Abstract

Seedling transplantation, a pivotal component in advancing the cultivation of vegetables and cash crops, significantly bolsters crops’ resilience against drought, cold, pests, and diseases, while substantially enhancing yields. The implementation of transplanting machinery not only remarkably alleviates the labor-intensive nature of transplantation but also elevates the precision and uniformity of the process, thereby facilitating mechanized plant protection and harvesting operations. This article summarizes the research status and development trends of mechanized field transplanting technology and equipment. It also analyzes and summarizes the types and current status of typical representative automatic seedling picking mechanisms. Based on the current research status, the challenges of mechanized transplanting technology were analyzed, mainly the following: insufficient integration of agricultural machinery and agronomy; the standards for each stage of transplanting are not perfect; the adaptability of existing transplanting machines is poor; the level of informatization and intelligence of equipment is low; the lack of innovation in key components, such as seedling picking and transplanting mechanisms; and the proposed solutions to address the issues. Corresponding solutions are proposed, such as the following: strengthening interdisciplinary collaboration; establishing standards for transplanting processes; enhancing transplanter adaptability; accelerating intelligentization and digitalization of transplanters; strengthening the theoretical framework; and performance optimization of transplanting mechanisms. Finally, the development direction of future fully automatic transplanting machines was discussed, including the following: improving the transplanting efficiency and quality of transplanting machines; integrating research and development of testing, planting, and seedling supplementation for transplanting machines; unmanned transplanting operations; and fostering collaborative industrial development.

1. Introduction

Transplanting is the process of transferring seedlings grown in biochar or other substrates from seedling trays to the field through technical means [1,2,3,4,5], including manual and mechanized transplanting. Transplanting technology can significantly improve the cropping index and prolong the utilization cycle of light and heat resources by shortening the field growth period and avoiding low temperature stress during the seedling stage, providing key technical support for crop yield and efficiency increase [6,7,8,9,10,11,12,13], and facilitating biomass allocation [14].

Among numerous crop varieties, most are suitable for transplanting operations, including rice, cotton, corn, vegetables, and rapeseed [15,16,17,18]. Since the 1920s, scholars have been researching transplanters, whose development exhibits typical regional characteristics [19]. For instance, European and American countries typically adopt mechatronic-hydraulic integrated technologies to develop transplanters, featuring intelligence, large-scale operation, high efficiency, and strong universality; while Japan, South Korea, and other nations prioritize compact and miniaturized transplanters. Korean scholars Habineza et al. [20] conducted a kinematic analysis on various transplanters and their main components, detailing the working principles, field efficiency, and transplanting accuracy of different vegetable transplanters. Turkish scholar Davut Karayel et al. [21] evaluated the transplanting performance of transplanters for tomato and watermelon plug seedlings under field conditions, finding that the angle between seedlings and the vertical plane was less than 30° after operation by all transplanters. Only disc-type transplanters caused seedling damage exceeding 3%, while all transplanters achieved a seedling survival rate above 90%. Bangladeshi scholars Miah et al. [22] designed, manufactured, and tested two semi-automatic vegetable transplanters—dibbler vegetable seedling transplanter and the furrow opener vegetable seedling transplanter—assessing their performance and impact on field crop productivity. Romanian scholars Mitrache et al. [23] conducted a comparative study on common transplanters and proposed optimal solutions based on agricultural technical requirements for seedling transplantation. China, though late-starting in transplanting machinery research, has developed diverse transplanters for different crops, including semi-automatic and fully automatic models. Some fully automatic transplanters integrate advanced auxiliary technologies, such as Beidou-based automatic navigation systems, sensors, and vision-based monitoring systems [24,25,26,27,28,29,30,31,32].

The fully automatic transplanting machine comprises multiple operating components, such as planting mechanisms, seedling picking mechanisms, seedling supply mechanisms, and auxiliary devices [33], with the seedling picking mechanism serving as its core component. Research on seedling picking mechanisms has been extensive. Korean scholars Min et al. [34] developed a top-ejecting onion seedling picking mechanism to meet the mechanized transplanting requirements of onions. Based on variations in needle diameter and operational speed, the study analyzed seedling pull-out resistance and damage rate, indicating that pull-out resistance increased with the increase in the push rod diameter. Dang et al. [35] designed a single-degree-of-freedom seedling picking and dropping robotic arm, driven by a four-bar mechanism and sliding mechanism to achieve precise seedling picking trajectories and postures. Experiments showed that the seedling picking success rate reached 96.7%, the seedling plug damage rate was 3.13%, the seedling dropping success rate was 97.74%, and the transplanting success rate was 91.32%, demonstrating high mechanism reliability. Liu et al. [36] devised a planetary non-circular gear mechanism enabling dual unequal transmission ratios. Tests revealed that the seedling extraction success rate exceeded 90%, but the substrate integrity rate decreased with increasing rotational speed, accompanied by an increase in seedling damage. Owing to the rapid advancement in seedling picking mechanisms, modern transplanting machines have evolved from semi-automatic models requiring manual seedling picking to fully automatic systems featuring integrated automatic seedling picking. This evolution has effectively addressed challenges such as labor shortages, high labor intensity, low efficiency, and elevated operational costs inherent in manual and semi-automatic transplanting. Seedling picking mechanisms have thus become a core research focus in vegetable transplanting technology [37,38].

In summary, transplanting is an indispensable component of modern agriculture. It can effectively increase crop yields and land resource utilization, while mechanized transplanting can significantly reduce labor demand in transplanting operations. For transplanting machinery, semi-automatic transplanters requiring manual seedling feeding and fully automatic transplanters capable of autonomous seedling extraction have been developed. Additionally, numerous researchers have conducted extensive studies on their key components (seedling picking mechanisms). However, there remains a lack of systematic synthesis in the field of dryland transplanting machinery. Therefore, this paper reviews the research progress of dryland mechanized transplanting technologies and equipment. It summarizes the research progress of mechanized transplanting technologies and equipment for arid regions. It outlines the research status of typical mechanized transplanting equipment and key technologies, focusing on the working principles, structural characteristics, and design methods of various transplanting mechanisms. The article further analyzes the challenges in mechanized transplanting in drylands, provides suggestions and references for the research of mechanized transplanting technologies and equipment, and forecasts the future development trends of mechanized transplanting technologies based on these analyses. This work aims to offer guidance and references for the research and development of dryland transplanting technologies and equipment.

2. Classification of Transplanters

Dryland transplanting machines face significant heterogeneity in working environments and diversity in crop varieties during operation. The differential coupling effect of key parameters—such as terrain and geomorphology, soil mechanical properties, crop biological attributes, and agronomic technical specifications—directly leads to significant technical differentiation in the mechanism configuration, operating parameters, and functional modules of transplanting equipment [37].

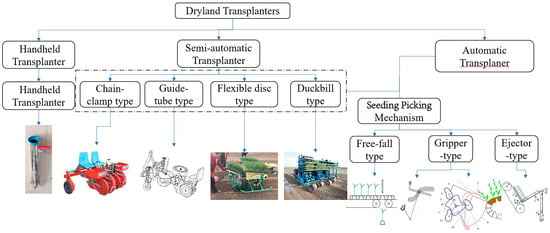

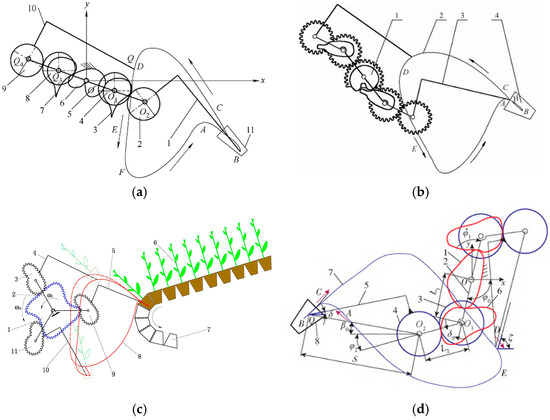

Transplanters can be classified into handheld, semi-automatic, and fully automatic types based on their operating principles. Figure 1 illustrates the overall classification of dryland transplanters according to planting principles, and Table 1 illustrates the differences among various transplanting machines. Semi-automatic and fully automatic transplanters share the same planting mechanism. Planting mechanisms are categorized into duckbill-type, chain-clip type, seedling guide-tube type, and flexible-disc type by operation mode. Among them, the duckbill-type planting mechanism exhibits strong adaptability to plug seedlings and wide applicability due to its structural features. It enables transplanting on mulch films and is currently the most widely used planting mechanism in semi-automatic transplanters for practical production [39]. During the operation of fully automatic transplanters, the seedling picking mechanism extracts seedlings from seedling trays and delivers them to the planting mechanism for transplantation. Scholars have borrowed the principle of rice carpet-seedling cutting and transplanting to design vegetable carpet-seedling transplanters [40]. This carpet-style seedling transplanting method can effectively reduce the manufacturing, maintenance, seedling–raising, and time costs of fully automatic transplanters. However, due to the constraints of crop biological characteristics, few vegetable varieties can be grown as carpet seedlings. Currently, only rapeseed [41], tobacco [42], chili peppers [43], and broccoli [44] are suitable for carpet-seedling cultivation.

Figure 1.

Overall classification of dryland transplanters.

Table 1.

The differences among various transplanters.

