2. Overview of Shielding Approaches for Different Types of Radiation

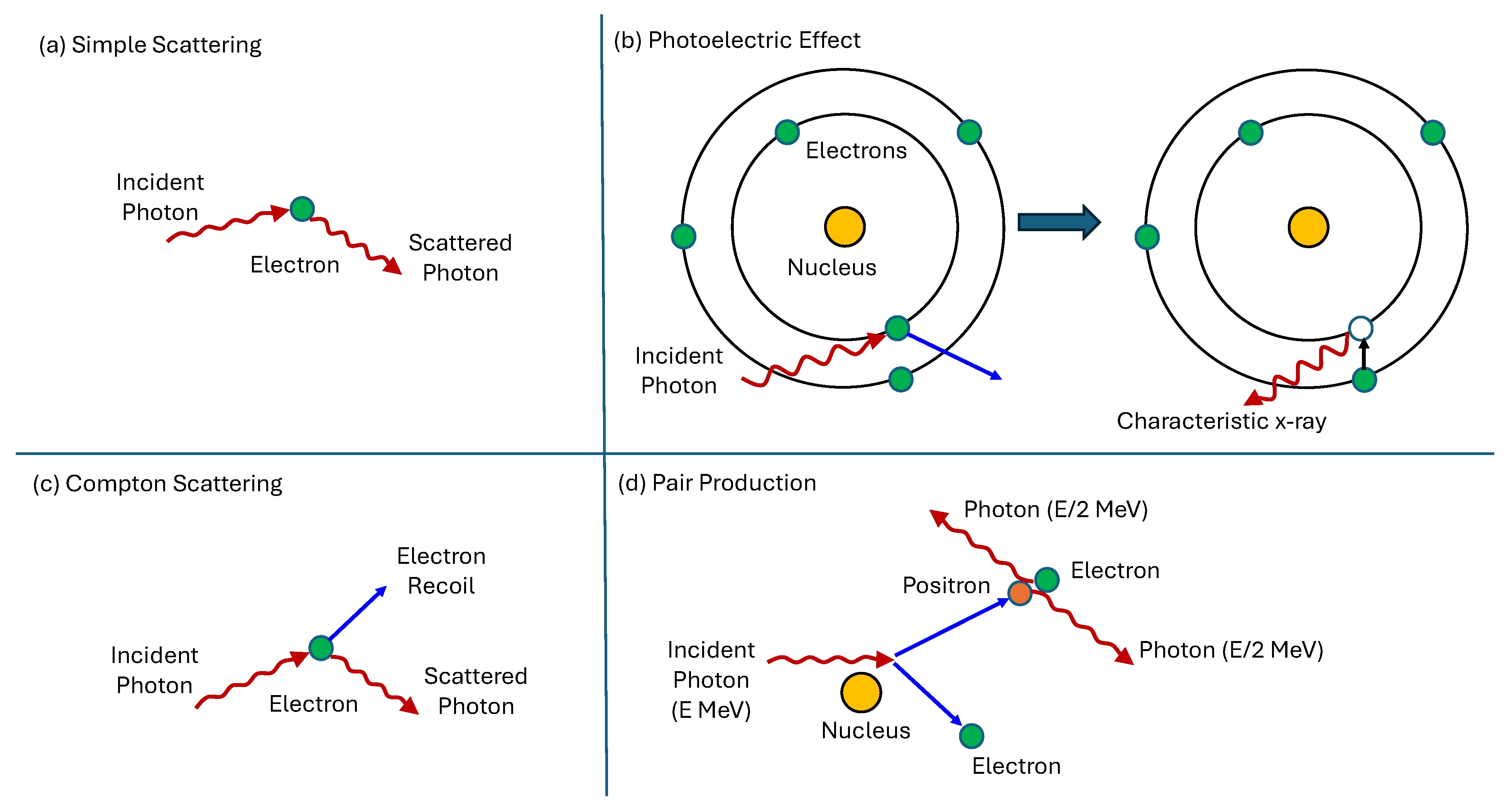

The primary mechanisms of radiation shielding are absorption and scattering, where the radiation interacts with the shielding material by either completely absorbing its energy or deflecting it by changing its direction, effectively reducing its intensity as it travels through the absorber. Radiation shielding primarily occurs through four types of interactions: (i) simple coherent scattering (low energy photons, no absorption), (ii) the photoelectric effect (dominant at low energies), (iii) Compton scattering (dominant at medium energies), and (iv) pair production (dominant at high energies). The interactions depend on the radiation energy and the material composition. Each process contributes to absorbing and deflecting radiation within a shielding material, effectively reducing its intensity by transferring energy to electrons within the material. Materials with high atomic numbers are generally better at shielding due to increased interaction probability with photons. The different mechanisms of X-ray and gamma ray shielding are illustrated in

Figure 1 and described briefly next [

5,

9,

13,

25,

29].

In simple coherent scattering (

Figure 1a), the photon has lower energy than the minimum energy needed to release an electron. Thus, the photon simply scatters, changing its direction, without losing energy. Higher energy (gamma) radiation ionizes atoms through three processes.

The first process is the photoelectric effect (

Figure 1b). This involves the complete absorption of the photon by an electron causing a secondary electron called a photoelectron to be ejected from the atom. The incoming photon is completely absorbed by an inner shell electron of an atom. This causes the electron to gain enough energy (excluding the binding energy) to escape from its orbit. The free photoelectron will ionize, excite, and produce bremsstrahlung radiation, which is an X-ray photon as it deposits energy along its path in the absorber until it stops. The kinetic energy of the photoelectron is equal to the energy of the incident gamma photon minus the binding energy that held the electron to the atom. The photoelectric effect is the main energy-transfer mechanism for X-ray and gamma ray photons with low energy, below 50 keV.

The second process is Compton scattering (

Figure 1c). This involves a collision between an incoming photon and an absorber electron in which some of the photon energy is shared with the electron. After the collision, the photon will have less energy and scatters in an arbitrary direction while the electron gains energy and scatters only in the forward direction. The scattered electron will ionize, excite, and produce bremsstrahlung in the absorber until it comes to rest. In Compton scattering, the incident gamma photon shares a fraction of its energy with an outer bound or free electron and is scattered at some direction from its original direction. Compton scattering is considered to be the principal absorption mechanism for gamma rays in the middle energy range 100 keV to 10 MeV. Compton scattering depends on the atomic number of the absorbing material.

The third process is pair production (

Figure 1d). Interactions of photons with energy greater than 1.02 MeV in an absorber may result in the annihilation of the photon producing a positive and negative electron each with half the energy of the photon. The positive and negative electrons will ionize, excite, and produce bremsstrahlung in the absorber until they stop. Following pair production, when the positron comes to rest in the absorber, it will annihilate with a free electron producing two 0.511 MeV photons that travel in opposite directions,

Figure 1d. These two photons will also ionize, excite, and produce bremsstrahlung in the absorber. Pair production mainly occurs at energies greater than 5 MeV. In pair production, the incident photon interacts with the electric field of a nucleus. The energy of the incident photon is converted into the mass of an electron–positron pair. Gamma ray energy greater than the equivalent rest mass of the two particles appears as the kinetic energy of the pair and in the recoil of the emitting nucleus. This interaction mechanism suggests that in the design of nanocomposites, the nano-particles should be distributed to maximize the probability that the incident photons would interact with the nucleus of the atoms in the nanoparticles. At the end of the positron’s range, it combines with a free electron. The two annihilate, and their entire mass is then converted into two gamma photons of 0.51 MeV each or higher energy depending on the kinetic energy of the annihilated particles. This suggests the use of a matrix material in a nanocomposite that can intercept secondary radiation. The secondary electrons or positrons produced in any of these three processes frequently have enough energy to produce ionization themselves.

Another effect is that gamma rays having energy generally in the range of 10 MeV or higher may cause the target atom to undergo photodisintegration where a nucleus absorbs a high-energy gamma ray and ejects subatomic particles such as a proton, neutron, or alpha particle. In some cases, photofission also occurs where a nucleus splits into two nearly equal fragments after absorbing a photon. Although photodisintegration can attenuate radiation, it also produces secondary radiation such as neutrons or protons that need to be shielded in materials prone to this reaction.

