Artificial Intelligence in the Oil and Gas Industry: Applications, Challenges, and Future Directions

Abstract

1. Introduction

2. Materials and Methods

- -

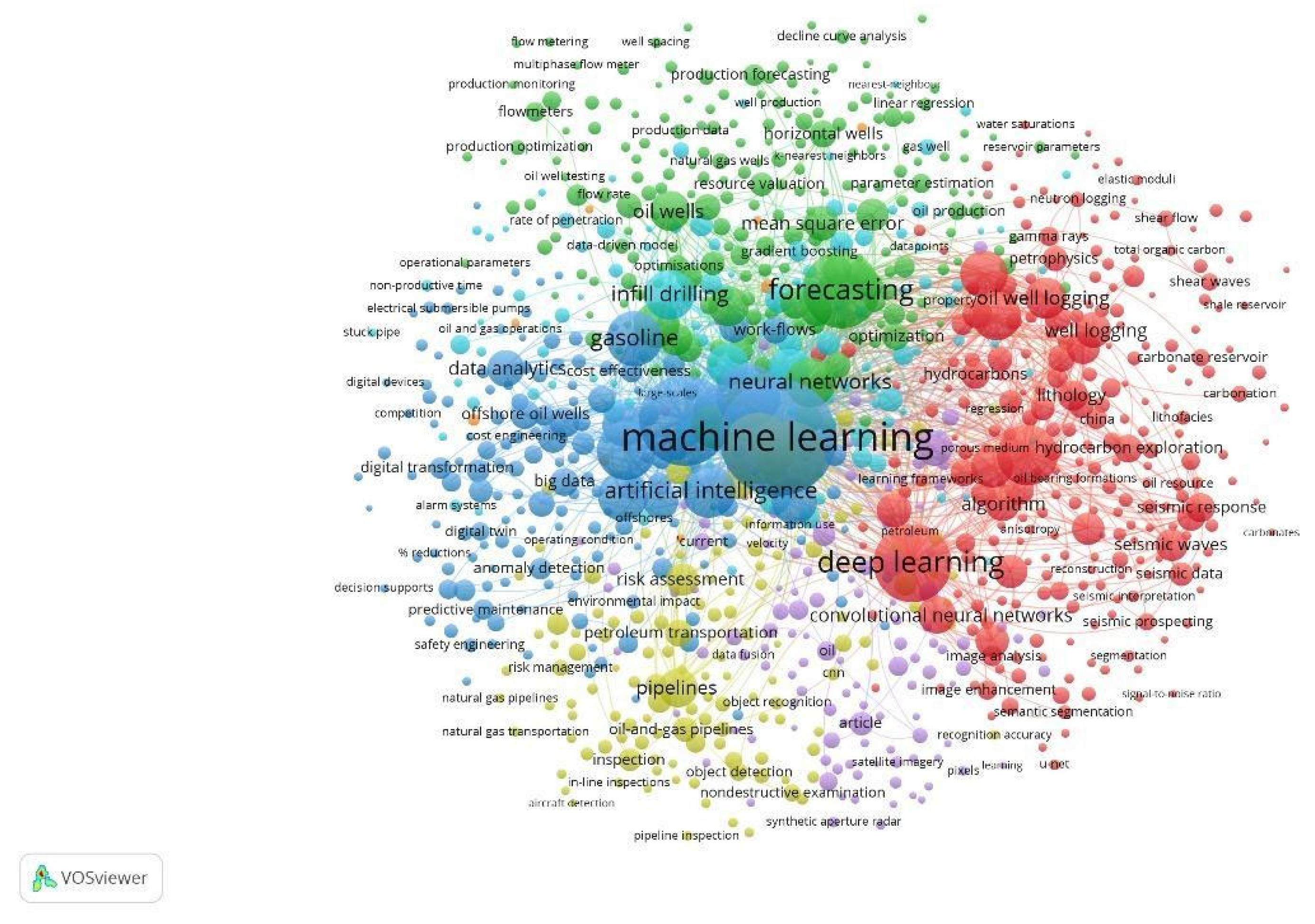

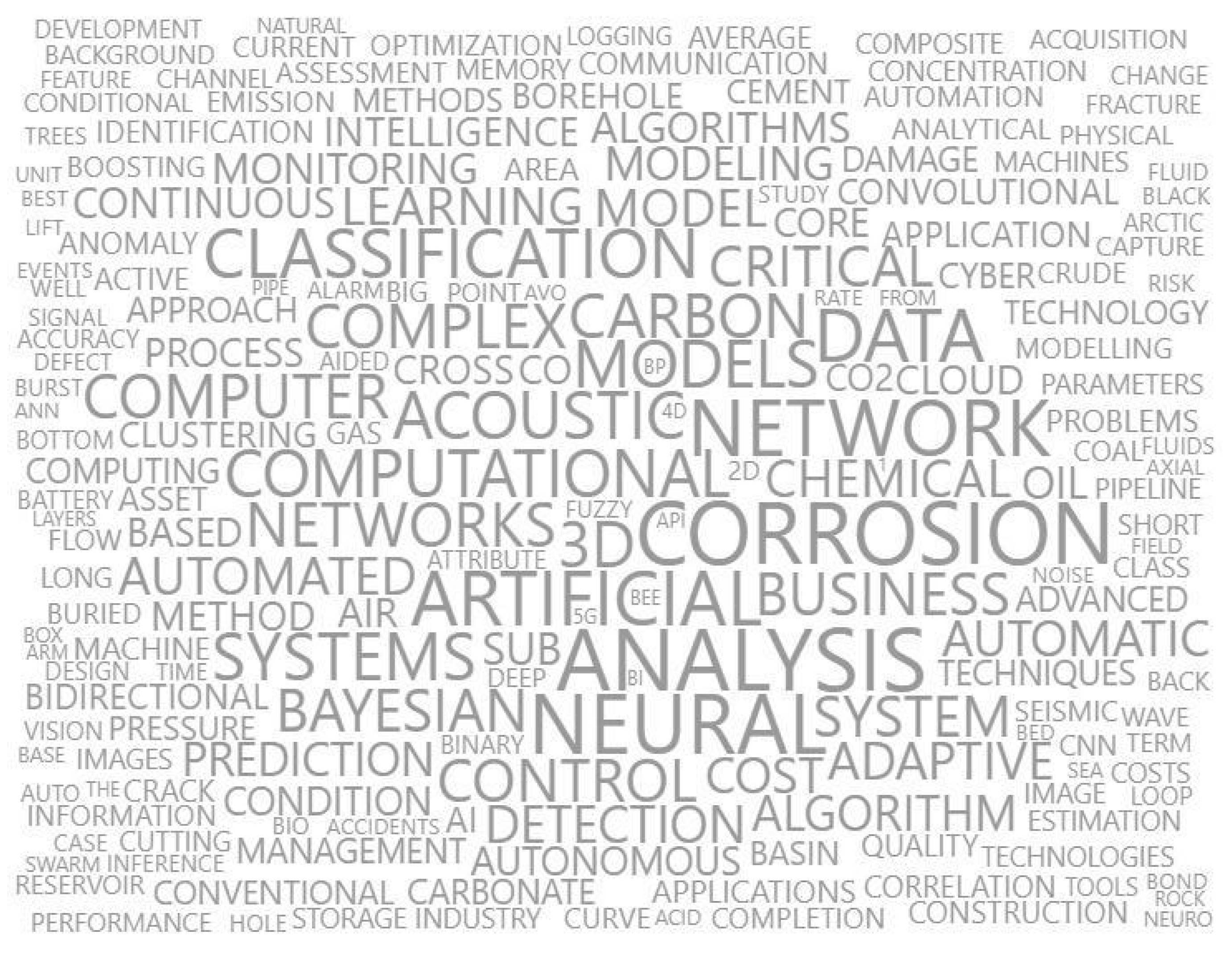

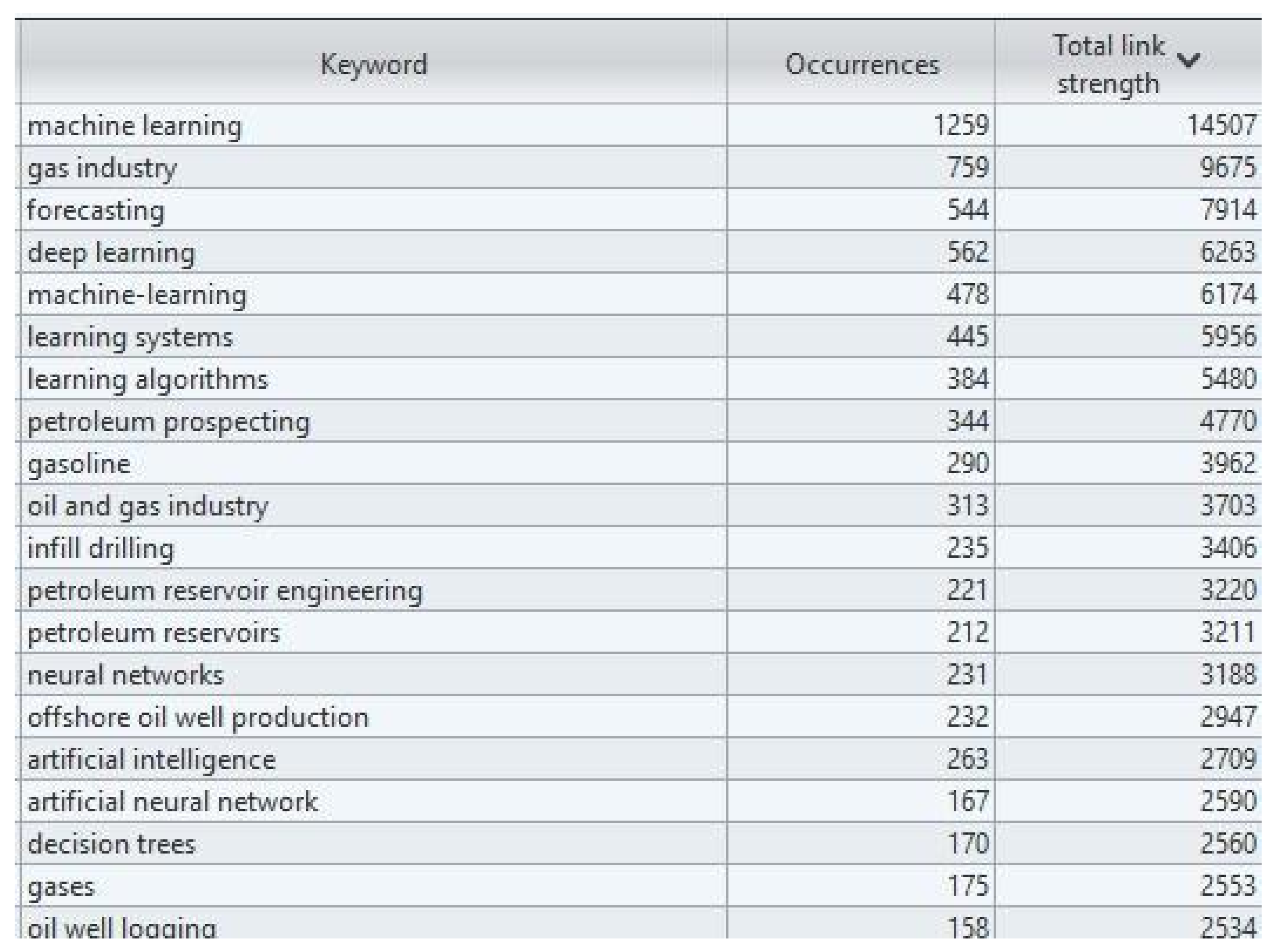

- Step 1: The first step involved preliminary exploration of scientific articles using the Scopus database. Keywords related to artificial and computational intelligence techniques were used (the search query for the SCOPUS database is: (TITLE-ABS-KEY (“oil” AND “gas”) OR TITLE-ABS-KEY (“O&G” OR “Petroleum” OR “OIL & GAS” OR “KDD” OR “knowledge-discovery” OR “knowledge discovery”) AND TITLE-ABS-KEY (“crisp” OR “crisp-dm” OR “crisp dm” OR “Cross Industry Standard Process for Data Mining” OR “Cross Industry Standard Process”) AND TITLE-ABS-KEY (“Artificial intelligence” OR “Deep Learning” OR “Machine Learning” OR “Neural Networks” OR “Convolutional Neural Network” OR “Artificial Neural Networks”)) for the search and the criteria adopted included: publication period between 2010 and 2024, English language and document types restricted to peer-reviewed articles and conferences. A total of 11,296 articles were selected, and a co-occurrence map was created with VOS Viewer software, identifying key terms and emerging trends in artificial intelligence that would guide the next phase of research.

