Research on Performance Testing Methods for Electrical Equipment in High-Speed and Complex Environments: A Case Study on Roof Insulators of High-Speed Trains

Abstract

1. Introduction

2. Rotating High-Speed Multiphase Flow Generator

2.1. Flow-Field Uniformity Metrics

2.1.1. Uniformity of Flow Rate

2.1.2. Uniformity of the Directional Field

2.2. Test Space and Rotating Device

2.3. Uniform-Flow Acceleration Duct

3. Numerical Model and Methodology

3.1. Computational Domain and Mesh

3.2. Governing Equations of Airflow Field

3.3. Governing Equations for the Parti Kelvin Phase

4. Equivalence Analysis Between Rotational and Linear Testing Methods

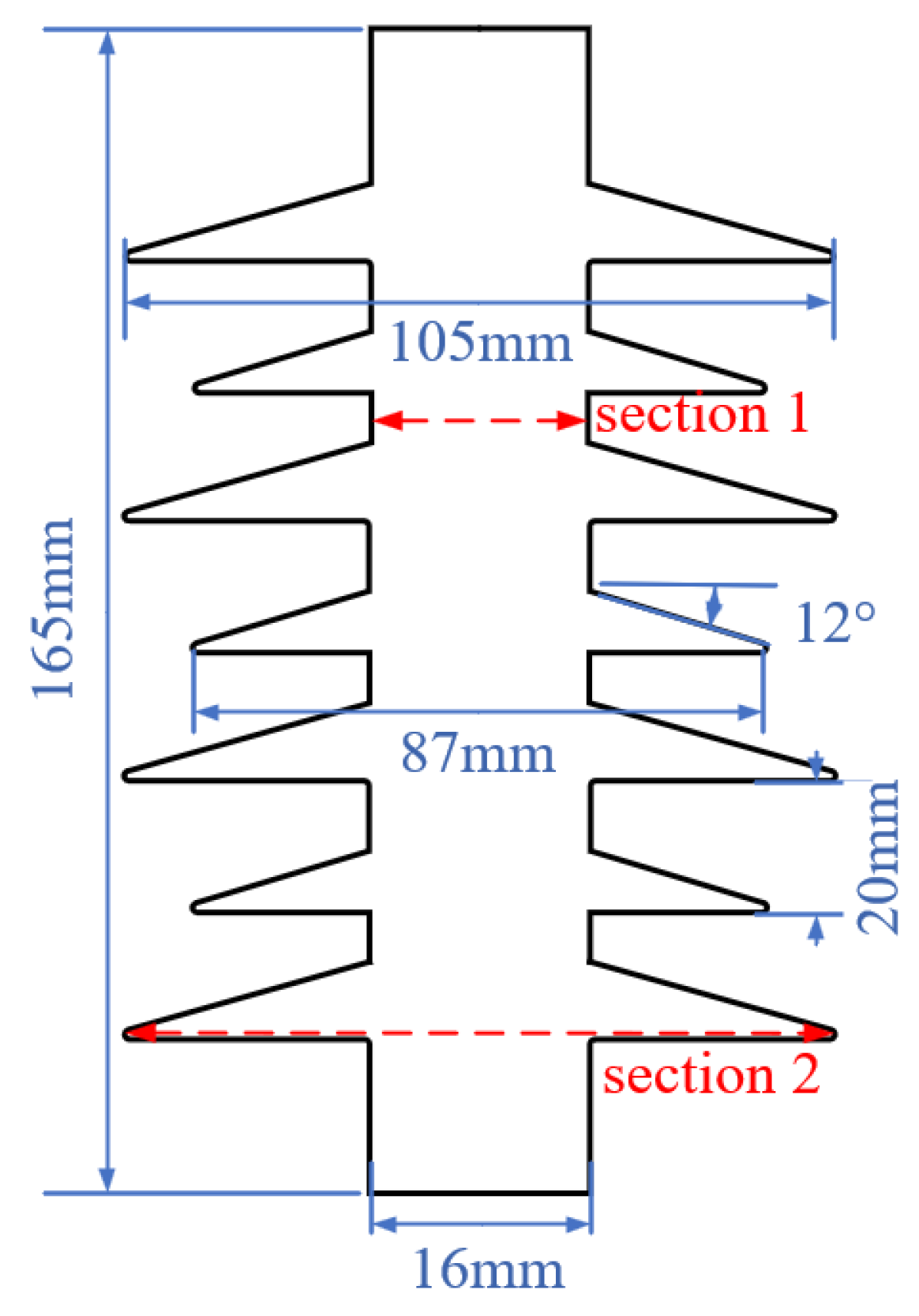

4.1. Test Insulator

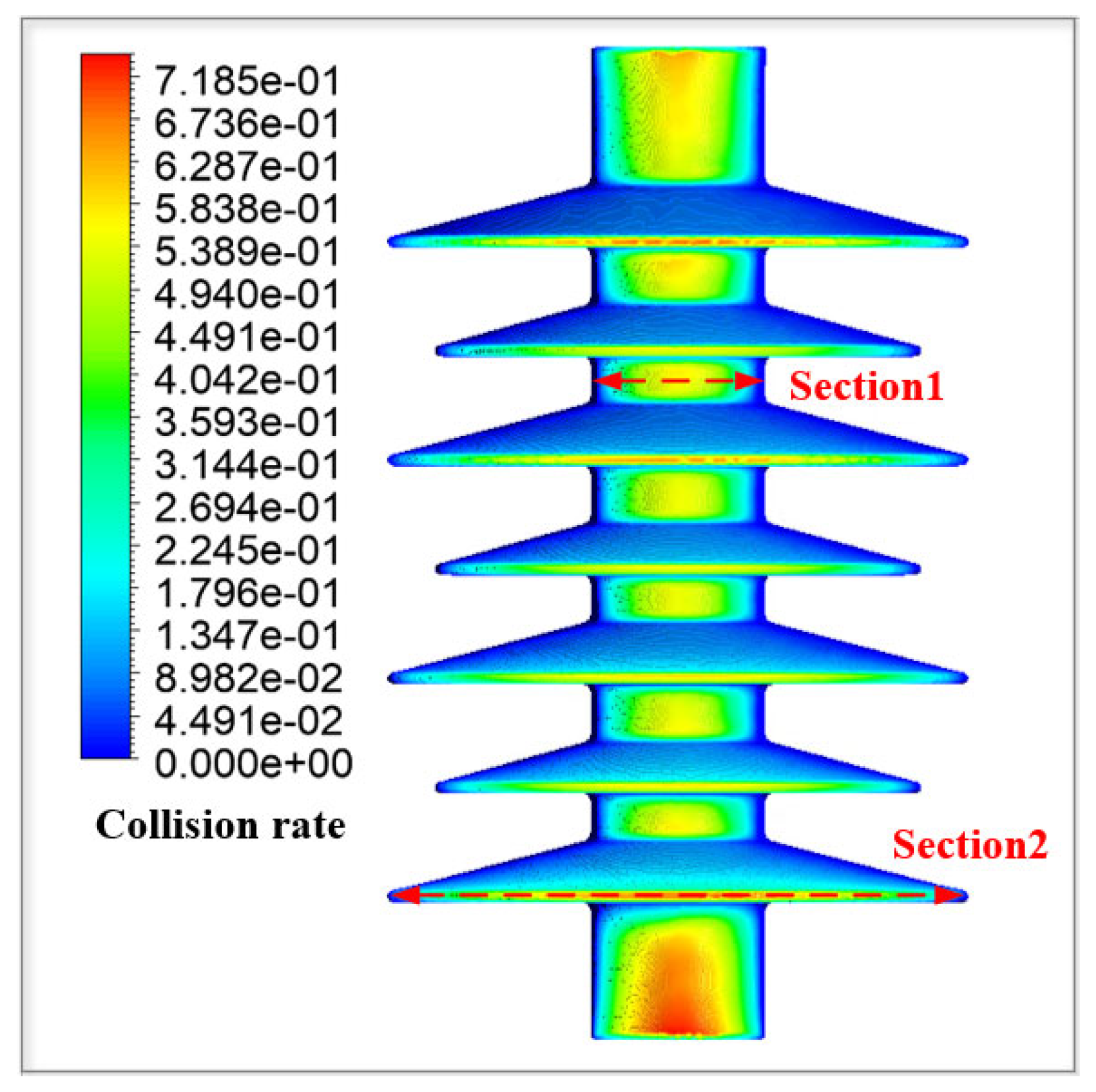

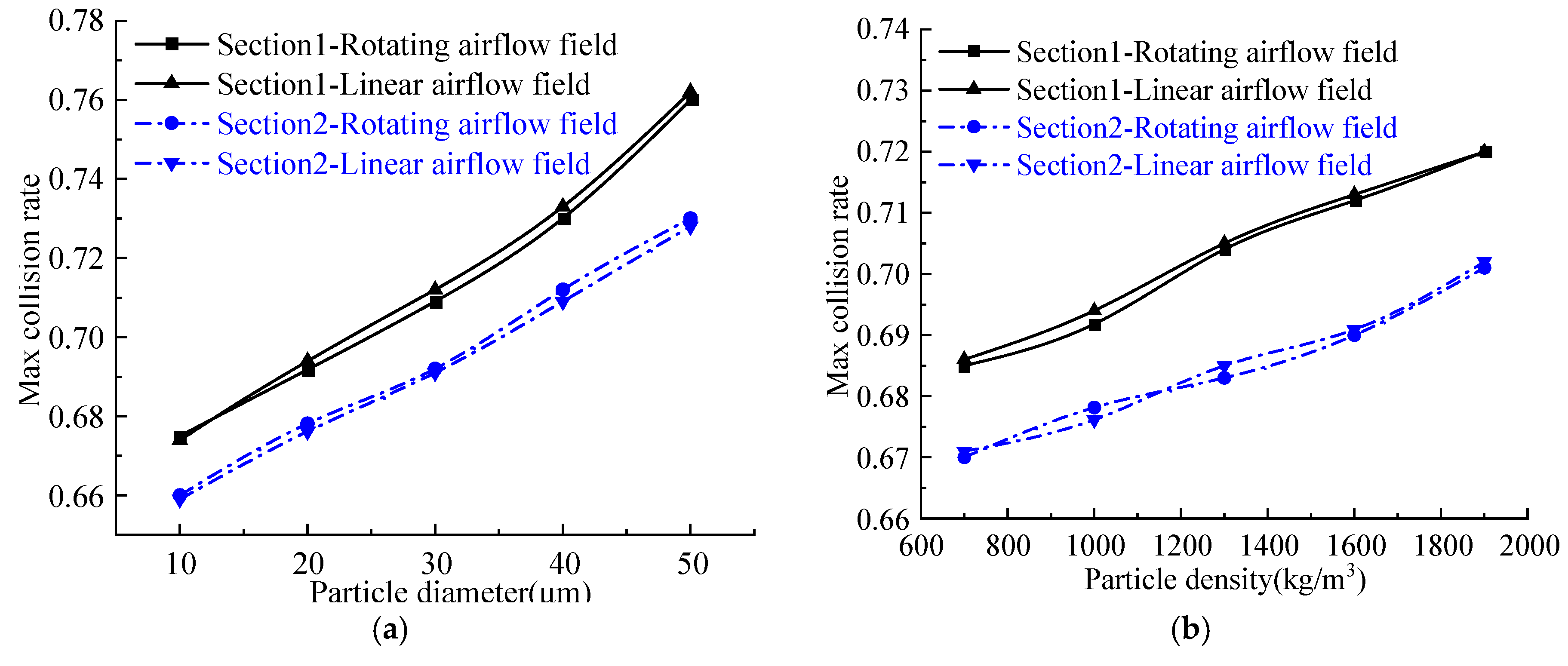

4.2. Equivalence on Collision Test

4.3. Equivalence on Accumulation Test

5. Equivalence Study by Icing Experiment

5.1. Test Object and Facility

5.2. Test Procedures

- (1)

- Sample preprocessing: Before the test, the insulator is cleaned to remove surface grease and contaminants and then air-dried naturally.

- (2)

- Precooling: The insulator is placed in front of the air duct of the climate chamber and the refrigeration system turned on. When the temperature reaches the test value, the spraying system to start spraying is turned on.

