A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology

Abstract

1. Introduction

2. Related Work

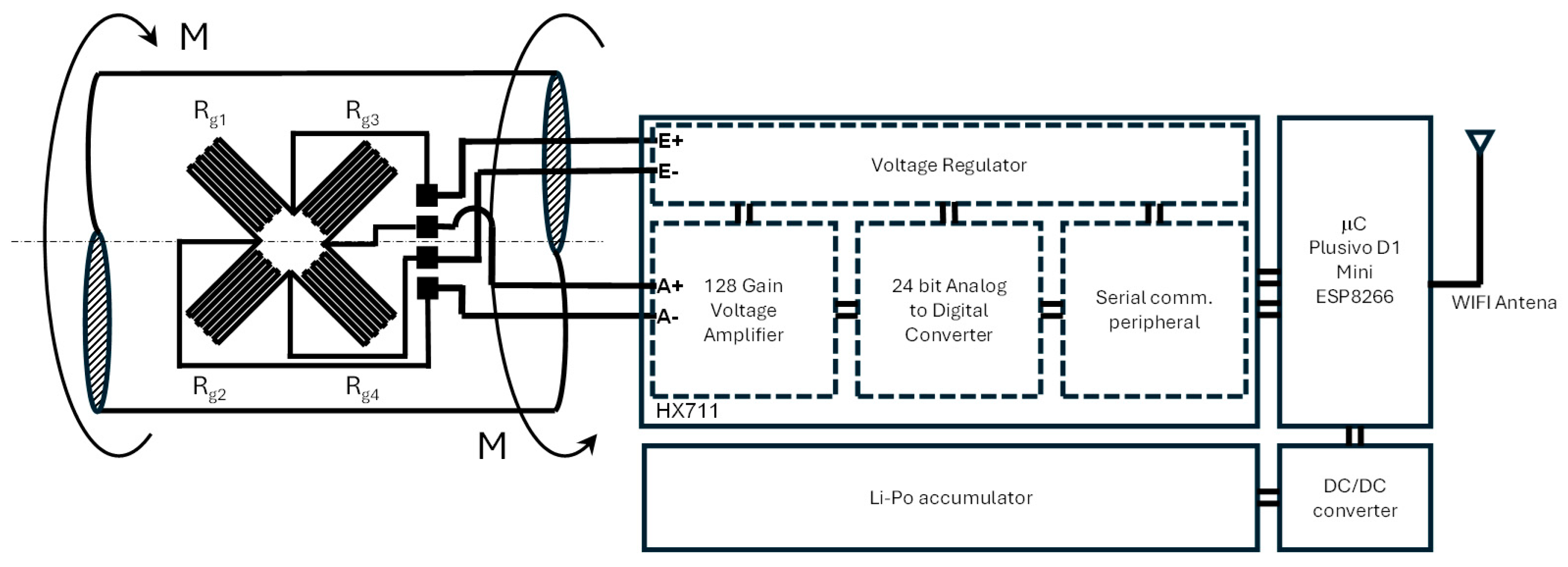

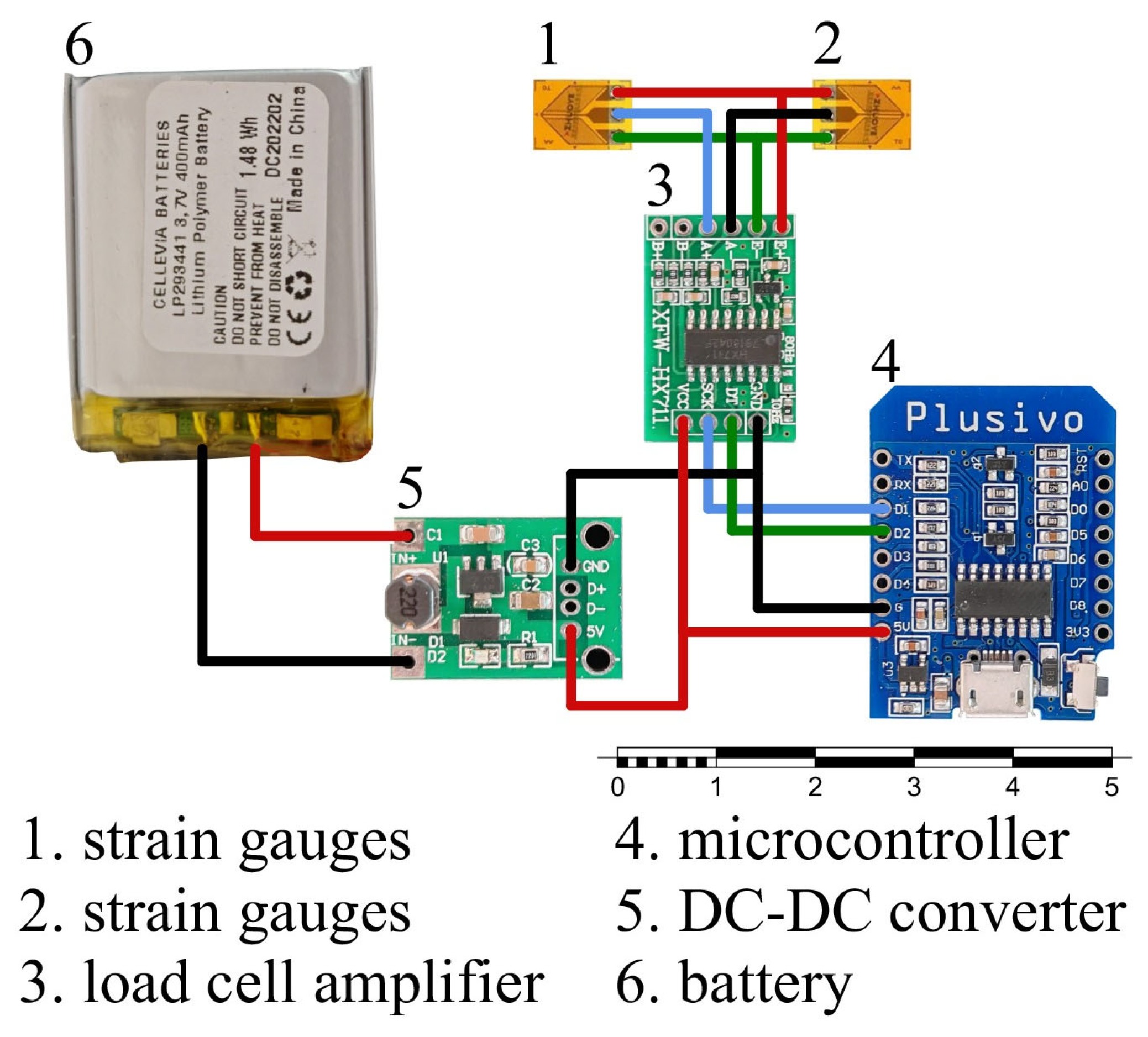

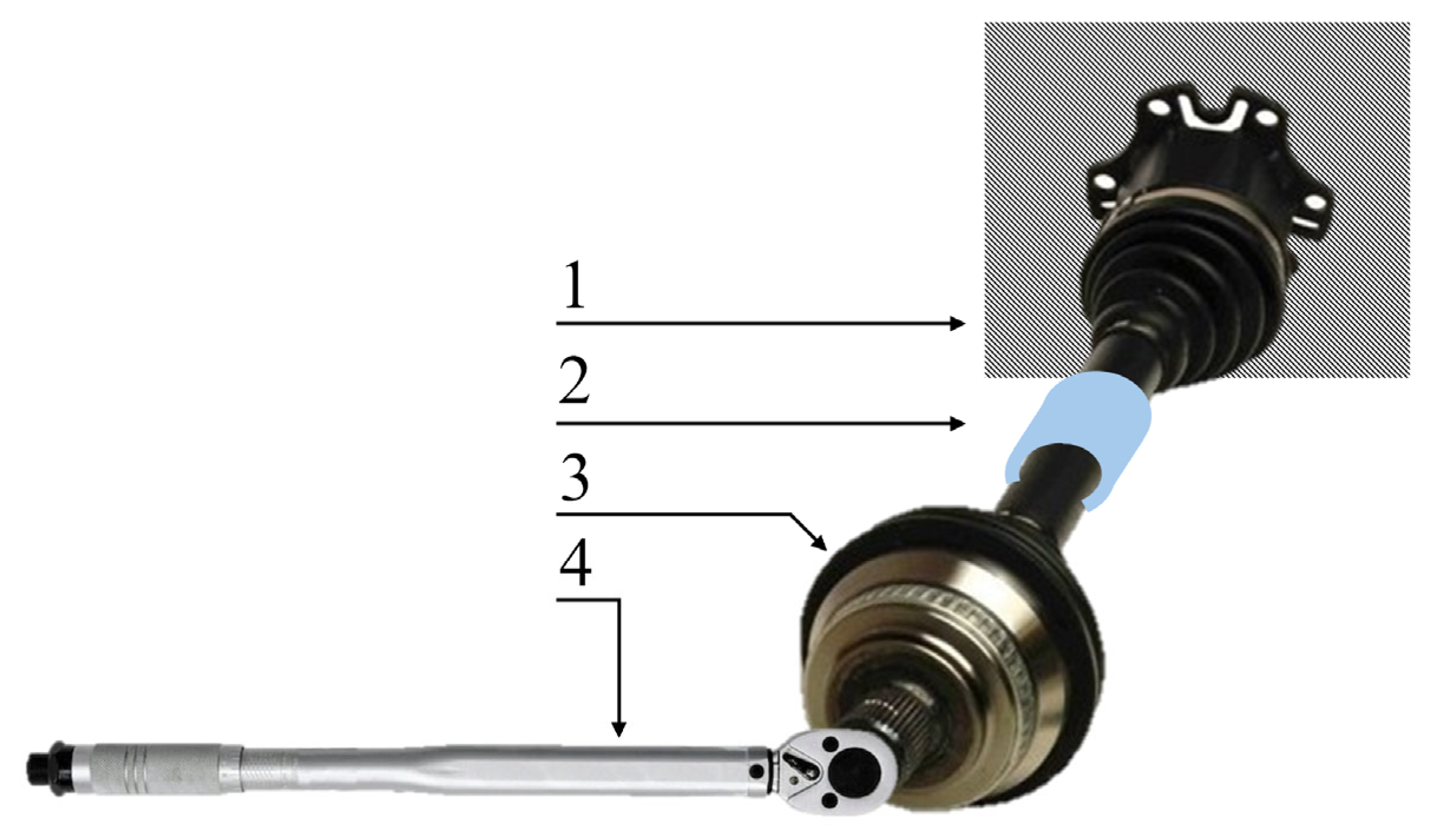

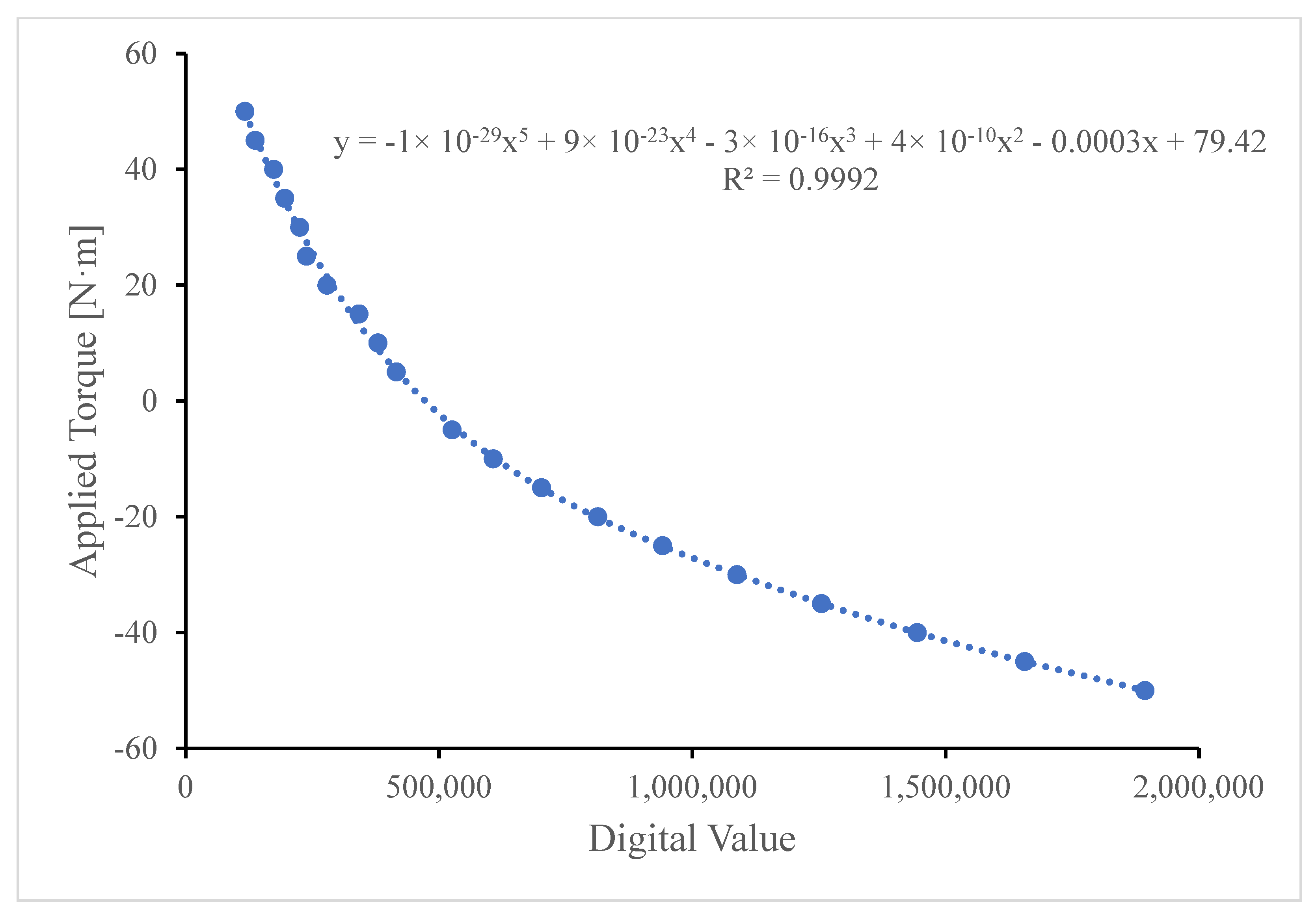

3. Materials and Methods

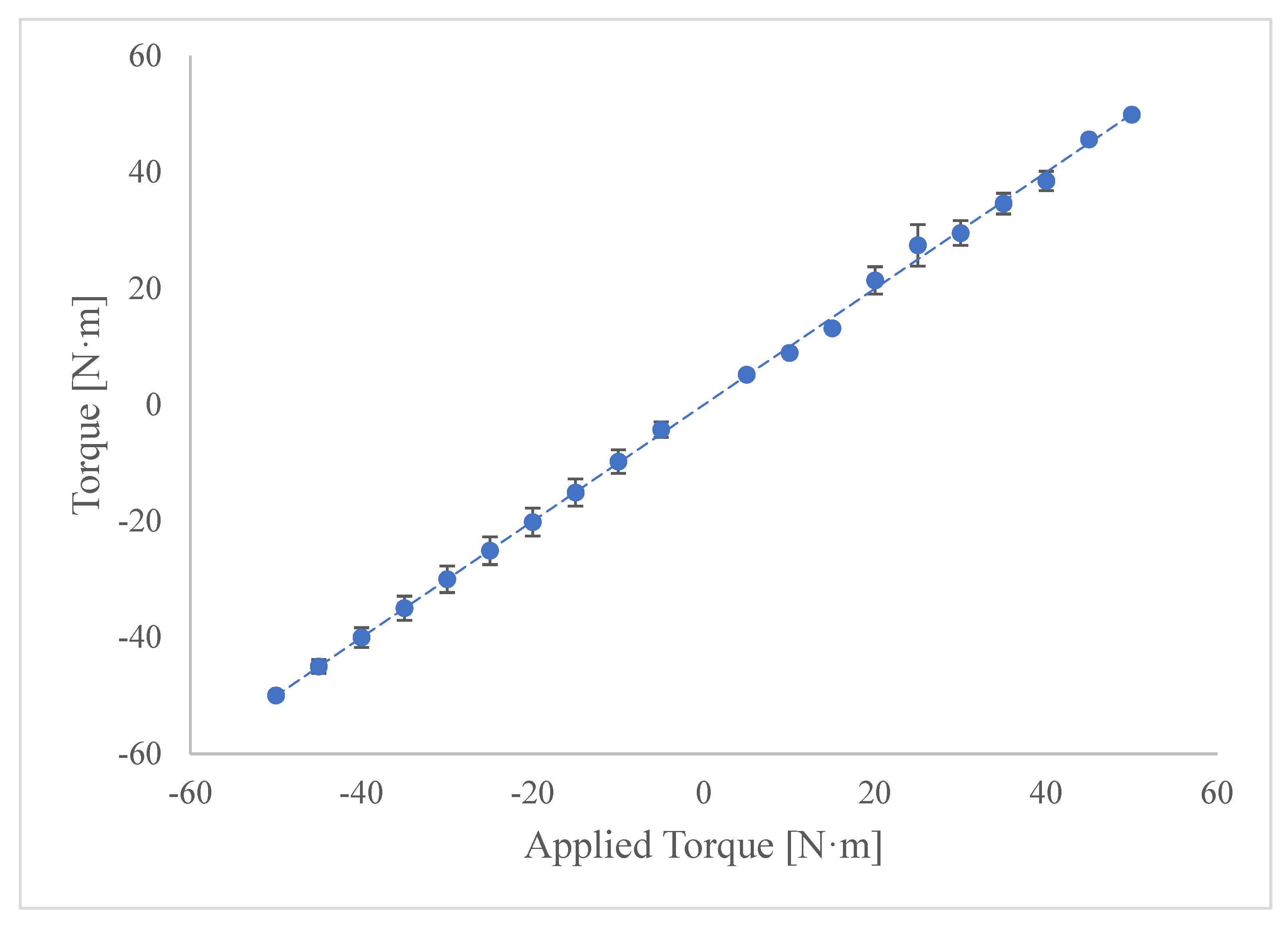

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| PCB | Printed Circuit Board |

| Wi-Fi | Wireless Fidelity |

| N·m | Newton Meter |

| OLS | Ordinary Least Squares |

| MAE | Mean Absolute Error |

| SD | Standard Deviation |

| CW | Clockwise |

| CCW | Counterclockwise |