Lead (Pb) and other heavy metals have traditionally been used for radiation shielding in industries such as healthcare, aerospace, defense, and nuclear energy [

32,

33]. However, due to its toxicity, lead can cause several health problems, including cancer, slowed growth, memory loss, and learning disabilities [

32,

33,

34]. Lead is also heavy, which is a limitation for many applications, especially for use in space travel. Consequently, developing suitable materials that can effectively absorb radiation to replace lead is crucial. For optimal radiation protection, shielding designs often incorporate multiple layers of materials to effectively attenuate radiation across a range of energy.

Scientists and engineers have been extensively investigating various alternatives to lead for radiation shielding. As an illustration, polydimethylsiloxane (PDMS), a versatile polymer composed mainly of silicon, oxygen, and carbon, has been widely considered in studies of radiation-shielding composites. PDMS has excellent physical properties such as resistance to heat, moisture, and chemicals, along with flexibility, transparency, stability, biocompatibility, and non-toxicity [

35,

36,

37,

38,

39]. An introduction explaining various approaches to shielding different types of radiation is given below.

According to Li et al. [

35], dispersing nanocomposites of single-walled carbon nanotubes (SWCNTs) in PDMS can enhance proton shielding. When tested under monoenergetic proton beams, the combination of PDMS and SWCNTs was lower in weight compared to adding other materials like aluminum (Al) to achieve the same proton-stopping capability. These findings indicated that the shielding properties of PDMS at high proton energies can be significantly improved by incorporating SWCNTs. This advancement holds substantial potential in the aerospace industry, where effective space radiation shielding and aircraft weight reduction are critical research areas.

Similarly, Cha et al. [

40] proposed a composite shield material system consisting of ultra-high molecular weight polyethylene (UHMWPE) combined with a hydrogen-rich benzoxazine composite. This structure was coated with polydopamine, and carbon nanotubes (CNTs) were grafted onto the composite. This innovative design was claimed to reduce cosmic radiation by approximately 16% compared to the glass-fiber reinforced plastics currently in use, while also offering weight savings of about 22%.

Zaman et al. [

41] proposed the idea of using a passive shield of Kevlar or water-soaked hygienic wipes to shield various types of space radiation. Using Monte Carlo simulations, they found that water-soaked hygienic wipes have better shielding effectiveness.

Choi et al. [

42] described the use of a cobalt-coated aramid fiber epoxy composite to create a stealth satellite shield for microwaves with excellent attenuation in the X-band (8.2–12.4 GHz).

Shang et al. [

43] reported excellent thermal conductivity and neutron attenuation, with about 4% of incident rays transmitted, achieved using alternating layers of low-density polyethylene and high-density polyethylene with a Hexagonal Boron Nitride additive for neutron shielding.

Mhareb et al. [

44] found that a ceramic compound, (YBa

2Cu

3Oy) doped with perovskite oxides, performed well as a ceramic alternative for radiation shielding.

Güngör et al. [

45] prepared different samples of Hexagonal Boron Nitride (hBN) within an Ethylene Propylene Diene Terpolymer (EPDM) matrix to evaluate shielding for thermal neutrons. They found that adding hBN particles to the EPDM matrix improved neutron shielding. An 8 mm-thick hBN sample containing 40%

w/

w boron (HBN40) absorbed up to 61.5% of thermal neutrons. They concluded that boron and boron-based composite materials are effective for neutron shielding.

Wilhelm and Jovanovic [

46] investigated the statistical use of the Compton scattering effect for gamma-ray spectroscopy and successfully demonstrated their new technique. Compton scattering occurs when a photon collides with an absorber electron and shares a fraction of its kinetic energy with the electron. This is different than photoelectric interaction in an absorber, where the original photon completely disappears and its energy is completely absorbed by a bound absorber election.

Daly and colleagues [

47] investigated the use of the bacteria Deinococcus radiodurans for attenuation. They found that this bacterium contained Mn

2+ ions within its filtrate, which protected its proteins from up to 50,000 Gray (Gy) of radiation. According to Daly, this amount of energy can destroy DNA. The Mn

2+ metabolite complex of this bacteria also protected human Jurkat T cells and

Escherichia coli from ionizing radiation.

Shruti Nambiar and TW Yeow [

48] showed that several factors must be considered in designing materials for radiation shielding, including the type of radiation (photons, charged particles, or neutrons), range of energies involved, dose amount, exposure time, conformability, affordability, permanence, toxicity, and weight. They also suggest that reinforcing polymers with micro and nanomaterials such as boron, metal oxides, and graphitic fibers can effectively shield radiation.

2.1. Design of Radiation-Shielding Materials

Radiation shielding design depends on the frequency of the radiation [

5,

13,

29]. Generally, two types of shielding are considered, lower-frequency electromagnetic non-ionizing radiation and higher-frequency ionizing radiation. Carbon nanotube hybrid fabric with nanoparticles can be designed for shielding each type of radiation. Electromagnetic waves in microwave radiation are considered first.

When microwave radiation contacts an electrically conductive shielding material, the radiation can be reflected, absorbed, or attenuated as illustrated in

Figure 2. Reflection occurs when most of the wave energy is initially reflected at the interface between the air and the shielding material depending on the material’s conductivity and impedance mismatch. Microwave radiation can propagate within the absorber, undergo multiple internal reflections, and be completely absorbed. Free electrons in the conductive shielding material can interact with the electric field of the wave, partly blocking its propagation beyond a shallow depth called the skin depth. The wave energy is absorbed by the material through the generation of eddy currents, converting the electromagnetic energy into heat. Eddy currents create their own magnetic fields, which can oppose the original magnetic field, thereby reducing the overall electromagnetic interference. They also lead to energy losses due to heating the shielding material.

Radiation of the second type includes X-ray and gamma rays, which are photons having wavelengths on the atomic scale [

13]. The atomic cross-section of the atom defines the probability of photon interaction, as per the processes shown in

Figure 1. A high electron density material is needed to shield gamma rays.

2.2. Why CNT–Nanoparticle Materials Need to Be Considered for Radiation Shielding

Materials for radiation attenuation are often formed as hybrid or composite materials [

38,

39,

40,

41,

42,

43]. Metal powders such as lead, tin, and bismuth can be mixed with poly(vinyl chloride) or CNT fabric to create a flexible matrix, which can then be cut into different shapes and layered to make protective clothing. CNT-based textiles can be good alternatives to conventional shielding approaches. Incorporating heavy metals like bismuth, zinc, iron, gadolinium, or tungsten can enhance the shielding performance of carbon nanostructures, as suggested by different studies.

Materials can be custom designed to maximize the attenuation or transmission loss of incoming waves. Shielding is important because radiation wave transmission can cause harmful health impacts [

5] and interfere with or damage electronic equipment. Additionally, wave reflection could reveal the location of a defense system. CNTs have emerged as compelling candidates for radiation shielding due to their excellent physical, mechanical, and chemical properties. Nanostructured materials such as CNTs are good candidates for radiation shielding because their nanostructure or nanoparticle size approaches the wavelength of waves like microwaves. Also, the compact, thin-layer hexagonal structure of CNTs with incorporated nanomaterials increases the likelihood of interactions with photons as they pass through the material.

Hybrid CNT materials are a convergence of diverse materials, including polymers, metals, and ceramics, with CNTs. This combination leverages the synergistic properties of the different materials to enhance radiation attenuation performance. CNT hybrid fabrics, known for their excellent mechanical properties, are being explored as innovative materials for photon attenuation in radiation-shielding applications. These fabrics are created through various techniques like weaving and knitting. Non-woven fabric can also be formed. Embedding CNTs into polymer matrices can provide good electromagnetic interference (EMI) shielding capabilities, which is crucial for protecting electronic devices. However, challenges such as enhancing CNT dispersion within polymers, optimizing production for scalability, and assessing long-term material stability under radiation remain.

3. CNT-Based Materials for X-Ray and Gamma Ray Attenuation

CNTs are cylindrical nanoscale tubes with carbon atoms arranged in a hexagonal lattice. CNTs in a powdered form are added to polymers to increase their radiation shielding. However, individual CNTs can also be assembled using different methods to form fabric. CNT-based fabrics have gained significant attention for their potential use in lightweight flexible radiation-protection materials due to their high toughness-to-weight ratio, good electrical and thermal conductivity, low density, and, depending upon the composition and additives, their ability to attenuate radiation through mechanisms such as electrical conductivity, photoelectric absorption, and Compton scattering [

49]. The lightweight carbon composition of CNTs provides moderate specific shielding effectiveness against ionizing radiation, including X-rays and gamma rays, making them valuable for the development of efficient shielding and attenuating materials [

49]. The addition of boron or cadmium to CNT fabric is especially effective for neutrons. The alignment and resin impregnation of CNT-based fabrics can enhance shielding properties [

50]. Studies conducted by Zhang et al. [

50], Zhu et al. [

51], and Abdeldaym et al. [

52] provide a comprehensive summary of the advancements in using CNT-based materials for gamma-ray shielding. Their collective work underscores the significant potential of CNT films in developing efficient and lightweight radiation-shielding solutions.

