Fuzzy Model Predictive Control for Unmanned Helicopter

Abstract

1. Introduction

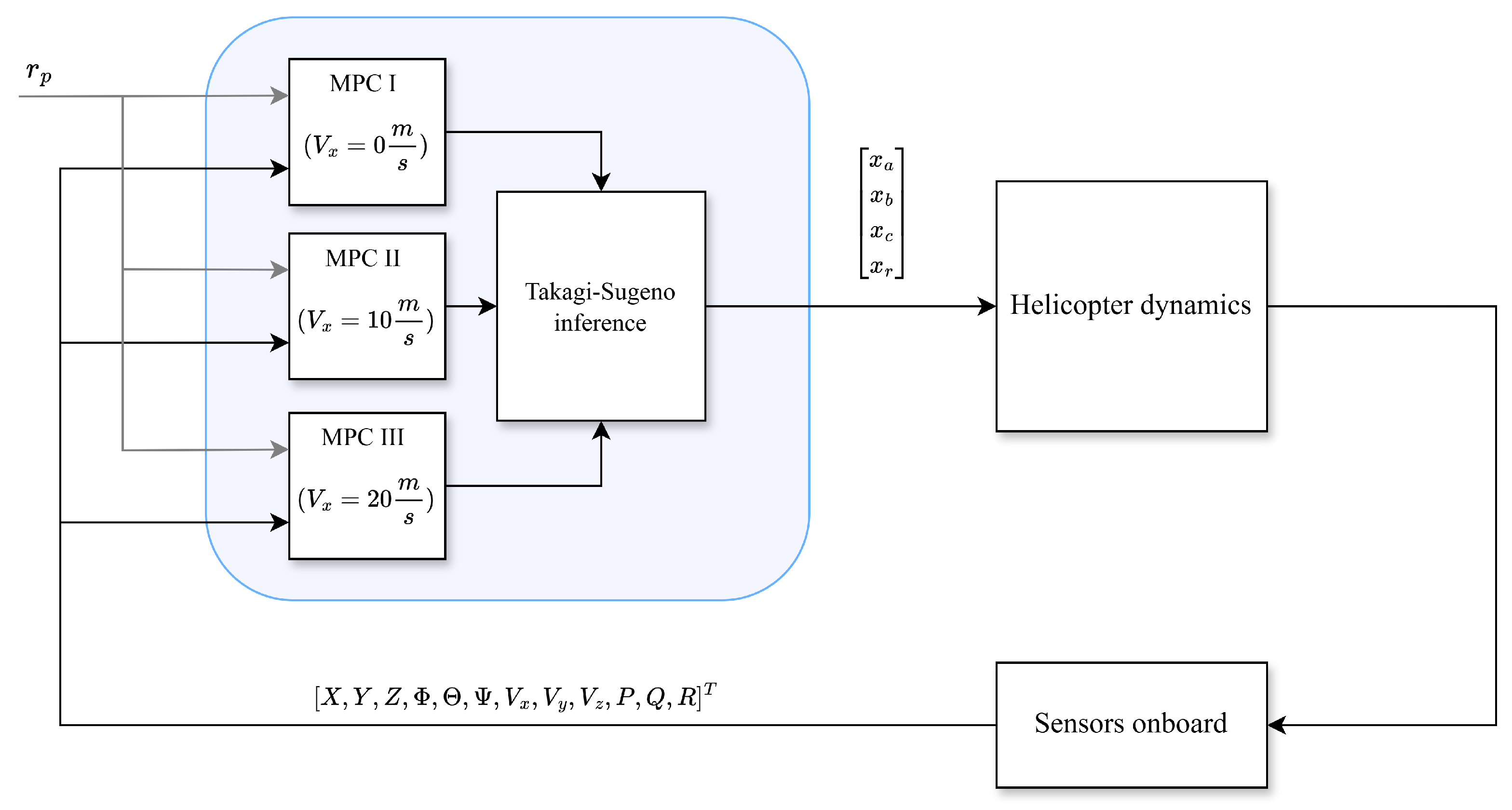

1.1. Motivation

1.2. Methods of Designing Control Systems for Unmanned Rotorcrafts

2. Materials and Methods

2.1. Control Plant Description

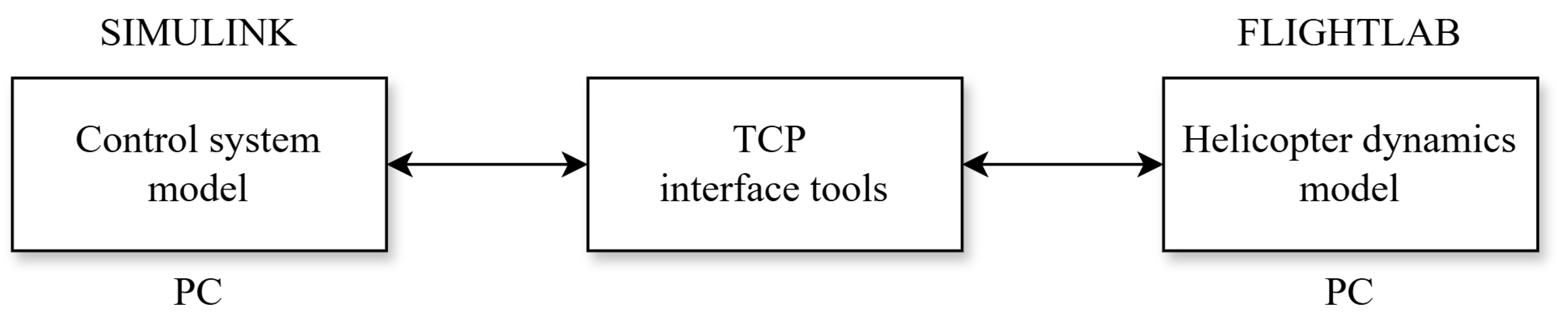

2.2. Simulation Model Description

- Fuselage dynamics (considered as a 6DOF rigid body).

- Main rotor dynamics.

- Tail rotor dynamics.

- Landing gear dynamics (for modeling ground contact).

- Powertrain dynamics (which combines engine dynamics and power transmission description).

- Atmosphere model.

- Actuators dynamics.

- Helicopter’s position in the inertial coordinate system (3).

- Helicopter’s linear velocities in the body-fixed coordinate system (3).

- Integrals of linear velocities in the body-fixed coordinate system (3).

- Helicopter’s fuselage attitude angles (3).

- Helicopter’s fuselage angular velocities (3).

- Integrals of angular velocities (3).

- Induced velocity components: uniform, zeroth harmonics, first harmonics (sine and cosine), and second harmonics (sine and cosine) (6).

- Induced flow state of the tail rotor (1).

- Coning angle of the tail rotor (1).

3. Control Methodology

- —position of the unmanned rotorcraft in the inertial reference coordinate system.

- —attitude (roll, pitch, yaw) angles of the rotorcraft with respect to the reference coordinate system.

- —linear velocities measured in the body-fixed coordinate system.

- —angular velocities of the rotorcraft.

- —cyclic pitch components of the main rotor;

- —collective pitch of the main rotor;

- —collective pitch of the tail rotor.

3.1. Model Predictive Control Principles

- refers to the state vector of the controlled system at time i;

- describes the reference trajectory vector in the state space at time i;

- describes the future control vector determined at time i;

- and are positive semi-definite weighting matrices that differentiate the impact of individual components of the cost function on its scalar value;

- N is the prediction horizon, which describes the number of prediction steps based on the measured state;

- is the control horizon, which denotes the number of different future control value increments determined by the algorithm.

- is the vector storing the state prediction of the control plant in the way presented by Equation (8) below:

- is the vector storing the resulting future control signal increments. The construction of the vector is presented below (9).

- Matrices and take the form presented by Equation (10):

- is the block vector .

- is the block diagonal matrix built from the matrices from definition (2).

- is the block diagonal matrix built from the matrices from definition (2).

- .

- .

