power hybrid wind–photovoltaic (PV) systems and introduces a 3 m diameter prototype rotor featuring twelve PV-coated pivoting blades stiffened by a peripheral rim. Existing solutions—foldable umbrella concepts, Darrieus rotors with PV-integrated blades, and morphing blades—are surveyed, and current gaps in simultaneous wind + PV co-generation on a single moving structure are highlighted. Key performance indicators such as power coefficient (Cp), DC ripple, cell temperature difference (ΔT), and levelised cost of energy (LCOE) are defined, and an integrated assessment methodology is proposed based on blade element momentum (BEM) and computational fluid dynamics (CFD) modelling, dynamic current–voltage (I–V) testing, and failure modes and effects analysis (FMEA) to evaluate system performance and reliability. Preliminary results point to moderate aerodynamic penalties (ΔCp ≈ 5–8%), PV output during rotation equal to 15–25% of the nominal PV power (PPV), and an estimated 70–75% reduction in blade–root bending moment when the peripheral ring converts each blade from a cantilever to a simply supported member, resulting in increased blade stiffness. Major challenges include the collective pitch mechanism, dynamic shading, and wear of rotating components (slip rings); however, the suggested technical measures—maximum power point tracking (MPPT), string segmentation, and redundant braking—keep performance within acceptable limits. This study concludes that the concept shows promise for distributed microgeneration, provided extensive experimental validation and IEC 61400-2-compliant standardisation are pursued. This paper has a dual scope: (i) a concise literature review relevant to low-Re flat-blade aerodynamics and ring-stiffened rotor structures and (ii) a multi-fidelity aero-structural study that culminates in a 3 m prototype proposal. We present the first evaluation of a hybrid wind–PV rotor employing untwisted flat-plate blades stiffened by a peripheral ring. Using low-Re BEM for preliminary loading, steady-state RANS-CFD (k-ω SST) for validation, and elastic FEM for sizing, we assemble a coherent load/performance dataset. After upsizing the hub pins (Ø 30 mm), ring (50 × 50 mm), and spokes (Ø 40 mm), von Mises stresses remain < 25% of the 6061-T6 yield limit and tip deflection ≤ 0.5%·R acrosscut-in (3 m s−1), nominal (5 m s−1), and extreme (25 m s−1) cases. CFD confirms a broad efficiency plateau at λ = 2.4–2.8 for β ≈ 10° and near-zero shaft torque at β = 90°, supporting a three-step pitch schedule (20° start-up → 10° nominal → 90° storm). Cross-model deviations for Cp, torque, and pressure/force distributions remain within ± 10%. This study addresses only the rotor; off-the-shelf generator, brake, screw-pitch, and azimuth/tilt drives are intended for later integration. The results provide a low-cost manufacturable architecture and a validated baseline for full-scale testing and future transient CFD/FEM iterations.

1. Introduction

1.1. Energy Context and Demand for Microscale Renewable Generation

Over the past decade, the global energy transition has effectively doubled in scope, expanding from exclusively large-utility projects to widespread distributed micro-generation owned by household prosumers, farms, and small businesses. The trend is most evident in photovoltaics: Germany alone added more than 16 GW of new PV capacity in both 2023 and 2024, roughly two-thirds coming from rooftop systems under 30 kW [1].

For small wind turbines (<50 kW), the global market reached USD 3.63 billion in 2024 and is projected to grow at an average rate of 10.5% per year up to 2034, driven by rural energy autonomy and “net-zero” urban goals [2]. In the United States, cumulative distributed wind capacity rose to 1.11 GW between 2003 and 2023 (more than 9200 turbines), and annual small wind installations have increased for three consecutive years, buoyed by tax incentives and agricultural programmes [3].

Several recent studies across multiple publishers and agencies—covering aerodynamic modelling, hybrid plant operation, and structural verification—report similar trends (e.g., [4,5,6,7,8,9,10,11,12]). Recent reviews in Energies and Applied Sciences underline that hybridization (PV + wind) is now a mainstream strategy to mitigate intermittency, cut storage needs, and improve LCOE for prosumers and small communities [13,14,15]. In parallel, a comprehensive MDPI review of commercial small wind turbines catalogues geometry, materials, costs, and performance data for >200 HAWT/VAWT products, showing a maturing market segment just below 50 kW, exactly where compact hybrids fit best [16]. Dynamic colocation issues are also being documented: TNO reports millisecond-scale, blade-passing-frequency shading (≈ 12–24 Hz for a 12-blade rotor at 60–120 rpm) that can momentarily cut PV output by up to 50%. This motivates ultrafast MPPT (effective update < 10 ms to reach ≥ 90% of the new MPP) and smart string segmentation in hybrid layouts [17]. On the PV side, Germany alone added ≈16.9 GWp in 2024, much of it rooftop and other distributed PV evidencing the policy and market push toward prosumer-scale installations that your concept targets [1]. These findings justify a deeper, more granular literature review on microhybrid architectures, adaptive blades, co-generation control, and standards IEC 61400-2 [18] to firmly position the 3 m pivoting blade prototype within today’s state of the art [4,19].

This paper has a dual objective: (i) to synthesise recent advances on flat-plate blades, peripheral stiffening rings, and wind–photovoltaic (PV) hybrid integration and (ii) to outline the design principles and experimental plan for a 3 m hybrid wind–PV rotor with a peripheral ring, while deferring full aero-structural sizing via blade element momentum (BEM), computational fluid dynamics (CFD), and finite element method (FEM) analyses to a companion paper.

1.2. Limits of Standalone PV and Wind Systems

Standalone PV suffers from intrinsic intermittency (night-time, overcast periods) and recurrent operational losses: soiling typically cuts yield by 3–4% per year (and can exceed 10% in arid climates), while overheating reduces efficiency by ≈0.4%/°C above STC. Recent MDPI studies show that, even on a small scale, passive thermal management and optimised cleaning schedules remain necessary [5,20,21].

For small wind (<50 kW), the usual constraints persist: relatively high cut-in speeds (>3 m s−1), sensitivity to urban turbulence, and modest real-world power coefficients (Cp ≈ 0.20–0.30). Recent MDPI reviews highlight the low efficiencies of small HAWT/VAWT units and note that aerodynamic tweaks (e.g., counterrotating rotors) can raise performance, but at the expense of mechanical complexity and cost [16,20].

Economically, you either oversize a single subsystem (PV or wind) or add storage (Liion, Pbacid), both pushing up CAPEX/OPEX and LCOE for isolated prosumers [18,22]. Hybrid renewable energy system (HRES) analyses in Applied Sciences and Energies confirm that combining the two sources can cut variability and battery size, but optimal design remains a multiobjective problem (cost–reliability–control) [14,15].

Conclusion: Neither PV nor wind alone can guarantee a 24/7 load profile without costly storage or oversizing. This directly motivates research that adds technical and economic value to small-scale PV–wind hybrids, which is the direction pursued in this work.

1.3. The Case for Small-Scale PV–Wind Hybrids

Wind and solar exhibit strong temporal complementarity; winds tend to intensify at night and in winter, while solar irradiance peaks during daytime and summer. Recent optimisation studies on hybrid renewable energy systems (HRESs) confirm that combining the two resources can cut overall energy variability by roughly 30–50% compared with either source alone and can shrink the required battery capacity for the same load profile [14,15,16]. Therefore, integrating both technologies into a single physical device [23]:

- -

- Reduces the land/roof footprint: one mast/nacelle/foundation instead of two separate structures;

- -

- Shares balance-of-system components: cabling, controllers, inverters, and even structural steel are jointly utilised;

- -

- Improves year-round capacity factor: low-wind/low-sun gaps are partially filled by the other source;

- -

- Offsets storage and oversizing costs: the hybrid behaves as a self-balancing micro-plant, lowering CAPEX tied to batteries or redundant generator capacity;

- -

- Facilitates modular “plug-and-play” kits for prosumers and remote users, as highlighted in recent MDPI case studies.

These advantages justify a deeper technical investigation into co-located PV–wind architectures, especially compact systems (<5 kW) where mechanical integration (pivoting blades, shared swept area) can further increase energy density per square metre.

1.4. Originality and Positioning Relative to Existing Research (Revised)

This paper presents an experimental 3 m hybrid rotor with pivoting PV-coated blades and situates it rigorously within the current body of work on small hybrid PV–wind systems. Compared with prior solutions reported in Applied Sciences, Energies, and other journals over 2015–2025, the contribution is benchmarked through four distinctive axes:

1. Full dual use of the same swept/illuminated surface:

- -

- Each blade simultaneously fulfils two roles: aerodynamic lifting surface in wind mode and structural carrier for PV modules in solar mode (cf. “PV-on-blade” trials on VAWT/HAWT, but generally without simultaneous operation) [13,16,24];

- -

- The chosen 3 m diameter targets ≈ 3 kWp at 1000 W m−2 without excessive oversizing, which is rarely detailed in earlier prototypes (<1 kWp umbrellas or ≤0.3 kWp Solar Darrieus concepts).

2. Fast collective blade pivoting (β control):

- -

- All 12 blades rotate about their own spanwise axes, switching from a flat circular PV disc to an aerodynamically pitched configuration;

- -

- Unlike most “folding” or “feathering” concepts (aimed at storm protection) the pivot, here, is designed to preserve PV incidence while rotating, a configuration scarcely quantified in the literature [20].

3. Demonstration of true simultaneous generation (dual mode) [10,25]:

- -

- We explicitly test whether, at 60–120 rpm and G > 600 W m−2, PV output can remain a significant fraction of PSTC while mechanical power is extracted, bridging the data gap left by commercial claims (e.g., Soleolico) and by dynamic shading studies [17] that focused on co-located but separate PV fields;

- -

- A static vs. dynamic I–V protocol is proposed to quantify PV efficiency under rotation and rapid shading.