Zhang et al. [

50] evaluated the effectiveness of CNT films against radiation emissions from Americium-241 (

241Am) and Caesium-137 (

137Cs) by assessing the mass attenuation coefficients of CNT film samples. Their systematic experimental characterization and comparative analysis with other materials provided valuable insights into the potential of CNTs for gamma-ray shielding. The findings from Zhang et al. demonstrated that CNT films could outperform certain common metals, such as aluminum, for gamma-ray shielding under specific conditions. Their research also suggested that the alignment and resin impregnation of CNT films could further enhance shielding performance. Comparisons with carbon fiber-reinforced composites and metals highlighted the potential of CNT films combined with nanoparticles for lightweight and efficient gamma-ray shielding, pointing out the importance of structural optimization to maximize this potential. The studies advocate for further research into structural optimization and enhancement techniques to fully realize their benefits.

Zhu et al. [

51] investigated the shielding properties of CNT films exposed to gamma-ray irradiation from a Cobalt-60 (

60Co) source in both air and vacuum environments. Their research focused on isolating and studying the effects of gamma-ray irradiation on individual components of CNT field-effect transistors (FETs) using controlled experimental methods. The study highlighted the relative vulnerability of the SiO

2 substrate compared to the CNT film and the gate oxide layer. Their findings indicate that CNT films not only possess radiation-hardened properties but also shield the underlying SiO

2 substrate from radiation exposure. This research sheds light on the differential effects of radiation on various components of CNT-based electronics, emphasizing the protective capabilities of CNT films in radiation-rich environments.

Abdeldaym et al. [

52] investigated the potential of natural rubber latex (NRL) reinforced with multi-walled carbon nanotubes (MWCNTs) for attenuating gamma rays emitted from Cobalt-60 sources. Employing a comprehensive approach, they used various characterization techniques, including scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and gamma radiation shielding tests, to evaluate the properties of MWCNT-reinforced NRL nanocomposites. Their observations revealed a positive correlation between MWCNT loading and the effectiveness of gamma radiation shielding in NRL composites. This enhancement in shielding properties suggests that incorporating MWCNTs into NRL significantly improves its suitability for radiation shielding applications. These findings are consistent with previous research demonstrating the effectiveness of carbon-based materials, such as CNTs, in enhancing the radiation shielding capabilities of polymer composites. CNTs often contain a significant weight fraction (up to 20%) of iron catalyst depending on the synthesis method. The iron contributes to the shielding effect of CNT materials.

CNT can be used for both EMI and higher energy radiation shielding [

53,

54,

55,

56]. Fujimori, Toshihiko et al. [

57] conducted X-ray attenuation experiments using various carbon-based nanomaterials, including single-wall carbon nanotubes (SWCNTs), multi-wall carbon nanotubes (MWCNTs), single-wall carbon nanohorns (SWCNHs), fullerenes (C60), graphene oxide (GO), and a fabric-textile coated with MWCNTs. These materials were compared with highly oriented pyrolytic graphite (HOPG). The study found that CNTs and CNT-coated fabrics efficiently absorb X-rays, with the attenuation coefficient of CNTs increasing as the sample thickness decreased. Their experiments produced results suggesting that CNT materials can be used to produce efficient and lightweight X-ray safety equipment and devices. The study also reported unexpectedly high X-ray attenuation in CNTs, with the mass attenuation coefficient of CNTs being 20–50% greater than that of HOPG and fullerenes. This increased attenuation was attributed to the nanoscale morphology of CNTs, which traditional absorption theory does not account for. Additionally, coating a textile fabric with CNTs resulted in enhanced X-ray attenuation of 70% for a textile thickness of 25 mm. The researchers proposed that the high shielding effect of CNTs could be due to their small size and cylindrical morphology. However, this conjecture needs further study to validate. Furthermore, the study considered the catalyst impurities in CNTs, which may have improved the attenuation properties. CNTs synthesized using the floating catalyst method can contain about 20 wt% of Fe catalyst, and intentionally adding impurities could enhance the attenuation properties of CNT-based sheets. This finding highlights the potential for using CNT materials in the fabrication of lightweight and efficient X-ray safety equipment and devices.

4. CNT-Based Materials for Electromagnetic Interference (EMI) Shielding

CNTs are being extensively developed for EMI shielding and a large volume of literature is available.

Figure 2 depicts an electromagnetic wave approaching a conductive shielding material, with the primary mechanisms of EMI shielding labeled: reflection (or multiple reflections) and absorption. Many different research efforts have explored the use of CNT films for electromagnetic shielding, with studies demonstrating the effectiveness of incorporating multi-wall carbon nanotubes (MWCNTs) into composites to enhance electrical conductivity and achieve high shielding effectiveness [

52,

53,

54,

55]. Studies conducted by Lai et al. [

54], Çakmakçı et al. [

55], Lan et al. [

53], and Chauhan et al. [

56] provide a representative summary of the advancements in the EMI-shielding effectiveness of CNT-based composites. Lai et al. [

54] investigated the use of MWCNTs in conjunction with polypropylene (PP) to fabricate conductive textiles with enhanced shielding effectiveness against electromagnetic waves. They evaluated the mechanical properties, surface resistivity, and electromagnetic shielding effectiveness (EMSE) of their PP/MWCNT-coated yarns and woven fabrics through a series of standardized testing methods, including ASTM standards for tensile testing and JIS standards for surface resistivity measurements. Their research examined the influence of the MWCNT content and processing parameters on the mechanical properties, electrical conductivity, and EMSE of PP/MWCNT composites. The findings suggest that incorporating MWCNTs enhances both the mechanical strength and electrical conductivity, with an optimal MWCNT content of 5 wt%. Additionally, the study highlights the significance of processing parameters such as the coiling speed and lamination angle in achieving optimal EMSE. This comprehensive evaluation underscores the potential of PP/MWCNT composites in developing advanced conductive textiles for effective electromagnetic shielding.

Çakmakçı et al. [

55] specifically examined how the addition of ferrite nanoparticles to CNT films could improve their efficiency in attenuating electromagnetic waves across a broad frequency range. They employed a straightforward and scalable process for synthesizing ferrite-decorated CNT films, enhancing their potential for practical applications. Techniques including scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and electromagnetic interference shielding effectiveness (EMI SE) were used to characterize the structural and shielding properties of the fabricated films. Ferrite-decorated CNT films provided higher EMI-shielding effectiveness than pristine CNT films. The high electrical conductivity of CNTs and the magnetic properties of ferrite nanoparticles led to the improved absorption and reflection of electromagnetic waves. Their research highlights the potential of composite films for use in advanced electromagnetic shielding applications.

Lan et al. [

53] evaluated the effectiveness of high-loading CNT/poly(allylamine hydrochloride) (PAH) nanocomposite coatings applied to fabrics for electromagnetic interference (EMI) shielding. They implemented a capillarity-assisted assembly technique to fabricate these coatings, offering precise control over CNT deposition and orientation on the fabric substrate. This method allowed for significantly increased CNT loading while maintaining the softness and flexibility of the fabric. Their findings demonstrated that high-loading CNT/PAH nanocomposite coatings exhibited promising EMI-shielding effectiveness, blocking up to 92% of incident electromagnetic radiation, while preserving the material flexibility, softness, and air permeability. However, the study also identified potential challenges in scaling up the fabrication process for industrial applications and emphasized the need for further optimization for different fabric types and thicknesses as areas for future research. This work highlights the potential of capillarity-assisted assembly techniques in developing effective and practical EMI-shielding fabrics.