| TARE | Zero-Load Reference Value |

| RAW | Loaded Sensor Value |

| DV | Digital Value (Raw Sensor Output) |

| R2 | Coefficient of Determination |

| ISO | International Organization for Standardization |

| AI | Artificial Intelligence |

| BLE | Bluetooth Low Energy |

| DV | Digital Value |

| FS | Full Scale |

| RMSA | Root Mean Square |

| ADC | Analog-to-Digital Converter |

| BF350-3HA-E | Foil Strain Gauge Element Employed for Torque Sensing |

| DC-DC | Direct-Current-to-Direct-Current (Power) Converter |

| DIY | Do It Yourself (Low-Cost, Hobbyist Approach) |

| ESP8266 | Wi-Fi-Enabled Microcontroller |

| FTM | Fine-Time Measurement |

| HX711 | 24-Bit Load Cell Amplifier and ADC |

| ID | Identifier (Used in Benchmark Table) |

| IP67 | Ingress-Protection Rating: Dust-Tight and Water-Resistant to 1 m for 30 min |

| Li-Po | Lithium Polymer (Rechargeable Battery) |

| OFDM | Orthogonal Frequency-Division Multiplexing |

| RBF | Radial Basis Function (Neural Network Kernel) |

References

- Garshelis, I.J. Torque and Power Measurement. In Mechanical Variables Measurement—Solid, Fluid, and Thermal; CRC Press: Boca Raton, FL, USA, 1999; ISBN 978-1-003-41821-4. [Google Scholar]

- Jubair, A.; Mazali, I.I.; Daud, Z.H.C.; CheKob, M.S.; Asus, Z.; Hamid, M.K.A. Torque Meter Calibration for Powertrain Test Bench. AIP Conf. Proc. 2025, 3056, 020007. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, Y.; Yu, W.; Liu, X. Design and calibration of the accurate torque measurement systems of the Precision Robot Reducer Detector. Meas. Control 2023, 56, 989–1003. [Google Scholar] [CrossRef]

- Matetić, I.; Štajduhar, I.; Wolf, I.; Ljubic, S. A Review of Data-Driven Approaches and Techniques for Fault Detection and Diagnosis in HVAC Systems. Sensors 2023, 23, 1. [Google Scholar] [CrossRef] [PubMed]

