Enhancing Wire Arc Additive Manufacturing for Maritime Applications: Overcoming Operational Challenges in Marine and Offshore Environments

Abstract

1. Introduction

2. Methodology

2.1. Current Research

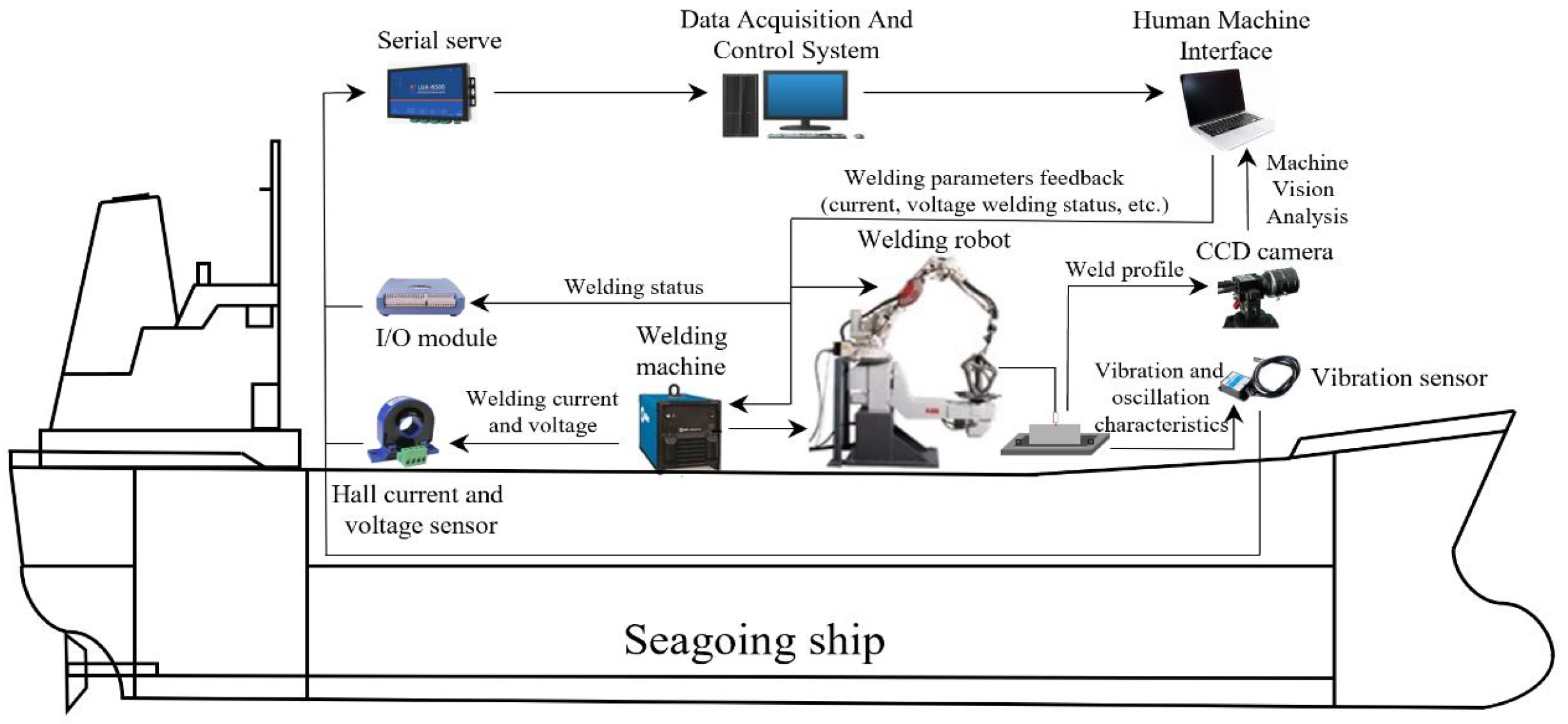

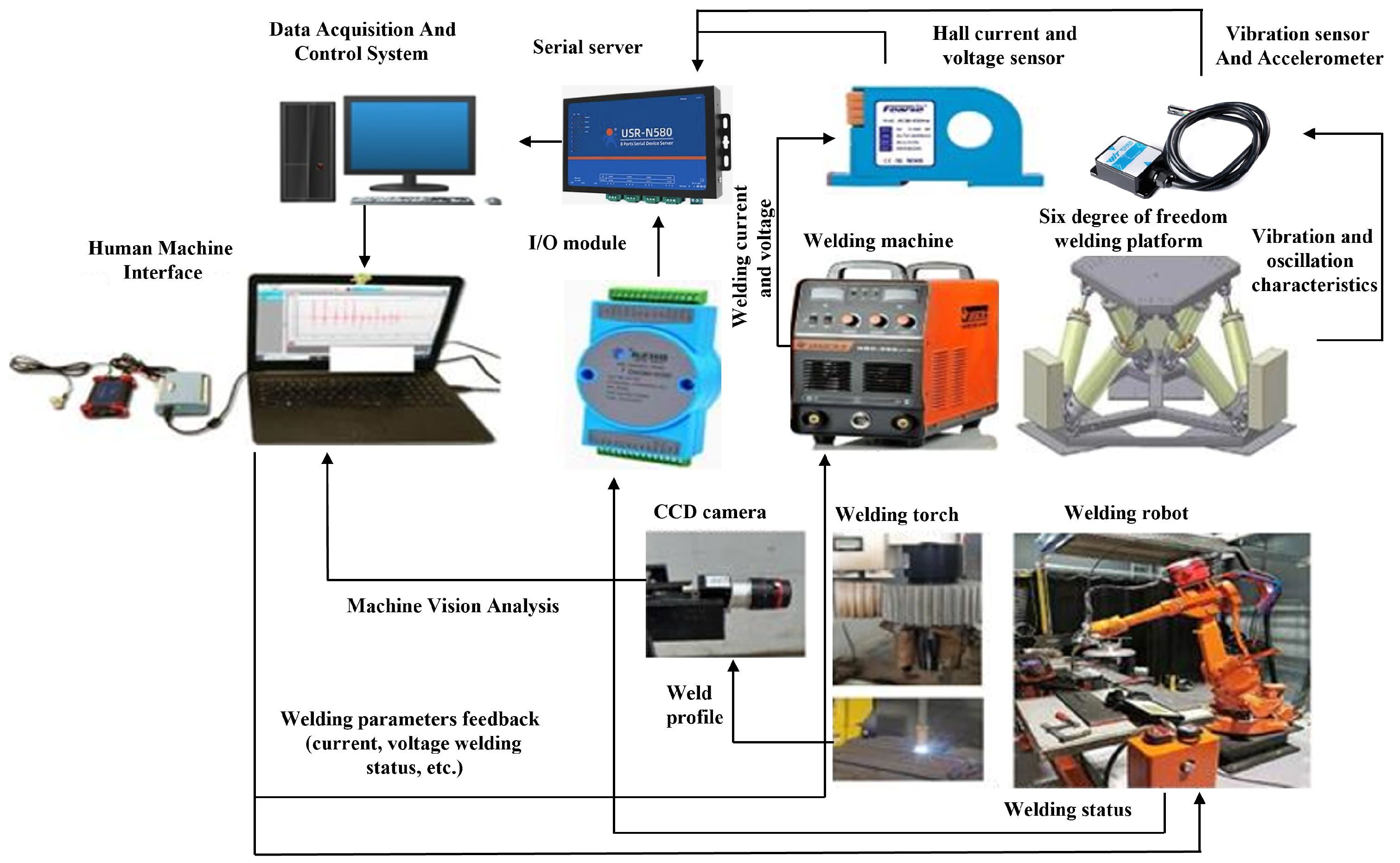

2.2. Instrumental Tools for Enhancing WAAM Technology in Maritime Environments

2.3. Digital Modeling, Monitoring, Diagnostics, and Control Tools for the WAAM Process

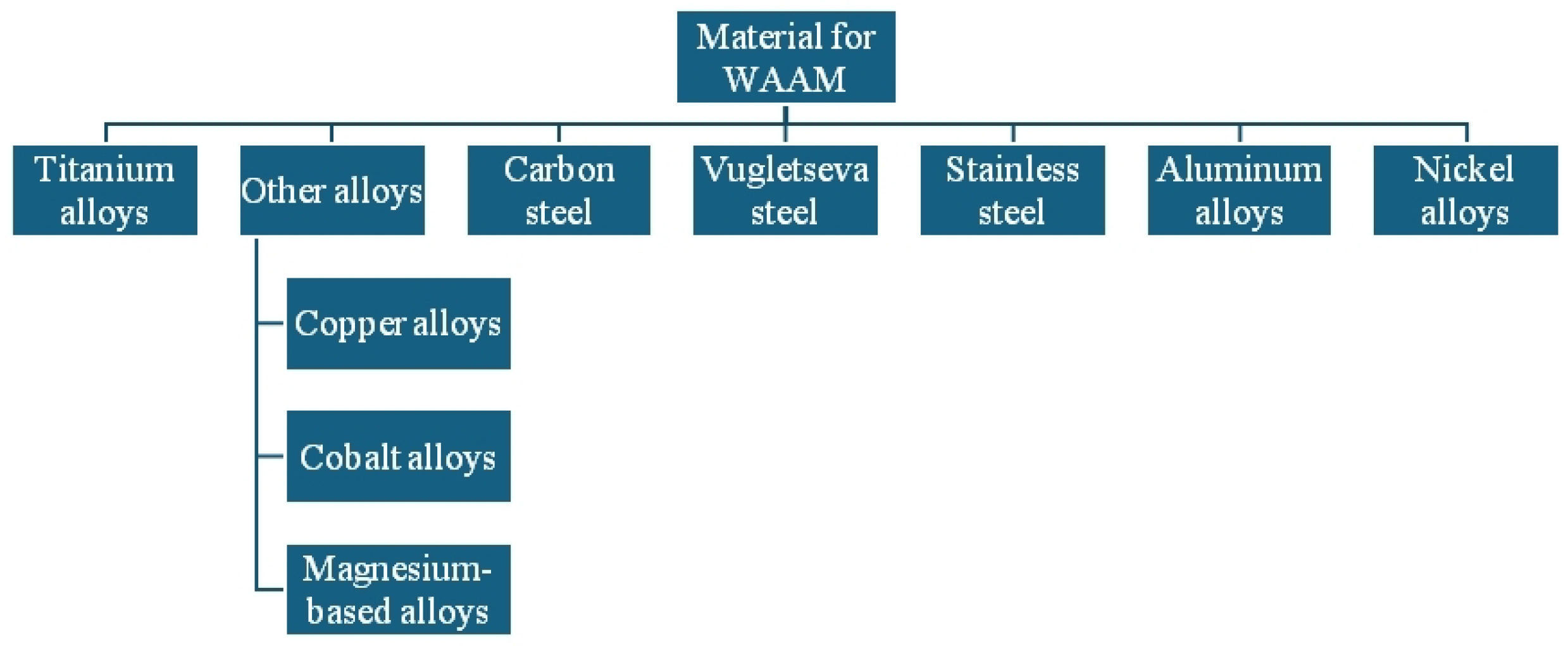

2.4. Metals Used in WAAM Technology for the Maritime Industry

3. Results

