Analytical Inertia Identification of Doubly Fed Wind Farm with Limited Control Information Based on Symbolic Regression

Abstract

1. Introduction

2. Modeling and Analytical Benchmarking of Equivalent Virtual Inertia for DFIGs

2.1. Dynamic Model of DFIG with Inertia Control Methods

2.2. Analytical Derivation of Equivalent Inertia Time Constant

2.3. The Model Overview of DFIG with Limited Control Information

- (1)

- Known Structural Layer: including modules whose functional structures are known from theory but whose parameters must be identified from data. This layer comprises the induction machine, rotor dynamics, and maximum power point tracking (MPPT) modules. These components exhibit a high degree of consistency with standard DFIG models and can be modeled using established physical equations with unknown coefficients.

- (2)

- Unknown Structural Layer: including the inertia control module, whose internal structure and control logic are not disclosed due to manufacturer confidentiality. As such, this module is treated as a black box, requiring both structural and parametric identification through input–output data.

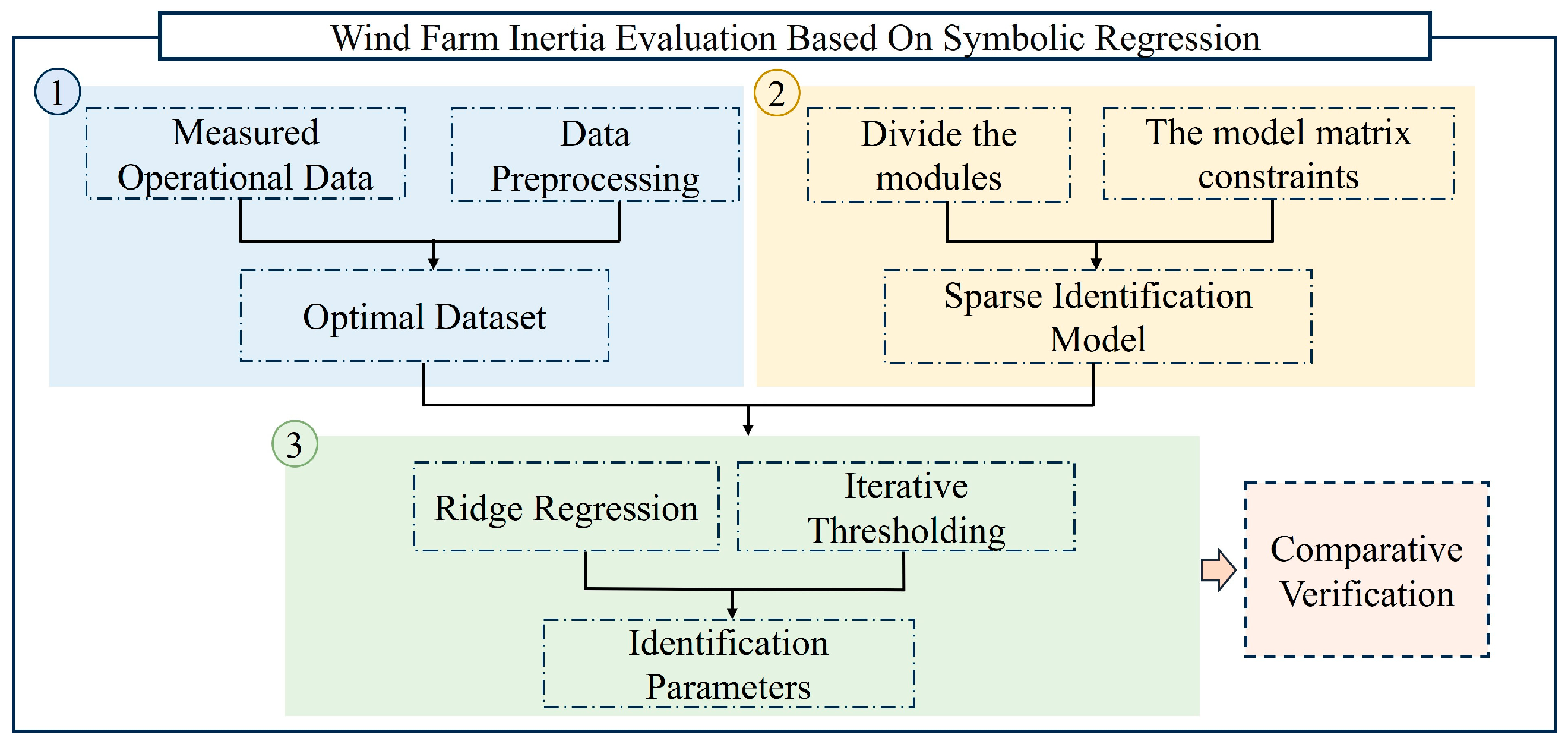

3. Sparse Dynamic Modeling and Convex Regression for Inertia Response

3.1. Fundamentals of Sparse Dynamic Modeling

3.2. The Methodology of Sparse Dynamic Modeling for DFIGs with Limited Control Information

3.2.1. Model-Prior-Integrated Sparse Dynamic Modeling with Matrix Constraints

3.2.2. Sparse Dynamic Modeling of Unknown Inertia Control Structures

3.3. Model Parameter Regression Based on Convex Optimization

4. Inertia Identification of Wind Farms Based on Analytical Optimization

4.1. Sparse Relaxed Regularization Algorithm

| Algorithm 1: SR3 |

| Input: Matrix

; Initial value: , Constraint matrices: , , Hyperparameters , , Output: The sparse matrix . Initialization. Steps: While err > do End |

4.2. Specific Steps for Identification Control Parameter and Structure

4.3. Analytical Inertia Identification of Wind Farms

5. Case Studies

5.1. Controller Structure and Parameter Identification

5.2. Validation of Inertia Evaluation Method for Wind Farms

- (1)

- The virtual inertia values derived from the proposed methodology closely align with the simulation outcomes, thereby confirming its precision and efficacy. Following a frequency disturbance, the inertia demonstrated by the wind farm equipped with inertia control is characterized by temporal variability, with the integrated inertia control exhibiting greater inertia support compared to the virtual inertia control;

- (2)

