1. Introduction

In modern aerospace manufacturing, the efficiency of production and the effectiveness of resource allocation in assembly workshops are critical determinants of product delivery timelines and quality standards [

1,

2]. With increasing structural complexity, the trend toward larger components, and the growing demand for customization, traditional workshop management and production scheduling models fall short of meeting manufacturing demands for high efficiency, precision, and flexibility [

3,

4,

5]. Consequently, a new approach that integrates intelligent logistics, lean production principles, and system-level simulation is urgently required to systematically optimize the aerospace assembly process.

In recent years, a growing body of research has focused on integrating Automated Guided Vehicles (AGVs) with modern production scheduling systems to overcome the inefficiencies and rigidity associated with traditional manual transportation methods [

6]. Owing to their high efficiency, flexibility, and level of automation, AGV systems have been widely adopted across various production settings, including automotive manufacturing, electronic assembly, and the aerospace industry [

7,

8]. Conventional AGV scheduling approaches primarily rely on priority-based rules [

9] and path planning algorithms [

10], such as shortest-path algorithms based on graph theory [

11], genetic algorithms [

12,

13], and ant colony algorithms [

14]. Prior studies have demonstrated that AGV scheduling not only reduces material transportation time but also significantly improves the flexibility and automation level of production systems [

15,

16].

For example, Wang et al. proposed a Mixed-Integer Programming (MIP) model to minimize job completion time in AGV scheduling and significantly enhanced scheduling efficiency using a customized branch-and-bound algorithm [

17]. Cao et al. optimized the AGV scheduling model by introducing a bidirectional conflict-free routing strategy, which demonstrated high efficiency in real-world applications at automated container terminals [

18]. Singh et al. presented a scheduling model that considers battery constraints and a heterogeneous AGV fleet, and solved it using Mixed-Integer Linear Programming and a large neighborhood search algorithm to optimize transport and charging tasks [

19]. Li et al. integrated the dynamic job shop scheduling problem (DJSP) with AGVs by formulating it as a Markov Decision Process (MDP) and optimizing it with a Deep Q-Network (DQN) algorithm, showing superior performance compared to rule-based dispatching methods [

20]. However, most existing studies concentrate solely on AGV scheduling, often overlooking the coordination between AGVs and other production resources—such as workstations, personnel, and machinery—in complex production environments. This limitation becomes particularly pronounced in assembly workshops constructing complex products, where large component sizes and complex processes create bottlenecks that cannot be resolved by AGV scheduling alone [

21,

22]. Although researchers have called for integrated optimization approaches, the coordination between AGVs and other resources remains insufficiently explored.

Discrete Event Simulation (DES) has been widely employed in the modeling and optimization of manufacturing systems [

23]. By simulating different production scenarios, researchers can assess the impact of various scheduling strategies and resource allocation schemes in a virtual environment, ultimately identifying the most efficient production processes [

24]. Numerous studies in the literature have applied DES to traditional manufacturing systems, yielding positive outcomes, especially in the areas of process scheduling and resource management [

25]. For instance, Kostrzewski used Plant Simulation to enhance the efficiency and resource utilization in warehouse order-picking operations [

26]; Sun et al. applied FlexSim to optimize AGV-based transport tasks within warehouse environments [

27]; and Skawina et al. integrated automated scheduling tools with DES models to create a safe simulation framework for mine scheduling, enabling rapid adjustments and evaluation of alternative strategies [

28]. However, most existing simulation studies have been limited to relatively simple manufacturing environments, with limited attention given to the practical application of DES in complex product assembly workshops.

In the aerospace manufacturing industry, particularly in the production of cabin sections, workshop-level resource allocation and workstation scheduling present substantial challenges. Existing simulation studies often fail to thoroughly investigate the coordination between AGV scheduling and workstation assignment, nor do they address the need for dynamic adjustments to material transport and task allocation during time-sensitive production cycles. As a result, although DES technology has been widely adopted across various industries, its application in complex product assembly workshops remains limited. This is especially true when it comes to optimizing scheduling under multi-resource constraints and dynamic operating conditions.