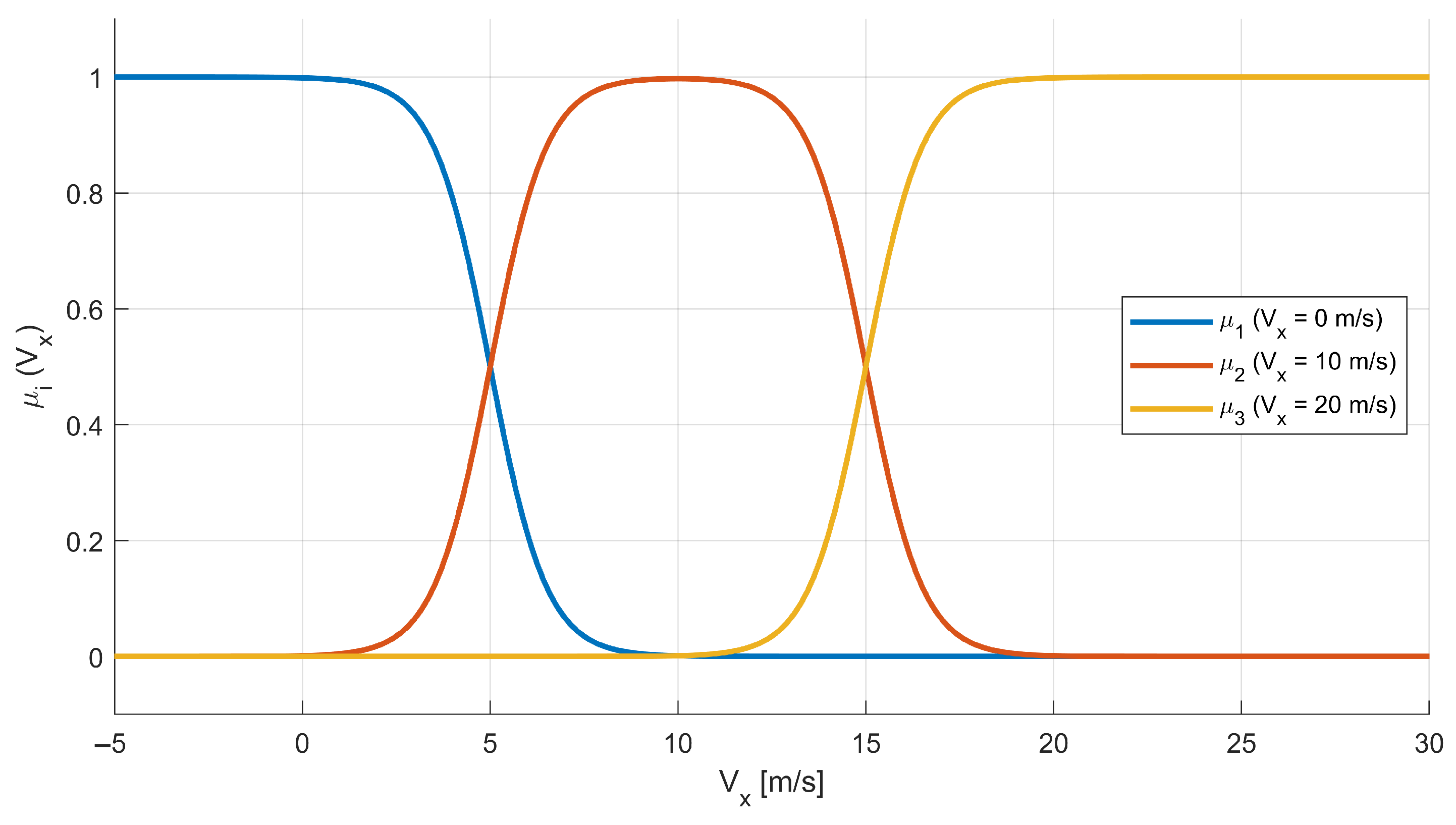

3.2. Takagi–Sugeno Inference Algorithm

- are input signals;

- are fuzzy sets;

- is a crisp output signal from rule i.