- In response to disturbances, the inertia control mechanism of the wind farm promptly discharges rotor kinetic energy to address the power shortfall. This results in a rapid increase in the equivalent virtual inertia, which effectively mitigates the rate of change in grid frequency. As the frequency reaches a state of stability, the virtual inertia gradually diminishes to zero, thereby concluding the inertia response.

5.3. Inertia Response Analysis of Wind Farms

- (1)

- The average wind speeds for the doubly fed wind farm are set to 9 m/s and 10 m/s, with the control parameters defined as follows: = 6, = 2, = 15, = 10, = 0.5;

- (2)

- The average wind speeds for the doubly fed wind farm are set to 9 m/s, with the control parameters defined as follows: = 6, = 2, = 20, = 10, = 0.5;

- (3)

- The average wind speeds for the doubly fed wind farm are set to 9 m/s, with the control parameters defined as follows: = 6, = 2, = 15, = 15, = 0.5;

- (4)

- The average wind speeds for the doubly fed wind farm are set to 9 m/s, with the control parameters defined as follows: = 6, = 2, = 15, = 10, = 1.

5.3.1. Comparison of Different Wind Speeds

5.3.2. Impact of Different Control Parameters on Inertia

6. Conclusions

- (1)

- The frequency domain analytical expression for the equivalent inertia time constant of DFIG under different control strategies is derived based on the inertia response model and the definition of the inertia time constant. The results indicate that the equivalent virtual inertia of the wind farm is influenced by its intrinsic parameters, initial operating conditions, and the inertia control strategy and parameters;

- (2)

- The proposed sparse dynamic modeling method divides the DFIG control modules and constructs input–output nonlinear feature libraries based on prior knowledge. The SR3 identification algorithm is used to estimate the model parameters. The simulation results validate the method’s effectiveness in evaluating the equivalent virtual inertia of wind farms in the IEEE three-machine nine-bus system, proving its feasibility and accuracy.

- (3)

- Compared to existing methods, the method proposed in this paper is capable of handling partially known or structurally opaque control components, which is critical in practical wind turbine systems, particularly when control structures and parameters are unknown or subject to commercial confidentiality constraints. The identified models retain a symbolic, interpretable form, unlike black-box neural networks. The sparse formulation promotes the compactness and physical relevance of the derived models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter Name | Value | |