This study integrates lean production principles with modern simulation technologies to achieve comprehensive optimization of complex product assembly workshops. By conducting a detailed analysis of the manufacturing process and adhering to smart factory standards, techniques such as pull-based production, single-piece flow, and continuous flow are implemented. Plant Simulation software is selected for production line layout and functional modeling due to its robust discrete event simulation capabilities, flexible scalability, and strong support for complex production systems. These features enable effective validation of process logic and equipment configurations [

29]. Compared to other simulation platforms, Plant Simulation demonstrates superior precision and adaptability when dealing with the complexity and dynamism of aerospace assembly lines. This integrated approach significantly enhances operational efficiency and equipment utilization, offering both theoretical and technical foundations for improving the sustainability and adaptability of aerospace manufacturing operations [

30,

31]. The primary objective of this study is to utilize simulation tools to analyze preconfigured assembly lines, formulate a comprehensive planning and design strategy for complex product assembly workshops, and identify and address inefficiencies for further optimization.

The main contributions of this study include the following:

(1) This study proposes a DES-based optimization model that integrates AGV scheduling, workstation configuration, material replenishment, and production task scheduling. It effectively addresses scheduling challenges in dynamic, multi-resource production environments, particularly suited to the needs of complex product assembly workshops.

(2) It fills a gap in the research on AGV scheduling optimization in aerospace assembly, introducing a novel integrated optimization framework that specifically tackles issues related to large component transportation and complex workstation coordination.

(3) Clear optimization objectives and key performance indicators (KPIs) are defined, enabling a rigorous evaluation of the method’s effectiveness in improving workstation utilization and overall production efficiency.

(4) Simulation results confirm that the proposed approach significantly enhances AGV scheduling efficiency and resource utilization, highlighting its practical value for application in complex product assembly workshops.

The structure of this article is as follows:

Section 2 presents the comprehensive planning and design of the aerospace assembly line.

Section 3 explains the modeling of the assembly workshop using simulation software.

Section 4 analyzes the simulation results and introduces optimization measures based on the identified shortcomings.

Section 5 concludes the study and proposes directions for future research.

2. Planning and Design of an Assembly Workshop

This chapter focuses on the planning and design of complex product assembly workshops, emphasizing production line layout, lean manufacturing principles, and the configuration of functional zones. DES technology is employed to analyze resource allocation and AGV scheduling within the workshop, ensuring efficient and coordinated operations. The design prioritizes the logical arrangement of functional areas and the smooth flow of logistics, with the objective of enhancing both production efficiency and operational safety.