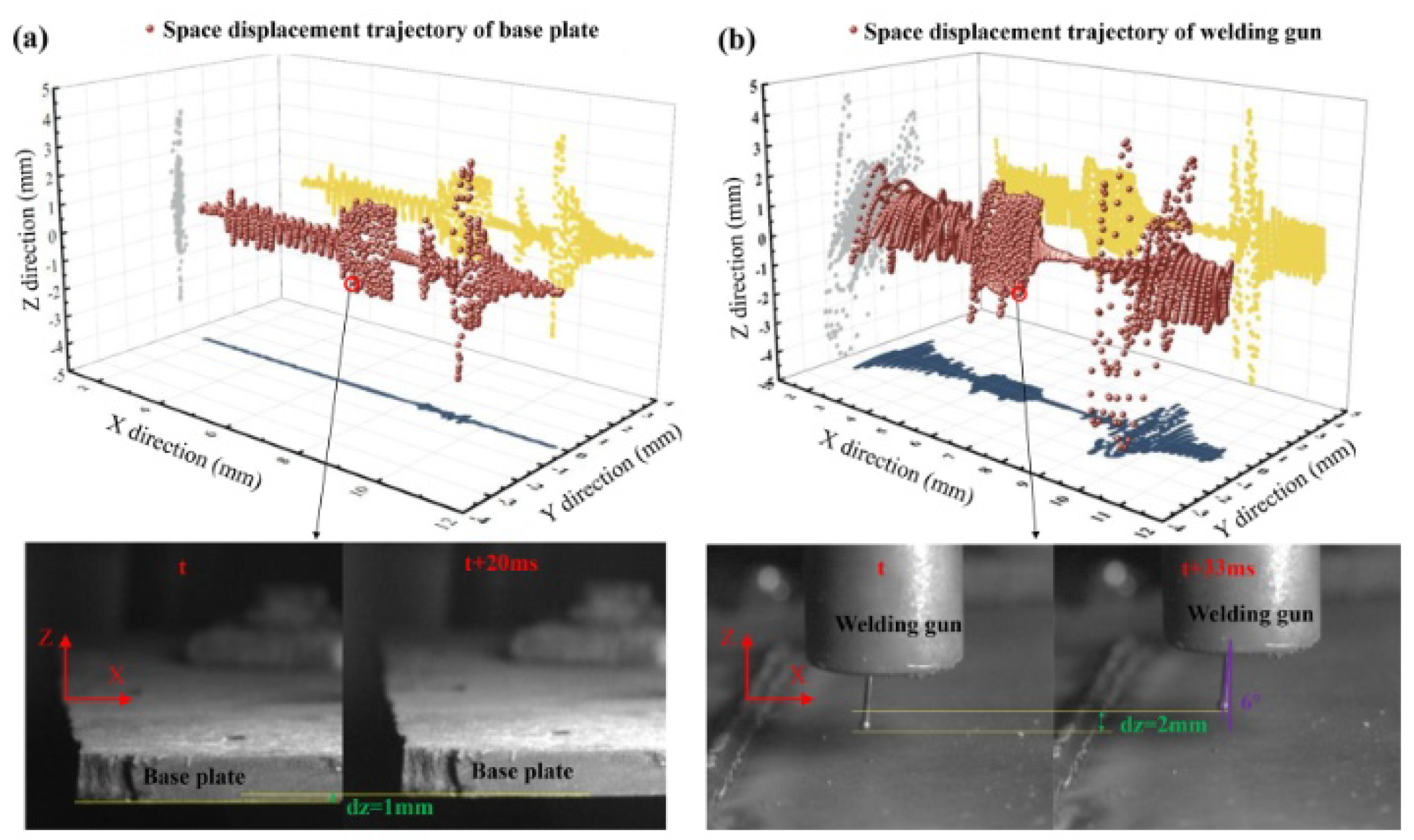

3.1. WAAM Technology in Maritime Environments

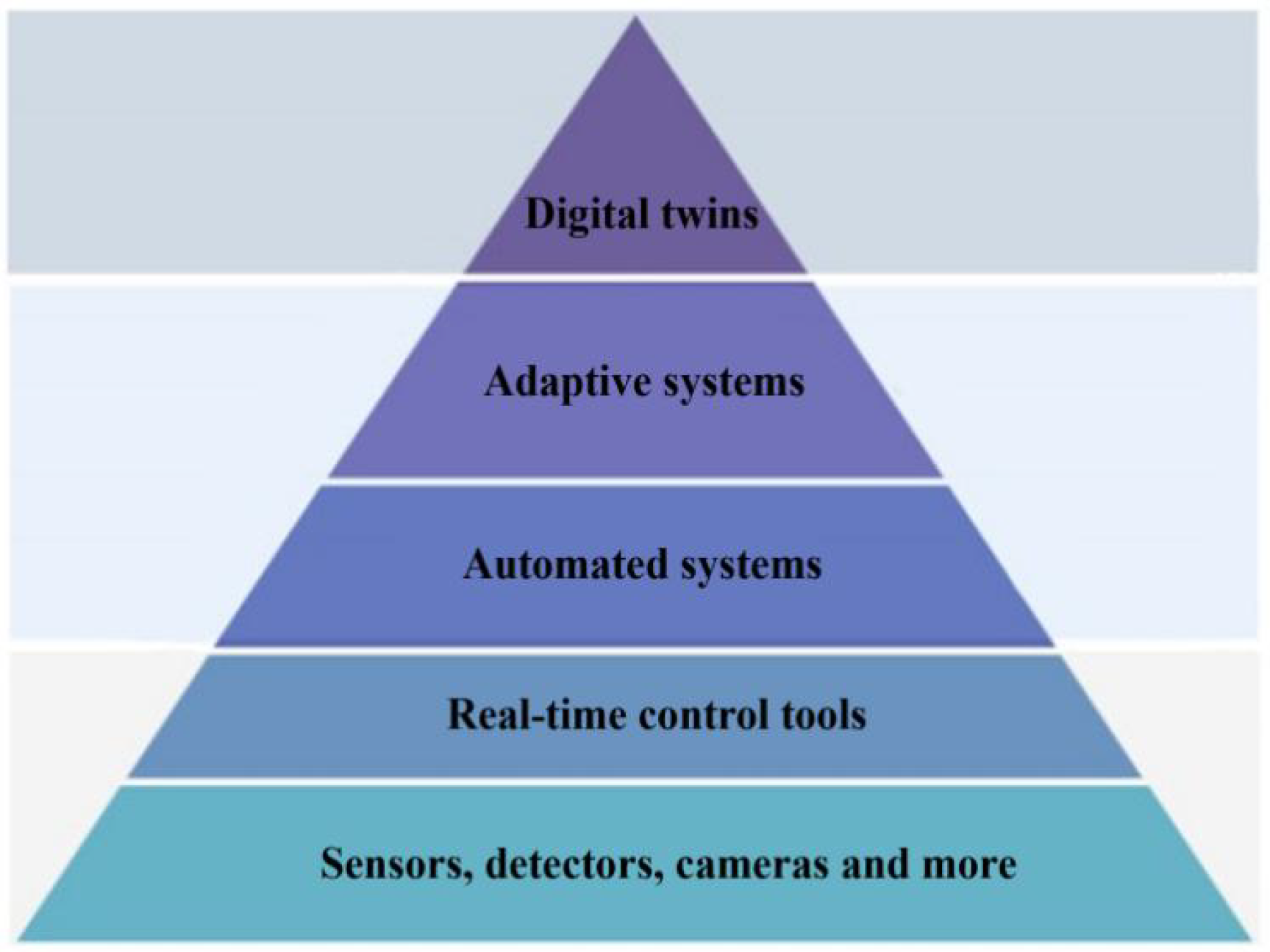

3.2. Technical and Software Instrumental Tools for Enhancing WAAM Technology in Marine Engineering Applications

3.3. Instrumental Tools for Digital Modeling, Monitoring, Diagnostics, and Process Control in WAAM Technology

3.4. Problematic Issues in the Selection of Metals for Marine Applications of WAAM Technologies

4. Discussion

5. Conclusions

- The formulation of specific technical requirements for WAAM hardware and software tools under shipborne motion conditions;