2.1. Handheld Transplanter

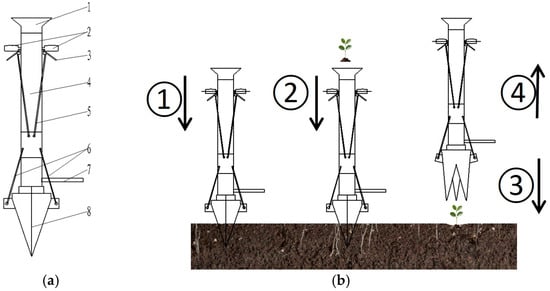

To reduce the labor intensity of small farmers during seedling transplantation, scholars have researched handheld transplanters [20,50,51]. As shown in Figure 2a, the handheld transplanter consists of a seedling feeding port, a handle, upper and lower cables, a seedling guide tube, a foot pedal, and a jaw-type planting mechanism. During operation, the operator manually holds the handle to move the transplanter, vertically inserts the planting mechanism into the soil, and then places seedlings into the seedling guide tube through the feeding port, allowing them to drop into the planting mechanism by gravity. Squeezing the handle opens the jaws of the planting mechanism, releasing the seedlings into the soil. Finally, lifting the transplanter causes the soil to backfill, completing the planting process. Figure 2b illustrates its workflow.

Figure 2.

Handheld Transplanter. (a) Structure diagram of the handheld transplanter: 1. Seedling feeding port; 2. Handle 1; 3. Handle 2; 4. Seedling guide tube; 5.Upper pull cable; 6. Lower pull cable; 7. Pedal; 8. Jaw-type planting device. (b) Planting process of the handheld transplanter: ① Press down; ② Feed seedlings; ③ Plant seedlings; ④ Lift.

2.2. Semi-Automatic Transplanter

After 1920, agricultural developed countries like European and American nations took the lead in adopting hand-fed seedling transplantation. To meet market demands, they introduced relatively simple transplanting equipment, filling the gap in transplanting machinery research. Following 1980, semi-automatic plug-seedling transplanters were gradually developed and refined, widely applied in agricultural production of developed countries, thus forming a relatively complete standardized dryland transplanting system [52]. After years of market validation, semi-automatic transplanters have matured and remain widely used today due to their stable and reliable performance and superior transplanting quality, making them the most prevalent models in the market [53,54].

2.2.1. Duckbilled Semi-Automatic Transplanter

During operation of the duckbill transplanter, the operator places plug seedlings into the duckbill planting mechanism. Once the planting mechanism penetrates the soil, the “duckbill” opens under cam control, allowing the plug seedlings to be planted. Transplanting is completed by the combined action of soil backfill and the soil covering mechanism. This type of transplanter enhances overall work efficiency by incorporating multiple planting units. However, due to manual seedling feeding, operators must promptly adjust the feeding speed to match increases in planting speed. Prolonged high-intensity manual labor often leads to an increase in seedling miss rate, significantly affecting transplanting performance [55]. Figure 3 illustrates the classification and working components of the duckbilled semi-automatic transplanter.

Figure 3.

Duckbilled Transplanter (Image source: ① Handheld transplanter; http://www.qzjyny.com/Product-detail-id-1478185.html, accessed on 15 July 2025 ② Self-propelled transplanter; http://www.ntflw.com/products/index.asp?typeid=11&lv=1, accessed on 15 July 2025 ③ Traction-type transplanter; https://www.kubota.com.cn/kams/productlist.do?method=list&&modelCodeNow=104, accessed on 15 July 2025).

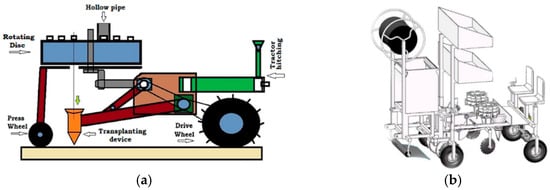

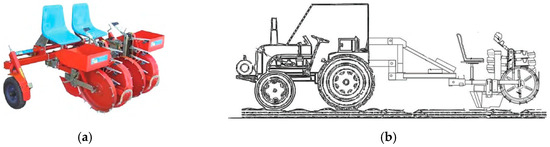

Sharma et al. [56] designed a two-row semi-automatic vegetable transplanter suitable for small-field transplanting, as shown in Figure 4a. During operation, the machine is towed by a tractor, and operators standing on the transplanter remove seedlings from trays and place them into a hollow pipe. As the rotating disc turns, seedlings are released at the seedling dropping point and dropped into the planting mechanism to complete transplantation. Shao et al. [57] developed a multifunctional semi-automatic vegetable transplanter (Figure 4b), which uses tractor traction for power and employs a linkage-duckbill planting mechanism. It can synchronously perform processes including drip irrigation tape laying, mulching, fertilization, transplanting, soil covering, and watering.

Figure 4.

Duckbilled semi-automatic transplanter. (a) Two-row semi-automatic vegetable transplanter [56]. (b) Multifunctional vegetable semi-automatic transplanter [57].

The duckbill-type seedling planting mechanism employs driving mechanisms such as linkage and planetary gear train types [19]. The linkage planting mechanism is widely used due to its low cost and ability to achieve diverse operating trajectories. Research on linkage planting mechanisms primarily focuses on mechanism configuration, which has evolved from the simplest four-bar linkage to seven-bar linkages and gear-linkage composite mechanisms.

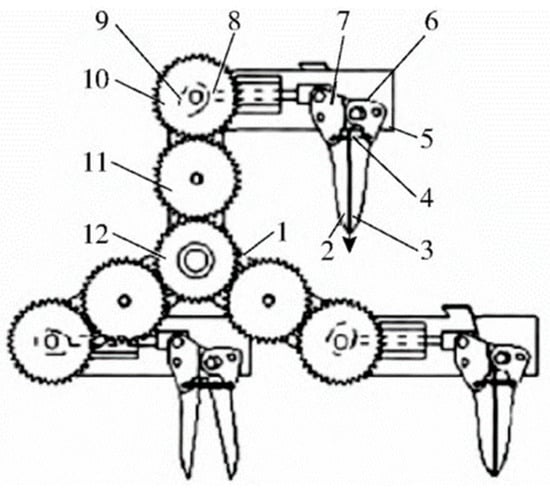

Although the linkage planting mechanism can meet the specific trajectory and posture requirements for vegetable transplanting, it has inherent characteristics such as high inertia and significant vibration, which hinder its adaptation to high-speed transplanting [37]. To further improve transplanting efficiency, scholars have proposed a planetary gear train planting mechanism [58,59], mainly composed of a planetary gear train and duckbill-type planter, as shown in Figure 5. During operation, the planting mechanism advances with the transplanter, and when driven by the planetary gear train, the duckbill-type planter traces a specific planting trajectory. A cam on the planter controls the opening and closing of the duckbill, enabling mechanized planting. A comparison of duckbill-type planting mechanisms is presented in Table 2.

Figure 5.

Planetary gear planting mechanism [58,59]. 1. Planetary carrier; 2. Left duckbill; 3. Right duckbill; 4. Tension spring; 5. Rotating arm; 6. Right opening plate; 7. Left opening plate; 8. Push rod; 9. Cam; 10. Planetary gear; 11. Intermediate gear; 12. Sun gear.

Table 2.

Comparison of various configurations of duckbill planting mechanisms.

2.2.2. Chain-Clip Semi-Automatic Transplanter

The chain-clamp transplanter consists of a soil covering wheel, transmission sprocket group, furrow opener, frame, seedling clamping and conveying device, seedling rack, and other components. During operation, when the clamping device rotates above the clamping slide via the sprocket, operators manually place seedlings onto the grippers. As the device moves along the sprocket to the clamping slide, the seedling grippers close and carry seedlings through the slide. Upon exiting the slide, the grippers open, allowing seedlings to fall into the furrow created by the furrow opener. Subsequently, the soil covering wheel compacts the soil around the seedlings, completing the transplanting process.

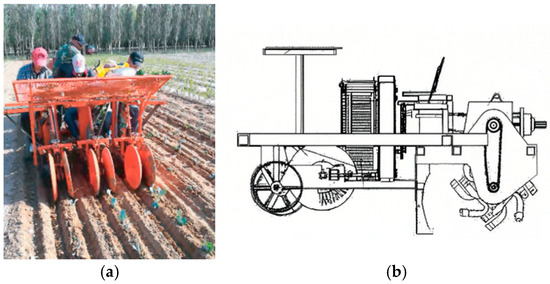

Based on the agronomic requirements for sweet potato cultivation, Nantong Fulaiwei Company designed the 2ZL-2 chain-clamp sweet potato transplanter [37] (Figure 6a). The transplanting mechanism clamps sweet potato seedlings via a slideway, opens the seedling gripper at the lowest point, and releases them into the planting furrow to complete transplantation. It features stable transplanting depth and plant spacing, low manufacturing cost, and an operating speed of 30–40 plants/min, but it suffers from low seedling verticality and high damage rate. Li [66] developed a semi-automatic chain-clip pineapple large-seedling transplanter with a self-balancing system (Figure 6b), which is tractor-towed and requires manual seedling feeding. Chen [67] designed a chain-clip chili pot-seedling transplanter, using a combination of seedling ejector and chain-clip planting mechanisms for plug-seedling transplanting, resulting in a low transplanting success rate.

Figure 6.

Chain-clip semi-automatic transplanter. (a) 2ZL-2 Chain-clamp sweet potato transplanter [37]. (b) Semi-automatic chain-clip pineapple seedling transplanter [66].