|---|---|---|

| Turbine | Vn | 575 V |

| Pn | 1.5 MW | |

| Rs | 0.00706 pu | |

| Ls | 0.171 pu | |

| Rr | 0.005 pu | |

| Lr | 0.156 pu | |

| Lm | 2.9 pu | |

| Hwind | 5.04 s | |

| vn | 12 m/s | |

| m | 60 | |

| Sn | 90 MVA | |

| 6 | ||

| 2 | ||

| 10 | ||

| 0.5 | ||

| 10 | ||

| 15 | ||

| G1 | Sn | 100 MVA |

| Un | 16.5 kV | |

| Xd | 0.146 | |

| Xd′ | 0.0608 | |

| Xd″ | 0.04 | |

| Xq | 0.0969 | |

| Xq′ | 0.06 | |

| Xq″ | 0.0336 | |

| Td0′ | 8.96 | |

| Td0″ | 0.04 | |

| Tq0″ | 0.06 | |

| HG1 | 23.64 | |

| G2 | Sn | 100 MVA |

| Un | 18 kV | |

| Xd | 0.8958 | |

| Xd′ | 0.1198 | |

| Xd″ | 0.089 | |

| Xq | 0.8645 | |

| Xq′ | 0.8645 | |

| Xq″ | 0.089 | |

| Td0′ | 6.0 | |

| Td0″ | 0.033 | |

| Tq0′ | 0.54 | |

| Tq0″ | 0.078 | |

| HG2 | 6.4 | |

| T1 | Sn | 100 MVA |

| Un | 0.575 kV/230 kV | |

| RT + jXT | 0.002 + j0.0 | |

| T2 | Sn | 100 MVA |

| Un | 16.5 kV/230 kV | |

| RT + jXT | 0.002 + j0.0 | |

| T3 | Sn | 100 MVA |

| Un | 18 kV/230 kV | |

| RT + jXT | 0.002 + j0.0 |

References

- Yang, D.; Wang, X.; Chen, W.; Yan, G.-G.; Jin, Z.; Jin, E.; Zheng, T. Adaptive Frequency Droop Feedback Control-Based Power Tracking Operation of a DFIG for Temporary Frequency Regulation. IEEE Trans. Power Syst. 2023, 39, 2682–2692. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, D.; Zou, X.; He, C.; Hu, J.; Kang, Y. Adaptive Temporary Frequency Support for DFIG-Based Wind Turbines. IEEE Trans. Energy Convers. 2023, 38, 1937–1949. [Google Scholar] [CrossRef]

- Cheng, H.; Li, C.; Ghias, A.M.Y.M.; Blaabjerg, F. Dynamic Coupling Mechanism Analysis Between Voltage and Frequency in Virtual Synchronous Generator System. IEEE Trans. Power Syst. 2023, 39, 2365–2368. [Google Scholar] [CrossRef]

- Ochoa, D.; Martinez, S. Fast-Frequency Response Provided by DFIG-Wind Turbines and its Impact on the Grid. IEEE Trans. Power Syst. 2016, 32, 4002–4011. [Google Scholar] [CrossRef]

- Yan, W.; Wang, X.; Gao, W.; Gevorgian, V. Electro-mechanical Modeling of Wind Turbine and Energy Storage Systems with Enhanced Inertial Response. J. Mod. Power Syst. Clean. Energy 2020, 8, 820–830. [Google Scholar] [CrossRef]

- Abouyehia, M.; Egea-Àlvarez, A.; Ahmed, K.H. Evaluating inertia estimation methods in low-inertia power systems: A comprehensive review with analytic hierarchy process-based ranking. Renew. Sustain. Energy Rev. 2025, 217, 115794. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, X. Impacts of Phase-Locked Loop and Reactive Power Control on Inertia Provision by DFIG Wind Turbine. IEEE Trans. Energy Convers. 2022, 37, 109–119. [Google Scholar] [CrossRef]

- Australian Energy Market Commission. Mechanisms to Enhance Resilience in the Power System—Review of the South Australian Black System Event. [2023-03-21]. Available online: https://www.aemc.gov.au/sites/default/files/documents/aemc_-_sa_black_system_review_-_final_report.pdf (accessed on 31 August 2019).

- Ruifeng, Y. The anatomy of the 2016 South Australia blackout: A catastrophic event in a high renewable network. IEEE Trans. Power Syst. 2018, 33, 5374–5388. [Google Scholar] [CrossRef]

- National Grid ESO. Technical Report on the Events of 9 August 2019; National Grid ESO: Warwick, UK, 2019. [Google Scholar]

- Miller, N.W.; Price, W.W.; Sanchez-Gasca, J.J. Dynamic Modeling of GE 1.5 and 3.6 Wind Turbine-Generators: GE-Power Systems Energy Consulting, 2003; Power Engineering Society General Meeting: Toronto, ON, Canada, 2003; pp. 1977–1983. [Google Scholar]