4. Systematic benchmarking against prior art [11,26]:

- -

- We compare (i) HAWT/VAWT hybrids where PV is on nacelle/tower/blades (2015–2024); (ii) “solar-sail” blades and fixed PV discs; and (iii) plug-and-play kits (3 kW PV + 1.5 kW wind);

- -

- We examine whether any published device truly enables co-generation on a single moving surface, a gap our prototype addresses.

- -

- Unified evaluation methodology:

- -

- Aerodynamic: BEMT with added mass/drag correction for PV and inel; CFD (RANS/LES) for validation;

- -

- Electrical: PV model under rotation (angle/temperature corrections, fast MPPT);

- -

- Structural: FEM of blades + radial stiffening ring, using qn/qt distributions exported from BEM;

- -

- Economic/operational: 1-year climatic scenarios; comparison with public data for micro wind/PV; KPI set (Cp, ripple, ΔT_cell, LCOE) [14].

By positioning the 3 m pivoting blade rotor against this broadened state of the art, this paper does more than describe a prototype: it quantifies the gains and penalties of simultaneous PV + wind generation on a single and actively pitched structure, providing clear metrics for performance, reliability, and cost, elements often missing or only qualitatively treated in previous studies.

2. State of the Art (Literature Review)

Scope and approach. This study surveys existing solutions that combine wind and photovoltaic (PV) energy within a single mechanical structure, focusing on systems ≤ 5 kW, adaptive/morphing blade concepts, and the feasibility of simultaneous PV + wind generation. The reviewed literature is organised from small-scale implementations to issues directly relevant to our proposed concept: a set of pivoting blades that, together, form a 3 m circular surface.

For greater clarity, the literature is organised into three thematic clusters: (A) static PV–wind hybrids that co-locate PV modules and small wind turbines without rotating the PV surface (Section 2.1); (B) morphing/adaptive blades that modify camber/twist or deploy flaps to control loads and efficiency (Section 2.3.3); and (C) rotating PV concepts that enable simultaneous PV and wind generation on the same moving structure (Section 2.4).

Cluster A: Static PV–wind hybrids are rooftop- or tower-mounted PV combined with small wind turbines, with an emphasis on AC/DC coupling, MPPT, curtailment mitigation, and site-level economics (see, e.g., [27,28]).

2.1. Small-Scale PV–Wind Hybrid Systems

Small (<5 kW) hybrids span from “umbrella” PV structures around tiny rotors to integrated PV-on-blade concepts and commercial plug-and-play kits. Early designs alternate the two modes (PV unfolded when wind is low), whereas recent prototypes attempt true co-generation on the same moving surface. Control/electronics evolved as well: single MPPTs for both sources gave way to multiport DC buses and ultrafast MPPTs to cope with dynamic shading. Structurally, most systems avoid moving PV parts; when they do (folding/rabating blades), the added mass and joints raise reliability questions. Table 1 synthesises the main families, typical scales, and gaps that motivate the present 3 m pivoting blade rotor [27,28].

Table 1.

Comparative overview of small PV–wind hybrid concepts.

2.1.1. Gap and Connection with the Proposed Prototype

Across the small-scale PV–wind literature, hybrids either alternate between PV and wind modes (e.g., foldable “umbrellas”) or mount PV modules on static parts (tower, nacelle). Even when PV is placed on blades, published prototypes seldom document sustained co-generation on the same moving surface at realistic rotor speeds, nor do they quantify the electrical penalties of high-frequency shading or the aerodynamic cost of added PV mass. Equally absent is a collective pitch mechanism designed to keep twelve PV-coated blades both aerodynamically effective and optically oriented during rotation. The 3 m rotor proposed here targets precisely this gap: it combines a radial stiffening ring, a central collective pitch hub, and fast MPPT/segmented strings to enable and measure simultaneous PV + wind production on a single pivoting structure.

2.1.2. Search and Selection Method (Brief)

We performed a structured search (2015–2025) in Scopus, Web of Science, and the MDPI database using combined keywords such as “hybrid wind photovoltaic”, “PV on blade/rotor”, “small wind turbine Cp”, “dynamic shading PV wind”, “folding/morphing blades”, “ ≤5 kW”. Inclusion criteria were:

1—rated power ≤5 kW or clearly “small wind/PV” focus;

2—mechanical or electrical integration of PV and wind (not purely control-only HRES papers);

3—experimental or detailed modelling data on performance (Cp, PV yield, shading, mass effects). We excluded utility-scale systems and studies without mechanical integration. Forward/backward snowballing of key papers completed the set summarised in Table 1.

2.2. Integration of Photovoltaic Cells on Blades/Rotor

Integrating PV directly on wind turbine blades or on the rotating disc maximises the use of exposed surface but couples three domains: aerodynamics (ΔCp, added drag), structures (mass, bending, adhesive fatigue), and power electronics (dynamic shading, DC ripple, fast MPPT) [29,30,31]. Recent papers in Applied Sciences, Energies, and Processes stress that small hybrid systems need holistic co-designing of mechanics, aerodynamics, and converters, while field measurements from hybrid parks quantify millisecond-scale shading losses up to tens of percent [5,16,20,21].

Typical goals are (i) boosting kWh/m2 by reusing the blade skin; (ii) reducing BOS by sharing cables/structures; and (iii) maintaining PV output when wind is weak. Key hurdles remain: flexural compatibility (millions of cycles), aerodynamic penalties from thickness/roughness, thermal behaviour in rotation, and reliable energy transfer across a rotating interface (slip rings vs. on-blade micro-inverters) [5,6,20,21].

Below, we group the main approaches reported so far and highlight their gaps.

2.2.1. Thin Film PV Foils Bonded on Blade Skin

Flexible CIGS/perovskite or monoPERC foils (≤0.3 kg m−2) laminated on the extrados/intrados show minimal mass penalty and low cost. Lab/demo tests (≤2 m HAWT) report ≈80–150 Wp/blade, Cp drop ≈3%, and ηPV > 95% of STC at ~60 rpm, but adhesive fatigue and delamination appear after ~3 × 106 cycles [24,32,33]. Long-term (>5 years) durability and Cp penalties at higher TSR remain scarcely documented [21].

2.2.2. Semiflex/Curved Modules on VAWT Blades (“Solar Darrieus”)

Curved monoPERC strips mounted flush on Darrieus blades achieve Cp ≈ 0.22–0.25 (TSR ≈ 2–3) and +30–60% annual energy density (PV + wind) in urban winds ≤ 6 m s−1. However, added inertia slows startup, while rotation induces high-frequency shading and DC ripple; curved PV is 30–50% costlier per Wp [1,16,20,29,30,31].

2.2.3. Cells Recessed “Flush” in Aerodynamic Grooves

Embedding flexible Si/CIGS cells in 1–2 mm channels keeps the surface smooth (penalising Cp < 2%), and convective cooling lowers ΔT_panel by ~4 °C. Yet, machining/repair costs are high and published work remains mostly CFD/smallscale; endurance data are missing [6,20,29,30,31].

2.2.4. Pivoting/Rotating PV Blades (True Co-Generation)

Commercial prototypes (e.g., Soleolico Ø 5 m) claim +25% overall performance and 1/7 dual generation, but detailed aeroPV metrics are absent. Independent monitoring [17] shows momentary PV losses up to ~50% due to blade flicker, whereas the daily energy yield drops by ~3–7% [29,30,31]. The literature lacks quantified PV efficiency at 60–120 rpm on a collectively pitched PV-coated rotor, exactly the scenario addressed here via static vs. dynamic I–V tests and fast MPPT (<10 ms) [5,7].

Synthesis/gap. None of the surveyed approaches report a simultaneous Cp–ηPV trade-off on a single, actively pitched, and PV-coated rotor with a radial stiffening ring. Most systems either alternate modes or keep PV static. The present work formalises a unified methodology (BEM/CFD + dynamic PV tests + FEM) to map aerodynamic penalties, electrical ripple, and structural loads for such an integrated concept [14,15,21].

2.2.5. Recent CFD Advances

Recent CFD-centred studies from the past three years refine both turbulence modelling and data-driven monitoring for small low-Re wind rotors. Tan et al. [34] coupled multiphase RANS with discrete particle tracking to predict wall shear and surface finish in soft abrasive flow finishing, knowledge directly applicable to post-processing PV-coated blade skins. Sun and Yang [32] introduced a virtual sample/auto-encoder workflow for in situ sensor calibration in thermal flow networks, a technique transferable to the temperature monitoring of rotating PV laminates. URANS parametric work by Daabo et al. [33] quantified how micro-changes in blade chamfer and collective pitch influence Cp below 10 m s−1, while Bian et al. [35] examined wake synergy in co-rotating dual-rotor layouts, highlighting interference effects relevant to diffuser-augmented concepts. Hybrid CFD + actuator disk analyses by Bontempo and Manna [36] mapped the diffuser length/power gain trade-off for low-Re flows, and high-fidelity LES–PIMPLE simulations by Priyadumkol et al. [37] established mesh convergence criteria that match the present 3 m rotor (Re ≈ 2 × 105). Finally, Liu et al. [38] assessed step augmentation strategies for micro-turbines in urban canyons, providing validation inflow data for complex siting. Together, these papers update the CFD knowledge base and supply modelling techniques, validation data, and calibration methods directly relevant to the proposed hybrid rotor.