- Kiuchi, M.; Nishino, A.; Ogushi, K. Calibration Procedures for Torque Measuring Devices by Using a Reference Type Torque Calibration Machine at NMIJ. Acta IMEKO 2020, 9, 179–183. [Google Scholar] [CrossRef]

- Manshin, Y.P.; Yu Manshina, E.; Geue, M. About the Dynamic Error of Strain Gauge Torque Measuring Devices. J. Phys. Conf. Ser. 2021, 2131, 052041. [Google Scholar] [CrossRef]

- Smith, J. Practical Problems in Calibration of Torque Tubes. Strain 2008, 13, 148–151. [Google Scholar] [CrossRef]

- Nadeau, P.; Garcia, M.R.; Wise, E.; Kelly, J. Automated Continuous Force-Torque Sensor Bias Estimation. arXiv 2024, arXiv:2403.01068. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, Y.; Yang, F.; Zhang, X.; Mu, J.; Chen, H.-H. Distributed Modulation Recognition for IoT Devices in Data-Limited Applications. IEEE Internet Things J. 2025, 12, 26740–26752. [Google Scholar] [CrossRef]

- Ma, H.; Tao, Y.; Fang, Y.; Chen, P.; Li, Y. Multi-Carrier Initial-Condition-Index-Aided DCSK Scheme: An Efficient Solution for Multipath Fading Channel. IEEE Trans. Veh. Technol. 2025, 1–14. [Google Scholar] [CrossRef]

- Passerini, F. Neural Network-Based Calibration of 6D Force-Torque Sensors in Humanoid Robots; Laurea: Politecnico di Torino, Italy, 2024. [Google Scholar]

- Lu, T.-F.; Lin, G.C.; He, J.R. Neural-Network-Based 3D Force/Torque Sensor Calibration for Robot Applications. Eng. Appl. Artif. Intell. 1997, 10, 87–97. [Google Scholar] [CrossRef]

- Oh, H.S.; Kang, G.; Kim, U.; Seo, J.K.; Choi, H.R. Calibration of 6 Axis Force/Torque Sensor by Using Deep-Learning Method. In Proceedings of the 2017 13th IEEE Conference on Automation Science and Engineering (CASE), Xi’an, China, 20–23 August 2017; pp. 1316–1317. [Google Scholar]

- Wang, H.; Zhang, P.; Zhang, H.; Wang, H. New Concepts in the Design of an IoT Electric Torque Wrench Based on a Smart Meter Chip. Eng. Rep. 2024, 6, 12941. [Google Scholar] [CrossRef]

- Tang, L.; Hui, X.; Jiang, X.; Xiong, X.; Li, Q.; Guo, H. Tribo-Electrostatic-Based High Precision and Interchangeable Dynamic Torque Sensing by Linear Elastomer Formed Phase Displacement. Nano Energy 2025, 135, 110636. [Google Scholar] [CrossRef]

- Tan, R.; Xia, Y.; Han, X.; Huang, L.; Gao, W.; Jia, C.; Yang, P.; Lin, Q.; Ding, S.; Wang, C.; et al. Miniaturized Silicon-Based Capacitive Six-Axis Force/Torque Sensor with Large Range, High Sensitivity, and Low Crosstalk. Microsyst. Nanoeng. 2024, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Othman, W.Z.; Ramli, A.F.; Mamat, N.H.; Abd Aziz, M.R. Cutting Force Measurement Using Strain Gauge and Arduino for Monitoring of Turning Tool Post. J. Phys. Conf. Ser. 2022, 2319, 012018. [Google Scholar] [CrossRef]

- Gillot, C.; Picoux, B.; Reynaud, P.; Cardoso Da Silva, D.; Rakotovao-Ravahatra, N.; Feix, N.; Petit, C. Wireless Strain Gauge for Monitoring Bituminous Pavements. Appl. Sci. 2024, 14, 2245. [Google Scholar] [CrossRef]

- Turlapati, S.H.; Nguyen, V.P.; Gurnani, J.; Bin Ariffin, M.Z.; Kana, S.; Yee Wong, A.H.; Han, B.S.; Campolo, D. Identification of Intrinsic Friction and Torque Ripple for a Robotic Joint with Integrated Torque Sensors with Application to Wheel-Bearing Characterization. Sensors 2024, 24, 7465. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.; Shin, J.; Jung, H.; Won, J.; Auh, E.; Moon, H. On-Site Implementation of External Wrench Measurement via Non-Linear Optimization in Six-Axis Force–Torque Sensor Calibration and Crosstalk Compensation. Appl. Sci. 2025, 15, 1510. [Google Scholar] [CrossRef]

- Bosmans, J.; Gallas, S.; Smeets, V.; Kirchner, M.; Geens, L.; Croes, J.; Desmet, W. Experimental Validation of Virtual Torque Sensing for Wind Turbine Gearboxes Based on Strain Measurements. Wind Energy 2025, 28, e2955. [Google Scholar] [CrossRef]

- Zhang, H.; Wenske, J.; Reuter, A.; Neshati, M. Proposals for a Practical Calibration Method for Mechanical Torque Measurement on the Wind Turbine Drive Train under Test on a Test Bench. Wind Energy 2020, 23, 1048–1062. [Google Scholar] [CrossRef]