- Zhao, J.; Gómez-Expósito, A.; Netto, M.; Mili, L.; Abur, A.; Terzija, V.; Kamwa, I.; Pal, B.; Singh, A.K.; Qi, J.; et al. Power System Dynamic State Estimation: Motivations, Definitions, Methodologies, and Future Work. IEEE Trans. Power Syst. 2019, 34, 3188–3198. [Google Scholar] [CrossRef]

- Ratnam, K.S.; Palanisamy, K.; Yang, G. Future low-inertia power systems: Requirements, issues, and solutions—A review. Renew. Sustain. Energy Rev. 2020, 124, 109773. [Google Scholar] [CrossRef]

- Makolo, P.; Zamora, R.; Lie, T.-T. The role of inertia for grid flexibility under high penetration of variable renewables—A review of challenges and solutions. Renew. Sustain. Energy Rev. 2021, 147, 111223. [Google Scholar] [CrossRef]

- Qi, Y.; Deng, H.; Liu, X.; Tang, Y. Synthetic Inertia Control of Grid-Connected Inverter Considering the Synchronization Dynamics. IEEE Trans. Power Electron. 2022, 37, 1411–1421. [Google Scholar] [CrossRef]

- Berizzi, A.; Bosisio, A.; Ilea, V.; Marchesini, D.; Perini, R.; Vicario, A. Analysis of Synthetic Inertia Strategies from Wind Turbines for Large System Stability. IEEE Trans. Ind. Appl. 2022, 58, 3184–3192. [Google Scholar] [CrossRef]

- Fernández-Guillamón, A.; Gómez-Lázaro, E.; Muljadi, E.; Molina-García, Á. Power systems with high renewable energy sources: A review of inertia and frequency control strategies over time. Renew. Sustain. Energy Rev. 2019, 115, 109369. [Google Scholar] [CrossRef]

- Wu, Z.; Gao, W.; Gao, T.; Yan, W.; Zhang, H.; Yan, S.; Wang, X. State-of-the-art review on frequency response of wind power plants in power systems. J. Mod. Power Syst. Clean. Energy 2018, 6, 1–16. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, T.; Nian, H.; Yang, D.; Yang, W.; Geng, H. Multi-Objective Adaptive Inertia and Droop Control Method of Wind Turbine Generators. IEEE Trans. Ind. Appl. 2023, 59, 7789–7799. [Google Scholar] [CrossRef]

- Sun, H.D.; Wang, B.C.; Li, W.F.; Yang, C.; Wei, W.; Zhao, B. Research on Inertia System of Frequency Response for Power System with High Penetration Electronics. Proc. CSEE 2020, 40, 5179–5191. [Google Scholar]

- Lu, Z.; Jiang, J.; Qiao, Y.; Min, Y.; Li, H. A Review on Generalized Inertia Analysis and Optimization of New Power Systems. Proc. CSEE 2023, 43, 1754–1776. [Google Scholar]

- Hosseini, S.A.; Fotuhi-Firuzabad, M.; Dehghanian, P.; Lehtonen, M. Coordinating Demand Response and Wind Turbine Controls for Alleviating the First and Second Frequency Dips in Wind-Integrated Power Grids. IEEE Trans. Ind. Inform. 2023, 20, 2223–2233. [Google Scholar] [CrossRef]

- Ye, Y.; Qiao, Y.; Lu, Z. Revolution of frequency regulation in the converter-dominated power system. Renew. Sustain. Energy Rev. 2019, 111, 145–156. [Google Scholar] [CrossRef]

- He, W.; Yuan, X.; Hu, J. Inertia provision and estimation of PLL-based DFIG wind turbines. IEEE Trans. Power Syst. 2017, 32, 510–521. [Google Scholar] [CrossRef]

- Tian, X.; Wang, W.; Chi, Y.; Li, Y.; Liu, C. Virtual inertia optimization control of DFIG and assessment of equivalent inertia time constant of power grid. IET Renew. Poer Gener. 2018, 12, 1733–1740. [Google Scholar] [CrossRef]

- Zhang, Y.; Bank, J.; Wan, Y.H.; Muljadi, E.; Corbus, D. Synchrophasor measurement-based wind plant inertia estimation. In Proceedings of the 2013 IEEE Green Technologies Conference, Denver, CO, USA, 4–5 April 2013; pp. 494–499. [Google Scholar]

