Identification of Torsional Fatigue Properties of Titanium Alloy Turned Surfaces and Their Distribution Characteristics

Abstract

1. Introduction

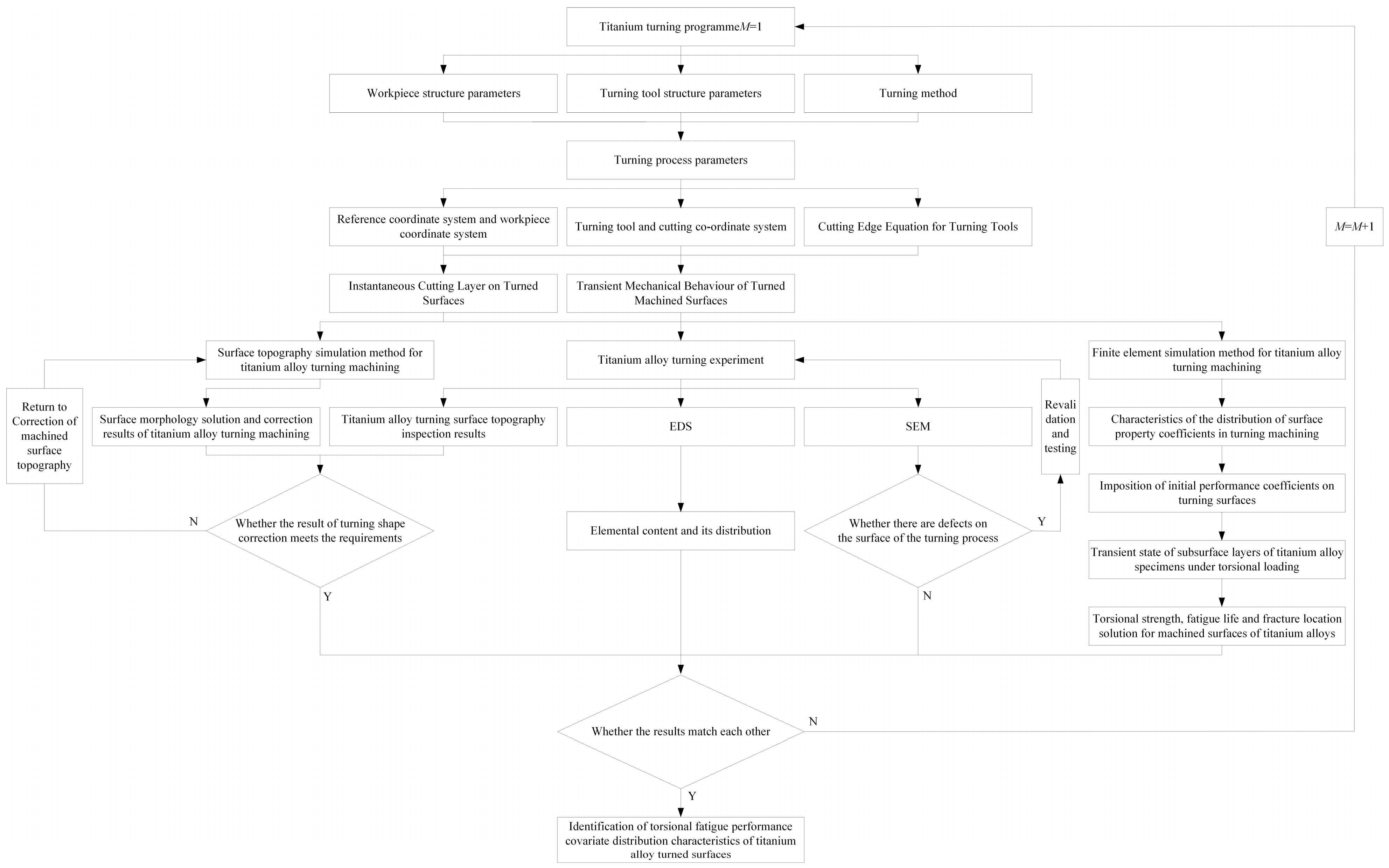

2. Characterization of Surface Structure and Properties of Titanium Alloy Turning Operations

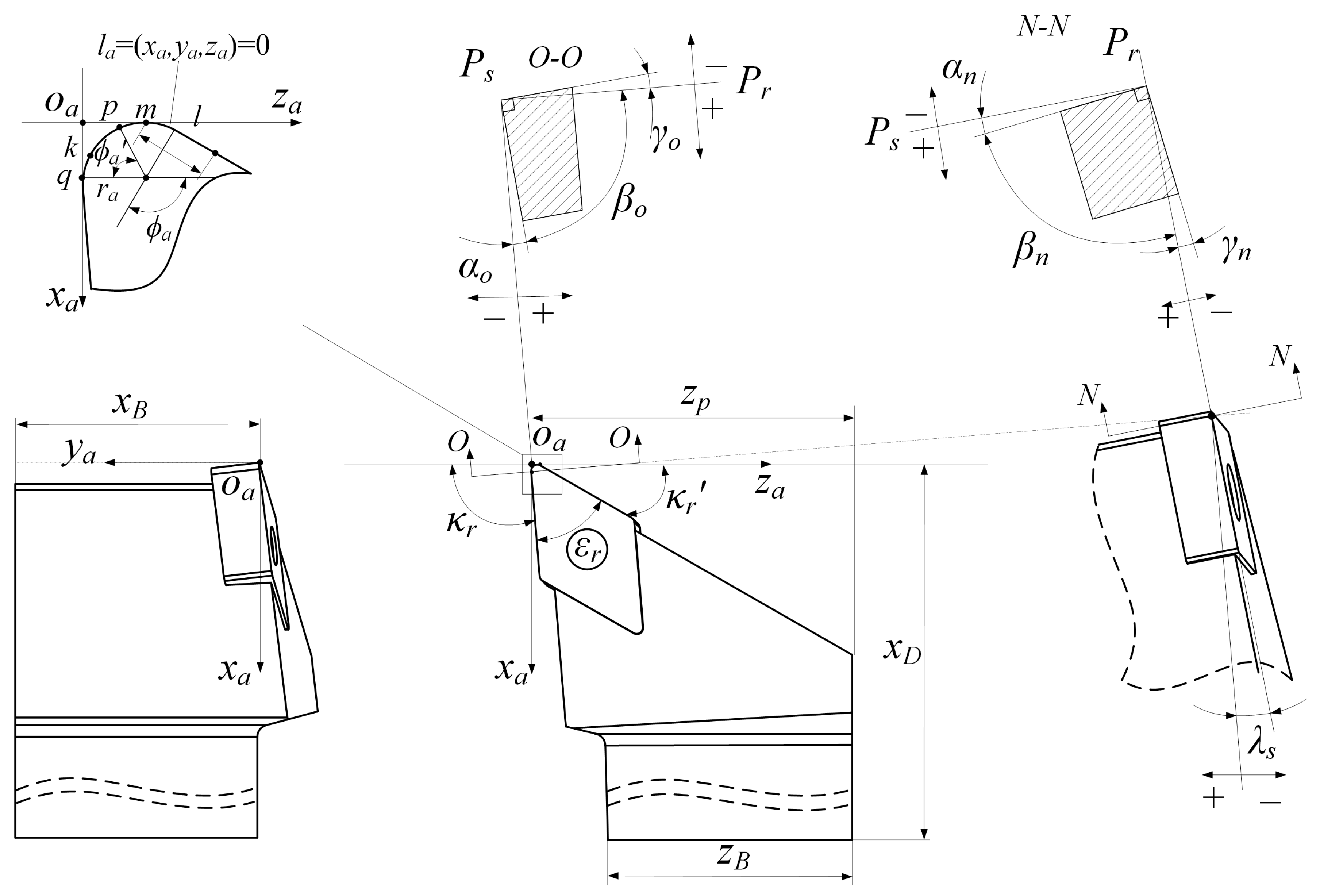

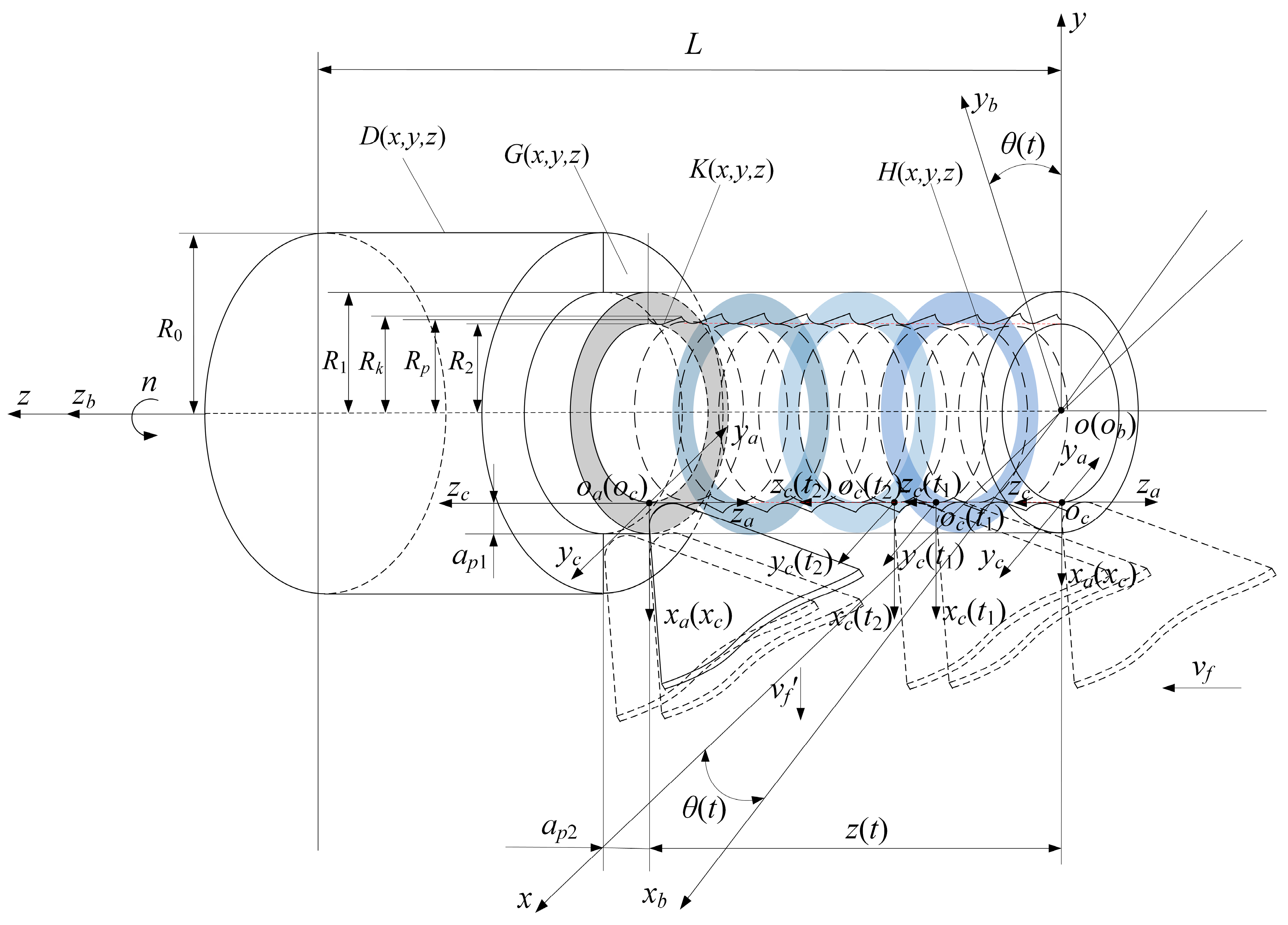

2.1. Turning Tool Structure and Instantaneous Cutting Position

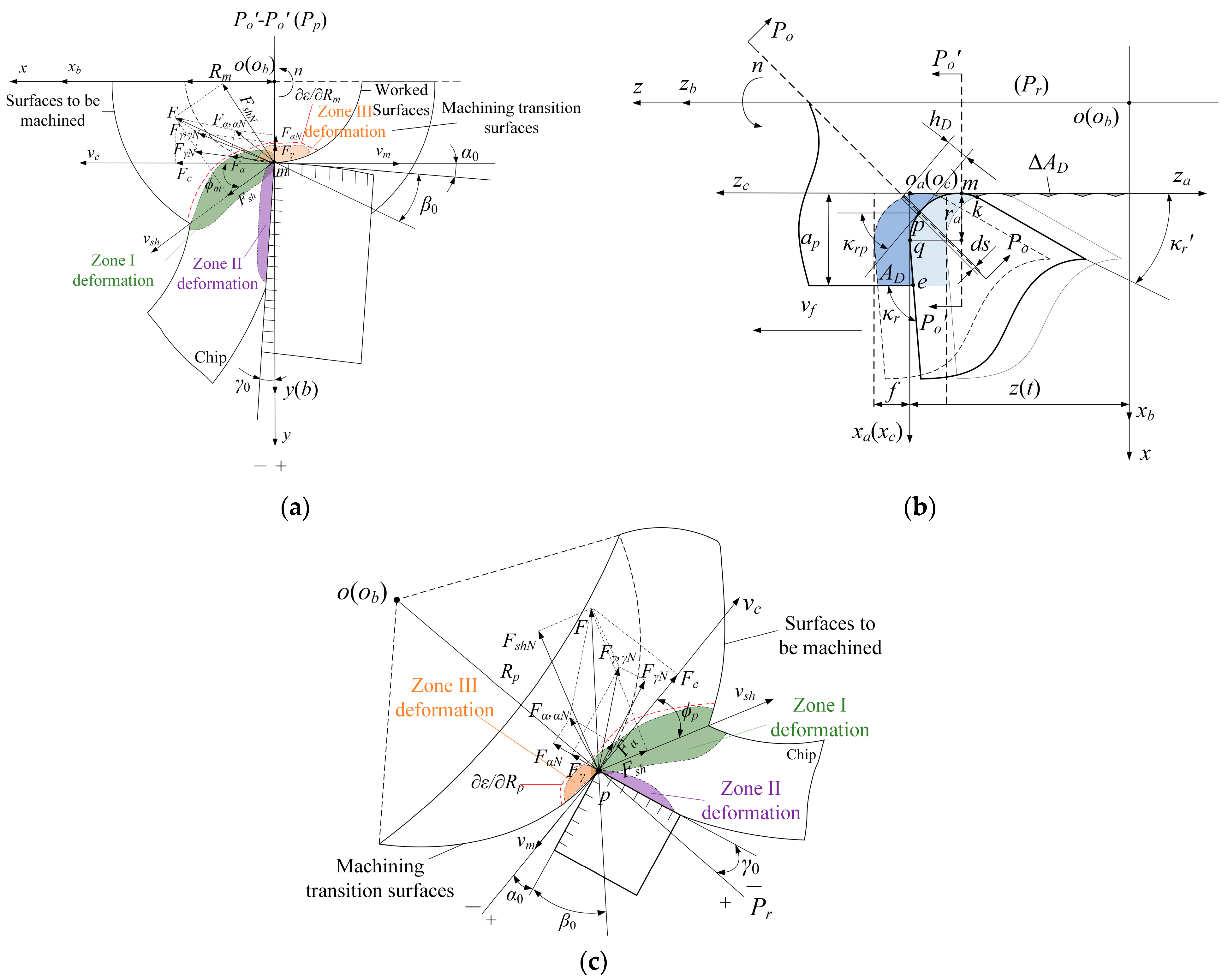

2.2. Transient Cutting Layer and Mechanical Behavior

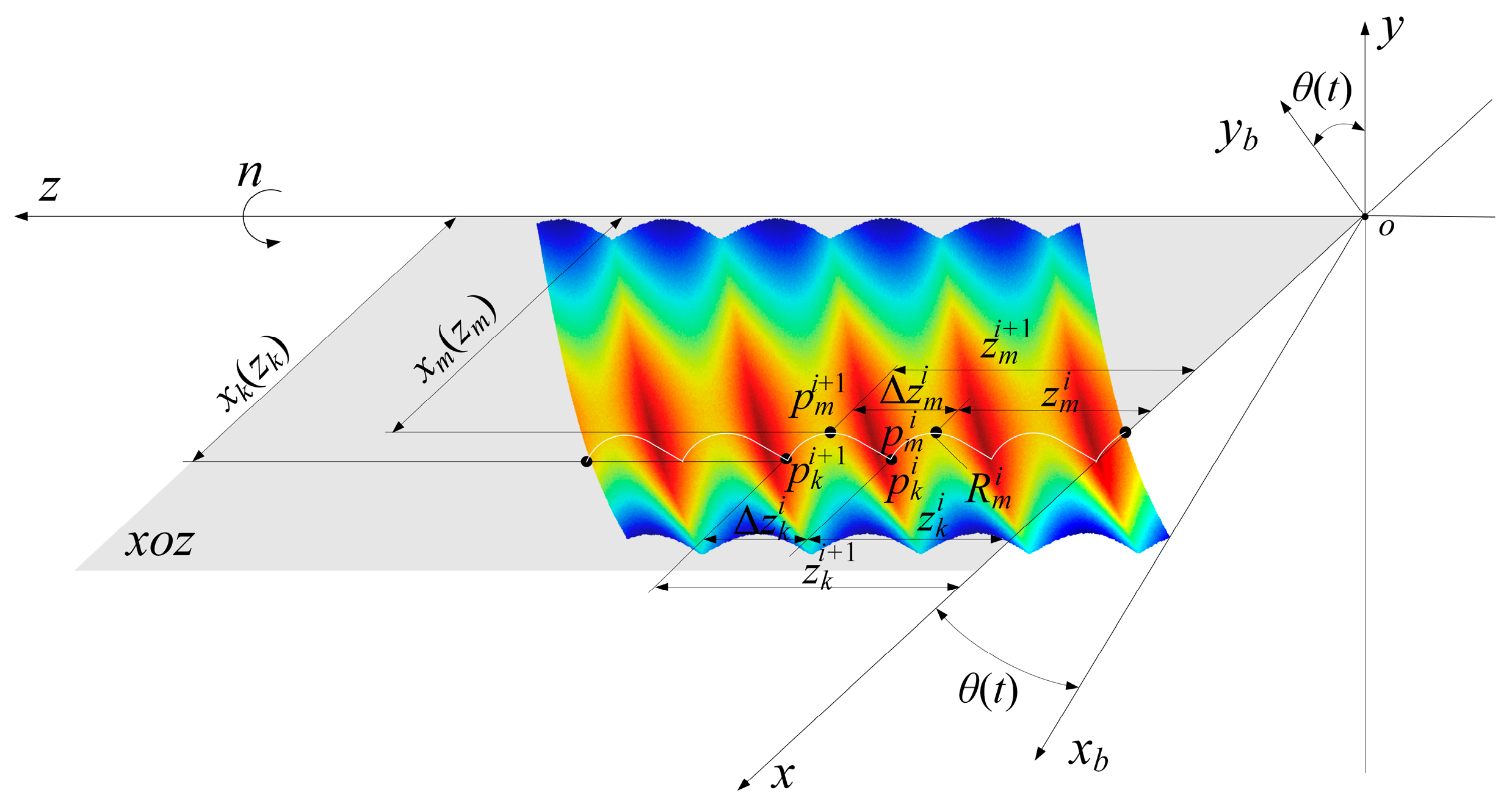

2.3. Surface Morphology Solution Method for Turning Machining

