Intelligent Fault Warning Method for Wind Turbine Gear Transmission System Driven by Digital Twin and Multi-Source Data Fusion

Abstract

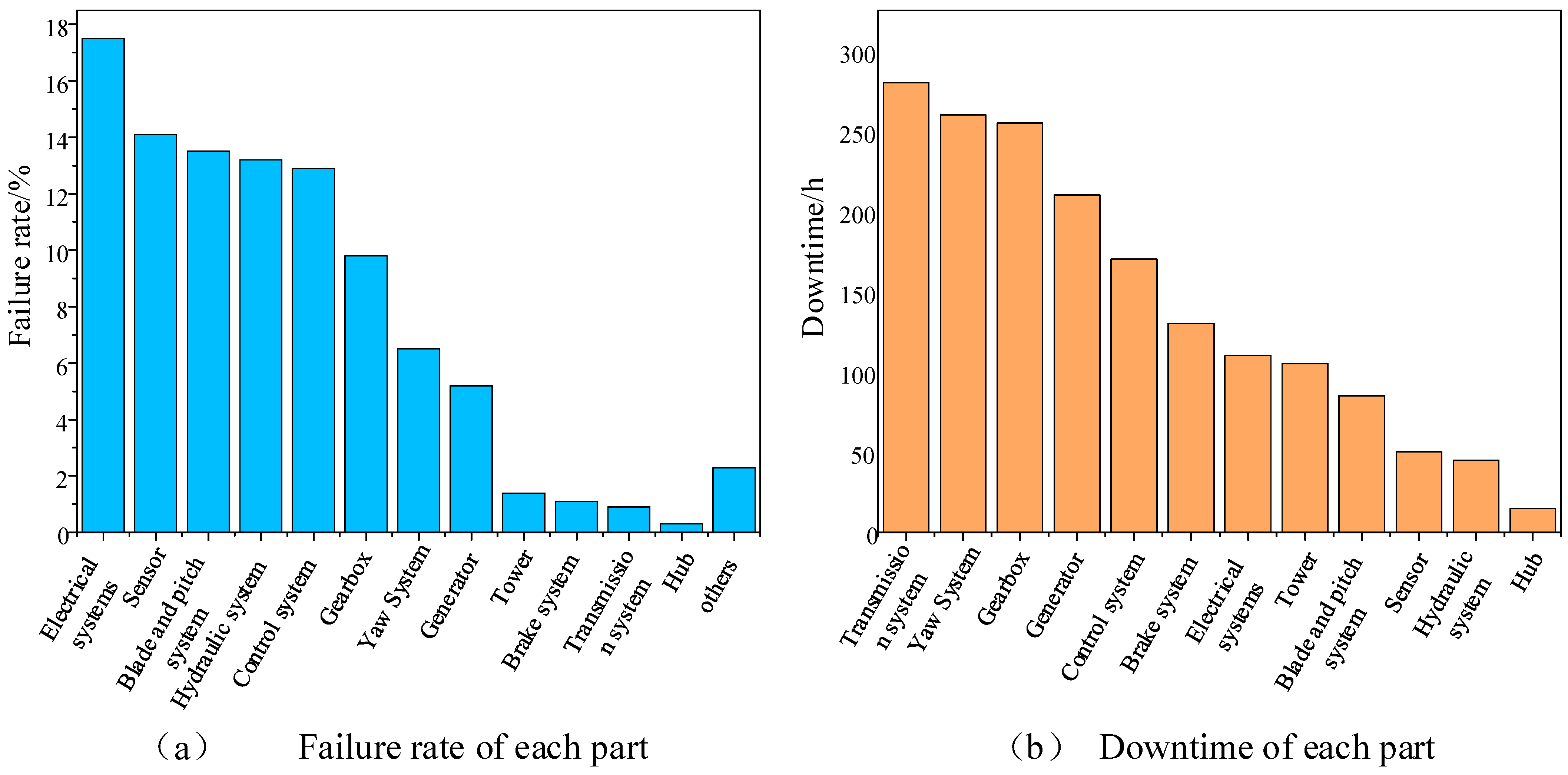

1. Introduction

2. Related Works

3. Materials and Methods

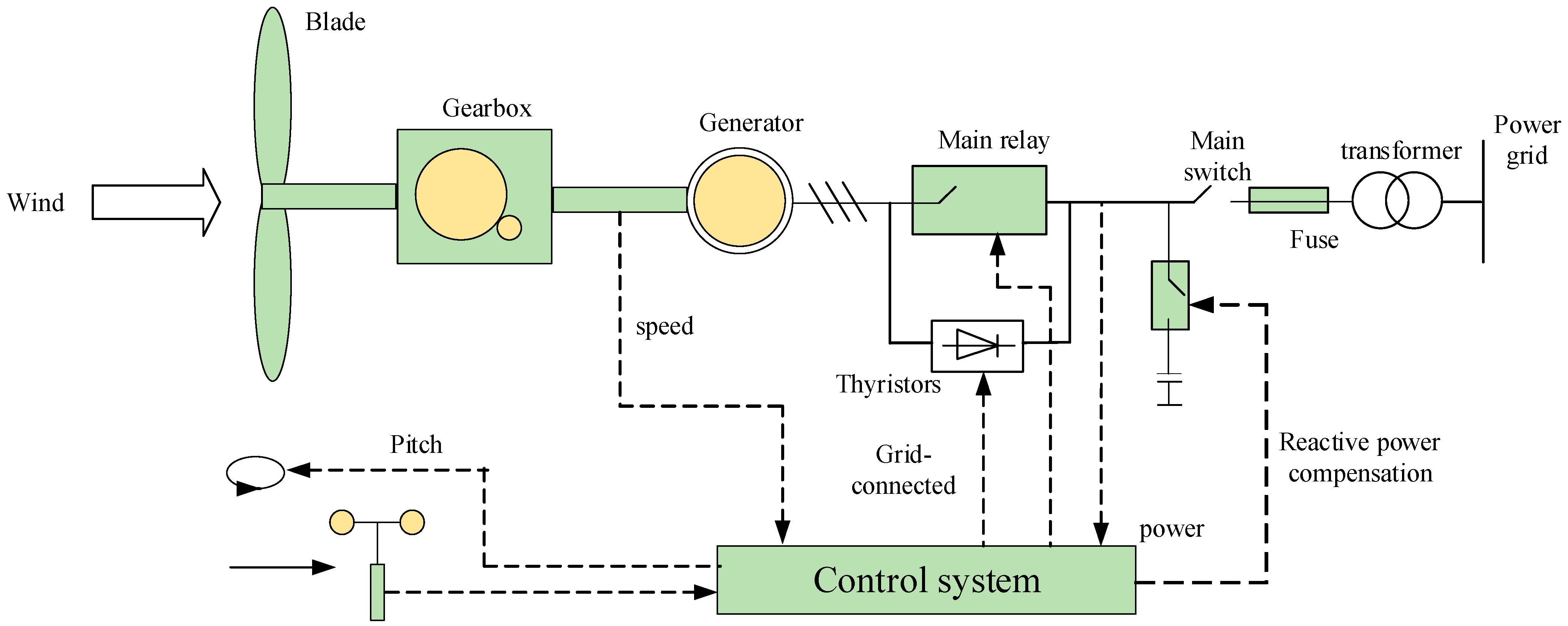

3.1. Basic Structure and Working Principle of the Wind Turbine Gear Transmission System

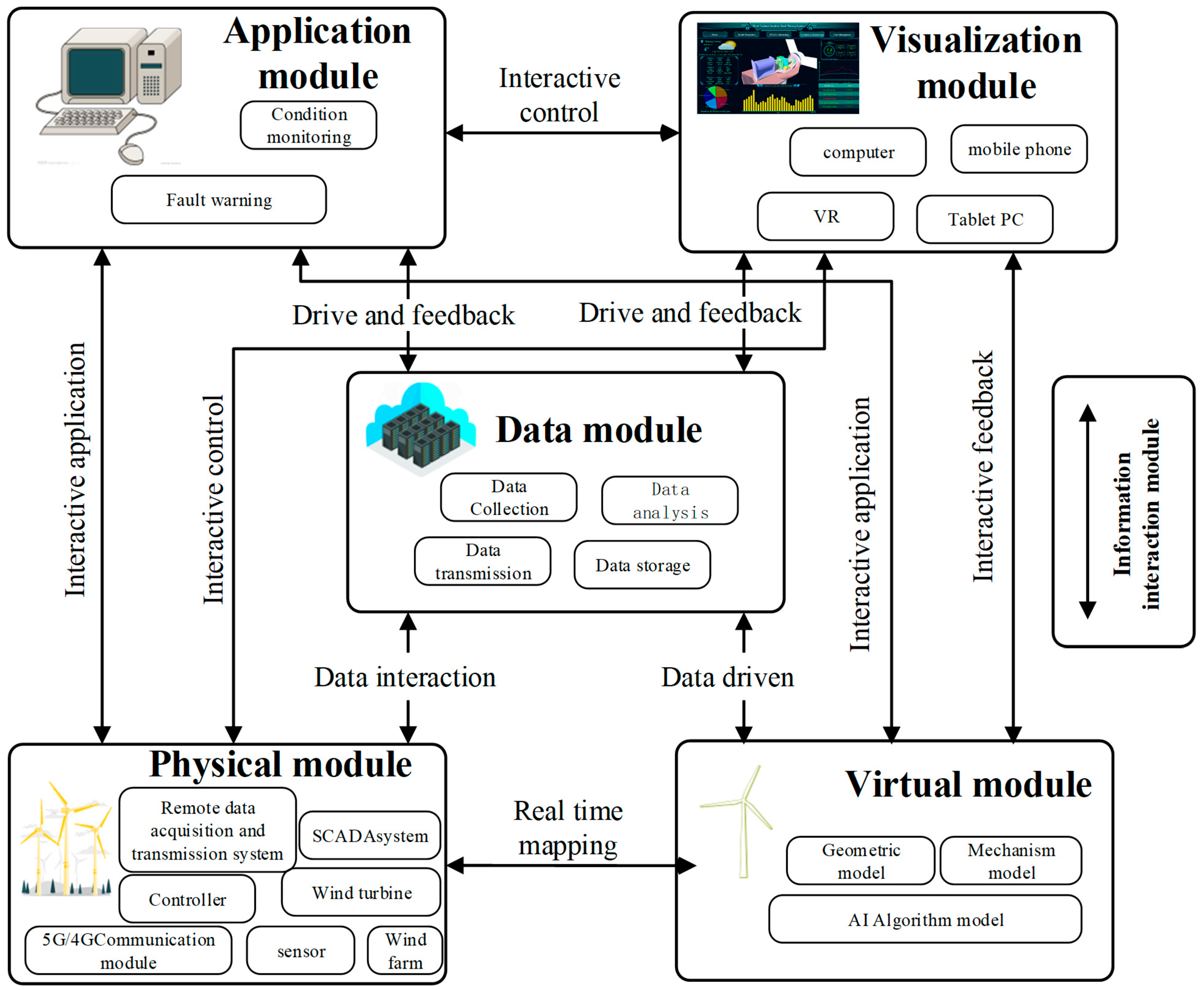

3.2. Overall Architecture Design of the Digital Twin for the Wind Turbine Gear Transmission System

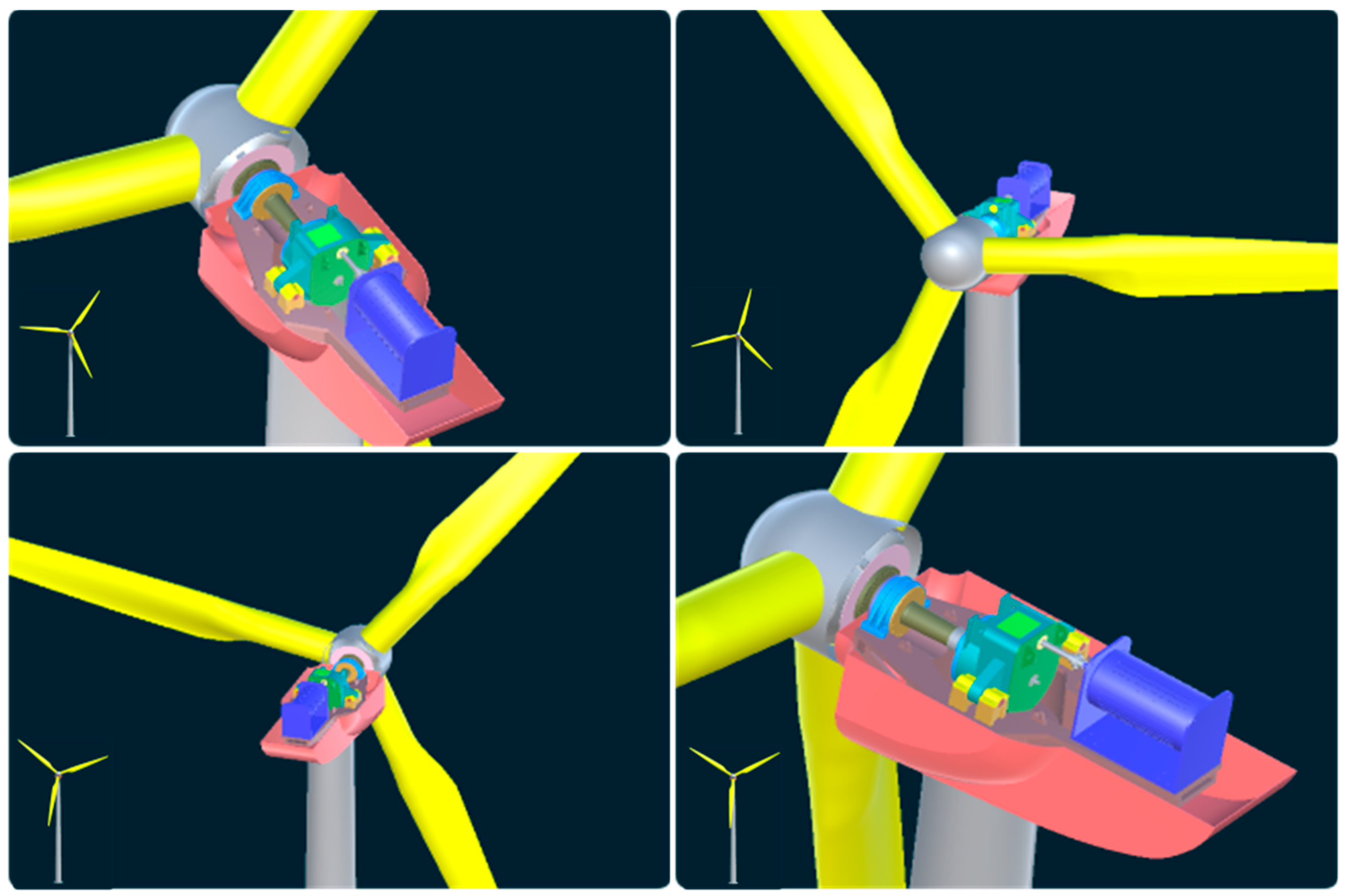

3.3. Construction of the Digital Twin Geometric Model for the Wind Turbine Gear Transmission System

3.4. Construction of the Digital Twin Mechanism Model for the Wind Turbine Gear Transmission System

3.5. Design of the CNN-LSTM-Attention-Based Digital Twin Fault Prediction Model

3.5.1. CNN-LSTM-Attention Model Architecture Design

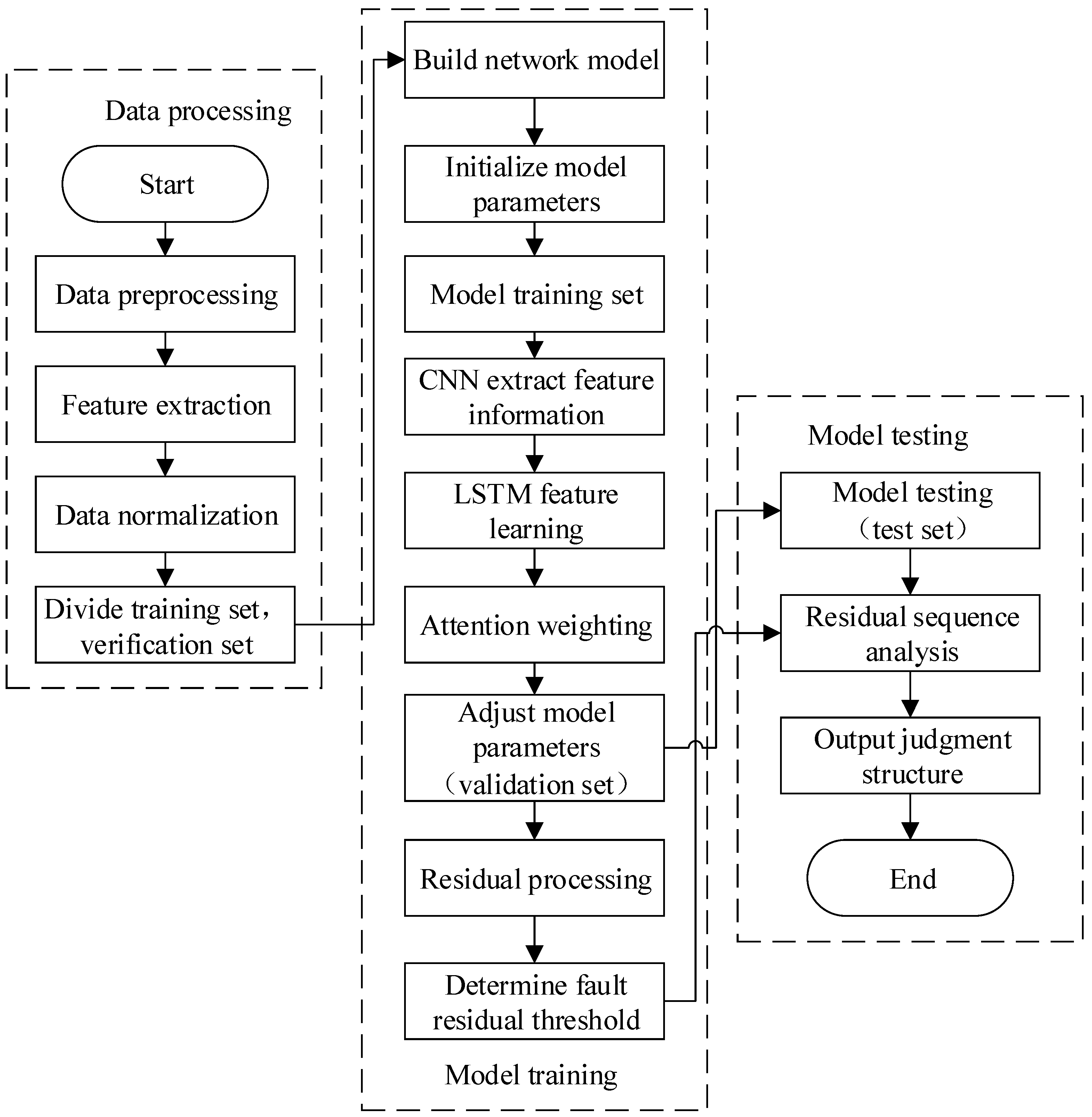

3.5.2. Fault Prediction Flow Based on the CNN-LSTM-Attention Model

4. Results

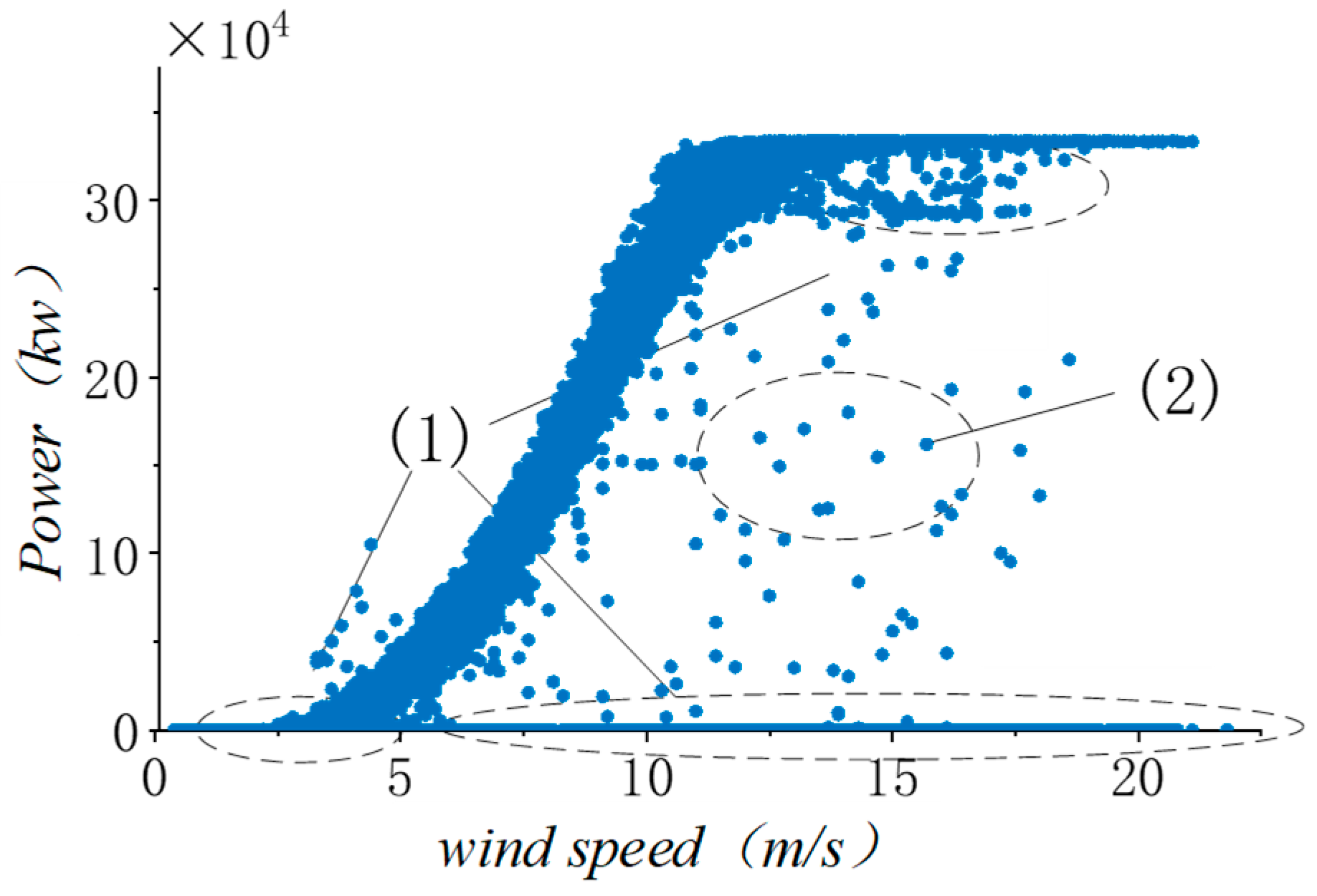

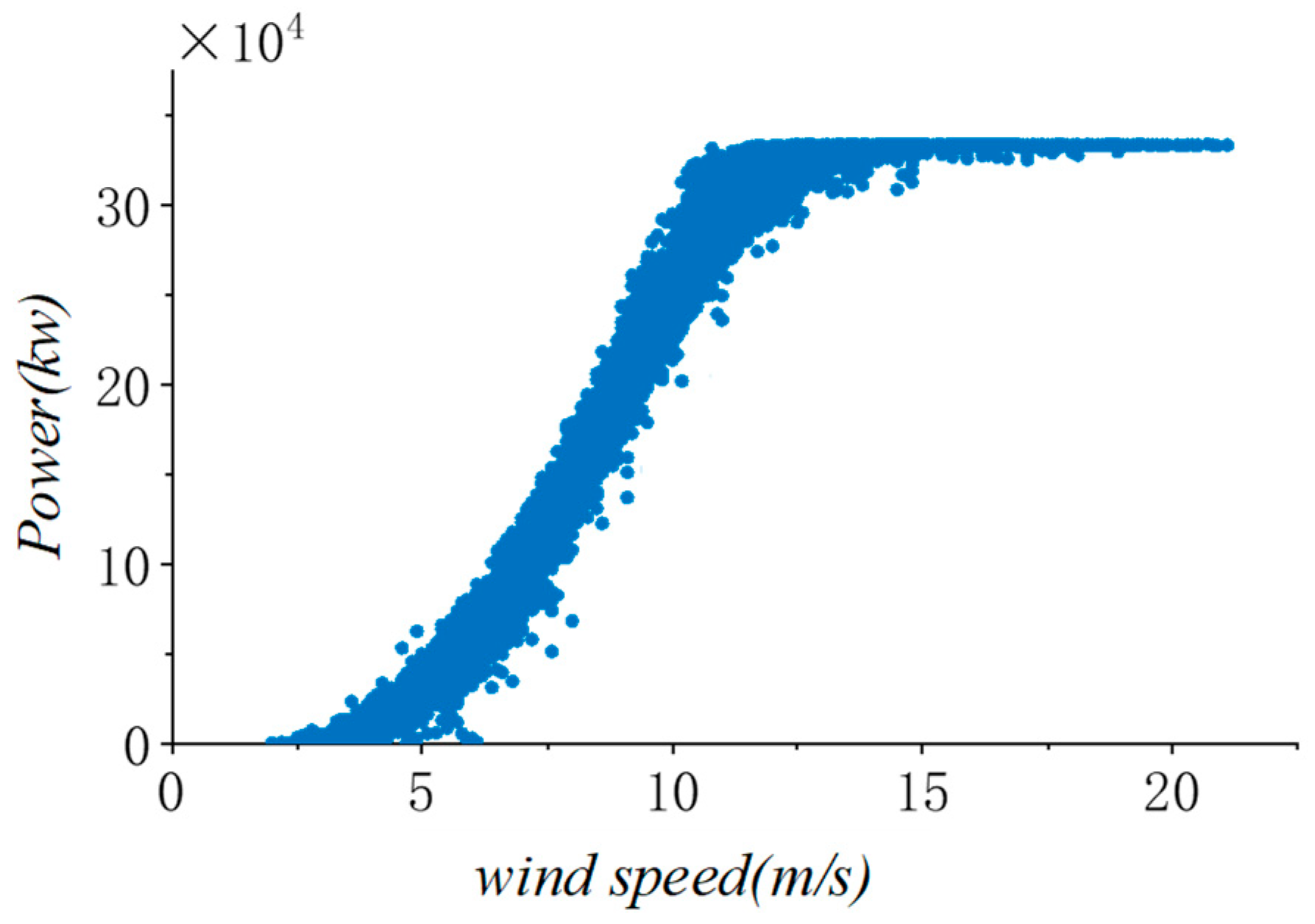