- A functional analysis of existing technical and software solutions, highlighting their capabilities and limitations;

- Recommendations for improving digital modeling, thermo-mechanical monitoring, and closed-loop control systems;

- An in-depth analysis of microstructural challenges related to material properties, which affect product quality under dynamic loading conditions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, X.; Jin, Y.; Wang, Y.; Petro, P.; Li, Z. Enhancing wire arc additive manufacturing in vibrational environments with longitudinal magnetic fields. Mater. Today Commun. 2024, 38, 108035. [Google Scholar] [CrossRef]

- Shi, X.; Cai, C.; Bao, P.; Li, Z. Influence of ship-basedvibration on characteristics of arc and droplet and morphology in wire arcadditive manufacturing. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100067. [Google Scholar]

- Sainath, K.; Prabagaran, S.; Soundararajan, R. A Comparison Study on Detailed Strengthening mechanism analysis on micro structure and mechanical properties of 3 phases FGM Material with vibrational behavior analysis is fabricated using WAAM process and traditional method. J. Alloys Compd. 2024, 1003, 175543. [Google Scholar] [CrossRef]

- Ji, F.; Qin, X.; Hu, Z.; Xiong, X.; Ni, M.; Wu, M. Influence of ultrasonic vibration on molten pool behavior and deposition layer forming morphology for wire and arc additive manufacturing. Int. Commun. Heat Mass Transf. 2022, 130, 105789. [Google Scholar] [CrossRef]

- Waheed, M.F.; Bernadin, S. In-Situ Analysis of Vibration and Acoustic Data in Additive Manufacturing. In Proceedings of the SoutheastCon 2024, Atlanta, GA, USA, 15–24 March 2024; IEEE: Piscataway Township, NJ, USA, 2024; pp. 812–817. Available online: https://ieeexplore.ieee.org/abstract/document/10500055/ (accessed on 23 June 2025).

- Rosli, N.A.; Alkahari, M.R.; Ramli, F.R.; Sudin, M.N.; Maidin, S. Influence of process parameters in wire and arc additive manufacturing (WAAM) process. J. Mech. Eng. 2021, 17, 69–79. [Google Scholar] [CrossRef]

- Tang, S.; Wang, G.; Song, H.; Li, R.; Zhang, H. A novel method of bead modeling and control for wire and arc additive manufacturing. Rapid Prototyp. J. 2021, 27, 311–320. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.; Zhao, Z.; Deng, W.; Han, J.; Bai, L.; Liang, X.; Yao, J. Coordinated monitoring and control method of deposited layer width and reinforcement in WAAM process. J. Manuf. Process. 2021, 71, 306–316. [Google Scholar] [CrossRef]

- Watanabe, I.; Sun, Z.; Kitano, H.; Goto, K. Multiscale analysis of mechanical behavior of multilayer steel structures fabricated by wire and arc additive manufacturing. Sci. Technol. Adv. Mater. 2020, 21, 461–470. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Pan, Z.; Polden, J.; Ding, D.; van Duin, S.; Li, H. Integration of a multi-directional wire arc additive manufacturing system with an automated process planning algorithm. J. Ind. Inf. Integr. 2020, 26, 100265. [Google Scholar] [CrossRef]

- Ding, D.; He, F.; Yuan, L.; Pan, Z.; Wang, L.; Ros, M. The first step towards intelligent wire arc additive manufacturing: An automatic bead modelling system using machine learning through industrial information integration. J. Ind. Inf. Integr. 2021, 23, 100218. [Google Scholar] [CrossRef]

- Chandra, M.; Vimal, K.E.K.; Rajak, S. In situ process monitoring and control in metal additive manufacturing. In Additive Manufacturing; CRC Press: Boca Raton, FL, USA, 2023; pp. 57–75. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781003258391-4/situ-process-monitoring-control-metal-additive-manufacturing-mukesh-chandra-vimal-sonu-rajak (accessed on 20 October 2024).

- Franke, J.; Heinrich, F.; Reisch, R.T. Vision based process monitring in wire arc additive manufacturing (WAAM). J. Intell. Manuf. 2024, 36, 1711–1721. [Google Scholar] [CrossRef]

- Cho, H.W.; Shin, S.J.; Seo, G.J.; Kim, D.B.; Lee, D.H. Real-time anomaly detection using convolutional neural network in wire arc additive manufacturing: Molybdenum material. J. Mater. Process. Technol. 2022, 302, 117498. [Google Scholar] [CrossRef]

- Yaseer, A. Process Planning of Robotic Wire Arc Additive Manufacturing (WAAM) Using Machine Learning. Master’s Thesis, Texas State University, San Marcos, TX, USA, 2021. Available online: https://digital.library.txstate.edu/bitstream/10877/15840/1/YASEER-THESIS-2021.pdf (accessed on 25 November 2024).

- Ruiz, C.; Jafari, D.; Venkata Subramanian, V.; Vaneker, T.H.; Ya, W.; Huang, Q. Prediction and control of product shape quality for wire and arc additive manufacturing. J. Manuf. Sci. Eng. 2022, 144, 111005. [Google Scholar] [CrossRef]

- Kostenko, A.O.; Tsurkan, D.O.; Salenko, O.F. Evaluation of the Achievable Accuracy of 3-D Products Obtained by the WAAM Process. 2021, pp. 50–51. Available online: https://www.nature.com/articles/s41529-023-00329-6 (accessed on 2 August 2025).

- Panicker, S.; Nagarajan, H.P.; Tuominen, J.; Patnamsetty, M.; Coatanéa, E.; Haapala, K.R. Investigation of thermal influence on weld microstructure and mechanical properties in wire and arc additive manufacturing of steels. Mater. Sci. Eng. A 2022, 853, 143690. [Google Scholar] [CrossRef]

- Maurya, A.K.; Yeom, J.T.; Kang, S.W.; Park, C.H.; Hong, J.K.; Reddy, N.S. Optimization of hybrid manufacturing process combining forging and wire-arc additive manufactured Ti-6Al-4V through hot deformation characterization. J. Alloys Compd. 2022, 894, 162453. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Sequeira-Almeida, P.M.; Ríos, S.; Ramos-Grez, J.A.; Williams, S.W. A machine learning approach for the prediction of melting efficiency in wire arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 120, 3123–3133. [Google Scholar] [CrossRef]

- Marefat, F.; Kapil, A.; Banaee, S.A.; Van Rymenant, P.; Sharma, A. Evaluating shielding gas-filler wire interaction in bi-metallic wire arc additive manufacturing (WAAM) of creep resistant steel-stainless steel for improved process stability and build quality. J. Manuf. Process. 2023, 88, 110–124. [Google Scholar] [CrossRef]

- Sufian, I.W.; Selda, O.; Erkan, O. Robotic welding techniques in marine structures and production processes: A systematic literature review. Mar. Struct. 2024, 95, 103608. [Google Scholar] [CrossRef]

- Li, Y.; Su, C.; Zhu, J. Comprehensive review of wire arc additive manufacturing: Hardwaresystem, physical process, monitoring, property characterization, application and future prospects. Results Eng. 2022, 13, 100330. [Google Scholar] [CrossRef]