3. Titanium Alloy Turning Process Morphology Correction Method

3.1. Workpiece Material and Tool Material

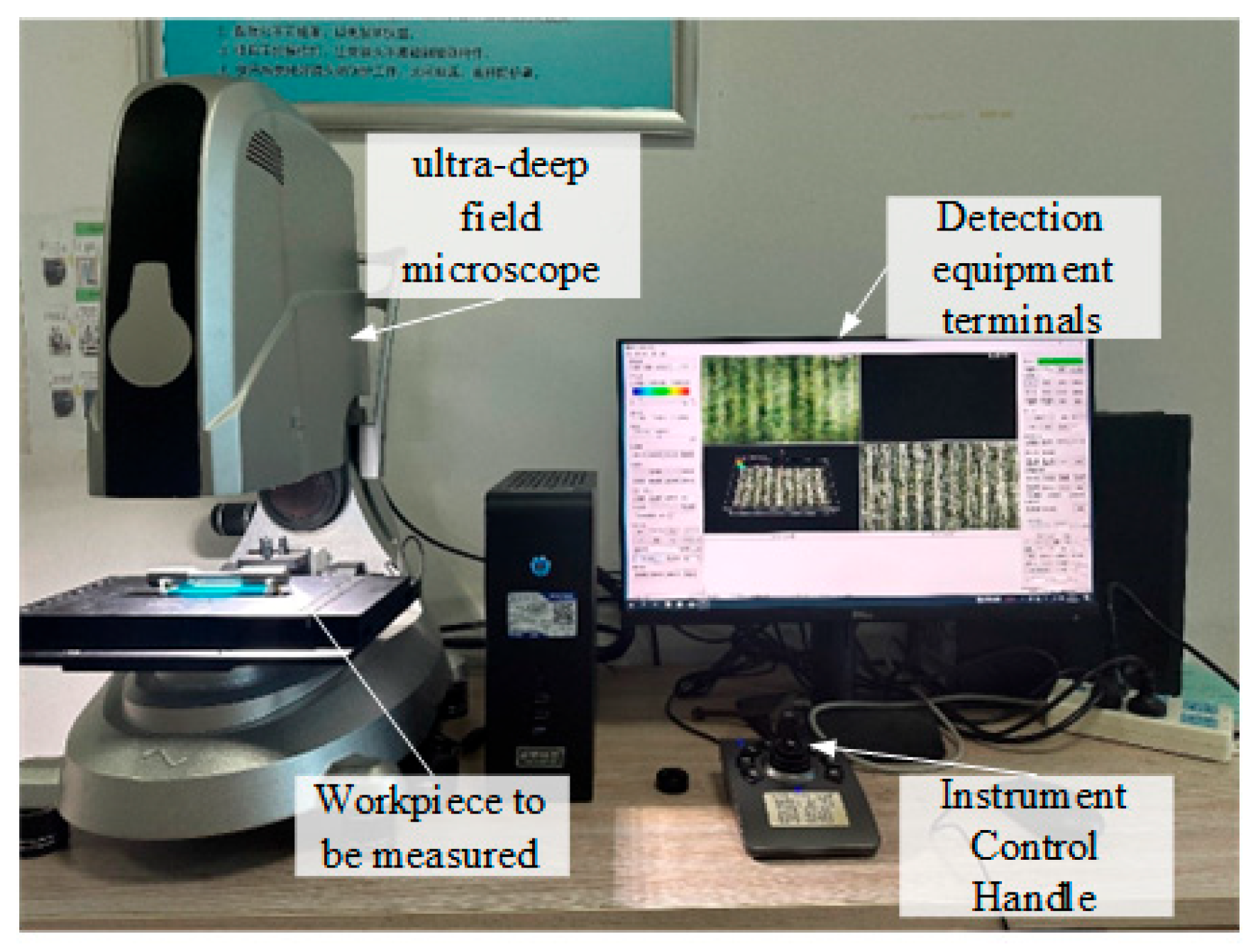

3.2. Experimental Conditions and Methods for Titanium Alloy Turning

3.3. Corrective Modeling of Surface Morphology for Turning of Titanium Alloys

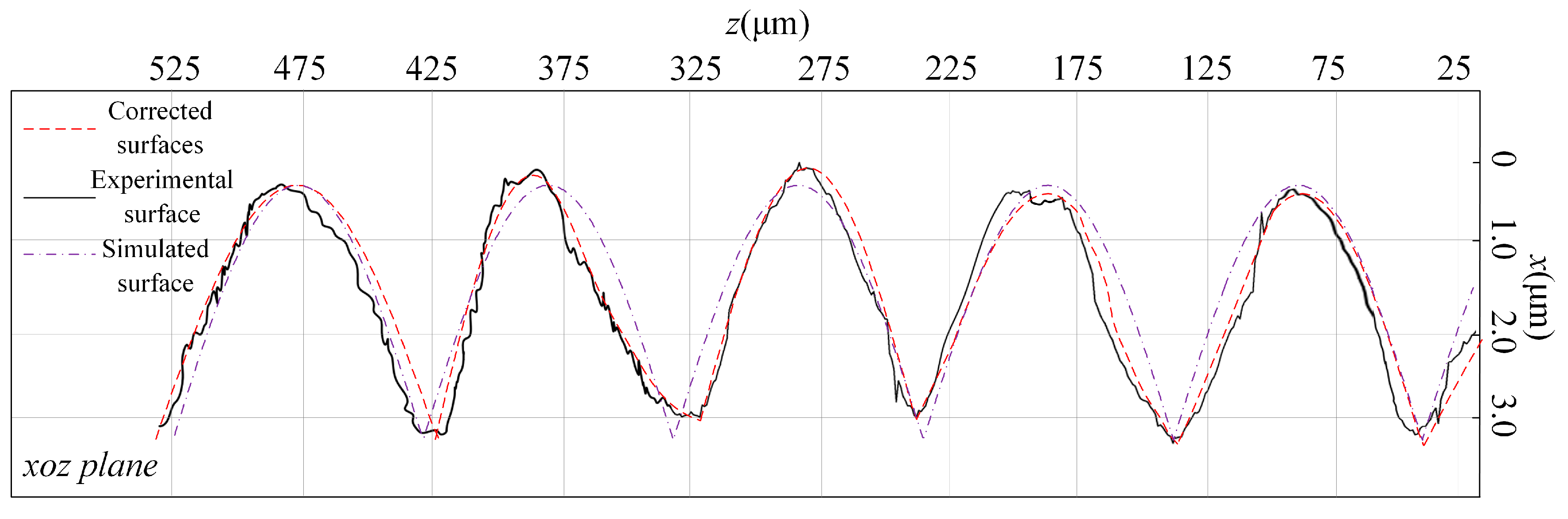

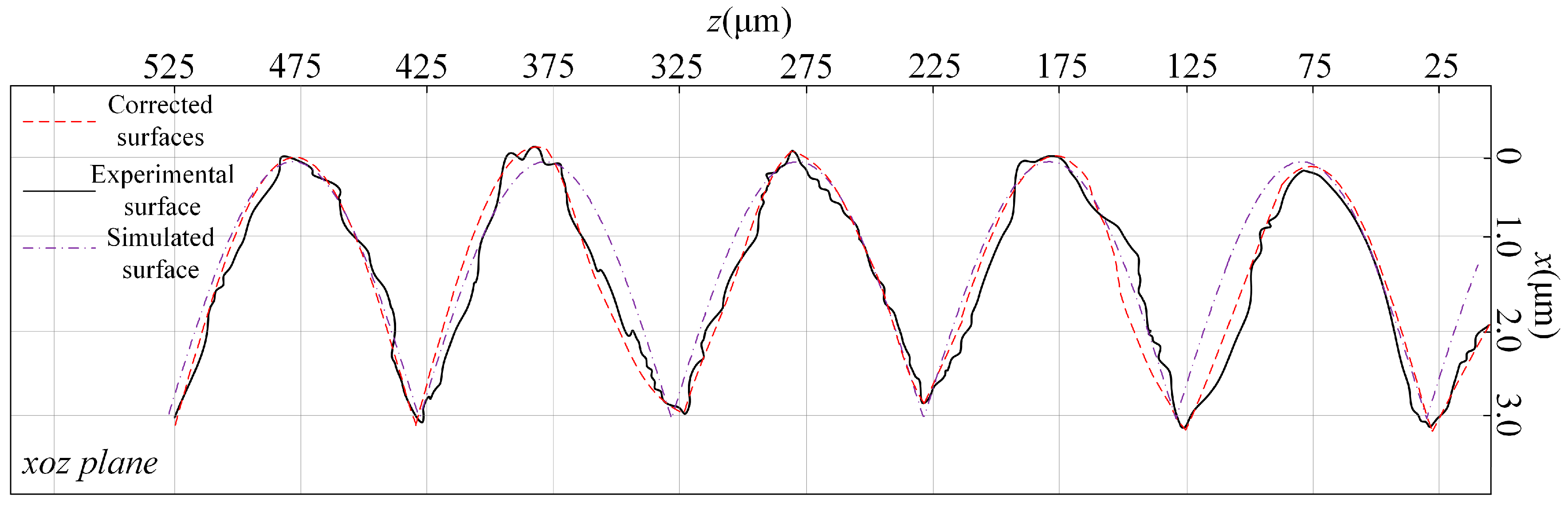

3.4. Comparison of Titanium Alloy Turning Surface Morphology Correction Results with Experimental Results

4. Method for Calculating the Distribution Characteristics of Surface and Subsurface Performance Parameters of Titanium Alloy Turned Parts

