Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction

Abstract

1. Introduction

2. Experimental Tests

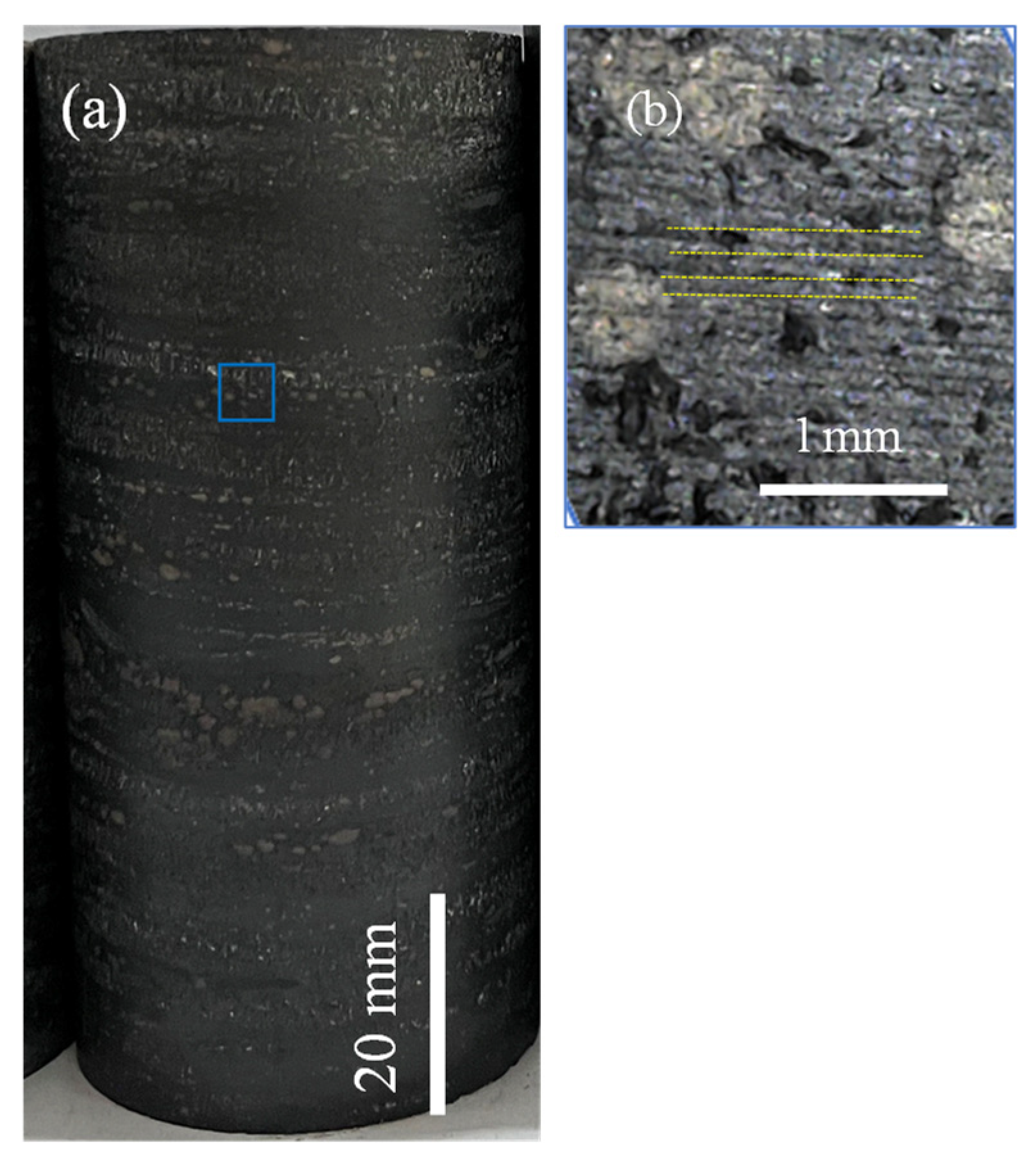

2.1. Basic Indicators of Coal Rock

2.2. Experimental Process

3. Results and Analyses