4.1. Data Collection and Preprocessing

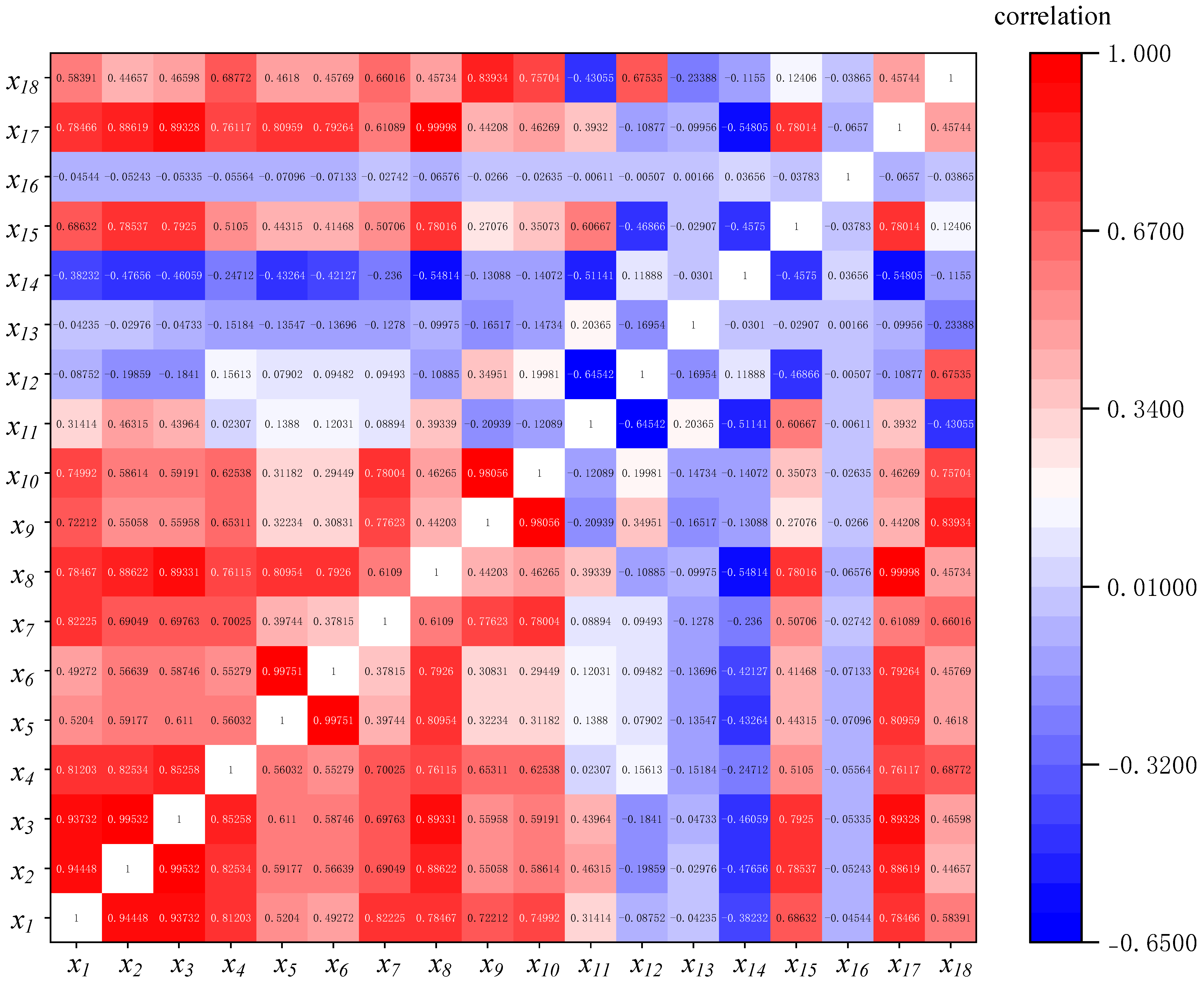

4.2. Feature Parameter Selection

4.3. Model Evaluation

4.3.1. Construction of Evaluation Metrics System

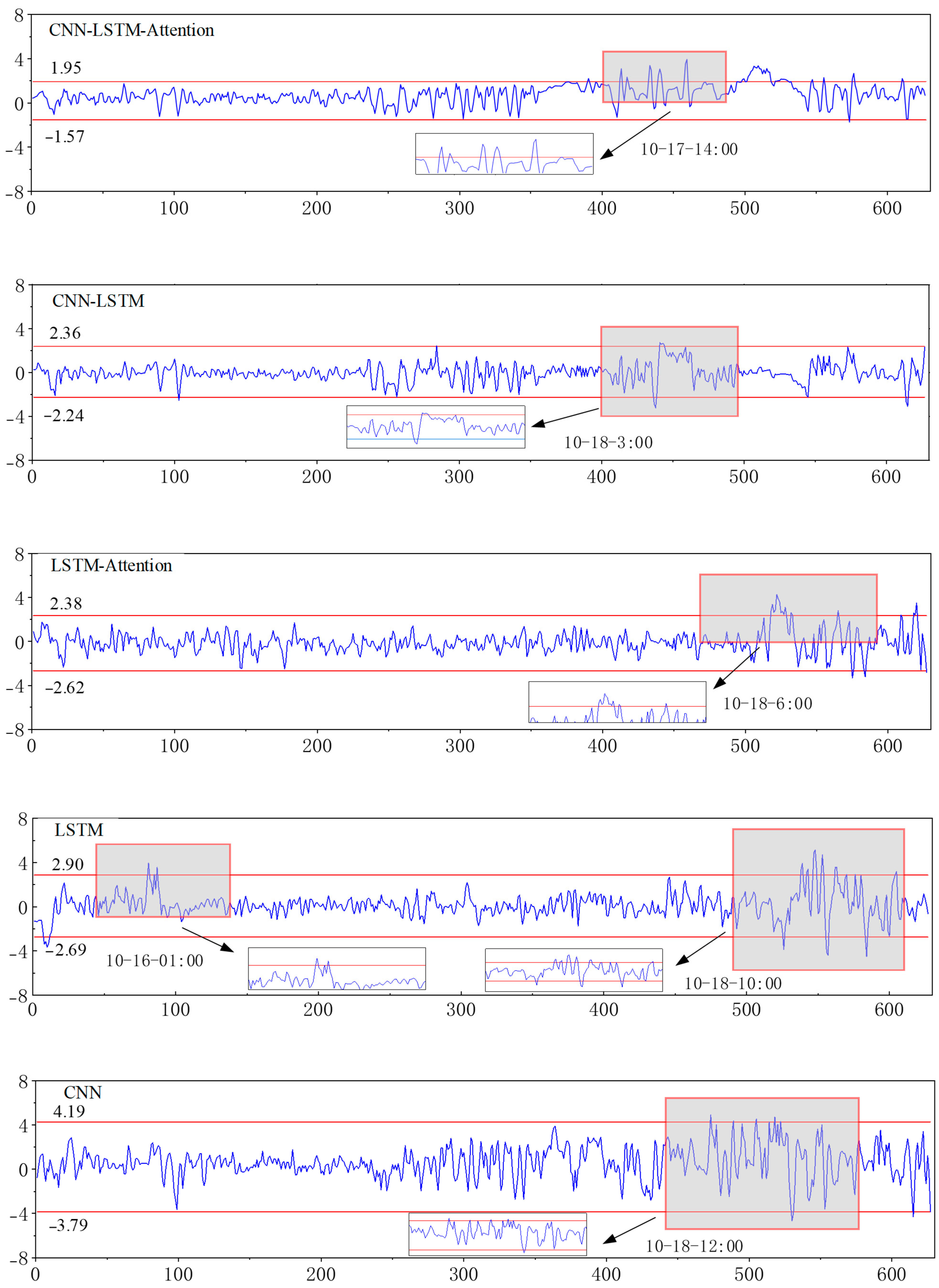

4.3.2. Analysis of Evaluation Results

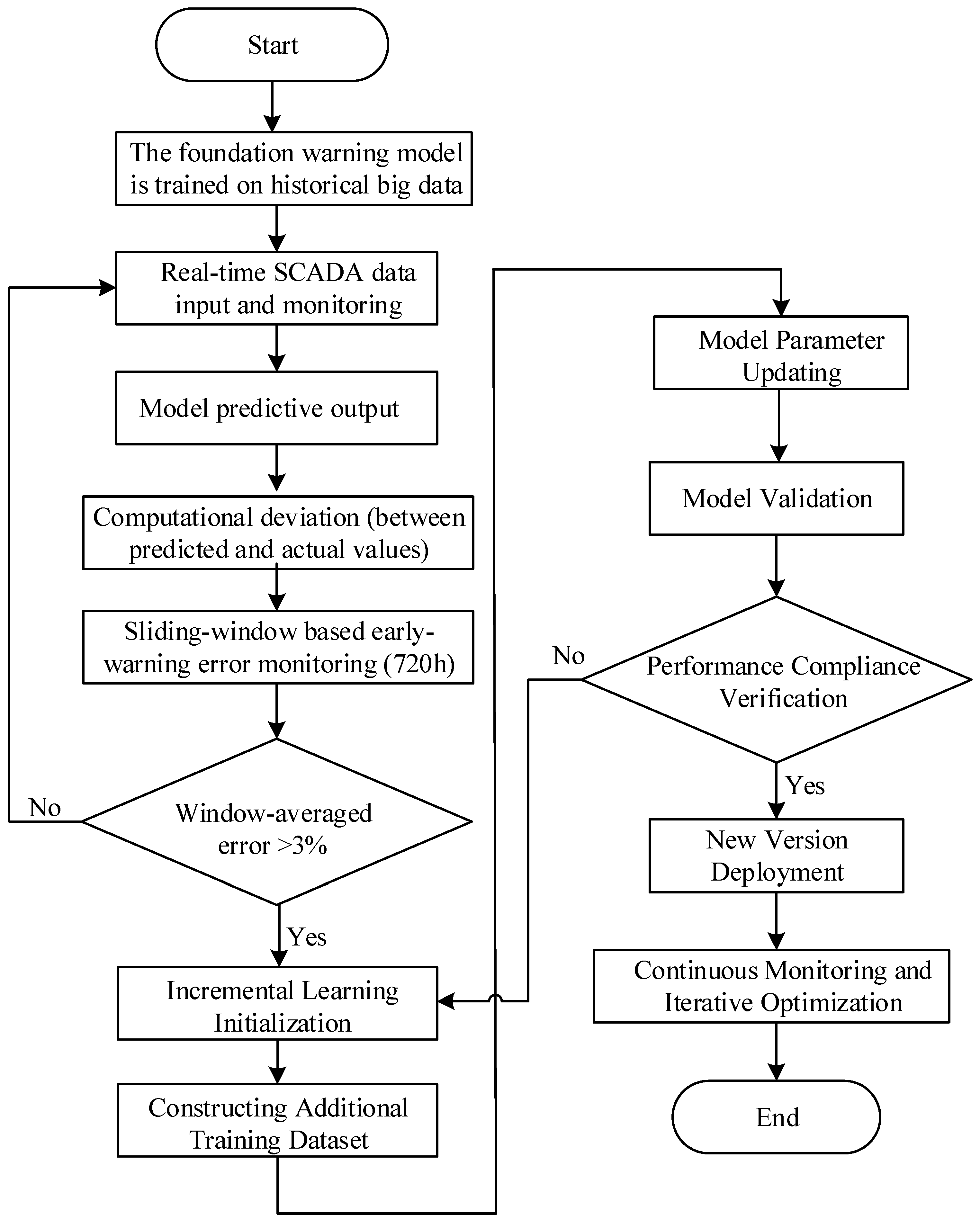

4.4. Model Update Strategy

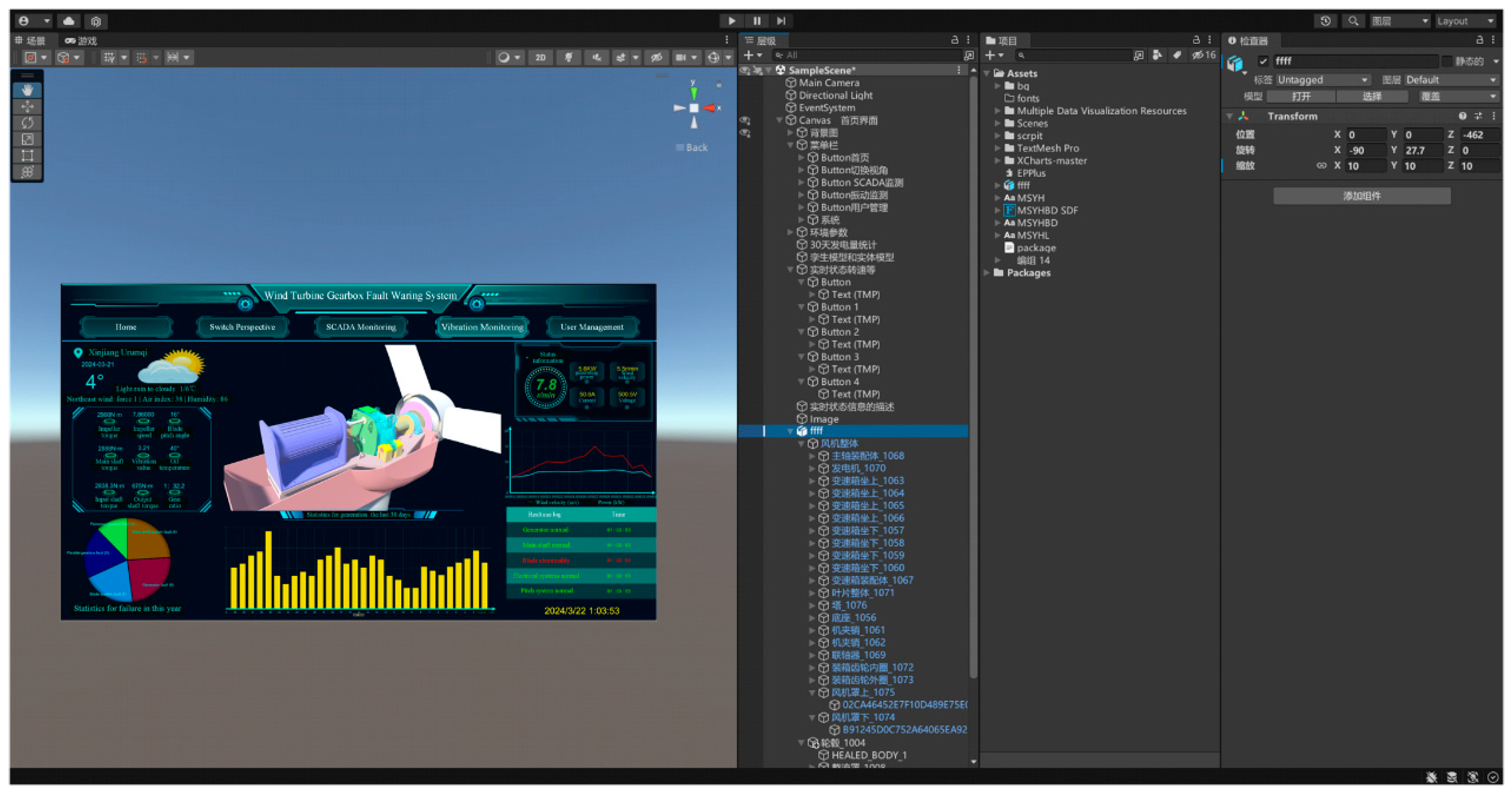

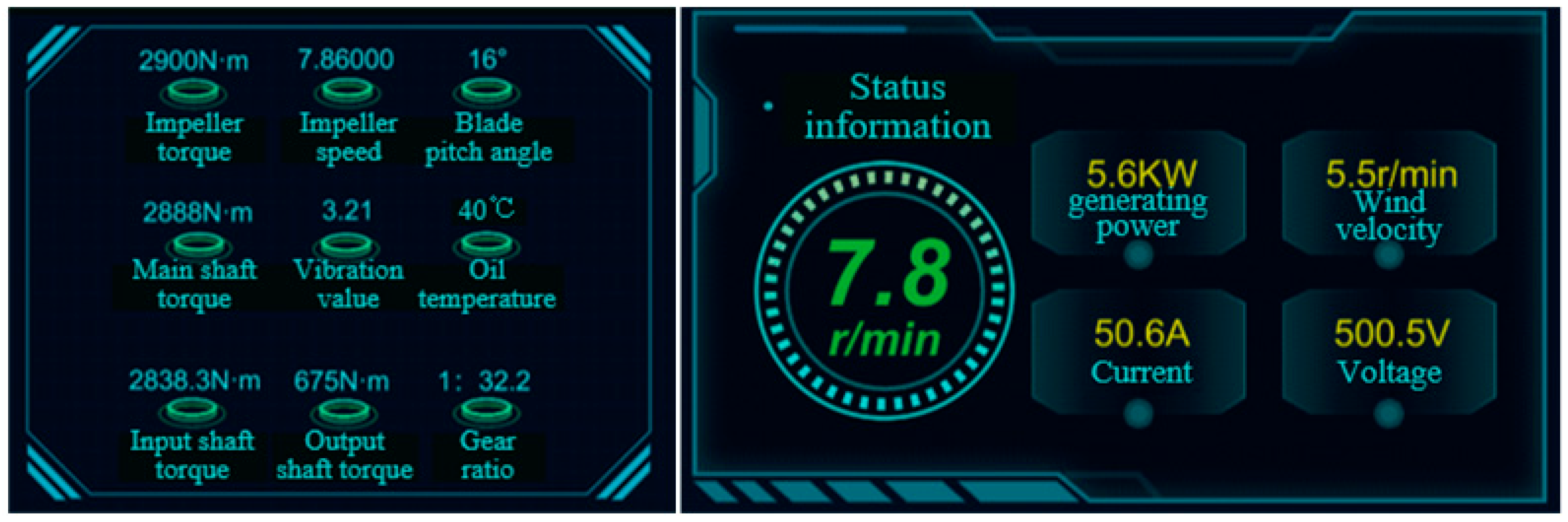

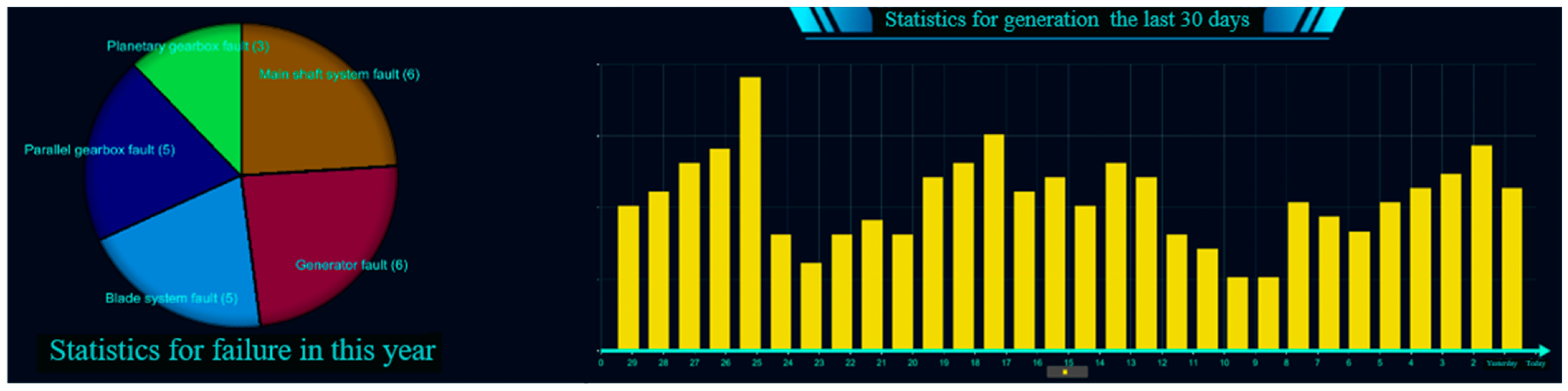

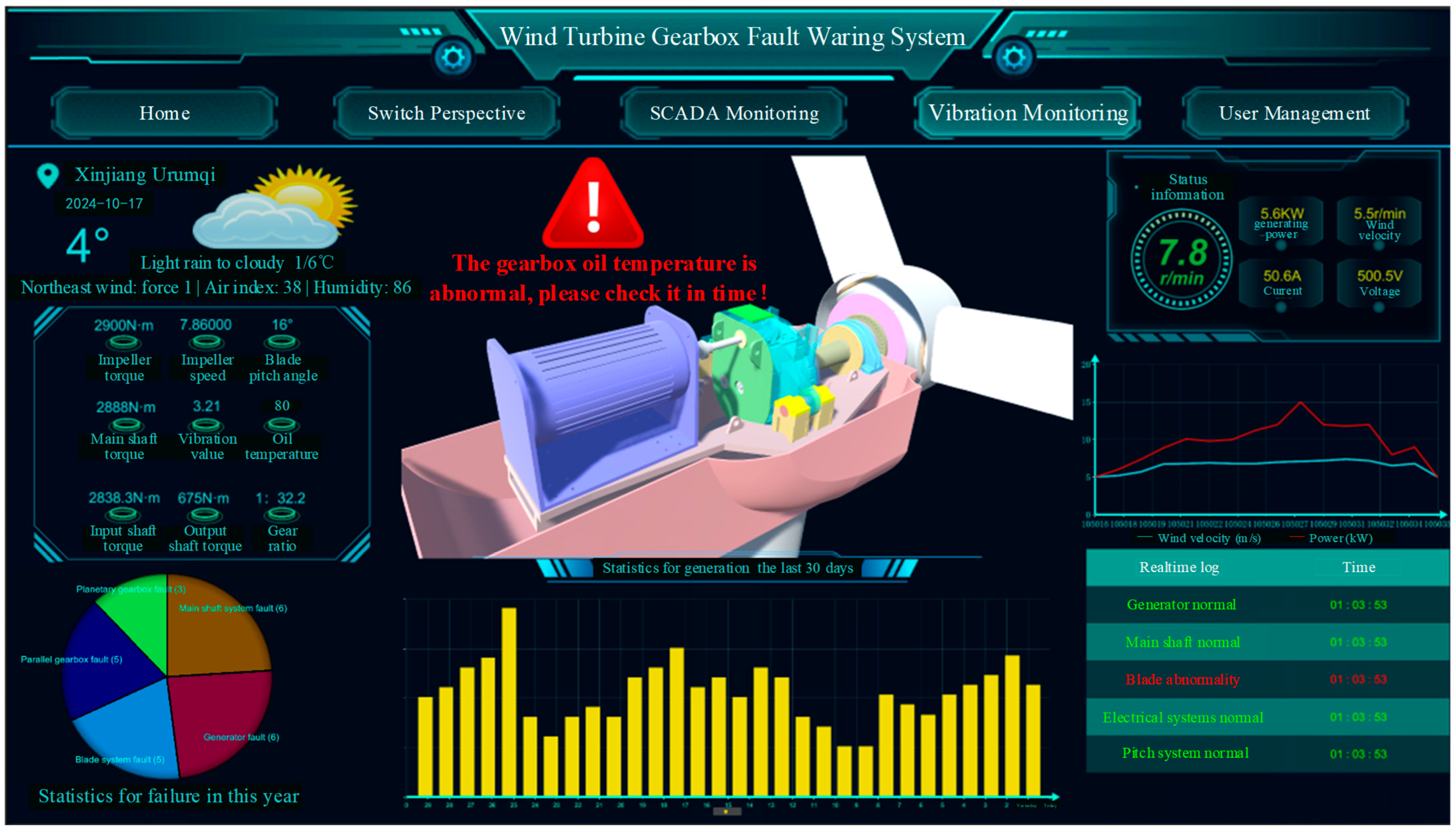

4.5. Implementation of Intelligent Monitoring and Fault Prediction for the Gear Transmission System of Wind Turbine

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, X.; Li, C.; Ye, K. Analysis on Vibration Signal Decomposition Methods of Wind Turbine Gearbox. J. Chin. Soc. Power Eng. 2021, 41, 323–329. [Google Scholar]

- Zhao, X.; Chen, C.; Liu, J.; Gu, Q. Nonlinear Dynamic Response Analysis of High Level of Wind Turbine Gearbox Transmission System Considering Eccentricity. Acta Energiae Solaris Sin. 2020, 41, 98–108. [Google Scholar]