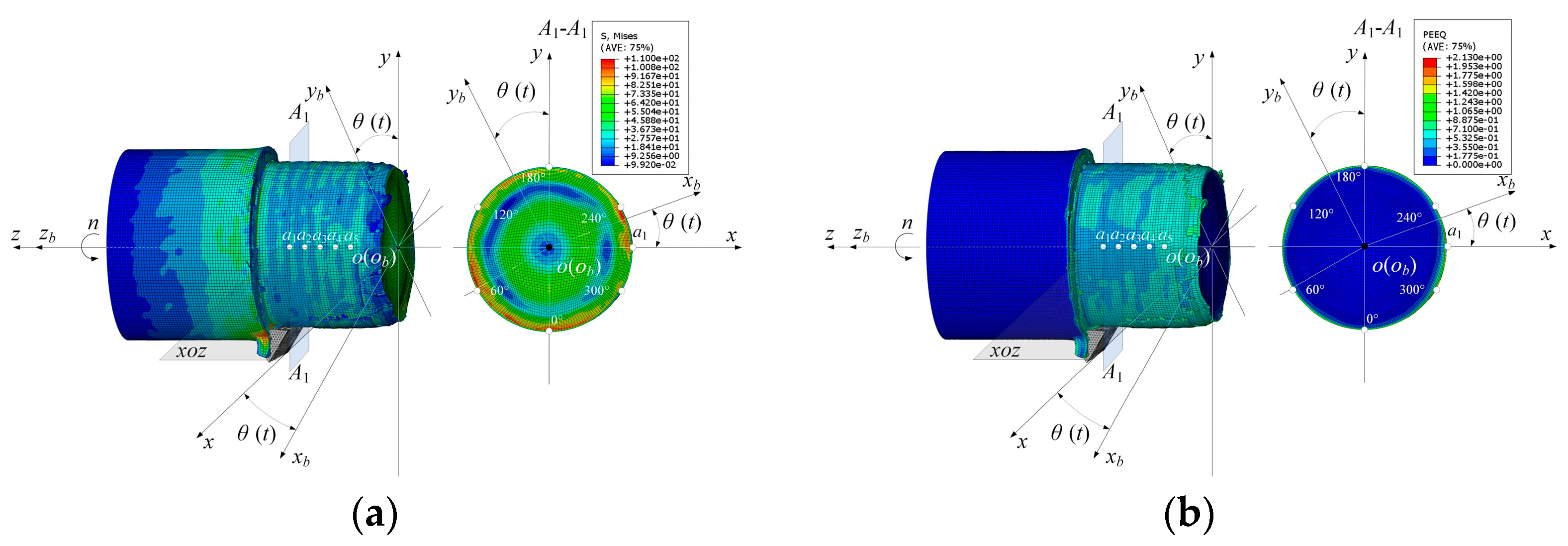

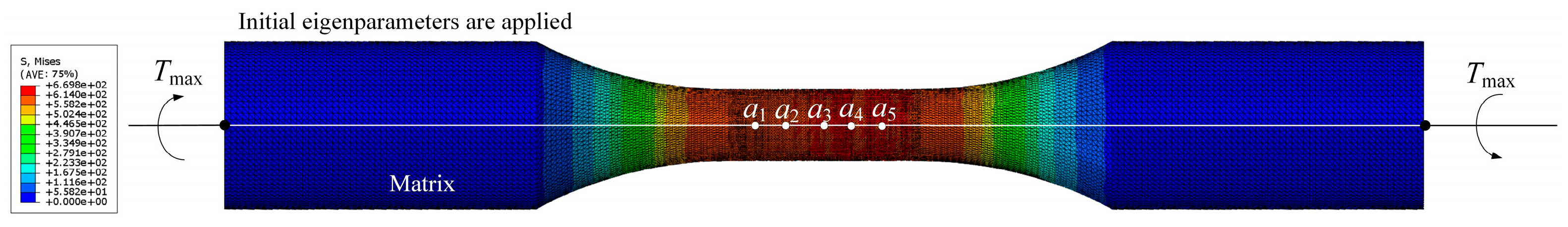

4.1. Finite Element Model Construction Method for Titanium Alloy Turning Process

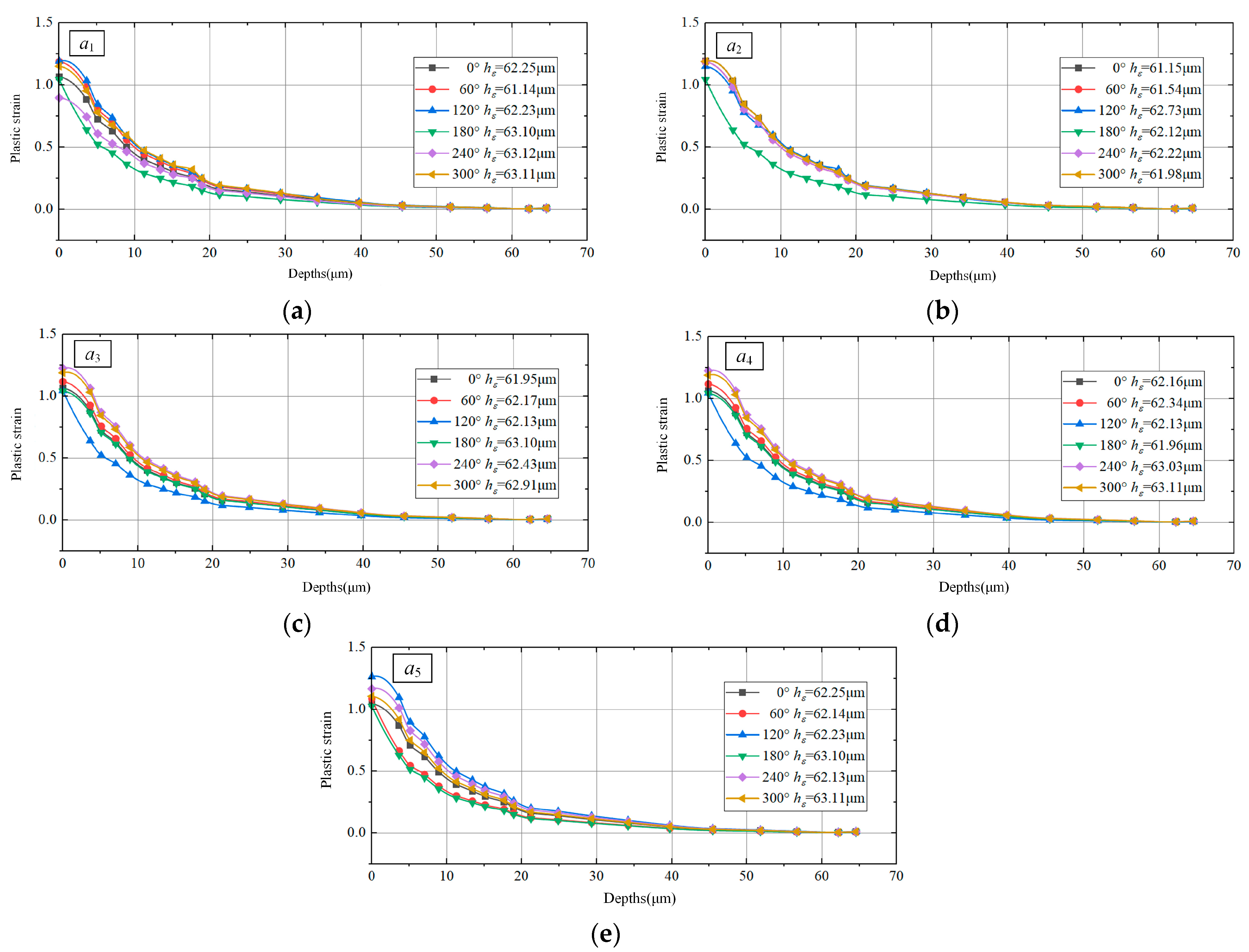

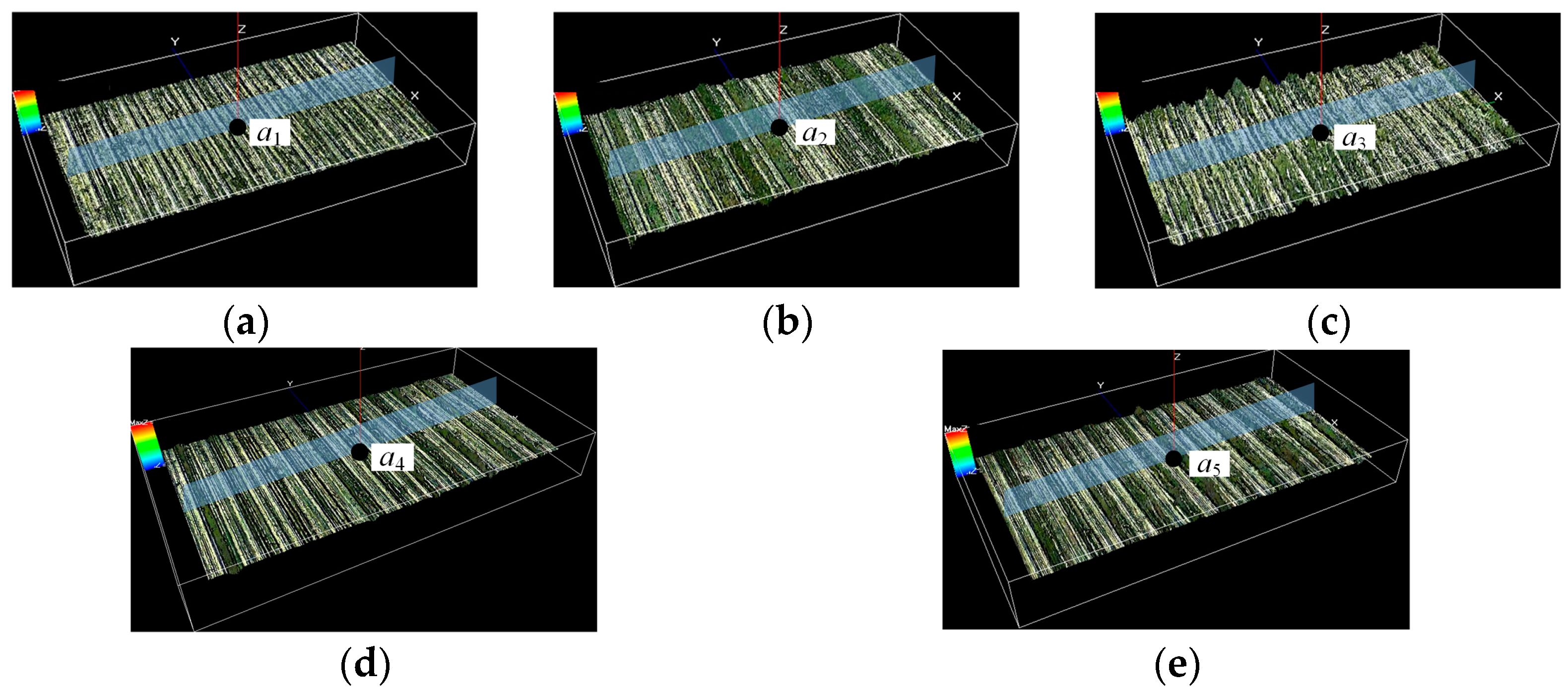

4.2. Method for Selecting Characteristic Points and Their Surface and Subsurface Performance Parameters

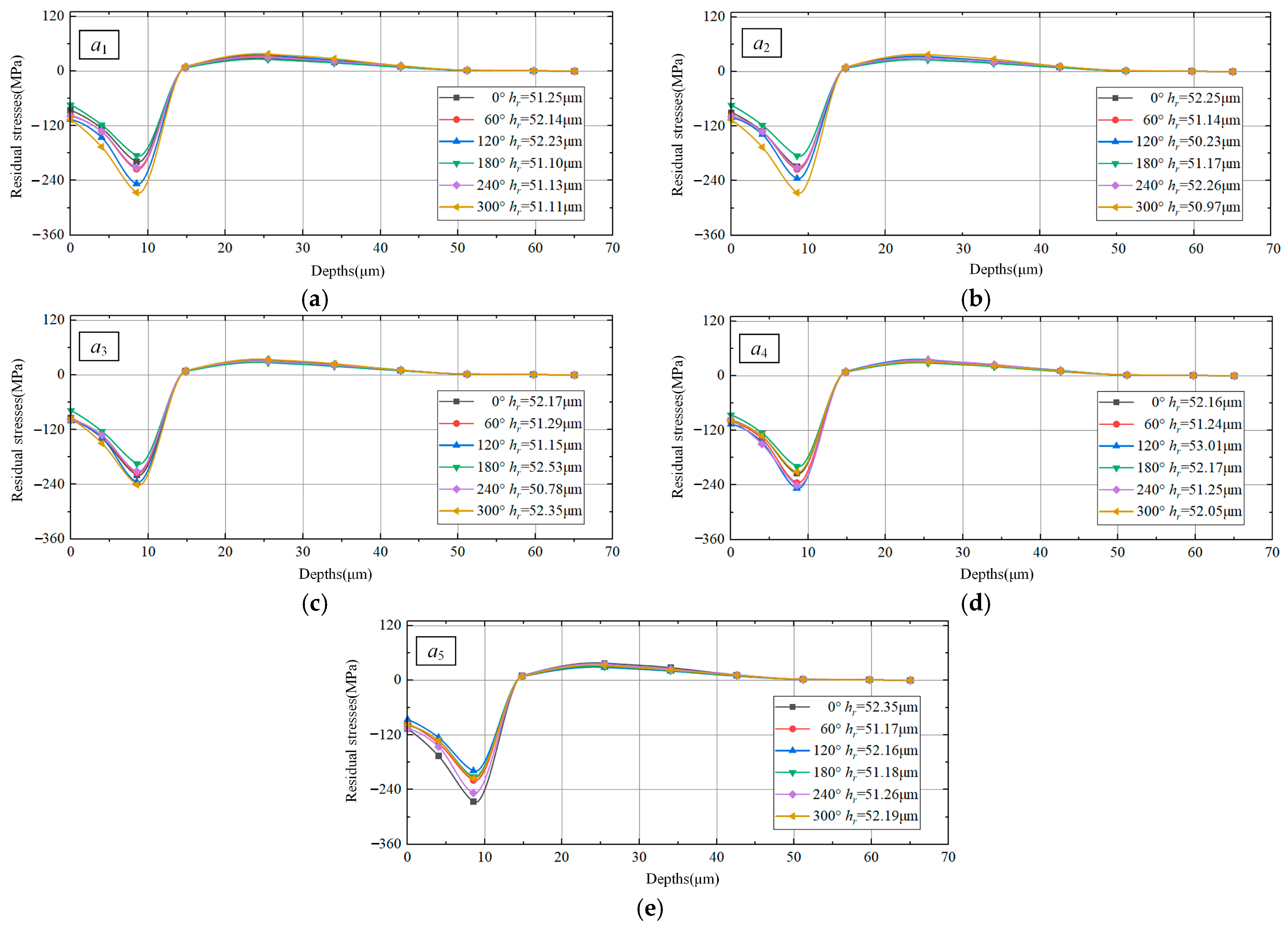

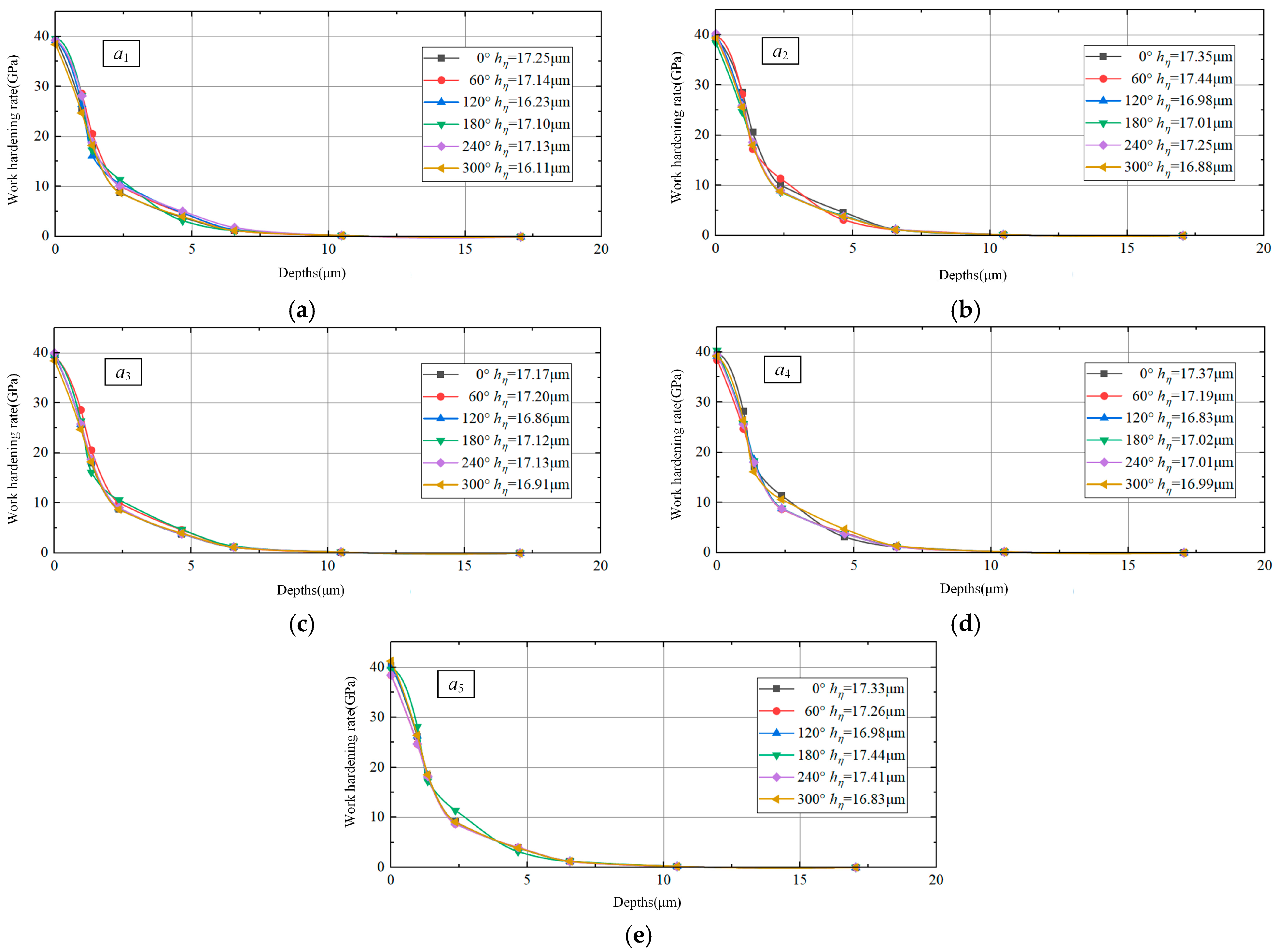

4.3. Surface and Subsurface Performance Parameter Calculation Results

5. Calculation Method for Torsional Fatigue Life of Titanium Alloy Turning Surface

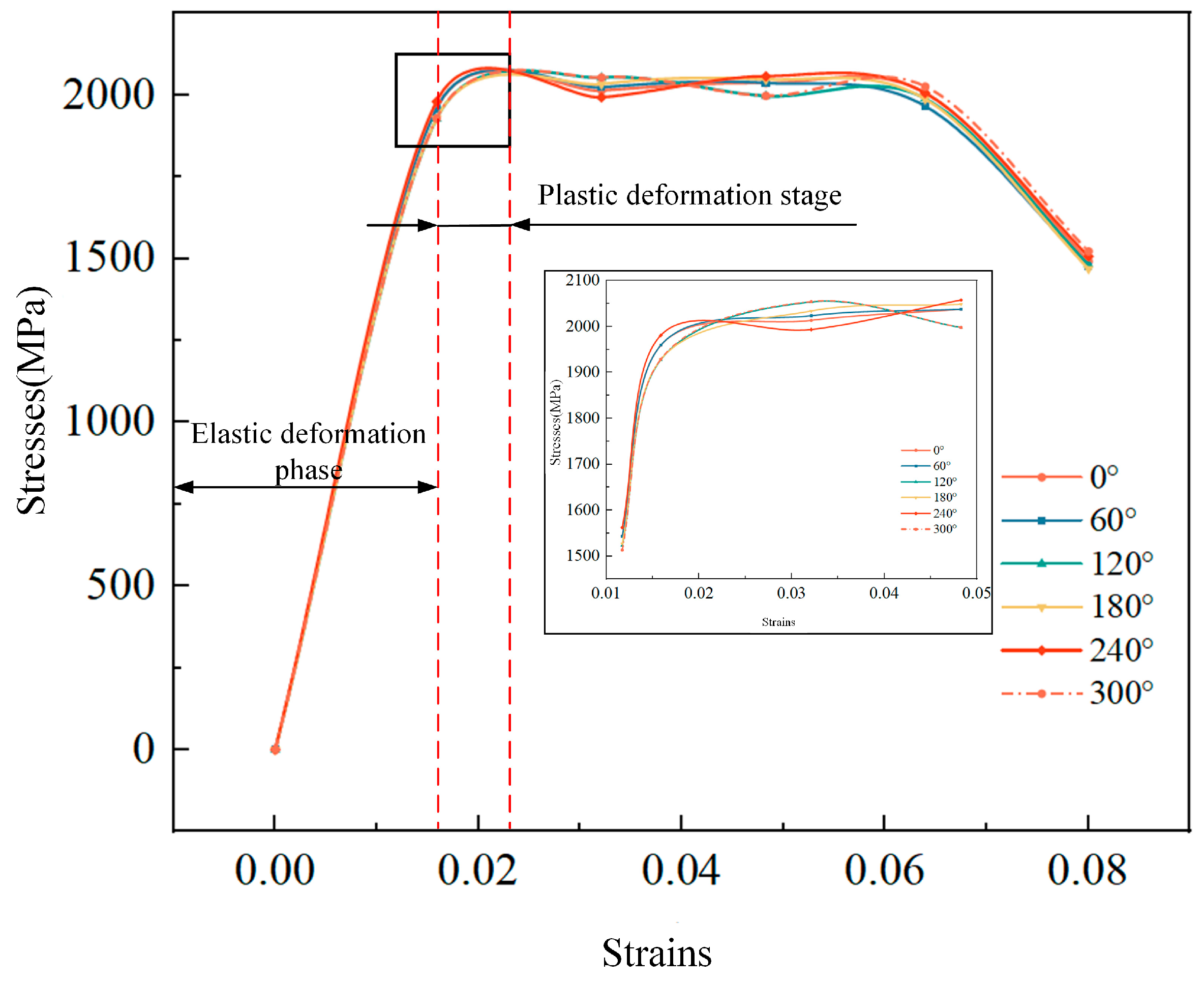

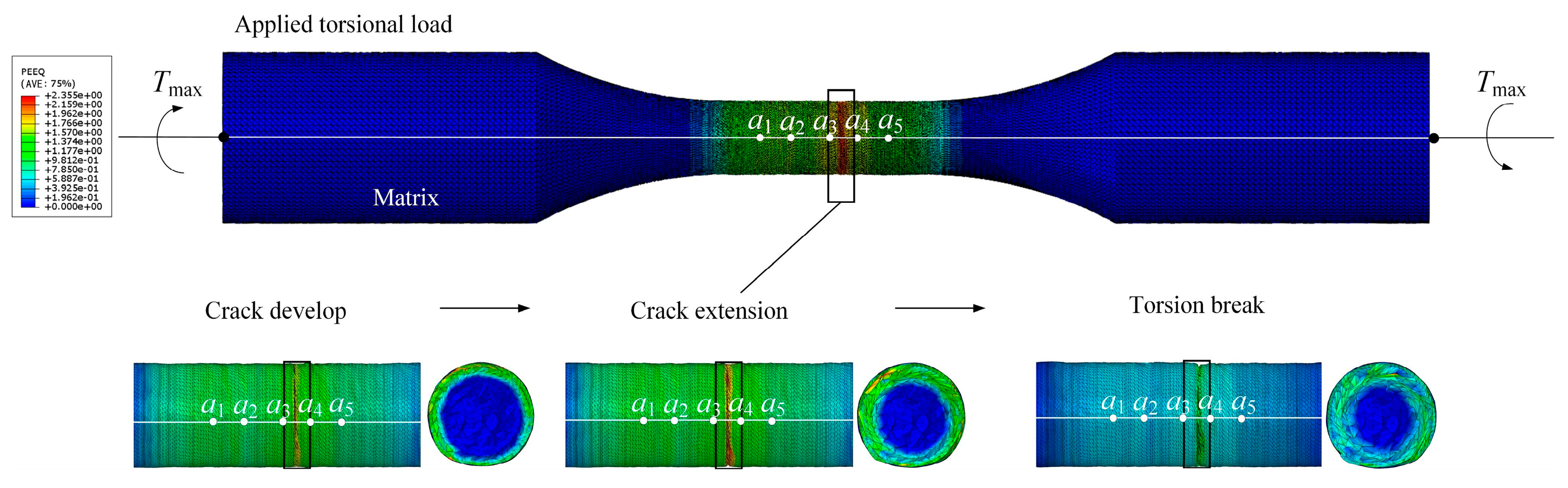

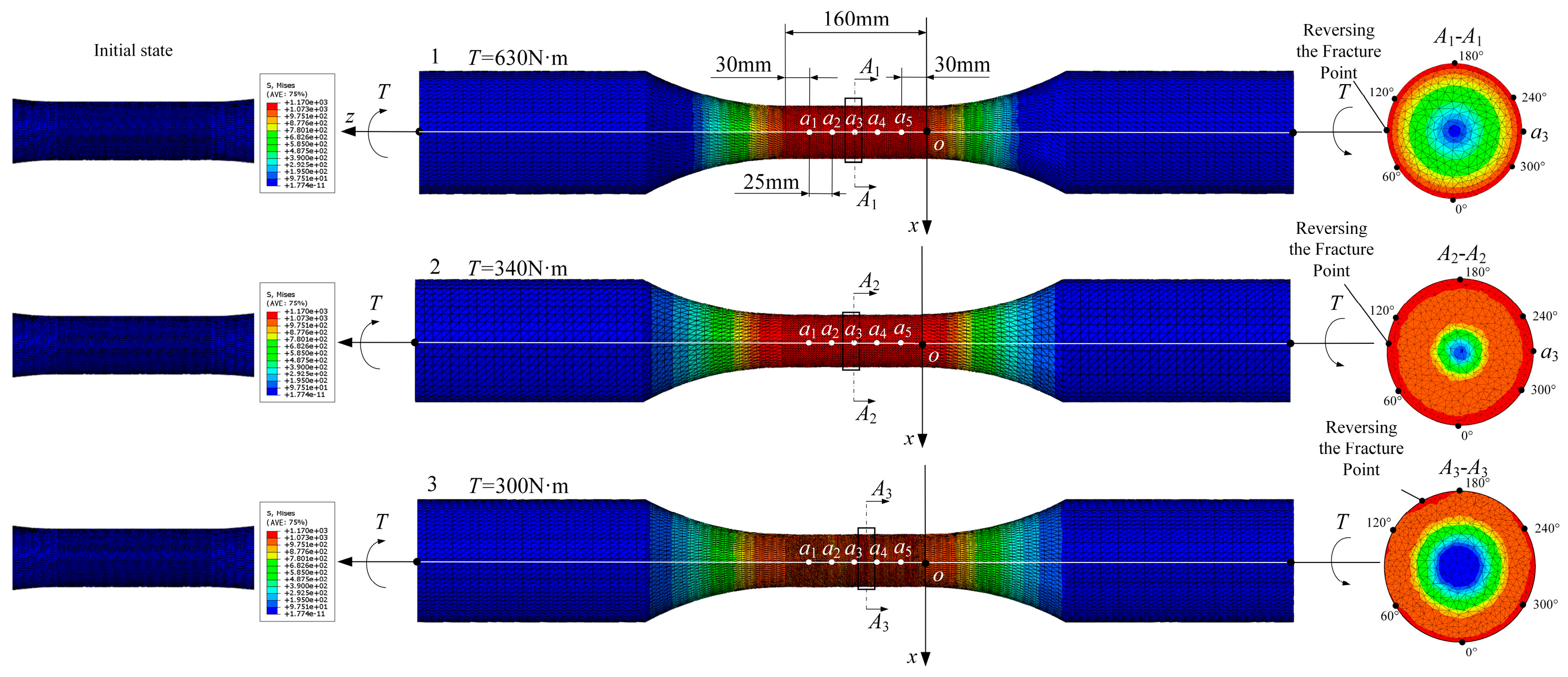

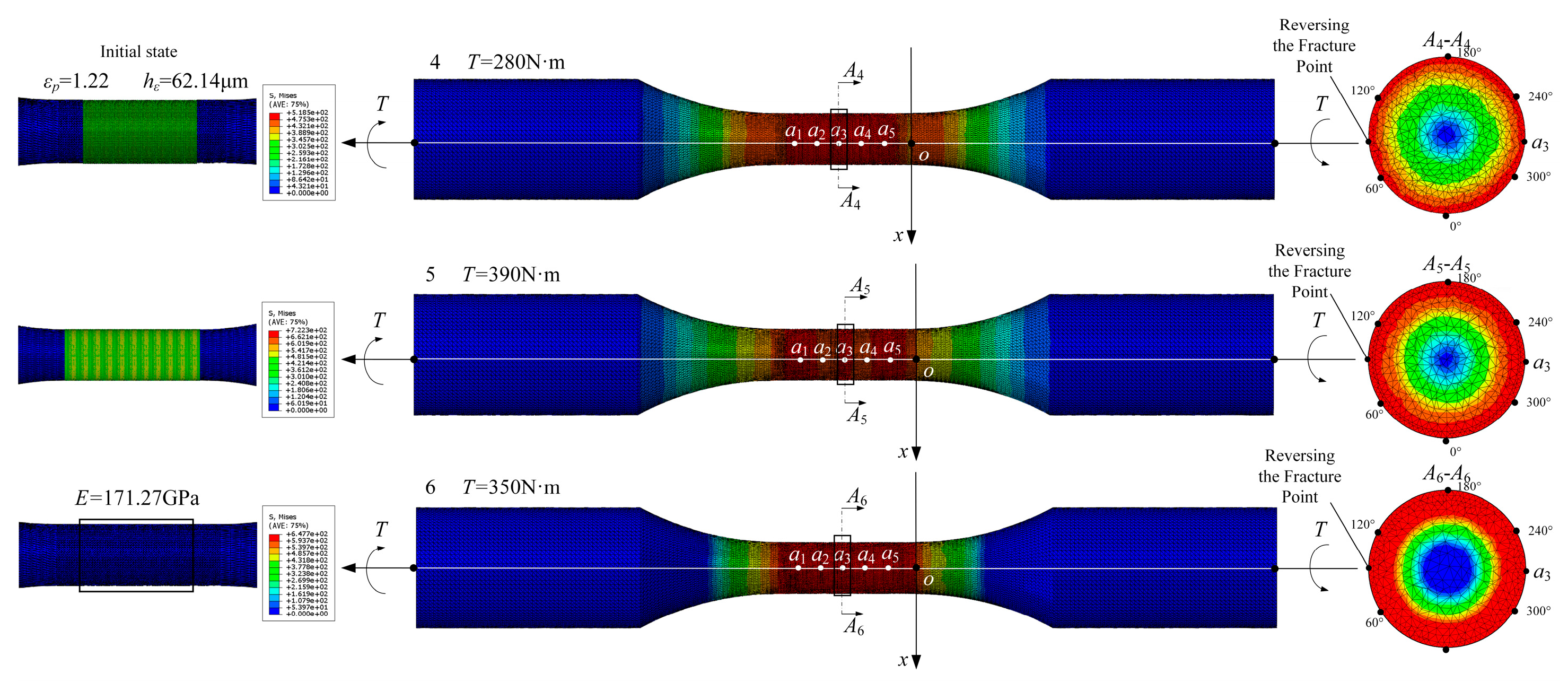

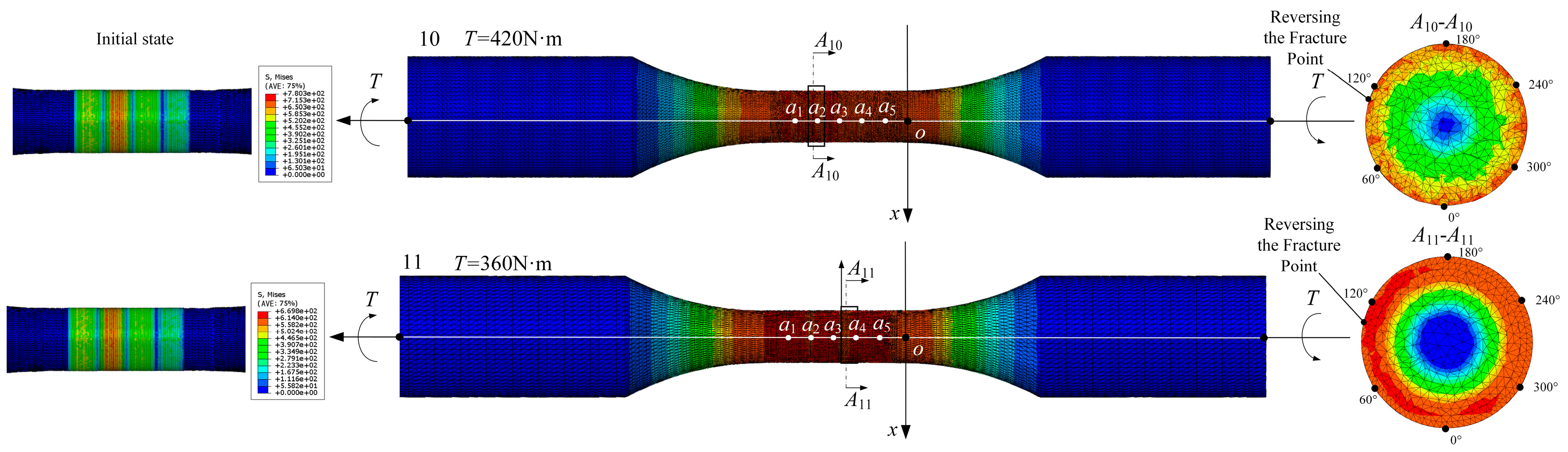

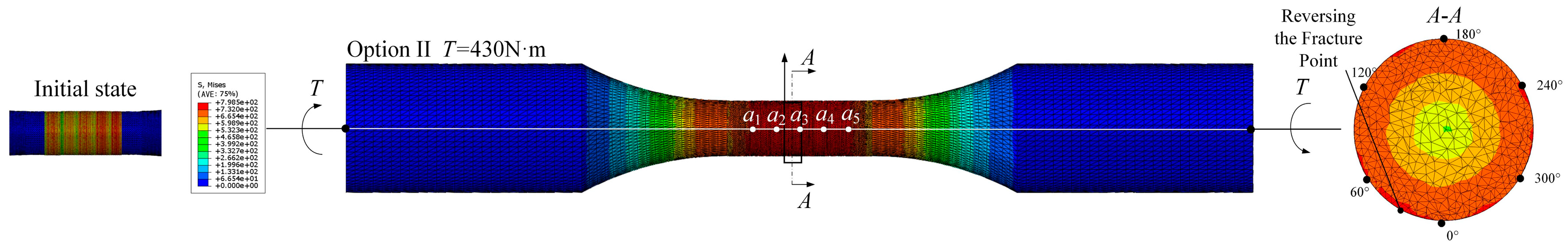