- Paidi, E.S.N.R.; Marzooghi, H.; Yu, J.; Terzija, V. Development and validation of artificial neural network-based tools for forecasting of power system inertia with wind farms penetration. IEEE Syst. J. 2020, 14, 4978–4989. [Google Scholar] [CrossRef]

- Cao, X.; Stephen, B.; Abdulhadi, I.F.; Booth, C.D.; Burt, G.M. Switching Markov Gaussian Models for Dynamic Power System Inertia Estimation. IEEE Trans. Power Syst. 2016, 31, 3394–3403. [Google Scholar] [CrossRef]

- Xing, Q.; Wang, T.; Huang, S. On-line identification of equivalent inertia for DFIG wind turbines based on extended Kalman filters. In Proceedings of the 2021 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Chengdu, China, 18–21 July 2021; pp. 834–839. [Google Scholar]

- Wu, Y.; Zhao, X.; Shao, J.; Chen, X.; Yuan, J.; Wang, J. Inertia Estimation for Microgrid Considering the Impact of Wind Conditions on Doubly-Fed Induction Generators. IEEE Trans. Sustain. Energy 2024, 15, 2115–2125. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, L.; Wang, W.; Chen, B.; Yu, L.; Xu, S.; Jia, H. Temporal Spatio Inertia Perception of Global Power Grid Based on Adaptive Variable-order Fitting of Second-order Penalty Function. Autom. Electr. Power Syst. 2024, 48, 69–79. [Google Scholar]

- Li, S.; Deng, C.; Long, Z.; Zhou, Q.; Zheng, F. Calculation of Equivalent Virtual Inertia Time Constant of Wind Farms. Autom. Electr. Power Syst. 2016, 40, 22–29. [Google Scholar]

- Guo, J.; Wang, X.; Ooi, B.T. Estimation of Inertia for Synchronous and Non-Synchronous Generators Based on Ambient Measurements. IEEE Trans. Power Syst. 2022, 37, 3747–3757. [Google Scholar] [CrossRef]

- Tuttelberg, K.; Kilter, J.; Wilson, D.H.; Uhlen, K. Estimation of Power System Inertia From Ambient Wide Area Measurements. IEEE Trans. Power Syst. 2018, 33, 7249–7257. [Google Scholar] [CrossRef]

- Zeng, F.; Zhang, J.; Chen, G.; Wu, Z.; Huang, S.; Liang, Y. Online estimation of power system inertia constant under normal operating conditions. IEEE Access 2020, 8, 101426–101436. [Google Scholar] [CrossRef]

- Qi, Y.; Yang, T.; Fang, J.; Tang, Y.; Potti, K.R.R.; Rajashekara, K. Grid Inertia Support Enabled by Smart Loads. IEEE Trans. Power Electron. 2020, 36, 947–957. [Google Scholar] [CrossRef]

- Dreidy, M.; Mokhlis, H.; Mekhilef, S. Inertia response and frequency control techniques for renewable energy sources: A review. Renew. Sustain. Energy Rev. 2017, 69, 144–155. [Google Scholar] [CrossRef]

- Mauricio, J.M.; Marano, A.; Gomez-Exposito, A.; Ramos, J.L.M. Frequency Regulation Contribution Through Variable-Speed Wind Energy Conversion Systems. IEEE Trans. Power Syst. 2009, 24, 173–180. [Google Scholar] [CrossRef]

- Wang, T.; Xing, Q.; Li, H. Online evaluation and response characteristics analysis of equivalent inertia of a doubly-fed induction generator incorporating virtual inertia control. Prot. Control. Mod. Power Syst. 2022, 50, 52–60. [Google Scholar]

- Li, H.; Zhang, X.; Wang, Y.; Zhu, X. Virtual inertia control of DFIG-based wind turbines based on the optimal power tracking. Proceeding CSEE 2012, 32, 32–39. [Google Scholar]

- Liu, H.M.; Ren, Q.Y.; Zhang, Z.K.; Li, Y. Calculation of Equivalent Inertial Time Constant for Doubly-fed Induction Generators and Slip-feedback Inertia Control Strategy. Autom. Electr. Power Syst. 2018, 42, 49–57. [Google Scholar]

- Champion, K.; Zheng, P.; Aravkin, A.Y.; Brunton, S.L.; Kutz, J.N. A Unified Sparse Optimization Framework to Learn Parsimonious Physics-Informed Models From Data. IEEE Access 2020, 8, 169259–169271. [Google Scholar] [CrossRef]

- Loiseau, J.-C.; Brunton, S.L. Constrained sparse Galerkin regression. J. Fluid Mech. 2018, 838, 42–67. [Google Scholar] [CrossRef]