2.2.3. Guide-Tube Semi-Automatic Transplanter

During operation of the guide-tube transplanter, operators manually remove plug seedlings from trays and place them into the feed hopper of the seedling feeder. As the feed nozzle rotates to the inlet of the guide tube, it opens, allowing seedlings to enter the tube by gravity. Guided by the tube, seedlings fall into the planting furrow, where a soil covering wheel then covers and compacts the soil to complete transplantation.

Javidan et al. [68] designed a semi-automatic vegetable transplanter where operators manually place seedlings into a distributor. As the distributor moves seedlings above the seedling guide tube, they are dropped into the tube, then fall into the furrow opened by the furrow opener under gravity and tube guidance. The soil is covered and compacted to complete planting. Zhang et al. [69] developed a semi-automatic sugarcane seedling transplanter based on sugarcane agronomy (Figure 7a), consisting of a seedling guide mechanism, blocking mechanism, pushing mechanism, and other components, resulting in a low transplanting success rate. Yan et al. [70] studied a guide-tube tobacco transplanter (Figure 7b) for tobacco transplantation. The operation featured a plant spacing of 500–650 mm, transplanting depth of 80–120 mm, and irrigation volume of 300–500 mL, improving tobacco transplanting quality and enabling large-scale mechanical transplanting.

Figure 7.

Guide-tube semi-automatic transplanter. (a) Semi-automatic transplanting machine for sugarcane seedlings 69]. (b) Guide-tube-type tobacco transplanter [70].

2.2.4. Flexible-Disc Semi-Automatic Transplanter

During transplanting machine operation, operators manually place seedlings onto the conveyor belt. When the belt delivers seedlings to the gripping position of the flexible disk, the plug seedlings are gripped by the disk and disengage from the belt. They rotate around the disk’s center and are conveyed to the ground. When the disk reaches the release position, it releases the seedlings, which fall into the planting furrow opened by the furrow disk under gravity. Finally, the soil is covered to complete the transplanting process.

Kubota, Japan, designed a KN-P6 flexible-disk onion transplanter based on agronomic requirements for onion planting [48]. The planter features a double-rubber flexible disk with a compact structure. During operation, plug seedlings are manually placed and conveyed by the belt to the open flexible disk, then fall into the planting furrow and are covered with soil. It offers low labor intensity and simple operation, but has a short service life and low productivity. Zhao et al. [71] developed the 2ZS-3 water-replenishing transplanter for bare-root cabbage seedlings (Figure 8a), capable of furrowing, planting, soil covering, and watering. Zhang et al. [72] designed a semi-automatic combined onion transplanter (Figure 8b), integrating rotary tillage, furrowing, ridging, transplanting, and compaction. Composed of a horizontal seedling placer, vertical gripper, and upright planter, it transfers seedlings from the placer to the gripper, then to the planting disk of the upright planter. Hua [73] designed a towed flexible-disk cranberry transplanter, combining flexible disks with synchronous belt transmission to improve seedling placement speed and transplanting efficiency for strip-shaped bare-root cranberry seedlings.

Figure 8.

Flexible-Disc Semi-Automatic Transplanter. (a) ZS-3 Flexible-Disc-Type Cabbage Water-Replenishing Transplanter [71]. (b) Semi-Automatic Combined-Type Scallion Transplanter [72].

2.3. Fully Automatic Transplanter

Fully automatic transplanters feature high automation, with all processes, including horizontal–vertical seedling feeding, extraction, and planting, completed by the machine. The presence of an automatic seedling extraction mechanism is the key criterion for classifying transplanters as semi-automatic or fully automatic [37]. Since the 1980s, semi-automatic transplanters in developed regions (e.g., Japan, South Korea, Europe, and America) have matured, with mechanized planting widely adopted for various cash crops. Driven by advancements in modern plug-seedling factory technology and control systems, fully automatic vegetable transplanters were developed [74]. Fully automatic transplanters are categorized into large models using mechatronic technology (e.g., Europe and America) and small models using mechanical transmission (e.g., Japan and South Korea). Based on operation mode, they are of two types: (1) plug seedling transplanters with automatic seedling picking mechanisms and planting devices in coordination; (2) single-device transplanters completing picking and planting in one cycle. The key distinction between the two lies in their operating objects. The operating object of the fully automatic plug-seedling transplanter consists of seedlings cultivated in individual cells of plug trays, while the operating object of the fully automatic carpet-seedling transplanter consists of seedlings bred in trays with interwoven roots forming a carpet structure.

2.3.1. Fully Automatic Plug-Seedling Transplanter

Numerous fully automatic transplanter models employ automatic seedling picking–placing devices in conjunction with planting mechanisms, though their structural configurations and working principles remain fundamentally similar. These transplanters typically comprise a power unit, traveling mechanism, seedling feeding system, seedling extraction mechanism, planting mechanism, and soil compaction device. The primary distinction from semi-automatic transplanters lies in the inclusion of an automatic seedling feeding system and seedling picking–placing system, while the planting mechanism remains consistent with semi-automatic models. During operation, operators manually place plug-seedling trays at the seedling feeding mechanism. The trays automatically advance to feed seedlings, which are extracted by the picking mechanism and transferred to the planting mechanism. The planting mechanism inserts seedlings into the soil, followed by soil compaction to complete transplanting. For fully automatic plug-seedling transplanters, in addition to variations in planting devices, the most notable difference lies in the diversity of seedling picking mechanisms, which is elaborated in detail in Chapter 3 of this paper.

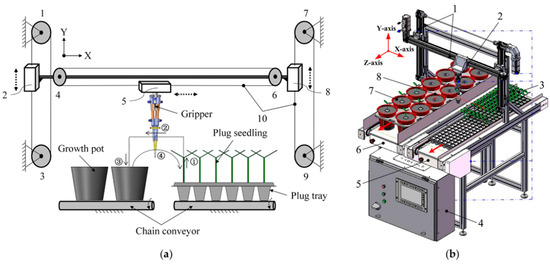

Khadatkar et al. [75] developed a fully automatic vegetable transplanter, including (1) a robotic control system; (2) a seedling picking mechanism (SPM); and (3) a traveling mechanism (VMS). The SPM is an electromechanically controlled finger–gripper extractor that clamps seedling stems, transports them above the guide tube, and releases them to fall into the furrow opened by the furrow opener under gravity and tube guidance. Magar et al. [76] developed a tractor-towed three-row automatic transplanter with an inclined magazine-type metering device for paper-tube vegetable seedlings. Khadatkar et al. [77] designed another tractor-towed transplanter featuring a seedling ejector, control system, furrow opener, and soil compaction device. Seedlings are ejected into the furrow via a guide tube, followed by soil compaction. Jin et al. [78] reviewed agricultural robots, including transplanting robots. Liu et al. [79] designed a strawberry transplanter for field testing. Wen et al. [80] developed a towed double-row transplanter (Figure 9a) composed of seedling feeder, combing device, ejector-type extractor, plate-turner, conveyor, separator, double-crank five-bar planter, empty tray recycler, and soil compactor, but high-speed operation causes replanting and missed planting issues. Shi et al. [81] proposed a close-planting transplanter for leafy vegetables with a duckbill planting mechanism (Figure 9b). Yao et al. [82] designed a flexible-disk onion transplanter (Figure 9c) using an ejector–gripper extractor: the ejector pushes out pot seedlings, which are gripped, horizontally conveyed, and planted by the flexible disk. Zhang et al. [83] developed a side-mounted close-planting transplanter for sweet potatoes (Figure 9d), adopting a single-sided chain-clamp mechanism to enhance transplanting efficiency.

Figure 9.

Fully automatic plug-seedling transplanter. (a) Traction double-row fully automatic transplanter [80]. (b) Automatic transplanter for densely planted vegetables [81]. (c) Flexible-disc automatic transplanting machine for scallions [82]. (d) Side dense transplanting machine for sweet potato seedlings [83].

Transplanting robots are equipped with reliable, mature navigation systems and automatic transplanting control systems, which enhance their automation level. However, due to the constraints of these complex systems, such transplanting robots are only suitable for transplanting operations in greenhouses with favorable working environments. In field transplanting, designers develop transplanters based on the specific agronomic requirements of crops for transplanting. For example, Reference [81] presents an automatic transplanter designed for vegetable plug seedlings, while Reference [83] describes a chain-clip transplanter developed to meet the special agronomic needs of sweet potato transplanting. Transplanters suitable for field transplanting operations differ not only in their operating methods but also significantly in their power sources. Generally, they either rely on tractor traction for power or are self-propelled transplanters with their own power systems.

2.3.2. Fully Automatic Carpet-Seedling Transplanter

Most existing fully automatic transplanters handle vegetable plug seedlings, but current plug-seedling transplanters suffer from issues like inconsistent seedling picking positions of the picking arms and “seedling dropout”, which significantly affect transplanting efficiency. Thus, researchers have adapted the block seedling cutting–picking principle from rice transplanters to design vegetable blanket-seedling transplanters. Ishizaki et al. [84] developed a vegetable transplanter based on the YR-6D rice transplanter chassis, through improving the transplanting mechanism and integrating components like a soil compaction device. Wu et al. [40] utilized the blanket-seedling cultivation method for rapeseed to design the 2ZY-6 rapeseed carpet-seedling transplanter (Figure 10a), capable of performing slotting, transplanting, and soil compaction in a single pass. Tang [85] developed a tractor-powered rapeseed blanket-seedling transplanter with an integrated picking–planting mechanism (Figure 10b), effectively addressing challenges of difficult land preparation, poor seedling insertion, and low seedling standing rate in rice stubble fields with sticky soil and full straw incorporation.

