Characterization of Spatial Variability in Rock Mass Mechanical Parameters for Slope Stability Assessment: A Comprehensive Case Study

Abstract

1. Introduction

2. Characterization of Spatial Variability and Slope Stability Assessment Methods

2.1. Ordinary Kriging Interpolation

2.2. Generalized Hoek–Brown Criterion

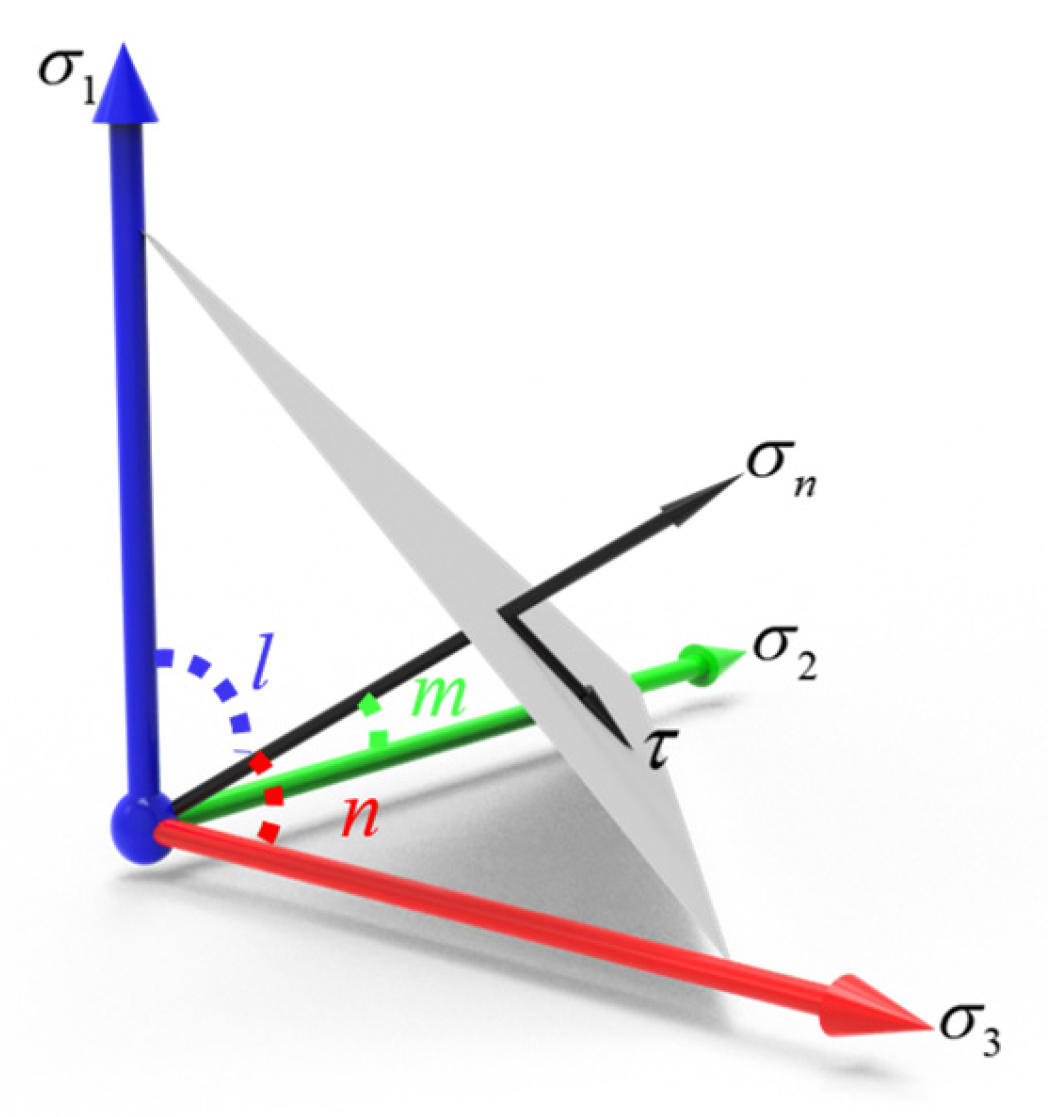

2.3. Point Safety Factor Method

3. Engineering Case Study

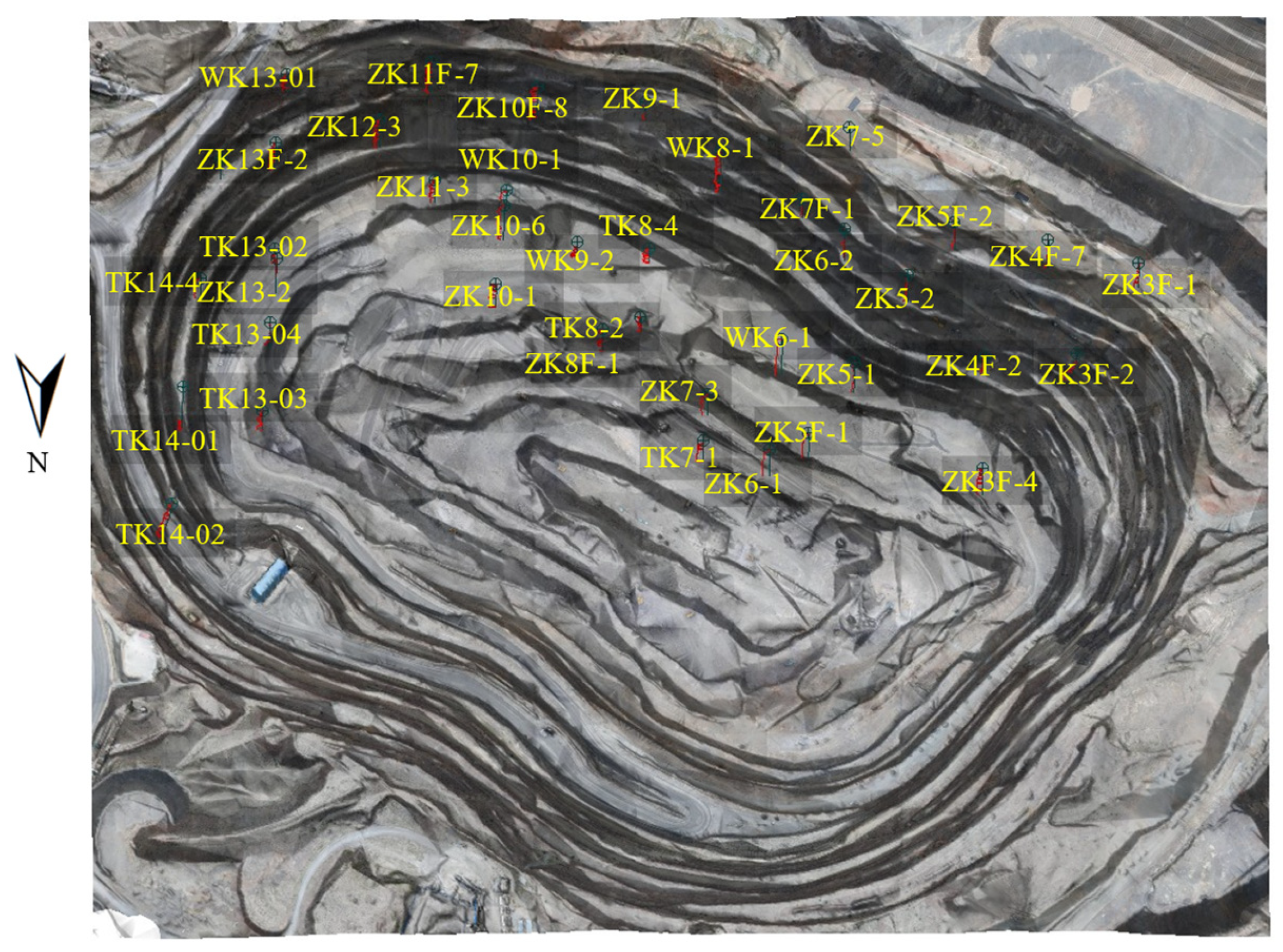

3.1. Engineering Overview

3.2. Determination of Representative Volume Element Size

3.3. Construction of Heterogeneous Mechanical Parameter Block Model

3.4. Slope Stability Assessment

4. Discussion

5. Conclusions

- By constructing three-dimensional DFNs at varying scales, this research elucidates the scale-dependent behavior of jointed rock masses. The analysis identifies an REV of 14 m × 14 m × 14 m for the study area. This optimal dimension accurately represents the in situ geological structures while balancing computational efficiency with analytical precision.