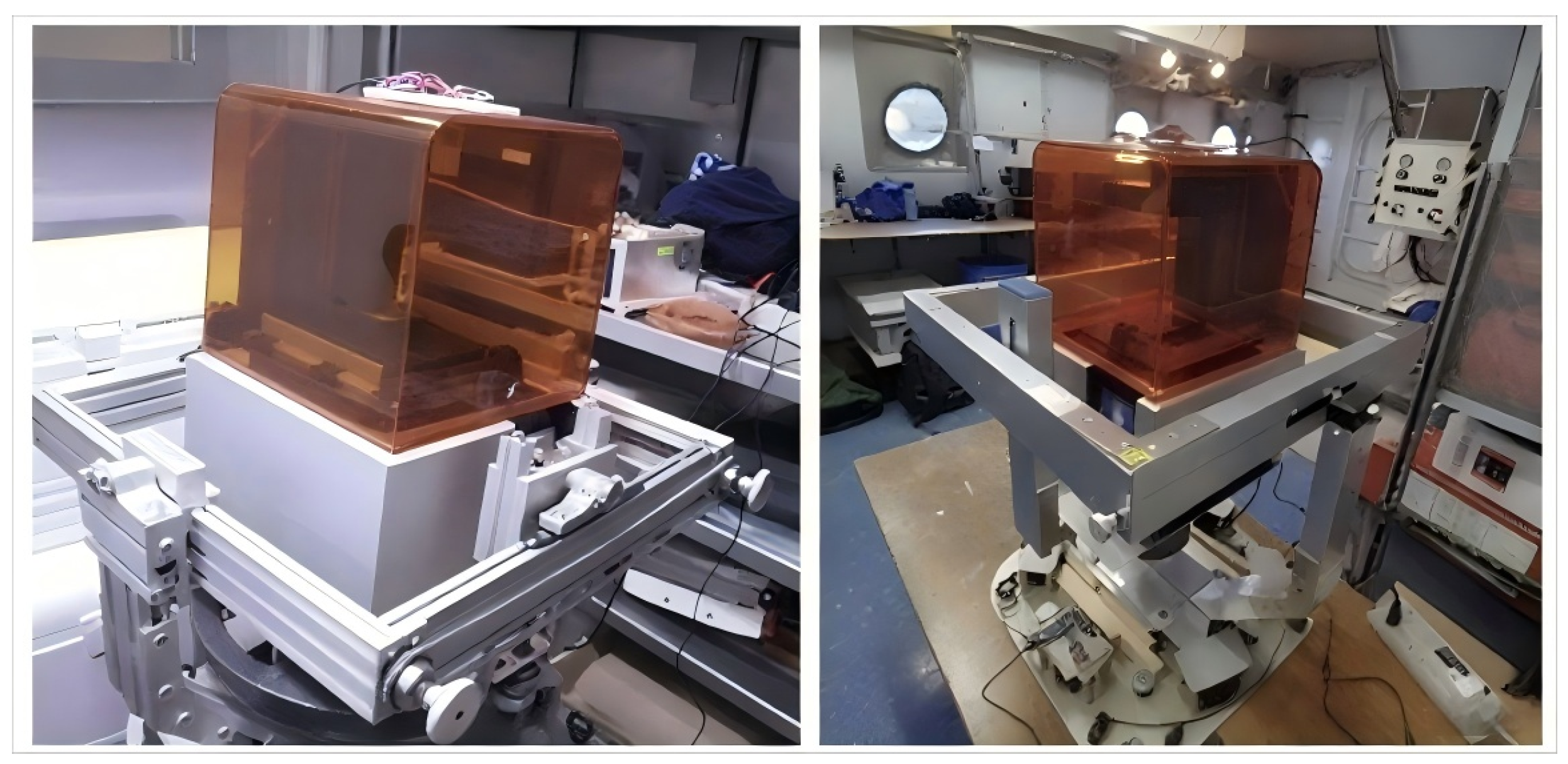

- Phillips, B.T.; Alldera, J.; Bolana, G.; Naglea, R.S.; Redingtona, A.; Hellebrekersc, T.; Bordend, J.; Pawlenkoe, N.; Lichta, S. Additive manufacturing aboard a moving vessel at sea using passively stabilized stereolithography (SLA) 3D printing. Addit. Manuf. 2022, 31, 100969. [Google Scholar] [CrossRef]

- Taşdemir, A.; Nohut, S. An overview of wire arc additive manufacturing (WAAM) in shipbuilding industry. Ships Offshore Struct. 2021, 16, 797–814. [Google Scholar] [CrossRef]

- Ziółkowski, M.; Dyl, T. Possible applications of additive manufacturing technologies in shipbuilding: A review. Machines 2020, 8, 84. [Google Scholar] [CrossRef]

- Mccauley, A., II; Trinh, J.T.; Zust, K.S. Navy Additive Manufacturing Afloat Capability Analysis; Naval Postgraduate School: Monterey, CA, USA, 2020; Available online: https://calhoun.nps.edu/handle/10945/64681 (accessed on 25 August 2024).

- Scott, S.; Chen, W.Y.; Heifetz, A. Multi-Task Learning of Scanning Electron Microscopy and Synthetic Thermal Tomography Images for Detection of Defects in Additively Manufactured Metals. Sensors 2023, 23, 8462. [Google Scholar] [CrossRef]

- Tonelli, L. Revealing the Hierarchical Microstructure of Innovative Additively Manufactured Metal Parts with Conventional Light Microscopy. Metallogr. Microstruct. Anal. 2021, 10, 278–282. [Google Scholar] [CrossRef]

- You, X.; Song, X.; Geng, W.; Li, Z. Influence of Ageing Treatment on Microstructure and Mechanical Properties of GH4169 Alloy Prepared Using Wire Arc Additive Manufacturing. Metals 2024, 14, 1111. [Google Scholar] [CrossRef]

- Renzo, D.A.; Crocco, M.C.; Maletta, C.; Pagnotta, L.; Sgambitterra, E.; Berto, F.; Furgiuele, F.; Filosa, R.; Beltrano, J.J.; Barberi, R.C.; et al. X-ray computed μ-tomography analysis to evaluate the crack growth in an additive manufactured Ti-6Al-4V alloy sample stressed with in-phase axial and torsional loading. Int. J. Fatigue 2023, 175, 107727. [Google Scholar] [CrossRef]

- Raffestin, M.; Domashenkov, A.; Bertr, P.; Faverjon, P.; Courbon, C. Ultrasonic diagnostic for in situ control in metal additive manufacturing. Measurement 2023, 206, 112244. [Google Scholar] [CrossRef]

- Shaloo, M.; Schnall, M.; Klein, T.; Huber, N.; Reitinger, B. A Review of Non-Destructive Testing (NDT) Techniques for Defect Detection: Application to Fusion Welding and Future Wire Arc Additive Manufacturing Processes. Materials 2022, 15, 3697. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Lian, H.; Luan, T.; Zhang, X.; Wu, B.; Wang, H. Lift analysis and anti-rolling control system design of Magnus rotating roll stabilizer at full speed range. Ocean Eng. 2023, 290, 116331. [Google Scholar] [CrossRef]

- Palraj, M.; Rajamanickam, P. Motion control studies of a barge mounted offshore dynamic wind turbine using gyrostabilizer. Ocean Eng. 2021, 237, 109578. [Google Scholar] [CrossRef]

- Watine, Y.; Lossouarn, B.; Gabillet, C.; Astolfi, J.A.; Deü, J.F. Mitigation of hydrofoil torsional flow induced vibrations by resonant piezoelectric shunt. Ocean Eng. 2024, 313, 119598. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, L.; Zhang, X.; Zhou, Y.; Yang, Q. Active vibration control for ship pipeline system based on PI-LQR state feedback. Ocean Eng. 2024, 310, 118559. [Google Scholar] [CrossRef]

- Liu, S.; Song, J.; Zhang, L. An adaptive bi-limit homogeneous sliding mode control for 3-DOF stabilized system of ship propulsion-assisted sail with prescribed performance. Ocean Eng. 2024, 302, 117624. [Google Scholar] [CrossRef]

- Sampaio, R.F.V.; Pragana, J.P.M.; Bragança, I.M.F.; Silva, C.M.A.; Nielsen, C.V.; Martins, P.A.F. Modelling of wire-arc additive manufacturing—A review. Adv. Ind. Manuf. Eng. 2023, 6, 100121. [Google Scholar] [CrossRef]