Figure 10.

Fully Automatic Carpet-Seeding Transplanter. (a) 2ZY-6 Rapeseed Carpet-Seedling Transplanter [40]. (b) Rape Blanket Seedling Combined Transplanter [85].

In summary, research on carpet-seeding vegetable transplanters can be divided into two directions. One is based on the rice transplanter chassis as described in references [40] and [86], which achieves the transplantation of vegetable carpet seedlings by improving the insertion mechanism and adding trenching and soil compaction devices. The other research direction is the traction-type combined transplanter that integrates land preparation, ridge formation, planting, and soil compaction devices as described in reference [87]. The transplanter modified from the rice transplanter chassis has a simpler structure and better adaptability to the working environment, but the quality of the operation is affected by the soil preparation effect. The joint transplanter is equipped with a ridge-raising device, which can obtain standard ridges that meet the transplanting requirements. The transplanting effect is good, but the structure is more complex.

3. Research Status of Seedling Picking Mechanism

The automatic seedling picking mechanism is the core component and hallmark of a fully automatic transplanter. Its performance directly impacts the quality and efficiency of transplanting operations, with the function of extracting, conveying, and placing pot seedlings from trays into seedling feeding devices or planters. Based on the characteristics of plug seedlings, scholars have proposed various seedling extraction methods, categorized into three types: ejector-type (ejector–gripper combined), gripper-type, and free-fall type [86].

During the current agricultural modernization process, different types of seedling picking mechanisms exhibit notable differences in technological maturity, application scenarios, and operational characteristics. A comprehensive evaluation of the implementation forms and features of various automatic seedling extraction methods is presented in Table 3.

Table 3.

Implementation forms and characteristics of automatic seedling picking methods.

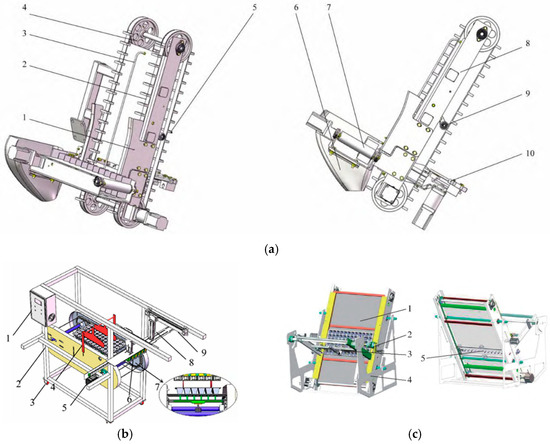

3.1. Ejector Type

The ejector-type seedling picking mechanism primarily uses an ejector rod to push plug seedlings out of the seedling tray onto the conveyor belt, completing the extraction operation. This structure is simple and features high extraction efficiency. Khadatkar et al. [77] developed an ejector-type extraction device with mechatronic control, while Chen et al. [87] designed a similar device (Figure 11a). Through motion analysis, they determined the optimal extraction point, horizontal movement distance of plug seedlings, and conveyor belt advance during extraction, addressing issues like uncontrollable seedling trajectory and poor placement consistency in automatic transplanter extraction systems. However, this method exhibits a relatively high growing medium fragmentation rate for plug seedlings.

To reduce the growing medium fragmentation rate while enhancing seedling picking success and qualification rates, researchers have proposed ejector–gripper combined seedling picking mechanisms. Peng et al. [88] developed an ejector–gripper pepper seedling extractor (Figure 11b) for plug seedlings. When the seedling tray reaches the extraction point, an ejector rod first loosens the pepper seedling, followed by a pneumatic gripper clamping the stem to complete extraction. This method achieved a high success rate, low medium loss, and a 4.17% seedling damage rate. Zhang et al. [89] studied the biological and mechanical properties of pepper plug seedlings during the development of an ejector–bowl–stem combined extractor, establishing force models for the pot and stem during ejection and gripping. Key parameters were designed, and tests showed 98% extraction success and 1.98% medium fragmentation at low speeds. Jorg et al. [90] designed two extractors—ejector–stem–gripper and ejector–bowl–gripper—testing them on fennel and other crops. Experiments indicated that stem-gripping after ejection outperformed bowl-gripping in extraction efficiency. The ejector–stem-gripping method effectively improves extraction success and qualification rates, reduces medium fragmentation, and maintains plug seedling root integrity.

Some scholars have researched seedling extraction mechanisms that grip the seedling pot after ejection. Wen et al. [91] integrated features of ejector-type and insertion-gripping extraction, designing an ejector–insertion seedling extractor based on the root system’s bottom-to-top thinning in plug trays and the composite properties of growing medium and roots. Through theoretical analysis and extraction tests, they optimized the device’s structure and parameters, achieving a low seedling damage rate but a high medium loss rate. Hu et al. [92] designed an ejector–gripper–pulling combined extractor (Figure 11c), determined the optimal working parameters, and found that the eject-first-then-grip mode yielded the highest extraction success rate and pot integrity rate of 94.12%.

Figure 11.

Ejector-type seeding picking mechanism. (a) Top out seedling picking mechanism [87]: 1. Seedling guide plate side panel; 2. Timing belt; 3. Guide rod; 4. Timing pulley; 5. Limit block; 6. Seedling guide tube; 7. Horizontal conveyor belt; 8. Base plate; 9. Tension pulley; 10. Ejector mechanism. (b) Top-clamp Combined Chili Seedling Picking Mechanism [88]: 1. Control box; 2. Frame; 3. Casters; 4. Platen mechanism; 5. Motor; 6. Seedling dividing mechanism; 7. Top seedling mechanism; 8. Lifting mechanism; 9. Shifting mechanism. (c) Top-clamping and pulling combined seedling picking mechanism [92]: 1. Seedling tray conveying mechanism; 2. Seedling tray pressure rod mechanism; 3. Seedling collection institution; 4. Bracket 5. Top-seedling institution.

3.2. Gripper Type

The gripper-type seedling picking mechanism primarily uses seedling grippers to directly clamp seedling stems or pot soil, extracting plug seedlings from the tray. According to control methods, it is classified into purely mechanical gripper-type and mechatronic gripper-type picking mechanisms. The mechanical gripper-type can be further divided into slideway-type, planetary-gear-train type, etc., based on implementation forms.

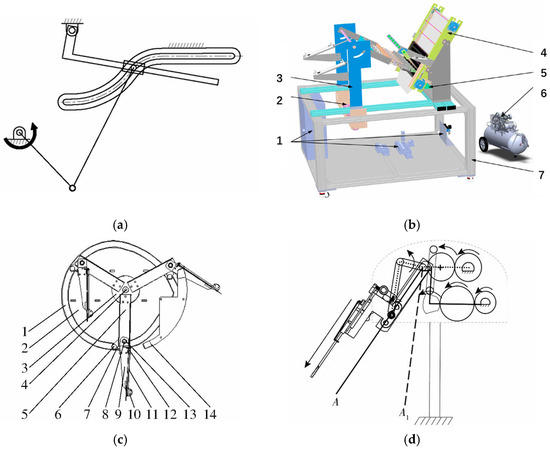

In the research on slideway-type seedling picking mechanisms, common configurations include multi-link seedling pickers and gear-link combined mechanisms. Choi et al. [93] from South Korea developed a five-link slideway seedling picker (Figure 12a), where crank rotation drives the rocker to reciprocate along the slideway, forming the picking trajectory. With a picking efficiency of 30 plants/(min·row), the success rate reaches 97%. Choio et al. [94] designed a five-bar sliding seedling picker for pepper plug seedlings, optimizing the parameters of each link. Han et al. [95,96,97,98] developed a series of slideway-type pickers (Figure 12b), achieving up to 70 plants/min with an average success rate exceeding 90%. Na et al. [99] proposed a slideway-type dry-field plug-seedling transplanting mechanism (Figure 12c), which controls the planting arm via a slideway to perform picking, feeding, planting, and resetting. This ensures optimal trajectories and speeds for picking and planting, resulting in high qualification rates at low speeds, but it cannot adapt to high-speed field transplanting.

Figure 12.

Slide-type Seedling Transplanting Mechanisms. (a) Five-link slideway-type seedling picking mechanism [93]. (b) Drank slideway-type seedling picking mechanism [96]: 1. automatic control system; 2. seedling cups; 3. seedling clamping device; 4. seedling transporting device; 5. seedling air loosening device; 6. air compressor; 7. fixed frame. (c) Fully Automatic Slide-Type Dryland Seedling Transplanting Mechanism [99]: 1. Slideway; 2. Slideway base plate; 3. Drive flange; 4. Drive shaft; 5. Crank; 6. Guide wheel; 7. Crank arm; 8. Crank arm shaft; 9. Planting arm; 10. Clamp plate; 11. Finger-clamp rod; 12. Finger-clamp opening arm; 13. Planting-arm base plate; 14. Finger-clamp opening guide plate. (d) Combination seedling picking mechanism [100].

Islam et al. [100] designed a seedling picking mechanism comprising gears, cams, and a crank–slider combination (Figure 12d). The linear extraction trajectory is achieved by a gear-driven crank–slider mechanism, while cam control enables the swinging of the extraction arm. The mechanism exhibits significant vibration at high speeds, with a maximum extraction efficiency of 60 plants/(min·row). Yanmar Company (Japan) adopted a planetary-gear–train-slideway combined picking mechanism, consisting of a planetary gear train, slideway, and extraction grippers. The gear train includes three gears, with the planet carrier as the driving component. Under the combined action of the gear train and slideway, the grippers form the required extraction trajectory. A spatial cam controls both extraction and placement actions: the gear train completes one revolution per extraction cycle, achieving an efficiency of 50–60 plants/(min·row) [101].