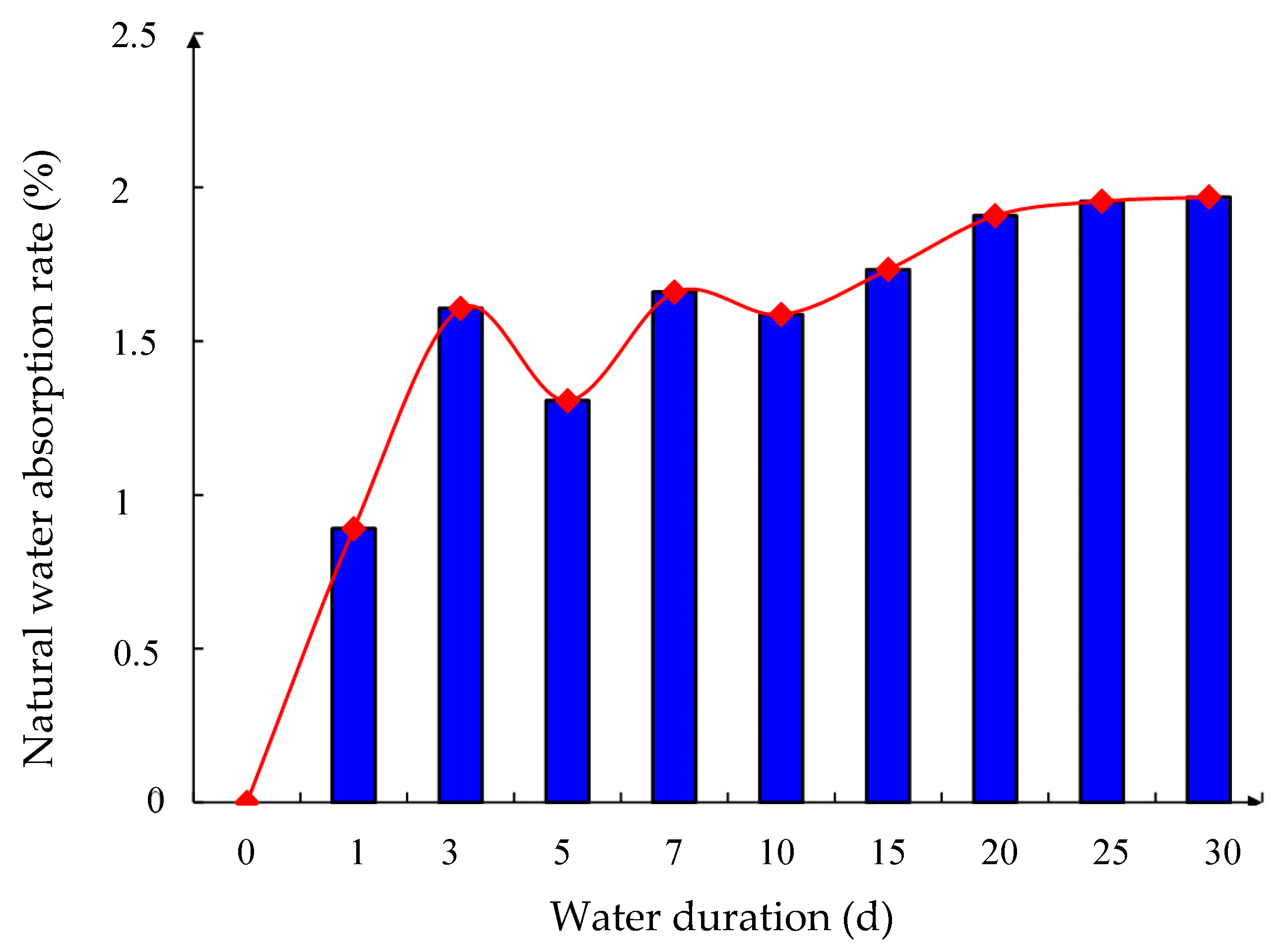

3.1. Changes in Natural Water Absorption Rate

3.2. Uniaxial Compressive Properties

