Abstract

Modified sulfur cake is a by-product of sulfuric acid and hydrometallurgical processes, and presents an underutilized resource in sustainable infrastructure with significant potential. This review evaluates the current technological innovations as pertaining to the use of modified sulfur cake in the manufacture of sulfur concrete and sulfur-modified bitumen. The processing strategies (thermal, chemical, and mechano-chemical processing, and effects of organic and inorganic additives to promote mechanical, chemical, and thermal behaviors) are discussed systematically. The effect of the modified sulfur cake on the workability, compressive strength, corrosion resistance, and environmental resistance of construction materials, in particular, is tested, with compression strengths beyond 40 MPa being reported, alongside the improved rutting resistance up to 40%. The most critical limitations associated with phase instability, toxic gas release during processing, compositional variability, and the absence of standardization are identified. Correspondingly, to alleviate them, new developments such as blends with sulfur, nano-reinforcements (e.g., carbon nanotubes (CNT), nano-silica), and the incorporation of formulation optimization by machine-learning are considered. The review particularly focuses on the life cycle performance, reduction in volatile organic compounds (VOC) emissions, and circular economy advantages, highlighting modified sulfur cake as an economical and low-carbon alternative to conventional concrete and bitumen. This review mainly aims to bridge the gap between waste valorization and green construction technologies, offering a roadmap for future research and industrial implementation in line with global climate and sustainability goals.

1. Introduction

The global production of elemental sulfur has seen a steady rise over the past few decades, primarily due to its large recovery as a by-product in the refining processes of oil, gas, and metal. Every year, approximately more than 70 million metric tons of sulfur are produced globally, consumed in the volatile desulfurization processes in fossil fuel plants [1]. Sulfur has commonly been used in welding and the fertilizer industry, yet having too much of it has caused problems related to storage, getting rid of waste, and maintaining a healthy environment [2]. Storing a massive supply in open areas is one of the major challenges of surplus sulfur which harms the environment. Although sulfur is generally stable, it tends to oxidize and may result in sulfur dioxide under humid and acidic conditions. This compound can contaminate the soil and water if released into the environment [3]. A sulfur waste called sulfur cake is produced during the production of sulfuric acid and other hydrometallurgy processes and contains high levels of sulfur and inorganic material [4]. The disposal of sulfur cake poses both logistical and ecological problems due to its semi-solid nature and impurity content, limiting its industrial use and necessitating energy-intensive treatment methods [5].

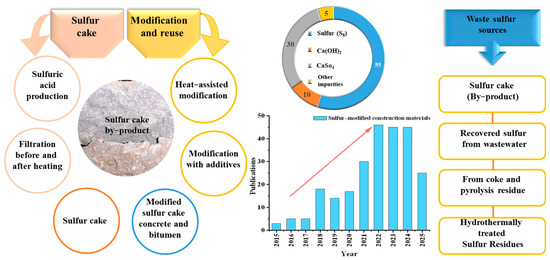

Recently, researchers have shown interest in modified sulfur cake and other sulfur-rich industrial by-products to make construction materials such as sulfur concrete and sulfur–bitumen, resulting in a reduction in the huge amount (around 12 metric tons annually) of sulfur waste materials. The diversity of sulfur waste sources, their compositions, and the growing research interest in sulfur-based construction materials are summarized in Figure 1. Sulfur cake is usually treated with chemicals or heat to improve its composition, eliminate any toxic impurities, and increase its compatibility with cement or asphalt binders [6]. The use of modified sulfur in these materials has the advantages of both mitigating the environmental risks of sulfur disposal and supporting the development of sustainable and corrosion-resistant construction products. The motivation behind this innovation lies in the urgent need to close material loops and establish low-carbon pathways in the building and infrastructure sectors [7].

Figure 1.

The left panel illustrates the production and treatment pathways of sulfur cake, the middle panel presents the composition of sulfur cake along with publication trends since 2015, and the right panel identifies various sources of waste sulfur. (Data retrieved from the Scopus database on 20 June 2025 using the search terms “Sulfur modified construction materials” within article title, abstract, and keywords).

Many studies aimed at improving the composition and the functionality of the sulfur-based construction composites to make them more long-lasting and environmentally friendly. Sulfur–polymer composite materials have evolved to be more advanced, with enhanced acid-exposure-resistant performance and have also been modified with the aim of being applied in highly chemically hostile environments like wastewater treatment plants and chemical storage plants. Such composites not only withstand degradation at low pH environments but are also able to achieve compressive strengths of greater than 40 MPa, which is competitive when compared to conventional concrete compositions [8]. Researchers have also been able to make structural modifications by adding bitumen and stone flour to sulfur concrete, which results in improved structural cohesion and rheological properties and hence greater load-bearing capabilities [9].

Other notable developments include the incorporation of sulfur with foam-treated limestone and ferrous sulfate to fabricate non-odorous sulfur concrete which has the ability to extract nutrients in wastewater. The composite has a 90% efficiency in removing nitrogen and phosphorous, providing a two-dimensional use as well: replacing traditional methods of producing infrastructure and cleaning up the environment [10]. The results of testing of sulfur–regolith concrete, which was printed on 3D infrastructure, under lunar and Martian conditions, have highlighted the excellent mechanical integrity and the benefits of water-free processing factors that it has, with either of these properties being useful for application in space-based construction [11].

Moreover, sulfur concrete has attracted much attention because of its high resistance to chemicals, impermeability to water, rapid setting, and recyclability. In contrast to Portland cement-based concretes, sulfur concrete does not depend on the process of hydration, so it can be cured fast and can survive under extreme conditions [12]. Sulfur concrete has been further strengthened with the introduction of finely dispersed local soil mineral additives, with an increase of 15–20% compressive strength and an enlargement of regional applicability [13]. Sulfur-modified bitumen is capable of enhancing the performance and durability of asphalt pavement by increasing resistance to rutting and thermal stability as well as decreasing in sensitivity to petroleum-based bitumen dependence [14].

Recent studies have focused on the improvement of sulfur-modified asphalt systems by the addition of bio-designer rubbers and organic copolymers. It has been demonstrated that sulfur can increase the compatibility between the bio-based rubber and bitumen, offering increased flexibility and thermal stability [15]. Moreover, the performance of sulfur–organic copolymer systems has shown an extreme decreased sensitivity to temperature, which is a vital characteristic for high-temperature areas [16]. The addition of sulfur-based industrial waste to asphalt concrete has been confirmed as a successful strategy and significant changes in the resistance to rutting and freeze–thaw have been observed, making such modified mixtures appropriate for use in the construction of climate-resilient roads [17].

Next-generation bio-bitumen advancements have revealed a favorable synergy between sulfur additives and biomass-derived polymers, especially when their roles in promoting the sustainability of asphalt binders [18]. Sulfur in bitumen has also been reported as a cheap modifier and alternative to styrene–butadiene–styrene (SBS) polymers and particularly in areas that have excess sulfur by-products [19]. The use of these by-products, including sulfur cake, provides a commendable model of circular economy practices within the construction industry.

In addition, recent advancements in material science and process engineering have led to the development of sulfur–polymer blends, microstructural modifiers, and low-temperature processing techniques that significantly enhance the performance and application range of sulfur-based concretes and bitumen [1]. The environmental motivation is further strengthened by the urgent necessity to reduce the carbon footprint of construction materials. Traditional cement production accounts for nearly 8% of global CO2 emissions, largely due to the calcination of limestone and the energy-intensive clinkerization process [3]. This work provides a comprehensive and critical analysis of the technological developments in the utilization of modified sulfur cake for producing sulfur concrete and sulfur–bitumen. The review evaluates recent progress of sulfur cake modification techniques and the mechanical and environmental performance of sulfur-based materials, along with identifying current limitations and future research directions.

This work is mainly aimed at bridging the gap between waste management strategies and green construction technologies by investigating the life cycle of modified sulfur cake, from production and treatment to its formulation into construction composites, highlighting innovations that contribute to both environmental remediation and sustainable infrastructure development. This aligns with global sustainability goals that emphasize resource efficiency, emissions reduction, and circular material flows within the construction industry.

2. Materials and Methods

This review paper was prepared based on a systematic and high-integrity bibliography analysis devoted to the assessment of the current state and technological progress of modified sulfur cake as a sustainable construction material, primarily in the context of sulfur concrete and sulfur-modified bitumen. Four major academic databases, including Scopus, Web of Science, PubMed, and Science Direct, were used to perform a literature search to guarantee the maximum coverage and scientific credibility, focusing on their range of science literature that is peer-reviewed in the fields of materials science, civil engineering, and environmental technology. The following Boolean formulation of search terms was used in the selection process: “modified sulfur cake”, “sulfur concrete”, “sulfur bitumen”, “sustainable binders”, “waste sulfur”, “elemental sulfur concrete”, “sulfur polymer blends”, and “road construction materials”. This ensured relevance and rigor. The search was confined to works published between 2015 and 2025, with a particular focus on the most recent developments from 2021 to 2025, to highlight advancements in processing techniques, application performance, and environmental impact mitigation.