Chauhan et al. [

56] conducted a study on the shielding properties of free-standing polymer/MWCNT composite thin films, contributing valuable insights into the potential applications of CNT films for EMI shielding. Their extensive investigation included both thermal conductivity and EMI-shielding effectiveness, providing a holistic understanding of the composite thin films’ properties. The use of a simple casting method for film fabrication enhanced the practicality of these composites for real-world applications. However, the researchers acknowledged potential variations in film thickness during casting and emphasized the need for further characterization techniques to fully elucidate the microstructure and interfacial properties of the composite films. Their findings suggest that these films exhibit tunable thermal conductivity and excellent EMI-shielding effectiveness due to the formation of a well-connected MWCNT network within the polymer matrix. The study emphasizes the scalability of the production methods and the multifunctionality of the composite films, highlighting their potential for customized thermal management and EMI-shielding solutions in industries such as aerospace, automotive, and telecommunications. The ability to tailor the thermal and shielding properties of these films makes them promising candidates for a wide range of advanced technological applications.

Sousa et al. [

58] demonstrated that coating knitted cotton textile substrates with multi-walled carbon nanotubes and graphene nanoplatelets (GNPs) through the Dip-Pad-Dry process resulted in higher EMI shielding. They concluded that the thickness and electrical properties of the EMI shield correlate with the shielding process, particularly absorption. In 2011, Wu, Zi Ping, et al. [

59] investigated the EMI-shielding effectiveness of CNT macro-films. They showed that a 4 µm-thick CNT macro-film achieved EMI shielding effectiveness of 61 to 67 dB, indicating that CNT macro-films can be used for EMI-shielding materials. Furthermore, adding iron particles to the CNT bundles can further enhance EMI-shielding effectiveness.

Adding metal ions to the ends of CNTs in a film can enhance radiation attenuation [

60]. According to Stafiej, copper ions bind to CNTs more effectively than other metal ions, with lead being the second-best. Shaaban [

61] found that copper, when bound to borate zinc-fluoride glasses, increases radiation protection. However, more research is needed to understand how different metal ions affect the attenuation coefficient of CNT film material. Polymer shielding has also been extensively investigated as a method of radiation attenuation. Polymers are cheap, flexible, and durable. Abualroos and colleagues [

62] showed that incorporating different elements into a polymer matrix increases radiation attenuation. Combining polymers with metal particles and CNTs can improve the shielding properties of films. For example, polymers with fillers such as bismuth oxide can provide customizable attenuation, with elements of higher atomic numbers typically used as fillers.

Different studies by Li et al., Hu et al., Liu et al., and Fang et al. [

63,

64,

65,

66] have established that CNT materials can be tailored to address specific challenges in radiation attenuation and EMI shielding. Each hybrid CNT material possesses unique properties, ranging from high thermal conductivity and EMI-shielding effectiveness to flexibility and lightweight construction. In today’s electronics landscape, where integration and miniaturization are key, hybrid nanofibrillated cellulose/Fe

3O

4+CNT/polyethylene oxide (NFC/Fe

3O

4+CNT/PEO) films have gained attention. These films boast flexibility and toughness due to their unique multilayered structures, offering robust radiation shielding and effective heat dissipation. Similarly, the integration of silver (Ag) and magnetic carbon nanotubes (mCNTs) onto PP fabrics marks a significant leap in flexible EMI shielding. These lightweight coatings, applied through a simple spray deposition technique, provide reliable shielding for flexible electronics. Incorporating magnetic nanoparticles and metal porphyrins shows promise in enhancing electromagnetic-wave-absorption capabilities, driving the development of advanced EM-shielding materials. Investigations into MXenes and carbon-based materials also reveal their potential in advancing EM-shielding and energy-storage applications. These innovations expand the use of CNTs beyond traditional metal-based shielding materials, offering a versatile, corrosion-resistant solution with broad industrial potential. This analysis highlights the impact of these materials on modern electronics, enabling future advancements.

Li et al. [

65] highlight the growing concern about electromagnetic radiation pollution due to the rise of wireless communication and electronic devices, which pose risks to both devices and human health. This has led to an increased demand for efficient EMI-shielding materials. While traditional metals provide satisfactory EMI-shielding effectiveness (SE), they suffer from issues such as corrosion, high density, and lack of flexibility. Conductive polymeric composites are promising alternatives, offering advantages like processability, elasticity, low cost, corrosion resistance, and lightweight properties. Since polymers are inherently nonmagnetic and insulative, they require conductive fillers to establish effective EMI-shielding networks. Various fillers, including metal powders, nanowires, graphene, CNTs, carbon nanofibers, and conductive ceramics, have been investigated to enhance EMI-shielding performance. Hybrids like graphene-carbon nanotubes and MXene-based composites show significant improvements in EMI-shielding effectiveness. Different structural architectures, such as multilayered, segregated, gradient, and foam structures, optimize the EMI-shielding performance. Foam structures enhance EMI shielding through high porosity, while layer-by-layer sandwich structures yield lightweight, and flexible EMI-shielding materials.

Li et al. also introduced a novel approach for fabricating flexible multilayered films for EMI shielding. These films consist of alternating layers of nanofibrillated cellulose (NFC)/Fe3O4 and CNT/polyethylene oxide (PEO), offering excellent electrical and thermal conductivity and outstanding EMI-shielding effectiveness. The inclusion of magnetic Fe3O4 particles further enhances EMI shielding. These films have improved toughness compared to pure NFC films, making them suitable for applications in the communication industry, portable electronics, and robot joints. The materials used in the study by Li et al. include NFC, ferro-ferric oxide (Fe3O4), MWCNT, polyethylene oxide (PEO), and deionized water. The films were fabricated through a layer-by-layer self-assembly process under alternating vacuum filtration (AVF). Characterization techniques included scanning electron microscopy (SEM), energy-dispersive spectrum (EDS) mappings, X-ray diffractometer (XRD) analysis, and an investigation of EMI- SE using a vector network analyzer (VNA). Mechanical properties were tested using a universal testing machine. The films demonstrated high electrical conductivity and outstanding EMI-shielding properties, surpassing single CNT/PEO films. Theoretical calculations suggested that both absorption and reflection mechanisms contributed to EMI shielding, with a dominant reflection mechanism observed. The films had high in-plane thermal conductivity and improved mechanical properties with an increasing layer number, making them suitable for flexible and wearable electronic devices. An EMI-shielding application showcased the films’ effectiveness in blocking electromagnetic wave transmission. This study underscores the potential of multilayered films for various modern electronics applications, particularly in fields requiring flexible materials with superior EMI-shielding capabilities and thermal conductivity.

Hu and Kang [

64] discuss how the evolution of stretchable electronics has introduced new demands for flexible EMI-shielding materials. These materials need to be effective, lightweight, flexible, and stable to meet the needs of next-generation electronic devices. Among the materials used for EMI shielding, conductive polymer fabric composites (CPFCs) have gained attention due to their cost-effectiveness, light weight, ease of fabrication, high tensile strength, and dimensional stability. CPFCs are typically fabricated by depositing conductive fillers onto flexible polymer fabric. Polypropylene (PP) fabric, known for its recyclability and economic benefits, aligns well with the requirements of flexible polymer fabric due to its lightweight, and good tensile properties, and chemical resistance. Silver, with its exceptional electrical properties, mechanical robustness, and chemical stability, has emerged as a favored conductive filler for CPFCs. Hu and Kang highlight that integrating silver nanoparticles onto substrates like polyacrylonitrile (PAN) nanofibers via wet electroless deposition or onto cotton fibers via electroless deposition has yielded flexible and highly effective EMI-shielding materials. Nevertheless, inherent gaps between silver particles within a single layer can interrupt the continuity of the conductive network structure. To overcome this, high-conductivity nano-fillers such as CNTs and graphene (GP) are introduced to bridge the gaps and also to enhance conductivity. Thus, silver nanostructures/CNT composites are promising candidates for various applications due to their exceptional chemical activity, electrical conductivity, and EMI-shielding effectiveness. Furthermore, doping magnetic inorganic particles such as Fe

3O

4, Co, and Ni will enhance the EMI SE and absorption properties of CPFCs. In situ precipitation and in situ polymerization methods have been used to fabricate magnetic conductive composites, but they often involve high manufacturing costs, complex chemical reactions, and structural modification and can reduce EMI-shielding performance. Hydrogen bonding is a simple, cost-effective, and environmentally friendly approach for addressing the challenges in preparing magnetic conductive materials.