2.1. Workshop Planning Architecture

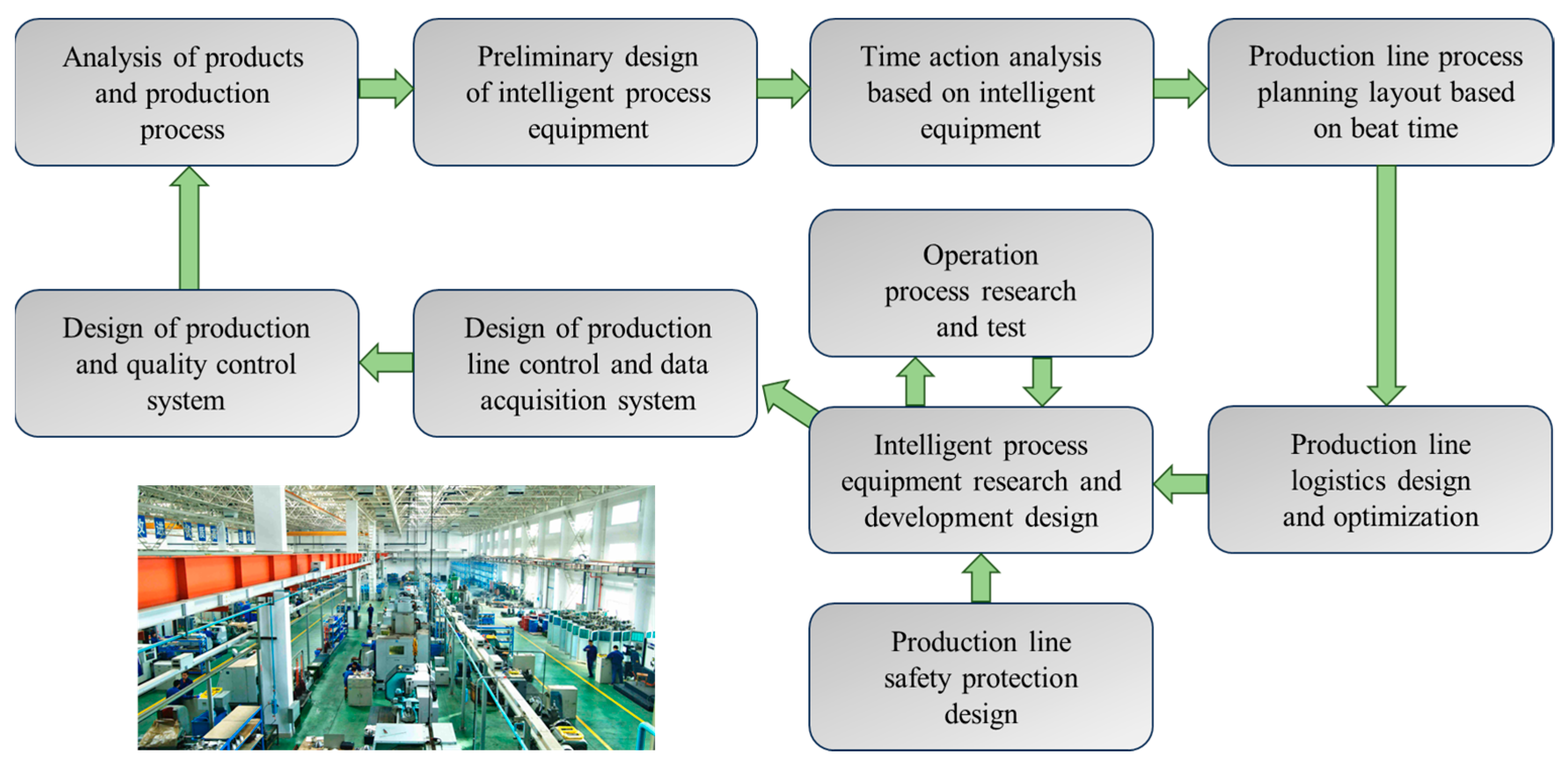

The overall production line planning adheres to smart factory guidelines, as illustrated in

Figure 1.

The overall planning process of the production line encompasses all stages from product and process analysis to system integration and control design. Initially, a detailed assessment of the product and its manufacturing requirements is performed, considering factors such as quantity, geometry, dimensions, weight, and specific process control needs. Concurrently, relevant data on operations, measurements, and quality inspections are collected. Subsequently, the preliminary design of intelligent processing equipment is developed, and time–motion analysis based on smart devices is conducted to support cycle time-driven production rhythm planning.

Based on the defined cycle time, the production line process layout is established and then refined through optimization of the internal logistics system to ensure efficient material handling and flow. On this basis, a safety protection plan for the production line is developed, and intelligent processing equipment is designed and improved. Coordination between equipment and personnel is enhanced through the study and testing of operational procedures. At the same time, the production line control system and data collection system are designed to ensure transparency and controllability of the production process. Finally, a complete production and quality management system is built, which includes efficiency, quality and safety control to support the stable and efficient operation of the production line.

2.2. Layout Principles of Assembly Workshops

Based on lean production principles and the specific characteristics of the product, the layout of the production line should follow these guidelines:

(1) Within the constraints of the factory environment, a standardized linear production line should be established in accordance with the manufacturing process, forming a single-piece flow layout that aligns with the operational sequence.

(2) Functional areas such as parts storage, assembly, testing, and buffer zones should be strategically arranged to ensure smooth and efficient logistics within each section.

(3) Sufficient safety passageways for personnel and logistics must be maintained, with their widths defined according to relevant standards to ensure unobstructed movement throughout the workspace.

2.3. Workshop Layout of a Complex Product Assembly Workshop

The complex product assembly workshop is part of a newly constructed workshop, and the layout of its functional areas is shown in

Figure 2.