- Lu, Z.; Zhou, J.; Cui, Q.; Wen, J.; Fei, X. Research on Reliability of Gear Transmission System of Wind Turbine Based on Dynamics. Acta Energiae Solaris Sin. 2023, 44, 397–404. [Google Scholar]

- Zhang, F.; Chen, M.; Zhu, Y.; Zhang, K.; Li, Q. A Review of Fault Diagnosis, Status Prediction, and Evaluation Technology for Wind Turbines. Energies 2023, 16, 1125. [Google Scholar] [CrossRef]

- Wang, J.; Hu, J.; Ma, K. Wind speed probability distribution estimation and wind energy assessment. Renew. Sustain. Energy Rev. 2016, 60, 881–899. [Google Scholar] [CrossRef]

- Han, Q.; Ma, S.; Wang, T.; Chu, F. Kernel density estimation model for wind speed probability distribution with applicability to wind energy assessment in China. Renew. Sustain. Energy Rev. 2019, 115, 109387. [Google Scholar] [CrossRef]

- Katinas, V.; Gecevicius, G.; Marciukaitis, M. An investigation of wind power density distribution at location with low and high wind speeds using statistical model. Appl. Energy 2018, 218, 442–451. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- Singh, U.; Rizwan, M.; Alaraj, M.; Alsaidan, I. A machine learning-based gradient boosting regression approach for wind power production forecasting: A step towards smart grid environments. Energies 2021, 14, 5196. [Google Scholar] [CrossRef]

- Hur, S. Short-term wind speed prediction using Extended Kalman filter and machine learning. Energy Rep. 2021, 7, 1046–1054. [Google Scholar] [CrossRef]

- Helbing, G.; Ritter, M. Deep Learning for fault detection in wind turbines. Renew. Sustain. Energy Rev. 2018, 98, 189–198. [Google Scholar] [CrossRef]

- Manero, J.; Béjar, J.; Cortés, U. “Dust in the wind… ”, deep learning application to wind energy time series forecasting. Energies 2019, 12, 2385. [Google Scholar] [CrossRef]

- Hong, Y.Y.; Satriani, T.R.A. Day-ahead spatiotemporal wind speed forecasting using robust design-based deep learning neural network. Energy 2020, 209, 118441. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, Z.; Zhang, H.; Wang, X.; Guo, Y. A short-term wind power prediction model based on CEEMD and WOA-KELM. Renew. Energy 2022, 189, 188–198. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, Z.; Liu, X. Short-term offshore wind power forecasting-A hybrid model based on Discrete Wavelet Transform (DWT), Seasonal Autoregressive Integrated Moving Average (SARIMA), and deep-learning-based Long Short-Term Memory (LSTM). Renew. Energy 2022, 185, 611–628. [Google Scholar] [CrossRef]

- Maheswari, R.U.; Umamaheswari, R. Trends in non-stationary signal processing techniques applied to vibration analysis of wind turbine drive train–A contemporary survey. Mech. Syst. Signal Process. 2017, 85, 296–311. [Google Scholar] [CrossRef]

- Vidal, Y.; Pozo, F.; Tutivén, C. Wind turbine multi-fault detection and classification based on SCADA data. Energies 2018, 11, 3018. [Google Scholar] [CrossRef]

- Tutivén, C.; Vidal, Y.; Insuasty, A.; Campoverde-Vilela, L.; Achicanoy, W. Early fault diagnosis strategy for WT main bearings based on SCADA data and one-class SVM. Energies 2022, 15, 4381. [Google Scholar] [CrossRef]

- Rashid, H.; Khalaji, E.; Rasheed, J.; Batunlu, C. Fault prediction of wind turbine gearbox based on SCADA data and machine learning. In Proceedings of the 2020 10th International Conference on Advanced Computer Information Technologies (ACIT), Deggendorf, Germany, 16–18 September 2020; IEEE: New York, NY, USA, 2020; pp. 391–395. [Google Scholar]

