Strength Deterioration and Sensitivity Analysis of Coal Samples Under Different Immersion Times for Underground Water Reservoirs

Abstract

1. Introduction

2. Sample Preparation and Test Methods

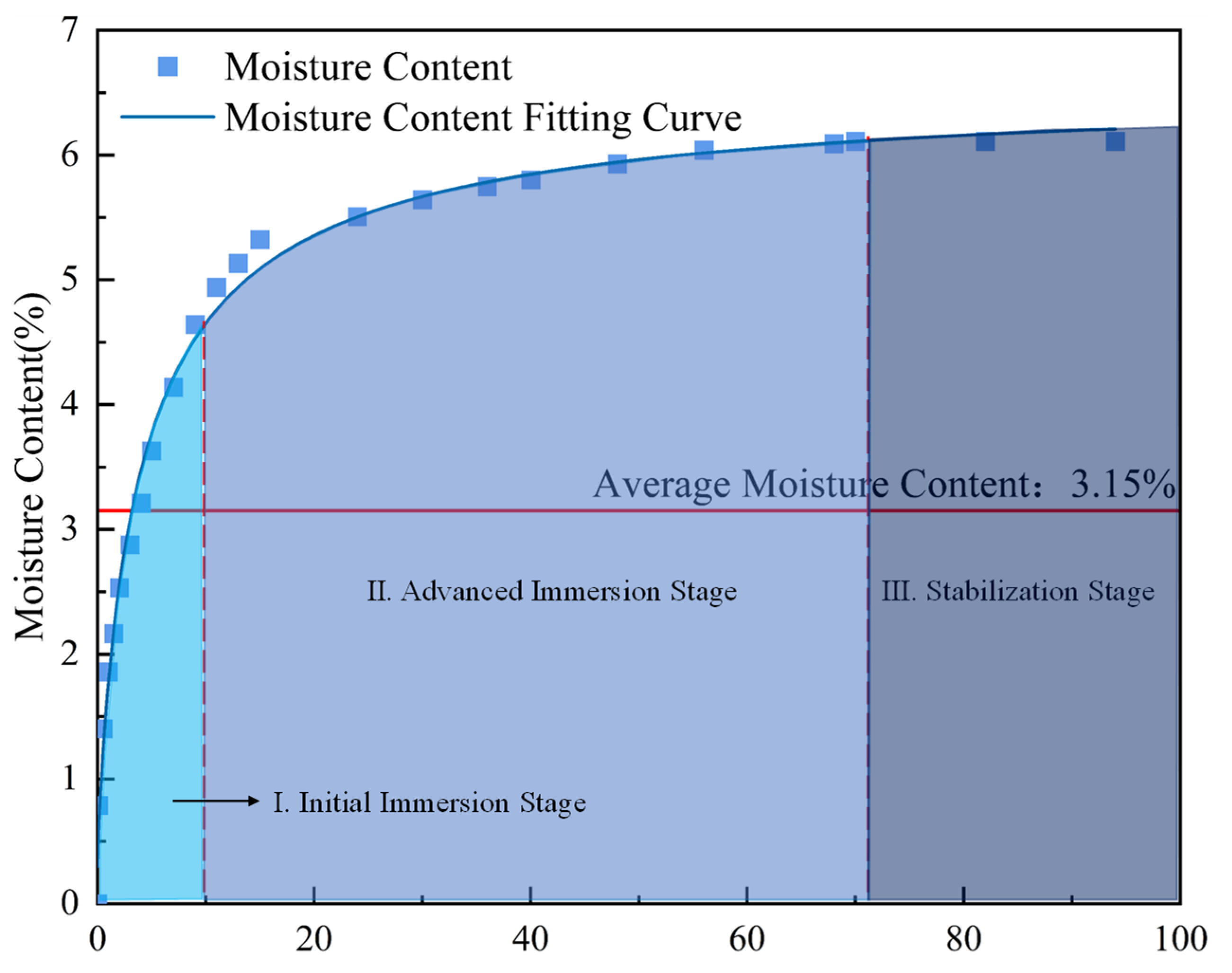

2.1. Preparation of Water-Immersed Coal Samples