Liu et al. [

66] highlight the challenges posed by the inherent dielectric loss capability of carbon nanomaterials, including CNTs, in electromagnetic wave (EMW) absorption applications. These challenges include impedance matching imbalances and significant surface reflection, which can degrade EMW absorption performance. Additionally, effectively dispersing agglomerated CNTs remains a key hurdle in fully exploiting their potential for EMW absorption. To address these challenges, researchers have incorporated magnetic nanoparticles to enhance magnetic loss capability and improve the impedance matching of nanocarbon, thereby boosting EMW absorption performance. For example, an Ni/CNT composite created using a microwave welding method has achieved high EMW absorption with minimal reflection loss. Similarly, Co-Ni nanoparticles decorated with nitrogen-doped CNT arrays on ultrathin-reduced graphene oxide sheets have demonstrated good EMW-absorption capabilities. Another encouraging avenue involves using metal porphyrins and their derivatives as EMW-absorbing materials. Metal porphyrin supported by carbon materials provides active sites for EMW absorption, while the carbon materials ensure a high specific surface area and efficient mass transport. Porphyrin-functionalized CNTs show good capability for high EMW absorption due to their improved electrical contact and large heterogeneous interfaces. Liu et al. combined 5,10,15,20-tetrakis (4-aminophenyl) porphyrin Ni (Ni-TAPP) with CNTs through non-covalent π–π interactions to form a composite with high EMW absorption. This is a simple, scalable self-assembly approach. The composite showed high EMW absorption even with a low Ni-TAPP content. This material outperformed other CNT-based composites for absorbing EMWs.

Fang et al. [

63] combined PANI with MXene to enhance EM shielding. MXenes are two-dimensional (2D) transition metal carbides and nitrides with the general formula Mn + 1XnTx, where M represents the transition metal, X denotes carbon and/or nitrogen, and Tx signifies surface functional groups. MXenes have applications in various domains, including supercapacitor electrodes, secondary batteries, electromagnetic (EM) shielding, microwave absorption, photocatalysis, and electrocatalysis. An important member of the MXene family, Ti

3C

2Tx, has been the focus of significant research due to its high electrical conductivity and favorable mechanical properties. It is considered a prime candidate for efficient EM shielding and supercapacitor electrodes, owing to its remarkable EM SE and volumetric capacitance. However, realizing the full potential of Ti

3C

2Tx poses challenges, leading researchers to explore composite materials as a potential solution. Carbon-based materials, such as CNTs, polypyrrole (PPy), and polyaniline (PANI), are recognized for their excellent electrical and mechanical properties, making them ideal for EM shielding and energy storage applications. PANI is notable for its tunable conductivity and environmental stability. Incorporating carbon-based materials into Ti

3C

2Tx optimizes its conductive networks, improves EM shielding, and reduces the problem of restacking of Ti

3C

2Tx nanosheets, thereby enhancing the charge-storage capacity in Ti

3C

2Tx-based electrodes.

The study by Fang et al. focused on fabricating a Ti3C2Tx–CNT/PANI composite (T@CP) and analyzing its EM-shielding and electrochemical properties. The integrated effects of Ti3C2Tx and CNT/PANI contribute to the superior EM-shielding performance and higher specific capacitance of the T@CP electrode compared to Ti3C2Tx alone. The synthesis process of Ti3C2Tx involves controlled reactions, starting with Ti3AlC2 powder subjected to a reaction environment comprising hydrochloric acid (HCl) and lithium fluoride (LiF). This leads to the exfoliation of aluminum (Al) atoms, forming Ti3C2, followed by reactions with water or hydrofluoric acid (HF) to yield compounds with hydroxyl (-OH) or fluorine (-F) functional groups. Fabricating the Ti3C2Tx-CNT/PANI composite (T@CP) involves dispersing MWCNTs in an HCl solution, followed by sequential additions of ammonium persulfate and liquid aniline to form a CNT/PANI (C-P) composite. This composite is then combined with a Ti3C2Tx solution to facilitate electrostatic self-assembly, resulting in the ternary composite T@CP. Various characterization techniques, including XRD, SEM, TEM, Raman spectroscopy, Fourier transform infrared (FTIR) spectroscopy, and X-ray photoelectron spectroscopy (XPS), provide an understanding of the structural and functional properties of the synthesized materials. The EM-shielding properties were evaluated using a vector network analyzer, while the electrochemical properties were assessed using a three-electrode system. These characterization methods reveal the superior performance of T@CP compared to its individual components. T@CP has enhanced the EM-shielding effectiveness and electrochemical stability, making it a candidate material for many practical applications. The study by Fang et al. offers a unique approach to developing advanced materials for EM shielding and energy storage. The synergistic effects of Ti3C2Tx and carbon-based materials highlight the potential of T@CP for various applications. Further research will likely lead to even more efficient materials for EM shielding and simultaneous energy storage.

In their study, Park et al. [

67] examined the EMI-shielding characteristics of textiles made from CNTs and discovered that these textiles showed exceptional EMI-shielding efficiency. This was attributed to the fabrics’ high electrical conductivity and the interconnected network structure of CNTs. Similarly, Tahalyani et al. [

68] developed flexible, elastic, and lightweight nanocomposites using FCNF/GNP/PU materials. These nanocomposites were highly effective in providing EMI shielding due to the formation of a three-dimensional interconnected network, which significantly improved the electrical conductivity, mechanical strength, and EMI-shielding efficacy. The nanocomposites maintained their effectiveness even under mechanical bending and water sonication, showing their potential for use in flexible electronic applications. Wang et al. [

69] created double-layered Cu-Ni composite foams enhanced with CNTs using chemical plating and electrodeposition techniques to improve mechanical strength and electromagnetic-shielding capabilities. The incorporation of CNTs resulted in a homogeneous distribution between the metallic layers, enhancing the compressive strength, energy-absorption capability, and electromagnetic-shielding efficiency compared to Cu-Ni foams alone. Although heat treatments improved the compressive strength by diffusing the copper and nickel layers, there was a slight reduction in the average shielding efficiency due to absorption loss, the principal mechanism for shielding.

Viegas et al. [

70] investigated the X-ray-shielding characteristics of poly(vinylidene fluoride) (PVDF) nanocomposites filled with graphene oxide (GO), pyrolytic graphite (PG), MWCNT, and amorphous carbon (soot). These conductive fillers are typically used for EMI shielding. However, PVDF/GO nanocomposites containing 1.88 wt% GO demonstrated mass attenuation coefficients four times greater than those of other graphite-based nanocomposites for 6.9 keV photons. These nanocomposites exhibited increased ability to absorb X-rays at photon energies between 6.9 and 17.5 keV, indicating that thin, lightweight PVDF/GO films have the potential to provide effective protection against X-ray radiation in radiology operations, eliminating the need for lead.

Dragoman et al. [

71] empirically measured the reduction in intensity and charge storage capacity of double-walled carbon nanotubes (DWCNTs) across a frequency range of 1–65 GHz. The DWCNT mixture was integrated into a micromachined coplanar waveguide (CPW) transmission line supported by a thin silicon (Si) membrane. By analyzing the S-parameter data, the research revealed that DWCNTs exhibit dielectric properties throughout this frequency range, with modest losses and a sudden shift in effective permittivity, indicating potential for use in integrated gas sensors.

Zhang et al. [

72] developed composites of Cu(0.48)Ni(0.16)Co(2.36)O

4/CuO (C-CuNiCoO) modified with urchin-like CNTs using a one-pot hydrothermal technique. These composites demonstrated the significant attenuation of optical, infrared, and microwave signals. The distinguishing urchin-like morphology and carbon modification resulted in exceptional light absorption, exceeding 90% in the optical range, and a high average mass extinction coefficient of 2.52 m

2·g

−1 in the infrared region. The C-CuNiCoO composites also exhibited notable microwave-absorption capabilities, with a peak reflection loss of −40.5 dB at 17.1 GHz, due to conduction loss, eddy current loss, polarization loss, and effective impedance matching.

Wen et al. [

73] investigated the microwave attenuation of SiO

2–matrix composites packed with various amounts of MWCNTs in the X-band frequency range (8.2–12.4 GHz) at temperatures ranging from 100 to 500 °C. The study found that electron movement within and between graphene layers in the MWCNT network significantly impacted the electrical conductivity, dielectric properties, and microwave-attenuation performance. Composites with 10 wt.% MWCNTs demonstrated electromagnetic interference shielding of 24.5 dB and a broad absorption bandwidth, indicating their promise as high-performance materials for microwave attenuation.