5.1. Construction Method of Torsional Strength and Fatigue Life Analysis Model of Titanium Alloys

5.2. Torsional Strength and Fatigue Life Analysis Program for Titanium Alloys

5.3. Titanium Alloy Torsional Strength Solution Results

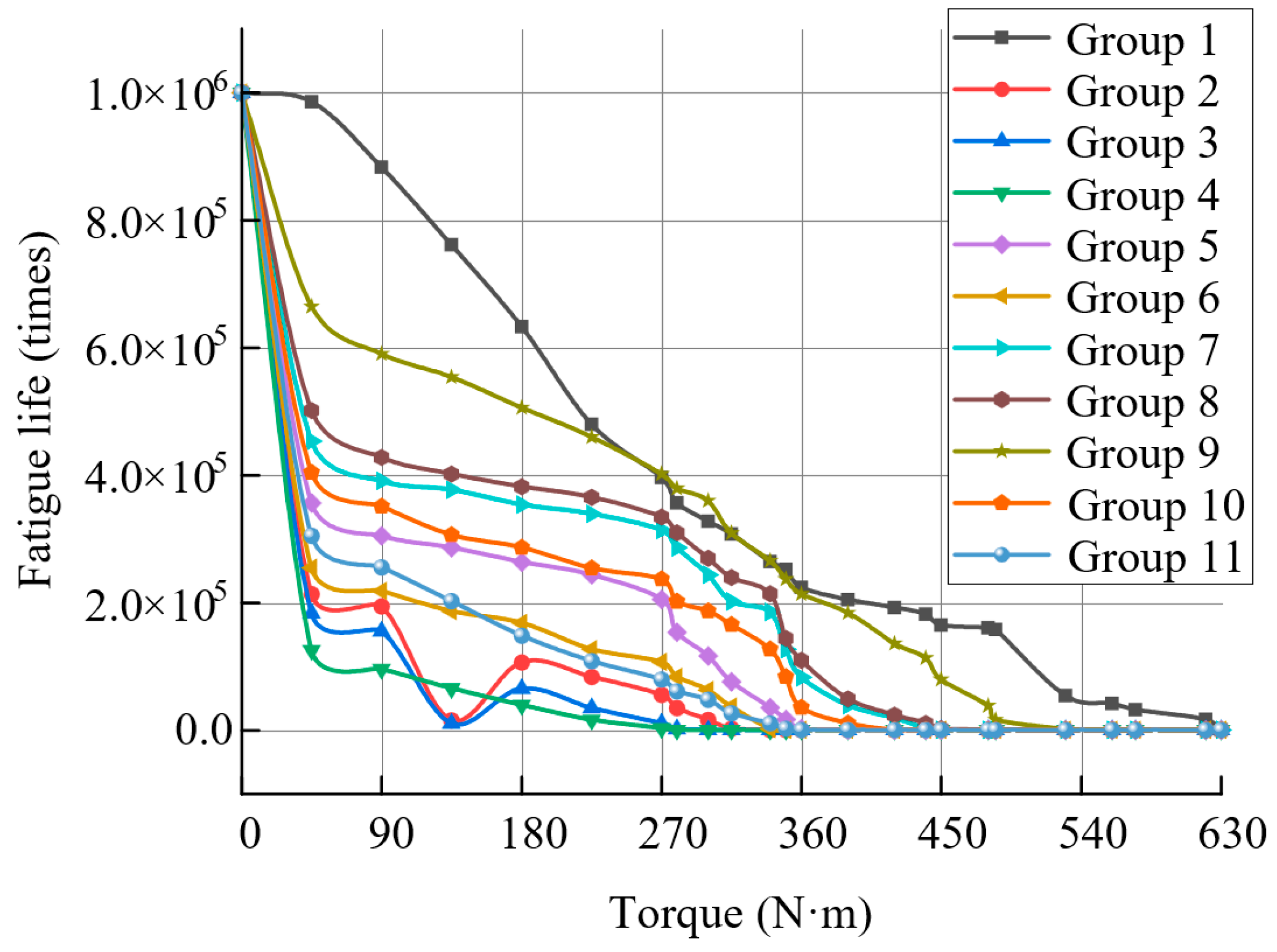

5.4. Titanium Alloys Fatigue Life Solution Results

6. Torsional Fatigue Property and Distribution Characteristic Identification Method of Titanium Alloy Turning Surface

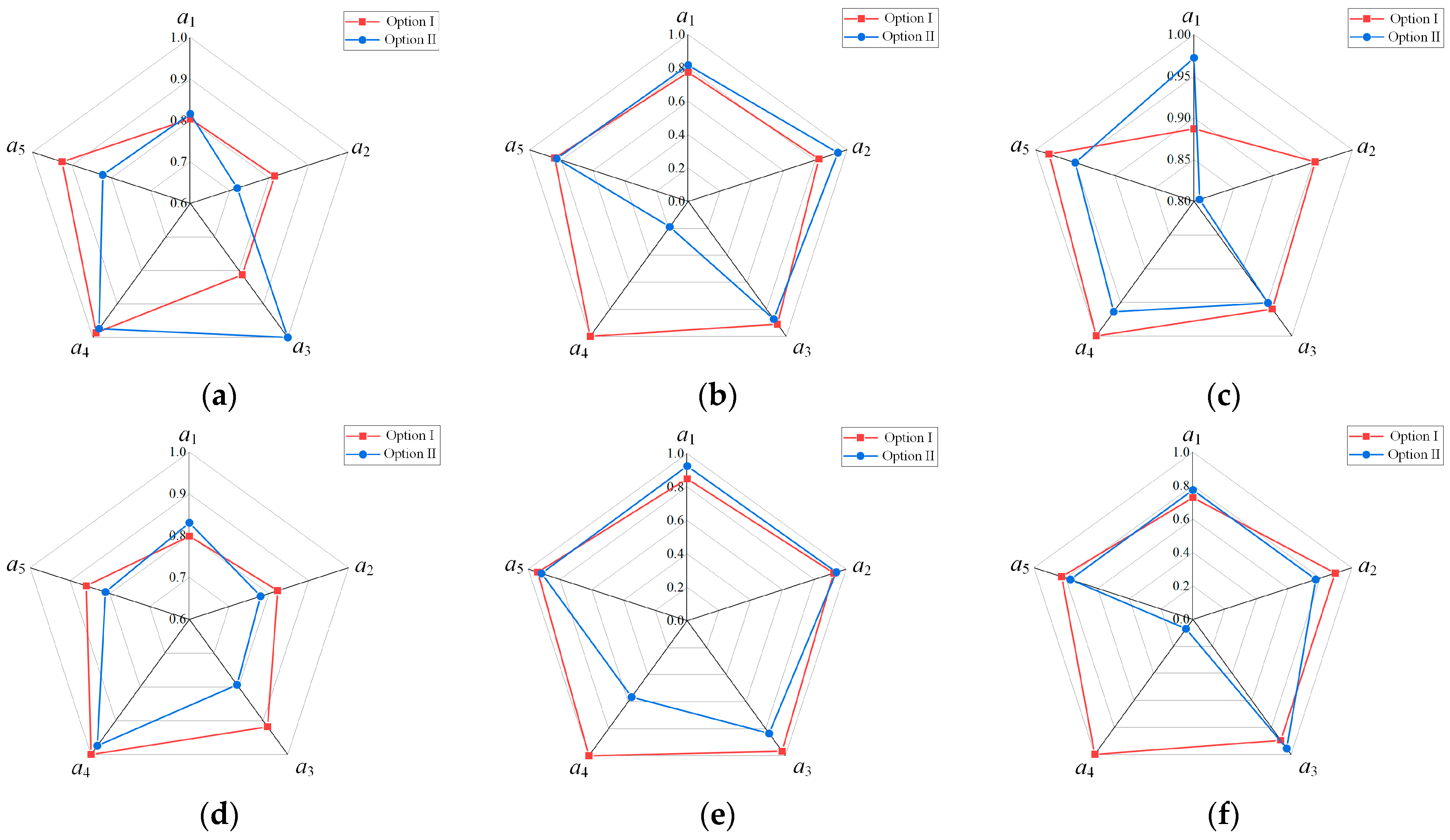

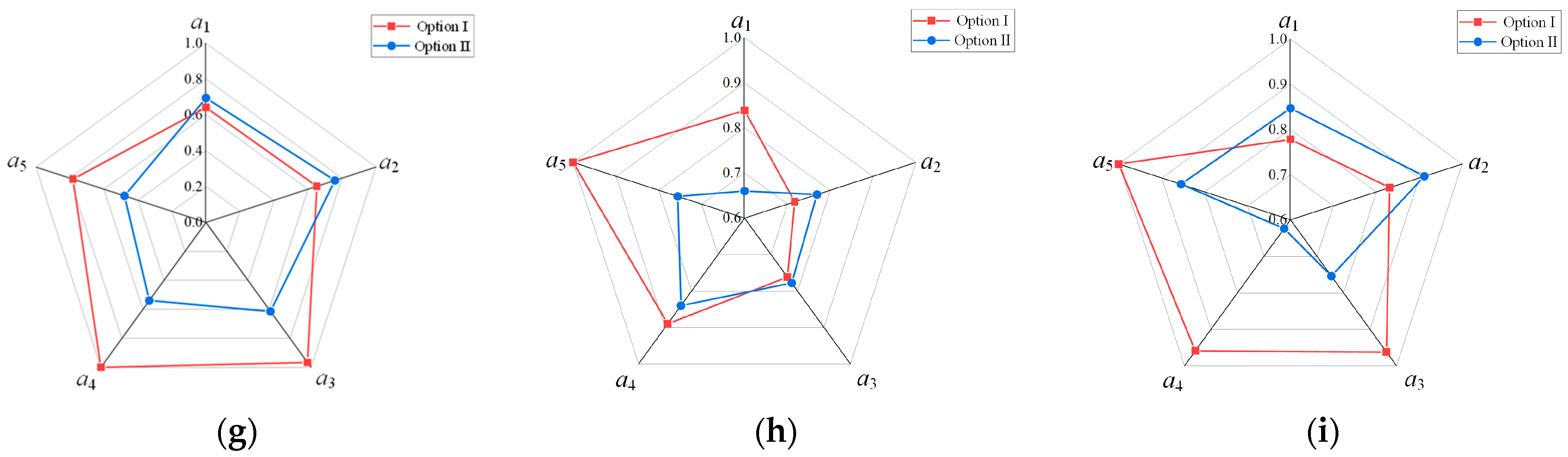

6.1. Identification Method for Torsion Fatigue Performance and Its Distribution Characteristics

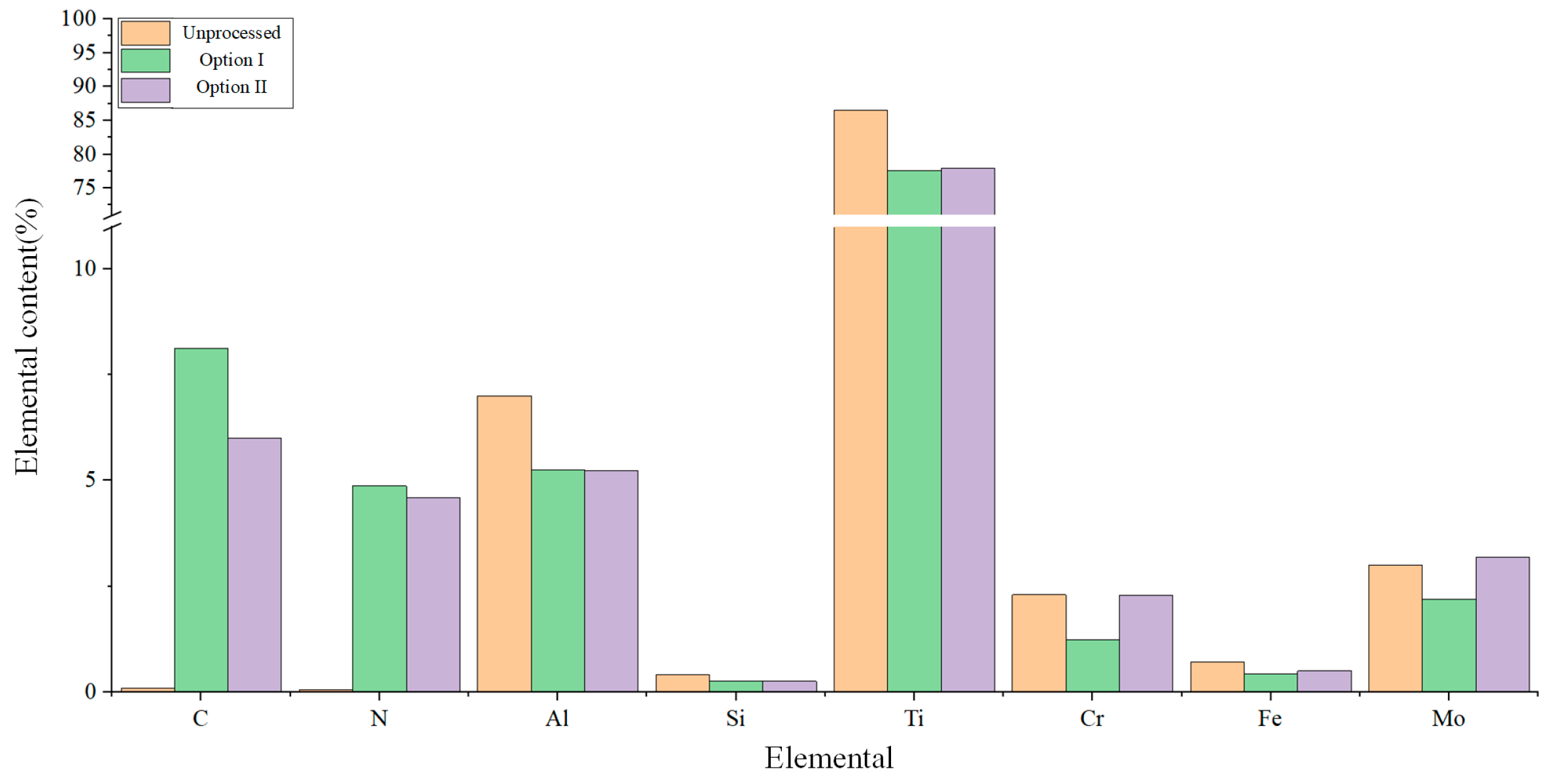

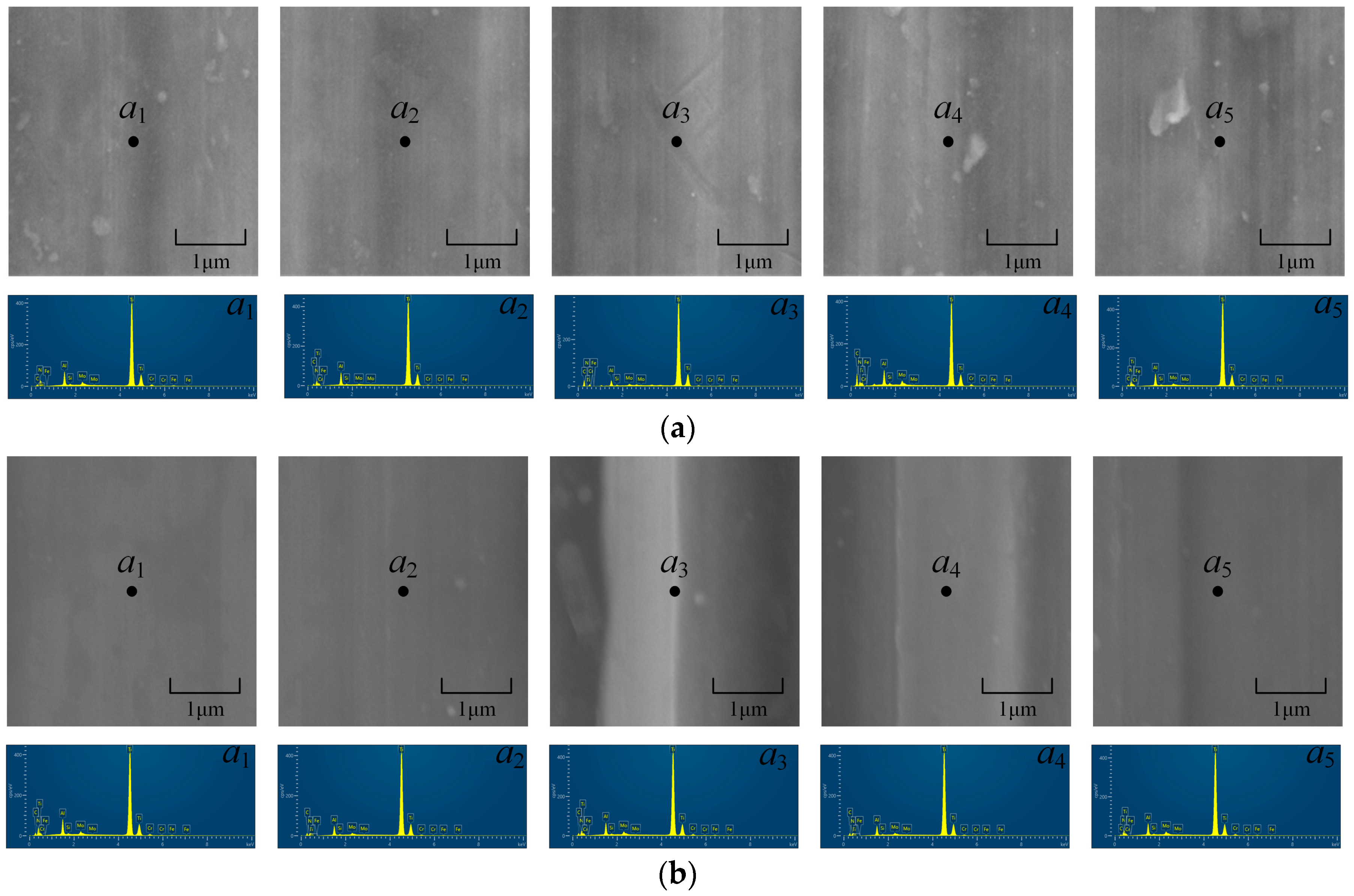

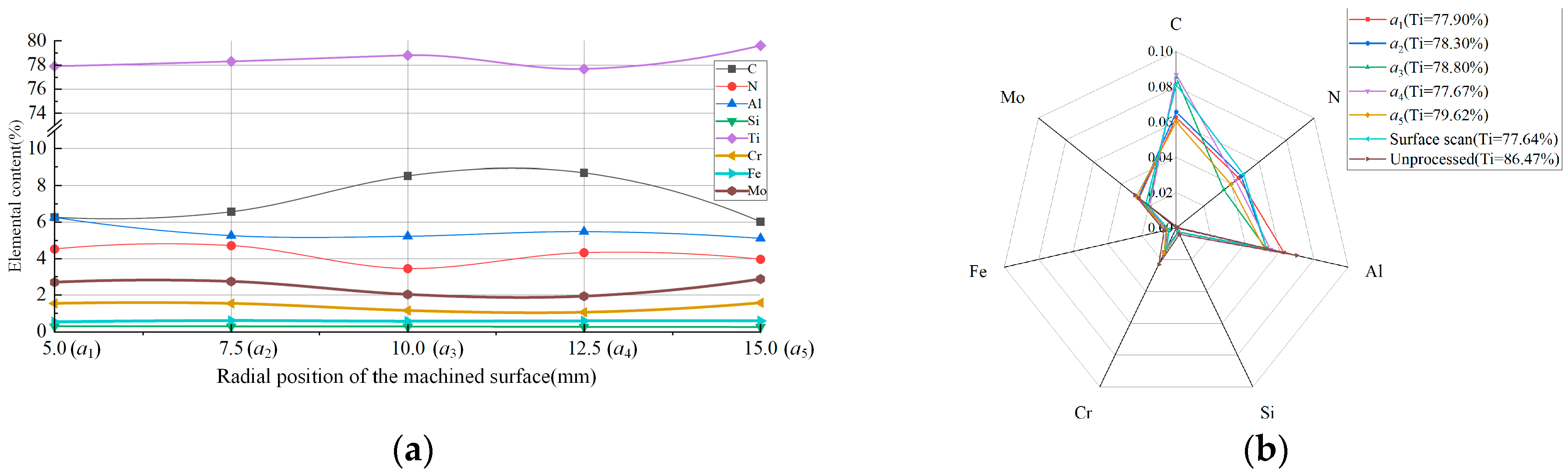

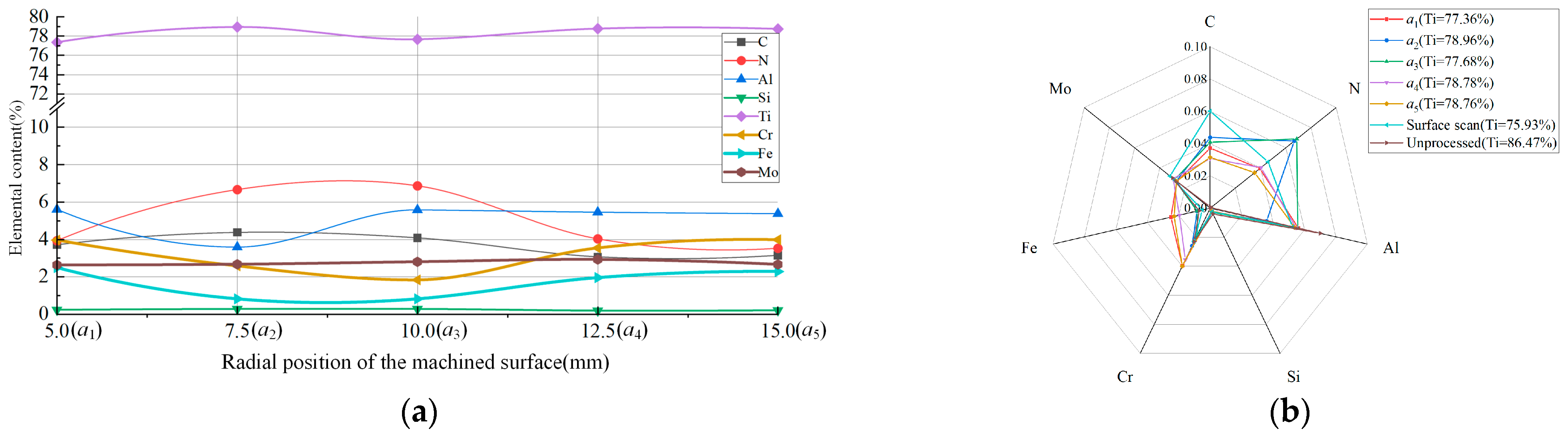