The identification of articles was determined by their priority, scientific level, and originality, as well as their empirical evidence and relevance to modified sulfur cake applications. Research articles were chosen which included experimental validation of sulfur usage in cementitious or bituminous composites and performance evaluations (e.g., strength, stability, thermal resistance, and chemical or structural characterization of the modified material). The review included high-impact journal articles, conference proceedings, and technical reports. Research articles exploring the mechanism of cycling of waste-derived sulfur, chemical stabilization of sulfur cake, and resulting performance in concrete mixtures and asphalts were searched. Important experimental data reported in the literature, such as compressive strength of 11.75 to 16.01 MPa as well as flexural strength of 4.63 to 10.32 MPa, and other data such as thermal stability, aging resistance, phase behavior, softening point, and penetration index, among other details, and characterization of the results using Fourier transform infrared spectroscopy (FTIR), X-Ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Differential Scanning Calorimetry (DSC), and rheological tests were selected.

In addition, studies focusing on the assessment of any hybrid systems, including sulfur–polymer composites, geopolymer–sulfur blends, and those that incorporate nanomaterials or chemical compatibilizers, were given priority in order to facilitate a future-looking discourse. Each selected reference provided robust, reproducible data, ensuring a critical synthesis of the state-of-the-art technologies for modified sulfur cake applications. This methodical approach ensured a comprehensive and technical foundation for evaluating the future of sulfur cake in sustainable infrastructure.

3. Sulfur Cake

3.1. Composition and Properties

Sulfur cake is a solid byproduct commonly produced in sulfuric acid manufacture and purification processes and there has been an emerging interest in the composition and properties of the product as it has the potential to be used as an infrastructure additive, such as in concrete or bitumen system applications. Sulfur cake usually contains a heterogenous mixture of calcium sulfate (CaSO4), calcium hydroxide (Ca(OH)2), and elemental sulfur, together with other inorganic and organic impurities whose make-up varies depending on the industrial process in which it was produced [20]. Sulfur cake mainly contains an amount of elemental sulfur comprising 40–65% of its weight. Calcium sulfate is found predominantly in the form of gypsum (CaSO4·2H2O), comprising 20–30% and calcium hydroxide can be found in weights of 5–10%. What is left behind are the minor components like silica, unreacted lime, heavy metals, and organic residues. CaSO4 and Ca(OH)2 are formed during the neutralization of flue gas (sulfur dioxide (SO2) or hydrogen sulfide (H2S) gases via lime or limestone in flue gas desulfurization or an analogous treatment system [21,22].

The exact balance of these constituents not only influences the physicochemical behavior of the cake but also its feasibility of use in material science. In addition to sulfur cake, there exist several categories of sulfur-containing wastes, including recovered sulfur in wastewater, sulfur in coke and pyrolysis residue waste, and hydrothermally treated sulfur sludges. These differ significantly in terms of sulfur content, impurities, and their reusability. Table 1 shows a comparative overview of these types in terms of their composition, sources, volume of production, and their applicability in environmental and constructive applications.

Table 1.

Comparison of sulfur-containing industrial waste types based on composition and production sources.

In terms of physico-chemical properties, sulfur cake exhibits a porous, friable structure with a specific surface area typically ranging from 10 to 25 m2/g, depending on the cooling and precipitation conditions. The material is typically yellow-gray and hydrophobic due to its sulfur content, though calcium-based components impart partial hydrophilicity. Its bulk density varies from 1.6 to 2.1 g/cm3, lower than that of pure gypsum but higher than that of purified elemental sulfur [23]. More importantly, the sulfur phase in sulfur cake exists primarily in orthorhombic crystalline form (α-S8), which exhibits good thermal stability and chemical resistance but poor compatibility with polar materials. However, in sulfur cake, the presence of calcium compounds significantly modifies interfacial properties, improving adhesion and composite performance in mixtures with concrete or asphalt binders.

The phase behavior and thermal stability of sulfur cake components are complex due to the interaction between sulfur and the mineral matrix. Elemental sulfur has a well-known allotropic transformation at ~95 °C, transitioning from orthorhombic to monoclinic form, and eventually melts at 115.2 °C. Upon heating, sulfur cake exhibits a multiphase transformation profile. Differential scanning calorimetry (DSC) studies have shown distinct thermal events at 100–120 °C and 600–700 °C, corresponding to sulfur melting and CaSO4 decomposition, respectively [27]. Moreover, the hydroxide component decomposes above 400 °C, releasing water vapor and forming reactive CaO. These transformations offer unique opportunities for tailoring sulfur cake for thermally processed composites, such as sulfur concrete and bitumen modifiers.

Compared to elemental sulfur, sulfur cake has several distinct advantages, particularly in terms of cost, availability, and environmental benefits. Elemental sulfur, though relatively abundant as a petroleum refining by-product, often requires costly purification to remove organic and metal impurities [28,29]. In contrast, sulfur cake, being a waste material from sulfuric acid or metal smelting plants, can be directly utilized with minimal processing, thus reducing raw material costs and addressing waste management issues simultaneously [26]. Moreover, studies indicate that sulfur cake retains many of the desirable characteristics of elemental sulfur—such as impermeability to water, chemical resistance, and self-healing thermal behavior—while its calcium content enhances chemical bonding in cementitious systems and acts as a latent hydraulic binder [20].

In the context of infrastructure applications, sulfur cake has demonstrated strong potential for use as a modifier in both concrete and bitumen formulations. In concrete, its combination of sulfur- and Ca-based compounds provides a dual function: elemental sulfur contributes to corrosion resistance and water impermeability, while CaSO4 and Ca(OH)2 participate in pozzolanic or latent hydraulic reactions, improving mechanical strength. A detailed comparison of the key properties of elemental sulfur and sulfur cake is presented in Table 2, highlighting their compositional differences and performance. Sulfur-based concrete made using sulfur cake can reach compressive strengths exceeding 35 MPa after 28 days, with enhanced durability under acidic or saline conditions compared to ordinary Portland cement concretes [25]. This makes it highly suitable for aggressive environments such as industrial floors, marine infrastructure, and wastewater treatment facilities.

Table 2.

Comparative properties of elemental sulfur and sulfur cake in terms of chemical composition, physical characteristics, and performance.

Sulfur cake is a cheap and environmentally friendly extender or partial substitute of binders in asphalt systems. The sulfur component helps in minimizing the viscosity of bitumen and enhancing rutting resistance, whereas the calcium sulfate enhances the interaction between the filler matrix and provides a load-carrying presence. Field tests have demonstrated that modifications of sulfur cake-modified asphalt may increase Marshall stability (up to 20%) and reduce temperature sensitivity, thereby lengthening pavement life in hot climates [24]. Sulfur cake is an emerging and novel alternative to purified elemental sulfur in civil engineering. Its special combination using elemental sulfur with reactive forms of calcium compounds provides physicochemical efficacy in addition to the benefits experienced environmentally. Increased demands for green construction materials also lead to the valorization of sulfur cake in concrete and bitumen, delivering the benefits of not only the minimization of industrial waste but also the creation of high-performance, resilient infrastructure.

3.2. Processing and Modification Technologies

The processing and modification technologies of sulfur cake are pivotal for its effective utilization in the construction and chemical industries. The purification and activation of sulfur cake includes removal of the impurities like unreacted calcium compounds, carbonaceous residues, and water. Sulfur cake modification has three major categories: thermal treatment, chemical treatment, and blending with additives. Thermal treatment involves the withdrawal of moisture and volatile impurities through heating; chemical pretreatment is based on the ability of acids or reagents to react with to rid a particular contaminant; and functional additives introduce into a blend to provide mechanical, chemical, or thermal performance enhancement in a specific application. The critical comparison of these treatment methods, as well as their mechanisms, advantages, and limitations, is provided in Table 3.

Table 3.

Critical analysis of sulfur cake processing and modification methods, comparing thermal, chemical, and additive-based techniques in terms of mechanisms.