- Zheng, P.; Askham, T.; Brunton, S.L.; Kutz, J.N.; Aravkin, A.Y. A Unified Framework for Sparse Relaxed Regularized Regression: SR3. IEEE Access 2018, 7, 1404–1423. [Google Scholar] [CrossRef]

- Liu, J.; Wang, C.; Zhao, J.; Tan, B.; Bi, T. Simplified Transient Model of DFIG Wind Turbine for COI Frequency Dynamics and Frequency Spatial Variation Analysis. IEEE Trans. Power Syst. 2023, 39, 3752–3768. [Google Scholar] [CrossRef]

- Jun, A.N.; Shuai, S.; Yibo, Z. Evaluation of equivalent virtual inertia of wind farm based on measured data. Power Syst. Technol. 2023, 47, 1819–1829. [Google Scholar]

- Zhou, T.; Huang, J.; Han, R.S. Inertial Support Capacity Analysis and Equivalent Inertia Estimation of Wind Turbines Under Integrated Inertial Control. J. Shanghai Jiaotong Univ. 2024, 58, 1–24. [Google Scholar]

| Module | The Number of Iterations | Training Time | Training Accuracy |

|---|---|---|---|

| Swing equation | 30 | 0.58 | 1.000 |

| Induction motors | 2000 | 3.15 | 0.999 |

| Speed controller | 46 | 1.54 | 1.000 |

| Virtual inertia controller | 1452 | 2.54 | 0.986 |

| Integrated inertia controller | 1654 | 2.78 | 0.964 |

| Characteristic Items | Mathematical Expressions | Virtual Inertia Control | Integrated Inertia Control |

|---|---|---|---|

| Frequency Deviation | × | ✔ | |

| Rate of change in frequency | × | × | |

| Power Output Deviation | ✔ | ✔ | |

| Power Rate of Change | × | × | |

| Frequency-Power Product Term | × | × |

| Parameters | Actual Values | Identified Values | Error/% |

|---|---|---|---|

| 5.04 | 4.99 | −0.99 | |

| 6 | 6.17 | 2.83 | |

| 2 | 2.01 | 0.5 | |

| 10 | 10.561 | 5.61 | |

| 0.5 | 0.514 | 2.8 |

| Parameters | Actual Values | Identified Values | Error/% |

|---|---|---|---|

| 5.04 | 4.95 | 1.79 | |

| 6 | 6.144 | 2.4 | |

| 2 | 2.073 | 3.65 | |

| 15 | 14.268 | 4.88 | |

| 10 | 10.587 | 5.87 | |

| 0.5 | 0.516 | 3.20 |

| Parameters | Actual Values | Identified Values | Error/% |

|---|---|---|---|

| 5.04 | 4.95 | 1.79 | |

| 6 | 6.144 | 2.4 | |

| 2 | 2.073 | 3.65 | |

| 15/20 | 14.268/18.986 | 4.88/5.07 | |

| 10/15 | 10.587/15.738 | 5.87/4.92 | |

| 0.5/1 | 0.516/0.954 | 3.20/4.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Li, Y.; Shi, X.; Shao, D.; Zhang, M.; Guo, D.; Cao, Y. Analytical Inertia Identification of Doubly Fed Wind Farm with Limited Control Information Based on Symbolic Regression. Appl. Sci. 2025, 15, 8578. https://doi.org/10.3390/app15158578

Shi M, Li Y, Shi X, Shao D, Zhang M, Guo D, Cao Y. Analytical Inertia Identification of Doubly Fed Wind Farm with Limited Control Information Based on Symbolic Regression. Applied Sciences. 2025; 15(15):8578. https://doi.org/10.3390/app15158578

Chicago/Turabian StyleShi, Mengxuan, Yang Li, Xingyu Shi, Dejun Shao, Mujie Zhang, Duange Guo, and Yijia Cao. 2025. "Analytical Inertia Identification of Doubly Fed Wind Farm with Limited Control Information Based on Symbolic Regression" Applied Sciences 15, no. 15: 8578. https://doi.org/10.3390/app15158578

APA StyleShi, M., Li, Y., Shi, X., Shao, D., Zhang, M., Guo, D., & Cao, Y. (2025). Analytical Inertia Identification of Doubly Fed Wind Farm with Limited Control Information Based on Symbolic Regression. Applied Sciences, 15(15), 8578. https://doi.org/10.3390/app15158578