2.2. Test Plan and Test Equipment

3. Mechanical Performance Degradation of Water-Immersed Coal Samples

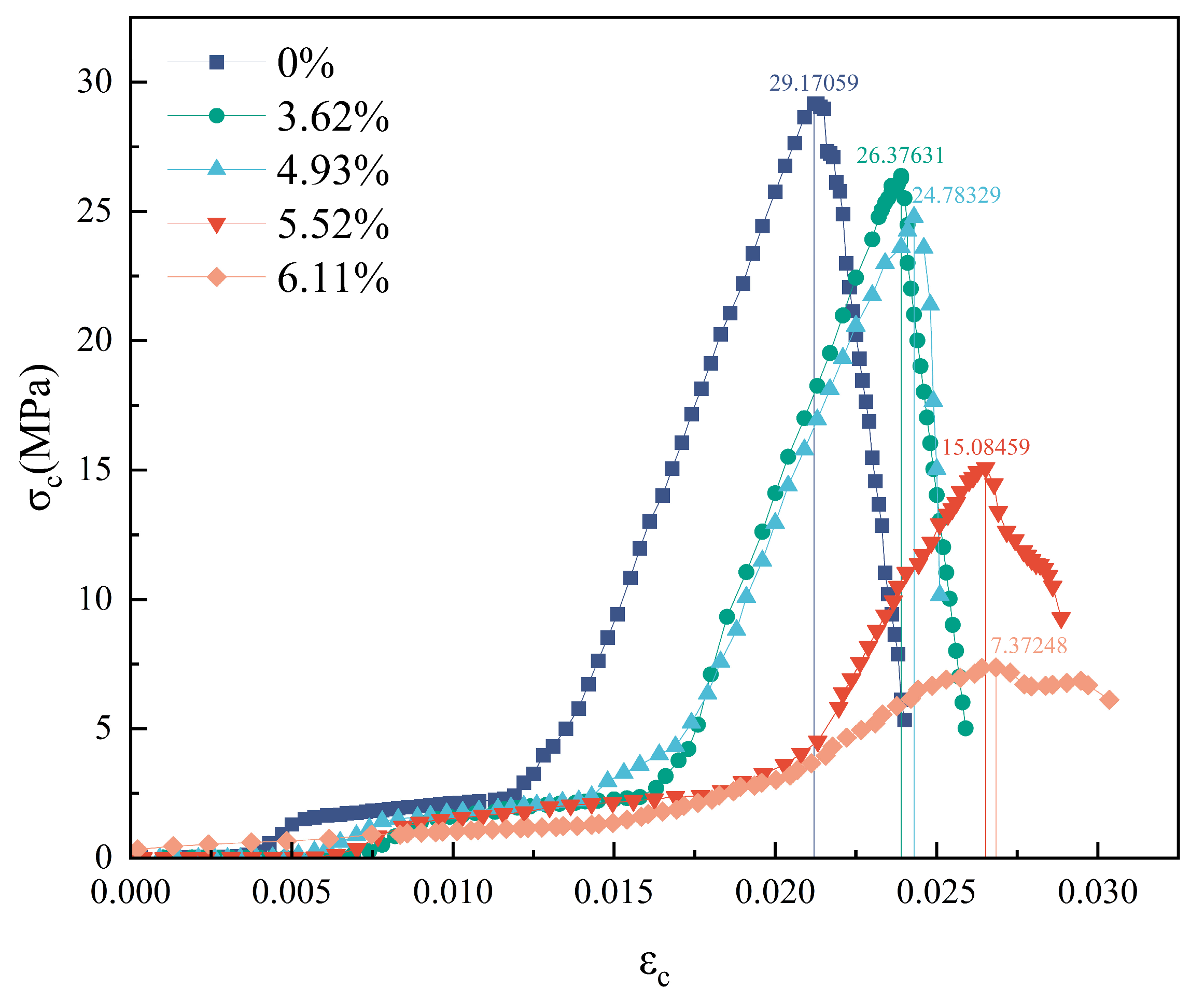

3.1. Effect of Moisture Content on the Compressive Performance of Coal Samples

3.1.1. Stress–Strain Curves