Slideway-type seedling picking mechanisms suffer from complex structures, low extraction efficiency, and unstable performance, making them unsuitable for high-speed transplanting. Planetary gear systems offer advantages like high transmission efficiency and easy dynamic balancing, with well-established design theories and methods. Thus, non-circular planetary gear train extraction mechanisms have broader application prospects compared to slideway-type counterparts.

The non-circular planetary gear train seedling picking mechanism typically reproduces the extraction trajectory and posture of the extraction arm through non-uniform-speed transmission of the non-circular-gear train. It features a compact structure, smooth operation, and enables efficient seedling extraction. This mechanism mainly comprises a driving unit and an extraction arm. The driving unit is a non-uniform-speed transmission planetary gear mechanism, while the extraction arm is equipped with a plug tray seedling clamping device. By adjusting gear transmission ratios, the phase angle of the extraction arm swing is controlled, thus planning the trajectories for seedling extraction and pushing.

Iqbal et al. [102,103] designed a pepper seedling picking mechanism using a gear train, integrating kinematic analysis, virtual simulation, and experimental research to achieve low-power, rapid, and precise seedling transplantation. Zhao et al. [104,105] proposed a series of non-circular-gear train picking mechanisms for vegetable transplanting, optimizing structural parameters via human–machine interaction, modeling under optimal parameters, and achieving mechanical seedling picking. Yu et al. [106] developed a novel rotary plug-seedling picking mechanism (Figure 13a). Based on its structural and operational principles, three transmission ratio functions were selected to derive a new non-circular gear’s pitch curve equation. A kinematic model was established, and parameters meeting operational requirements were obtained through human–machine interaction. Virtual simulation verified the mechanism’s feasibility and operational smoothness. Ye et al. [107] proposed a planetary gear train rotary picking mechanism (Figure 13b) driven by a combination of partially variable eccentric circular gears and non-circular gears. Parameter optimization via human–machine interaction yielded a high picking success rate. Sun Liang, Zhao Xiong, Tong Junhua et al. [108,109,110,111,112] optimized non-circular-gear train parameters, designing various planetary gear train extractors to reproduce the trajectories and postures required for crop plug transplantation. The team of Zhou [113,114,115] from Jiangsu University researched non-circular-gear train extractors, developing effective mechanisms like the probing-type chili extractor (Figure 13c). Zhou et al. [116] designed a planetary gear train extractor with non-circular complete gears and a large seedling–pushing angle, meeting vegetable transplanting requirements (Figure 13d).

Figure 13.

Non-circular planetary gear train seedling picking mechanism. (a) Rotary Plug-Seedling Picking Mechanism [106]: 1, 10. Seedling picking claws; 2, 9. Planetary gears; 3, 7. Intermediate gear-1; 4, 8. Intermediate gear-2; 5. Planetary carrier; 6. Sun gear; 11. Plug-seedling tray. (b) Rotary plug-seedling pick-up mechanism [107]: 1. Planetary gear train; 2. Motion trajectory; 3. Seeding pick-up arm; 4. Plug-seedling tray. (c) Penetrating chili seedling picking mechanism [114]: 1. Non-circular Central Gear; 2. Planet Carrier; 3. Non-circular Planet Gear II; 4. Picking Arm II; 5. Picking Arm I 6. Seedling; 7. Plug Tray; 8. Trajectory; 9. Non-circular Planet Gear I; 10. Picking Arm III; 11. Non-circular Planet Gear III. (d) Seedling Picking Mechanism for Helical-Gear–Non-Circular-Gear–Planetary-Gear System [116]: 1. Sun gear; 2. Planetary carrier; 3. Intermediate helical gear; 4. Planetary helical gear; 5. Seedling arm; 6. Non-circular middle gear; 7. Seedling picking trajectory; 8. Pot tray.

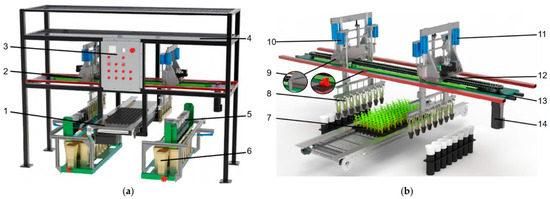

In addition to purely mechanical gripper-type automatic seedling picking mechanisms, many scholars have proposed various gripper-type automatic picking mechanisms with mechatronic–hydraulic–pneumatic integrated control. Rahul [117] designed a seedling picking device based on mechatronics, effectively reducing energy loss and improving extraction efficiency during operation. Khadatkar [118] developed a gripper-type vegetable transplanting robot, which uses a PLC control system to regulate the opening/closing of the picking mechanism and seedling placement. It primarily performs transplanting in protected agriculture but exhibits low operational quality. Yue et al. [119] designed a double-row seeding picking device and control system (Figure 14), reducing seedling pot damage by coordinating lifting and clamping cylinders. Han et al. [120] developed a mechanical-electric seedling picking device for greenhouse transplanting (Figure 15), achieving a maximum seedling transplanting success rate of 95.47%.

Figure 14.

Double row transplanter [119]. (a) A schematic diagram of the seedling picking and throwing system. (b) A schematic diagram of the seedling pick-up device. 1. Seedling tray conveying mechanism; 2. seedling pick-up device; 3. control panel; 4. seedling tray frame; 5. seedling separating mechanism; 6. rotating seedlingcup mechanism; 7. 128-hole seedling tray; 8. seedling pick-up end-effector; 9. zero position sensorand induction device; 10. clamping cylinder; 11. lifting cylinder; 12. drive chain; 13. linear guide rail; 14. servo motor.

Figure 15.

Structure drawing of the simplified greenhouse robotic transplanting workcell [120]. (a) Mechanism principles: 1, 3, 4, 6, 7, 9. belt pulley; 2, 5, 8. slider; 10. synchronous belt. (b) Mechanical structures: 1. transplanting manipulator, 2. seedling gripper; 3. plug seedling; 4. control system; 5. chain conveyor for plug trays; 6. chain conveyor for growth pots; 7. growth pot; 8. working trajectory.

The end-effector is a key component of mechatronic–hydraulic–pneumatic integrated seedling picking mechanisms, and its operational reliability directly impacts the extraction performance. End-effectors for seedling picking mechanisms can be categorized into finger-gripper type [121,122,123], adsorption type [124], adjustable plant-spacing type [125], pneumatic double-row type [126,127], etc.

3.3. Free-Fall Type

Free-fall seedling extraction technology has unique application scenarios. Compared with conventional plug-seedling cultivation, the nutrient pot seedling cultivation adapted to free-fall extraction exhibits distinct differences: its pot cavity features a frustum-shaped structure with a larger base and smaller top. During extraction, plug seedlings detach from the tray in a nearly vertical posture and directly fall into the seedling delivery device or planting mechanism.

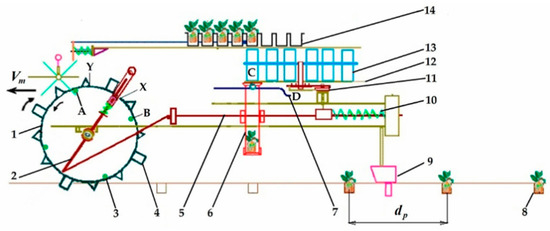

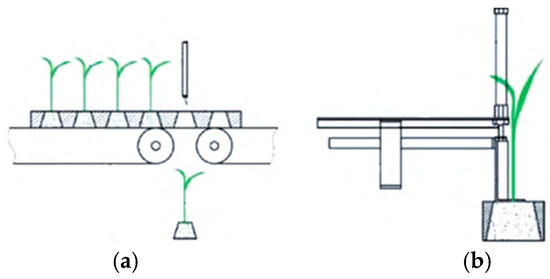

Vlahidis et al. [128] employed a gravity-based seedling picking method, leveraging coordinated tray and distributor operation to transport seedlings via gravity from the tray through the distributor into the planting unit. A single-row transplanter (Figure 16) was developed, achieving transplanting speeds of 54–69 plants/min in soil tank tests. Dihingia et al. [129] designed a free-fall seedling picking and planting device, testing it on a walking tractor-driven vegetable transplanter. Zhang et al. [130] developed a closed multi-channel air-blowing plug-seedling extractor, using high-speed airflow to blow seedlings into a guide tube for planting, achieving a high extraction success rate. Wang [131,132] designed a pneumatic down-pressure high-speed extractor with a combined plug tray. Through processes like “orderly tray supply, continuous seedling feeding, pneumatic down-pressure extraction, and free seedling placement”, it enabled 120 plants/min extraction but with high medium loss. Lai [133] developed a vibration-assisted air-suction device for directional transplanting of Panax notoginseng seedlings. Wang [134] proposed two vegetable transplanting extraction schemes: air-blowing and cylinder-pushing (Figure 17).

Figure 16.

Schematics regarding the constructive and functional parameters of the automatic trans planter [128]. 1. planting driving wheel; 2. oscillating lever;3. control rod; 4. spur; 5. sliding rods; 6. planting device; 7. cam guide; 8. seedling; 9. fixed winged skids; 10. return springs; 11. ratchetsystem; 12. holding-release screen; 13. receiving tube of the distribution apparatus; 14. Seedlingstray.