- Murgia, A.; Verbeke, R.; Tsiporkova, E.; Terzi, L.; Astolfi, D. Discussion on the suitability of SCADA-based condition monitoring for wind turbine fault diagnosis through temperature data analysis. Energies 2023, 16, 620. [Google Scholar] [CrossRef]

- Encalada-Dávila, Á.; Moyón, L.; Tutivén, C.; Puruncajas, B.; Vidal, Y. Early fault detection in the main bearing of wind turbines based on gated recurrent unit (GRU) neural networks and SCADA data. IEEE/ASME Trans. Mechatron. 2022, 27, 5583–5593. [Google Scholar] [CrossRef]

- Castellani, F.; Astolfi, D.; Natili, F. SCADA data analysis methods for diagnosis of electrical faults to wind turbine generators. Appl. Sci. 2021, 11, 3307. [Google Scholar] [CrossRef]

- Rama, V.S.B.; Hur, S.H.; Yang, J.M. Short-term fault prediction of wind turbines based on integrated RNN-LSTM. IEEE Access 2024, 12, 22465–22478. [Google Scholar] [CrossRef]

- Encalada-Dávila, Á.; Puruncajas, B.; Tutiven, C.; Vidal, Y. Wind turbine main bearing fault prognosis based solely on scada data. Sensors 2021, 21, 2228. [Google Scholar] [CrossRef] [PubMed]

- Chokr, B.; Chatti, N.; Charki, A.; Lemenand, T.; Hammoud, M. Bi-LSTM Autoencoder SCADA based Unsupervised Anomaly Detection in Real Wind Farm Data. In Proceedings of the 2024 IEEE International Conference on Prognostics and Health Management (ICPHM), Spokane, WA, USA, 17–19 June 2024; IEEE: New York, NY, USA, 2024; pp. 174–183. [Google Scholar]

- Liao, T.; Qian, S.; Meng, Z.; Xie, G.F. Early fault warning of wind turbine based on BRNN and large sliding window. J. Intell. Fuzzy Syst. 2020, 38, 3389–3401. [Google Scholar]

- Qi, T.F.; Fang, H.R.; Chen, Y.F.; He, L.T. Research on digital twin monitoring system for large complex surface machining. J. Intell. Manuf. 2022, 35, 977–990. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, J.; Chen, J.; Hu, P.; Wang, X.; Xu, J.; Zhou, B. A digital-twin visualized architecture for Flexible Manufacturing System. J. Manuf. Syst. 2021, 60, 176–201. [Google Scholar] [CrossRef]