The functional areas of the complex product assembly workshop are described as follows:

(1) Component Unboxing and Storage Area: This area is designated for unpacking and temporarily storing incoming components.

(2) Assembly and Inspection Area: Components are assembled and subjected to quality inspections in this section.

(3) Component Kit Assembly Area: Individual parts are grouped into kits to support subsequent assembly stages.

(4) Automated Assembly Area: Automated equipment is used here for efficient component assembly.

(5) Final Assembly Area: This area handles the complete assembly of the final product.

(6) Product Testing and Coding Area: Products undergo functionality testing and are assigned identification codes.

(7) Electrical Performance Testing Area: This section focuses on testing the electrical properties of products.

(8) Repainting Area: Products requiring touch-up or repainting are processed in this area.

(9) Dehumidifying Area for Products and Packaging: Moisture is removed from products and their packaging to prevent damage.

(10) Packaging Turnover Area: Manages the circulation and storage of packaging materials.

(11) Product Boxing and Packaging Coding Area: Final packaging and labeling of products are carried out here.

Before initiating the simulation,

Figure 3 illustrates the designated AGV routes within the production line. AGVs navigate along yellow-marked paths, execute arrival operations at red-marked locations, and reduce speed at green-marked zones. This color-coded routing system enables operators to quickly identify AGV positions and statuses, thereby improving both operational efficiency and workplace safety. Furthermore, the visual cues provided by the color system facilitate intuitive navigation and contribute to maintaining a streamlined and orderly production flow.

3. Model Establishment

The production modeling process of the complex product assembly workshop is conducted using Plant Simulation to establish a DES model aimed at evaluating and optimizing the assembly workflow. This model incorporates AGV scheduling and production control strategies, offering essential data support for refining both the layout and process configuration of the assembly workshop.

3.1. The Method of Modelling Process

In this study, DES technology is employed to model the complex product assembly workshop, as it effectively simulates complex dynamic systems under multiple resource constraints. The production process in such workshops involves multi-stage assembly of large components, requiring a high degree of coordination between resources and logistics scheduling. DES enables detailed modeling of tasks, resources, logistics flows, and event sequences, accurately reproducing workshop operations and offering reliable support for developing and evaluating optimization strategies.

The overall process of the complex product assembly workshop production model, based on DES, is illustrated in

Figure 4. During model construction, the system first initializes the processing status of each workpiece and machine, as well as the standby positions of all AGVs, ensuring that all resources are in their designated states before the simulation begins. Once initialization is complete, the production tasks commence. If all tasks are finished, the process ends; otherwise, the system continues executing production tasks and checks for material shortages. If materials are available, the assembly tasks proceed. Upon completing an assembly task, if transportation is not required, the system advances to the next task. If transportation is needed, the system issues a transport instruction and assigns an available AGV. If materials are lacking, the system dispatches a replenishment request to an idle AGV to complete the delivery.

The overall process of the AGV transport task is as follows. First, an idle AGV receives a transport request from the system and prepares to execute the task. Before the task begins, the system verifies whether the AGV meets the necessary transport conditions. If deemed suitable, the AGV is selected based on task priority, workstation status, and the condition of the workpiece. Once assigned, the AGV proceeds to the designated location for pickup. After collecting the cargo, it transports the items to the specified destination, completing the transport operation. The AGV then returns to its standby position and awaits the next transport instruction.

The pseudocodes for the AGV cargo transfer process and the production control process are respectively Algorithm 1 and Algorithm 2.

| Algorithm 1 Pseudocode of production process control |

|

- 2.

If AGV is idle then

|

- 3.

Perform transhipment tasks

|

- 4.

If transport conditions are met then

|

- 5.

Select AGV according to the selection strategy

|

- 6.

AGV runs to the pickup position

|

- 7.

AGV pickup

|

- 8.

AGV runs to the sending position

|

- 9.

Send AGV to the standby position

|

- 10.

Else

|

- 11.

// Handle the case where transport conditions are not met

|

- 12.

End if

|

- 13.

Else

|

- 14.