- -

- Step 2: Based on the relevant terms and insights identified in Step 1, the focus shifted to a more specific domain: the oil industry. The OnePetro database, a key resource for petroleum engineering research, was explored using keywords such as “production system”, “machine learning”, and “neural network.” This step aimed to connect broader AI applications with practical use cases in production optimization and well drilling.

- -

- Blue: Indicates areas related to algorithms and techniques, such as neural networks and supervised learning.

- -

- Red: Represents practical applications, including computer vision and natural language processing.

- -

- Green: Relates to forecasting and statistical analysis.

- -

- Yellow: Suggests intersections with big data, cloud computing, and optimization.

- -

- Purple: Includes oil, satellite, and data fusion.

3. Results

3.1. Oil and Gas Industry and AI

- -

- Reopening: Occurs when there is a need to reopen intervals that have already been drilled to correct problems with restrictions or reduction in the diameter of the well, which prevents the continuation of operations in a safe manner.

- -

- Diversion and re-drilling: When a section of the well is lost, it is necessary to place a plug and divert the route at a point above the incident in order to re-drill to the desired depth.

- -

- Loss of circulation: Occurs when the pressure in the well exceeds the resistance of the geological formations, leading to the invasion of drilling fluids. This can compromise the integrity of the well, damage possible reservoirs, and cause the column to jam.

- -

- Kick and blowout: The “kick” refers to the invasion of the well by formation fluids, which, if not controlled, can evolve into a “blowout”, a serious accident with risk to the well, the platform and the team. Although rare, these events have the potential to cause great damage.

- -

- Fishing: Involves the recovery of parts or materials that have fallen or become trapped in the well, blocking normal operation. The time dedicated to this activity can vary, and in some cases, the fishing operation is not successful, resulting in the loss of parts of the well.

- -

- Solid formation: Such as hydrates, paraffins and asphaltenes, which can be deposited in the production line due to pressure and temperature variations, affecting the flow of oil.

- -

- Well integrity failures: Problems with components such as Christmas trees, valves and piping can compromise integrity and cause leaks, in addition to affecting production.

- -

- Reservoir problems: Include excessive production of gas or water, which can reduce the profitability of the well, and the presence of sand or fine particles, which can increase water and sediment levels, in addition to causing erosion in equipment.

3.2. Bibliometric Analysis

4. Discussion

- Operations Optimization: AI is utilized to optimize production processes by analyzing vast amounts of operational data. Machine learning algorithms can predict demand patterns, adjust operational parameters in real-time, and identify opportunities to increase the efficiency of equipment and systems. This results in better resource allocation and maximization of production.

- Predictive Maintenance: Instead of adopting a reactive approach to maintenance, AI enables the implementation of predictive maintenance, allowing for proactive maintenance strategies. AI models analyze sensor data and historical failures to predict when and where potential failures are likely to occur. This enables proactive interventions, reducing downtime and costs associated with unexpected repairs.