- A spatially variable block model of the rock mass mechanical parameters was developed to support the slope stability assessments. The RQD data were extracted from 40 borehole cores using digital image processing techniques. The three-dimensional spatial interpolation for the unsampled regions employed a spherical semivariogram model (nugget effect = 60; sill = 420; range = 230 m), establishing an RQD block model. The geological parameters were subsequently transformed into mechanical parameters via the generalized Hoek–Brown criterion, enabling the spatial visualization of the rock mass’s mechanical properties.

- The model’s credibility is supported by the leave-one-out cross-validation, which indicates minimal interpolation bias and spatially unstructured errors. The lithology-grouped regressions reveal an exponential E–GSI relation and a near-linear depth dependence of the equivalent cohesion, which together rationalize the observed increase in stiffness and cohesion with depth.

- Comparative stability analyses of the homogeneous and heterogeneous slope models were conducted using the PSF method. When contrasted against three homogeneous baselines (5th/25th/50th percentiles), the heterogeneous parameterization not only aligns with the mapped 2020 sliding surface but also avoids the underestimation (Fs < 1.0) seen in the 5th percentile case and the overestimation (Fs ≫ 1.0) in the 50th percentile case; the commonly used 25th percentile baseline still overpredicts the stability (Fs ≈ 1.17–1.34). These results indicate that spatial heterogeneity governs both the magnitude and geometry of instability, and that homogeneous benchmarks—regardless of the percentile chosen—are insufficient to reproduce the observed failure. Notably, the stability assessments reveal that the limestone formation within the southern slope represents a critical instability hazard, necessitating prioritized geotechnical monitoring and reinforcement measures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nguyen, T.S.; Keawsawasvong, S.; Phan, T.N.; Tanapalungkorn, W.; Likitlersuang, S. Probabilistic Analysis of Rock Slope Stability Considering the Spatial Variability of Rock Strength Parameters. Int. J. Geomech. 2025, 25, 04025002. [Google Scholar] [CrossRef]

- Gravanis, E.; Pantelidis, L.; Griffiths, D.V. An analytical solution in probabilistic rock slope stability assessment based on random fields. Int. J. Rock Mech. Min. Sci. 2014, 71, 19–24. [Google Scholar] [CrossRef]

- Li, J.D.; Gao, Y.; Yang, T.H.; Zhang, P.H.; Zhao, Y.; Deng, W.X.; Liu, H.L.; Liu, F.Y. Integrated simulation and monitoring to analyze failure mechanism of the anti-dip layered slope with soft and hard rock interbedding. Int. J. Min. Sci. Technol. 2023, 33, 1147–1164. [Google Scholar] [CrossRef]

- Zhang, W.G.; Meng, F.S.; Chen, F.Y.; Liu, H.L. Effects of spatial variability of weak layer and seismic randomness on rock slope stability and reliability analysis. Soil Dyn. Earthq. Eng. 2021, 146, 106735. [Google Scholar] [CrossRef]

- Li, L.L.; Guan, J.F.; Liu, Z.Y. A random discrete element method for modeling rock heterogeneity. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 12. [Google Scholar] [CrossRef]

- Lan, H.X.; Zhang, Y.X.; Macciotta, R.; Li, L.P.; Wu, Y.M.; Bao, H.; Peng, J.B. The role of discontinuities in the susceptibility, development, and runout of rock avalanches: A review. Landslides 2022, 19, 1391–1404. [Google Scholar] [CrossRef]

- Vick, L.M.; Böhme, M.; Rouyet, L.; Bergh, S.G.; Corner, G.D.; Lauknes, T.R. Structurally controlled rock slope deformation in northern Norway. Landslides 2020, 17, 1745–1776. [Google Scholar] [CrossRef]