// Handle the case where no AGV is idle

|

- 15.

End if

|

- 16.

Else

|

- 17.

// No action needed if no transhipment request

|

- 18.

End if

|

- 19.

End

|

| Algorithm 2 Pseudocode of AGV transfer process |

|

- 2.

Initialize system

|

- 3.

Initialize AGV standby position

|

- 4.

Begin production tasks

|

- 5.

Repeat

|

- 6.

If production task is finished then

|

- 7.

If there is a lack of materials then

|

- 8.

Request for supplementary material

|

- 9.

Else

|

- 10.

Perform assembly tasks

|

- 11.

End if

|

- 12.

End if

|

- 13.

Until production tasks are no longer active

|

- 14.

End

|

3.2. Application of Simulation Software

This study employs Plant Simulation software to model and optimize the AGV scheduling problem. To evaluate the effectiveness of the proposed method, comparisons were conducted with other widely used simulation tools, including FlexSim [

32], Arena Simulation [

33], and AnyLogic [

34]. These tools were applied to simulate the same scheduling scenario, and their performance was evaluated based on production efficiency, workstation utilization, and transportation time. Experimental results indicate that Plant Simulation significantly reduces total transportation time in multi-AGV collaborative scheduling and complex task scenarios, while also exhibiting strong stability under high-load conditions.

By comparing key performance indicators before and after optimization, the proposed method enhances process efficiency, reduces idle time, and improves both workstation utilization and AGV scheduling performance. These improvements highlight the method’s practical applicability in complex assembly workshop environments.

The Plant Simulation software used in this study, as shown in

Figure 5, builds a comprehensive workshop simulation model, including assembly stations, material flow paths, and AGV routes to replicate the production process. By configuring key parameters such as workstation processing times and AGV operating speed parameters, the model effectively mirrors real workshop conditions. During the simulation, real-time data on task execution and idle times at each station are collected, enabling bottleneck identification and supporting resource allocation optimization. This provides a solid foundation for process improvement.

To ensure the accuracy of the simulation results, several key parameters were defined in the model, as summarized in

Table 1. The workshop includes 11 workstations, covering essential stages from part storage and segmented assembly to final packaging. The processing time for each assembly operation ranges from 20 to 35 min, with an average of approximately 28 min, based on actual process data provided by the enterprise. AGVs serve as the primary means of material transport, with their quantity set between one and three units. Each AGV has a maximum operating speed of 1.2 m/s, and both acceleration and deceleration are set at 0.3 m/s

2. The loading and unloading time per AGV is configured at 45 s. To account for energy constraints, each AGV is equipped with a battery capacity that supports continuous operation for up to 3 h. When the battery level falls below a designated threshold, the system automatically initiates a return-to-charge protocol.

To clearly define the optimization objectives and ensure the comparability of the results, workstation utilization and the number of rework items were established as KPIs. Each simulation cycle was set to 8 h per day, and every configuration scenario was independently executed 30 times. The average values were then calculated to minimize random errors, enhance result stability, and reduce the likelihood of being affected by local optima.

3.3. Simulation Modelling and Optimization

The initial simulation results indicated notable discrepancies in workstation task durations and insufficient coordination among stations, which led to low utilization rates. To address these issues and improve efficiency, the optimization strategy involved increasing the number of AGVs responsible for product transport from one to three while maintaining two AGVs for material delivery, along with the implementation of workstation buffers. After optimization, workstation utilization rose to over 26%, significantly enhancing the overall efficiency of the assembly line.

4. Experimental Results and Analysis

To ensure the reliability of the experimental results, the experiments were carefully designed with close attention to key variables. Critical factors such as the number of workstations and AGVs were determined based on the specific task distribution within the workshop. A simulation model was developed using Plant Simulation software to accurately replicate real-world factory conditions. During the simulation process, real-time data on task execution and workstation idle times were collected to evaluate system performance. Based on this preliminary data, optimization strategies including increasing the number of AGVs and rebalancing workloads among workstations were implemented to improve overall operational efficiency.