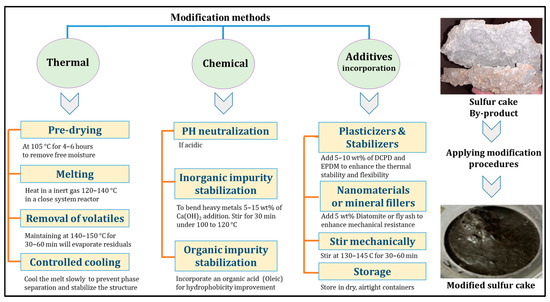

The thermal treatments are normally performed at temperatures exceeding 120 °C, where the moisture is volatilized and some impurities are partially decomposed resulting in high purity of sulfur and high reactivity [30]. Experimental measurements have also shown that under thermal conditions, moisture can be removed from above 5 wt% to below 0.5 wt%, which is important to optimize downstream processing operational efficiency and the stability of the material itself [31]. The major techniques for sulfur cake modification are presented in Figure 2, including thermal, chemical, and additive-based treatments, supporting the role of each route in impurity removal and performance enhancement. The chemical treatment procedures augment the thermal procedures by tackling particular impurities. An example of acid washing is the use of dilute HCl, which washes out calcium hydroxide and calcium sulfate [32], which can be used to enhance the sulfur level by as much as 80%. Moreover, the adoption of selection agents, like cyclo-dextrin polymers, has been shown to effectively remove tricyclic organic sulfur pollutants, with a purification efficiency of over 90% [33].

Figure 2.

Schematic outline of three major techniques for modifying sulfur cake, including thermal treatment, chemical purification, and additive-assisted enhancement.

Biomass coke modification that uses mechanical activation, named mechano-chemical activation, increases both surface area and reactivity, with the possibility of simultaneous physical and chemical purification [34]. It has also been used as an absorbent in purifying ethyl ester using activated carbon prepared using de-oiled seed cake, implying the similar potential in sulfur cake refinement [35]. The combination of high-temperature fusion and vacuum condensation in the separation of impurities is supported in the patent literature [36]. Furthermore, integrated treatment systems involving the use of the dynamic membrane and elemental sulfur beds have been promising in processes such as denitrification and management of sulfur-based pollutants, with an efficiency of more than 95% treatment [37]. The combination of chemical, thermal, and mechano-chemical processes provides a powerful set of mechanisms to purify the sulfur cake, which has been demonstrated to reduce the moisture content, clean the impurities, and activate the product.

3.2.1. Chemical Modifications

The chemical modification of sulfur cake significantly enhances its structural and functional properties, primarily through sulfur polymerization and interaction with inorganic components such as calcium hydroxide and calcium sulfate. Sulfur polymerization occurs via two dominant mechanisms: cyclization and crosslinking. The data in Table 4 provides the chemical modification mechanisms and their effects on the features of the sulfur cake. Elemental sulfur undergoes ring-opening polymerization, producing linear polysulfide chains at certain (160–180 °C) temperatures. These chains can be stabilized through inverse vulcanization, a process where unsaturated organic crosslinkers (e.g., di- or tri-vinyl monomers) react with sulfur to form thermally and chemically stable copolymers [38].

Table 4.

Comparative evaluation of chemical modification strategies for sulfur cake, highlighting key operational conditions, product characteristics, and limitations.

The mechanical properties (specifically crosslinking density) are very dependent on the crosslinker structure. For example, the crosslinkers with stiff aromatic center cores produce sulfur polymers which have a stronger tensile load (up to 5.1 MPa) and a higher thermal stability (glass transition temperature (Tg) exceeding 100 °C) [39] than the flexible compositions utilizing aliphatic crosslinkers, which result in a more elastic material.

According to measurements, this ratio between sulfur and crosslinker should be from 70:30 to 80:20 by mass, which optimizes the rigidity of the structure and process ability. When residual calcium hydroxide (Ca(OH)2) and calcium sulfate (CaSO4) are present in sulfur cakes, they are used in two possible ways, predominantly as a source of neutralization and also as a type of chemical reactant in a modification reaction. Calcium hydroxide may also be combusted with hydrogen sulfide (H2S) or organosulfur intermediates to form calcium sulfides, which fix sulfur species and inhibit emissions [40]. In addition, CaSO4 can facilitate thermochemical sulfate reduction (TSR) at elevated temperatures (250–280 °C), which creates agent sulfide, such as H2S or polysulfide-free radicals [42]. These radicals are capable of spurring on additional sulfur cross-linking reactions which affect the end polymer network.

The reactivity of sulfate species with organic functional groups has also been documented in theoretical models, with activation energies for C–S bond formation as low as 45–55 kJ/mol, indicating high feasibility [43]. However, excess Ca(OH)2 can result in undesired side products like calcium silicates or carbonates, especially in the presence of CO2 or siliceous impurities [41]. Thus, the chemical environment of sulfur cake, including sulfur speciation and inorganic residues, plays a critical role in defining the success and efficiency of polymerization and crosslinking reactions essential for high-performance applications.

3.2.2. Blending with Additives

The blending of sulfur cake with organic and inorganic additives has been shown to be very effective in improving the suitability of the cake for construction activities. Table 5 offers insights into the characteristics and performance improvements of sulfur cake with the addition of organic (e.g., dicyclopentadiene (DCPD), plasticizers) and inorganic (e.g., fly ash, silica fume, carbon materials) additives, with an indication of their particular roles, loading, and the obtained overall enhancement of mechanical, thermal, and chemical properties as construction material. Sulfur cake, normally made of elemental sulfur, calcium sulfate, and hydroxide, has a number of limitations including brittleness and resistance to cracking. Additional organic plasticizers, such as DCPD and other similar plasticizers, have been shown to contribute to major changes in the mechanical flexibility and long-term durability of sulfur-type composites. These additives also allow cyclisation and crosslinking reactions to occur in the heating process, forming sulfur polymers which do not recrystallize and thermally degrade. Experimental data have demonstrated that introducing sulfur–organic polymers into composites can enhance compressive strength by up to 30% and significantly improve protection against microbial and chemical corrosion in harsh conditions, including sewers and acidic soil [45].

Table 5.

Characteristics of modified sulfur cake with organic and inorganic additives, corresponding the enhancements in mechanical and chemical properties.

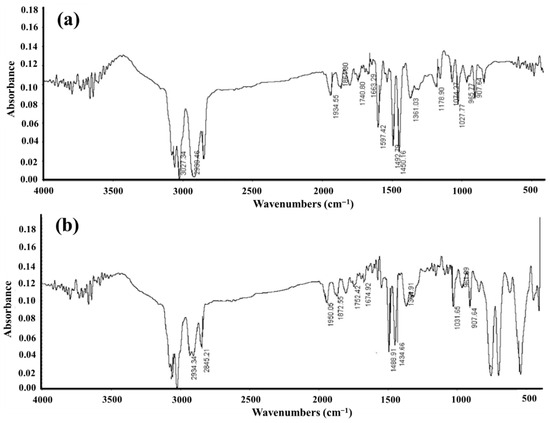

The FTIR spectra presented in (Figure 3a,b) offer valuable insight into the functional group compositions of the olefinic hydrocarbon and modified sulfur, respectively, which are critical for understanding their behavior and performance in infrastructure applications such as sulfur concrete and sulfur-modified bitumen. In both spectra, there are typical absorption bands of organic and inorganic functional groups to help explain the degree of chemical interaction and structural enhancement of modified sulfur.

Figure 3.

Fourier transform infrared (FTIR) spectra of (a) olefinic hydrocarbon and (b) modified sulfur, illustrating the characteristic functional group vibrations and chemical modifications associated with sulfur incorporation. Both images are reproduced from Souaya et al., 2015 [50], in their original form under the terms of the Creative Commons Attribution–NonCommercial–NoDerivatives 4.0 International License (CC BY-NC-ND 4.0).

Figure 3a depicts the spectrum of the olefinic hydrocarbon presenting high peak intensities, which were at 2972, 2936, and 2894 cm−1 and were attributed to C-H asymmetric and symmetric stretch vibrations. These indications can be considered as evidence of hydrocarbonous remnants, probably belonging to organic binders or leftover bituminous matter. Moreover, carbonyl (C=O) and C=C groups were determined by the presence of absorption bands at 1730–1740 cm−1 and 1597 cm−1, which are usually found in oxidative degradation products or aromatic compounds [50].

By comparison, in Figure 3b, the FTIR spectrum of the modified sulfur reveals notable changes. The C–H stretching region (2934 and 2845 cm−1) remains evident, but the bands are slightly less intense, implying partial thermal degradation or chemical transformation of organic content. The carbonyl band at 1752 cm−1 is similar but shifted further and is now more distinct, indicating more pronounced incorporation of oxidized sulfur components or bituminous by-products. In addition, the 600–1100 cm−1 range shows greater and more ordered peaks especially at 1031 and 907 cm−1, suggesting higher conjugation of C-S and S-O bonds. These changes correspond to a successful procedure of sulfur polymerization or crosslinking, leading to more durable and asphalt- and concrete-ready materials [51].