- Performing fuzzification, i.e., determining the degree of membership of the input signal values to fuzzy sets.

- Determining the activation levels of the rules () based on the values from the fuzzification stage.

- Determining the output signal value according to Formula (21).

- is the measured forward flight velocity;

- is the reference forward flight velocity, corresponding to the center of each membership function;

- is the standard deviation of each membership function.

- is the state matrix of the i-th local model;

- is the control matrix of the i-rule model;

- is the corresponding state-feedback gain.

3.3. Set of Fuzzy Rules

- is the control input at the operating point associated with rule i;

- is the current state vector;

- is the extended reference trajectory vector over the prediction horizon;

- , are the state and input prediction matrices for local model i;

- , are the block-diagonal weighting matrices for the state and input errors.

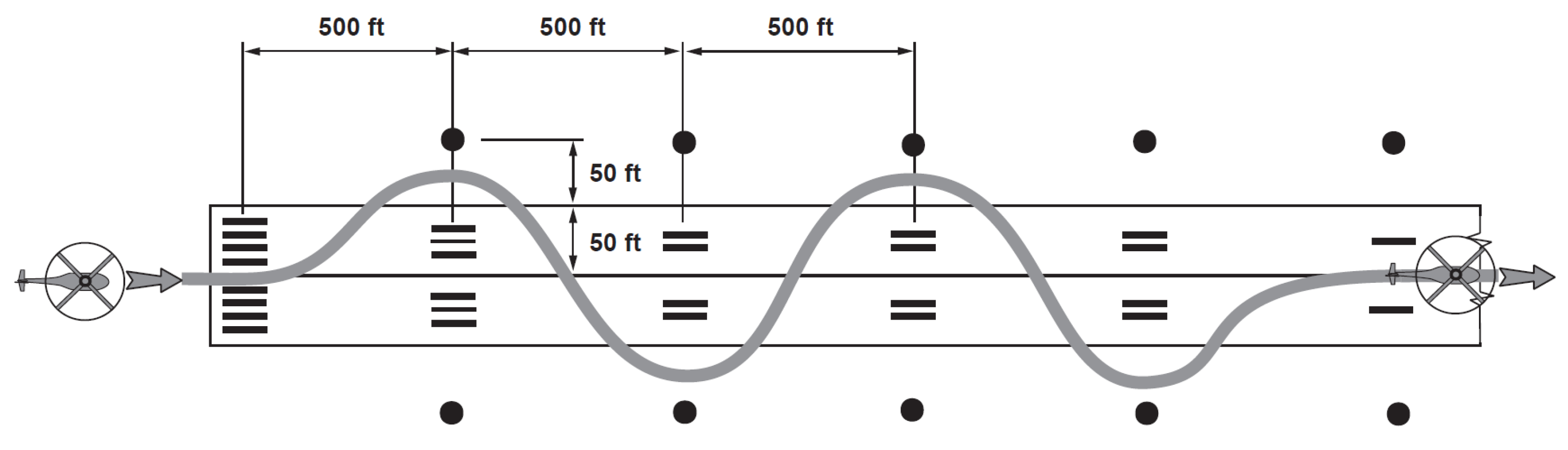

4. System Validation

- Case 1: The helicopter maintains its initial altitude while changing its forward flight velocity, respectively, by 2, 6, and 10 . The total simulation time was 12 s.