- (3)

- Spraying system adjustment: The LWC is regulated by the tuning water pressure, while the MVD is controlled via air pressure adjustment (after water pressure stabilization). The nozzle opening is fine-tuned to optimize atomization. The parameters are maintained once the target LWC and MVD values are achieved.

- (4)

- Measurement of airflow velocity: The air duct system and fan power to control the airflow velocity is adjusted using a handheld anemometer to sample the airflow velocity at multiple horizontal and vertical positions at the windward side of the insulator and the average value taken.

- (5)

- Measurement of ice: The icing test lasts 60 min, keeping the temperature, wind speed, and water spray volume unchanged. The icing mass of the insulator is weighed every 10 min, and the local icing thickness measured by slicing after icing.

5.3. Experiment Results

6. Conclusions

- Based on the principle of relative rotating motion, a test method is proposed to realize the test conditions of complex environments combining high-speed airflow.

- Numerical simulation shows that the collision and accumulation test results of the rotating airflow fields agree with the linear airflow field. The collision rate distribution and icing shape are basically the same. The maximum difference in the collision rate and the ice mass is 3.23% and 4.34%, respectively. It should be noted that the similarity conclusions presented herein are derived solely from comparative CFD results; their further validation will necessarily depend on forthcoming data obtained from an actual rotating test facility.

- It should be noted that this paper only verifies the feasibility of the proposed method in principle. Further research is needed to address practical engineering issues such as the duct wake effect and the stability of the rotating structure during high-speed rotation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramalingam, B.; Manuel, V.; Elara, M.R.; Vengadesh, A.; Lakshmanan, A.K.; Ilyas, M.; James, T.J. Visual Inspection of the Aircraft Surface Using a Teleoperated Reconfigurable Climbing Robot and Enhanced Deep Learning Technique. Int. J. Aerosp. Eng. 2019, 2019, 5137139. [Google Scholar] [CrossRef]

- Gao, L.; Tao, T.; Liu, Y.; Hu, H. A field study of ice accretion and its effects on the power production of utility-scale wind turbines. Renew. Energy 2021, 167, 917–928. [Google Scholar] [CrossRef]

- Drapalik, M.; Zajicek, L.; Purker, S. Ice aggregation and ice throw from small wind turbines. Cold Reg. Sci. Technol. 2021, 192, 103399. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.; Kang, Y.; Yin, X.; Gao, G.; Wu, G. Flashover characteristics of cylindrical insulator in high-speed sand environment. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 455–461. [Google Scholar] [CrossRef]

- Kang, Y.; Zhang, X.; Shi, C.; Zhou, Y.; Liu, Y.; Gao, G.; Wei, W.; Wu, G. Breakdown Characteristics and Mechanisms of Short Needle–Plate Air Gap in High-Speed Airflow. IEEE Trans. Plasma Sci. 2017, 45, 2406–2415. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, R.; Ma, J.; Wang, X.; Ma, L.; Zhao, Z.; Wu, Y. Effects of Static Icing on Flashover Characteristics of High-Speed Train Roof Insulators. Coatings 2022, 12, 950. [Google Scholar] [CrossRef]

- Mu, Z.; Guo, W.; Li, Y.; Tagawa, K. Wind tunnel test of ice accretion on blade airfoil for wind turbine under offshore atmospheric condition. Renew. Energy 2023, 209, 42–52. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, W.; Wang, W.; Li, X.; Qi, S.; Wang, B.; Michailides, C. Investigation on the interaction between ice and monopile offshore wind turbine using a coupled CEM–FEM model. Ocean Eng. 2023, 281, 114783. [Google Scholar] [CrossRef]

- Jolin, N.; Bolduc, D.; Swytink-Binnema, N.; Rosso, G.; Godreau, C. Wind turbine blade ice accretion: A correlation with nacelle ice accretion. Cold Reg. Sci. Technol. 2019, 157, 235–241. [Google Scholar] [CrossRef]

- Pei, Y.; Cai, C.; Chen, Z.; Li, W.; Xiao, H.; Li, C.; Liu, K. An Experimental Study on Icing on Superhydrophobic Surfaces of Wind Turbine Blades in Offshore Environments. Coatings 2025, 15, 236. [Google Scholar] [CrossRef]