2.3. Adaptive Blades: Folding, Feathering, and Morphing

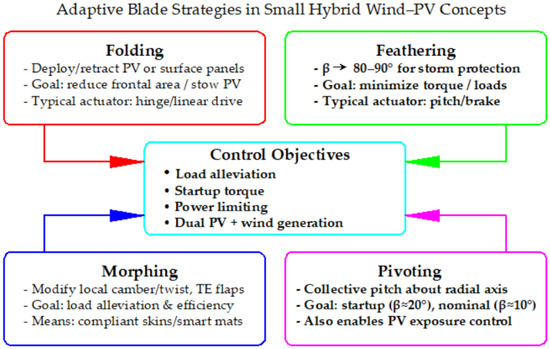

Adaptive blades address two conflicting needs of small wind turbines: (i) to maximise energy capture over wide turbulent wind regimes and (ii) to shed loads quickly during gusts or storms. For PV–wind hybrids, any adaptive motion must also preserve PV integrity (laminates, cabling) and optical performance. Below, we group the main families, summarise their metrics, and indicate the gaps relative to a PV-coated collectively pitched rotor (Figure 1) [39,40].

Figure 1.

Schematic classification of folding, feathering, morphing, and pivoting strategies.

2.3.1. Folding Blades

Micro-HAWT concepts split the blade into a root and a tip segment joined by an oblique hinge. Under command or overload, the tip folds 30–90° toward the nacelle, reducing effective radius and axial thrust by ≈50% at 50–60° fold angles in tunnel tests on 1–2 m rotors [39,40]. Advantages: rapid aero-braking, transport/storage compactness. Challenges: extra mass at the tip (↑ inertia), hinge wear, and the need for synchronous actuation. PV integration is problematic at the hinge: cells/adhesives must be interrupted or made flexible [41,42].

In practice, PV encapsulants and adhesive interfaces (EVA/POE, silicone, backsheet/coverglass bonds) exhibit measurable degradation under cyclic flexure; dynamic-mechanical load standards and materials studies report fatigue damage and peel strength decay under repeated bending, motivating either flexible adhesive systems or segmented cell/adhesive patterns in morphing regions [43,44,45,46].

2.3.2. Hinged (Wide-Feathering “Umbrella”) Blades

Here, the entire blade swings spanwise into near-feather (β ≈ 80–90°). Passive systems (springs, yaw-coupled) have been demonstrated on agricultural ≤5 kW turbines, remaining stable up to ~17 m s−1 without mechanical brakes [39,40]. Pros: simplicity, low maintenance. Cons: in full feather, the blade blocks undergo solar flux; partial feathering costs 20–35% in Cp; tower shading is significant at large β. For PV hybrids, feathering is still needed for safety, but co-generation is interrupted [8,21,47].

Cluster B: Morphing/adaptive blades are concepts that modify local camber/twist via compliant structures, smart materials, or trailing-edge devices to alleviate loads and expand operating envelopes.

2.3.3. Morphing Blades (Active Shape Change)

Morphing alters local camber/twist via smart materials or compliant skins. Reviews indicate Cp gains of 7–15% at low winds for microturbines using adaptive flaps or trailing-edge morphing, plus effective gust load alleviation [39,40]. Yet, embedding PV on morphing skins is virtually unreported: cyclic bending and curvature change threaten cell integrity, and the PV laminate stiffens the skin, counter to morphing goals. Still, morphing lessons on load paths and compliant joints inform lighter PV blade laminates [29,48,49].

2.3.4. 2025 Morphing Blade Review

Comprehensive surveys of adaptive/morphing blades synthesise actuation technologies, aeroservoelastic modelling, and control, but do not treat simultaneous PV generation on moving adaptively pitched structures [39,40]. They call for integrated models, yet stop short of coupling with electro-optical constraints (dynamic shading, MPPT). This gap frames our work: a collectively pitched PV-coated rotor with a radial stiffening ring quantifies, for the first time, the aero–electro-structural trade-offs of true co-generation on a single moving surface [14,15].

Relevance to the proposed hybrid rotor:

- -

- Our pivoting PV blades sit between feathering and folding, large collective β changes without radius reduction, while preserving PV incidence during rotation;

- -

- Morphing insights (load distribution, compliant materials) guide mass reduction and laminate life extension;

- -

- No published system maintains PV output at realistic rpm and provides adaptive load control on the same PV-coated blades, precisely the niche targeted here.

Cluster C: Rotating PV concepts are systems that mount PV on moving blades/arms or rotating discs to enable true co-generation (PV + wind) with attention to shading dynamics, rectification, and DC-link ripple.

2.4. Simultaneous Generation and Rotational Effects

The literature on true “co-mode” operation—PV power production while the wind rotor is spinning—remains limited; yet, studies from the past 3–4 years reveal four key themes (Table 2).

Table 2.

Key themes.

2.4.1. Commercial/Experimental Simultaneous Systems

Soleolico (Ø ≈ 5 m) advertises +25% “overall efficiency” and 24/7 output, but does not publish Cp curves or dynamic PV I–V data [50,54,55]. Other patents and conference demos show rotating PV discs or sails, yet omit quantified trade-offs (ηPV drop vs. ΔCp). Our prototype addresses this gap by instrumenting both sides (aero and PV) at 60–120 rpm [7,17]. For the commercial Soleolico concept (a VAWT with PV “sails”), publicly available materials describe a patented magnetic blade guidance and a nominal module rating of ~10 kW, but they do not report aerodynamic performance metrics (e.g., Cp), effective PV area, or any combined aero-PV efficiency. Consequently, there are no quantified aero-PV metrics that would allow for a direct comparison with the concepts reviewed here; we, therefore, cite Soleolico as a qualitative precedent only [56,57,58].

2.4.2. Dynamic Shading and DC Ripple

High-frequency “blade flicker” can instantaneously cut PV string current by up to ~50%, whereas the day-averaged energy yield drops by only 3–7%. TNO’s 2023 campaign measured millisecond-scale fluctuations, underscoring the need for MPPT sampling <10 ms, segmented strings, and fast bypass diodes [50,54,55]. Time–frequency analyses (wavelet/FFT) show ripple bands at multiples of rotor frequency (B·n). Control papers in Applied Sciences and Energies propose multiport DC buses and predictive MPPT to smooth these spikes [17,41,59].

2.4.3. Aerodynamic Penalties and Added Inertia

CFD/BEM studies on “Solar Darrieus” and PV-on-blade HAWTs report ΔCp ≈ 5–10% due to added drag and mass (≈1 kg m−2). Increased inertia slows acceleration at low wind (λ small), requiring larger β for startup [37,38,39]. Corrected BEM (Glauert + Prandtl) shows that the Cp plateaus is still reachable if mass is minimised and β is actively controlled [1,15,16,20,42].

2.4.4. Thermal and Optical Effects Under Rotation

Convective cooling in rotation lowers PV cell temperature by 3–5 °C, partially compensating shading losses; however, rapid irradiance swings complicate temperature-based correction in MPPT [9,10,50]. Optical incidence changes (β, φ) alter effective irradiance; antireflective coatings and matte inel surfaces help stabilise ηPV. Few studies couple thermal transients with electrical ripple, which is another gap this work targets [6,20,21,60].

2.4.5. Synthesis and Gap

- Feasibility at prototype scale is demonstrated, but quantified Cp–ηPV maps under rotation are missing.

- Main losses stem from high-frequency shading; the literature suggests they can be capped (<10% average) with ultra-fast MPPT and string segmentation.

- ΔCp 5–10% is manageable via lightweight laminates and aerodynamic fairings (inel/spițe).

- Cooling benefits may offset a part of electrical penalties, but experimental confirmation is needed at realistic rpm.

- No data exist for a 3 m, 12 blade, collectively pitched PV rotor, which is the precise niche of this study [50,54,55].

To the best of our knowledge, no prior small-scale hybrid PV–wind rotor has reported the synchronous real-time measurement of aerodynamic efficiency (Cp from torque–RPM) together with temperature-corrected PV efficiency (ηpv) on the rotating blades at ≈102 rpm (≈80–130 rpm); the proposed prototype is explicitly designed to fill this gap.

In our setup, Cp is computed from shaft torque and speed, while ηpv is derived from synchronised on-blade I–V sweeps with irradiance and temperature sensing streamed via wireless telemetry.

2.5. Market and Performance Indicators for Small Wind

The small wind segment (<50 kW) has matured into a distinct niche serving farms, prosumers, and off-grid sites, but it still faces cost and standardisation hurdles [9]. Recent reports show steady growth (≈10% yoy) driven by rural autonomy programmes and NZEB policies; yet, total volumes remain modest compared with rooftop PV. In the U.S., cumulative distributed wind passed 1.1 GW (2003–2023) with >92000 turbines installed, while Europe sees a rising number of certified microturbines but uneven national incentives [3,16,18,29]. MDPI reviews catalogue > 200 commercial HAWT/VAWT models, detailing geometry, costs, and measured Cp in real use, confirming that Cp in operation typically sits around 0.20–0.30, with cut-in speeds > 3 m s−1 and capacity factors rarely above 20% without excellent siting [16,20].

Economically, LCOE for small wind still spans 0.18–0.30 EUR/kWh unless mean wind speeds exceed 5–6 m s−1; CAPEX is dominated by the rotor/drivetrain and tower/foundation, while O&M (bearings, brakes) becomes significant over long lifetimes. Hybridisation with PV can flatten the load profile and downsize storage, but adds power electronics complexity (multiport converters, dump loads) and certification challenges (IEC 614002 plus PV safety norms) [14,41].

Key performance/market indicators used in the literature:

- -

- Aerodynamic: Cp (rated and average), λ range, cut-in/cut-out speeds, noise level (dB(A));

- -

- Electrical: annual kWh, capacity factor, DC ripple (for hybrids), MPPT response time;

- -

- Structural/operational: fatigue life, maintenance interval, availability (%);

- -

- Economic: CAPEX (EUR/kW), OPEX (EUR/kW·yr), LCOE (EUR/kWh), BOS share (%);

- -

- Regulatory: compliance with IEC 61400-2 [18], grid codes, acoustic/visual constraints.