Figure 17.

Seedling picking plan [134]. (a) Air-sweeping type. (b) Cylinder push-out type.

3.4. Discussion on the Current Situation of the Seedling Picking Mechanism

The ejector-type seedling picking mechanism, with its straightforward operational principle, excels in transplanting scenarios requiring relatively low seedling integrity and uniform seedling pot specifications. For example, it efficiently ejects vegetable plug seedlings from trays. However, this mechanism is sensitive to pot material and hardness; overly rigid or deformed pots may cause extraction failure, and it struggles to adapt to seedlings with irregular shapes or sizes, limiting its applicability. Consequently, standalone research on ejector-type mechanisms has diminished, with most studies focusing on combined ejector–gripper systems. These mechanisms first loosen the seedling pot with an ejector and then extract and transport the seedling to the planting mechanism using a gripper.

The gripper-type seedling picking mechanism encompasses various subtypes. The slideway-type achieves extraction through slideway-gripper coordination, featuring a relatively simple structure and easy maintenance. However, its single-mode slideway motion compromises the balance between extraction accuracy and efficiency during high-speed operations, and adaptability to diverse seedling types remains to be improved. Non-circular-gear train seeding picking mechanisms leverage the unique kinematics of non-circular gears to execute complex gripping motions, enhancing extraction flexibility, efficiency, and stability. They suit crops with specific trajectory requirements for seedling extraction. Yet, their complex design, high manufacturing precision demands, and elevated costs restrict large-scale adoption. Mechatronic-controlled seeding picking integrates sensing and control technologies, enabling precise seedling position/posture perception for intelligent, accurate operations. Row-wise extraction boosts efficiency. However, reliance on complex control systems incurs high equipment costs and strict operator skill requirements, hindering popularization in economically underdeveloped regions or among small-scale farmers and rendering them unsuitable for field transplanting.

The free-fall seedling picking mechanism utilizes gravity with appropriate auxiliary devices to drop plug seedlings directly into the planting position, causing minimal seedling damage but high medium fragmentation, and failing to preserve intact pots. This method imposes strict requirements on seedling morphology and falling path control, resulting in relatively low operational efficiency, along with high demands for mechanism installation precision and terrain evenness.

Current research on seedling picking mechanisms faces significant challenges. On one hand, they must meet extraction demands for diverse crop varieties, planting patterns, and complex field conditions; on the other, they need to strike a better balance between enhancing extraction quality/efficiency and reducing equipment costs.

4. Questions and Suggestions

4.1. Existing Challenges

(1) Insufficient integration of agricultural machinery and agronomy

Current R&D of dryland transplanters primarily focuses on mechanical performance, failing to adequately consider agronomic factors like biological characteristics of different crops and cultivation technical requirements. Agronomic techniques mainly prioritize yield, neglecting the adaptability of agricultural machinery operations, thus resulting in insufficient integration between machinery and agronomy. During transplanting, farmers expect quick completion for earlier returns, but existing transplanters struggle to precisely meet this demand for speed and efficiency. The disconnect between equipment and agronomy leads to issues such as missed planting and seedling damage, reducing transplanting efficiency and quality, affecting crop survival rates and yields, and causing overall planting benefits to fall short of expectations.

(2) Incomplete standards for each transplanting stage

In seedling raising and transplanting, unified standards for plug-seedling specifications and growing medium composition are lacking, leading to significant variations in the morphological characteristics of plug seedlings for the same crop. During transplanting, high consistency is required for operation targets during seedling extraction and feeding, resulting in ineffective integration of agricultural machinery and agronomy. Moreover, current land preparation conditions vary widely across regions, with poor soil conditions in some areas restricting the application of transplanting machinery. Technical standards for transplanting operations exist for only a handful of crops, causing fragmentation between standards for seedling cultivation, land preparation, and transplanting. This fragmentation disintegrates transplanting procedures, making it difficult for transplanters to achieve optimal performance in practical operations.

(3) Poor adaptability of existing agricultural machinery

Existing dryland transplanters exhibit prominent adaptability issues, primarily in two aspects: terrain adaptability and soil condition adaptability. Dryland terrains are complex and diverse, encompassing mountainous, hilly, and plain areas. Most transplanters are designed for plains, struggling with poor trafficability and instability in complex terrains like mountains and hills, which hinders normal operation. Moreover, soil texture and moisture vary significantly across regions. Some transplanters face issues like soil accumulation and clogging in cohesive or dry compacted soils, compromising seedling extraction and planting efficiency. In sandy soils, plug seedlings often fail to anchor firmly after planting. These challenges result in significant functional disparities, poor universality, and limited adaptability of transplanters across regions, impeding their promotion and causing substantial resource waste.

(4) Low level of informatization and intelligence in existing agricultural machinery

Current dryland transplanters exhibit low levels of informatization and intelligence, primarily evidenced by the lack of monitoring-feedback mechanisms and subpar automation. Most transplanters lack real-time operation monitoring and data feedback, making it difficult for operators to promptly grasp working status and planting quality, thus impeding timely issue detection and resolution and leading to unstable operation quality. Moreover, numerous auxiliary personnel are required during the transplanter’s operation, limiting transplanting speed and productivity. Low efficiency and high labor intensity hinder the promotion of transplanting technology, resulting in marginal comprehensive benefits for agricultural production.

(5) Lack of innovation in key components such as seedling picking and transplanting mechanisms

Although seedling picking mechanisms exist in various forms—multi-link, slideway, finger-gripper, and gear train—the innovative design process still heavily relies on experience and inspiration. Despite recent advances in innovating and optimizing transplanting technologies and device structures to enhance transplanting quality and efficiency, most developments remain in the research and testing phase, yet to be commercialized. This has led to a shortage of high-stability, fully automated transplanting equipment in the market.

4.2. Suggestions

(1) Strengthening Interdisciplinary Collaboration: Establish a joint R&D team of agricultural machinery and agronomy experts. In the initial design phase of transplanters, fully consider the biological and physical characteristics of crops, as well as agronomic factors such as planting density, row spacing, and plant spacing, to promote deep integration of machinery design with agronomic requirements. Conduct extensive adaptability trials, including numerous field transplanting experiments in diverse regions and planting environments, followed by yield analysis. Based on trial results, make targeted adjustments and optimizations to transplanters to ensure they achieve optimal performance in actual operations.

(2) Establish Standards for Transplanting Processes: Land preparation conditions vary significantly across regions, with poor land conditions in some areas limiting the application of transplanting machinery. In the future, the first priority should be to unify land leveling requirements and crop planting specifications based on the actual development of different crop industries. Secondly, relevant agricultural departments or industry associations should lead the organization of experts and technicians to formulate scientific, reasonable, and unified seedling raising and planting standards. These standards should be based on the growth requirements of different crops, specifying seedling quality indicators and transplanting machine parameter ranges to provide a clear basis for seedling production and transplanting operations. Unified technical standards for soil preparation, substrate mixture ratio, bowl forming dimensions, plug tray specifications, and factory-based seedling cultivation will facilitate the automated operation of transplanters, thereby enhancing operation quality and production efficiency. The ultimate goal is to achieve integrated development of land preparation, bowl forming, seedling raising, seedling extraction, and planting.

(3) Enhancing Transplanter Adaptability: Strengthen research on transplanter adaptability under diverse terrains and soil conditions. Apply advanced design concepts and technical methodologies to optimize the chassis structure, traveling system, and working components of transplanters. Develop transplanters equipped with all-terrain intelligent chassis and adaptive soil operation systems to enhance their passability and stability in complex environments. Adopt a modular design approach to achieve serialization and standardization of non-seedling-extraction core mechanisms. This allows for selecting suitable seedling picking mechanisms based on different soil conditions and crops, enabling the planting of various plug seedlings. Such an approach improves the stability and adaptability of automatic transplanters, facilitates maintenance, and suits large-scale production requirements. While enhancing transplanter adaptability, attention should also be paid to cost control, and a balance should be struck between adaptability improvement and cost management.

(4) Accelerating Intelligentization and Digitalization of Transplanters: Install intelligent monitoring systems on transplanters to real-time monitor plug seedling’s status, soil conditions, and transplanter operation parameters via visual detection technology, soil moisture sensors, planting depth sensors, etc. Monitoring data is uploaded to the control terminal through a data transmission module, enabling operators to adjust the operation status in a timely manner and ensure operation quality. Meanwhile, vigorously promote the application of automation technologies. Introduce advanced automatic control technologies, such as autonomous driving systems, to achieve functions like automatic navigation, seedling extraction, and planting for transplanters. This approach reduces manual operation steps, enhances work efficiency and accuracy, alleviates labor intensity, improves operation quality, and boosts resource utilization.

(5) Strengthening Theoretical Framework and Performance Optimization of Transplanting Mechanisms: Enhance comprehensive basic theoretical research on transplanting mechanisms, and conduct a comprehensive analysis of key technologies, including seedling delivery, separation, extraction, and planting. Integrate crop biological and physical characteristics, innovative mechanism design, and interaction mechanisms among machinery, crops, and soil into a comprehensive research system, ultimately developing a systematic framework of theories and methods for innovative design of transplanting mechanisms. Meanwhile, strengthen performance testing and optimization of key components. Utilize modern virtual simulation technologies to establish a comprehensive performance testing platform, conduct systematic testing, optimize based on experimental data, and enhance performance indicators of transplanting mechanisms.