- He, Y.; Li, Z.; Ou, J.L.; Yuan, R. Random Finite-Element Analysis of Slope Considering Strength Anisotropy and Spatial Variability of Soil. Nat. Hazards Rev. 2024, 25, 04024010. [Google Scholar] [CrossRef]

- Cho, S.E. Effects of spatial variability of soil properties on slope stability. Eng. Geol. 2007, 92, 97–109. [Google Scholar] [CrossRef]

- Liu, F.Y.; Yang, T.H.; Zhou, J.R.; Deng, W.X.; Yu, Q.L.; Zhang, P.H.; Cheng, G.W. Spatial Variability and Time Decay of Rock Mass Mechanical Parameters: A Landslide Study in the Dagushan Open-Pit Mine. Rock Mech. Rock Eng. 2020, 53, 3031–3053. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Kang, X.; Ge, L. Evaluation of the scale of fluctuation of geotechnical parameters by autocorrelation function and semivariogram function. Eng. Geol. 2016, 214, 43–49. [Google Scholar] [CrossRef]

- Eivazy, H.; Esmaieli, K.; Jean, R. Modelling Geomechanical Heterogeneity of Rock Masses Using Direct and Indirect Geostatistical Conditional Simulation Methods. Rock Mech. Rock Eng. 2017, 50, 3175–3195. [Google Scholar] [CrossRef]

- Chen, K.J.; Jiang, Q.H. Stability and reliability analysis of rock slope based on parameter conditioned random field. Bull. Eng. Geol. Environ. 2024, 83, 306. [Google Scholar] [CrossRef]

- Pinheiro, M.; Vallejos, J.; Miranda, T.; Emery, X. Geostatistical simulation to map the spatial heterogeneity of geomechanical parameters: A case study with rock mass rating. Eng. Geol. 2016, 205, 93–103. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, L.; Li, X.R. Slope-Dynamic Reliability Analysis Considering Spatial Variability of Soil Parameters. Int. J. Geomech. 2020, 20, 04020068. [Google Scholar] [CrossRef]

- Chen, L.L.; Zhang, W.A.; Paneiro, G.; He, Y.W.; Hong, L. Efficient numerical-simulation-based slope reliability analysis considering spatial variability. Acta Geotech. 2024, 19, 2691–2713. [Google Scholar] [CrossRef]

- Liu, Z.J.; Liu, Z.X.; Peng, Y.B. Dimension reduction of Karhunen-Loeve expansion for simulation of stochastic processes. J. Sound Vib. 2017, 408, 168–189. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, X.D.; Li, J. Modeling of unstable creep failure of spatial variable rocks subjected to sustained loading. Comput. Geotech. 2022, 148, 104847. [Google Scholar] [CrossRef]

- Bozorgpour, M.H.; Binesh, S.M.; Fathipour, H. Stability analysis of the slopes composed of heterogeneous and anisotropic clay. Acta Geotech. 2025, 20, 69–87. [Google Scholar] [CrossRef]

- Chen, D.F.; Xu, D.P.; Ren, G.F.; Jiang, Q.; Liu, G.F.; Wan, L.P.; Li, N. Simulation of cross-correlated non-Gaussian random fields for layered rock mass mechanical parameters. Comput. Geotech. 2019, 112, 104–119. [Google Scholar] [CrossRef]

- Zhang, W.G.; Goh, A.T.C. Reliability analysis of geotechnical infrastructures: Introduction. Geosci. Front. 2018, 9, 1595–1596. [Google Scholar] [CrossRef]

- Liu, W.F.; Leung, Y.F. Spatial variability of saprolitic soil properties and relationship with joint set orientation of parent rock: Insights from cases in Hong. Eng. Geol. 2018, 246, 36–44. [Google Scholar] [CrossRef]

- Chi, S.C.; Feng, W.Q.; Jia, Y.F.; Zhang, Z.L. Application of the soil parameter random field in the 3D random finite element analysis of Guanyinyan composite dam. Case Stud. Constr. Mater. 2022, 17, e01329. [Google Scholar] [CrossRef]