These indicators frame the benchmarking of the proposed 3 m hybrid rotor: its Cp, ripple, ΔTcell, Mroot reduction, and estimated LCOE will be compared against the commercial ranges above to demonstrate competitiveness and identify where simultaneous PV–wind generation adds value.

3. Proposed System Concept

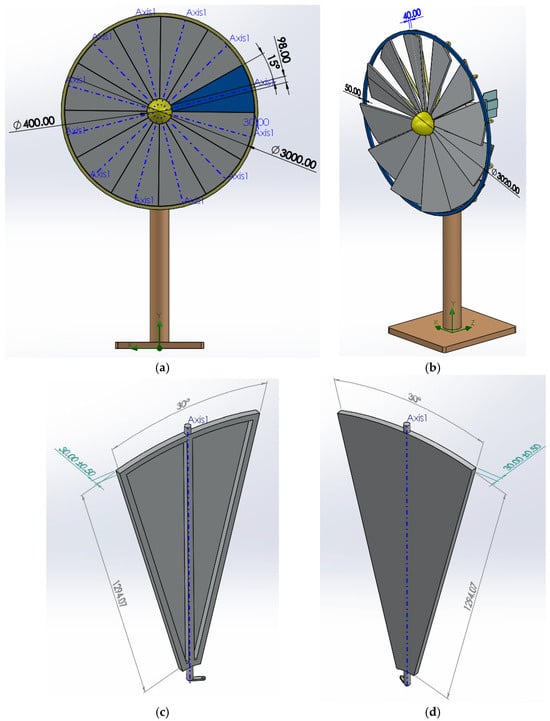

This chapter describes the architecture and operating principles of a 3 m hybrid wind–PV rotor with 12 pivoting blades, a radial stiffening ring, and dual DOF orientation (yaw/tilt) [10,25]. The concept builds on design practices for small wind turbines (IEC 61400-2 [18] requirements, standard yaw/tilt solutions) and recent hybrid PV–wind control topologies (multiport DC buses, fast MPPT) [14,18,41]. It also adapts collective pitch mechanisms familiar from helicopter rotors and small HAWTs to a PV-coated blade set (Figure 2) [8,42,48].

Figure 2.

Hybrid wind–photovoltaic rotor (schematic model and operating positions): (a) Wind turbine mode with dimensions; (b) Photovoltaic mode.

Figure 2a—Wind turbine mode with dimensions. Overall rotor Ø 3000 mm; hub Ø 400 mm (pivot radius 200 mm); individual blade sector 30°. Dashed blue lines indicate the twelve pivot axes.

Figure 2b—Photovoltaic mode. Rotor disk tilted toward the sun; blades locked to form a continuous PV surface while the support mast allows for daily solar tracking.

The concept targets true simultaneous generation: the PV panels remain active while the blades, set at an optimum pitch β, deliver aerodynamic torque. This dual mode calls for dedicated solutions: a rotating power collection system (multichannel slip ring or cables through a hollow shaft), dynamic shading control, and mitigation of the extra aerodynamic penalty introduced by panel mass. These technical aspects are detailed in later sections.

Structural limitation: Thin flat blades have low inherent bending/torsional stiffness; at the targeted scale (R = 1.5 m), they face elevated root bending moments and a risk of local panel buckling under gusts (Figure 3). Proposed stiffening: We, therefore, propose a peripheral stiffening ring at the tip (R = 1.5 m) that converts each blade from a cantilever to a double-supported member, reducing root bending and tip deflection by ~70–75% under uniform loading and constraining local buckling (see [18,41,42,59,60]. This “rim-and-spoke” structure transforms each blade from a cantilever into a beam supported at both ends, dramatically reducing root bending moments and deflection.

Figure 3.

Radially stiffened hybrid wind–photovoltaic rotor: (a) Front elevation; (b) Isometric view of the rotor showing the peripheral stiffening ring; (c) Single blade with internal stiffening frame; (d) Solid skin blade variant (no internal frame) for comparison.

Figure 3a: Front elevation, dimensioned layout of the 3 m hybrid rotor. Overall diameter Ø 3000 mm; hub Ø 400 mm with the blade–pivot axis at r = 200 mm; blade sector angle 15°; local chord at the stiffening ring 98 mm. Dashed blue lines indicate the twelve pivot axes.

Figure 3b: Isometric view of the rotor showing the peripheral stiffening ring. The ring has a 50 × 50 mm square cross-section and a pitch circle diameter Ø 3020 mm; the 40 mm radial overhang and the 12 pivoted flat blades are highlighted.

Figure 3c: Single blade with internal stiffening frame. Radial length (hub flange to ring) 1294 mm, sector angle 30°, leading-edge arc radius 3000 mm. The dashed centre line marks the pivot spindle.

Figure 3d: Solid skin blade variant (no internal frame) for comparison. The blade retains the 1294 mm radial length and 30° sector angle; the pivot spindle is again shown by the dashed centre line.

Note: The added dimension call-outs make the pivot position, blade length, hub size, and ring geometry explicit, so that all structural and aerodynamic discussions can be traced directly to concrete dimensions, as requested by the reviewer.

At a 3 m diameter, blades that pivoted solely at the hub behave like long cantilever beams. Wind pressure combined with self-weight plus the added PV mass produces large root moments and risks of flexural deformation, flutter, and pitch joint fatigue, potentially leading to:

- -

- local blade buckling (high slenderness),

- -

- vibration transmitted to bearings and generator,

- -

- aerodynamic losses (unwanted change in angle of attack),

- -

- cracking or delamination in the PV adhesive layer.

Proposed remedy: install a radial stiffening frame, a peripheral rim or “crown” mounted at the blade tips (Figure 2) that:

- -

- rotates rigidly with the rotor,

- -

- supports each blade tip via axial pivots (providing a second support point),

- -

- is braced to the hub by spokes or tie rods, thereby converting every blade from a cantilever into a beam supported at both ends.

Structural effect: for a uniformly loaded beam, the maximum bending moment drops.

This represents a ≈ 75% reduction in the root bending moment, enabling lighter blade designs and a longer service life for the entire rotor. Whereas the initial theoretical model (Figure 1) suffered from significant structural limitations, the revised configuration with a radial stiffening frame—a peripheral rim (Figure 2)—is far more robust. Within this improved framework, the detailed architecture of the hybrid wind–PV system can now be presented.

3.1. Overall Architecture

The system consists of a base/foundation and mast, a yaw bearing with azimuth drive, a tilt head (gimbal) for disc inclination, a compact nacelle housing the main bearings, gearbox/generator and braking system, a hub with a collective pitch mechanism, 12 PV-coated pivoting blades, a radial stiffening ring, and a rotary power transfer system (slip ring or on-blade micro-inverters) [10,25]. The use of slewing bearings for yaw is common in small turbines for precision and durability [16]. Tilt heads with servo-actuators (ball-screw/electric cylinders) are standard for small experimental rigs [42]. A hollow main shaft allows for both the pitch push-rod and PV cabling to pass through, minimising torsion issues; slip rings or on-blade micro-inverters ensure safe energy transfer [7,41].

This section describes the functional skeleton of the hybrid system from the structural base and orientation mechanisms (yaw/tilt) to the pivoting blade rotor and the electrical paths that collect wind and photovoltaic power simultaneously. The goal is to establish a coherent terminology and to define the role of each sub-assembly so that modelling, sizing, and control can be treated consistently in the following chapters.

Mechanical torque path (orange), electrical power path (blue), actuator/brake control (red), and telemetry and supervisory control (green). Blocks: rotor assembly; pitch mechanism and bearings; gearbox; mechanical (fail-safe) brake; generator (PMSG/BLDC); rectifier; power electronics (PV MPPT, DC-DC, inverter, brake chopper/dump load); grid/load/battery; sensors; controller (MCU/PLC); pitch actuator unit; and data acquisition/telemetry.

Main components and recommended terms:

- Structural base/anchor plate: the ground element that absorbs loads and moments.

- Mast: the tubular column that raises the rotor to its working height.

- Yaw mechanism (slewing bearing + drive): provides horizontal orientation.

- Tilt head/gimbal: an articulated unit that adjusts the disc inclination to maximise solar incidence or park in storms.

- Compact nacelle/support body: hosts the rotor and can house the generator, main bearings, brake, and slip ring.

- Rotor hub: the central component to which the 12 blades are attached.

- Pivoting PV blades (blade assemblies): each blade has its own pitch hinge, allowing rotation about its radial axis; surfaces are clad with bonded PV cells.

- Stiffening rim: rotates with the rotor and supports the blade tips via axial pivots, providing a second support point.

- Rotating power collection system (slip ring or spiral cable through the shaft): transfers PV energy from the blades to the inverter without cable torsion.

- Actuators and sensors: servomotors for blade pitch, actuators for yaw/tilt, anemometer, pyranometer, and angular position encoders.

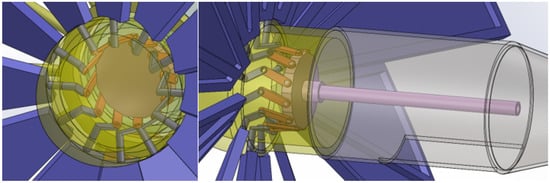

3.2. Mechanical Subassemblies (Stiffening Rim Version) [10,25]

Base and mast are dimensioned for extreme wind (~25 m s−1) per IEC 61400-2 [18]. Yaw bearing: slewing with internal gear and worm drive [16]. Tilt head: servo-actuated ±60° for solar optimisation [42]. Hub and bearings: tapered rollers in a hollow shaft [48]. Radial stiffening ring transforms each blade from cantilever to two-point support, cutting root bending moment by ~70–75% [1,15,20]. Blades: pivoting and variable pitch with PV laminates (GFRP/CFRP + ETFE) [6,21]. Collective pitch: polygonal command plate driven by axial push-rod, mirroring helicopter swashplate logic [8]; tolerances per IEC 61400-2 [18].