- Fidelus, J.D.; Puchalski, J.; Trych-Wildner, A.; Urbański, M.K.; Weidinger, P. Estimation of Uncertainty for the Torque Transducer in MNm Range—Classical Approach and Fuzzy Sets. Energies 2023, 16, 6064. [Google Scholar] [CrossRef]

- Voronin, S.S.; Loginov, B.M.; Gasiyarova, O.A.; Evdokimov, S.A.; Karandaev, A.S.; Khramshin, V.R. Telemetry System to Monitor Elastic Torque on Rolling Stand Spindles. J. Manuf. Mater. Process. 2024, 8, 85. [Google Scholar] [CrossRef]

- Yu, Z.; Yu, W. Shafting Misalignment Malfunction Quantitative Diagnosis Based on Speed Signal SVD-HT and CSF-PPSO-ESN Method. Comput. Intell. Neurosci. 2022, 2022, 7016597. [Google Scholar] [CrossRef] [PubMed]

- Chahmi, A. Study and Realization of a Torque Measurement Sensor Based on Strain Gauges Dedicated to Bending and Torsion. In Proceedings of the 2022 2nd International Conference on Advanced Electrical Engineering (ICAEE), Constantine, Algeria, 29–31 October 2022; pp. 1–5. [Google Scholar]

- Popelka, J.; Mikulanin, L.; Scholz, C. Construction of the Measuring Device for Analyzing the Internal Combustion Engine Torque. Appl. Mech. Mater. 2015, 799–800, 947–951. [Google Scholar] [CrossRef]

- Lopot, F.; Dub, M.; Flek, J.; Hadraba, D.; Havlíček, M.; Kučera, L.; Štoček, O.; Veselý, T.; Janáček, J. Gearbox Mechanical Efficiency Determination by Strain Gauges Direct Application. Appl. Sci. 2021, 11, 11150. [Google Scholar] [CrossRef]

- Ehsani, A.; Khomami, N.A.; Ghaneie, M.; Masouleh, M.T. Design and Fabrication of an Optimized Six-Axis Force-Torque Sensor. In Proceedings of the 2023 11th RSI International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 19 December 2023; pp. 598–605. [Google Scholar]

- Suciu, C.C.; Stoica, V.; Ilie, M.; Ionel, I. A Novel Approach to Real-Time Torque Measurement through IoT-Integrated Strain Gauges and Neural Network Calibration. In Proceedings of the CIE/C2I 2025: International Conference on Industrial Engineering and Computer Integrated Manufacturing, Timișoara, Romania, 12–14 June 2025. presented, not yet published. [Google Scholar]

- Hemeda, S.G.; Aboukarima, A.M.; Minyawi, M. Developing a logging unit for measuring and recording power data using arduino board. Misr J. Agric. Eng. 2017, 34, 2053–2072. [Google Scholar] [CrossRef]

- Tarakçi, S.; Aldemir, O.; Solmaz, T.; Işik, E. External Torque Sensor Design Providing Wireless and Real-Time Data Customized for Drivetrain. Int. J. Automot. Eng. Technol. 2022, 11, 18–27. [Google Scholar] [CrossRef]

- Szybicki, D.; Obal, P.; Kurc, K.; Gierlak, P. Programming of Industrial Robots Using a Laser Tracker. Sensors 2022, 22, 6464. [Google Scholar] [CrossRef] [PubMed]

- Kalcher, R.; Ellermann, K.; Kelz, G. Load Torque Estimation for an Automotive Electric Rear Axle Drive by Means of Virtual Sensing Using Kalman Filtering. Int. J. Veh. Perform. 2021, 8, 1–30. [Google Scholar] [CrossRef]

- Xia, K.; Lou, Y.; Yuan, Q.; Zhu, B.; Li, R.; Du, Y. Optoelectronic Torque Measurement System Based on SAPSO-RBF Algorithm. Sensors 2024, 24, 1576. [Google Scholar] [CrossRef] [PubMed]

- Usui, T.; Ishizuka, H.; Kawasetsu, T.; Hosoda, K.; Ikeda, S.; Oshiro, O. Soft Capacitive Tactile Sensor Using Displacement of Air–Water Interface. Sens. Actuators A Phys. 2021, 332, 113133. [Google Scholar] [CrossRef]

- Kim, J. Real-Time Torque Estimation of Automotive Powertrain with Dual-Clutch Transmissions. IEEE Trans. Control Syst. Technol. 2022, 30, 2269–2284. [Google Scholar] [CrossRef]

- Kružić, S.; Musić, J.; Papić, V.; Kamnik, R. Strain Gauge Neural Network-Based Estimation as an Alternative for Force and Torque Sensor Measurements in Robot Manipulators. Appl. Sci. 2023, 13, 10217. [Google Scholar] [CrossRef]

- Kraus, A.; Stiegelmeyr, A. Dynamic Brake Test Stand; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Aguirre Rodriguez, J.; Castano, J.; Saeed, A. Modular Torque Wrench Extension with Heads-up Display. In Engineering, Integration, and Alliances for A Sustainable Development. Hemispheric Cooperation for Competitiveness and Prosperity on A Knowledge-Based Economy, Proceedings of the 18th LACCEI International Multi-Conference for Engineering, Education, and Technology, Virtual, 27–31 July 2020; Latin American and Caribbean Consortium of Engineering Institutions: San Jose, CA, USA, 2020. [Google Scholar]