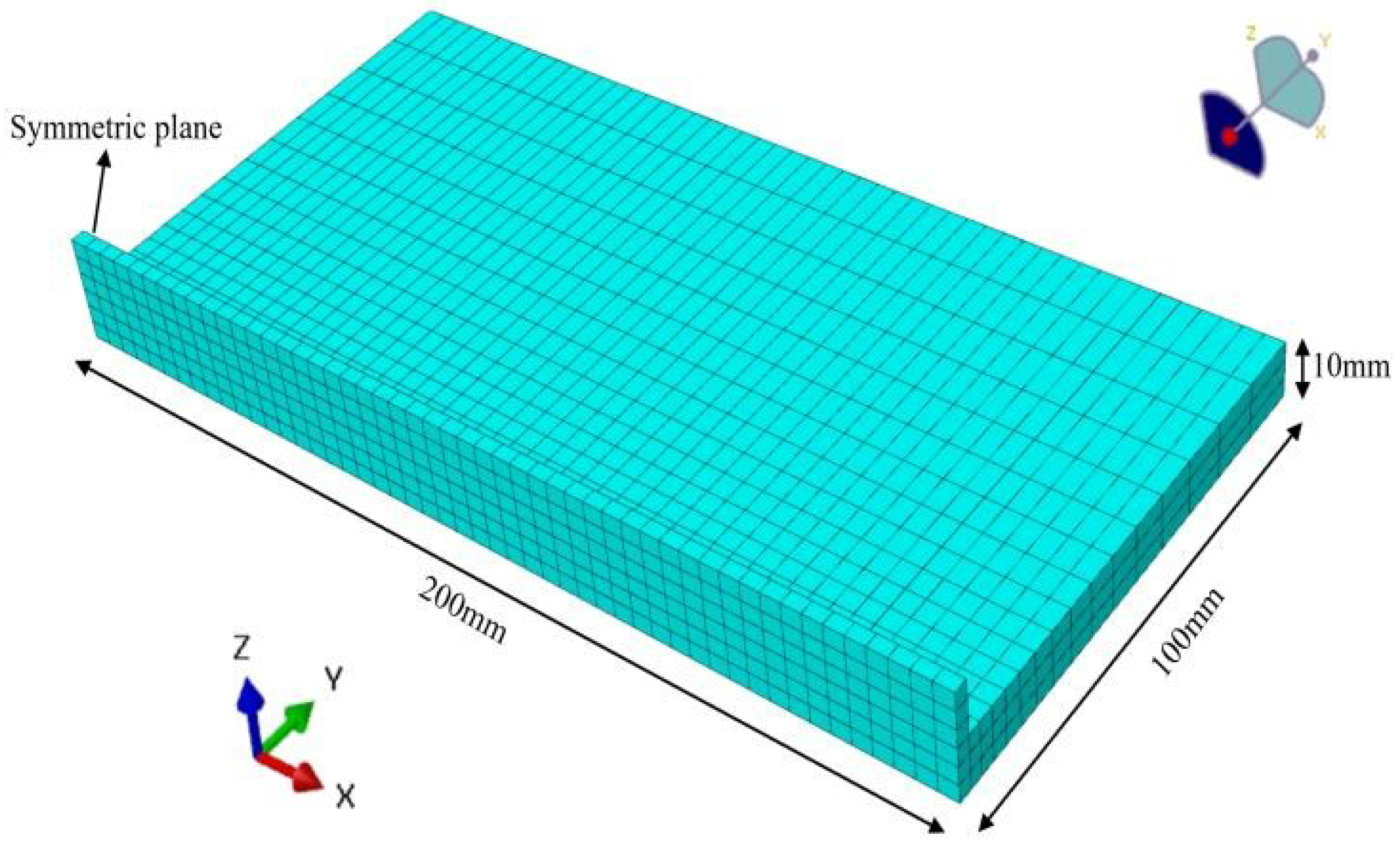

- Yang, Y.; Lin, H.; Li, Q. A computationally efficient thermo-mechanical model with temporal acceleration for prediction of residual stresses and deformations in WAAM. Virtual Phys. Prototyp. 2024, 19, e2349683. [Google Scholar] [CrossRef]

- Li, N.; Fan, D.; Huang, J.; Yu, S.; Yuan, W.; Han, M. Self-Adaptive Control System for Additive Manufacturing Using Double Electrode Micro Plasma Arc Welding. Chin. J. Mech. Eng. 2021, 34, 59. [Google Scholar] [CrossRef]

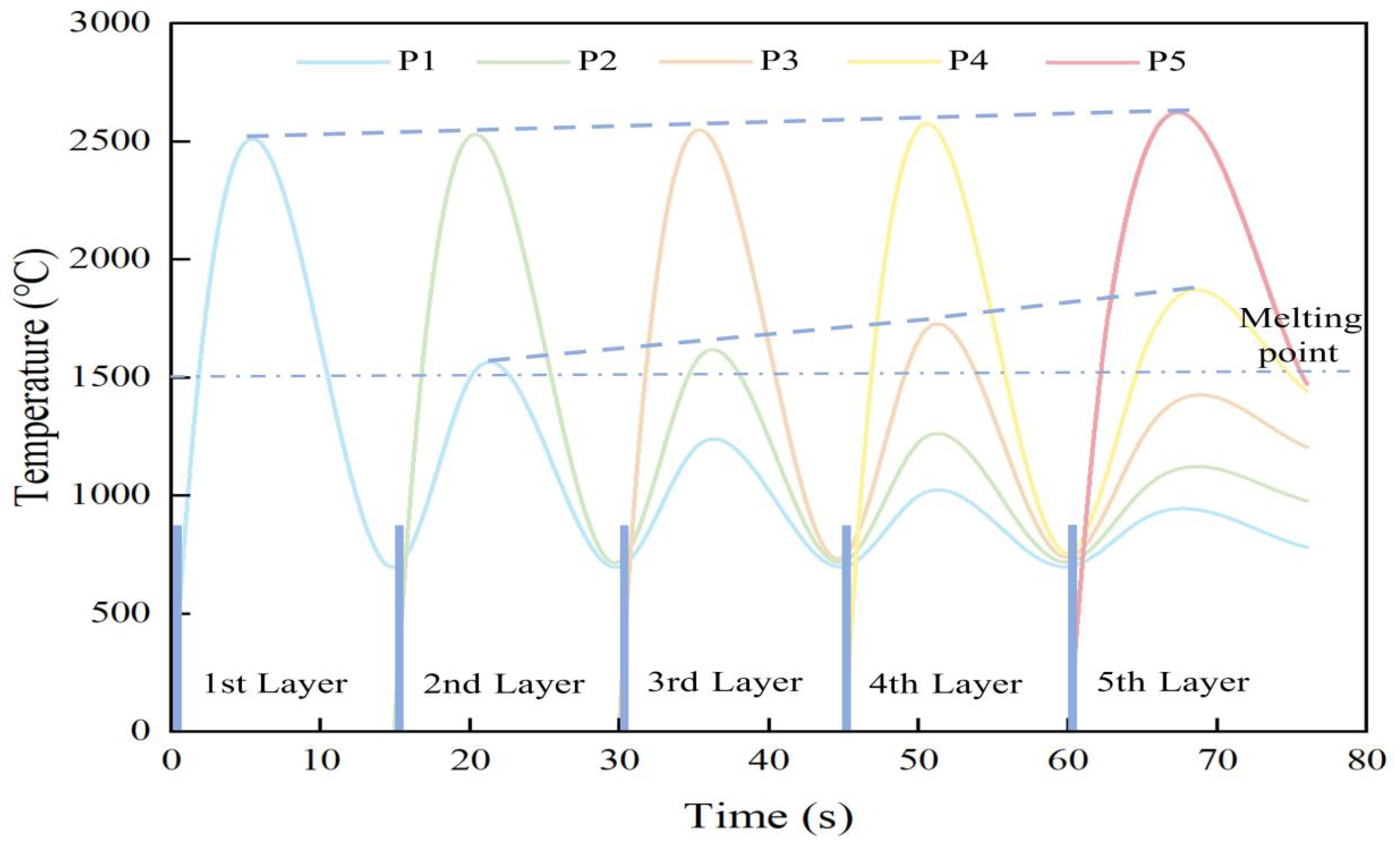

- Farias, F.W.C.; da Cruz Payão Filho, J.; e Oliveira, V.H.P.M. Prediction of the interpass temperature of a wire arc additive manufactured wall: FEM simulations and artificial neural network. Addit. Manuf. 2021, 48, 102387. [Google Scholar] [CrossRef]

- Saadatmand, M.; Talemi, R. Study on the thermal cycle of Wire Arc Additive Manufactured (WAAM) carbon steel wall using numerical simulation. Frat. Integrità Strutt. 2020, 14, 98–104. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Wang, Z.; Ye, J.; Zhao, W. Mechanical properties, microstructural characteristics and heat treatment effects of WAAM stainless-steel plate material. J. Build. Eng. 2023, 75, 106988. [Google Scholar] [CrossRef]

- Xu, S.; Yin, B.; Wang, J.; Jin, L.; Yin, Y.; Li, Z.; StJohn, D.H.; Pavlenko, P.; Guo, Y. Eliminating cracks in Ti–47Al–2Cr–2Nb/Ti–6Al–4V micro-laminated composites fabricated by dual-material laser powder bed fusion. J. Mater. Res. Technol. 2025, 34, 2344–2357. [Google Scholar] [CrossRef]

- Vo, H.T.; Grandvallet, C.; Vignat, F. A model for manufacturing large parts with WAAM technology. In Advances in Manufacturing Technology XXXIV; IOS Press: Grenoble, France, 2021; pp. 79–84. Available online: https://ebooks.iospress.nl/doi/10.3233/ATDE210016 (accessed on 25 August 2024).