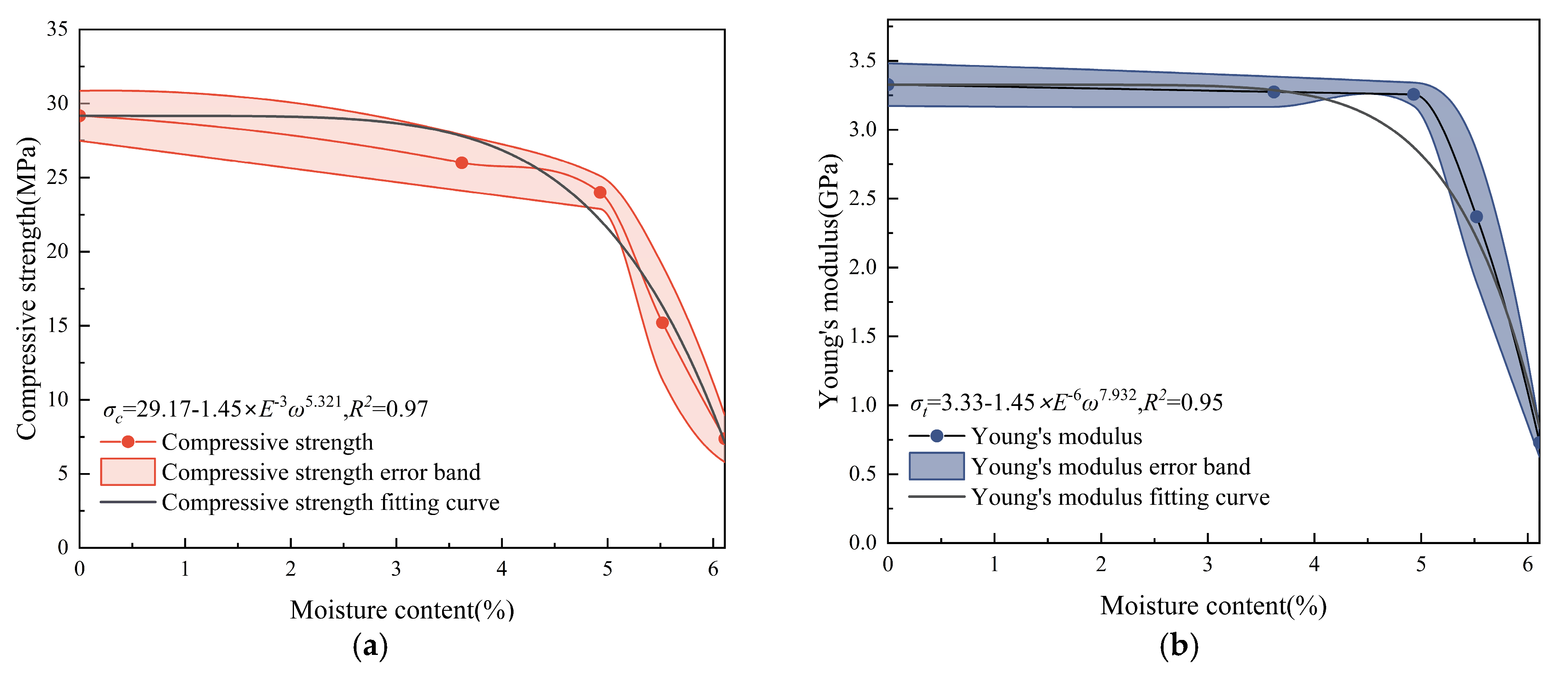

3.1.2. Compression Performance

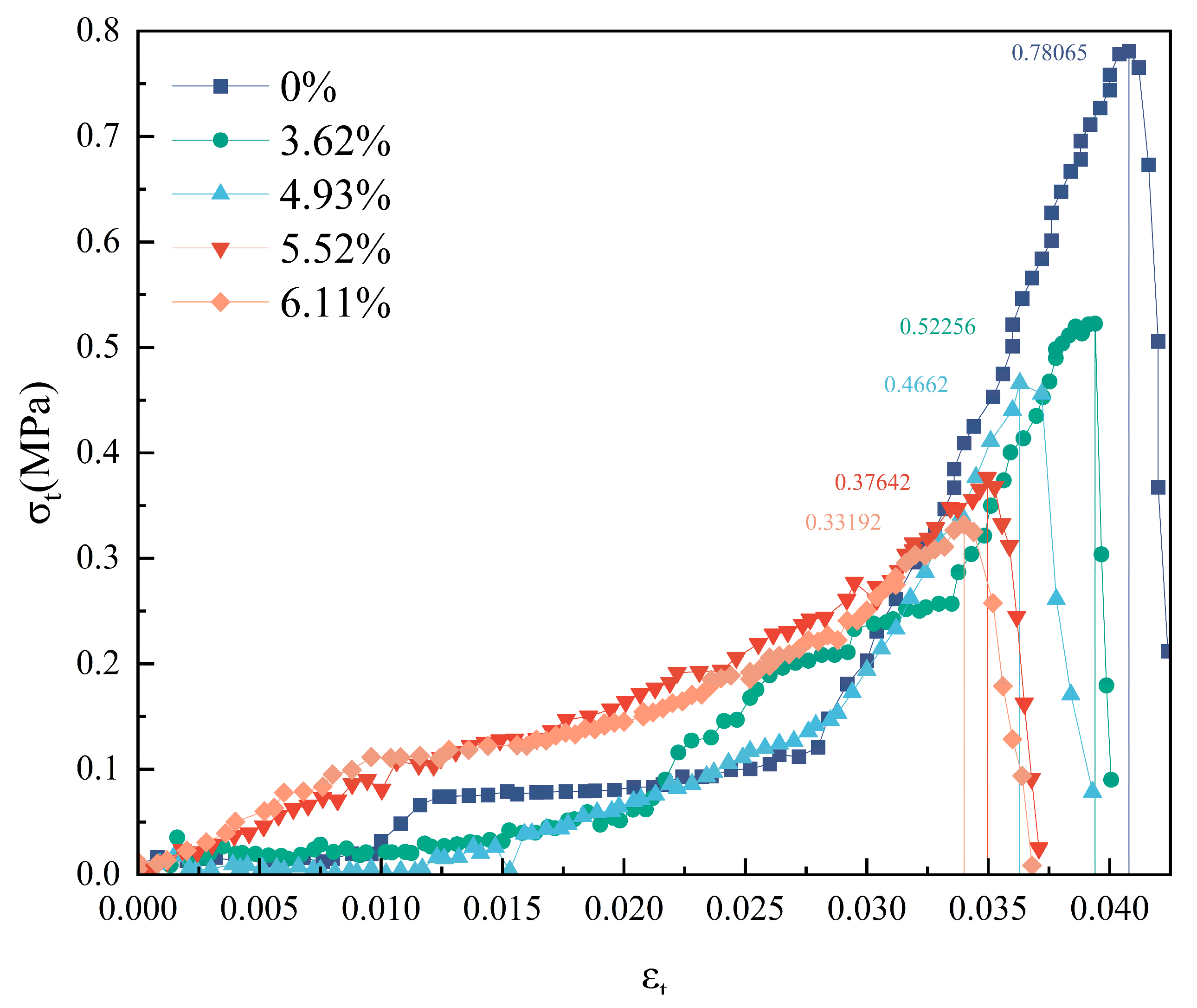

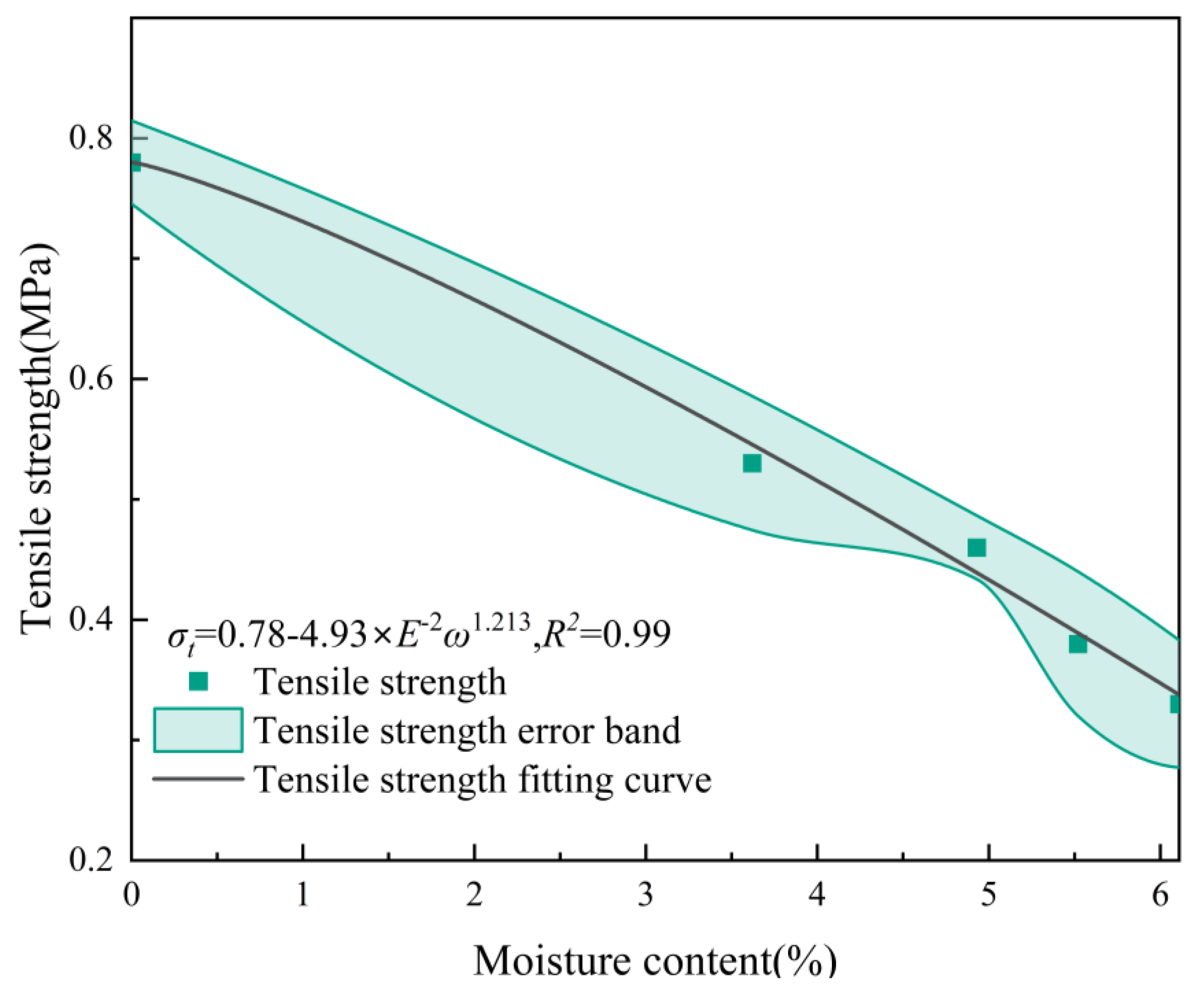

3.2. Effect of Moisture Content on Tensile Performance of Coal Samples

3.2.1. Stress–Strain Curves

3.2.2. Tensile Performance