These spectral changes are highly associated with enhanced mechanical and chemical behavior of modified sulfur-based binders within infrastructures. The formation of stable sulfur–oxygen and carbon–sulfur functional groups plays a role in the increased water resistance, chemical durability, and thermal performance of sulfur concrete, which seems to be an appropriate sulfur-based material for withstanding harsh environments [52]. Similarly, integration between oxidized sulfur species and hydrocarbons at the chemical level facilitates improved adhesion and elasticity in the case of the sulfur-extended hot-mix asphalt, hence improving rutting resistance and service life [53]. The structural reinforcement exhibited in Figure 4 is essential as a consequence of sulfur modification, confirming the functionality of the structural reinforcement for practical applicability in structural reinforcement.

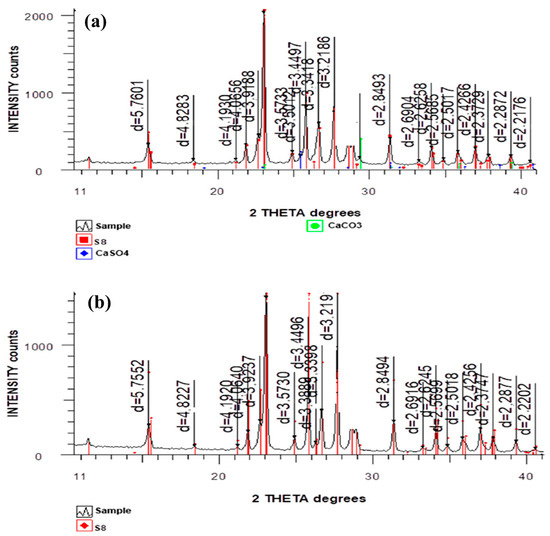

Figure 4.

X-ray diffraction (XRD) patterns of the analyzed samples: (a) unmodified sulfur cake and (b) sulfur cake modified with oleic acid. This figure is reproduced from Ongarbayev et al., 2024 [6], under the terms of the Creative Commons Attribution 4.0 International License (CC BY 4.0).

The XRD patterns in Figure 4a,b are a comparative analysis of unmodified and oleic acid-modified sulfur cake, respectively. These diffractions provide important differences in phase content and crystal structure, which have direct impacts on their capability to be used in infrastructure applications such as in sulfur concrete and sulfur-modified bitumen. As Figure 4a shows, the complex pattern of the unmodified sulfur cake consists of sharp and intense peaks belonging to orthorhombic sulfur (S8), as well as some less intense reflections of calcium sulfate (CaSO4) and calcium carbonate (CaCO3). These peaks, especially those at d = 5.76 A, 4.89 A, and 3.57 A, point to a highly crystalline state of sulfur. Furthermore, the existence of secondary phases of CaSO4 and CaCO3 indicates the incomplete separation of impurities normally contained in the waste of sulfuric acid production. In addition to sulfur purity, these inorganic residues may create problems in the mechanical aspects through the poor brittleness and non-homogeneity of the final binder matrix [6].

Conversely, Figure 4b, representing the sulfur cake modified with oleic acid, demonstrates a cleaner and more refined crystalline. The peaks demonstrate the majority of sulfur with suppressed or reduced CaSO4 and CaCO3 signals. This further indicates a good surface passivation or a chemical reaction between the oleic acid and the calcium-based impurities by forming organo-calcium complexes that are either stable as amorphous structures or are removed in thermal processing. The incorporation of oleic acid, a long-chain unsaturated fatty acid, may have the effect of a surfactant or compatibilizer and improve the dispersion of the sulfur particles and minimize the agglomeration of the crystallites [54].

The structural simplification and higher purity observed in the XRD data can be attributed to the better performance of sulfur-based construction materials. The improved homogeneity and lower proportion of rigid crystalline impurities in sulfur concrete lead to improved thermal expansion compatibility and lower development of internal stresses, which is important to long-term durability in aggressive environments [55]. In the context of sulfur-modified bitumen, the inhibition of non-sulfur crystalline phases results in enhanced flexibility and adhesion, particularly when the modified sulfur is involved in crosslinking or co-polymerization during the mixing of the asphalt [56]. Moreover, the observed structural refinement is consistent with the wider endeavors in materials science to create polymeric or composite forms of sulfur with improved process ability and environmental performance [57]. Oleic acid modification is also a sustainable chemical approach to up-cycle sulfur waste, which complies with the principles of green chemistry, as it decreases the use of synthetic polymers and enhances the compatibility of sulfur binders in different infrastructure applications [58].

Inorganic stabilizers and fillers like fly ash, silica fume, and carbon-based materials further reinforce the structural integrity of sulfur composites. Fly ash, particularly at loading levels between 20 and 30 wt%, acts as a fine filler and pozzolanic agent, reducing the overall density while increasing compressive strength by more than 40%. The porous nature of fly ash particles also enhances the bonding and dispersion of sulfur, resulting in a more homogeneous and durable composite [46]. Silica fume, characterized by its high specific surface area and rich silicon dioxide content, refines the microstructure of sulfur binders and greatly improves their resistance to sulfate and sulfuric acid attack. Sulfur matrices blended with a combination of silica fume and fly ash have demonstrated a 50% increase in resistance to chemical degradation, making them particularly valuable in aggressive industrial and marine environments [47].

To further substantiate these advantages, a quantified performance comparison between modified sulfur cake (MSC)-based composites and traditional concretes is provided in Table 6. The data demonstrate that MSC-based systems incorporating fly ash and silica fume exhibit up to 45–60% higher acid resistance than ordinary Portland cement (OPC), and tensile strength improvements of approximately 25–30% compared to conventional asphalt binders [59,60]. Freeze–thaw stability is significantly enhanced in bitumen-modified sulfur concretes, with less than 5% mass loss after 100 cycles, as compared to 12–15% in standard concrete [61]. These improvements align with the findings of Stel’makh et al. [62] and Wang et al. [63], confirming the mechanical and chemical durability of the modified sulfur composites under aggressive environmental stressors.

Table 6.

Comparative performance of MSC-based composites and conventional materials.

Carbon additives (carbon black, graphite, and other carbonaceous fillers) serve as more than mechanical reinforcement because they also enhance the thermal conductivity and impermeability of sulfur composites. The additives minimize shrink and crack formation as the sample cools as well as improve the thermal efficiency of the final product. Also, carbon materials contribute to the immobilization of harmful elements located in the sulfur matrix reducing possible hazards to the environment related to leaching, particularly when utilizing wastes or otherwise recycled materials [48,49]. The synergetic mixture of organic and inorganic modifiers causes a sea change when it takes the lowly industrial byproduct of sulfur cake and produces a high performance, natural, durable, and sustainable construction material with superior strength and chemical resistance [65,66].

4. Technological Developments of Sulfur in Construction

4.1. Modified Sulfur Cake Concrete

The potential use of sulfur concrete technologies as a durable and sustainable alternative to conventional Portland cement concrete, particularly in infrastructure exposed to an aggressive environment, has garnered substantial attention. The main ingredient of the sulfur concrete is a molten thermoplastic binder with sulfur, that can be supplemented with other materials in the form of additives by way of improved performance of the composite made of the sulfur concrete and modified sulfur cake. Sulfur concrete commonly follows a mix design, utilizing binder to aggregate ratios of 1:3 to 1:5, depending on the required mechanical properties and usage. To place sulfur concrete’s mechanical and durability performance into perspective, a comparative review of various modified concretes is provided in Table 7. In addition to its mechanical and chemical advantages, sulfur concrete offers significant environmental benefits—most notably in reducing CO2 emissions. Unlike Portland cement, whose production is responsible for approximately 0.8–1 ton of CO2 per ton of cement due to limestone calcination and energy-intensive kiln operations, sulfur concrete requires no hydration reaction, no water, and no high-temperature clinker production [3]. The primary binder for elemental sulfur or modified sulfur cake is often a by-product of oil refining or gas desulfurization, representing a waste-to-resource approach that offsets industrial disposal needs while minimizing raw material extraction [1,4]. When sulfur is sourced from industrial residues like modified sulfur cake, the associated carbon footprint is further reduced, as the production process becomes a low-energy, circular economy model. Life-cycle analyses from the recent literature suggest that sulfur concrete can lead to 60–80% lower embodied CO2 emissions compared to ordinary Portland cement concrete, especially when manufactured and applied under ambient or mildly elevated temperatures [67].