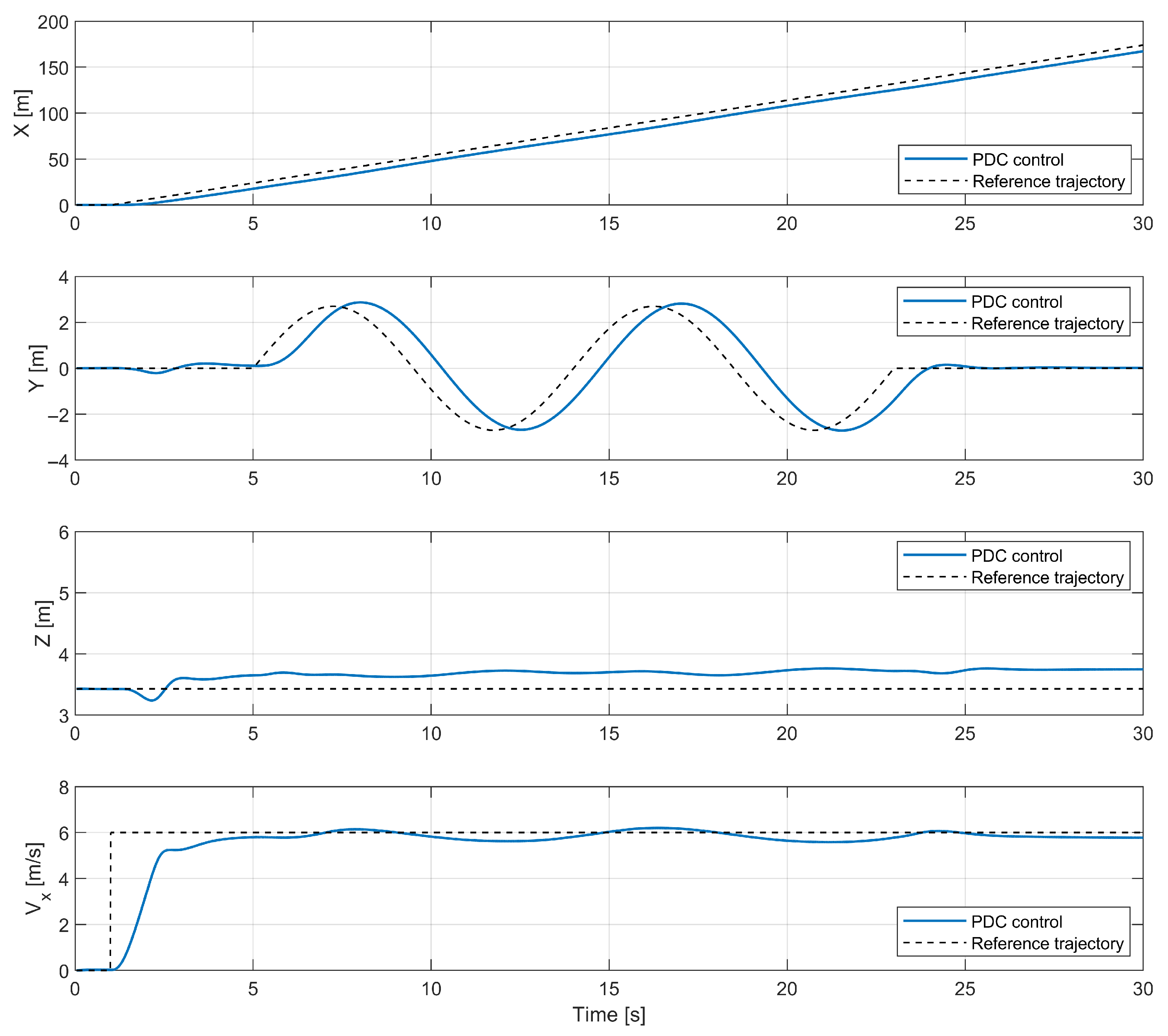

- Case 2: The helicopter follows a predefined flight path that includes

- −

- A step change in forward flight velocity at the first second to 6 .

- −

- At the 5th second, following the predefined position on the Y-axis of the reference coordinate system while maintaining a forward flight velocity pf and initial altitude of m. The function describing the predefined trajectory on the Y-axis is presented below (32). This corresponds to the sinusoidal change of position on the Y-axis, where the amplitude is 8.9 m and the oscillation period s.

- −

- After 18 s of performing a slalom flight, the rotorcraft returns to forward flight in the initial direction.

- V is the airflow velocity .

- g is the gravitational acceleration .

- L is the reference linear dimension .

Results

- is the overshoot value expressed as a percentage.

- is the maximum observed forward flight velocity.

- is the reference forward flight velocity.

- is the integral of absolute error.

- T is the total simulation duration.

- v is the measured forward flight velocity at time t.