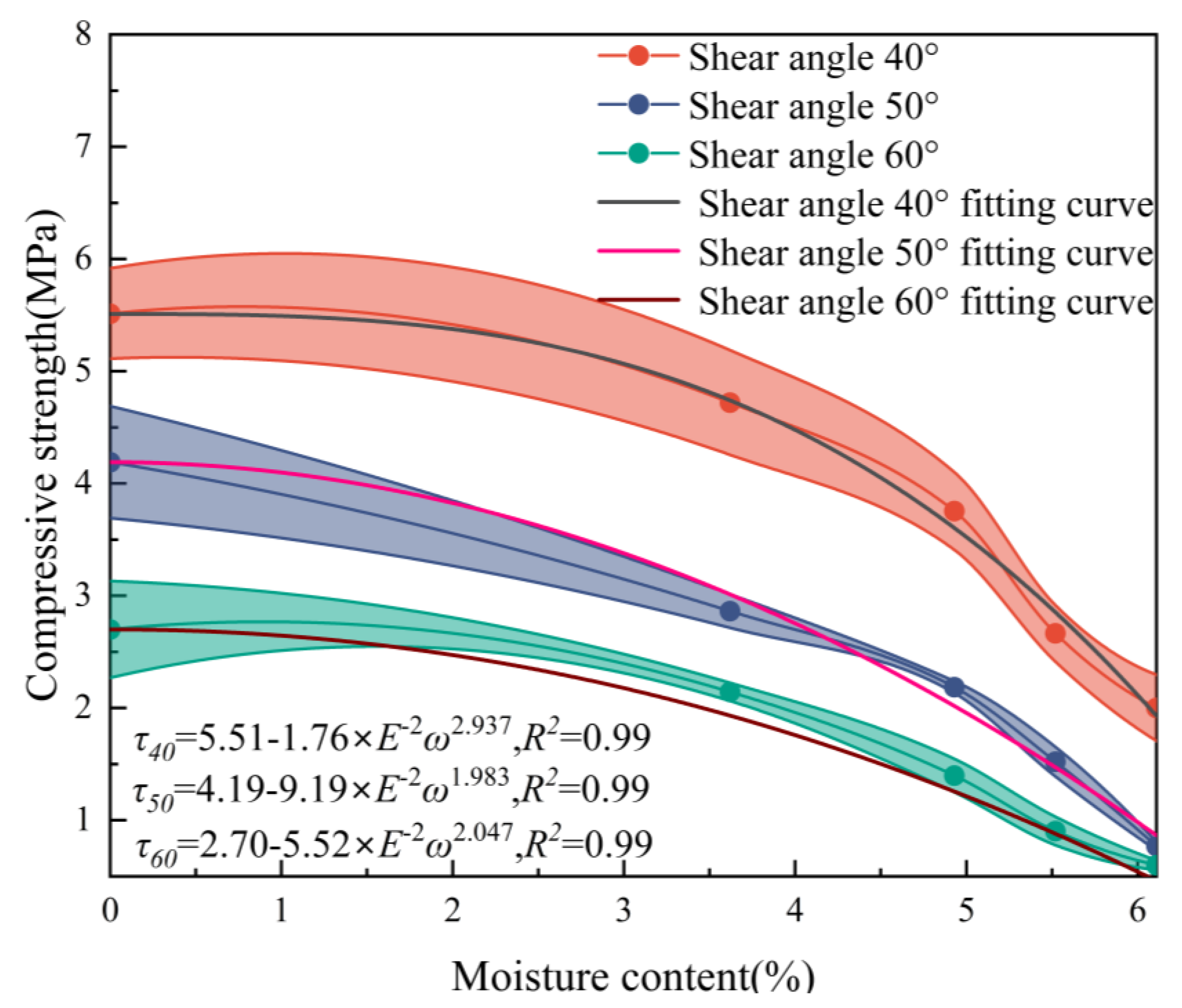

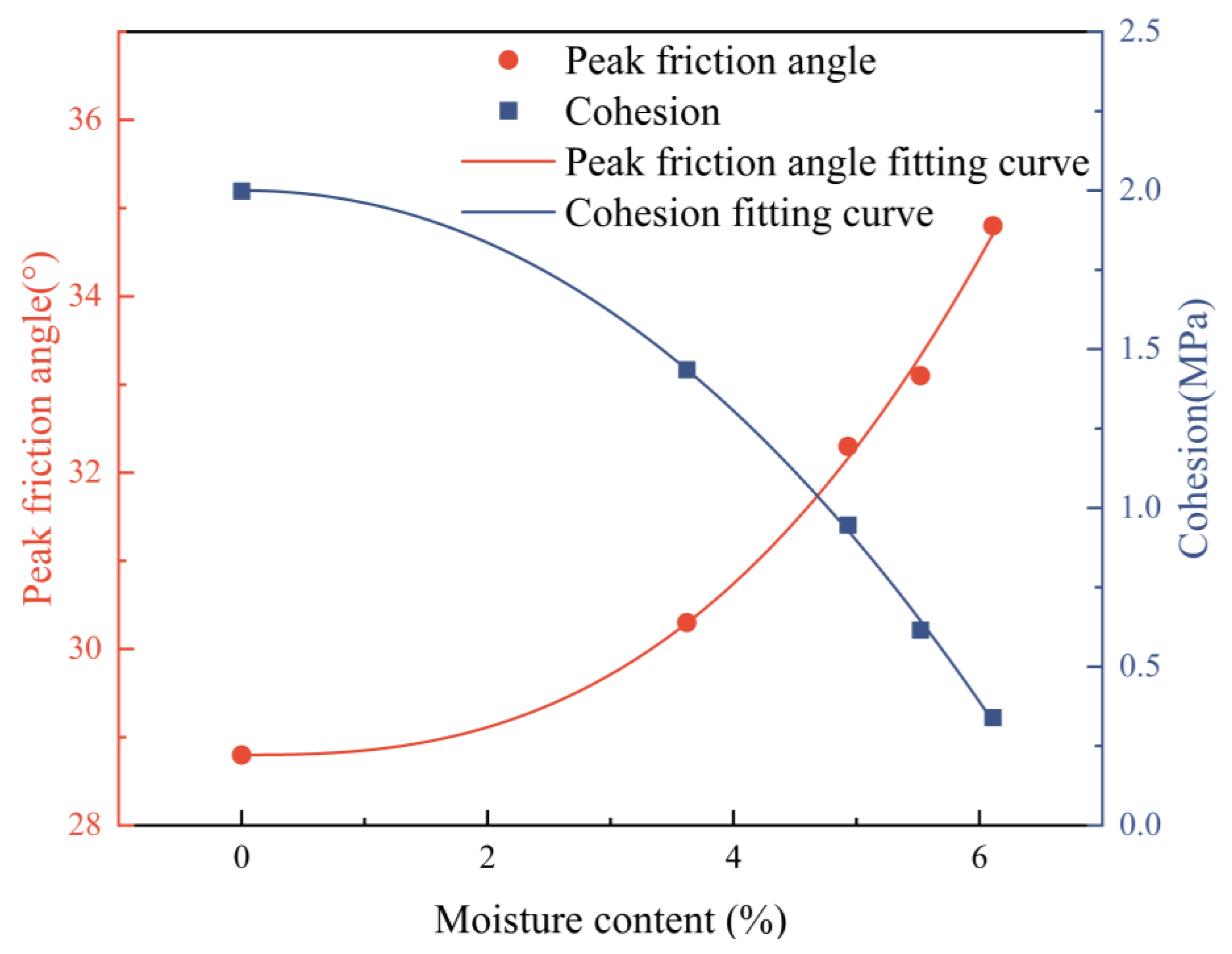

3.3. Effect of Moisture Content on the Shear Performance of Coal Samples

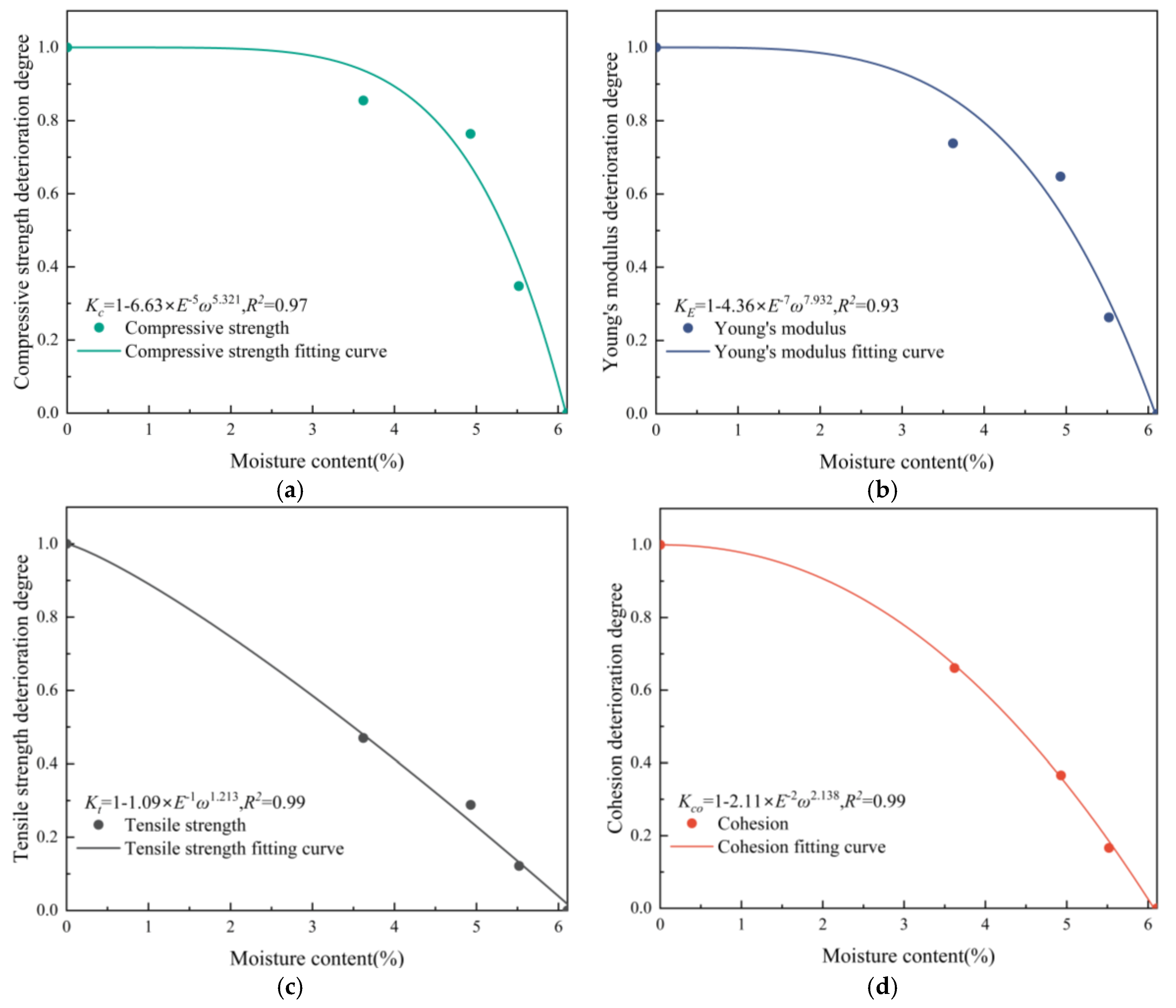

4. Degradation Degree for Mechanical Performance of Coal Samples Under Different Moisture Contents and Sensitivity Analysis