3.3. Analysis of Damage Patterns

4. Discussion

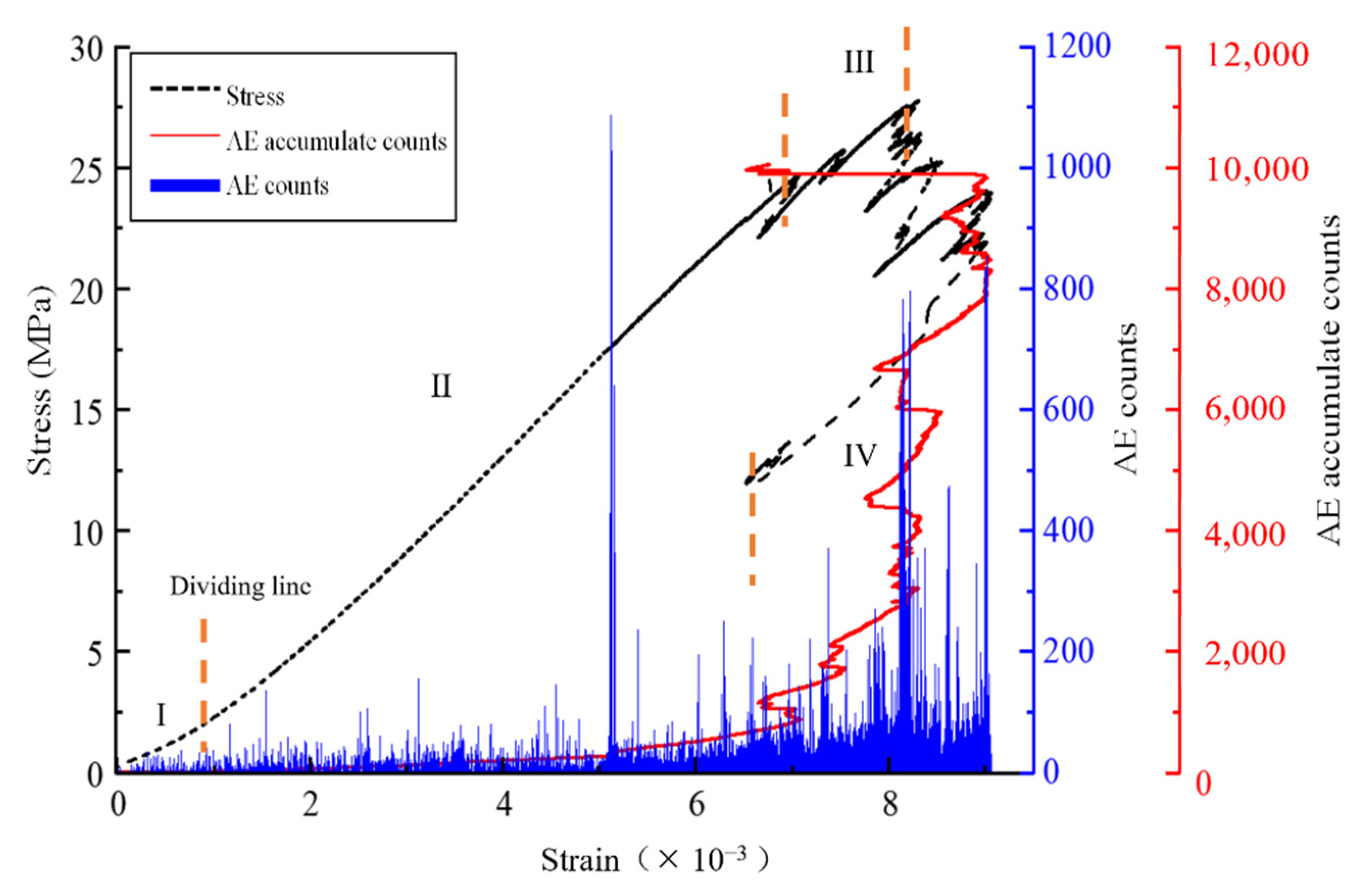

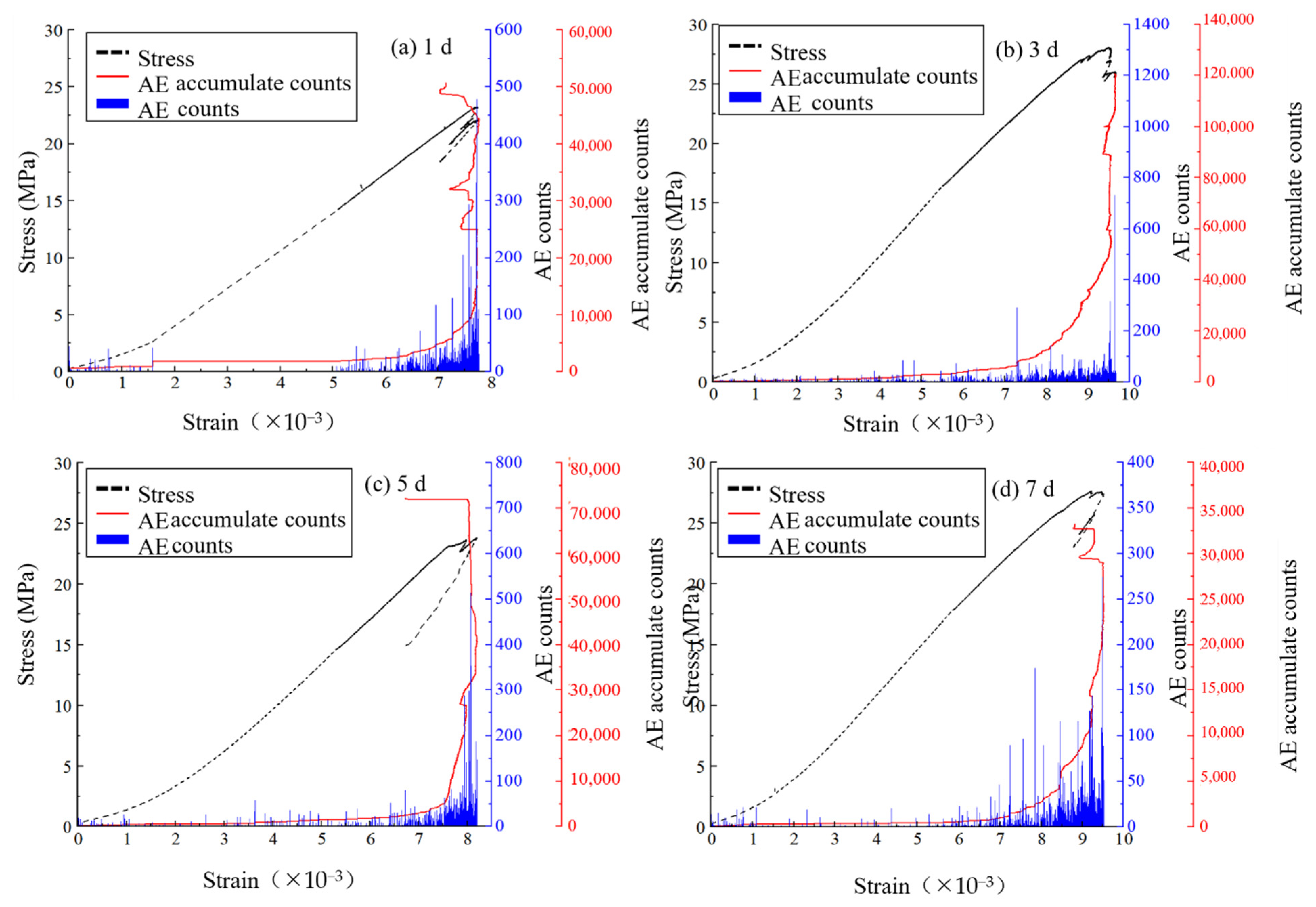