6.2. Comparison and Analysis of Calculation Results for Different Turning Process Solutions

6.3. Comparison and Analysis of Experimental Methods and Measurement Results

7. Conclusions

- To account for the influence of tool geometry parameters, cutting parameters, and cutting forces on tool-workpiece surface morphology, an instantaneous cutting behavior model was developed. Parametric equations describing the primary and secondary cutting edges, along with their transitional arc segments, were formulated. Solutions for machining transition surfaces across adjacent cutting cycles were derived. A methodology for characterizing instantaneous cutting layers and mechanical responses during titanium alloy machining was established. Furthermore, a simulation framework and surface morphology correction model were implemented to analyze machined titanium alloy surfaces.

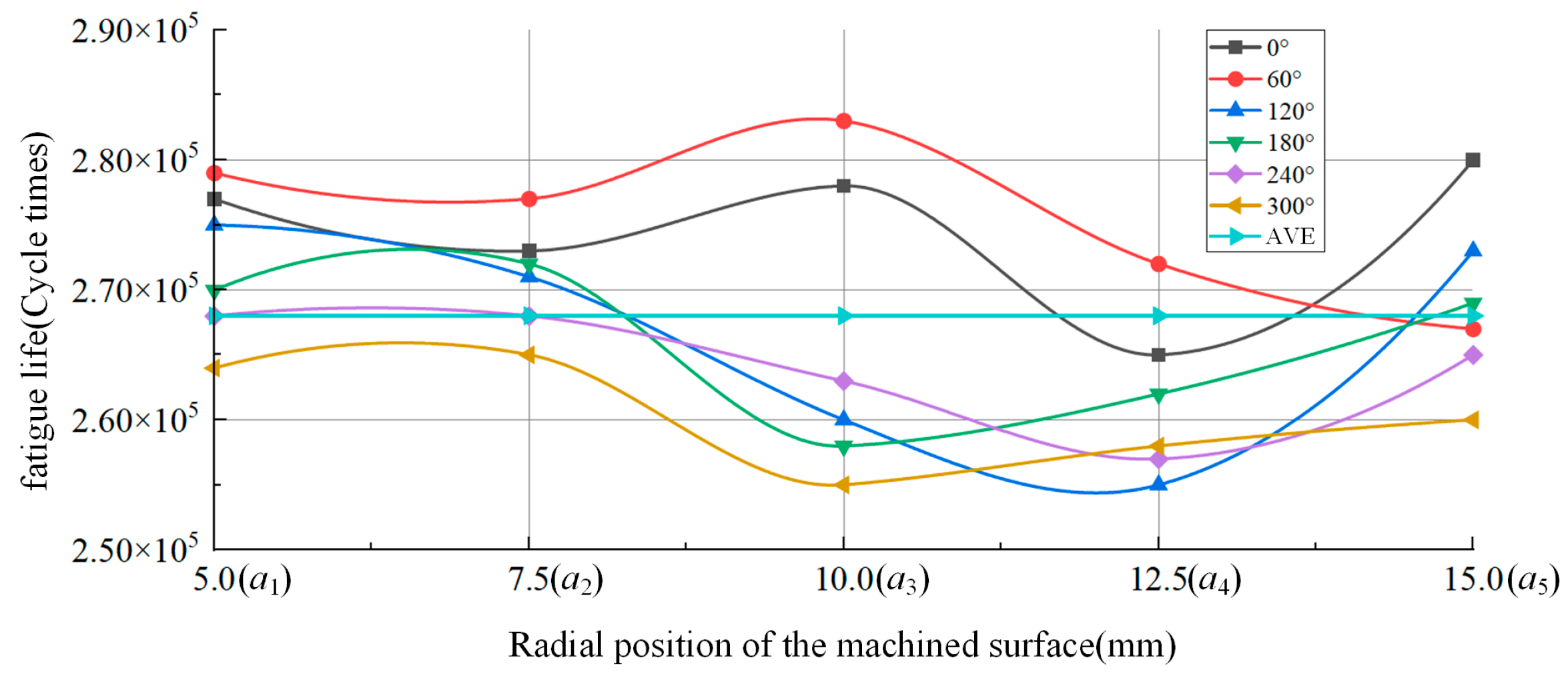

- To address the non-uniform distribution of surface feature parameters in titanium alloy turning, the instantaneous subsurface state during machining was characterized. A finite element model and analytical framework were developed to investigate axial and radial distributions of surface feature parameters on machined titanium alloy surfaces. Results demonstrate positional variations in both axial and radial dimensions for the size and depth of machined surface features during titanium alloy processing.

- A torsional fatigue life prediction model for turned titanium alloys was developed, incorporating torque loading conditions and torsional strength variations induced by non-uniform initial load distributions. Fatigue life analysis of machined surfaces with heterogeneous parameter distributions was performed, accounting for surface feature parameter discrepancies across distinct regions. This investigation quantifies the influence of parameter heterogeneity on fatigue performance. Experimental results demonstrate significant variations in fatigue life distribution among titanium alloy workpieces under identical torque conditions, directly attributable to differences in surface feature parameters. Comparative analysis and experimental verification demonstrate that tool parameter optimization enables modification of titanium alloy turned surfaces’ performance parameters, elemental composition, and distribution characteristics. This adjustment enhances surface mechanical properties, effectively improving torsional strength and fatigue life in titanium alloy components.