CNT composites can be used as multi-spectral shielding materials and multifunctional materials. Rahman et al. [

74] carefully examined the design and assessment of CNT-based materials for optical power limiters (OPLs). The study reviewed various OPL methods, types of optical power limiters, and OPL chromophores, highlighting CNTs’ potential as broadband optical limiters due to their distinctive characteristics. Integrating CNTs with other organic and inorganic chromophores was highlighted to create synergistic effects, expanding the applications of optical materials across a broad range of frequencies. Materials for radiation attenuation often form composite materials. Metal powders such as lead, tin, and bismuth are mixed with poly(vinyl chloride) to create flexible matrices, which are then cut and layered to make protective clothing. Heavy metals like iron, zinc, bismuth, and gadolinium and less common metals like cerium, americium, and thallium, or salts can be incorporated into polymers to enhance the shielding effectiveness of carbon-nanostructured materials.

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. Graphene is known for its high electron density, high absorption coefficient, photoelectric absorption, mechanical strength, chemical stability, flexibility, and conformability [

49,

75]. Combining PDMS, boron-based materials, and graphene with CNT hybrid fabric offers multiple benefits, such as joint shielding, enhanced structural integrity, optimized properties, and improved compatibility. Integrating component materials with diverse properties will further increase the shielding capabilities of host materials against radio waves and microwaves and higher-energy radiation like X-rays and gamma rays. Including graphene within the CNT fabric provides structural support and improves the mechanical properties, ensuring durability and integrity under radiation exposure. Adjusting the thickness and composition of this CNT hybrid fabric material can optimize and enhance its performance for different radiation environments. The materials used to form this hybrid material are biocompatible, making the entire hybrid material suitable for use in biomedical applications. Depositing or coating thin layers of graphene with the rest of the materials will enhance mechanical properties and functionalities while maintaining flexibility and conformability. However, creating materials with multiple components requires precise control over the coating process, including the deposition techniques, uniformity, and adhesion between layers. Achieving consistency and uniform coatings can be particularly challenging, especially for large-scale applications. The thickness or volume fraction of each component in the hybrid material is crucial to attain the desired shielding effectiveness. However, the increased weight and bulkiness of this material may limit its applications in certain industries, such as aerospace and healthcare. Moreover, this new hybrid CNT fabric material must meet regulatory requirements and standards for radiation-shielding materials, particularly in sectors like healthcare and nuclear energy.

5. Potential Applications and Associated Challenges of Shielding Materials

5.1. Applications

The potential applications of CNT-based fabrics span across numerous fields, including medical diagnostic imaging, radiation therapy, aerospace, the nuclear industry, and military sectors, highlighting their versatility and effectiveness in radiation shielding. Therefore, CNT materials should be considered when designing different types of radiation-shielding materials. Ongoing research is anticipated to expand the applications and efficiency of CNT-based fabrics in radiation shielding.

Zhang et al. [

50] demonstrated the potential of CNT films for gamma-ray shielding, outperforming certain common metals under specific conditions. Zhu et al. [

51] enhanced our understanding of the radiation response of CNT-based electronics, highlighting their potential for space applications and high-radiation environments. Abdeldaym et al. [

52] found a clear correlation between increased MWCNT loading and improved gamma-radiation-shielding effectiveness in natural rubber latex (NRL) composites. Beyond gamma-ray shielding, Lai et al. [

54] showed that PP/MWCNT composites effectively block electromagnetic radiation (EMR). Çakmakçı et al. [

55] synthesized a ferrite-decorated CNT film that further improved shielding properties. Lan et al. [

53] explored high-loading CNT/PAH nanocomposite coatings for effective EMI shielding on fabric substrates, retaining desirable fabric properties and suggesting applications in industries requiring flexible and lightweight EMI-shielding solutions. Chauhan et al. [

56] demonstrated that polymer/MWCNT composite thin films offer high thermal conductivity and prominent EMI shielding, advancing material design for industries with combined thermal management and electromagnetic compatibility needs. Other studies not included in this paper have also demonstrated the tailoring of CNT based shielding materials for various applications. Hence, the importance of CNT films and additives in need-based and tailored shielding applications is well established.

Attenuating radiation exposure is crucial for astronauts, pilots, flight attendants, and scientists working with high-frequency radiation. Protective clothing made from CNT-infused fabrics could provide significant benefits, particularly for vulnerable populations such as the fetus. Additionally, shielding buildings from nuclear electromagnetic pulses could be achieved using CNT hybrid lightweight fabrics. General application areas for CNT-based hybrid materials include medical X-ray shielding, aerospace shielding, the nuclear industry, military applications, laboratory research settings, medical imaging and radiotherapy, and wearable electronics [

76,

77,

78,

79]. Radiation shielding for wearable electronics, medical X-rays, and concrete for construction materials is described in [

80,

81,

82,

83].

Medical X-ray Shielding and Imaging: Potential applications of CNT-based fabrics for X-ray shielding include the development of lightweight, flexible, and lead-free X-ray protective clothing for healthcare workers, the fabrication of CNT-based fabrics for use in X-ray room shielding, such as curtains, screens, or wall coverings, and the creation of patient shielding devices, such as thyroid collars or gonadal shields, using CNT-based fabrics. Lightweight materials are of special interest to avoid fatigue and excessive muscle strain on physicians during lengthy fluoroscopic procedures. CNT-based fabrics are being developed for multiple applications in medical imaging to reduce unnecessary radiation exposure to attending staff and patients. These innovative materials are used to create shielding garments for patients undergoing CT scans or PET imaging, significantly reducing their exposure to radiation. Additionally, CNT-based fabrics can shield X-ray detectors and gamma cameras. In medical imaging like CT scans, Compton scattering can contribute to image noise due to scattered photons reaching the detector.

Aerospace radiation shielding: Aerospace radiation shielding applications of CNT-based fabrics include integrating these materials into spacecraft structures to provide radiation shielding for astronauts and sensitive electronic equipment, developing CNT-based fabrics for satellite shielding to protect against cosmic radiation and solar flares, and fabricating lightweight, radiation-resistant spacesuits using CNT-based nanocomposite fabrics.

Nuclear industry: In the nuclear industry, CNT-based fabrics have several potential applications. These include the development of protective clothing for nuclear power plant workers, the fabrication of radiation-shielding materials for nuclear waste storage containers, and the creation of portable radiation-shielding devices, such as lightweight barriers or tents, for emergency response situations.

Military applications: Military applications of CNT-based fabrics include developing lightweight, radiation-resistant body armor for military personnel, fabricating portable radiation shielding structures, such as command centers or medical facilities, and integrating these fabrics into military vehicles to provide radiation shielding for personnel and equipment. CNT-based hybrid fabrics using tungsten and other nanoparticles can be customized to shield different types of electromagnetic radiation.

Research and laboratory settings: In research and laboratory settings, CNT-based fabrics can be utilized for developing shielding materials to protect sensitive scientific instruments from background radiation, fabricating radiation shielding enclosures for research laboratories working with radioactive materials, and creating personal protective equipment, such as gloves or aprons, for researchers handling radioactive samples.

Wearable electronics: CNT-based fabrics are being integrated into various wearable technologies to enhance user safety and functionality. These fabrics are incorporated into wearable electronic devices, providing both EMI shielding and higher energy radiation protection. Additionally, CNT-based fabrics are utilized in developing smart textiles, such as radiation-resistant clothing designed for workers in high-risk environments. Furthermore, these innovative materials are used to fabricate flexible, radiation-shielding components for wearable medical devices, including pacemakers and insulin pumps, offering added protection and durability. These applications demonstrate the versatility and potential of CNT-based fabrics for photon attenuation in various industries and settings.

Emerging area of Countering Directed Energy Weapons (DEWs): The current development of DEWs around the world jeopardizes the security of national defense and civil infrastructure systems. Consequently, there is a need for developing shielding materials to partially block the transmission of different forms of high-power directed energy. Developing various materials to counter DEWs is an emerging application area [

84,

85,

86]. There are different forms of DEWs, which include high-power microwaves (HPWs), high-power lasers (HPLs), and nuclear radiation (NR) including Nuclear Electromagnetic Pulse (NEMP) and Enhanced Radiation Weapons (ERWs) [

82]. Concepts for shielding materials are described below. These are proposed new areas of application. Manufacturing these materials includes fabricating textiles and polymeric composite layered structures and intercalating appropriate particles within the materials, along with integrating different types of fabrics within these materials. Understanding Compton scattering is important for radiation shielding design as it can lead to scattered radiation.