- Reservoir Management: AI enhances reservoir management through advanced modeling and simulation techniques. AI algorithms can analyze seismic, drilling, and production data to create more accurate reservoir models. These models help predict reservoir behavior and optimize extraction strategies.

- Image and Video Analysis: AI-based computer vision techniques are utilized to monitor and inspect equipment and facilities in real time. Automatic analysis of images and videos helps identify flaws, corrosion, or other visual issues that may impact operations. This contributes to more efficient maintenance and rapid response to emerging problems.

- Safety and Control: AI improves operational safety by analyzing real-time data to identify patterns and early warning signs that may indicate hazardous conditions. AI systems can predict and prevent accidents by continuously monitoring working conditions and implementing automatic controls to mitigate risks.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; Pang, S.; Zhang, Y. Enhancing Fluid Identification via an Innovative Transformer Model with Bidirectional Recurrent Units Network Leveraging Well Logging Data. Phys. Fluids 2024, 36, 076626. [Google Scholar] [CrossRef]

- Wei, S.; Huang, X.; Su, Y.; Li, J.; Peng, S. Application of Machine Learning Algorithm in Predicting Estimated Ultimate Reserves of Shale Gas. In Computational and Experimental Simulations in Engineering; Li, S., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 1151–1161. [Google Scholar] [CrossRef]

- Morovat, K.; Panda, B. A Survey of Artificial Intelligence in Cybersecurity. In Proceedings of the 2020 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 16–18 December 2020; pp. 109–115. [Google Scholar] [CrossRef]

- Ahmad, S.F.; Rahmat, M.K.; Mubarik, M.S.; Alam, M.M.; Hyder, S.I. Artificial Intelligence and Its Role in Education. Sustainability 2021, 13, 12902. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, Q.; Xu, Q.; Yan, J.; Lu, Q.; Yin, Y.; Sævik, S.; Ye, N. Deep Learning-Driven Optimization Design for the Configuration of Lazy-Wave Umbilical Cables. Appl. Ocean Res. 2024, 150, 104097. [Google Scholar] [CrossRef]

- Taha, A.; Amani, M. Overview of Water Shutoff Operations in Oil and Gas Wells; Chemical and Mechanical Solutions. ChemEngineering 2019, 3, 51. [Google Scholar] [CrossRef]

- Xu, K.; Liu, Z.; Chen, Q.; Zhang, Q.; Ling, X.; Cai, X.; He, Q.; Yang, M. Application of Machine Learning in Wellbore Stability Prediction: A Review. Geoenergy Sci. Eng. 2024, 232, 212409. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Minh, D.; Wang, H.X.; Li, Y.F.; Nguyen, T.N. Explainable Artificial Intelligence: A Comprehensive Review. Artif. Intell. Rev. 2022, 55, 3503–3568. [Google Scholar] [CrossRef]

- Chen, Z. Deep Learning for Cybersecurity: A Review. In Proceedings of the 2020 International Conference on Computing and Data Science (CDS), Stanford, CA, USA, 1–2 August 2020; pp. 7–18. [Google Scholar] [CrossRef]

- Shah, P.; Kendall, F.; Khozin, S.; Goosen, R.; Hu, J.; Laramie, J.; Ringel, M.; Schork, N. Artificial Intelligence and Machine Learning in Clinical Development: A Translational Perspective. NPJ Digit. Med. 2019, 2, 69. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Gui, J.; Wang, H.; Cheng, S.; Li, Z.; Ran, L. Application of Machine Learning in On-Line Calibration of Flow Measurement Errors. AIP Adv. 2024, 14, 085131. [Google Scholar] [CrossRef]

- Nishant, R.; Kennedy, M.; Corbett, J. Artificial Intelligence for Sustainability: Challenges, Opportunities, and a Research Agenda. Int. J. Inf. Manag. 2020, 53, 102104. [Google Scholar] [CrossRef]