- Comparative analysis and experimental verification results show that by adjusting the cutting tool process parameters to alter the performance parameters, element content, and distribution of the machined surface of titanium alloys, it is possible to improve the mechanical properties of the machined surface to a certain extent, thereby enhancing its torsional strength and fatigue life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, X.; Liu, H.; Yu, T.; Guo, R.; Sun, Y.; Chen, M. Experimental and Modeling Study of Surface Topography Generation Considering Tool-Workpiece Vibration in High-Precision Turning. Chin. J. Aeronaut. 2023, 36, 194–212. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Yu, T. Study on Surface Integrity and Surface Roughness Model of Titanium Alloy TC21 Milling Considering Tool Vibration. Appl. Sci. 2022, 12, 4041. [Google Scholar] [CrossRef]

- Tepla, T.L.; Izonin, I.V.; Duriagina, Z.A.; Tkachenko, R.O.; Trostianchyn, A.M.; Lemishka, I.A.; Kulyk, V.V.; Kovbasyuk, T.M. Alloys selection based on the supervised learning technique for design of biocompatible medical materials. Arch. Mater. Sci. Eng. 2018, 93, 32–40. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Kiran, M.; Khanna, N.; Pintaude, G.; Vasco, M.C.; da Silva, L.R.R.; Giasin, K. Review of Improvement of maChinability and Surface Integrity in Machining on Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2023, 129, 4743–4779. [Google Scholar] [CrossRef]

- Singh, A. Experimental Investigations on Surface Integrity in Thin Structure Machining of Aluminum 6061-T6. J. Mater. Eng. Perform. 2025, 34, 1959–1973. [Google Scholar] [CrossRef]

- Guo, S.; Lu, S.; Zhang, B.; Cheung, C.F. Surface Integrity and Material Removal Mechanisms in High-Speed Grinding of al/SiCp Metal Matrix Composites. Int. J. Mach. Tools Manuf. 2022, 178, 103906. [Google Scholar] [CrossRef]

- Chen, G.; Caudill, J.; Chen, S.; Jawahir, I.S. Machining-Induced Surface Integrity in Titanium Alloy Ti-6Al-4V: An Investigation of Cutting Edge Radius and Cooling/Lubricating Strategies. J. Manuf. Process. 2022, 74, 353–364. [Google Scholar] [CrossRef]

- Li, M.; Zhao, W.; Li, L.; He, N.; Stepan, G. Influence of Milling Stability on Machined Surface Integrity and Fatigue Performance of Ti-6Al-4V Titanium Alloy. Eng. Fail. Anal. 2025, 168, 109103. [Google Scholar] [CrossRef]

- Yang, S.; Li, X.; Wang, Z.; Guan, C. Influence of Side Milling on Surface Integrity and Fatigue Behavior of TC4 Specimens. Surf. Technol. 2019, 48, 372–380. [Google Scholar]

- Shen, H.; Wang, C.; Li, J. Study on Effect of Feed on Fatigue Life in Cutting Titanium Alloy Process. Tool Eng. 2022, 56, 35–39. [Google Scholar]

- Zhao, W.; Zheng, G.; Zhang, H.; Ji, R.; Li, X. Effect of tool wear on machined surface integrity and fatigue propertiesof FGH96 specimen. Mod. Manuf. Eng. 2023, 3, 8–14. [Google Scholar]

- Jiang, A.; Zhao, J.; Cui, P.; Liu, Z.; Wang, B. Effects of TiAlN Coating Thickness on Machined Surface Roughness, Surface Residual Stresses, and Fatigue Life in Turning Inconel 718. Metals 2024, 14, 940. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, W.; Liu, Y.; Liu, S.; Chen, H.; Liu, Z. Distinguishing effect of turning and grinding on the surface integrity and fatigue performance of ultra-high strength steel. Int. J. Adv. Manuf. Technol. 2024, 133, 4317–4330. [Google Scholar] [CrossRef]

- Lai, X.; Wang, Y.; Wang, D.; Zhao, G.; Yang, Y. Research on Surface Integrity and Fatigue Properties in the Turning of TC17 Titanium Alloy Based on the Response Surface Method. Materials 2023, 16, 7180. [Google Scholar] [CrossRef]

- Wang, D.; Chen, X.; Lai, X.; Zhao, G.; Yang, Y. Effect of Cutting Surface Integrity on Fatigue Properties of TC17 Titanium Alloy. Materials 2023, 16, 5658. [Google Scholar] [CrossRef]

- Wang, S.; He, C.; Wang, Z.; Yan, J. Subsurface amorphization-induced ultrasmooth and ultrahard surface during the diamond turning of polycrystalline pure copper. Mater. Des. 2025, 249, 113549. [Google Scholar] [CrossRef]

- Imran, M.; Shuangfu, S.; Yuzhu, B.; Yuming, W.; Raheel, N. Optimising subsurface integrity and surface quality in mild steel turning: A multi-objective approach to tool wear and machining parameters. J. Mater. Res. Technol. 2025, 35, 3440–3462. [Google Scholar] [CrossRef]

- Bartarya, G.; Choudhury, S.K. FEM and experimental analysis to study the effect of tool wear on the surface integrity of finish hard turned EN31 steel. Sādhanā 2024, 49, 189. [Google Scholar] [CrossRef]

- Xia, J.; Jin, H. Numerical Analysis for Controlling Residual Stresses in Welding Design of Dissimilar Materials Girth Joints. Int. J. Precis. Eng. Manuf. 2018, 19, 57–66. [Google Scholar] [CrossRef]

- Bang, H.S.; Park, C.S.; Bang, H.S. Structural Analysis of Automotive Cowl Parts Considering Welding Residual Stress. Int. J. Precis. Eng. Manuf. 2017, 18, 729–737. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, W. Comprehensive Impact of Machined Surface Integrity on Stress Corrosion Cracking Initiation in 316 Austenitic Stainless Steel. J. Mater. Eng. Perform. 2025, 34, 4230–4239. [Google Scholar] [CrossRef]

- Yue, Q.; He, Y.; Li, Y.; Tian, S. Investigation on Effects of Single- and Multiple-Pass Strategies on Residual Stress in Machining Ti-6Al-4V Alloy. J. Manuf. Process. 2022, 77, 272–281. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, D.; Xu, L.; Sun, T.; Zhang, P.; Lei, J. Effect of Notch on Torsional Fatigue Performance of 34crni3mo Alloy Steel. J. Wuhan Univ. Technol. 2024, 48, 309–314. [Google Scholar]

| Material | Density (g/cm3) | Poisson Ratio | Hardness (N/mm2) | Yield Strength (MPa) | Tensile Strength (MPa) | Compressive Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| TC6 | 4.51 | 0.34 | 340 | 1231 | 1300 | 1687 | 109.8 |

| Material | Density (g/cm3) | Elastic Modulus (GPa) | Poisson Ratio | Thermal Conductivity (W/m·°C) | Specific Heat Capacity (J/kg·°C) |

|---|---|---|---|---|---|

| WC | 15.7 | 705 | 0.23 | 24 | 178 |

| Plan | Turning Process Parameters | ||

|---|---|---|---|

| ap (mm) | n (r/min) | f (mm) | |

| 1 | 0.1 | 590 | 0.1 |

| 2 | 0.15 | 590 | 0.1 |

| 3 | 0.2 | 590 | 0.1 |

| 4 | 0.25 | 590 | 0.1 |

| 5 | 0.2 | 491 | 0.1 |

| 6 | 0.2 | 786 | 0.1 |

| 7 | 0.2 | 1180 | 0.1 |

| 8 | 0.2 | 590 | 0.06 |

| 9 | 0.2 | 590 | 0.14 |

| 10 | 0.2 | 590 | 0.2 |

| Characteristic Parameter: (sa) | Coefficients of the Fitted Equations | |||||

|---|---|---|---|---|---|---|

| β | α1 | α2 | α3 | α4 | α5 | |

| xk | 0.0003 | −0.0108 | 0.03 | 1.9188 | 0.0586 | −0.0290 |

| xm | 0.0002 | 2.2266 | −0.741 | 0.3109 | 0.0482 | −0.0376 |

| Δxk | 6.9255 × 10−5 | 1.9741 | −0.7651 | 0.8547 | 0.0076 | 0.0003 |

| Δxm | 3.7007 × 10−5 | 1.9987 | −0.701 | 0.8742 | 0.0108 | 0.0092 |

| Rm | 3326.3511 | −0.3473 | 0.196 | −0.3868 | 0.012 | 0.0174 |

| Ra | 7.0221 × 10−8 | 4.4540 | −1.6163 | 0.7695 | −0.0015 | −0.0008 |

| Group | Highest Point of Machined Surface Topography pk | Lowest Point of Machined Surface Topography pm | |||||

|---|---|---|---|---|---|---|---|

| xk (μm) | Δxk (μm) | Δzk (μm) | xm (μm) | Δxm (μm) | Δzm (μm) | Rm (μm) | |

| 1 | 0 | 0 | 0 | 0 | 0 | 0 | ∞ |

| 2 | 3 | 0 | 100 | 0 | 0 | 100 | 400 |

| 3 | 2.73~4.05 | 0~1.32 | 97.86~101.12 | −0.75~1.08 | 0~1.83 | 98.76~102.11 | 383.54~415.24 |

| Direction | Highest Point of Surface Topography for Different Machining Cycles pki | Minimum Point of Surface Topography for Different Machining Cycles pmi | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | |||

| Corrected surfaces | x (μm) | 2.88 | 3.20 | 2.61 | 3.02 | 2.98 | 0.17 | 0.18 | −0.29 | −0.69 | 0.09 | |

| z (μm) | 28.89 | 127.05 | 227.17 | 312.76 | 424.25 | 79.84 | 179.57 | 275.84 | 380.56 | 478.57 | ||

| Δx (μm) | - | 0.32 | −0.59 | 0.41 | −0.04 | - | 0.01 | −0.47 | −0.40 | 0.78 | ||

| Δz (μm) | - | 98.16 | 100.12 | 85.59 | 111.49 | - | 99.73 | 96.27 | 104.72 | 98.01 | ||

| Experimental surface | x (μm) | 2.92 | 3.24 | 2.73 | 2.95 | 3.00 | 0.18 | 0.19 | −0.26 | −0.75 | 0.09 | |

| z (μm) | 29.17 | 127.03 | 227.12 | 313.68 | 424.14 | 80.32 | 181.14 | 276.33 | 379.97 | 480.18 | ||

| Δx (μm) | - | 0.32 | −0.51 | 0.22 | 0.05 | - | 0.01 | −0.45 | −0.49 | 0.66 | ||

| Δz (μm) | - | 97.86 | 100.09 | 86.56 | 110.36 | - | 100.82 | 95.19 | 103.64 | 100.21 | ||

| Absolute error | x (μm) | 0.04 | 0.04 | 0.12 | 0.07 | 0.02 | 0.01 | 0.01 | 0.03 | 0.06 | 0 | |

| z (μm) | 0.28 | 0.02 | 0.05 | 0.92 | 0.11 | 0.48 | 1.57 | 0.49 | 0.59 | 1.61 | ||

| Δx (μm) | - | 0 | 0.08 | 0.19 | 0.01 | - | 0 | 0.02 | 0.11 | 0.12 | ||

| Δz (μm) | - | 0.30 | 0.03 | 0.97 | 4.13 | - | 1.09 | 1.08 | 1.08 | 2.2 | ||

| Relative error | x (%) | 1.37 | 1.23 | 4.40 | 2.37 | 0.67 | 5.56 | 5.26 | 11.54 | 8.00 | 0 | |

| z (%) | 6.71 | 0.99 | 2.36 | 8.13 | 12.79 | 9.02 | 25.57 | 36.84 | 11.87 | 31.08 | ||

| Δx (%) | - | 0 | 15.69 | 53.66 | 20.00 | - | 0 | 4.44 | 22.45 | 18.18 | ||

| Δz (%) | - | 0.31 | 0.01 | 1.12 | 3.74 | - | 1.08 | 1.13 | 1.04 | 2.20 | ||

| Group | Machined Surface Topography | Residual Stress Distribution | Hardening Rate Distribution | Plastic Strain Distribution | Elastic Modulus Distribution | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| σr1 (MPa) | σr2 (MPa) | hr (μm) | η (GPa) | hη (μm) | εp | hε (μm) | E (GPa) | hE (μm) | ||

| 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 109.80 | 0 |

| 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 109.80 | 0 |

| 3 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 109.80 | 0 |

| 4 | 2 | 0 | 0 | 0 | 0 | 0 | 1.22 | 62.14 | 109.80 | 0 |

| 5 | 2 | −94.57 | −221.95 | 53.01 | 0 | 0 | 0 | 0 | 109.80 | 0 |

| 6 | 2 | 0 | 0 | 0 | 39.41 | 17.05 | 0 | 0 | 171.27 | 17.05 |

| 7 | 2 | −73.69 | −184.87 | 51.10 | 38.40 | 16.11 | 0.89 | 63.12 | 168.85 | 16.11 |

| 8 | 2 | −94.57 | −221.95 | 53.01 | 39.41 | 17.05 | 1.22 | 62.14 | 171.27 | 17.05 |

| 9 | 2 | −106.04 | −247.01 | 52.23 | 41.21 | 16.83 | 1.26 | 62.23 | 175.77 | 16.83 |

| 10 | 2 | −73.69 ~ −106.04 | −184.87 ~ −247.01 | 51.1 ~ 52.23 | 38.4 ~ 41.21 | 16.11 ~ 16.83 | 0.89 ~ 1.26 | 51.1 ~ 52.23 | 168.85 ~ 175.77 | 16.11 ~ 16.83 |

| 11 | 3 | −73.69 ~ −106.04 | −184.87 ~ −247.01 | 51.1 ~ 52.23 | 38.4 ~ 41.21 | 16.11 ~ 16.83 | 0.89 ~ 1.26 | 51.1 ~ 52.23 | 168.85 ~ 175.77 | 16.11 ~ 16.83 |

| Scheme | Maximum Torque Tmax (N m) | Fatigue Life Nf (×105) | Fracture Line | |

|---|---|---|---|---|

| z (mm) | θ (°) | |||

| 1 | 360 | 2.55 | 68 | 282 |

| 2 | 430 | 3.72 | 83 | 31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Wang, D.; Zhao, P.; Sang, H. Identification of Torsional Fatigue Properties of Titanium Alloy Turned Surfaces and Their Distribution Characteristics. Appl. Sci. 2025, 15, 6767. https://doi.org/10.3390/app15126767

Jiang B, Wang D, Zhao P, Sang H. Identification of Torsional Fatigue Properties of Titanium Alloy Turned Surfaces and Their Distribution Characteristics. Applied Sciences. 2025; 15(12):6767. https://doi.org/10.3390/app15126767

Chicago/Turabian StyleJiang, Bin, Dengyun Wang, Peiyi Zhao, and Hongchao Sang. 2025. "Identification of Torsional Fatigue Properties of Titanium Alloy Turned Surfaces and Their Distribution Characteristics" Applied Sciences 15, no. 12: 6767. https://doi.org/10.3390/app15126767

APA StyleJiang, B., Wang, D., Zhao, P., & Sang, H. (2025). Identification of Torsional Fatigue Properties of Titanium Alloy Turned Surfaces and Their Distribution Characteristics. Applied Sciences, 15(12), 6767. https://doi.org/10.3390/app15126767