4.1. Establishment of Classification Standard for Degradation Degree of Mechanical Performance of Coal Samples

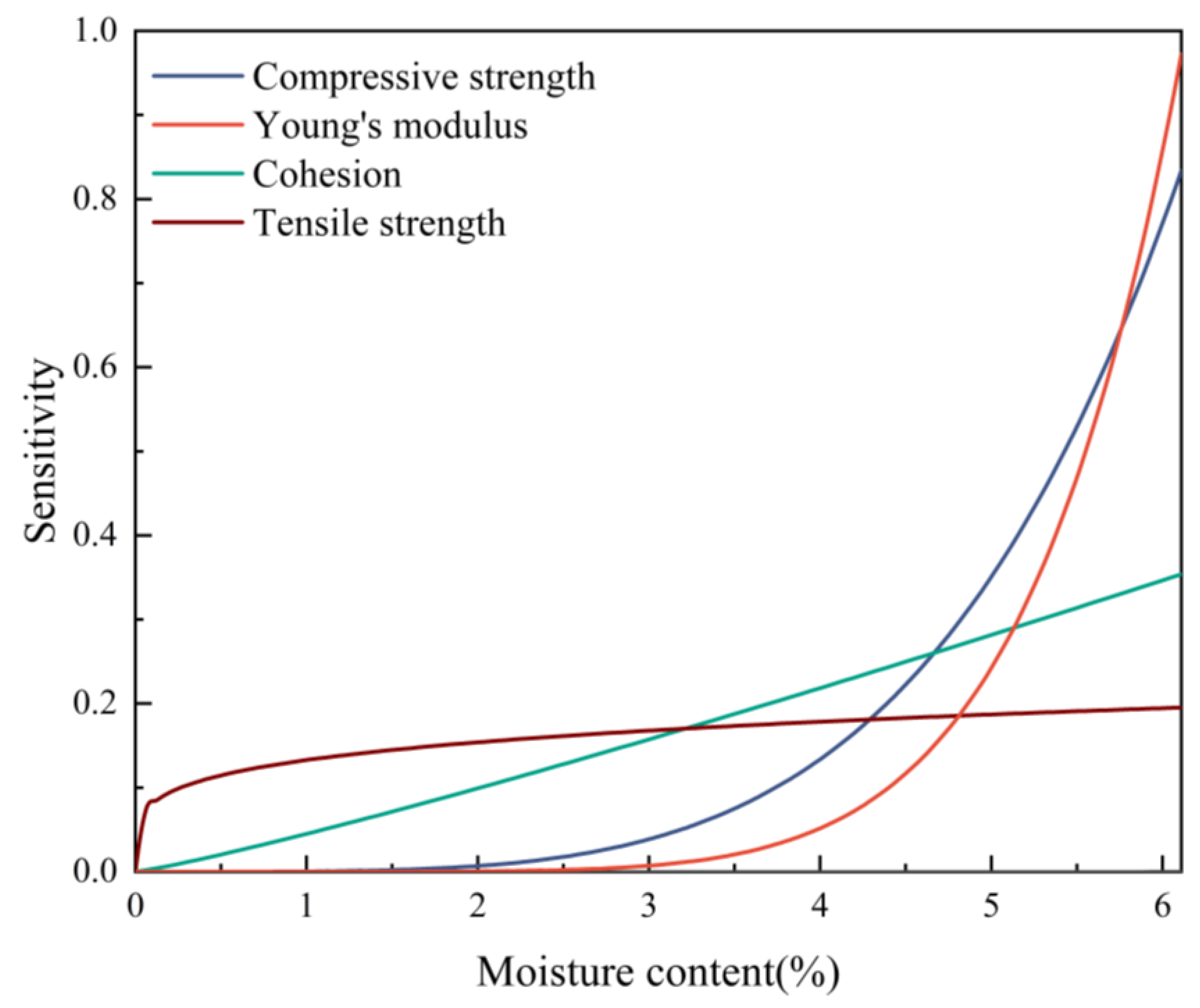

4.2. Sensitivity Index of Mechanical Performance to Moisture Content and Its Stage Division

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.X.; Zeng, Y.F.; Wu, Q.; Meng, S.H.; Liang, J.Y.; Hou, Z.P. Ecological-based mining: A coal–water–thermal collaborative paradigm in ecologically fragile areas in western China. Engineering 2024, 38, 209–222. [Google Scholar] [CrossRef]