Blocking High Energy Lasers (HPLs). Layered CNT hybrid materials are proposed for blocking high-energy lasers. These materials can reduce penetration from a laser because the laser must burn through multiple layers and interfaces one by one. Each layer produces smoke and dross that partially block the laser. Each layer can be designed to conduct heat away from the laser spot and to produce debris to partly block the laser for a short time. Shielding materials to combine with CNT fabric may include reactive borides, boron nitride nanotubes, radiation-sensitive coatings, and metal–organic frameworks.

Blocking High Power Microwaves (HPMs). CNT fabric composites are highly effective for attenuating and reflecting microwaves and can carry a structural load. HPMs damage electronic components and can be blocked by designing CNT hybrid fabric with sufficient thickness. Boundary effects and layering can also help to reduce the thickness of the material to block HPMs.

Blocking Space Radiation from Solar Flares. A problem that threatens thousands of satellites surrounding earth is solar storms. Solar storms (flares and coronal mass ejections) release streams of charged particles such as electrons and protons at high speeds. X-rays and ultraviolet light can also accompany solar flares. These eruptions from the sun can interact with Earth’s magnetic field and produce a geomagnetic storm, which is a major disturbance of Earth’s magnetosphere or the space environment surrounding earth. The geomagnetic storms also cause electrical flows within the Earth’s ionosphere. Operation of the space internet constellation is affected by the geomagnetic storms. Radiation shielding in small satellites cannot completely protect the satellite from the powerful geomagnetic storms. Particles from the storm can penetrate satellite hardware and damage electronic components, including circuits, solar panels, and sensitive instruments. During a geomagnetic storm, the Earth’s atmosphere can also heat up and expand, increasing the density of the thermosphere. This increased density increases the drag on satellites in a low earth orbit, potentially causing them to fall to earth sooner than expected. Lightweight CNT-based hybrid fabrics can be designed to increase the shielding of radiation from solar storms.

Multifunctional applications. CNT nanoparticle composite materials can be designed to be multifunctional or multi-use. Examples are using a CNT fabric with nanoparticles as a thermal insulation material and a radiation-shielding material for simultaneous electronics cooling and shielding applications. Another example is using CNT nanoparticle composite materials to increase electrical conductivity and provide radiation shielding of structural composite materials that use epoxy or polyimide matrices. Another application is using WS2 nanoparticles that act as a dry lubricant in CNT fabrics for simultaneous lunar dust shielding and cosmic radiation shielding. Other applications are possible based on the wide selection of combinations of nanoparticles available. Improved modeling of CNT nanoparticle composites is needed to fully understand the effects of the nanoparticle size, shape, concentration, distribution, and interaction with other particles and nanotubes.

5.2. Associated Challenges in Shielding

Though the promising effectiveness of CNT-based materials for gamma-rays and EMI shielding was demonstrated in different research, improvements are needed to overcome various associated challenges, mainly long-term performance, scalability, low-cost synthesis, and optimization, as summarized below [

50,

51,

52,

53,

54,

55,

56].

Long-term performance and scalability: While existing research demonstrates the potential of CNT-based materials for shielding applications, a comprehensive understanding of their long-term performance and scalability is crucial for commercialization. There is a particular need for studies on the durability, environmental stability, and cost scalability of CNT films and additives. Investigations into the durability of NRL/MWCNT nanocomposites under various environmental conditions, such as temperature and humidity, are warranted. Life cycle assessments to understand the environmental footprint of these materials are also important.

Synthesis and multifunctional applications: Further research is necessary to explore cost-effective synthesis methods for the industrial-scale production of CNT-based shielding materials. Optimizing synthesis methods can enhance material properties while reducing production costs. The cost of CNT sheets is much greater than the cost of powder CNT. Additionally, research into integrating CNTs with other materials for multifunctional composite coatings or layers for radiation protection holds promise.

Advanced characterization and modeling: Investment in advanced characterization techniques and predictive modeling tools can accelerate the development and optimization of CNT composites. In-depth spectroscopic analysis can elucidate the interfacial interactions between CNTs and the polymer matrix, while computational modeling can predict the electromagnetic-shielding performance of composite structures.

Expanding EMI-shielding research: Beyond the influence of environmental factors on the performance of CNT composites, future research should explore alternative nanoparticle types with the potential for superior EMI-shielding performance. Metal–organic frameworks and other carbon-based nanomaterials are promising candidates. Continued research efforts could involve advanced characterization techniques, such as in situ spectroscopy and electron microscopy, to elucidate the underlying mechanisms governing EMI shielding. Systematic optimization studies to identify the most effective fabrication processes and life cycle assessments to evaluate the environmental impact throughout the lifecycle are also recommended.

Microstructural mechanisms and durability: Future research can benefit from employing advanced characterization techniques like electron microscopy and spectroscopy to understand the microstructural mechanisms underlying the observed thermal and electromagnetic properties of CNT hybrid composites. Specific research areas could involve studying the effects of the functionalization and surface treatment of MWCNTs on composite film properties, exploring synergistic effects achieved by incorporating combinations of nanomaterials and nanoparticles, the effect of the shape (spherical, rod, platelet, dendrite) of the nanoparticles on shielding effectiveness, and investigating the durability of composite films in harsh operating environments. The effect of the size and shape of nanoparticles on shielding performance should be comprehensively studied.

6. Example: Design of a CNT–Nanoparticle Material for Photon Attenuation

This section presents an example of designing a material for photon attenuation at energy levels in the X-ray and higher frequency range. The number of photons in a beam that interact in an absorber per unit time is called the intensity,

I (e.g., gamma rays/sec). If the initial intensity is designated as

Io, the reduction in intensity is related to the likelihood of photon interaction per unit pathlength, where

and

x (cm) is the thickness of the absorber and

μ (cm

−1) is the linear attenuation coefficient. Values of

μ depend upon the photon energy and the absorber material. If the absorber is fabricated as a mixture of atoms, values of

μ are calculated as the weighted percentage content of each element in the mixture. The attenuation of photons in an n-layer composite is thus given by the ratio of the transmitted to the incident photons:

where

μi is the attenuation coefficient for the

ith component material and

xi is the thickness of the

ith layer. This model of attenuation is based on the type and thickness of material. It does not depend on the configuration of the material. The National Institute for Standards and Technology (NIST) offers tables of values for

μ/

ρ (cm

2/g) which is called the mass attenuation coefficient. The mass attenuation coefficient is related to the photon interaction cross-section, σ, that is described in [

85].

Consider an absorber fabricated from a pure carbon material,

6C

12.

Figure 3a illustrates how the mass attenuation coefficient,

μ/

ρ, decreases with an increasing photon energy in the energy range from 10 keV up to 10

4 MeV. The mass attenuation coefficient represents the interaction probability and decreases with increasing photon energy. Thus, the likelihood of the photon being absorbed or scattered by the target decreases significantly as photon energy increases. Data for the C (100%) material are as follows. The Atomic Number and Fraction by Weight are: carbon Z = 6: 1.0. Density of C = 2.26 g/cc.

Table 2 gives attenuation coefficients for C material in the lower energy range.

Using the data in

Table 2,

Figure 3b was produced and shows the relative intensity,

I/

Io, of photons with energies between 0.010 MeV and 1 MeV as they penetrate increasingly thick carbon-only targets, where

Io is the initial intensity of the photon beam, and

I is the intensity after penetrating the carbon target having a thickness

x cm. It is apparent that mainly low-energy photons are attenuated by carbon targets.

The above analysis demonstrates that carbon does not significantly attenuate photons with energy greater than 1 MeV. Thus, particles or fibers must be added to CNT fabric to attenuate high-energy photons. As an example, W particles can be added to CNT fabric during the CNT synthesis process. Fe is also present in the CNT fabric from the residual catalyst.

Figure 4a shows the mass attenuation coefficient for a C-Fe-W composite mixture material. This material represents a solid C-Fe-W material. The objective of using CNT hybrid fabric is to achieve significant attenuation using a lightweight material. CNTs are not solid materials and thus may behave differently than solid C analyzed in XCOM [

85]. Integrating nanoparticles into a CNT fabric provides a large surface area to scatter photon radiation. The Fe and W greatly increase the linear attenuation coefficient compared to C, but the mass attenuation coefficient is similar at high energies. Data for the C-Fe-W (24/6/70) material are as follows. The Atomic Number and Fraction by Weight are: carbon Z = 6: 0.24, iron Z = 26: 0.06, and tungsten Z = 74: 0.7. Density carbon = 2.26 g/cc, density iron = 7.87, density tungsten = 19.28 g/cc. Volume fraction carbon = 0.24, volume fraction iron = 0.06, volume fraction tungsten = 0.7. Equivalent density = densityC × vol fraction C + densityFe × vol fraction Fe + densityW × vol fraction W = 14.5106 g/cc.