- Farivar, F.; Sayad Haghighi, M.; Jolfaei, A.; Alazab, M. Artificial Intelligence for Detection, Estimation, and Compensation of Malicious Attacks in Nonlinear Cyber Physical Systems and Industrial IoT. IEEE Trans. Ind. Inform. 2019, 16, 1551–3203. [Google Scholar] [CrossRef]

- Elliot, K.; Damingo, L. Application of artificial intelligence in the oil and gas industry. Int. Res. J. Mod. Eng. Technol. Sci. 2024, 6, 2582–5208. [Google Scholar] [CrossRef]

- Mancini, L.; Paz, M.J. Oil Sector and Technological Development: Effects of the Mandatory Research and Development (R&D) Investment Clause on Oil Companies in Brazil. Resour. Policy 2018, 58, 131–143. [Google Scholar] [CrossRef]

- Kumar, P.; Sonawane, A.K. Engineering Significance and Consequences of Gas Hydrates in Deep and Ultra Deep Water Development. In Proceedings of the Fourteenth International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004. [Google Scholar]

- Wang, H.; Guo, Z.; Kong, X.; Zhang, X.; Wang, P.; Shan, Y. Application of machine learning for shale oil and gas “sweet spots” prediction. Energies 2024, 17, 2191. [Google Scholar] [CrossRef]

- Bastian, B.T.; Jaspreeth, N.; Ranjith, S.K.; Jiji, C.V. Visual Inspection and Characterization of External Corrosion in Pipelines Using Deep Neural Network. NDT E Int. 2019, 107, 102134. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Q.; Yusifov, A.; Shi, Y. Applications of supervised deep learning for seismic interpretation and inversion. Lead. Edge 2019, 38, 526–533. [Google Scholar] [CrossRef]

- Zhang, Z.; Ning, H.; Shi, F.; Farha, F.; Xu, Y.; Xu, J.; Zhang, F.; Choo, K.-K.R. Artificial Intelligence in Cyber Security: Research Advances, Challenges, and Opportunities. Artif. Intell. Rev. 2022, 55, 1029–1053. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. A Review of Modern Approaches of Digitalization in Oil and Gas Industry. Upstream Oil Gas Technol. 2023, 11, 100098. [Google Scholar] [CrossRef]

- Collins, C.; Dennehy, D.; Conboy, K.; Mikalef, P. Artificial Intelligence in Information Systems Research: A Systematic Literature Review and Research Agenda. Int. J. Inf. Manag. 2021, 60, 102383. [Google Scholar] [CrossRef]

- Assi, A.H. Non-Productive Time Reduction during Oil Wells Drilling Operations. J. Pet. Res. Stud. 2022, 12, 34–50. [Google Scholar] [CrossRef]

- D’Almeida, A.L.; Bergiante, N.C.R.; de Souza Ferreira, G.; Leta, F.R.; de Campos Lima, C.B.; Lima, G.B.A. Digital Transformation: A Review on Artificial Intelligence Techniques in Drilling and Production Applications. Int. J. Adv. Manuf. Technol. 2022, 119, 5553–5582. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, L.F.F.M.; Nascimento, A.; Mathias, M.H.; de Carvalho, J.A. Machine Learning Methods Applied to Drilling Rate of Penetration Prediction and Optimization—A Review. J. Pet. Sci. Eng. 2019, 183, 106332. [Google Scholar] [CrossRef]

- Kaur, R.; Gabrijelčič, D.; Klobučar, T. Artificial Intelligence for Cybersecurity: Literature Review and Future Research Directions. Inf. Fusion 2023, 97, 101804. [Google Scholar] [CrossRef]