Moreover, the rapid-setting and reusable nature of sulfur concrete contributes to reduced construction time and lower on-site energy consumption, supporting sustainable infrastructure goals [68]. These attributes make sulfur-based composites particularly promising for environmentally sensitive applications such as coastal structures, desert regions, and fast-deployable military or emergency infrastructure, where both durability and carbon efficiency are paramount [51,69]. This ratio is an important parameter to optimize because a higher sulfur content, in general, increases workability and chemical resistance, whereas excessive amounts of sulfur can discourage compressive strength because of decreased rigidity in the matrix [70].

Table 7.

Comparative analysis of sulfur concrete with other advance modified concrete types, detailing additive composition, properties, and durability.

Table 7.

Comparative analysis of sulfur concrete with other advance modified concrete types, detailing additive composition, properties, and durability.

| Concrete Type | Additive(s) | Additive Content | Compressive Strength MPa | Tensile/Flexural Strength MPs | Durability | Ref. |

|---|---|---|---|---|---|---|

| Sulfur concrete | Sulfur binder (100% replacement) | 100% of binder | 40–60 (24 h cure) | 3–8 flexural | High chemical resistance, very low water absorption (<0.05%), high acid/alkali resistance, excellent freeze–thaw stability | [68,71,72,73] |

| Fiber-reinforced | Steel/glass/polypropylene fibers | 0.5–2.5% vol | 35–70 | 5–12 tensile; up to 15 flexural | Enhanced toughness, crack control, impact and fatigue resistance | [74,75] |

| Polymer-modified | SBR, acrylics, epoxy, silanes | 5–20% by cement weight | 45–70 | 4–7 tensile; 7–12 flexural | Improved permeability, early strength gain, chemical/weather resistance | [76,77] |

| Fly ash concrete | Class F/C fly ash | 15–40% cement replacement | 35–60 (28–90 d) | 2.5–4.5 tensile | Long-term strength gain, Improved sulfate/chloride resistance; lower heat of hydration | [78,79] |

| Silica fume concrete | Amorphous SiO2 | 5–15% cement replacement | 60–90 | 5–8 (tensile), 9–14 (flexural) | Ultra-low permeability; enhanced early strength; ASR mitigation | [80,81] |

| Geopolymer concrete | Fly ash/GGBS + NaOH/Na2SiO3 activators | ~100% binder replacement | 40–80 | 4–6 tensile; 6–10 flexural | Excellent acid resistance, thermal stability >400 °C, 80% CO2 reduction | [43,67,82] |

Modified sulfur cake, containing elemental sulfur mixed with calcium hydroxide, calcium sulfate, and stabilizers, is a significant contributor to improving the structural matrix. Its formation will enhance a stronger bonding between aggregates and sulfur, decrease shrinking, and enhance chemical attack resistance of the matrix. Compressive strength gains of up to 25% have been recorded when conventional sulfur is substituted by modified sulfur cake at a ratio of 10–20 wt% of the binder because of a denser, more cohesive binder matrix [62]. In addition, the incorporation of fly ash and bitumen-modified sulfur along with the sulfur cake makes the pore structure more refined and increases the mechanical properties as well as thermal stability. The process of sulfur modification is not merely a physical dispersion of additives but involves chemical transformations, particularly when sulfur is heated with hydrocarbon-based stabilizers or additives like bitumen. These reactions include the formation of polysulfide chains, crosslinking networks, and sulfur–carbon bonding, which enhance the rheological behavior and stability of the final matrix. Recent studies confirm that sulfur-extended binders undergo significant chemical changes that affect curing behavior and long-term performance [83,84]. Moreover, the nano-structural evolution of aged and rejuvenated sulfur-modified binders demonstrates molecular interactions beyond simple blending, further proving the chemical nature of the modification process [85].

A response surface methodology (RSM) is used to optimize concrete of sulfur using micro- and macro-steel fiber-similar formulations. Findings indicate a 30–40% increase in tensile strength and up to a 45% increase in flexural strength when fiber was at optimum levels, between 1.0 and 1.5 vol% [86]. Additionally, sulfur concrete offers rapid setting times (less than one hour at ambient temperature) and can be fully cured within 24 h, enabling faster construction cycles [87].

Durability studies demonstrate that sulfur concrete exhibits excellent resistance to acids, salts, and freeze–thaw cycles, outperforming conventional concrete in long-term exposure tests [88]. In structural applications, sulfur concrete reinforced with rebar showed comparable load-bearing capacity and better corrosion resistance than ordinary concrete [89]. Furthermore, due to its recyclability, sulfur concrete can be re-melted and reused without significant loss of properties, contributing to circular construction practices [88,90]. The integration of modified sulfur cake into sulfur concrete technologies provides a balanced approach to improving matrix structure, mechanical performance, and environmental durability positioning it as a highly viable construction material for critical and corrosive environments.

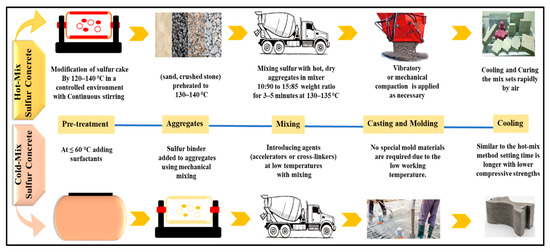

The production of sulfur concrete involves distinct techniques that significantly affect its mechanical properties, durability, and application scope. Both hot-mix and cold-mix sulfur concrete production techniques are commonly used, each with specific casting, molding, and curing protocols that influence final performance characteristics. Figure 5 provides the sequential steps involved in both hot-mix and cold-mix sulfur concrete production, highlighting differences in processing temperatures, mixing conditions, and curing methods.

Figure 5.

Hot-mix and cold-mix sulfur concrete production routes, process steps, and curing stages, with emphasis on operational differences in temperature and processing conditions.

The most commonly used method is noted to be hot-mix sulfur concrete, in which the element sulfur is pre-heated to 120–140 °C in order to obtain the molten phase and then mixed with the dry aggregates. In comparison, the dry mixing process is operationally simple and well-suited for field or precast applications; however, it may face limitations in terms of uniformity, especially if the sulfur is not adequately modified or pre-reacted. Alternatively, wet blending, where modified sulfur is pre-processed with organic stabilizers before mixing with aggregates, can improve homogeneity and long-term stability, but requires more controlled production conditions. Sulfur which is modified by the addition of stabilizers, such as dicyclopentadiene (DCPD) or sulfur cake, has been employed to minimize recrystallization and increase durability. After the hot sulfur concrete has been mixed well it is placed in molds. It also sets rapidly by cooling down without water-based curing, taking only 30 min to reach initial set, with full strength being reached in less than 24 h [91]. This makes it suitable for quick construction applications and is especially favorable for precast building parts and emergency subsidizing [92]. Optimally designed mixes and aggregate gradations enhance hot-mix sulfur concrete’s compressive strength to more than 50 MPa [93].

Cold-mix sulfur concrete, in contrast, uses lower manufacturing temperatures, typically below 60 °C, and uses pre-polymerized or emulsified sulfur. The technique is in the development stages and is not widely used because of the problems in obtaining the total polymerization and the homogeneity. The cold-mix method usually involves the utilization of chemical substances or mechanical agitation to mix sulfur-based binders with aggregates. Cold mixing consumes less energy and has fewer emissions but may have decreased compressive strength (usually <30 MPa) and setting time compared to hot-mix versions [94,95]. Cold-mix processes have the potential to use recycled material, like polluted soil or industrial waste [96], thereby aligning with sustainable construction practices.

Casting and molding are essential stages in both techniques. Hot-mix sulfur concrete requires molds capable of withstanding thermal shock and maintaining dimensional stability during rapid cooling [97]. Molds produced of metallic or thermally resistant polymer are desirable. Cold-mix concrete, conversely, can be poured into conventional molds, as applied in Portland cement. In both cures, the method of curing is not similar to the one used in conventional cement concrete. Sulfur concrete does not need water in the curing process; it will solidify through a physical cooling process. This removes any waiting times associated with curing as well as any risks of cracking due to moisture.

Recent advancements, such as automated contour crafting with sulfur concrete, have demonstrated the possibility of 3D printing large-scale structures in extraterrestrial environments, where water is scarce and rapid deployment is crucial [51,98]. Overall, hot-mix remains the most effective technique for producing high-performance sulfur concrete, while cold-mix is emerging as a sustainable alternative, with further research needed to optimize mechanical behavior and scalability [92,93].