- Wang, K.J.; Lee, Y.H.; Angelica, S. Digital twin design for real-time monitoring—A case study of die cutting machine. Int. J. Prod. Res. 2021, 59, 6471–6485. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, Z.; Zhang, J.; Li, W.; Gao, C. A digital twin-based operation status monitoring system for port cranes. Sensors 2022, 22, 3216. [Google Scholar] [CrossRef]

- Qin, S.; Cheng, L.; He, Z.; Chen, S. Review of research and application on the wind power-generation system. J. Mach. Des. 2021, 38, 1–8. [Google Scholar]

- Wang, X.; Wang, L.; Yu, Y.; Ao, Z.; Sun, L. Survey on Characteristics, Architecture and Applications of Digital Twin Power Grid. J. Electron. Inf. Technol. 2022, 44, 3721–3733. [Google Scholar]

- Fang, F.; Yao, G.; Hu, Y.; Wu, X.; Liu, J. Digital twin system of a wind turbine. Sci. Sin. (Technol.) 2022, 52, 1582–1594. [Google Scholar] [CrossRef]

- Su, D. Study on Key Technologies of Wind Turbine Operation and Maintenance Digital Twin System. Master’s Thesis, Chang’an University, Xi’an, China, 2023. [Google Scholar]

- Zhao, X. Design and Development of a Wind Farms Digital Twin Software System Based on High-Precision Wind Turbine Models and Real-Time Simulators. Master’s Thesis, Shandong University, Jinan, China, 2023. [Google Scholar]

- Moghadam, F.K.; Nejad, A.R. Nejad. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Process. 2022, 162, 108087. [Google Scholar] [CrossRef]

- Zhao, X.; Dao, M.H.; Le, Q.T. Digital twining of an offshore wind turbine on a monopile using reduced-order modelling approach. Renew. Energy 2023, 206, 531–551. [Google Scholar] [CrossRef]

- Olatunji, O.; Adedeji, P.A.; Madushele, N.; Jen, T.C. Overview of digital twin technology in wind turbine fault diagnosis and condition monitoring. In Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021; IEEE: New York, NY, USA, 2021; pp. 201–207. [Google Scholar]

- Mahmoud, M.; Semeraro, C.; Abdelkareem, M.A.; Olabi, A.G. Designing and prototyping the architecture of a digital twin for wind turbine. Int. J. Thermofluids 2024, 22, 100622. [Google Scholar] [CrossRef]

- Liu, S.; Ren, S.; Jiang, H. Predictive maintenance of wind turbines based on digital twin technology. Energy Rep. 2023, 9, 1344–1352. [Google Scholar] [CrossRef]

- Wang, B.; Sun, W.; Wang, H.; Xu, T.; Zou, Y. Research on rapid calculation method of wind turbine blade strain for digital twin. Renew. Energy 2024, 221, 119783. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, C.; Wang, J.; Peyrano, O.G.; Gu, F.; Wang, S.; Lv, D. Research on main bearing life prediction of direct-drive wind turbine based on digital twin technology. Meas. Sci. Technol. 2022, 34, 13–25. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Hnydiuk-Stefan, A.; Feng, S.; Atilla, I.; Li, Z. Recent progress on reliability analysis of offshore wind turbine support structures considering digital twin solutions. Ocean Eng. 2021, 232, 109168. [Google Scholar] [CrossRef]

| Data Type | Data Name |

|---|---|

| Meteorology | Ambient temperature, Average wind speed, Instantaneous wind speed, Instantaneous wind direction, Average wind direction, Instantaneous wind direction of the wind vane, etc. |

| Environment | Humidity in the tower, Tower base control cabinet temperature, Ambient temperature, Engine room temperature, Cabin humidity, and Cabin control cabinet temperature |

| Spindle | Spindle front bearing temperature, Spindle rear bearing temperature |

| Yaw | Yaw speed, Yaw azimuth, Yaw pressure, Engine room direction, Shaft brake hydraulics, Counterclockwise yaw running time, Clockwise yaw running time, etc. |

| Wind turbines | Operating time, Manual downtime, Uptime, Power generation time, Storm downtime, Daily power consumption, Total power generation, Daily power generation, Self-fault downtime, Service time, Working mode, Service time and Fault code, etc. |

| Generator | Generator reactive power, Generator winding temperature, Generator cooling water temperature, Generator front bearing temperature, Generator rear bearing temperature, Generator torque, Generator speed, Generator active power, Generator slip ring room temperature, Generator slip ring room humidity, etc. |

| Grid parameters | Grid frequency, Grid power factor, Grid reactive power, Voltage, Current, Grid active power, etc. |

| Gearbox | Gearbox high-speed shaft front end temperature, Gear high-speed shaft rear end temperature, Gearbox oil pool temperature, Gearbox inlet oil temperature, Gearbox inlet pressure, Gearbox oil pump outlet pressure, and Gearbox cooling water temperature |

| Frequency converter | Converter voltage, Temperature inside the converter, Converter line current, Converter cooling water temperature, Active power, Average active power, Reactive power, Average reactive power, etc. |

| Wind wheel | Wind wheel speed, Wind wheel speed 1, Wind wheel speed 2, Wind wheel speed difference, and Wind wheel position |

| Parameter Type | Value | Parameter Type | Value |

|---|---|---|---|

| Rated power | 2 MW | Rated wind speed | 15 m/s |

| Rated voltage | 690 V | Cut-in wind speed | 4 m/s |

| Frequency | 50 Hz | Cut-out wind speed | 25 m/s |

| Wind wheel diameter | 80 m | Gearbox ratio | 1:100.6 |

| Sweeping area | 5027 m2 | Blade length | 39 m |

| Hub height | 67 m | Pitch range | −5–90° |

| Unit ID | Sampling Time | Fault Time | Fault Reason | Reason |

|---|---|---|---|---|

| 03 | 1 January 2024–31 December 2024 | None | None | None |

| 07 | 1 January 2024–31 December 2024 | 19 October 2024/8:51 | Unplanned Downtime | Excessive Gearbox Oil Temperature |

| Parameter Name | Unit | Parameter Name | Unit |

|---|---|---|---|

| Gearbox oil sump temperature x1 | °C | Main bearing (rear) temp. x10 | °C |

| Gearbox HSS (front) temp. x2 | °C | Avg. wind speed within 60 s x11 | m/s |

| Gearbox HSS (rear) temp. x3 | °C | Ambient temperature x12 | °C |

| Gearbox oil inlet temp. x4 | °C | Engine compartment temperature x13 | °C |

| Gearbox oil inlet pressure x5 | bar | Engine compartment humidity x14 | g/m3 |

| Gearbox oil pump outlet pressure x6 | bar | Generator’s active power x15 | KW |

| Gearbox cooling water temp. x7 | °C | Generator’s reactive power x16 | KW |

| Rotor speed x8 | r/min | Generator speed x17 | r/min |

| Main bearing (front) temp. x9 | °C | Engine compartment control cabinet temp. x18 | °C |

| Model | RMSE | MAPE | r2 |

|---|---|---|---|

| CNN-LSTM-Attention | 0.619 | 0.937 | 0.987 |

| CNN-LSTM | 0.756 | 1.153 | 0.964 |

| LSTM-Attention | 0.932 | 1.324 | 0.951 |

| LSTM | 0.984 | 1.337 | 0.919 |

| CNN | 1.382 | 2.118 | 0.8699 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, T.; Zhang, X.; Sun, W. Intelligent Fault Warning Method for Wind Turbine Gear Transmission System Driven by Digital Twin and Multi-Source Data Fusion. Appl. Sci. 2025, 15, 8655. https://doi.org/10.3390/app15158655

Xu T, Zhang X, Sun W. Intelligent Fault Warning Method for Wind Turbine Gear Transmission System Driven by Digital Twin and Multi-Source Data Fusion. Applied Sciences. 2025; 15(15):8655. https://doi.org/10.3390/app15158655

Chicago/Turabian StyleXu, Tiantian, Xuedong Zhang, and Wenlei Sun. 2025. "Intelligent Fault Warning Method for Wind Turbine Gear Transmission System Driven by Digital Twin and Multi-Source Data Fusion" Applied Sciences 15, no. 15: 8655. https://doi.org/10.3390/app15158655

APA StyleXu, T., Zhang, X., & Sun, W. (2025). Intelligent Fault Warning Method for Wind Turbine Gear Transmission System Driven by Digital Twin and Multi-Source Data Fusion. Applied Sciences, 15(15), 8655. https://doi.org/10.3390/app15158655