- Hameed, M.; Saleh, M. Study the Opportunity of Using Arduino Controller for Practical Stress Measurement Induced in Mechanical Loaded Members. J. Mech. Eng. Autom. Control Syst. 2025, 6, 14–26. [Google Scholar] [CrossRef]

- Suryawanshi, R. AI in Sensor Calibration. IJRASET 2025, 13, 1197–1200. [Google Scholar] [CrossRef]

- Karki, D.; Dura, H.B.; Poudel, L. Design, Construction and Performance Analysis of Dynamic Torque Transducer. J. Innov. Eng. Educ. 2023, 6, 118–123. [Google Scholar] [CrossRef]

- ISO 376:2011. Available online: https://www.iso.org/standard/44661.html (accessed on 25 June 2025).

- Linear Regression: Estimation and Distribution Theory. In Linear Regression Analysis; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; pp. 35–95. ISBN 978-0-471-72219-9.

- Nagelkerke, N.J.D. A Note on a General Definition of the Coefficient of Determination. Biometrika 1991, 78, 691–692. [Google Scholar] [CrossRef]

- Taylor, M.H.; Losch, M.; Wenzel, M.; Schröter, J. On the Sensitivity of Field Reconstruction and Prediction Using Empirical Orthogonal Functions Derived from Gappy Data. J. Clim. 2013, 26, 9194–9205. [Google Scholar] [CrossRef]

- Taylor, B.N. Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results; National Bureau of Standards: Gaithersburg, MD, USA, 1994. [Google Scholar]

- Preethichandra, D.M.G.; Piyathilaka, L.; Sul, J.-H.; Izhar, U.; Samarasinghe, R.; Arachchige, S.D.; de Silva, L.C. Passive and Active Exoskeleton Solutions: Sensors, Actuators, Applications, and Recent Trends. Sensors 2024, 24, 7095. [Google Scholar] [CrossRef] [PubMed]

- Ubeda, R.P.; Gutiérrez Rubert, S.C.; Zotovic Stanisic, R.; Perles Ivars, Á. Design and Manufacturing of an Ultra-Low-Cost Custom Torque Sensor for Robotics. Sensors 2018, 18, 1786. [Google Scholar] [CrossRef] [PubMed]

- Billeschou, P.; Albertsen, C.; Larsen, J.C.; Manoonpong, P. A Low-Cost, Compact, Sealed, Three-Axis Force/Torque Sensor for Walking Robots. IEEE Sens. J. 2021, 21, 8916–8926. [Google Scholar] [CrossRef]

- Kim, H.-B.; Choi, K.-H.; Kim, K.-S. A Compact Optical Six-Axis Force/Torque Sensor for Legged Robots Using a Polymorphic Calibration Method. arXiv 2023, arXiv:2309.04720. [Google Scholar]

| Applied Torque [N·m] | Averaged Digital Value (Clockwise) | Averaged Digital Value (Counterclockwise) |

|---|---|---|

| 5 | 416,014.40 | 526,014.00 |

| 10 | 379,772.40 | 607,232.00 |

| 15 | 342,533.00 | 702,498.00 |

| 20 | 279,097.20 | 813,371.00 |

| 25 | 238,616.20 | 941,406.00 |

| 30 | 225,340.20 | 1,088,161.00 |

| 35 | 195,485.80 | 1,255,192.00 |

| 40 | 174,029.80 | 1,444,057.00 |

| 45 | 137,405.80 | 1,656,311.00 |

| 50 | 117,235.80 | 1,893,513.00 |

| Applied Torque [N·m] | Indicated Torque [N·m] | MAE [N·m] |

|---|---|---|

| 50 | 49.88658495 | 0.113415 |

| 45 | 45.64236065 | 0.642361 |

| 40 | 38.48384461 | 1.516155 |

| 35 | 34.59844455 | 0.401555 |

| 30 | 29.54496305 | 0.455037 |

| 25 | 27.42266205 | 2.422662 |

| 20 | 21.39366942 | 1.393669 |

| 15 | 13.15642551 | 1.843574 |

| 10 | 8.926782281 | 1.073218 |

| 5 | 5.188683855 | 0.188684 |

| −5 | −4.244757547 | 0.755242 |

| −10 | −9.750358511 | 0.249641 |

| −15 | −15.06403354 | 0.064034 |

| −20 | −20.14973559 | 0.149736 |

| −25 | −25.07085006 | 0.070850 |

| −30 | −29.96374104 | 0.036259 |

| −35 | −34.94836928 | 0.051631 |

| −40 | −40.00695376 | 0.006954 |

| −45 | −44.96933359 | 0.030666 |

| −50 | −49.9673941 | 0.032606 |

| Applied Torque [N·m] | Indicated Torque [N·m] | Standard Deviation [N·m] | 2 × Standard Deviation [N·m] |