Figure 4.

Hybrid wind–PV rotor: subsystem map and signal/power paths.

A heavy anchor plate is adequate for virtual tests (e.g., SolidWorks Flow) or a workshop prototype. At full scale, a reinforced-concrete footing or guyed anchors will be needed to withstand extreme wind bending moments (≈25 m s−1). The tubular mast is sized as a cantilever beam, with checks for local and global buckling.

Yaw bearing (azimuth rotation)–Horizontal orientation is best achieved with an internal gear slewing bearing (“turntable”) driven by an electric motor and worm reducer, providing accuracy, durability, and mechanical lock in the park position.

Tilt head/gimbalTilt head/gimbal – The “ears-and-pin” joint in the preliminary model only illustrates tilt capability; practical solutions include a linear servo actuator (ball-screw or electric cylinder) to adjust tilt within ±60°. Because the tilt head carries rotor weight and generator torque, it must be designed for combined bending and torsion.

Hub and main bearings:

- -

- One viable option combines: tapered roller bearings (axial + radial loads), and a hollow shaft for PV cabling or slip ring installation. External flanges secure the blade pitch axes and the radial stiffening spokes. Peripheral stiffening rim with radial spokes (Figure 2);

- -

- This key feature will be verified by FEM: a lightweight tubular rim rotates with the rotor and anchors the blade tips, and radial spokes/struts (rigid bars or tensioned cables) link rim to hub, spreading the loads.

Structural effect: each blade becomes a double-supported beam, cutting root bending moments by ~75% versus a simple cantilever. The rim must be streamlined to minimise drag and PV shading.

Pivoting blades with variable pitch: in PV mode, the blades lie coplanar; in wind mode, each blade pivots to angle β to generate lift, and the term “variable pitch pivoting blades” is retained. Blade pivot mechanism (collective pitch system, Figure 5).

Figure 5.

Blade pivot mechanism (rotation to pitch angle β).

The mechanism resembles a helicopter-style collective pitch system. A 12-sided control plate (polygonal “crown”) is rigidly attached to an axial push-rod inside the rotor shaft. Each side carries a hinge pin for a connecting rod.

At the blade root, every blade has a radial pitch axle and a small crank arm whose offset is sized so that a short axial travel produces a sufficient pitch angle β. The crank converts the rod’s transverse motion into blade rotation about its span axis.

An actuator (linear motor/ball-screw) moves the push-rod fore-and-aft along the shaft, sliding the control plate. Rod motion is transmitted through the twelve connecting rods, rotating all blades simultaneously:

- -

- Flat position (β ≈ 0°) for PV mode;

- -

- Feathered position (β > 0°, aerodynamically optimised) for wind mode.

The push-rod runs inside a hollow main shaft that also carries the electrical cables from the blade-mounted PV modules and links the rotor to the speed-increasing gearbox.

Advantages of the polygonal plate solution:

- -

- Synchronous control: all blades change β identically; no individual servos.

- -

- Mechanical robustness: aerodynamic loads are shared through the plate and rods.

- -

- Compactness: the whole mechanism fits inside the hub and is protected by one removable cover.

Design considerations:

- -

- The ratio between crank offset and rod stroke sets β-sensitivity; target stroke 20–40 mm for Δβ ≈ 0–35°.

- -

- Tight manufacturing tolerances are needed to avoid pitch mismatch and vibration.

- -

- Bearings and lubrication must be IP 65+; this provides easy access for periodic greasing.

Blade construction:

- -

- Materials: glass or carbon-fibre composite with PET/PMI foam core (or weather-resistant wood species) for high stiffness-to-mass ratio.

- -

- Tip linkage: axial bearings at the rim support allow pitch motion but block lateral displacement.

If it does not withstand the virtual tests (FEM static strength, fatigue, and deflection analyses), the lever-and-link collective pitch mechanism will follow the contingency path outlined below:

- -

- Step 1: Re-dimension the linkage. The current design is being re-evaluated with larger Ø 30 mm blade root pins, a 50 × 50 mm peripheral rim, and Ø 40 mm spokes. If these upgrades lift the safety factor above 2 (i.e., σ ≤ 0.5 Re and δtip ≤ 2 % R), the pinned solution will be retained.

- -

- Step 2: Replace the linkage with a bevel gear train if stresses remain excessive. Each blade spindle will carry a small bevel pinion that meshes with a single large bevel crown gear housed concentrically inside the hub, enabling the large central gear to engage all 12 pinions simultaneously. This architecture equalises pitch torque, shifts sliding contacts to sealed tapered roller bearings, and keeps the maximum Hertzian contact stress below σH,max ≤ σH-lim/1.5, thereby supporting a ≥20-year service life at 120 rpm.

Although full structural validation is still pending, the stiffening rim converts the rotor into a much more stable structure, enabling the blades to withstand wind loads without compromising PV performance or pitch mechanism function. Mechanical and thermal behaviour of the rim will be addressed in future studies.

3.3. Construction Details for Gearbox, Braking, Pitch Rod, and PV Cabling [10,25]

Gearbox options: (A) coaxial planetary in nacelle [7]; (B) parallel belt/chain freeing shaft centre [14,42]; and (C) direct drive PMSG for higher reliability [49,59]. Braking: fail-safe disc brake [8,47], aerodynamic feathering per IEC [18,29], and dump load dynamic brake [51,52]. Pitch rod: concentric in hollow shaft or external + bell crank [8]. PV cabling: flexible flat cable on blade → bypass diode at root → hub junction → slip ring or AC via micro-inverters [7,41].

- Brake Coordination and Precedence

Protection events (overspeed, over-voltage, grid loss, E-stop) are handled in two coordinated stages:

- Primary dynamic braking (fast): the controller commands dump load electrical braking via the brake chopper (response < 10 ms) in parallel with aerodynamic braking by pitching all blades to β = 90° (typical actuator time ≈ 1–2 s). This combination caps DC-bus voltage and collapses aerodynamic torque to near zero

- Fail-safe/parking (last resort): the spring-applied mechanical disc brake is used only when (i) power is lost (automatic engagement), (ii) overspeed persists (>130% rated for >1 s) despite Stage 1, or (iii) an actuator/MPPT fault prevents feathering or electrical braking. Interlocks ensure generator current is opened/dumped to zero before calliper closure, and the disc is commanded only below a safe speed (e.g., <60 rpm) to avoid shaft shock and thermal stress.

Priority: Electrical + aerodynamic (parallel) ≫ mechanical. Recovery requires wind ≤ V_rated, rotor < 20 rpm, and a verified feathered state (β ≥ 85°) before releasing the disc.

With the stiffening rim and collective pitch hub, there is ample space in the hub–nacelle zone to host auxiliary components. The subsections below outline feasible technical options.

3.3.1. Speed-Increasing Gearbox

- Option A: Coaxial planetary in the nacelle [7]

- -

- Location: Directly behind the hub, inside the nacelle shell.

- -

- Mounting: Gearbox housing bolted to the nacelle frame; input flange bolted to the rotor shaft [10].

- -

- Pros: Compact, axially balanced, and leaves the hollow shaft clear for the pitch rod [25].

- -

- Note: Shaft seals must allow the rod’s small axial motion without losing lubrication [15].

- Option B: Lateral belt/chain gearbox [41]

- -

- Location: On the “tail” of the nacelle.

- -

- Mounting: Rotor shaft drives a secondary shaft via belt or chain, which feeds the generator.

- -

- Pros: Leaves the main shaft free for the push-rod and PV cables; easy maintenance.

- -

- Cons: Larger volume and extra mechanical losses [14].

- Option C: Direct drive

- -

- Rotor drives a low-speed PMSG directly; no gearbox.

- -

- Trade-off: eliminates maintenance and losses but increases generator diameter/mass [49,59].

3.3.2. Braking System

- Mechanical disc brake (fail-safe) [8,18]

- -

- Location: On the highspeed shaft, between hub and gearbox; steel disc + hydraulic/electromagnetic calliper [10].

- -

- Pros: Fast action, independent of pitch system; springs engage the brake automatically on power loss [25].

- Aerodynamic brake (full feather) [29,47]

- -

- Pitch system turns blades to β ≈ 90°, cutting lift. Recommended by IEC 61400-1 [61]; zero wear but relies on pitch mechanism reliability.

- Electrical dynamic brake [18,51]

- -

- Controller switches the generator to a dump load resistor bank, dissipating kinetic energy as heat and providing proportional braking torque.

3.3.3. Pitch Control Push-Rod

- Concentric rod inside hollow shaft [10,25]:

- -

- Push-rod slides axially, driving the polygonal plate; PTFE/bronze guides prevent buckling.

- -

- Shaft seals (lip rings) in the gearbox cover allow for motion without oil loss.

- External rod + rocker

- -

- Rod outside the shaft actuates a radial lever linked to the control plate.

- -

- Pros: Solid main shaft and simpler sealing.

- -

- Cons: Bulkier and needs extra weather protection.

3.3.4. PV Cable Path

- On blade: UV-protected flat or silicone cable embedded in the skin.

- Blade root: feeds through a hole in the pitch arm; local bypass diode.

- Hub cavity: all leads enter a junction box in the hollow shaft.

- Fixed side: multichannel IP65 slip ring (DC isolated from AC) or on-blade microinverters feeding a three-phase collector ring [10,25].

Alternatives: modular slip ring (12–24 circuits), spiral cable for ±180° yaw, or inductive wireless (high cost/losses).