5. Conclusions

- Increase the number of “local” control laws in the PDC architecture.

- Increase the dimensionality of input data for the Takagi–Sugeno inference mechanism, where local models can be linearized with respect to forward flight velocity and flight altitude.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, Y.; Ho, C.; Lee, Y.; Li, B. Development of a Solar-Powered Unmanned Aerial Vehicle for Extended Flight Endurance. Drones 2021, 5, 44. [Google Scholar] [CrossRef]

- Croon, G.; Groen, M.; De Wagter, C.; Remes, B.; Ruijsink, R.; Oudheusden, B. Design, aerodynamics and autonomy of the DelFly. Bioinspiration Biomim. 2012, 7, 025003. [Google Scholar] [CrossRef]

- Padfield, G.D. Modelling Helicopter Flight Dynamics: Building a Simulation Model. In Helicopter Flight Dynamics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2007; Chapter 3; pp. 87–185. [Google Scholar]

- Johnson, W. Model for Vortex Ring State Influence on Rotorcraft Flight Dynamics. Ames Research Center; Mofett Field, California 2005. Available online: https://api.semanticscholar.org/CorpusID:18712216 (accessed on 17 March 2025).

- Faust, J.; Jung, Y.S.; Baeder, J.; Bauknecht, A.; Rauleder, J. Interactional Aerodynamic Analysis of an Asymmetric Lift-Offset Compound Helicopter in Forward Flight. J. Am. Helicopter Soc. 2021, 66, 1–17. [Google Scholar] [CrossRef]

- Matus-Vargas, A.; Rodriguez-Gomez, G.; Martinez-Carranza, J. Ground effect on rotorcraft unmanned aerial vehicles: A review. Intell. Serv. Robot. 2021, 14, 99–118. [Google Scholar] [CrossRef]

- Van Hoydonck, W.; Haverdings, H.; Pavel, M. A review of rotorcraft wake modeling methods for flight dynamics applications. In Proceedings of the 35th European Rotorcraft Forum 2009, Hamburg, Germany, 22–25 September 2009; Volume 1, pp. 27–53. [Google Scholar]

- Shim, D.; Kim, H.J.; Sastry, S. Control system design for rotorcraft-based unmanned aerial vehicles using time-domain system identification. In Proceedings of the 2000 IEEE International Conference on Control Applications, Anchorage, AK, USA, 27 September 2000; pp. 808–813. [Google Scholar]

- Gadewadikar, J.; Chen, B.; Subbarao, K. Structured H∞ Command and Control-Loop Design for Unmanned Helicopters. J. Guid. Control. Dyn. 2008, 31, 1093–1102. [Google Scholar] [CrossRef]

- Dul, F.; Lichota, P.; Rusowicz, A. Generalized Linear Quadratic Control for a Full Tracking Problem in Aviation. Sensors 2020, 20, 2955. [Google Scholar] [CrossRef] [PubMed]

- Topczewski, S.; Narkiewicz, J.; Bibik, P. Helicopter Control During Landing on a Moving Confined Platform. IEEE Access 2020, 8, 107315–107325. [Google Scholar] [CrossRef]

- Topczewski, S.; Bibik, P. LQR and LQG control of the helicopter during landing on the ship deck. Aircr. Eng. Aerosp. Technol. 2023, 95, 1344–1352. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Lu, G.; Zhong, Y. Modeling and LQR control of small unmanned helicopter. In Proceedings of the 32nd Chinese Control Conference, Hefei, China, 22–24 August 2020; pp. 4301–4305. [Google Scholar]

- Jan, S.S.; Lin, Y.H. Integrated Flight Path Planning System and Flight Control System for Unmanned Helicopters. Sensors 2011, 11, 7502–7529. [Google Scholar] [CrossRef]

- Kadmiry, B.; Driankov, D. Fuzzy Control of an Autonomous Helicopter. In Proceedings of the IFSA World Congress and 20th NAFIPS International Conference, Vancouver, BC, Canada, 25–28 July 2001. [Google Scholar]