- Lin, Z.; Liu, P.; Yu, X. A literature review on the wire and arc additive manufacturing—Welding systems and software. Sci. Adv. Mater. 2021, 13, 1391–1400. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Baier, D.; Wolf, F.; Weckenmann, T.; Lehmann, M.; Zaeh, M.F. Thermal process monitoring and control for a near-net-shape Wire and Arc Additive Manufacturing. Prod. Eng. 2022, 16, 811–822. [Google Scholar] [CrossRef]

- Pavlenko, P.; Yu, B. WTC-Auto Former-based additive manufacturing failure prediction in digital twins. In Proceedings of the Proc. SPIE 13574, Fourth International Conference on Electronic Information Engineering and Data Processing (EIEDP 2025), Kuala Lumpur, Malaysia, 17–19 January 2025; p. 135743. [Google Scholar]

- Luo, L.; Qian, E.; Lu, T.; Pan, J.; Liu, M.; Liu, C.; Guo, Y.; Bi, L. Vision-Based Estimation of Force Balance of Near-Suspended Melt Pool for Drooping and Collapsing Prediction. Sensors 2024, 24, 3270. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Li, C.; Fu, Y.; Li, R.; Zhang, H.; Wang, G. A two-stage unsupervised approach for surface anomaly detection in wire and arc additive manufacturing. Comput. Ind. 2023, 151, 103994. [Google Scholar] [CrossRef]

- Zahidin, M.R.; Yusof, F.; Rashid, S.H.A.; Mansor, S.; Raja, S.; Jamaludin, M.F.; Manurung, Y.H.P.; Adenan, M.S.; Hussein, N.I.S. Research challenges, quality control and monitoring strategy for Wire Arc Additive Manufacturing. J. Mater. Res. Technol. 2023, 24, 2769–2794. [Google Scholar] [CrossRef]

- Diao, Z.; Yang, F.; Chen, L.; Wang, R.; Zhang, Y.; Sun, J.; Wu, Y.; Rong, M. Effects of deposition height stability of CuCrZr alloy based on arc voltage sensing: Influence of materials and energy saving on wire arc additive manufacturing. J. Clean. Prod. 2023, 425, 138665. [Google Scholar] [CrossRef]

- Mattera, G.; Nele, L.; Paolella, D. Monitoring and control the Wire Arc Additive Manufacturing process using artificial intelligence techniques: A review. J. Intell. Manuf. 2024, 35, 467–497. [Google Scholar] [CrossRef]

- Sharifi, S.S.; Fritsche, S.; Holzinger, C.; Enzinger, N. Selection of Parameters for Optimized WAAM Structures for Civil Engineering Applications. Materials 2023, 16, 4862. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Cai, C.; Li, Z. Effect of Vertical Vibration on Morphology, Microstructure and Properties of Carbon Steel Produced by Wire and Arc Additive Manufacturing. J. Mech. Eng. 2024, 60, 342–352. [Google Scholar]

- Rodrigues, T.A.; Bairrão, N.; Farias, F.W.C.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J.P. Steel-copper functionally graded material produced by twin-wire and arc additive manufacturing (T-WAAM). Mater. Des. 2022, 213, 110270. [Google Scholar] [CrossRef]

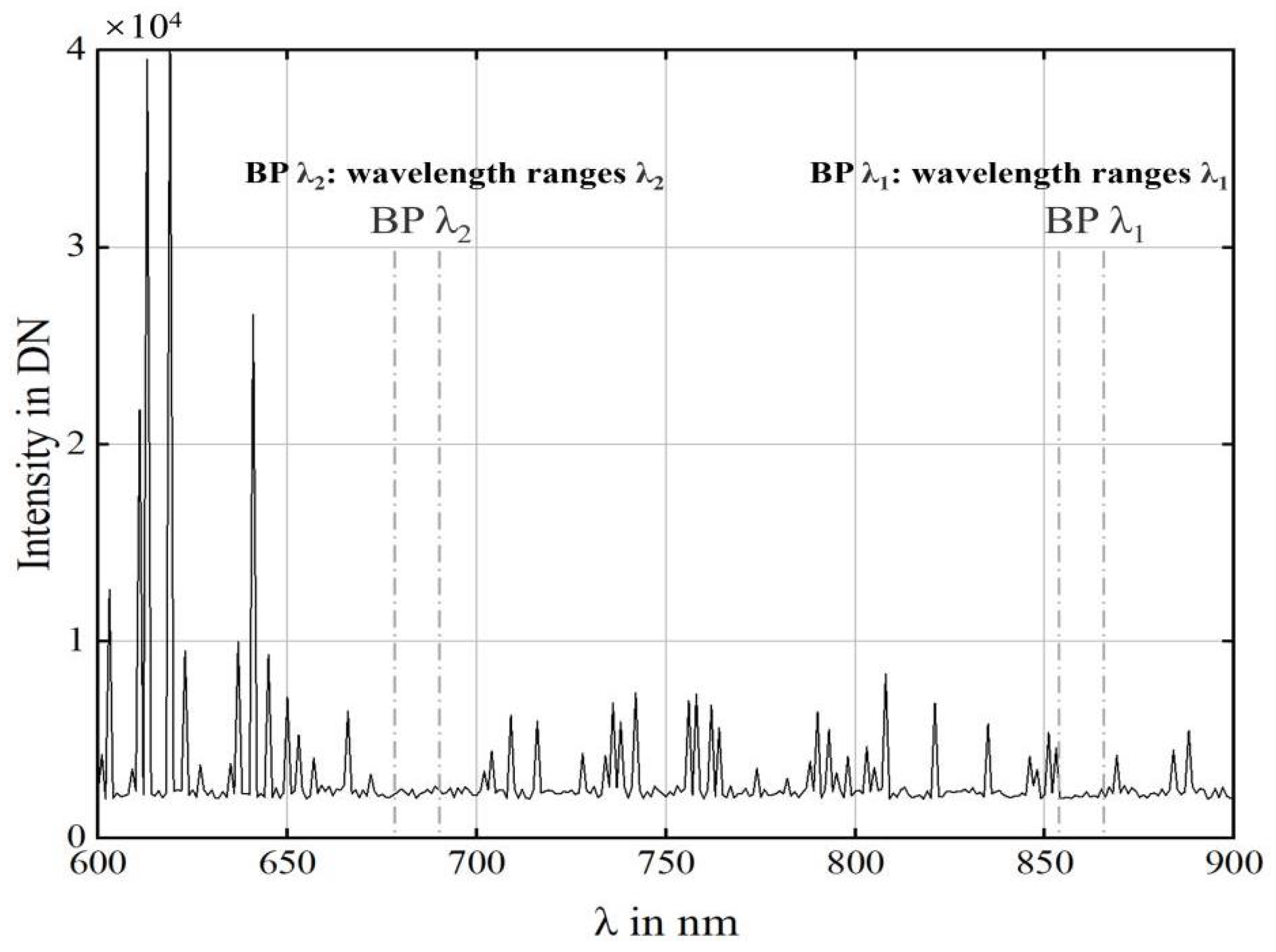

- Richter, A.; Rembe, C.; Gehling, T.; Treutler, K.; Wesling, V. chtzeittemperaturmessung bei additivem Lichtbogenschweißen/Real-time temperature measurement at wire arc additive welding. Tech. Mess. 2019, 86, 112–116. [Google Scholar] [CrossRef]

- He, F.; Yuan, L.; Mu, H.; Ros, M.; Ding, D.; Pan, Z.; Li, H. Research and application of artificial intelligence techniques for wire arc additive manufacturing: A state-of-the-art review. Robot.-Comput.-Integr. Manuf. 2023, 82, 102525. [Google Scholar] [CrossRef]

- Pavlenko, P.; Yu, B. Digital twin and reinforcement learning-based additive manufacturing optimization. In Proceedings of the Proc. SPIE 13574, Fourth International Conference on Electronic Information Engineering and Data Processing (EIEDP 2025), Kuala Lumpur, Malaysia, 17–19 January 2025; p. 1357418. [Google Scholar] [CrossRef]

- Kerber, E.; Knitt, H.; Fahrendholz-Heiermann, J.L.; Ergin, E.; Brell-Cokcan, S.; Dewald, P.; Sharma, R.; Reisgen, U. Variable Layer Heights in Wire Arc Additive Manufacturing and WAAM Information Models. Machines 2024, 12, 432. [Google Scholar] [CrossRef]

- Zimermann, R.; Mohseni, E.; Vasilev, M.; Loukas, C.; Vithanage, R.K.W.; Macleod, C.N.; Lines, D.; Javadi, Y.; Espirindio E Silva, M.P.; Fitzpatrick, S.; et al. Collaborative robotic wire+ arc additive manufacture and sensor-enabled in-process ultrasonic non-destructive evaluation. Sensors 2022, 22, 4203. [Google Scholar] [CrossRef]

- Azizul Izham, E.D.I.; Alkahari, M.R.; Hussein, N.I.S.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Online monitoring of wire arc additive manufacturing process: A review. Adv. Mater. Process. Technol. 2024, 10, 1412–1427. [Google Scholar] [CrossRef]

- Petro, P.; Zhou, Y. Digital twin and deep learning-based metal weld defect detection system Proceedings. In Proceedings of the Proc. SPIE 13574, Fourth International Conference on Electronic Information Engineering and Data Processing (EIEDP 2025), Kuala Lumpur, Malaysia, 17–19 January 2025; p. 135740F. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with artificial intelligence in additive manufacturing: A systematic review. J. Mech. Eng. Sci. 2023, 45, 303. [Google Scholar] [CrossRef]

- Kunchala, B.K.R.; Gamini, S.; Anilkumar, T.C. Inclusion of IoT technology in additive manufacturing: Machine learning-based adaptive bead modeling and path planning for sustainable wire arc additive manufacturing and process optimization. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 120–132. [Google Scholar] [CrossRef]

- Mu, H.; He, F.; Yuan, L.; Commins, P.; Wang, H.; Pan, Z. Toward a smart wire arc additive manufacturing system: A review on current developments and a framework of digital twin. J. Manuf. Syst. 2023, 67, 174–189. [Google Scholar] [CrossRef]

- Li, H.; Shi, X.; Wu, B.; Corradi, D.R.; Pan, Z.; Li, H. Wire arc additive manufacturing: A review on digital twinning and visualization process. J. Manuf. Process. 2024, 116, 293–305. [Google Scholar] [CrossRef]

- Chen, Z.; Surendraarcharyagie, K.; Granland, K.; Chen, C.; Xu, X.; Xiong, Y.; Davie, C.; Tang, Y.L. Service oriented digital twin for additive manufacturing process. J. Ind. Inf. Integr. 2024, 74, 762–776. [Google Scholar] [CrossRef]

- Mahdi, M.M.; Bajestani, M.S.; Noh, S.D. Digital twin-based architecture for wire arc additive manufacturing using OPC UA. Robot. Comput. Manuf. 2025, 94, 102944. [Google Scholar] [CrossRef]

- Azarian, M.; Yu, H.; Solvang, W.D. Integrating additive manufacturing into a virtual Industry 4.0 factory. In Advanced Manufacturing and Automation X 10; Springer: Singapore, 2021; pp. 587–594. Available online: https://link.springer.com/chapter/10.1007/978-981-33-6318-2_73 (accessed on 25 August 2024).