Sulfur concrete exhibits distinct mechanical and durability advantages over traditional Portland cement concrete, especially in environments where water, chemicals, and temperature fluctuations are major concerns. Its thermoplastic nature allows rapid setting and curing, while modified sulfur formulations enhance mechanical integrity and long-term performance.

Compressive strength is one of the most notable attributes of sulfur concrete. Values typically range from 40 to 55 MPa for properly mixed hot-sulfur concrete, which is comparable to or even exceeds that of standard concrete mixes. Studies show that sulfur concrete with optimized aggregate gradation and modified sulfur binder can achieve a compressive strength of up to 60 MPa after just 24 h of curing [71]. Compared to traditional water-cured concrete, this represents a significant time and energy efficiency advantage [68]. Its tensile and flexural strengths, although lower than compressive strength as expected, can also be improved with the inclusion of additives such as fly ash, rubber crumb, or recycled aggregates. For instance, the addition of 10% waste tire crumb rubber resulted in an increase in tensile strength by 20% and flexural strength by 15% due to improved stress distribution and elasticity [73]. Shin et al. [72] also demonstrated that fly ash addition led to enhanced bond strength and reduced brittleness, increasing the flexural capacity of sulfur concrete up to 8.5 MPa.

Durability performance is where sulfur concrete outperforms conventional systems. Its water resistance is exceptionally high due to the hydrophobic nature of sulfur. Water absorption rates are typically below 0.05%, significantly lower than Portland cement concrete, which may absorb up to 5–10% water by mass [99]. This property directly contributes to improved freeze–thaw stability, as minimal internal water reduces cracking and scaling under cyclic freezing conditions [71]. Sulfur concrete also demonstrates superior acid and alkali resistance. In immersion tests in 5% sulfuric acid for 90 days, sulfur concrete showed less than 2% mass loss, compared to over 15% for ordinary concrete [72]. Modified sulfur concrete retained more than 90% of its compressive strength, even after a long-time exposure to both acidic and alkaline conditions, making it suitable for use in industrial floors, sewage, and marine infrastructure applications [69,100].

The material is also of superior chemical stability as well as aging resistance. In contrast to Portland cement concrete, which is still hydrating and reacting as time passes, the strength of sulfur concrete does not increase with subsequent cooling, and its durability remains virtually unaffected after years of exposure to aggressive environments [83,101]. These attributes make sulfur concrete a prime material for use in severe and aggressive construction environments.

4.2. Modified Sulfur Cake Bitumen Technologies

Modified sulfur cake has become a prospective additive in bitumen technology, having economic and performance-based benefits. Modified sulfur cake, which contains elemental sulfur combined with calcium compounds and other components, has proven to be rather promising as an alternative to the traditional way of using pure sulfur in the process of improving the properties of asphalt binders. Specifically, its addition to bitumen alters the chemical properties and rheology of the binder, enhancing binder performance with regard to softening point, viscosity, and age resistance [102]. Modified sulfur cake might be an affordable and effective method of enhancing the performance of asphalt binder. It has a better thermal resistance, higher mechanical stability and aging character, and a reasonable compatibility with blending compatibilities when employed in optimal proportions. This enhancement makes it a strategic additive to high-performance and sustainable asphalt pavement systems [102].

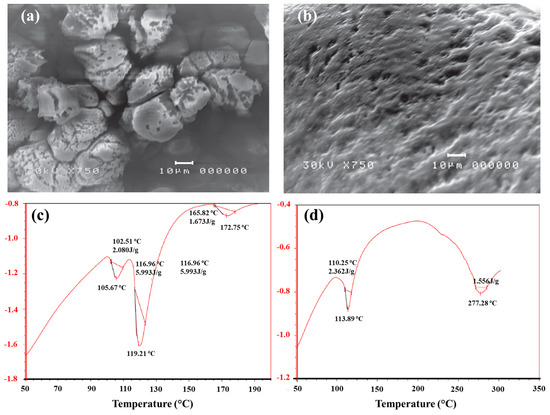

The SEM and DSC analyses in Figure 6a–d offer a critical understanding of the microstructural and thermal behavior of pure sulfur (Figure 6a,c) and modified sulfur (Figure 6b,d), the latter synthesized through a controlled oil bath procedure. This modification process involved blending 90 wt% molten sulfur with 10 wt% of a hydrocarbon mixture comprising 7% residual olefinic hydrocarbons and 3% bituminous residue at 145 °C for 3 h, followed by controlled cooling. These alterations are intended to improve the compatibility and performance of sulfur binders in construction materials.

Figure 6.

SEM and DSC analysis of sulfur-based materials: (a) SEM image of pure sulfur; (b) SEM image of modified sulfur cake; (c) DSC curve of pure sulfur; (d) DSC curve of modified sulfur cake. All images are reproduced from Souaya et al., 2015 [50], in their original form under the terms of the Creative Commons Attribution–NonCommercial–NoDerivatives 4.0 International License (CC BY-NC-ND 4.0).

The SEM image of a sample of pure sulfur (Figure 6a) displays a rough and crystalline structure and tightly fitted angularly shaped particles are observed, possessing clear and sharp boundaries and having observable micro-pores. This morphology is characteristic of pure elemental sulfur which crystallizes when cooled, and is itself brittle. All these microstructural characteristics are associated with low flexibility and mechanical integrations when sulfur is applied in concrete or bitumen directly [50]. Conversely, Figure 6b shows that the morphological surface pattern is significantly much smoother and more homogeneous in the altered sulfur. The particles are denser and smoother; their number of voids is smaller. This means that the increase in intermolecular contacts and the inhibition of the recrystallization of the sulfur are chemically stabilized under the effect of the olefinic hydrocarbons and the bitumen modification. Such an enhanced microstructure provides superior dispersion and bonding in concrete or asphalt matrices and finally, the resulting mechanical strength and durability are improved as well [14].

The DSC thermograms also explain the thermal transitions resulting from the modification process. In Figure 6c, pure sulfur shows the characteristic endothermic transitions around 119.2 °C and 165.8 °C, associated with the melting of orthorhombic S8 and a lower-intensity transition, possibly due to some polymerization or allotropic transformation of sulfur. This narrow thermal range highlights sulfur’s low thermal stability and its tendency toward recrystallization upon cooling [62].

However, in Figure 6d, the DSC curve of modified sulfur shows broader thermal transitions, extending up to 277 °C, with a reduced peak at 113.9 °C, and the emergence of a new thermal event at 250–277 °C. This indicates the formation of polymeric sulfur or sulfur–hydrocarbon copolymers with higher thermal stability and delayed crystallization, resulting from the prolonged reaction and chemical integration of hydrocarbon chains. Such thermal behavior is advantageous for infrastructure applications, as it ensures greater stability during mixing and laying operations in road construction and reduces the risk of thermal cracking [103].

The morphological and thermal enhancements observed validate the modified sulfur’s potential as a sustainable, high-performance alternative in sulfur concrete and sulfur-modified asphalt. The smoother matrix and improved thermal resistance lead to stronger adhesion, better compaction, and superior resistance to environmental degradation [104,105]. This modified binder aligns with current innovations in green infrastructure materials, offering a viable route for valorizing sulfur waste while enhancing mechanical performance and service life in demanding construction environments.

The primary role of modified sulfur in asphalt binders lies in its ability to act as a crosslinking agent, establishing molecular bridges between bitumen components. This crosslinking enhances the elastic recovery and stiffness of the asphalt, contributing to improved high-temperature performance and rutting resistance [106]. The Density Functional Theory (DFT) and macroscopic experimental investigations confirmed that sulfur atoms form stable S–S and C–S bonds within the binder matrix, strengthening its network and reducing phase separation [107]. The blending behavior and compatibility of sulfur cake with conventional bitumen are critical to achieving desired binder performance. Studies have shown that sulfur can be successfully blended at temperatures between 120 °C and 150 °C without significant segregation or exudation issues when properly formulated [108]. In hot mix asphalt production, sulfur content ranging from 10% to 40% by weight of the binder has been reported to be compatible, with 20% being the optimum for balancing workability and performance [109]. The presence of calcium hydroxide and calcium sulfate in the sulfur cake enhances the dispersion of sulfur within the bitumen matrix, acting as stabilizing agents and improving interfacial bonding [110].