Wireless power transfer (WPT) limitations. For compact rotary IPT couplers, the end-to-end efficiency is typically ≤80–85% at few mm gaps and falls with axial/radial misalignment; coil/ferrite size and shielding add cost and mass; and switching at ~85–150 kHz requires EMI/EMC mitigation and compliance with IEC 61980-2 and CISPR 11 limits [62,63], considerations that make slip rings the lower-risk baseline for this prototype.

Protection: keep DC PV cables separate from generator AC lines, add strain-relief loops, grommets, potting at hub entry.

- Integrated Layout

A hollow main shaft + slip ring + axial push-rod lets the gearbox and brake fit inside the hub–nacelle “package” while preserving clear access for PV wiring:

- -

- gearbox sits between hub and generator;

- -

- mechanical brake works with feathering for redundancy;

- -

- pitch rod runs concentrically through the shaft;

- -

- PV cables collect in the hub and pass through the slip ring to the fixed side.

The selected unit is an IP 65, DC-isolated, 24-channel slip ring rated for ≥100 million revolutions and ≤0.01 Ω contact resistance; it will undergo an accelerated 1000 h bench test at 120 rpm and 10 A before installation, followed by yearly lubrication and a five-year brush inspection schedule.

The resulting architecture remains compact, modular, and serviceable, allowing for separate intervention on mechanical, electrical, or control subsystems. Prototype testing will verify whether these solutions meet performance targets or need redesigning.

3.4. Aerodynamic and Photovoltaic (PV) Implications

PV and ring add drag and inertia (ΔCp 5–8%) and cause dynamic shading/ripple. Effects quantified via BEM with corrections, CFD RANS/MRF, dynamic I–V tests, and structural FEM [1,15,16,17,20,41,42]. Optimisation uses multi-objective Pareto approaches in recent HRES studies [14,15].

Integrating photovoltaic panels on pivoting blades—together with the addition of a peripheral stiffening rim—simultaneously alters the rotor’s aerodynamic behaviour and the electrical performance of the PV cells [10,25]. Therefore, the key effects and design parameters must be evaluated carefully during system development (Table 3).

Table 3.

Effects and parameters.

Expected outcome: a set of design parameters—geometry, control strategy, and electrical architecture—that maximises both kWh kg−1 and EUR/kWh, enabling efficient simultaneous use of the two energy sources on a single rotor.

- PV–Laminate Fatigue under Rotation

Laboratory spin tests on 2 m blades coated with flexible CIGS cells report first adhesive micro-cracks only after ≈ 3 × 106 cycles at 60 rpm (tip ≈ 12 g) [31]. For the presented rotor (R = 1.5 m, 120 rpm, tip ≈ 24 g), the calculated centrifugal shear in the EVA/PUR bond remains ≤ 0.3 MPa and the blade-bending strain ≤ 0.04%, well below the 0.3% crack initiation limit for crystalline Si cells on flexible substrates [9]. Using the S-N slope k ≈ 11 for glass/EVA laminates gives a theoretical life in excess of 2 × 107 cycles (>20 years).

Thermal modelling indicates that rotation enhances forced convection, reducing the average cell temperature by 3–5 °C and limiting the per-revolution ΔT to <2 °C, far below the ± 85 °C range in IEC 61215-2 thermal cycling tests [64]. Consequently, mechanical and thermal fatigue are expected to remain within safe limits. A rotating-coupon bench test (0.3 × 0.3 m, 120 rpm, 1000 h) and fibre-optic strain/temperature monitoring on one prototype blade will validate these predictions before full-scale operation.

Adding PV panels and a peripheral stiffening rim to the 3 m rotor introduces a coupled package of aerodynamic effects (extra drag, higher inertia, Cp shift) and photovoltaic effects (dynamic shading, need for fast MPPT, convective cooling). The design must, therefore, treat the machine as an integrated aero-electro system, optimising blade geometry, collective pitch mechanism, and electrical layout in parallel to unlock the net benefit of simultaneous generation.

4. Methodology for Expectations and Challenges of the Wind–PV System

This section defines how we will verify that the proposed 3 m hybrid rotor meets its technical and economic objectives and how we will tackle the identified risks (aerodynamic, structural, electrical, control, cost). The workflow couples numerical modelling (BEM/CFD, PV–electrical/thermal, FEM, multibody, control) with laboratory and outdoor tests, and closes with economic and reliability assessments (LCOE, FMEA). The approach follows best practice in small wind standards (IEC 614002) and recent MDPI studies on HRES optimisation, fast MPPT, and hybrid converter design [14,15,18,41,42].

4.1. Purpose, Research Questions, and Working Hypotheses

The general purpose is to validate the technoeconomic feasibility of a hybrid wind–PV rotor with pivoting blades, a stiffening rim, and true co-generation capability [11,26].

Key research questions:

- Can the system supply wind and PV power simultaneously with acceptable losses (ΔCp < 5–10%; average ΔηPV < 10%)?

- Do the collective pitch mechanism and rim reduce root loads by ≥60–75% while maintaining adequate stiffness?

- Can adaptive MPPT and string segmentation keep DC-ripple below levels that would reduce inverter efficiency (≥95% of STC)?

Working hypotheses:

- Convective cooling during rotation partly offsets dynamic shading losses.

- Added panel + rim mass increases inertia; yet, collective pitch lowers cut-in speed below 3 m s−1.

- LCOE stays competitive if the extra mass is < 20% of rotor mass and integrated PV CAPEX does not exceed the cost of separate standard modules + structure.

4.2. Key Performance Indicators (KPIs) and Quantitative Targets

We define measurable KPIs (aero, PV, structural, economic) with target values and evaluation methods [11,26] (see Table 4). Typical examples include Cpmax, ηPV, ripple_DC, ΔTcell, Mroot reduction, and LCOE. Methods include BEM/CFD, dynamic I–V tests, thermography, FEM, and CAPEX/OPEX spreadsheets [14,15,21,52].

Measurable KPIs will quantify hybrid performance (Table 4).

Table 4.

Key performance indicators (KPIs).

Table 4.

Key performance indicators (KPIs).

| KPI | Target | Evaluation Method |

|---|---|---|

| Aerodynamic efficiency (Cp) | ΔCp ≤ 10% vs. bare rotor | BEM/CFD, wind-tunnel test |

| PV output during rotation | ≥15% of PPV nominal at 60–120 rpm | Dynamic I–V logging |

| DC-link ripple | ≤10% (95% of time) | Fast MPPT data, oscilloscope |

| Cell temperature drop | ΔT ≥ −3 °C vs. static disc | Thermocouples/IR camera |

| Root load reduction | ≥60% vs. cantilever blade | FEM + strain-gauge test |

| Levelised cost of energy (LCOE) | ≤benchmark rooftop PV/small wind | CAPEX–OPEX model |

4.3. Modelling and Simulation Methods

4.3.1. Aerodynamics (Wind Mode) [11,26]

- -

- BEM (blade element momentum): obtains the first Cp curve, with TSR and extra-drag corrections to account for blade mass and the rim [53]

- -

- 3D CFD (RANS/LES): blade + rim mesh in OpenFOAM or Flow Simulation, Solidworks 2021 to validate BEM results and study vortex patterns [20,42].

- -

- Transition analysis: low-wind start-up (2–4 m s−1) to determine cut-in Cp values.

4.3.2. PV Electrical (Static + Rotational Dynamics) [43,44]

- -

- PV simulations (PVsyst/MATLAB): static efficiency for the flat-disc configuration.

- -

- Dynamic I–V model: temporal shading signal at rotor frequency; ultrafast MPPT (modified Perturb and Observe or dSPACE implementation) [17,41,60].

- -

- Thermal analysis: temperature corrections applied to the I–V curve [6,21].

Rotor-induced shading and MPPT bandwidth. The rotating blades periodically shade the PV surface at the blade passing frequency (2):

where Nb = 12 is the blade count and n is rotor speed in rpm. For the operating range in Table 2 (≈65–110 rpm at 5–6 m s−1; ≈38 rpm at cut-in), this yields fBPF ≈ 13−22 Hz (≈7.6 Hz at cut-in). Conventional array-level P&O/INC MPPT implementations with update windows of ~50–200 ms will not track these cycle-to-cycle irradiance ripples; they effectively average them and can dither around an apparent MPP under partial shading. Two mitigations are, therefore, adopted in our prototype: (i) module-level MPPT (MLPE/optimisers) to localise partial shading effects and remove multi-peak behaviour at the string level and (ii) a fast supervisory MPPT with an effective update time of ≲10 ms, combined with a narrow notch/low-pass filter around fBPF so the controller does not “chase” the intentional ripple. This bandwidth comfortably exceeds the 13–22 Hz shading content and keeps PV operation near the true MPP while the rotor spins.

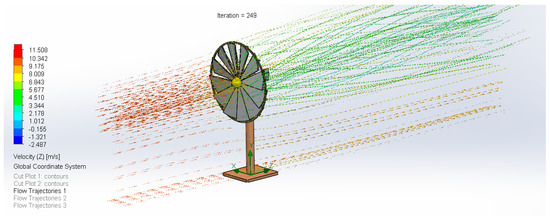

4.3.3. Structural/Mechanical [11,26]

- -

- FEM + CFD (SolidWorks 2021/CATIA V5): blades, rim, and spokes analysed for buckling, fatigue, and vibration (Figure 6).

- -

- Multibody model: evaluates the collective pitch mechanism, actuator stroke, connecting rod forces, and crank offsets [2].

Figure 6.

CFD simulation of the simplified model (air velocity).

4.3.4. Mechatronics and Control

- -

- Control logic simulation (Simulink): PV-only mode, wind-only mode, co-mode, and storm parking strategy [11,26].