- Yu, D.; Han, Z.; Zhang, B.; Zhang, M.; Liu, H.; Chen, Y. A multi-autoencoder fusion network for fast image prediction of aircraft ice accretion. Phys. Fluids 2022, 34, 76107. [Google Scholar] [CrossRef]

- Liu, X.; Niu, C.; Chen, X.; Wang, Z.; Cheong, K. Experimental investigation on the characteristics of saltwater droplets ice accretion on an NACA0018 airfoil. Appl. Therm. Eng. 2025, 264, 125420. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, W.; Li, Y.; Chi, H.; Zhao, P.; Tagawa, K. An experimental study of icing distribution on a symmetrical airfoil for wind turbine blade in the offshore environmental condition. Ocean. Eng. 2023, 273, 113960. [Google Scholar] [CrossRef]

- Guo, W.; Shen, H.; Li, Y.; Feng, F.; Tagawa, K. Wind tunnel tests of the rime icing characteristics of a straight-bladed vertical axis wind turbine. Renew. Energy 2021, 179, 116–132. [Google Scholar] [CrossRef]

- Malik, Y.A.; Karpen, N.; Bonaccurso, E.; Roisman, I.; Hussong, J.; Villedieu, P. Experimental investigation of the accretion and shedding process on a heatable NACA0012 airfoil in ice crystal icing conditions. Cold Reg. Sci. Technol. 2024, 217, 104030. [Google Scholar] [CrossRef]

- Han, Z.; Si, J.; Wu, D. Contrast Icing Wind Tunnel Tests between Normal Droplets and Supercooled Large Droplets. Aerospace 2022, 9, 844. [Google Scholar] [CrossRef]

- Yang, C.; Guo, Y.; Shi, Z.; Li, B.; Zhang, X.; Xiao, S.; Wu, G. Discharge Characteristics of Roof Insulators in Strong Wind and Sand Environment: A Review. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 3231–3242. [Google Scholar] [CrossRef]

- Yang, L.; He, H.C.; Mei, L.L.; Hao, Y.P.; Li, L.C.; Lin, X.H. Ultrasonic Monitoring Technology of Equivalent Ice Thickness Under Slightly Uneven Ice Cover on Overhead Distribution Lines and Its Device Application. IEEE Trans. Instrum. Meas. 2025, 74, 3551310. [Google Scholar] [CrossRef]

- Fan, L.; Xia, M.Y.; Liu, J.; Li, B.; Zhu, T.; Zhao, Y.Y.; Song, L.B.; Yuan, Y. Fabrication of Superhydrophobic Coatings by Using Spraying and Analysis of Their Anti-Icing Properties. Coatings 2023, 13, 1792. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Q.; Lin, H.; Xu, H.; Shu, L.; Yin, P.; Jiang, X. Effect of icing on the AC flashover voltage of 220 kV composite insulators. Electr. Power Syst. Res. 2025, 238, 111117. [Google Scholar] [CrossRef]

- Qiu, Z.; Sun, Y.; Cui, Y.; Zhang, Z.; Liu, Y.; Chen, X.; Wu, Y.; Li, C.; Wang, L.; Lei, Z. Optimized Design of Shed Parameters for Polluted Hollow Porcelain Insulators at High Altitude. IEEE Access 2023, 11, 63451–63462. [Google Scholar] [CrossRef]

- Zhang, X.; Kuang, S.; Wu, S.; Zhuang, W.; He, C. Analysis of Aging Characteristics of Umbrella Skirts of Composite Insulators Operating under the Influence of a Wind and Sand Environment in South Xinjiang. Materials 2024, 17, 680. [Google Scholar] [CrossRef] [PubMed]

- Si, Q.R.; Yuan, J.; Pei, J.; Lu, R. Practical Technique of Numerical Simulation of Centrifugal Pump, 1st ed.; Jiangsu University Press: Zhenjiang, China, 2018; pp. 62–94. [Google Scholar]

- Jung, S.P.; Kim, Y.G.; Park, T.W. A Study on Thermal Characteristic Analysis and Shape Optimization of a Ventilated Disc. Int. J. Precis. Eng. Manuf. 2012, 13, 57–63. [Google Scholar] [CrossRef]