- Fan, H.; Liu, C.; Bian, S.; Ma, C.; Huang, J.; Liu, X.; Doyle, M.; Lu, T.; Chow, E.; Chen, L.; et al. New era towards autonomous additive manufacturing: A review of recent trends and future perspectives. Int. J. Extrem. Manuf. 2025, 7, 032006. [Google Scholar] [CrossRef]

- Kang, M.-S.; Lee, D.-H.; Bajestani, M.S.; Kim, D.B.; Noh, S.D. Edge Computing-Based Digital Twin Framework Based on ISO 23247 for Enhancing. Machines 2025, 13, 19. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Ayed, A.; Valencia, A.; Bras, G.; Bernard, H.; Michaud, P.; Balcaen, Y.; Alexis, J. Effects of WAAM process parameters on metallurgical and mechanical properties of Ti-6Al-4V deposits. In Advances in Materials, Mechanics and Manufacturing, Proceedings of the Second International Conference on Advanced Materials, Mechanics and Manufacturing (A3M’2018), Hammamet, Tunisia, 17–19 December 2018; Springer Cham: Cham, Switzerland, 2020; pp. 26–35. Available online: https://link.springer.com/chapter/10.1007/978-3-030-24247-3_4 (accessed on 20 December 2024).

- Vázquez, L.; Rodríguez, N.; Rodríguez, I.; Alberdi, E.; Álvarez, P. Influence of interpass cooling conditions on microstructure and tensile properties of Ti-6Al-4V parts manufactured by WAAM. Weld. World 2020, 64, 1377–1388. [Google Scholar] [CrossRef]

- Karpagaraj, A.; Baskaran, S.; Arunnellaiappan, T.; Kumar, N.R. A review on the suitability of wire arc additive manufacturing (WAAM) for stainless steel 316. Aip Conf. Proc. 2020, 2247, 050001. [Google Scholar]

- Vinoth, V.; Sathiyamurthy, S.; Natarajan, U.; Venkatkumar, D.; Prabhakaran, J.; Prakash, K.S. Examination of microstructure properties of AISI 316L stainless steel fabricated by wire arc additive manufacturing. Mater. Today Proc. 2022, 66, 702–706. [Google Scholar] [CrossRef]

- Emanet, S. Optimization Modeling of the Experimental Coefficient of Thermal Expansion of SLM Processed Materials: 316l Stainless Steel, Ti6Al4v and AlSiMg10. Master’s Thesis, Southern University and Agricultural and Mechanical College, Baton Rouge, LA, USA, 2020. Available online: https://www.proquest.com/openview/c4fb40ceae9e8e2bef4f48ec519bf8ec/1?pq-origsite=gscholar&cbl=18750&diss=y (accessed on 25 August 2024).

- Nagasai, B.P.; Malarvizhi, S.; Balasubramanian, V. Mechanical properties and microstructural characteristics of Al–Mg alloy cylindrical component manufactured by wire arc additive manufacturing process. Metallogr. Microstruct. Anal. 2022, 11, 199–211. [Google Scholar] [CrossRef]

- Hussein, N.I.S.; Ket, G.C.; Rahim, T.A.; Ayof, M.N.; Abidin, M.Z.Z.; Srithorn, J. Process and Heat Resources for Wire Arc Additive Manufacturing of Aluminium Alloy ER4043: A Review. J. Mech. Eng. 2023, 20, 21–41. [Google Scholar] [CrossRef]

- Xu, X.; Ding, J.; Ganguly, S.; Williams, S. Investigation of process factors affecting mechanical properties of INCONEL 718 superalloy in wire+ arc additive manufacture process. J. Mater. Process. Technol. 2019, 265, 201–209. [Google Scholar] [CrossRef]

- Chen, Z.; Soh, G.S. Microstructure and mechanical properties of Wire Arc Additive Manufactured (WAAM) Inconel 718 parts via post heat treatments. Mater. Today Proc. 2022, 70, 567–573. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.; Gong, H.; Wu, Y.; Chen, X.; Zhang, X. Study on location-related thermal cycles and microstructure variation of additively manufactured inconel 718. J. Mater. Res. Technol. 2022, 18, 3056–3072. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Tiwari, A.; Dongre, M. Wire arc additive manufacturing of metals: A review on processes, materials and their behaviour. Mater. Chem. Phys. 2023, 294, 126988. [Google Scholar] [CrossRef]

- Lettori, J.; Esposto, C.; Peruzzini, M.; Raffaeli, R. Geometrical characterization of circular multi-layered CMT WAAM specimens by 3D structured light scanning. Int. J. Adv. Manuf. Technol. 2025, 136, 5303–5334. [Google Scholar] [CrossRef]

- Abe, T.; Mori, D.; Sonoya, K.; Nakamura, M.; Sasahara, H. Control of the chemical composition distribution in deposited metal by wire and arc-based additive manufacturing. Precis. Eng. 2019, 55, 231–239. [Google Scholar] [CrossRef]

- Youssef, A.; Nikhil, G. Assisted defect detection by in-process monitoring of additive manufacturing using optical imaging and infrared thermography. Addit. Manuf. 2023, 67, 103483. [Google Scholar] [CrossRef]

- Hauser, T.; Reisch, R.T.; Kamps, T.; Kaplan, A.F.; Volpp, J. Acoustic emissions in directed energy deposition processes. Int. J. Adv. Manuf. Technol. 2022, 119, 3517–3532. [Google Scholar] [CrossRef]

- Yu, M.; Weng, Z.; Hu, J.; Wang, S.; Liu, T.; Song, Z.; Xu, H.; Wang, Z. Laser interference additive manufacturing ordered Cu microstructure. Appl. Surf. Sci. 2023, 615, 156312. [Google Scholar] [CrossRef]

- Permana, E.; Yayat. Design and Development of Impact Load Sensor for Dynamic Testing Purposes. IOP Conf. Ser. Mater. Sci. Eng. 2018, 288, 012060. [Google Scholar] [CrossRef]

- Huang, C.; Kyvelou, P.; Zhang, R.; Britton, T.B.; Gardner, L. Mechanical testing and microstructural analysis of wire arc additively manufactured steels. Mater. Des. 2022, 216, 110544. [Google Scholar] [CrossRef]

- Chen, H.; Gao, W.; Liu, T.; Lin, W.; Li, M. An experimental study on the effect of salt spray testing on the optical properties of solar selective absorber coatings produced with different manufacturing technologies. Int. J. Energy Environ. Eng. 2019, 10, 231–242. [Google Scholar] [CrossRef]

- Aarfane, A.; Bensemlali, M.; Elmelouky, A.; Hatimi, B.; Zaim, S.; Jaffrezic-Renault, N.; Baraket, A.; Errachid, A.; Mohamed, M.; Nasrellah, H. Electrocoagulation efficiency probed using electrochemical impedance spectroscopy. Chin. J. Chem. Eng. 2024, 75, 266–273. [Google Scholar] [CrossRef]

- Jiang, X.; Lu, J.; Zhao, N.; Chen, Z.; Zhao, Z. A Review of Wear in Additive Manufacturing: Wear Mechanism, Materials, and Process. Lubricants 2024, 12, 321. [Google Scholar] [CrossRef]

- Gong, P.; Li, X.; Zhou, X.; Wang, F.; Zhang, Y.; Zhao, Y. Temperature-compensated optical fiber sensor for urea detection based on the femtosecond laser-inscribed process. Sens. Actuators B Chem. 2025, 426, 136795. [Google Scholar] [CrossRef]

- Bi, C.; Wu, M.S.; Law, A.W. Stabilisation of compliant floating platforms with sheet barriers under wave action. Ocean Eng. 2025, 240, 109933. [Google Scholar] [CrossRef]

- Lan, H.; Bai, L.; Fu, J.; Nie, S.; Wang, H.; Lin, G. Experimental study on the thermal performance of a novel vapor chamber manufactured by 3D-printing technology. Therm. Sci. Eng. Prog. 2024, 55, 102989. [Google Scholar] [CrossRef]