5. Future Development Prospects

(1) Enhance transplanting efficiency and quality of transplanters

Enhancing transplanting efficiency and quality remains the core objective for transplanter development. To meet the demands of field mechanized transplanting, continuous optimized design of key components—including seedling feeding systems and seedling extraction–planting systems—is essential to boost unit–time operation efficiency and quality. Additionally, improving transplanters’ adaptability and stability across diverse operational environments ensures that transplanting adheres to design parameters under complex conditions. In alignment with national and global environmental strategies, efforts should focus on developing eco-friendly and energy-efficient transplanters. This will enhance their economic and environmental viability, promoting widespread adoption.

(2) Integrated R&D of detection, planting, and seedling replenishment for transplanters

With the advancement in multi-sensor integration, visual inspection technology, and intelligent control systems, transplanters will increasingly incorporate intelligent and autonomous technologies. Sensors monitor basic environmental parameters like soil moisture; vision systems focus on plug seedlings’ status, accurately identifying morphological traits such as height, stem diameter, and leaf count, while detecting issues like pests, diseases, or damage. Using deep-learning algorithms, the system analyzes collected data in real time, filters and selects high-quality seedlings that meet transplanting standards, and provides timely feedback on abnormal seedlings. Transplanting mechanisms and planting parameters are intelligently adjusted based on the acquired data. During operation, the seedling replenishment system continuously monitors planting quality in the planted area and promptly performs replenishment. The ultimate goal is to achieve precise, efficient, and stable planting by integrating tray feeding, seedling extraction, planting, replenishment, and monitoring, promoting mechanized, informationized, and automated transplanting.

(3) Unmanned transplanting operations

Unmanned transplanting represents the future mode of transplanting operations. With the advancement and widespread application of technologies such as automatic navigation, intelligent measurement and control, lithium battery energy storage, and operational decision-making models, electric unmanned transplanters for dryland will emerge as a new development hotspot. Under the coordination of the unmanned agricultural machinery collaborative operation system, electric unmanned transplanters can achieve automatic startup and complete tasks, including garage entry/exit, transplanting operations, and seedling transfer. In the future, transplanting operations will advance toward unmanned operation through automatic navigation technology, intelligent measurement and control technology, and operational decision-making models. Eventually, a three-dimensional operation system integrating space-based satellite remote sensing, aerial unmanned aerial vehicle (UAV) monitoring, and ground-based robotic collaboration will be established. This system will drive the evolution of transplanting toward full-process unmanned and facilitate the green transformation and sustainable development of transplanters’ operations.

(4) Collaborative Industrial Development

The development of dryland transplanter technology will drive collaborative development among related industries—agricultural machinery manufacturing, seedling cultivation, and agricultural services. Agricultural machinery manufacturers will increase R&D investment, continuously launching high-performance, multifunctional transplanters to meet diverse market needs. Plug-seedling cultivation enterprises will provide higher-quality, standardized seedlings based on industry standards, ensuring robust support for transplanting operations. Agricultural service organizations will offer farmers professional technical guidance and operational services, assisting them in optimizing transplanter use and enhancing productivity. Through collaborative industrial development, a complete value chain can be established, promoting overall upgrading of the agricultural industry and advancing agricultural modernization.

Overall, this paper summarizes the research status of four types of semi-automatic transplanters, two types of fully automatic transplanters, and the core mechanism (seedling picking mechanism) of fully automatic transplanters. It clarifies the existing problems in transplanter development and proposes corresponding suggestions. However, the primary task in transplanter development is to improve transplanting efficiency and quality, which necessitates strengthening research on seedling extraction mechanisms. Only when the seedling picking mechanism achieves extremely low damage rates and extremely high seedling picking success rates can the development of unmanned transplanters have positive significance, ultimately driving the collaborative development of the industry.

Author Contributions

T.X. conducts document organization, writing, and editing; X.L., J.H., S.H. and G.W. are responsible for literature collection and organization; M.Z. and D.Y. provides project management and financial support. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by the Key R&D Plan of Zhenjiang City—Modern Agriculture (Grant No. NY2023003), Jiangsu Province Young Scientific and Technological Talents Promotion Plan (Grant No. JSTJ-2024-613), Natural Science Foundation of Jiangsu Province, Key Laboratory of Modern Agricultural Equipment and Technology (Jiangsu University), High-Tech Key Laboratory of Agricultural Equipment and Intelligence of Jiangsu Province. The project is also funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (Grant No. PAPD 2023-87).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to laboratory data privacy.

Conflicts of Interest

The authors declare no competing or financial interests.

References

- Zhang, C.; Li, X.; Yan, H.; Ullah, I.; Zuo, Z.; Li, L.; Yu, J. Effects of irrigation quantity and biochar on soil physical properties, growth characteristics, yield and quality of greenhouse tomato. Agric. Water Manag. 2020, 241, 106263. [Google Scholar] [CrossRef]

- Ma, G.; Shi, Q.; Wu, Y.; Liu, Y.; Han, L.; Hu, J.; Mao, H.; Zuo, Z. Effects of biochar on the growth and physiological and mechanical properties of cucumber plug seedlings before and after transplanting. Agriculture 2024, 14, 2012. [Google Scholar] [CrossRef]

- Ma, G.; Chen, X.; Liu, Y.; Hu, J.; Han, L.; Mao, H. Effects of compound biochar substrate coupled with water and nitrogen on the growth of cucumber plug seedlings. Agronomy 2022, 12, 2855. [Google Scholar] [CrossRef]

- Han, L.; Mo, M.; Gao, Y.; Ma, H.; Xiang, D.; Ma, G.; Mao, H. Effects of new compounds into substrates on seedling qualities for efficient transplanting. Agronomy 2022, 12, 983. [Google Scholar] [CrossRef]

- Ma, G.; Mao, H.; Bu, Q.; Han, L.; Shabbir, A.; Gao, F. Effect of compound biochar substrate on the root growth of cucumber plug seedlings. Agronomy 2020, 10, 1080. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Wang, J.; Fu, W. Growth, photosynthesis, and nutrient uptake at different light intensities and temperatures in lettuce. HortScience 2019, 54, 1925–1933. [Google Scholar] [CrossRef]

- Zhao, S.; Lei, X.; Liu, J.; Jin, Y.; Bai, Z.; Yi, Z.; Liu, J. Transient multi-indicator detection for seedling sorting in high-speed transplanting based on a lightweight model. Comput. Electron. Agric. 2023, 211, 107996. [Google Scholar] [CrossRef]

- Han, Z.; Yan, H.; Chen, K.; He, Y. Application status and prospect of planting depth profiling technology for transplanting machinery. Agric. Eng. 2018, 8, 1–7. [Google Scholar]

- Yu, X.; Zhao, Y.; Chen, B.; Zhou, M.; Zhang, H.; Zhang, Z. Current situation and prospect of transplanter. Trans. Chin. Soc. Agric. Mach. 2014, 45, 44–53. (In Chinese) [Google Scholar]

- Yao, M.; Hu, J.; Liu, W.; Shi, J.; Jin, Y.; Lv, J.; Sun, Z.; Wang, C. Precise servo-control system of a dual-axis positioning tray conveying device for automatic transplanting machine. Agriculture 2024, 14, 1431. [Google Scholar] [CrossRef]

- Bankole, O.O.; Danso, F.; Zhang, N.; Zhang, J.; Zhang, K.; Dong, W.; Lu, C.; Zhang, X.; Li, G.; Raheem, A.; et al. Integrated effects of straw incorporation and n application on rice yield and greenhouse gas emissions in three rice-based cropping systems. Agronomy 2024, 14, 490. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Wang, J. Effects of light intensity and temperature on the photosynthesis characteristics and yield of lettuce. Horticulturae 2022, 8, 178. [Google Scholar] [CrossRef]

- Yan, H.; Ma, J.; Zhang, J.; Wang, G.; Zhang, C.; Akhlaq, M.; Huang, S.; Yu, J. Effects of film mulching on the physiological and morphological parameters and yield of cucumber under insufficient drip irrigation. Irrig. Drain. 2022, 71, 897–911. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, H.; Zhang, W.; Hanan, J.S.; Ge, D.; Cao, J.; Xia, J.; Xuan, S.; Liang, W.; Zhang, L.; et al. An aboveground biomass partitioning coefficient model for rapeseed (Brassica napus L.). Field Crops Res. 2020, 259, 107966. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, J.; Jin, Y.; Bai, Z.; Liu, J.; Zhou, X. Design and testing of an intelligent multi-functional seedling transplanting system. Agronomy 2022, 12, 2683. [Google Scholar] [CrossRef]

- Gavric, T.; Omerbegovic, O. Effect of transplanting and direct sowing on productive properties and earliness of sweet corn. Chil. J. Agric. Res. 2021, 81, 39–45. [Google Scholar] [CrossRef]

- Huang, M.; Tang, Q.; Song, Z.; Liu, H.; Wu, Y.; Zhu, T. Development status and trends of the development of seedling pick-up mechanism of transplanter in dry land. J. Intell. Agric. Mech. 2023, 4, 57–64. [Google Scholar]

- Khadatkar, A.; Magar, A.P.; Sawant, C. Need for automation in vegetable transplanter for Indian agriculture. Indian Farming 2023, 73, 31–34. [Google Scholar]

- Cheng, B.; Wu, H.; Zhu, H.; Liang, J.; Miao, Y.; Cui, Y.; Song, W. Current status and analysis of key technologies in automatic transplanters for vegetables in China. Agriculture 2024, 14, 2168. [Google Scholar] [CrossRef]