- Aminpour, M.; Alaie, R.; Kardani, N.; Moridpour, S.; Nazem, M. Highly efficient reliability analysis of anisotropic heterogeneous slopes: Machine learning-aided Monte Carlo method. Acta Geotech. 2023, 18, 3367–3389. [Google Scholar] [CrossRef]

- Li, J.D.; Yang, T.H.; Liu, F.Y.; Zhao, Y.; Liu, H.L.; Deng, W.X.; Gao, Y.; Li, H.B. Modeling spatial variability of mechanical parameters of layered rock masses and its application in slope optimization at the open-pit mine. Int. J. Rock Mech. Min. Sci. 2024, 181, 105859. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek-Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. Eng. 2019, 11, 445–463. [Google Scholar] [CrossRef]

- Lu, N.; Sener-Kaya, B.; Wayllace, A.; Godt, J.W. Analysis of rainfall-induced slope instability using a field of local factor of safety. Water Resour. Res. 2012, 48, W09524. [Google Scholar] [CrossRef]

- Nie, W.P.; Shi, C. Study on dynamic stability of large-scale underground cavern group during construction period of hydropower station. Appl. Mech. Mater. 2012, 152–154, 820–825. [Google Scholar] [CrossRef]

- Loyola, A.C.; Pereira, J.M.; Neto, M.P.C. General Statistics-Based Methodology for the Determination of the Geometrical and Mechanical Representative Elementary Volumes of Fractured Media. Rock Mech. Rock Eng. 2021, 54, 1841–1861. [Google Scholar] [CrossRef]

- Guo, J.T.; Zhang, Z.R.; Mao, Y.C.; Liu, S.N.; Zhu, W.C.; Yang, T.H. Automatic Extraction of Discontinuity Traces from 3D Rock Mass Point Clouds Considering the Influence of Light Shadows and Color Change. Remote Sens. 2022, 14, 5314. [Google Scholar] [CrossRef]

- Pan, M.; Jiang, S.H.; Liu, X.; Song, G.Q.; Huang, J.S. Sequential probabilistic back analyses of spatially varying soil parameters and slope reliability prediction under rainfall. Eng. Geol. 2024, 328, 107372. [Google Scholar] [CrossRef]

- Loáiciga, H.A. Groundwater and earthquakes: Screening analysis for slope stability. Eng. Geol. 2015, 193, 276–287. [Google Scholar] [CrossRef]

- Huang, M.L.; Sun, D.A.; Wang, C.H.; Keleta, Y. Reliability analysis of unsaturated soil slope stability using spatial random field-based Bayesian method. Landslides 2021, 18, 1177–1189. [Google Scholar] [CrossRef]

- Yao, W.M.; Li, C.D.; Yan, C.B.; Zhan, H.B. Slope reliability analysis through Bayesian sequential updating integrating limited data from multiple estimation methods. Landslides 2022, 19, 1101–1117. [Google Scholar] [CrossRef]

- Yao, W.M.; Fan, Y.B.; Li, C.D.; Zhan, H.B.; Zhang, X.; Lv, Y.M.; Du, Z.B. A Bayesian bootstrap-Copula coupled method for slope reliability analysis considering bivariate distribution of shear strength parameters. Landslides 2024, 21, 2557–2567. [Google Scholar] [CrossRef]

- Pang, R.; Xu, B.; Zhou, Y.; Song, L.F. Seismic time-history response and system reliability analysis of slopes considering uncertainty of multi-parameters and earthquake excitations. Comput. Geotech. 2021, 136, 104245. [Google Scholar] [CrossRef]

- Liu, S.L.; Wang, L.Q.; Zhang, W.A.; Sun, W.X.; Fu, J.; Xiao, T.; Dai, Z.W. A physics-informed data-driven model for landslide susceptibility assessment in the Three Gorges Reservoir area. Geosci. Front. 2023, 14, 101621. [Google Scholar] [CrossRef]