The softening point of bitumen increases significantly with the inclusion of sulfur. For example, a base bitumen with a softening point of 48 °C can reach up to 61 °C after modification with 20% sulfur cake, indicating enhanced thermal resistance [111]. Similarly, penetration values decline, showing increased hardness, critical for high-temperature stability. Modified sulfur also increases binder viscosity, particularly at elevated temperatures, helping resist flow and deformation under load. At 135 °C, the viscosity of sulfur-modified bitumen rose from 0.35 Pa·s (neat bitumen) to 0.49 Pa·s with 20% sulfur addition [108]. Aging resistance is another critical factor improved by sulfur modification. Sulfur’s crosslinking reduces the volatilization of lighter components during thermal aging, leading to a lower aging index. The aging index based on dynamic shear rheometer (DSR) data dropped from 2.1 in unmodified bitumen to 1.5 in sulfur-modified samples after RTFO aging, indicating better durability [107]. Furthermore, the modified binder exhibits enhanced stiffness modulus and maintains viscoelastic properties under prolonged oxidative conditions. To more accurately quantify the high-temperature performance and viscoelastic behavior of sulfur-modified asphalt binders, dynamic shear rheometer (DSR) testing provides essential parameters. The complex shear modulus (G) and phase angle (δ) are key indicators in this context. For example, a 20% sulfur-modified binder exhibited a G value of 7.8 kPa and a phase angle of 62°, compared to 5.2 kPa and 68° for the neat binder at 64 °C [106,107]. These results reflect increased stiffness and reduced viscous deformation, which directly translate to improved rutting resistance under traffic loads. Such DSR-based metrics allow for reliable performance grading (PG) classification and ensure compliance with Superpave specifications, thereby supporting the engineering design of durable sulfur-modified pavements.

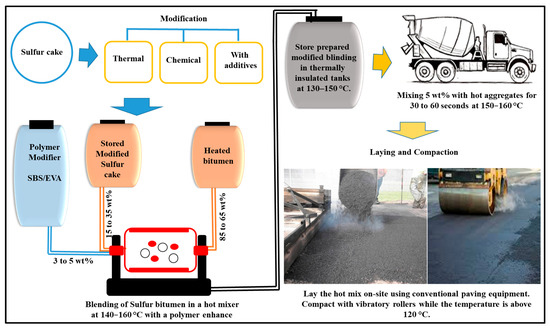

Sulfur-extended asphalt formulations (SEAF), particularly sulfur-extended hot mix asphalt (SEHMA), are gaining prominence in sustainable road construction due to their cost-effectiveness, improved performance characteristics, and integration of industrial by-products like modified sulfur cake. A step-by-step production procedure of modified sulfur–bitumen is presented in Figure 7. The design of SEHMA involves partially substituting conventional bitumen with elemental sulfur or sulfur-rich wastes such as modified sulfur cake, typically at levels ranging from 15% to 50% by binder weight. This substitution requires careful formulation to maintain optimal workability, moisture resistance, and mechanical integrity. Sulfur-modified mixes often employ compatibility enhancers such as poly-phosphoric acid or warm-mix additives to improve dispersion and interfacial bonding [112].

Figure 7.

Process steps of the sulfur cake use in sulfur modified bitumen production for road construction.

Field trials and laboratory-scale evaluations have validated the potential use of SEHMA in real-world applications. Pavements constructed with sulfur-extended binders demonstrate significantly enhanced rutting resistance, especially under heavy traffic and high-temperature conditions. For instance, rutting depth reductions of up to 45% have been observed compared to conventional asphalt mixtures, due to the stiffening and crystallization effects of sulfur within the binder matrix [113]. However, one of the key design challenges is managing moisture susceptibility, as sulfur can reduce the adhesive strength between binder and aggregate if not adequately stabilized. This issue has been addressed using lime treatment or blending agents to restore moisture resistance in SEHMA [114].

SEHMA offers compelling advantages. The substitution of expensive petroleum-based binders with low-cost industrial sulfur waste significantly reduces material costs. Field projects reported up to 30% savings in binder-related expenses, especially when sulfur is sourced locally [84]. Additionally, SEHMA supports the valorization of low-quality aggregates that would otherwise be unsuitable for use in standard asphalt, as sulfur helps enhance the load-distribution characteristics of the composite [115]. Overall, sulfur-extended asphalt formulations, particularly those utilizing modified sulfur cake, present a viable, scalable, and sustainable alternative for modern road infrastructure, with continued improvements being achieved through field validation and advanced binder chemistry [90].

The integration of modified sulfur cake into bitumen offers substantial environmental, mechanical and economic benefits, positioning it as a sustainable and high-performance alternative to conventional asphalt binders. The data in Table 8 supports the importance of the modified sulfur cake in construction. One of the most notable environmental advantages is the significant reduction in volatile organic compounds (VOC) emissions. During mixing and paving operations, traditional bitumen emits considerable amounts of harmful VOCs, which contribute to air pollution and health hazards. Modified sulfur cake lowers these emissions due to its partial replacement of petroleum-based constituents and its stabilization of the binder matrix. It has been demonstrated that VOC emissions can be minimized by up to 35% by the use of sulfur-based modifiers over unmodified binders [116,117]. Also, sulfur-modified binders allow the use of lower production temperatures, with energy savings of 10 to 20%, translating into both environmental and economic savings [118].

Table 8.

Critical comparative environmental, mechanical, and economic performance indicators of modified sulfur cake bitumen versus traditional petroleum-based binders.

Modified sulfur cake improves the durability of asphalt pavements by increasing resistance to rutting, fatigue, and thermal cracking. Sulfur addition enhances binder stiffness and elasticity, which helps in the provision of high rutting resistance when it is exposed to high temperatures and heavy traffic conditions. More than a 40% reduction in rutting depth of test tracks was realized when sulfur content increased to 20% in the combination of the binder [126]. Fatigue life is also increased by the enhanced flexibility and cohesive strength of the binder and in laboratory tests, 25–30% greater fatigue life has been recorded than with average mixtures [127]. Thermal cracking is a major issue in cold climates, which is mitigated by the improved low-temperature performance of sulfur-modified binders, maintaining the viscoelastic balance without embrittlement [128]. Overall, the use of modified sulfur cake in bitumen not only improves environmental metrics but also strengthens pavement longevity and performance reliability [105].

Using modified sulfur cake to produce bitumen offers large economic and environmental implications that will provide a holistic approach to addressing the issues of sustainability globally. Modified sulfur cake, which is a by-product of industrial wastes from processes like oil refining and sulfur scrubbing techniques, has been crucial in reducing the accumulation of harmful wastes and boosting economic circular activities. This strategy also aids in the implementation of resources, decreases the reliance on landfills, and enhances the reuse of assets between industries through the addition of sulfur-containing wastes to asphalt binder mixtures [121,123].

The modification and incorporation of sulfur cake in bitumen entails the valorization of a waste stream that would otherwise go unrealized in disposal into the environment. An example is the utilization of sulfur cake, potentially combined with calcium sulfate and other non-reactive products, which can lessen virgin bitumen consumption, an unrefined, fossil-based product with a large carbon footprint. This replacement directly helps the circular economy because a low-value output or even a harmful by-product that would have been discarded is now converted to a construction material [122]. Furthermore, sulfur cake can be mixed with other industrial wastes, e.g., steel slag or phosphogypsum, and form hybrids that enhance the performance of the binders even more and avert the waste of several by-products [124].

In a climate sense, the life-cycle effect of sulfur cake-modified bitumen is significantly reduced compared with conventional petroleum binders. The hot-mix asphalt production and paving procedure is energy-intensive and includes a high level of greenhouse gas (GHG) emissions. However, the sulfur cake that has been modified minimizes the temperatures required during processing by up to 20 °C and reduces the amount of fossil binder needed, which in turn reduces the emissions of GHGs by about 30 °C across the life cycle of the pavement [119]. Moreover, research shows that life cycle CO2 emissions can go down to below 250 kg CO2/ton of asphalt (sulfur-based binder) compared to 350 kg CO2/ton of asphalt (conventional); this is an absolute must towards achieving decarbonization goals in construction industries [120].

The cost analysis strongly favors modified sulfur cake binders, especially in regions where sulfur is readily available as a by-product. Bitumen is one of the most costly components in asphalt production, and replacing 20–50% of it with sulfur cake can lead to material cost savings of 15–25%, depending on regional sulfur availability and market conditions [129]. Furthermore, due to its enhanced thermal stability and aging resistance, sulfur-modified asphalt pavements often exhibit longer service life and reduced maintenance costs. This extended lifespan results in a lower life cycle cost (LCC), with reports suggesting that roads built with sulfur-modified binders can achieve 20–30% reductions in overall operational costs over a 20-year period [130]. Modified sulfur cake bitumen offers a compelling combination of environmental stewardship and economic viability. It addresses waste management challenges, reduces emissions and energy use, and lowers infrastructure costs, making it an ideal material for sustainable road construction aligned with global circular economy and climate objectives [121].