- Marlantes, K.E.; Bandyk, P.J.; Maki, K.J. Predicting ship responses in different seaways using a generalizable force correcting machine learning method. Ocean Eng. 2024, 312, 119110. [Google Scholar] [CrossRef]

- Ye, X.; Sun, Z.; Lu, J. Prediction and early warning of wind-induced girder and tower vibration in cable-stayed bridges with machine learning-based approach. Eng. Struct. 2023, 275, 115261. [Google Scholar] [CrossRef]

- Coutinho, F.; Lizarralde, N.; Mendes, M.; Bostrom, R.; Silva, T.; Couto, M.; Lizarralde, F. iWAAM: An automated system for monitoring and control of wire-arc additive manufacturing. IFAC-Pap. Line 2023, 56, 6576–6581. [Google Scholar] [CrossRef]

- Khader, N.; Yoon, S.W. Adaptive optimal control of stencil printing process using reinforcement learning. Robot.-Comput.-Integr. Manuf. 2021, 71, 102132. [Google Scholar] [CrossRef]

- Kumar, V.; Roy, B.K.; Mandal, A. Thermal Modeling of Wire Arc Additive Manufacturing Process Using COMSOL Multiphysics. In Advances in Manufacturing Engineering, Proceedings of the ICFAMMT 2022, Ahmedabad, India, 20–21 January 2022; Lecture Notes in Mechanical Engineering; Springer Nature: Singapore, 2022; pp. 223–232. [Google Scholar] [CrossRef]

- Ansys Granta MI Enterprise—Material Data Management Software. Available online: https://www.ansys.com/products/materials/granta-mi/ (accessed on 25 August 2024).

- Ling, Y.; Ni, J.; Antonissen, J.; BenHamouda, H.; Voorde, J.V.; Wahab, M.A. Numerical prediction of microstructure and hardness for low carbon steel wire Arc additive manufacturing components. Simul. Model. Pract. Theory 2023, 122, 102664. [Google Scholar] [CrossRef]

- FLOW-3D AM Additive Manufacturing Simulation Software. Available online: https://www.flow3d.com/products/flow3d-am/ (accessed on 25 August 2024).

- Kayadelen, A.; Ateş, H.; Yilmaz, O. Wire Arc Additive Manufacturing (Metal Inert Gas-Cold Metal Transfer) of ER70S-6: Experimental and Computational Analysis on Process, Microstructure, and Mechanical Property Relationships. J. Mater. Eng. Perform. 2025, 34, 8917–8933. [Google Scholar] [CrossRef]

- Rai, C.; Bhanuprakash, S.; Kianian, B.; Ståhl, J.E. Additive Manufacturing Decision Support Systems: A Systematic Literature Review Discerning Current and Future Directions. Adv. Transdiscipl. Eng. 2022, 21, 553–565. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Topczak, M.; Mrugalski, M.; Rehm, M. An Intelligent Support System for Additive Manufacturing technology investment decisions. IFAC-Pap. Line 2023, 56, 21212126. [Google Scholar] [CrossRef]

- Pradhan, A.A.; Srivastava, R.; Sarma, A. Modelling and Simulation of Wire DED Additive Manufacturing Process. In Machining and Additive Manufacturing; Sharma, V.S., Dixit, U.S., Gupta, A., Verma, R., Sharma, V., Eds.; CPIE 2023. Lecture Notes in Mechanical Engineering; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- SIMULIA Simulation Software—Dassault Systèmes 1. Available online: https://www.3ds.com/products/simulia (accessed on 25 August 2024).

- Sigma Labs Print Rite 3D. Available online: https://3dprintingindustry.com/news/sigma-labs-printrite3d-technology-validated-by-darpa-study-154944/ (accessed on 25 August 2024).

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Software for Additive Manufacturing. In Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021; Available online: https://link.springer.com/chapter/10.1007/978-3-030-56127-7_17#citeas (accessed on 20 October 2024).

- Sbrugnera Sotomayor, N.A.; Caiazzo, F.; Alfieri, V. Enhancing Design for Additive Manufacturing Workflow: Optimization, Design and Simulation Tools. Appl. Sci. 2021, 11, 6628. [Google Scholar] [CrossRef]

- La Plate-Forme 3DEXPERIENCE- Dassault Systèmes. Available online: https://www.3ds.com/fr/3dexperience/ (accessed on 25 August 2024).

- Belšak, R.; Plevčak, R.; Gotlih, J.; Vuherer, T.; Ficko, M.; Karner, T. Developing 3D Welding Process with SIEMENS NX and KUKA Robot Manipulator. In New Technologies, Development and Application VII; Karabegovic, I., Kovačević, A., Mandzuka, S., Eds.; Springer: Cham, Switzerland, 2024; Volume 1069. [Google Scholar] [CrossRef]

- Staroselsky, A.; Klecka, M.; Deutchman, H. Optimization of WAAM Process to Produce AUSC Components with Increased Service Life; Raytheon Technologies Research Center: East Hartford, CT, USA, 2022. [Google Scholar] [CrossRef]

| №. | Name | Purpose | Advantages | Disadvantages |

|---|---|---|---|---|

| 1 | Metallographic Analysis [28,29]

|

|

|

|

| 2 | Transmission Electron Microscopy (TEM) [30] | Analyze microstructure at the atomic level to study phase transformations and crystal lattices | High resolution, atomic-level investigation | Expensive method, complex sample preparation |

| 3 | Non-destructive

testing (NDT) [31,32,33]

|

|

|

|

| №. | Name | Purpose | Advantages | Disadvantages |

|---|---|---|---|---|

| 1 | Gyroscopic Stabilizers [34,35] |

|

|

|

| 2 | Active Vibration Damping Systems [36,37].

|

|

|

|

| 3 | Adaptive Stabilization on Systems [38]. |

|

|

|

| №. | Name | Purpose | Advantages | Disadvantages |

|---|---|---|---|---|

| 1 | ANSYS 2025 R1: numerical simulation and analysis software covering mechanical, thermal, and electrical studies [39]. |

|

|

|

| 2 | ABAQUS 2024 GA: Powerful finite element analysis software for solving complex engineering problems [40]. |

|

|

|

| 3 | MATLAB/Simulink Numerical R2024b: computation, modeling, and simulation software [41]. |

|

|

|

| Material | Weld-Ability | Micro-Structural Stability | Interlayer Temp. Sensitivity | Depo-Sition Rate | Vibration Sensitivity | Corrosion Resistance | WAAM Suitability |

|---|---|---|---|---|---|---|---|

| Ti-6Al-4V | Moderate | Moderate (Widmanstätten formation) | High sensitivity (>200 °C defects) | Medium | High | High | Suitable, needs precise thermal control |

| Inconel 718 | Good | High (/ phase stabilization) | Moderate-High (overheating risks) | Low | Medium | Very High | Recommended for high-stress components |

| 316 L Stainless Steel | Excellent | High (stable austenitic) | Moderate (150–200 °C) | Medium-High | Moderate | High | Well-suited for structural elements |

| Alumi num 6061 | Poor (oxide film) | Low (porosity prone) | Very sensitive (<100°C) | High | High | Moderate | Limited use, needs controlled shielding |

| S235 Carbon Steel | Excellent | Moderate (coarse grains) | Low sensitivity | High | Moderate | Low | Requires corrosion protection |

| Inconel 625 | Good | Very High | Moderate | Medium | Low | Very High | Ideal for extreme environments |

| Co-Cr-Mo | Moderate | High | High | Low | High | High | Good for marine biomedical uses |

| AZ31 (Mg) | Good | Low | Very High | High | High | Moderate | Challenging, for lightweight parts |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petro, P.; Shi, X.; Wang, J.; Li, Z.; Yin, B.; Zhou, H.; Zhou, Y.; Yu, B.; Wang, Z. Enhancing Wire Arc Additive Manufacturing for Maritime Applications: Overcoming Operational Challenges in Marine and Offshore Environments. Appl. Sci. 2025, 15, 9070. https://doi.org/10.3390/app15169070

Petro P, Shi X, Wang J, Li Z, Yin B, Zhou H, Zhou Y, Yu B, Wang Z. Enhancing Wire Arc Additive Manufacturing for Maritime Applications: Overcoming Operational Challenges in Marine and Offshore Environments. Applied Sciences. 2025; 15(16):9070. https://doi.org/10.3390/app15169070

Chicago/Turabian StylePetro, Pavlenko, Xuezhi Shi, Jinbao Wang, Zhenhua Li, Bo Yin, Hanxiang Zhou, Yuxin Zhou, Bojian Yu, and Zhun Wang. 2025. "Enhancing Wire Arc Additive Manufacturing for Maritime Applications: Overcoming Operational Challenges in Marine and Offshore Environments" Applied Sciences 15, no. 16: 9070. https://doi.org/10.3390/app15169070

APA StylePetro, P., Shi, X., Wang, J., Li, Z., Yin, B., Zhou, H., Zhou, Y., Yu, B., & Wang, Z. (2025). Enhancing Wire Arc Additive Manufacturing for Maritime Applications: Overcoming Operational Challenges in Marine and Offshore Environments. Applied Sciences, 15(16), 9070. https://doi.org/10.3390/app15169070