- Strawn, R.C.; Caradonna, F.X.; Duque, E. 30 Years of Rotorcraft Computational Fluid Dynamics Research and Development. J. Am. Helicopter Soc. 2006, 51, 5–21. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Brucato, A.; Ciofalo, M. CFD Simulations of Dense Solid-Liquid Suspensions in Baffled Stirred Tanks: Prediction of Suspension Curves. Chem. Eng. J. 2011, 178, 324–341. [Google Scholar] [CrossRef]

- Jia, W.; Zhang, F.; Zhang, Z. Numerical and experimental investigation of the supercooled large droplets icing of rotating spinner. Appl. Therm. Eng. 2024, 257, 124159. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, X.; Virk, M.S. Ice accretion study of FXBW4-220 transmission line composite insulators and anti-icing geometry optimization. Electr. Power Syst. Res. 2021, 194, 107089. [Google Scholar] [CrossRef]

| D11 (m) | D12 (m) | Dynamic Pressure Coefficient | Flow Deviation Angle | |

|---|---|---|---|---|

| Original | 0.5 | 0.5 | 0.0214 | 0.2011 |

| Optimized | 0.4 | 0.6 | 0.0134 | 0.1209 |

| Boundary Conditions | Mesh Information | ||

|---|---|---|---|

| Items | Description | Items | Description |

| Inside domain | Rotates at 60 rpm about the Z-axis | Inside domain | tetrahedral elements, 0.1 m size |

| Outside domains | Remains stationary relative to the absolute coordinate system. | Outside domains | hexahedral elements, 0.5 m size |

| Duct and insulator walls | No-slip and stationery relative to adjacent cells. | Interfaces | topology share, 0.04 m size |

| Outside walls | No-slip and stationery to the absolute coordinate. | Duct wall boundary layers | 5 boundary layers, 1.2 growth ratio, 0.0001 m first element height, 30 < y+ < 60 |

| Sphere body of influence (SBOI) | SBOI1: 0.04 m size SBOI2: 0.015 m size | ||

| Quality Criterion | Warning Limit | Error (Failure) Limit | Worst |

|---|---|---|---|

| Maximum Aspect Ratio | Default (5) | Default (1000) | 32.751 |

| Minimum Cell Quality | Default (0.05) | Default (5 × 10−4) | 0.047 |

| Minimum Cell Quality | Default (0.05) | Default (5 × 10−3) | 0.15 |

| Maximum Skewness | Default (0.9) | Default (0.999) | 0.85 |

| Test Group | Airflow Velocity (m/s) | Temperature (°C) | LWC (g/m3) | MVD (μm) |

|---|---|---|---|---|

| Test 1 | 15 | −10 | 0.6 | 20 |

| Test 2 | 10 | −10 | 0.6 | 20 |

| Test 3 | 15 | −10 | 0.9 | 20 |

| Test 4 | 15 | −10 | 0.6 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Jiang, X.; Jin, J.; Yang, Z. Research on Performance Testing Methods for Electrical Equipment in High-Speed and Complex Environments: A Case Study on Roof Insulators of High-Speed Trains. Appl. Sci. 2025, 15, 9076. https://doi.org/10.3390/app15169076

Huang Y, Jiang X, Jin J, Yang Z. Research on Performance Testing Methods for Electrical Equipment in High-Speed and Complex Environments: A Case Study on Roof Insulators of High-Speed Trains. Applied Sciences. 2025; 15(16):9076. https://doi.org/10.3390/app15169076

Chicago/Turabian StyleHuang, Yafei, Xingliang Jiang, Jiayi Jin, and Zhongyi Yang. 2025. "Research on Performance Testing Methods for Electrical Equipment in High-Speed and Complex Environments: A Case Study on Roof Insulators of High-Speed Trains" Applied Sciences 15, no. 16: 9076. https://doi.org/10.3390/app15169076

APA StyleHuang, Y., Jiang, X., Jin, J., & Yang, Z. (2025). Research on Performance Testing Methods for Electrical Equipment in High-Speed and Complex Environments: A Case Study on Roof Insulators of High-Speed Trains. Applied Sciences, 15(16), 9076. https://doi.org/10.3390/app15169076