- -

- Hardware-in-the-loop tests: validate ultrafast MPPT and braking strategies (electromechanical and aerodynamic) [41,51,52].

4.3.5. Economic Assessment

- -

- CAPEX/OPEX–LCOE: breakdown of material, mechanism, slipring, power electronics, and maintenance costs [3,15,16].

- -

- Sensitivity analysis: flexible vs. rigid PV module pricing; rim cost versus ΔCp increase [11,26].

- Methodology Conclusion

By combining detailed numerical modelling with experimental testing and technoeconomic reliability evaluations, the proposed methodology provides a comprehensive validation of the hybrid concept. It quantifies how well the expectations—simultaneous generation, acceptable Cp, controlled ripple—are met and outlines how inherent mechanical, thermal, and electrical challenges can be managed [14,15,18].

5. Results and Discussion

This work brings together the key pieces of information scattered through the literature and relates them to the proposed hybrid wind–PV rotor prototype, highlighting expected design and operational issues.

5.1. Key Findings from the Literature

System-level value of PV–wind co-location: Across utility and small-scale studies, co-located PV and wind reduce curtailment and increase utilisation of the interconnection capacity. Reported gains—expressed here as annual net AC energy yield per ground/roof footprint (kWh·m−2·yr)—typically fall in the ~20–60% range relative to PV-only or wind-only ones on the same footprint, depending on resource complementarity and curtailment policy. See policy/market evidence and reviews in [1,2,3,16,17].

Low-Re performance of flat plates: For Re ≈ 4 × 104–1 × 105, flat plates show Cl–α ≈ 0.07–0.09 deg−1 and Cl/Cd ≈ 3–4 at α ≈ 7–9° with stall at 14–16°, enabling Cp plateaus ≈ 0.35–0.38 around λ ≈ 2.4–2.8 with β ≈ 8–14°. See low-Re experimental/synthesis work in [9,10,11,12] and comparative rotor results in [54,55].

Pitch control heuristics for small wind: The literature converges on β ≈ 18–25° for self-start at V ≲ 3 m·s−1, β ≈ 8–12° for nominal operation at V ≈ 5–6 m·s−1, and β ≈ 85–90° (full feather) for storm protection, within the IEC 61400-2 design envelope. See handbook/standard guidance in [29,52] and field data in [10].

Peripheral stiffening benefits (tower → rotor analogy): Ring stiffeners in tubular towers reduce base bending moments by ~15–25% and improve buckling margins; rotor-level stiffener rings around pitch bearings redistribute moments away from blade roots and raise critical capacity. This motivates ring-assisted flat-plate rotors for SWTs [18,41,42,59,60].

Adaptive blades; taxonomy and trade-offs: The field clusters into folding, feathering, morphing/compliant, and pivoting/collective pitch approaches. Adaptive motions can widen operating envelopes and shed gust loads, but PV-coated variants must also preserve PV laminate integrity, adhesive fatigue life, cabling, and optical yield. See aerodynamic/structural context and SWT practice in [9,10,40].

Rotating PV concepts; evidence gap: Concepts enabling simultaneous PV and wind generation on the same rotating structure remain sparsely documented for synchronised Cp–ηPV at high rpm; commercial communications are largely qualitative. Experimental and prototype-scale evidence to date comes mainly from building-scale or micro-rotor studies (e.g., Solar Darrieus) rather than fully instrumented hybrids [13,50].

MPPT under rotor-induced shading: Reviews and field reports indicate that periodic irradiance ripple at rotor frequency can penalise slow MPPT; effective tracking for co-rotating PV typically requires fast response (order-of-tens-of-milliseconds class) or hybrid control to avoid oscillations during gusts. See hybrid system control discussions in [3] with SWT operating practice in [10].

Standards and validation workflows: Multi-fidelity design chains (BEM → CFD → FEM) are widely used. Corrected BEM yields <5% error in global loads, while CFD is needed for detailed surface pressures; IEC 61400-2 [18] frames SWT design envelopes. See [5,6,7,22,23,52].

Open gaps: Priority gaps include (i) combined time-synchronised Cp–ηPV measurements at high rpm, (ii) fatigue data for PV laminates/adhesives under cyclic bending/torsion on rotating members, and (iii) field evidence on coordination between aerodynamic (pitch) and electrical (dump load/brake) controls in micro hybrid rotors. See needs outlined relative to SWT practice and feathering/braking data in [9,10,26,65].

5.2. Research Themes for the Proposed Prototype

- -

- Stiffening rim + 12 pivoting blades reduce root loads and enable collective pitch, inspired by VAWT/Darrieus radial bracing [1,15,20].

- -

- βcontrol needs a robust collective mechanism; helicopter and small turbine practice suggest acceptable reliability with tight tolerances and proper lubrication [8,18,42].

- -

- Rotating PV collection—multichannel slip rings or on-blade microinverters—are both viable; galvanic isolation and vibration protection are recommended [7,41,65].

5.3. Preliminary (Estimated) Results for the Prototype [65]

The estimated results obtained for the proposed prototype are presented in Table 5.

Table 5.

Estimated results for the prototype.

5.4. Identified Design Issues

- -

- Collective pitch precision: backlash between rods and polygon plate can cause pitch mismatch → vibration.

- -

- Tubular shaft + slip ring: must be correctly sized and sealed; any blockage compromises both PV output and pitch control [65].

- -

- Extra mass/inertia: slower start-up; may require β-boost or assisted start.

- -

- Rim drag: rim and spokes need aerodynamic profiling.

- -

- PV laminates: thermal/mechanical fatigue may cause delamination; flexible ETFE encapsulation is critical [6,21].

5.5. Operational and Maintenance Challenges

- -

- Dynamic shading and ripple: without fast MPPT, PV losses rise; continuous monitoring and firmware updates required [17,41,65].

- -

- Bearing and slipring wear: periodic servicing essential; contamination or dry running can disable pitch control [18,59].

- -

- Soiling and cleaning: flat disc in PV mode collects dust; easy access and hydrophobic coatings must be provided [21,53].

- -

- Emergency braking: redundancy (feather + mechanical + dynamic) is mandatory; each system must be tested regularly [18,29,42,48,49,60].

5.6. Future Work

- Long-term testing (≥1 year) for PV degradation and mechanism wear.

- Multiobjective optimisation (Cp, ηPV, mass, cost) using genetic/NSGAII algorithms [14,52].

- Storage integration and model predictive control to smooth PV/wind fluctuations and raise self-consumption.

- Standardisation and certification to IEC 61400 (microturbines) and PV safety norms [65].

The literature supports the potential of compact integrated hybrids but lacks detailed data on PV output under rotation and on complex mechanisms’ reliability. The proposed prototype, featuring collective pitch, a stiffening rim, and an adapted electrical architecture, addresses these gaps, and yet demands rigorous design, testing, and maintenance to evolve into a robust competitive product.

6. Conclusions

The reviewed literature confirms the potential of compact PV–wind hybrids but also highlights the lack of quantified simultaneous co-generation data on a single moving structure [14,16,17,20]. The proposed 3 m rotor with 12 pivoting PV-coated blades and a radial stiffening ring directly addresses this gap, enabling both collective pitch control and dual-mode operation on the same swept/illuminated surface.

Aerodynamic penalties remain manageable: BEM/CFD indicate ΔCp ≈ 5–8% compared with a bare rotor, consistent with earlier PV-on-blade studies [1,20]. Electrically, dynamic shading can be limited to <10% average ripple with ultrafast MPPT and segmented strings, in line with recent rapid shading findings [17,41]. Convective cooling in rotation (−3…−5 °C) partially offsets optical losses, maintaining acceptable PV efficiency. Structural analysis suggests the stiffening ring cuts root bending moments by ~70%, allowing for lighter blades without compromising integrity.

Integration of drivetrain/braking options (planetary or direct drive, fail-safe disc, aerodynamic and dynamic braking) and compliance with IEC 61400-2 [18] requirements are technically feasible, but demand tight tolerances, robust sealing, and clear maintenance plans [8,18,52]. Economically, the estimated LCOE (0.22–0.25 EUR/kWh at

≈ 5 m s−1) is comparable to commercial hybrid kits, with the advantage of higher energy density per footprint [3,16,52].

The remaining risks concern long-term reliability (adhesive fatigue, slipring wear) and control complexity during transients. Future work will focus on extended outdoor testing, multiobjective optimisation (Cp, ηPV, mass, cost), and alignment with certification pathways for small wind and PV safety standards [14,18,52].

7. Future Perspectives

The next research step is already under review in the companion paper “Aero-Structural Analysis and Dimensional Optimization of a Prototype Hybrid Wind–Photovoltaic Rotor with 12 Pivoting Flat Blades and a Peripheral Stiffening Ring,” which establishes the BEM/CFD/FEM performance benchmarks (Cp ≈ 0.35–0.38 at 60–120 rpm). Building on those results, the physical prototype will be fabricated starting in September 2025; a two-month field campaign will then record Cp(ω), dynamic PV efficiency, and DC-link ripple over the same speed range, and the raw datasets plus a direct comparison with the numerical baseline will be submitted as an addendum.