|---|---|---|---|

| 50 | 49.88658495 | 0.112584012 | 0.225168025 |

| 45 | 45.64236065 | 0.155528737 | 0.311057475 |

| 40 | 38.48384461 | 0.832847645 | 1.66569529 |

| 35 | 34.59844455 | 0.889128071 | 1.778256143 |

| 30 | 29.54496305 | 1.061565722 | 2.123131444 |

| 25 | 27.42266205 | 1.782940305 | 3.565880609 |

| 20 | 21.39366942 | 1.174873253 | 2.349746505 |

| 15 | 13.15642551 | 0.133933479 | 0.267866959 |

| 10 | 8.926782281 | 0.166290230 | 0.332580460 |

| 5 | 5.188683855 | 0.298111577 | 0.596223154 |

| −5 | −4.244757547 | 0.674121561 | 1.348243122 |

| −10 | −9.750358511 | 1.007054651 | 2.014109302 |

| −15 | −15.06403354 | 1.170535944 | 2.341071889 |

| −20 | −20.14973559 | 1.215338251 | 2.430676502 |

| −25 | −25.07085006 | 1.196657446 | 2.393314893 |

| −30 | −29.96374104 | 1.143910161 | 2.287820322 |

| −35 | −34.94836928 | 1.037376598 | 2.074753196 |

| −40 | −40.00695376 | 0.845718874 | 1.691437749 |

| −45 | −44.96933359 | 0.583960687 | 1.167921373 |

| −50 | −49.9673941 | 0.328666241 | 0.657332481 |

| Component | Specification | Cost [EUR] | Date of Purchase |

|---|---|---|---|

| Strain Gauge (×4) | BF350-3HA-E | 8 | May 2025 |

| Amplifier | HX711 | 4 | May 2025 |

| Microcontroller | Wemos D1 Mini ESP8266 | 7 | May 2025 |

| Battery | 400 mAh Li-Po | 5 | May 2025 |

| DC-DC Converter | 3.3/5 V | 3 | May 2025 |

| Total | 27 | May 2025 |

| ID | System | Price Quoted in Paper | Measurement Range [N·m] | Accuracy | Bidirectional |

|---|---|---|---|---|---|

| 1 | Proposed System | EUR 27 | ±50 | ±2.5 N·m | Yes |

| 2 | Exoskeleton Sensor [49] | USD 50 | ±50 | ±2 N·m | Yes |

| 3 | 1 N·m Sensor [50] | EUR < 100 | 1 | 1.92% FS | Not stated |

| 4 | 5 N·m Sensor [50] | EUR < 100 | 5 | 1.27% FS | Not stated |

| 5 | 20 N·m Sensor [50] | EUR < 100 | 20 | 1.27% FS | Not Stated |

| 6 | Walking Robot Sensor [51] | USD 213 | ±15 | <2% FS | Yes |

| 7 | Optical Sensor [52] | USD < 250 | ±5 | ±1.5% FS | Yes |

| ID | System | Calibration Method | Wireless | Enclosure | Distinct Strengths |

|---|---|---|---|---|---|

| 1 | Proposed System | Fifth-order polynomial | Yes | No | Yes |

| 2 | Exoskeleton Sensor | Commercial torque-transducer comparison | Yes | Yes | Telemetry |

| 3 | 1 N·m Sensor | Benchmarked to ATI Delta SI-330-30 | No | No | Economy for benchtop use |

| 4 | 5 N·m Sensor | Benchmarked to ATI Delta SI-330-30 | No | No | Economy for benchtop use |

| 5 | 20 N·m Sensor | Benchmarked to ATI Delta SI-330-30 | No | No | Economy for benchtop use |

| 6 | Walking Robot Sensor | Six-axis load cell reference | Yes | Yes | IP67 enclosure |

| 7 | Optical Sensor | Optical scale-factor fit | No | Yes | CNC-milled aluminum enclosure |

| Aspect | Advantages | Disadvantages/Limitations |

|---|---|---|

| Cost | Significantly lower than commercial systems; affordable components | May lack some features of high-end commercial solutions |

| Modularity | Easily adapted to various shaft sizes and applications | Customization requires mechanical adaptation and recalibration |

| Calibration | Bidirectional, high-order polynomial fit enables accurate reversible/oscillatory load measurement | Calibration process is more complex than simple linear fit |

| Open-Source Design Maintenance | Firmware and interface are open, enabling community-driven improvements and integration | Requires user expertise for modification or troubleshooting |

| Accuracy and Repeatability | High R2, low MAE and SD; comparable to commercial systems | Performance may degrade if installation quality is poor |

| Scalability | Easily replicated for multi-point or distributed sensing | Network congestion possible with many devices |

| Maintenance | Simple, low-cost replacement of components | Long-term stability and drift require periodic recalibration |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suciu, C.C.; Stoica, V.; Ilie, M.; Ionel, I.; Ionel, R. A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology. Appl. Sci. 2025, 15, 8158. https://doi.org/10.3390/app15158158

Suciu CC, Stoica V, Ilie M, Ionel I, Ionel R. A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology. Applied Sciences. 2025; 15(15):8158. https://doi.org/10.3390/app15158158

Chicago/Turabian StyleSuciu, Cosmin Constantin, Virgil Stoica, Mariana Ilie, Ioana Ionel, and Raul Ionel. 2025. "A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology" Applied Sciences 15, no. 15: 8158. https://doi.org/10.3390/app15158158

APA StyleSuciu, C. C., Stoica, V., Ilie, M., Ionel, I., & Ionel, R. (2025). A Low-Cost IoT-Based Bidirectional Torque Measurement System with Strain Gauge Technology. Applied Sciences, 15(15), 8158. https://doi.org/10.3390/app15158158