- Zeng, Y.F.; Meng, S.H.; Wu, Q.; Mei, A.S.; Bu, W.Y. Ecological water security impact of large coal base development and its protection. J. Hydrol. 2023, 619, 129319. [Google Scholar] [CrossRef]

- Chi, M.B.; Zhang, D.S.; Zhao, Q.; Yu, W.; Laing, S.S. Determining the scale of coal mining in an ecologically fragile mining area under the constraint of water resources carrying capacity. J. Environ. Manag. 2021, 279, 111621. [Google Scholar] [CrossRef]

- Mardonova, M.; Han, Y.S. Environmental, hydrological, and social iMPacts of coal and nonmetal minerals mining operations. J. Environ. Manag. 2023, 332, 117387. [Google Scholar] [CrossRef]

- Jiang, B.B.; Gao, J.; Du, K.; Deng, X.; Zhang, K. Insight into the water–rock interaction process and purification mechanism of mine water in underground reservoir of Daliuta coal mine in China. Environ. Sci. Pollut. Res. 2022, 29, 28538–28551. [Google Scholar] [CrossRef]

- Jiang, B.B.; Zhao, Z.; Liu, D.Q.; Cao, Z.G.; Tang, J.W.; Wu, M.; Zhang, H.Q.; Li, P.; Liang, D.C. Study on the interaction mechanism between residual coal and mine water in goaf of coal mine underground reservoir. Sustainability 2023, 15, 15106. [Google Scholar] [CrossRef]

- Chi, M.B.; Li, Q.S.; Cao, Z.G.; Fang, J.; Wu, B.Y.; Zhang, Y.; Wei, S.R.; Liu, X.Q.; Yang, Y.M. Evaluation of water resources carrying capacity in ecologically fragile mining areas under the influence of underground reservoirs in coal mines. J. Clean. Prod. 2022, 379, 134449. [Google Scholar] [CrossRef]

- Fan, J.Y.; Li, Z.; Feng, G.R.; Zhang, H.D.; Qi, C.G.; Zhang, J.Y. Failure analysis of coal pillars and overburden from underground water reservoir under the mining-water invasion coupling effect. Eng. Fail. Anal. 2023, 151, 107406. [Google Scholar] [CrossRef]

- Qian, R.P.; Liu, X.L.; Ma, Q.; Feng, G.R.; Bai, J.W.; Guo, J.; Zhang, S.; Wen, X.Z. Effect of water intrusion on mechanical behaviors and failure characteristics of backfill body and coal pillar composite specimens under uniaxial compression. J. Clean. Prod. 2025, 502, 145388. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Skyrda, A.; Popova, O. Numerical modeling of controlling a floor heave of coal mine roadways with a method of reinforcing in wet soft rock. Geofluids 2022, 2022, 3855799. [Google Scholar] [CrossRef]

- Qian, R.P.; Feng, G.R.; Guo, J.; Wang, P.F.; Wen, X.Z.; Song, C. Experimental investigation of mechanical characteristics and cracking behaviors of coal specimens with various fissure angles and water-bearing states. Theor. Appl. Fract. Mech. 2022, 120, 103406. [Google Scholar] [CrossRef]

- Wang, J.; Wan, Z.; Wang, Y.; Liu, Z.; Liu, S.; Zhang, H.; Pei, Q. Effect of Stress and Moisture Content on Permeability of Gas-Saturated Raw Coal. Geofluids 2020, 2020, 8837758. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, C.Q.; Yin, Z.Q.; Hou, J.L. Research on soft coal mechanics characteristic test for moisture content effect. J. Min. Saf. Eng. 2016, 33, 1145–1151. [Google Scholar] [CrossRef]

- Karakul, H.; Ulusay, R. Empirical correlations for predicting strength properties of rocks from P-wave velocity under different degrees of saturation. Rock Mech. Rock Eng. 2013, 46, 981–999. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of water content on the strength and deformability of gypsum. Int. J. Rock Mech. Min. Sci. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Iyare, U.C.; Blake, O.O.; Frash, L.P.; Carey, J.W.; Jones, D.; Ramjarrie, K. Water-weakening effects on the failure behavior of mudstones. Rock Mech. Rock Eng. 2023, 56, 9171–9185. [Google Scholar] [CrossRef]

- Talesnick, M.; Shehadeh, S. The effect of moisture content on the mechanical response of a high-porosity chalk. Int. J. Rock Mech. Min. Sci. 2007, 44, 584–600. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock Mech. Min. Sci. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Kim, E.; Stine, M.A.; de Oliveira, D.B.M.; Changani, H. Correlations between the physical and mechanical properties of sandstones with changes of moisture content and loading rates. Int. J. Rock Mech. Min. Sci. 2017, 100, 255–262. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S. Numerical studies of floor heave mechanism and the effectiveness of grouting reinforcement of roadway in soft rock containing the mine water. Int. J. Rock Mech. Min. Sci. 2023, 170, 105484. [Google Scholar] [CrossRef]

- Hashiba, K.; Fukui, K. Effect of water on the deformation and failure of rock in uniaxial tension. Rock Mech. Rock Eng. 2015, 48, 1751–1761. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, P.; Zhang, K.; Gao, Y.; Qi, Z.; Cai, M. Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction. Appl. Sci. 2025, 15, 6700. [Google Scholar] [CrossRef]

- Han, P.; Zhao, Y.; Zhang, C.; Wang, X.J.; Wang, W. Effects of water on mechanical behavior and acoustic emission characteristics of coal in Brazilian tests. Theor. Appl. Fract. Mech. 2022, 122, 103636. [Google Scholar] [CrossRef]

- Yao, Q.L.; Chen, T.; Tang, C.J.; Sedighi, M.; Wang, S.W.; Huang, Q.X. Influence of moisture on crack propagation in coal and its failure modes. Eng. Geol. 2019, 258, 105156. [Google Scholar] [CrossRef]