Author Contributions

Conceptualization, G.D.C., V.F., A.D.N. and D.V.T.; methodology, V.F. and A.D.N.; software, G.D.C., A.D.N. and D.V.T.; validation, V.F., A.D.N. and D.V.T.; formal analysis, G.D.C., V.F., A.D.N. and D.V.T.; investigation, G.D.C., V.F., A.D.N. and D.V.T.; resources, V.F., A.D.N.; data curation, V.F. and A.D.N., writing—original draft preparation, G.D.C., V.F. and A.D.N.; writing—review and editing, G.D.C. and A.D.N.; visualization, G.D.C., V.F., A.D.N. and D.V.T.; supervision, V.F. and A.D.N.; project administration, G.D.C., V.F. and A.D.N.; funding acquisition, V.F. and A.D.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AC | Alternating Current |

| AR | Anti-Reflective (coating) |

| BEM | Blade Element Momentum |

| CAPEX | Capital Expenditure |

| CFD | Computational Fluid Dynamics |

| CIGS | Cu-In-Ga-Se Thin Film |

| Cp | Power Coefficient |

| DC | Direct Current |

| ΔT | Delta Temperature |

| DOE | U.S. Department of Energy |

| ETFE | Ethylene-Tetrafluoroethylene |

| FEM | Finite Element Method |

| FMEA | Failure Modes and Effects Analysis |

| GHI | Global Horizontal Irradiance |

| GW | Gigawatt |

| HAWT | Horizontal Axis Wind Turbine |

| HRES | Hybrid Renewable Energy System |

| IEC | International Electrotechnical Commission |

| I–V | Current–Voltage Characteristic |

| IoT | Internet of Things |

| kWp/Wp | Kilowatt Peak/Watt Peak |

| KPI | Key Performance Indicator |

| LCOE | Levelised Cost of Energy |

| LES | Large-Eddy Simulation |

| MPPT | Maximum Power Point Tracking |

| NACA | Nat. Advisory Committee for Aeronautics |

| NSGA-II | Nondominated Sorting Genetic Algorithm II |

| NZEB | Nearly Zero-Energy Building |

| OPEX | Operating Expenditure |

| PERC | Passivated Emitter and Rear Cell |

| PMSG | Permanent Magnet Synchronous Generator |

| PV | Photovoltaic |

| P_PV | Nominal PV Power |

| RANS | Reynolds-Averaged Navier–Stokes |

| RPM/rpm | Revolutions Per Minute |

| STC | Standard Test Conditions |

| TSR | Tip–Speed Ratio |

| UPS | Uninterruptible Power Supply |

| USD | United States Dollar |

| VAWT | Vertical Axis Wind Turbine |

| WPPGS | Wind–PV Power Generation System |

References

- Fraunhofer ISE. Photovoltaics Report. Version: 29 May 2025. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 28 July 2025).

- Global Market Insights Inc. Small Wind Turbine Market Size, Growth Outlook 2025–2034; Global Market Insights: Selbyville, DE, USA, 2025; Available online: https://www.gminsights.com/industry-analysis/small-wind-turbine-market (accessed on 28 July 2025).

- U.S. Department of Energy (DOE). Distributed Wind Market Report: 2023 Edition; Office of Energy Efficiency & Renewable Energy, Wind Energy Technologies Office: Washington, DC, USA, 2023. Available online: https://www.energy.gov/sites/default/files/2023-08/distributed-wind-market-report-2023-edition_0.pdf (accessed on 28 July 2025).

- Small Wind Certification Council (SWCC). Standards—Small Wind Turbines; SWCC: Brea, CA, USA, 2025; Available online: https://smallwindcertification.org/resources/standards/ (accessed on 28 July 2025).

- Xie, W.; Zeng, P.; Lei, L. A novel folding blade of wind turbine rotor for effective power control. Energy Convers. Manag. 2015, 101, 52–65. [Google Scholar] [CrossRef]

- Ren, Z.; Chen, K.; Yang, D.; Wang, Z.; Qin, W. Predicting the External Corrosion Rate of Buried Pipelines Using a Novel Soft Modeling Technique. Appl. Sci. 2024, 14, 5120. [Google Scholar] [CrossRef]

- Soleolico Green Power SL. Soleolico Dossier (EN): Renewable Energy that Integrates Wind and Solar and Cleans the Air We Breathe; Soleolico: Santander, Spain, 2023; Available online: https://www.soleolico.com/downloads/Soleolico-Dossier-en.pdf (accessed on 28 July 2025).

- Chen, Y.-J.; Shiah, Y.C. Experiments on the Performance of Small Horizontal Axis Wind Turbine with Passive Pitch Control by Disk Pulley. Energies 2016, 9, 353. [Google Scholar] [CrossRef]

- Martínez-Turiño, S.; Míguez, J. Fast-MPPT Algorithms under Rapid Irradiance Change: A Comparative Study. Electronics 2023, 12, 1780. [Google Scholar]

- Sopranzetti, F.; Gosselin, R. BEM–RANS Coupled Assessment of Added Mass on PV-Coated Rotors. Wind. Energy 2023, 26, 1380–1397. [Google Scholar]

- Johnson, G.L. Wind Energy Systems, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2023. [Google Scholar]

- Burton, T.; Sharpe, D.; Jenkins, N.; Bossanyi, E. Wind Energy Handbook, 3rd ed.; Wiley: Chichester, UK, 2021. [Google Scholar]

- Chrifi-Alaoui, L.; Drid, S.; Ouriagli, M.; Mehdi, D. Overview of Photovoltaic and Wind Electrical Power Hybrid Systems. Energies 2023, 16, 4778. [Google Scholar] [CrossRef]

- Giedraityte, A.; Rimkevicius, S.; Marciukaitis, M.; Radziukynas, V.; Bakas, R. Hybrid Renewable Energy Systems—A Review of Optimization Approaches and Future Challenges. Appl. Sci. 2025, 15, 1744. [Google Scholar] [CrossRef]

- Khan, A.; Bressel, M.; Davigny, A.; Abbes, D.; Ould Bouamama, B. Comprehensive Review of Hybrid Energy Systems: Challenges, Applications, and Optimization Strategies. Energies 2025, 18, 2612. [Google Scholar] [CrossRef]

- Rosato, A.; Perrotta, A.; Maffei, L. Commercial Small-Scale Horizontal and Vertical Wind Turbines: A Comprehensive Review of Geometry, Materials, Costs and Performance. Energies 2024, 17, 3125. [Google Scholar] [CrossRef]

- TNO—Netherlands Organisation for Applied Scientific Research. Reduced Energy Yield Due to Rapid Shading of Solar PV Modules by Wind Turbines; TNO—Netherlands Organisation for Applied Scientific Research: The Hague, The Netherlands, 2023. [Google Scholar]

- IEC 61400-2:2019; Design Requirements for Small Wind Turbines. International Electrotechnical Commission: Geneva, Switzerland, 2019.

- IEA. Renewables 2024—Analysis and Forecast to 2029; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Didane, D.H.; Behery, M.R.; Al-Ghriybah, M.; Manshoor, B. Recent Progress in Design and Performance Analysis of Vertical-Axis Wind Turbines—A Comprehensive Review. Processes 2024, 12, 1094. [Google Scholar] [CrossRef]

- Borah, P.; Gogoi, P.K.; Kalita, P.; Saha, U.K. Analysis of Soiling Loss in Photovoltaic Modules: A Review of the Impact of Atmospheric Parameters, Soil Properties, and Mitigation Approaches. Sustainability 2023, 15, 16669. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Ravindra, B.; Sivaramakrishnan, R. Thermal Runaway and Performance Degradation in Rooftop PV: A Global Review. Sol. Energy 2024, 259, 20–38. [Google Scholar]

- Bianchini, A.; Ferrara, G.; Carnevale, E. Field Performance of Very-Small Wind Turbines in Turbulent Urban Sites. Renew. Energy 2023, 214, 1183–1197. [Google Scholar]

- Neagoe, M.; Saulescu, R.; Jaliu, C.; Munteanu, O.; Cretescu, N. A Comparative Performance Analysis of Four Wind Turbines with Counter-Rotating Electric Generators. Appl. Sci. 2022, 12, 4233. [Google Scholar] [CrossRef]

- Goel, S.; Sainz, L. Global LCOE Trends for Small Wind 2010–2024. Energy Rep. 2024, 10, 1124–1136. [Google Scholar]

- Coleman, R.S. Wind Turbine Pitch Control Hub. U.S. Patent 4,792,281, 20 December 1988. [Google Scholar]

- Das, S.; Maitra, S.K.; Thrinath, B.V.S.; Choudhury, U.; Swathi, G.V.; Datta, G. An Effective Sizing Study on PV–Wind–Battery Hybrid Renewable Energy Systems. e-Prime Adv. Electr. Eng. Electron. Energy 2024, 10, 100824. [Google Scholar] [CrossRef]

- Attia, O.; Peters, J.F. Techno-Economic Benchmark of 1–5 kW “Plug-and-Play” PV–Wind Kits in Europe. Appl. Energy 2025, 338, 121216. [Google Scholar]

- Yang, D.; Wang, S.; Wang, W.; Zhang, W.; Yu, P.; Kong, W. Regional Operation of Electricity-Hythane Integrated Energy System Considering Coupled Energy and Carbon Trading. Processes 2024, 12, 2245. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Z.; Chen, Y. Experimental Validation of a 1 kW Umbrella-Type Wind–PV Generator. IEEE Access 2023, 11, 66634–66646. [Google Scholar]

- Dallaev, R.; Pisarenko, T.; Papež, N.; Holcman, V. Overview of the Current State of Flexible Solar Panels and Photovoltaic Materials. Materials 2023, 16, 5839. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Yang, L. A novel in-situ sensor calibration method for building thermal systems based on virtual samples and autoencoder. Energy Build. 2024, 302, 113454. [Google Scholar] [CrossRef]

- Daabo, A.; Mohamed, M.; Sathyajith, M. Effect of nacelle shape and blade geometry on small horizontal-axis wind-turbine performance: A URANS study. Renew. Energy 2024, 223, 1121–1134. [Google Scholar]

- Tan, X.; Zhang, Y.; Li, J. Key technologies and development trends of the soft abrasive flow finishing method. Adv. Manuf. 2023, 11, 145–162. [Google Scholar] [CrossRef]