- Ohalete, N.C.; Aderibigbe, A.O.; Ani, E.C.; Ohenhen, P.E.; Akinoso, A. Advancements in Predictive Maintenance in the Oil and Gas Industry: A Review of AI and Data Science Applications. World J. Adv. Res. Rev. 2023, 20, 167–181. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of Artificial Intelligence in Construction Engineering and Management: A Critical Review and Future Trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Khodayari-Rostamabad, A.; Reilly, J.P.; Nikolova, N.K.; Hare, J.R.; Pasha, S. Machine Learning Techniques for the Analysis of Magnetic Flux Leakage Images in Pipeline Inspection. IEEE Trans. Magn. 2009, 45, 3073–3084. [Google Scholar] [CrossRef]

- Nwachukwu, A.; Jeong, H.; Pyrcz, M.; Lake, L.W. Fast Evaluation of Well Placements in Heterogeneous Reservoir Models Using Machine Learning. J. Pet. Sci. Eng. 2018, 163, 463–475. [Google Scholar] [CrossRef]

- Paltrinieri, N.; Comfort, L.; Reniers, G. Learning about Risk: Machine Learning for Risk Assessment. Saf. Sci. 2019, 118, 475–486. [Google Scholar] [CrossRef]

- Chen, W.; Yang, L.; Zha, B.; Zhang, M.; Chen, Y. Deep Learning Reservoir Porosity Prediction Based on Multilayer Long Short-Term Memory Network. Geophysics 2020, 85, WA213–WA225. [Google Scholar] [CrossRef]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine Learning Approach Using MLP and SVM Algorithms for the Fault Prediction of a Centrifugal Pump in the Oil and Gas Industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Yuan, C.; Liu, S.; Chen, Z.; Li, W. Locating Induced Earthquakes with a Network of Seismic Stations in Oklahoma via a Deep Learning Method. Sci. Rep. 2020, 10, 1941. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.; Zhang, Z.; Liu, E.; Liu, W.; Qiao, W. A New Hybrid Algorithm Model for Prediction of Internal Corrosion Rate of Multiphase Pipeline. J. Nat. Gas Sci. Eng. 2021, 85, 103716. [Google Scholar] [CrossRef]

- Sircar, A.; Yadav, K.; Rayavarapu, K.; Bist, N.; Oza, H. Application of Machine Learning and Artificial Intelligence in Oil and Gas Industry. Pet. Res. 2021, 6, 379–391. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. External Corrosion of Oil and Gas Pipelines: A Review of Failure Mechanisms and Predictive Preventions. J. Nat. Gas Sci. Eng. 2022, 100, 104467. [Google Scholar] [CrossRef]

- Anaba, D.C.; Kess-Momoh, A.J.; Ayodeji, S.A. Digital Transformation in Oil and Gas Production: Enhancing Efficiency and Reducing Costs. Int. J. Manag. Entrep. Res. 2024, 6, 2153–2161. [Google Scholar] [CrossRef]

- De Souza, K.A.; De Moraes, J.B.; Barbosa, L.C.M. Social responsibility in the context of the oil and gas industry: Lessons from offshore decommissioning. In Proceedings of the Rio Oil & Gas Expo and Conference, Rio de Janeiro, Brazil, 26–29 September 2022; pp. 478–479. [Google Scholar] [CrossRef]

- Vieira, G.V. Eficiência Energética Através da Implementação da Cultura ESG. 2022. Available online: http://hdl.handle.net/11449/238455 (accessed on 30 June 2025).

| Grouping | Author(s) | Year | Problem |

|---|---|---|---|

| Machine Learning Techniques for the Analysis of Magnetic Flux Leakage Images in Pipeline Inspection | Khodayari-Rostamabad et al. [30] | 2009 | Analysis of magnetic flux leakage (MFL) images for pipeline inspection using machine learning, focusing on defect detection and severity assessment. |

| Fast evaluation of well placements in heterogeneous reservoir models using machine learning | Nwachukwu et al. [31] | 2018 | Develop a machine learning-based proxy model to predict reservoir responses considering geological complexity and well locations. |

| Applications of supervised deep learning for seismic interpretation and inversion | Zheng et al. [20] | 2019 | Use convolutional neural networks for seismic interpretation and elastic geology model building. |