- Zhang, W.G.; Wu, C.Z.; Tang, L.B.; Gu, X.; Wang, L. Efficient time-variant reliability analysis of Bazimen landslide in the Three Gorges Reservoir Area using XGBoost and LightGBM algorithms. Gondwana Res. 2023, 123, 41–53. [Google Scholar] [CrossRef]

- Bai, G.X.; Hou, Y.L.; Wan, B.F.; An, N.; Yan, Y.H.; Tang, Z.; Yan, M.C.; Zhang, Y.H.; Sun, D.Y. Performance Evaluation and Engineering Verification of Machine Learning Based Prediction Models for Slope Stability. Appl. Sci. 2022, 12, 7890. [Google Scholar] [CrossRef]

| Slate | Intact slate block | Young’s modulus (GPa) | Poisson’s ratio | Cohesion (Mpa) | Friction angle (°) | Tensile strength (Mpa) |

| 3.895 | 0.26 | 13.12 | 35.5 | 3.94 | ||

| Joint | Normal stiffness (GPa/m) | Shear stiffness (GPa/m) | Cohesion (Mpa) | Friction angle (°) | Tensile strength (Mpa) | |

| 10 | 5 | 0.06 | 25.1 | 0.04 |

| Lithologies | (kN/m3) | (MPa) | Poisson’s Ratio | ||

|---|---|---|---|---|---|

| Slate | 20 | 8 | 28.6 | 50.44 | 0.26 |

| Weathered slate | 11 | 7 | 25.5 | 21.19 | 0.27 |

| Dolomite | 25 | 12 | 30.1 | 86.92 | 0.21 |

| Mica schist | 20 | 7 | 29.9 | 54.40 | 0.19 |

| Limestone | 16 | 6 | 26.5 | 28.73 | 0.28 |

| Fault | 7 | 4 | 23.3 | 7.25 | 0.30 |

| Lithologies | Number of Blocks | (Log-Linear Fits) | (Linear Fits) | ||||

|---|---|---|---|---|---|---|---|

| Slate | 130,311 | −1.429 | 0.0576 | 1.000000 | 196.936 | 0.564 | 0.210 |

| Weathered slate | 9539 | −1.862 | 0.0576 | 0.999988 | 6.087 | 0.535 | 0.909 |

| Dolomite | 10,665 | −1.157 | 0.0576 | 1.000000 | 221.260 | 1.406 | 0.540 |

| Mica schist | 6308 | −1.710 | 0.0576 | 1.000000 | 99.195 | 0.204 | 0.214 |

| Limestone | 2848 | −1.391 | 0.0576 | 1.000000 | 139.222 | 0.489 | 0.577 |

| Fault | 9905 | −2.398 | 0.0576 | 0.999998 | 21.364 | 0.122 | 0.342 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Yang, T.; Gao, Y.; Liu, F.; Zhang, Z.; Niu, P.; Liu, Y.; Zhao, Y. Characterization of Spatial Variability in Rock Mass Mechanical Parameters for Slope Stability Assessment: A Comprehensive Case Study. Appl. Sci. 2025, 15, 8609. https://doi.org/10.3390/app15158609

Dong X, Yang T, Gao Y, Liu F, Zhang Z, Niu P, Liu Y, Zhao Y. Characterization of Spatial Variability in Rock Mass Mechanical Parameters for Slope Stability Assessment: A Comprehensive Case Study. Applied Sciences. 2025; 15(15):8609. https://doi.org/10.3390/app15158609

Chicago/Turabian StyleDong, Xin, Tianhong Yang, Yuan Gao, Feiyue Liu, Zirui Zhang, Peng Niu, Yang Liu, and Yong Zhao. 2025. "Characterization of Spatial Variability in Rock Mass Mechanical Parameters for Slope Stability Assessment: A Comprehensive Case Study" Applied Sciences 15, no. 15: 8609. https://doi.org/10.3390/app15158609

APA StyleDong, X., Yang, T., Gao, Y., Liu, F., Zhang, Z., Niu, P., Liu, Y., & Zhao, Y. (2025). Characterization of Spatial Variability in Rock Mass Mechanical Parameters for Slope Stability Assessment: A Comprehensive Case Study. Applied Sciences, 15(15), 8609. https://doi.org/10.3390/app15158609