4.1. Initial Workstation Utilization

Using the established workshop simulation model, we evaluated the utilization rates of different workstations during the initial phase. As illustrated in

Figure 6a, the proportion of parts in the buffer remains consistently low when the quantity ranges from zero to nine, staying below 10%. A significant increase is observed only when the buffer quantity reaches 10, at which point the proportion rises to approximately 50%.

Figure 7a shows that the working time proportions for the three assembly stations, the testing station, and the packaging station are all 6% or less, with the majority of time spent in idle states. This low utilization primarily results from insufficient initial planning and a lack of synchronization between workstations.

In the aerospace workshop, substantial differences in processing times across workstations and the inability to consolidate stations with varying tasks contribute to low utilization rates. This inefficiency leads to increased assembly costs and resource waste. Therefore, optimizing the entire complex product assembly workshop is economically essential to improve assembly efficiency and reduce overall operational costs. The optimization strategy primarily involves adjusting key parameters, notably increasing the number of AGVs for transporting cabin sections from one to three, while keeping the number of material delivery AGVs unchanged. Additionally, buffer zones are introduced in front of each assembly workstation to alleviate mismatches in processing times.

4.2. Optimized Workstation Utilization

During the optimization process, the number of AGVs was increased while the workload distribution and other related parameters were adjusted through multiple iterations. As a result, workstation utilization improved significantly, rising from less than 6% to more than 26%.

Figure 6b shows that the number of parts in the buffer decreased from 11 to 3. When the buffer contained only one part, the proportion rose to approximately 46%, with similar increases observed when the buffer held zero or two parts. These changes helped avoid excessive accumulation in the buffer and contributed to improved production efficiency.

As shown in

Figure 7b, workstation utilization reaches a peak of over 42% and seldom falls below 26%. Compared to the initial rates, this represents an improvement of up to 36%. The optimized workshop demonstrates a substantial enhancement in production efficiency while contributing to cost reduction.

After analyzing the data, we compared the operational metrics of each workstation before and after optimization, as shown in

Table 2 and

Figure 8. A noticeable increase in the working time percentage was observed across all stations following the optimization. Assembly Station 1 showed the most significant improvement, with a 36.54% increase in working time. This substantial reduction in idle time, particularly at Assembly Station 1, has significantly enhanced the overall production efficiency of the workstations.

Several assembly stations were observed to have low workloads. This was primarily caused by discrepancies in task durations, insufficient coordination among workstations, and delays in material supply. Task complexity and processing time varied significantly between workstations. Some stations handled simpler tasks that were completed quickly, resulting in prolonged idle periods, while others faced more complex operations and heavier workloads. The lack of synchronization among workstations led to waiting times, as some stations had to wait for previous tasks to be completed. This reduced overall production efficiency. Furthermore, delays in material delivery prevented some stations from proceeding as planned, which further contributed to underutilization. Future research should focus on improving AGV scheduling, strengthening material supply chain management, and implementing more balanced task distribution to enhance workstation utilization and increase production efficiency.

4.3. Practical Application and Impact

The AGV scheduling optimization method proposed in this study holds substantial practical value, particularly in complex production environments such as complex product assembly workshops. These settings, especially when dealing with large and heavy components like cabin sections, often suffer from inefficiencies, resource waste, and transportation bottlenecks due to reliance on manual scheduling and transport. The proposed method enhances the precision of AGV scheduling, shortens transportation time, and improves workstation utilization, thereby significantly boosting overall production efficiency.

Efficient AGV scheduling and path planning are critical for ensuring smooth operations during the transportation of large aerospace components. For instance, in the production of cabin sections, AGVs are tasked with moving bulky and heavy parts between various processing stages. An optimized scheduling scheme minimizes equipment idleness and resource waste, eliminates bottlenecks associated with traditional transport methods, and ensures seamless task coordination. Although this study focuses primarily on the aerospace sector, the proposed optimization method is equally applicable to other manufacturing industries, such as automotive and electronics assembly. In these fields, similar AGV scheduling strategies can significantly reduce production costs and enhance logistics efficiency. To apply this method in practice, enterprises can construct simulation models of their workshops, configure key operational parameters, and perform scheduling optimization to achieve more flexible and efficient production planning.