- Lin, K.; Li, D.; Li, Y.; Chen, S.; Wu, X. FHCPL: An Intelligent Fixed-Horizon Constrained Policy Learning System for Risk-Sensitive Industrial Scenario. IEEE Trans. Ind. Inform. 2024, 20, 5794–5804. [Google Scholar] [CrossRef]

- Lin, K.; Li, Y.; Chen, S.; Li, D.; Wu, X. Motion Planner with Fixed-Horizon Constrained Reinforcement Learning for Complex Autonomous Driving Scenarios. IEEE Trans. Intell. Veh. 2024, 9, 1577–1588. [Google Scholar] [CrossRef]

- Liu, B.; Cai, Y.; Li, D.; Lin, K.; Xu, G. A Hybrid ARO Algorithm and Key Point Retention Strategy Trajectory Optimization for UAV Path Planning. Drones 2024, 8, 644. [Google Scholar] [CrossRef]

- Lin, K.; Li, D.; Li, Y.; Chen, S.; Liu, Q.; Gao, J.; Jin, Y.; Gong, L. TAG: Teacher-Advice Mechanism With Gaussian Process for Reinforcement Learning. IEEE Trans. Neural Netw. Learn. Syst. 2024, 35, 12419–12433. [Google Scholar] [CrossRef]

- Lin, K.; Li, Y.; Liu, Q.; Li, D.; Shi, X.; Chen, S. Almost surely safe exploration and exploitation for deep reinforcement learning with state safety estimation. Inf. Sci. 2024, 662, 120261. [Google Scholar] [CrossRef]

- Gong, X. Model Predictive Control for an Unmanned Helicopter. In Proceedings of the 2019 IEEE International Conference on Unmanned Systems (ICUS), Beijing, China, 17–19 October 2019; pp. 361–366. [Google Scholar]

- Alexis, K.; Papachristos, C.; Siegwart, R.; Tzes, A. Robust Model Predictive Flight Control of Unmanned Rotorcrafts. J. Intell. Robot. Syst. 2015, 81, 443–469. [Google Scholar] [CrossRef]

- Lindqvist, B.; Mansouri, S.S.; Agha-mohammadi, A.a.; Nikolakopoulos, G. Nonlinear MPC for Collision Avoidance and Control of UAVs With Dynamic Obstacles. IEEE Robot. Autom. Lett. 2020, 5, 6001–6008. [Google Scholar] [CrossRef]

- Stella, L.; Themelis, A.; Sopasakis, P.; Patrinos, P. A simple and efficient algorithm for nonlinear model predictive control. In Proceedings of the 2017 IEEE 56th Annual Conference on Decision and Control (CDC), Melbourne, VIC, Australia, 12–15 December 2017; pp. 1939–1944. [Google Scholar]

- Li, Z.; Xue, Y.; Li, Z.; Jin, X.; Wang, P. Resilience-Oriented Asynchronous Decentralized Restoration Considering Building and E-Bus Co-Response in Electricity-Transportation Networks. IEEE Trans. Transp. Electrif. 2025, 1. [Google Scholar] [CrossRef]

- Ding, B.; Li, Z.; Li, Z.; Xue, Y.; Chang, X.; Su, J. Cooperative Operation for Multiagent Energy Systems Integrated With Wind, Hydrogen, and Buildings: An Asymmetric Nash Bargaining Approach. IEEE Trans. Ind. Inform. 2025, 21, 6410–6421. [Google Scholar] [CrossRef]

- Bedyńska, A.; Curyło, P.; Czarnota, N.; Ceniuk, M.; Grabowski, Ł.; Łukasiewicz, M.; Bibik, P. ARCHER—Autonomous Reconfigurable Compound Helicopter for Education and Research. Paper Presented at the 45th European Rotorcraft Forum, Warsaw, Poland, 17–20 September 2019. [Google Scholar]

- Żugaj, M.; Edawdi, M.; Iwański, G.; Topczewski, S.; Bibik, P. An Unmanned Helicopter Energy Consumption Analysis. Energies 2022, 15, 2067. [Google Scholar] [CrossRef]