| Learning about risk: Machine learning for risk assessment | Paltrinieri et al. [32] | 2019 | Application of machine learning for dynamic risk analysis in safety-critical industries, addressing challenges such as continuous updates and big data processing. |

| Machine learning methods applied to drilling rate of penetration prediction and optimization | Barbosa et al. [26] | 2019 | Review machine learning methods for predicting and optimizing the rate of penetration (ROP) in well drilling. |

| Visual inspection and characterization of external corrosion in pipelines using deep neural network | Bastian et al. [19] | 2019 | Detection of external corrosion in pipelines based on computer vision, using convolutional neural networks (CNN) to automate corrosion identification and classification. |

| Deep learning reservoir porosity prediction based on multilayer long short-term memory network | Chen et al. [33] | 2020 | The high cost and difficulty of obtaining reservoir porosity data using traditional methods, along with the need for efficient and low-cost predictions. |

| Machine Learning Approach Using MLP and SVM Algorithms for the Fault Prediction of a Centrifugal Pump in the Oil and Gas Industry | Orrù et al. [34] | 2020 | The need to predict failures in centrifugal pumps in the oil and gas industry to prevent unplanned failures, high costs, and unexpected plant shutdowns. |

| Locating induced earthquakes with a network of seismic stations in Oklahoma via a deep learning method | Zhang, X et al. [35] | 2020 | Automated determination of small earthquakes induced by industrial activities, facing challenges of low signal-to-noise ratio and the need for fast and accurate predictions for monitoring and regulation. |

| A new hybrid algorithm model for prediction of internal corrosion rate of multiphase pipeline | Peng et al. [36] | 2021 | Accurate prediction of internal corrosion rate in multiphase pipelines due to the complexity of corrosion factors and nonlinear interactions between them. |

| Application of machine learning and artificial intelligence in oil and gas industry | Sircar et al. [37] | 2021 | Challenges in processing and analyzing large data volumes in the oil and gas industry, aiming to improve efficiency and reduce risks using AI and machine learning techniques. |

| External corrosion of oil and gas pipelines | Wasim and Djukic [38] | 2022 | Analysis of failures due to external corrosion in oil and gas pipelines, covering mechanisms such as hydrogen-induced cracking, corrosion fatigue, and microbial influences. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Póvoas, M.d.S.; Moreira, J.F.; Neto, S.V.M.; Carvalho, C.A.d.S.; Cezario, B.S.; Guedes, A.L.A.; Lima, G.B.A. Artificial Intelligence in the Oil and Gas Industry: Applications, Challenges, and Future Directions. Appl. Sci. 2025, 15, 7918. https://doi.org/10.3390/app15147918

Póvoas MdS, Moreira JF, Neto SVM, Carvalho CAdS, Cezario BS, Guedes ALA, Lima GBA. Artificial Intelligence in the Oil and Gas Industry: Applications, Challenges, and Future Directions. Applied Sciences. 2025; 15(14):7918. https://doi.org/10.3390/app15147918

Chicago/Turabian StylePóvoas, Marcelo dos Santos, Jéssica Freire Moreira, Severino Virgínio Martins Neto, Carlos Antonio da Silva Carvalho, Bruno Santos Cezario, André Luís Azevedo Guedes, and Gilson Brito Alves Lima. 2025. "Artificial Intelligence in the Oil and Gas Industry: Applications, Challenges, and Future Directions" Applied Sciences 15, no. 14: 7918. https://doi.org/10.3390/app15147918

APA StylePóvoas, M. d. S., Moreira, J. F., Neto, S. V. M., Carvalho, C. A. d. S., Cezario, B. S., Guedes, A. L. A., & Lima, G. B. A. (2025). Artificial Intelligence in the Oil and Gas Industry: Applications, Challenges, and Future Directions. Applied Sciences, 15(14), 7918. https://doi.org/10.3390/app15147918