- Habineza, E.; Reza, N.; Bicamumakuba, E.; Haque, A.; Park, S.-H.; Lee, D.-H.; Chung, S.-O.; Lee, Y.-S. Pepper transplanting mechanisms and kinematic simulation analysis: A review. Precis. Agric. Sci. Technol. 2024, 6, 17–32. [Google Scholar] [CrossRef]

- Karayel, D.; Çanakci, M.; Topakci, M.; Aktaş, A.; Aytem, H.; Kriauciuniene, Z. Technical evaluation of transplanters’ performance for potted seedlings. Turk. J. Agric. For. 2023, 47, 116–123. [Google Scholar] [CrossRef]

- Miah, S.; Rahman, M.; Hoque, M.A.; Ibrahim, S.M.; Sultan, M.; Shamshiri, R.R.; Ucgul, M.; Hasan, M.; Barna, T.N. Design and evaluation of a power tiller vegetable seedling transplanter with dibbler and furrow type. Heliyon 2023, 9, e17827. [Google Scholar] [CrossRef] [PubMed]

- Mitrache, P.; Saracin, I.; Ciuperca, R. Comparative research on realization of agrotehnical indices by seedling planting machines with bucket dispensers. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Jelgava, Łotwa, 20–22 May 2020. [Google Scholar] [CrossRef]

- Wei, L.; Jianping, H.; Jiaxin, L.; Rencai, Y.; Tengfei, Z.; Mengjiao, Y.; Jing, L. Method for the navigation line recognition of the ridge without crops via machine vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar] [CrossRef]

- Sun, J.; He, X.; Ge, X.; Wu, X.; Shen, J.; Song, Y. Detection of key organs in tomato based on deep migration learning in a complex background. Agriculture 2018, 8, 196. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Shi, J.; Zhou, C.; Hu, J. SN-CNN: A lightweight and accurate line extraction algorithm for seedling navigation in ridge-planted vegetables. Agriculture 2024, 14, 1446. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic measurement method for steering wheel angle of autonomous agricultural vehicles. Agriculture 2024, 14, 1602. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.; Liu, Y.; Zhang, T.; Yan, M.; Chen, J.; Zhou, C.; Hu, J.; Chen, X. An ultrasonic ridge-tracking method based on limiter sliding window filter and fuzzy pure pursuit control for ridge transplanter. Agriculture 2024, 14, 1713. [Google Scholar] [CrossRef]

- Cui, B.; Cui, X.; Wei, X.; Zhu, Y.; Ma, Z.; Zhao, Y.; Liu, Y. Design and testing of a tractor automatic navigation system based on dynamic path search and a fuzzy stanley model. Agriculture 2024, 14, 2136. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Yao, M.; Shi, J.; Hu, J. Seedling-yolo: High-efficiency target detection algorithm for field broccoli seedling transplanting quality based on YOLOV7-tiny. Agronomy 2024, 14, 931. [Google Scholar] [CrossRef]

- Ji, X.; Wei, X.; Wang, A.; Cui, B.; Song, Q. A novel composite adaptive terminal sliding mode controller for farm vehicles lateral path tracking control. Nonlinear Dyn. 2022, 110, 2415–2428. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Syed, T.; Lakhiar, I.; Chandio, F.A. Machine vision technology in agriculture: A review on the automatic seedling transplanters. Int. J. Multidiscip. Res. Dev. 2019, 6, 79–88. [Google Scholar]

- Min, Y.-B.; Han, C.-W.; Kweon, G.-Y. Study on optimum operating conditions of a pushing unit for onion plug seedlings. J. Agric. Life Sci. 2014, 48, 435–445. [Google Scholar] [CrossRef]

- Dang, Y.; Jin, X.; Li, H.; Wang, J.; Lu, Y.; Ding, B.; Li, X. Design of single-degree-of-freedom four-bar seedling-taking and throwing manipulator. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 39–47, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Liu, J.; Yu, G.; Tong, Z.; Hua, Y. Design and experimental study of a planetary gearing mechanism based on twice unequal amplitude transmission ratio. Int. J. Agric. Biol. Eng. 2022, 14, 155–163. [Google Scholar] [CrossRef]

- Yu, G.; Wang, L.; Sun, L.; Zhao, X.; Ye, B. Advancement of mechanized transplanting technology and equipments for field crops. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–20, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Chen, F.; Yue, R.; Yao, M.; Li, J. Simulation optimization and experiment of finger-clamping seedling picking claw based on EDEM-Recurdyn. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–85, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, G.; Wang, J.; Li, S.; Lu, L.; Dong, Z. Research status and development trend of upland crops mechanized transplanting key technologies. J. Chin. Agric. Mech. 2022, 43, 22–31, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wu, J.; Yu, W.; Zhang, M.; Wu, C.; Jiang, L.; Tang, Q. Design and test of 2ZY-6 rapeseed carpet seedling transplanter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 95–102, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Jiang, L.; Wu, C.; Tang, Q.; Zhang, M.; Wang, G.; Wu, J. Critical equation of seedling block falling off in transplanting process and the optimization experiment of rape blanket seedling transplanter. Int. J. Agric. Biol. Eng. 2019, 12, 87–96. [Google Scholar] [CrossRef]

- Tobacco Research Institute of Chinese Academy of Agricultural Sciences. A Method for Cultivating Carpet Seedlings of Chili Peppers. CN202411499743.8, 27 December 2024. [Google Scholar]

- Yu, Y.; Zhao, X.; Zhang, P.; Zhang, B. Optimization Design and Experiment of Transplantation Mechanism for Vegetable Blanket Seedlings. J. Agric. Mech. Res. 2024, 1–10. Available online: http://kns.cnki.net/kcms/detail/23.1233.S.20250218.1713.030.html (accessed on 14 July 2025).

- Liu, D. Optimization Design and Experimental Study on Integrated Transplanting Mechanism of Take and Plant For Vegetable Blanket Seedlings. Master’s Thesis, Zhejiang Sci-Tech University, Hangzhou, China, 2022. [Google Scholar]

- Jo, J.S.; Okyere, F.G.; Jo, J.M.; Kim, H.T. A Study on Improving the Performance of the Planting Device of a Vegetable Transplanter. J. Biosyst. Eng. 2018, 43, 202–210. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Zhang, H.; Guo, X. Design and Simulate on the Staggered Chain Clip Type Pepper Transplanting Machine. Mach. Des. Manuf. 2018, 4, 68–71. [Google Scholar] [CrossRef]

- Qin, W.; Yu, Y.; Lai, Q.; Zhan, C.; Yuan, H.; Zhang, H. Parameter optimization experiment of seedling guiding tube transplanting machine of Panax notoginseng seedling. Acta Agric. Zhejiangensis 2022, 34, 614–625. [Google Scholar] [CrossRef]

- Li, H. Design and Experiment of Planting Mechanism of Tobacco Transplanter Based on PLC Control. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2021. [Google Scholar]

- Ji, D.; Liu, L.; Zeng, F.; Zhang, G.; Liu, Y.; Diao, H.; Tian, S.; Zhao, Z. Design and Experimental Study of a Traction Double-Row Automatic Transplanter for Solanum Lycopersicum Seedlings. Horticulturae 2024, 10, 692. [Google Scholar] [CrossRef]

- Habineza, E.; Ali, M.; Reza, N.; Woo, J.-K.; Chung, S.-O.; Hou, Y. Vegetable transplanters and kinematic analysis of major mechanisms: A review. Korean J. Agric. Sci. 2023, 50, 113–129. [Google Scholar] [CrossRef]

- Sharma, A.; Khar, S. Current developments in vegetable transplanters in developing countries: A comprehensive review. Int. J. Veg. Sci. 2022, 28, 417–440. [Google Scholar] [CrossRef]

- Wang, Q. Optimization Design and Simulation Analysis of Transplanting Mechanism of Pascal Gear Pepper Pot Seedling. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2017. [Google Scholar]

- Lv, Z.; Shan, Y.; Wang, J.; Zhao, Y. Research progress of vegetable transplanting machine and prospects of seed-ling-picking machinery of transplanter. J. Chin. Agric. Mech. 2017, 38, 30–34, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chen, B. Research on Automatic Seedling Supply Device of Pepper Seedling Transplanting Machine. Ph.D. Thesis, Hunan Agricultural University, Changsha, China, 2023. [Google Scholar]

- Lawrence, M.J.; Buckmaster, D.R.; Lamont, W.J., Jr. A pneumatic dibbling machine for plastic mulch. Appl. Eng. Agric. 2007, 23, 419–424. [Google Scholar] [CrossRef]

- Sharma, A.; Khar, S. Conceptualization and development of a semi-automatic vegetable transplanter prototype for small landholdings. Heliyon 2024, 10, e31540. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.; Liu, Y.; Xuan, G.; Hu, Z.; Han, X.; Wang, Y.; Chen, B.; Wang, W. Design and Test of Multifunctional Vegetable Transplanting Machine. IFAC-PapersOnLine 2019, 52, 92–97. [Google Scholar] [CrossRef]

- Yu, G.; Liao, Z.; Xu, L.; Zhao, P.; Wu, C. Optimization Design and Test of Large Spacing Planetary Gear Train for Vegetable Pot-seedling Planting Mechanism. Trans. Chin. Soc. Agric. Mach. 2015, 46, 38–44, (In Chinese with English Abstract). [Google Scholar] [CrossRef]