- Abdelgawad, K.; Hassan, B.; Berssenbrügge, J.; Stöcklein, J. A Modular Architecture of an Interactive Simulation and Training Environment for Advanced Driver Assistance Systems. Int. J. Adv. Softw. 2015, 8, 247–261. [Google Scholar]

- Val, R.; He, C. FLIGHTLAB Modeling for Real Time Simulation Applications. Int. J. Model. Simul. Sci. Comput. 2017, 8, 1743003. [Google Scholar] [CrossRef]

- Peters, D.A.; He, C. Correlation of Measured Induced Velocities with a Finite-State Wake Model. J. Am. Helicopter Soc. 1991, 36, 59–70. [Google Scholar] [CrossRef]

- Wang, H.; Tanaka, K.; Griffin, M. Parallel distributed compensation of nonlinear systems by Takagi-Sugeno fuzzy model. In Proceedings of the 1995 IEEE International Conference on Fuzzy Systems, Yokohama, Japan, 20–24 March 1995; Volume 2, pp. 531–538. [Google Scholar]

- Camacho, E.F.; Bordons, C. Model Predictive Control, 2nd ed.; Springer: London, UK, 2004. [Google Scholar]

- Takagi, T.; Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 1985, SMC-15, 116–132. [Google Scholar] [CrossRef]

- Tanaka, K.; Sano, M. Fuzzy stability criterion of a class of nonlinear systems. Inf. Sci. 1993, 71, 3–26. [Google Scholar] [CrossRef]

- Bibik, P.; Kopyt, A.; Żugaj, M. LIGHTLAB & SIMULINK—Coupling of modern simulation tools of modelling and testing of rotorcraft control systems. Inst. Aviat. Work. Wars. 2011, 219, 5–12. [Google Scholar]

- ADS-33E-PRF; Aeronautical Design Standard, Performance Specification, Handling Qualities Requirements for Military Rotorcraft. United States Army Aviation and Missile Command: Red Stone, AL, USA, 2000.

- Chang, I.K.; Ryu, B.S.; Kim, J.H.; Kim, Y.J. Stability Test Using Froude Scaling Method of Emergency Flotation System for Helicopter. J. Korean Soc. Aeronaut. Space Sci. 2015, 43, 1089–1096. [Google Scholar] [CrossRef][Green Version]

| Parameter | Value | Unit |

|---|---|---|

| Main rotor diameter | 1.78 | m |

| Number of main rotor blades | 2 | - |

| Main rotor angular velocity | 1500–2000 | RPM |

| Tail rotor diameter | 0.158 | m |

| Number of tail rotor blades | 2 | - |

| Tail rotor angular velocity | 7200 | RPM |

| Takeoff weight (TOW) | 8 | kg |

| MPC | PDC | |

|---|---|---|

| 7.5% | 8.13% | |

| 9.62% | 4.81% | |

| 14.59% | −0.7% |

| MPC | PDC | |

|---|---|---|

| 0.15 | 0.163 | |

| 0.577 | 0.289 | |

| 1.459 | −0.07 |

| MPC | PDC | |

|---|---|---|

| 2.788 | 2.886 | |

| 8.729 | 8.838 | |

| 15.230 | 15.227 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiciński, Ł.; Topczewski, S. Fuzzy Model Predictive Control for Unmanned Helicopter. Appl. Sci. 2025, 15, 8120. https://doi.org/10.3390/app15148120

Kiciński Ł, Topczewski S. Fuzzy Model Predictive Control for Unmanned Helicopter. Applied Sciences. 2025; 15(14):8120. https://doi.org/10.3390/app15148120

Chicago/Turabian StyleKiciński, Łukasz, and Sebastian Topczewski. 2025. "Fuzzy Model Predictive Control for Unmanned Helicopter" Applied Sciences 15, no. 14: 8120. https://doi.org/10.3390/app15148120

APA StyleKiciński, Ł., & Topczewski, S. (2025). Fuzzy Model Predictive Control for Unmanned Helicopter. Applied Sciences, 15(14), 8120. https://doi.org/10.3390/app15148120