5. Challenges and Future Prospects

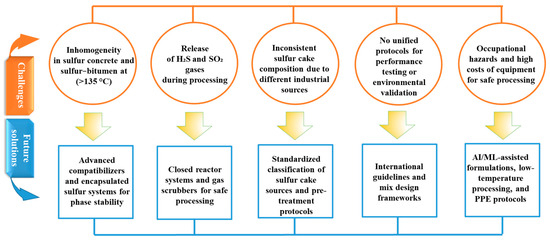

Modified sulfur cake concrete and bitumen technologies present promising advancements for sustainable infrastructure and road construction, while also accompanied by overlying limitations, challenges, and future perspectives that need to be studied to lead to effective usage in industries. A roadmap is presented in Figure 8, summarizing the major technological and environmental challenges in the utilization of modified sulfur cake for construction materials and their prospective solutions. Addressing these challenges through nanotechnology, process engineering, and regulatory frameworks will enable safer, scalable, and standardized applications of sulfur-based binders in sustainable infrastructure.

Figure 8.

Challenges and future prospects for modified sulfur cake utilization in construction materials.

The problem of stability and phase separation of the modified sulfur binders is a major restriction. Because of the complicated multi-phase nature sulfur cake is made up of, comprising elemental sulfur, calcium sulfate, calcium hydroxide, and other by-products, thermal processing tends to cause phases of separation as a result of higher temperatures (>135 °C). This deteriorates the uniformity of sulfur bitumen and sulfur–concrete composites, reduces their mechanical properties, and enhances the possibility of cracking or delamination of sulfur under cyclic loading [131]. For instance, SBS/sulfur-modified bitumen is found to be phase unstable in storage as an extreme result of sedimentation detectable after only 72 h of storage at elevated temperatures (160 °C) is observed unless compatibilizers are used [132]. This underlines the urgent need for more in-depth thermodynamic modeling of sulfur systems and molecular-level studies to better predict phase behavior. Future reviews and meta-analyses could comparatively assess compatibilizer effectiveness across formulations, which is currently lacking in the literature.

Health and safety issues are also a significant problem when processing sulfur cake in hot conditions both in bitumen melting and in concrete production. The thermal decomposition of sulfur above 160 °C may release toxic hydrogen sulfide (H2S) and sulfur dioxide (SO2) gases, posing significant occupational hazards and requiring advanced ventilation and gas scrubbing systems for safe large-scale deployment [133]. To mitigate these emissions, several strategies have been proposed, such as incorporating metal oxides (e.g., ZnO, CaO) or industrial alkaline fillers that can chemically absorb H2S/SO2 gases during processing. Additionally, pre-treatment of sulfur cake to remove ammonium salts and the use of multistage crystallization techniques, as described by Cheng et al. [133], can significantly reduce volatile emissions during thermal cycles. Moreover, the controlling of chemically modified residues especially those that contain ammonium salts or poly-sulfur species, requires strict temperature control and protective equipment, elevating high costs for industrial production [134].

Another limitation is the lack of standardization and scale-up mechanisms, which hinders the broader adoption of sulfur cake materials in infrastructure. Currently, no unified protocols exist for performance classification, long-term durability, or environmental impact assessment of sulfur-modified materials, which limits regulatory approval and cross-regional acceptance [135]. Furthermore, batch-to-batch variability in sulfur cake composition, especially in modified forms derived from flue gas desulfurization or coke treatment, leads to inconsistent curing behavior and workability [136]. Critically, many studies fail to directly compare sulfur cake from different industrial sources or analyze its variability quantitatively, which weakens the reliability of performance claims. A more systematic classification based on sulfur cake origin, composition, and thermal reactivity would enhance reproducibility across studies and enable better industrial integration.

Future prospects remain promising in spite of these challenges. Innovations in machine learning (ML)-driven formulation optimization, reactive compatibilizers, and encapsulated sulfur additives can enhance dispersion, reduce emissions, and prolong performance life [135,137]. Additionally, techno-economic studies suggest that utilizing waste sulfur cake can reduce binder cost by up to 30%, with CO2 emissions lowered by approximately 40 kg per ton of material compared to conventional Portland cement or asphalt binders [138]. These benefits align well with global climate and circular economy goals, provided that technical barriers and safety protocols are properly addressed.

To advance the practical implementation of the modified sulfur cake-based materials on infrastructure, a number of future directions and research needs are proposed. The development of modified sulfur cake technologies as viable and sustainable alternatives to use in contemporary construction will require a blend of material innovation, veracious field testing and backing of the regulatory system. One key source of attention is the use of nano/micro additives to address the shortfalls in performance, increase structural and environmental durability, and benefit both the sulfur concrete and the sulfur-modified bitumen. With the introduction of nano-carbonaceous materials—nano-silica, carbon nanotubes or cellulose nanocrystals—the mechanical strength, thermal stability, and water resistance of composites can be greatly improved. Specifically, cellulose nanocrystals enhanced the fatigue life and rutting resistance of bituminous mixtures by more than 25%, which shows promise in improving pavement life [104]. Similarly, nano-carbon addition increases the binder’s elastic recovery and reduces temperature susceptibility, essential characteristics for high-stress applications [139].

The combination of sulfur with polymers or geopolymers represents another transformative direction, for the enhancement of the performance. Sulfur–polymer hybrid binders, such as sulfur-styrene-butadiene or sulfur-polyethylene systems, not only mitigate phase separation but also improve elongation at break and enhance compatibility under dynamic loads. Recent studies reported an increase of 30–50% in tensile strength and improved softening point stability in a field simulation for sulfur-modified polymer binders [140]. Similarly, geopolymer–sulfur blends are being explored as low-carbon, alkali-activated alternatives, promising better early strength and chemical resistance, particularly for marine or industrial environments [141].

Despite these advances, few comparative performance studies have been conducted to rank these sulfur modification approaches under consistent environmental and loading conditions. The authors suggest that future research prioritizes the multi-parameter benchmarking (durability, cost, environmental impact) of polymer-, nano-, and geopolymer-based systems to determine optimal use cases. Long-term durability studies and field trials are critically needed to validate laboratory findings. To date, only limited field-scale evaluations exist for sulfur concrete or sulfur-modified asphalt binders. Nevertheless, preliminary U.S. Department of Transportation trials demonstrated that sulfur-extended asphalt (SEA) can reduce rutting depth by 20–30% over five years while maintaining serviceability in freeze–thaw conditions [142]. Multi-climatic and wide-traffic-load field trials should now be extended to various climates and traffic loads with the aid of multi-year monitoring programs.

Also, policy and regulation frameworks need to radically change to accommodate the industrial shift to sulfur-based technologies. The lack of a uniform way of testing systems that are modified with sulfur cake has left contractors and regulators uneasy at the moment. Adoption will be facilitated by the development of detailed guidelines on the design of mixes, safe handling, and environmentally friendly mixes. Integration into green building codes and sustainability benchmarks, especially for carbon footprint reductions of up to 40%, could incentivize broader use [143]. To aid this transition, new layered double hydroxide (LDH) additives have demonstrated the potential to reduce asphalt binder aging by 15%, which means that even greater improvements can be made as regulatory-supported innovation is embraced [144]. In summary, to transform modified sulfur cake from a promising idea to a market-ready material, future research should shift toward comparative frameworks, cross-sector pilot studies, and policy integration. A critical approach that combines material science innovation, environmental assessment, and economic modeling will be vital to achieve full-scale deployment.

6. Conclusions

Modified sulfur cake is an industrial by-product rich in elemental sulfur and calcium compounds, offering a promising, low-cost alternative to conventional construction binders, which aligns with economic, environmental, and performance demands. This review critically evaluated the recent advancements in the valorization of modified sulfur cake for sustainable construction purposes and its potential applications.

Through chemical/thermal treatment and the incorporation of organic and inorganic additives, sulfur cake can be transformed into a durable, water-resistant, and mechanically strong composite. Compressive strengths exceeding 40 MPa in concrete and substantial improvements in rutting resistance and thermal stability in asphalt binders have been reported. However, several challenges persist, including phase separation at elevated processing temperatures, toxic gas emissions during thermal treatment, and the variability of waste composition across different sources. Furthermore, the absence of standardized performance evaluation methods and comprehensive safety guidelines presents a barrier to its widespread utilization.

To address and find solutions for these limitations, further research efforts should prioritize the development of reactive compatibilizers, encapsulation strategies, and advanced nanostructured additives (e.g., CNTs, nano-silica) to enhance composite stability and long-term durability. Additionally, field trials under realistic environmental conditions are essential to validate laboratory findings and support the establishment of regulatory standards.