- Wang, D.; Ju, F.; Xu, J.; Yan, C.S.; Xiao, M.; Ning, P.; Wang, T.F.; Si, L.; Wang, Y.B. Effects of Moisture Content and Loading Rate on Coal Samples: Mechanical Properties and Failure Mechanisms. Rock Mech. Rock Eng. 2024, 58, 3391–3416. [Google Scholar] [CrossRef]

- Hou, P.Y.; Cai, M.; Zhang, X.W.; Feng, X.T. Post-peak stress–strain curves of brittle rocks under axial-and lateral-strain-controlled loadings. Rock Mech. Rock Eng. 2022, 55, 855–884. [Google Scholar] [CrossRef]

- Hou, P.Y.; Cai, M. Post-peak stress–strain curves of brittle hard rocks under different loading environment system stiffness. Rock Mech. Rock Eng. 2022, 55, 3837–3857. [Google Scholar] [CrossRef]

- Singh, S.P. Brittleness and the mechanical winning of coal. Min. Sci. Technol. 1986, 3, 173–180. [Google Scholar] [CrossRef]

- Liu, Y.B.; Yin, G.Z.; Li, M.H.; Zhang, D.M.; Huang, G.; Liu, P.; Liu, C.; Zhao, H.G.; Yu, B.C. Mechanical properties and failure behavior of dry and water-saturated anisotropic coal under true-triaxial loading conditions. Rock Mech. Rock Eng. 2020, 53, 4799–4818. [Google Scholar] [CrossRef]

- Xie, H.X.; Li, X.H.; Shan, C.H.; Xia, Z.; Yu, L.Q. Study on the damage mechanism and energy evolution characteristics of water-bearing coal samples under cyclic loading. Rock Mech. Rock Eng. 2023, 56, 1367–1385. [Google Scholar] [CrossRef]

- Yao, Q.L.; Chen, T.; Ju, M.H.; Liang, S.; Liu, Y.P.; Li, X.H. Effects of water intrusion on mechanical properties of and crack propagation in coal. Rock Mech. Rock Eng. 2016, 49, 4699–4709. [Google Scholar] [CrossRef]

- Lyu, K.; Jiang, N.; Yin, D.W.; Meng, S.Y.; Gao, Z.Y.; Lyu, T. Deterioration of compressive properties of coal rocks under water and gas coupling. J. Cent. South Univ. 2024, 31, 477–495. [Google Scholar] [CrossRef]

- Fang, Z.; Harrison, J.P. A mechanical degradation index for rock. Int. J. Rock Mech. Min. Sci. 2001, 38, 1193–1199. [Google Scholar] [CrossRef]

- Fahimifar, A.; Soroush, H. A moisture index classification system for rocks (MiC System). Rock Mech. Rock Eng. 2007, 40, 63–79. [Google Scholar] [CrossRef]

- Mousavi, S.Z.S.; Mohammad, R. Correlation assessment between degradation ratios of UCS and non-destructive properties of rock under freezing-thawing cycles. Geoderma 2022, 428, 116209. [Google Scholar] [CrossRef]

- Leng, Y.Q.; Peng, J.B.; Wang, S.; Lu, F. Development of water sensitivity index of loess from its mechanical properties. Eng. Geol. 2021, 280, 105918. [Google Scholar] [CrossRef]

| Immersion time/h | 0 h | 5 h | 11 h | 24 h | 96 h |

| Moisture content/% | 0 | 3.62 | 4.93 | 5.52 | 6.11 (saturated) |

| Moisture Content/% | Compression Performance Test Number | Size/mm × mm | Tensile Performance Test Number | Size/mm × mm | Shear Performance Test Number | Shear Angle/° | Size/mm × mm |

|---|---|---|---|---|---|---|---|

| 0 | Y-1 | 50 × 100 | L-1 | 50 × 25 | J-40-1 | 40° | 50 × 50 |

| J-50-1 | 50° | ||||||

| J-60-1 | 60° | ||||||

| 3.62 | Y-2 | L-2 | J-40-2 | 40° | |||

| J-50-2 | 50° | ||||||

| J-60-2 | 60° | ||||||

| 4.93 | Y-3 | L-3 | J-40-3 | 40° | |||

| J-50-3 | 50° | ||||||

| J-60-3 | 60° | ||||||

| 5.52 | Y-4 | L-4 | J-40-4 | 40° | |||

| J-50-4 | 50° | ||||||

| J-60-4 | 60° | ||||||

| 6.11 | Y-5 | L-5 | J-40-5 | 40° | |||

| J-50-5 | 50° | ||||||

| J-60-5 | 60° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhang, Y.; Yin, Z.; Wang, L.; Wu, Y.; Xing, S. Strength Deterioration and Sensitivity Analysis of Coal Samples Under Different Immersion Times for Underground Water Reservoirs. Appl. Sci. 2025, 15, 8957. https://doi.org/10.3390/app15168957

Li M, Zhang Y, Yin Z, Wang L, Wu Y, Xing S. Strength Deterioration and Sensitivity Analysis of Coal Samples Under Different Immersion Times for Underground Water Reservoirs. Applied Sciences. 2025; 15(16):8957. https://doi.org/10.3390/app15168957

Chicago/Turabian StyleLi, Meng, Yong Zhang, Zhangjie Yin, Lujun Wang, Yang Wu, and Shihao Xing. 2025. "Strength Deterioration and Sensitivity Analysis of Coal Samples Under Different Immersion Times for Underground Water Reservoirs" Applied Sciences 15, no. 16: 8957. https://doi.org/10.3390/app15168957

APA StyleLi, M., Zhang, Y., Yin, Z., Wang, L., Wu, Y., & Xing, S. (2025). Strength Deterioration and Sensitivity Analysis of Coal Samples Under Different Immersion Times for Underground Water Reservoirs. Applied Sciences, 15(16), 8957. https://doi.org/10.3390/app15168957