Table 3 gives attenuation coefficients for the C-Fe-W material.

Figure 4b shows the relative intensity,

I/

Io, of photons with energies between 0.010 MeV and 1 MeV as they penetrate increasingly thick C-Fe-W targets, where

Io is the initial intensity of the photon beam, and

I is the intensity after penetrating the carbon target having a thickness of

x cm. W increases the relative photon linear attenuation coefficient as compared to C alone. The mass attenuation coefficient of the C-Fe-W material is larger than for C at low energy levels and similar at a high energy. This points to the need to improve photon shielding at higher energy levels. This might be done by using smaller-size nanoparticles and a fabric material that is thick with many layers with a large number of interfaces due to the nanoparticles.

Material Design Based on Compton Scattering

Compton scattering is a reaction that involves the partial absorption of X-rays or gamma rays that are in the middle energy range. The X-rays or gamma rays give up some of their energy as they strike an outer-shell electron in an absorbing material. Nanoparticles, particularly those made from high-atomic-number elements with a high electron density, like lead, bismuth, and tungsten, can attenuate X-ray and gamma radiation. These nanoparticles can be incorporated into composites for radiation shielding. A CNT fabric with nanoparticles inside potentially offers better protection on a per weight basis than traditional shielding materials like lead alone. However, the effectiveness of CNT composites depends on the specific nanoparticle composition, size, shape, and concentration within the material.

The energy of a Compton scattered photon depends upon the energy of the incident photon and the angle of scatter, where the energy is given as

where

Eo is the energy of the incident photon, and

θ is the scattering angle of the photon. Thus, the photon scattering angle following a Compton interaction is determined only by the difference in energy between the incident and scattered photons. The probability of an interaction is dependent upon the incident photon energy and the type of absorber material. In Compton scattering, the photon interacts with a single electron, and the scattering angle is calculated based on the electron’s mass and the incident photon’s energy, not the properties of the atom or material to which it is bound. The photon primarily interacts with loosely bound electrons in the outer shells of atoms. This means that the Compton wavelength shift (the change in wavelength after scattering) is the same for all materials, as it only depends on the scattering angle and the electron’s properties. The probability of Compton scattering occurring within a material does depend on the bulk material properties. The higher the electron density in a material, the more likely it is for a Compton scattering event to occur. While not directly affecting the scattering angle, the atomic number of the material can influence the probability of Compton scattering due to its correlation with electron density. During the collision, the photon transfers some of its energy to the electron, causing the electron to recoil. The scattered photon has a longer wavelength (lower energy) compared to the original photon. The angle at which the photon is scattered depends on the energy transfer and is described by the equation

where λ

2 − λ

1 are the wavelength of the photon after and before the collision, respectively, h is Planck’s constant, m is the mass of an electron, c is the speed of light, and

θ is the photon scattering angle. Note that the angle

θ is not a direct function of the material properties. The angle is modeled using the Klein–Nishina formula [

88]. These formulas are not very useful to optimize the atomic cross-sections of materials to control Compton scattering and to block radiation. The equations that define gamma ray cross-sections are given in Wikipedia. The cross-sections can be computed using NIST XCOM software, version 1.5, November 2010. Nanoparticle composites can be manufactured with different thicknesses, shapes, and volume fractions of nanoparticles to shield different energies of radiation. But an obstacle is that modeling the radiation absorption of nanoparticle composites using the Wikipedia equations or XCOM does not account for the nanoparticles size, shape, distribution, and the interactions in the composite matrix. Improved modeling is needed to optimize the design of nanoparticle composites for radiation shielding.

Some characteristics of nanoparticles and gamma radiation are given. Due to their penetrating nature, gamma rays require a large shielding mass to reduce the health risk to cells of living tissue. High-Z elements have high density and provide high shielding per material volume. Nanoparticles made from elements with high atomic numbers (Z) like lead oxide (PbO), bismuth oxide (Bi2O3), or tungsten trioxide (WO3) are most effective at absorbing gamma rays due to their high electron density. An increased interaction surface may also be important. The small size of nanoparticles creates a larger surface area and more interfaces for interactions with gamma radiation, potentially enhancing absorption compared to larger particles. Nanocomposites also provide multiple components for shielding. A limitation of nanoparticle composites is they may require a significant thickness for effective protection, which increases the cost. CNT fabric can be sealed to contain the nanoparticles and form a composite with a thin sealant or binder material. An example of a nanocopmosite is CNT-Fe-W fabric, which can be custom designed for radiation shielding.

In forming CNT fabric nanocomposites, particles are added to CNT fabric to shield different types of radiation. The structure and composition of the fabric are customized to optimize the shielding. As an example, micro-size W particles are added as CNT fabric is wound onto a drum. The synthesis process is described in [

89,

90,

91]. The Fe in the fabric is a residual catalyst, which is about 20% of the weight of the CNT. Shielding higher energy radiation will require a thick/dense shield. The CNT-Fe-W fabric is flexible and manufacturable, and the cost of the W particles is low. The research is continuing with the goal of reducing the weight of the fabric by using smaller nanoparticles. CNT-Fe-W fabric is also multifunctional—besides attenuating photon and particle radiation, CNT fabric is flame-resistant, attenuates microwave radiation, and is thermally conductive.

The CNT-Fe-W fabric designed has a low density and is thick and may produce different shielding than solid material as predicted by XCOM [

87]. Improved modeling is needed to predict the attenuation of low-density nanoparticle composites especially at high radiation energy levels.

7. Mechanisms for Small Particles to Block Radiation

Different studies have indicated that small particles distributed in a matrix material are more effective in blocking radiation than large size particles on an equal mass basis. However, the literature does not satisfactorily explain the mechanisms whereby small particles in a matrix material can block radiation more effectively than large-size particles. Another open question is whether small particles will block radiation better than an equal mass of the same type of solid material. The literature does not explain mechanistically if small particles can block radiation better than solid metal. This section reviews some of the literature related to the effect of the size or thickness of a small particle on its ability to block radiation.

Hwang et al. discussed mechanophysical synthesis of core/shell hybrid supraparticles [

92]. Supraparticles are formed by embedding hard nanoparticles into soft polymer microparticles. The surface modification of the polymer microparticles is performed by dry mixing and the impact of nanoparticles and polymer microparticles that have different elastic moduli. This is called mechanical physical synthesis and is a new method for the assembly of heterogeneous microparticles that can be used for water filtering, sensing, and other applications. It is possible that the polymer microparticles could also be used for radiation blocking because the multivalent assembly of the hybrid supraparticles can be performed with different materials. Materials in the nanoscale range that can be used include boron nitride, molybdenum disulfide, copper, and different combinations of elements. Hybrid supraparticles can be formed using multiple gas materials assembled onto the same microparticle. This enables the design of multifunctional materials. Overall, this paper offers a new method not yet explored for fabricating multiscale and multifunctional hybrid particles for radiation shielding that provides properties that are improved in many cases from the properties of bulk materials.

Xu, Tung, and Sun studied the effect of the size and the concentration of gold nanoparticles on X-ray attenuation [

93]. They used computed tomography as a measurement method and showed that smaller gold nanoparticles have greater X-ray attenuation than larger gold particles. Increasing the concentration of nanoparticles also increased the X-ray attenuation. It was hypothesized that the smaller gold nanoparticles had greater X-ray attenuation than the larger gold particles because of the increase in the surface area to volume ratio for the smaller gold nanoparticles. For the same mass of gold, smaller nanoparticles have a larger surface area. X-ray attenuation is dependent on the target area. Thus, small gold nanoparticles with large surface area should have greater X-ray attenuation. Smaller particles therefore will be more efficient as a computed tomography contrast agent. It was also shown that coated gold nanoparticles with sizes ranging from 4 nm to 60 nm were stable in physiological conditions and non-toxic to certain cells. The 4 nm and 20 nm gold nanoparticles showed higher X-ray attenuation than a commercial contrast agent under the same molarity. X-ray attenuation from gold nanoparticles is therefore both size and concentration dependent. Smaller gold nanoparticles at higher concentrations provided greater attenuation and may be an alternative to commercial contrast agents. A comprehensive study considering different types of materials and size nanoparticles and microparticles needs to be performed.

Polymer composite materials were studied for radiation protection by Nambiar and Yeow [