4.1. Acoustic Emission Characteristics

4.2. Fracture Evolution

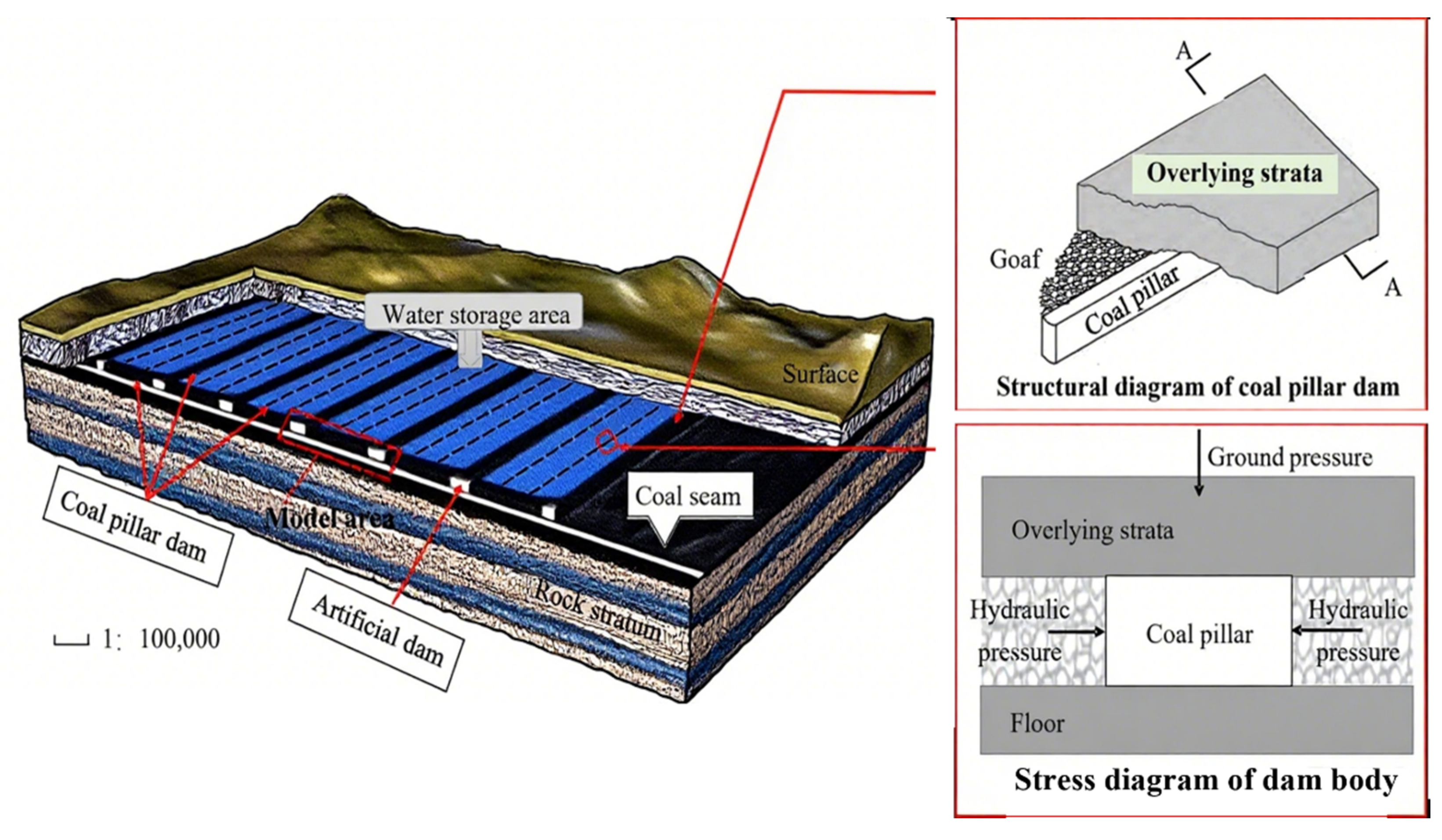

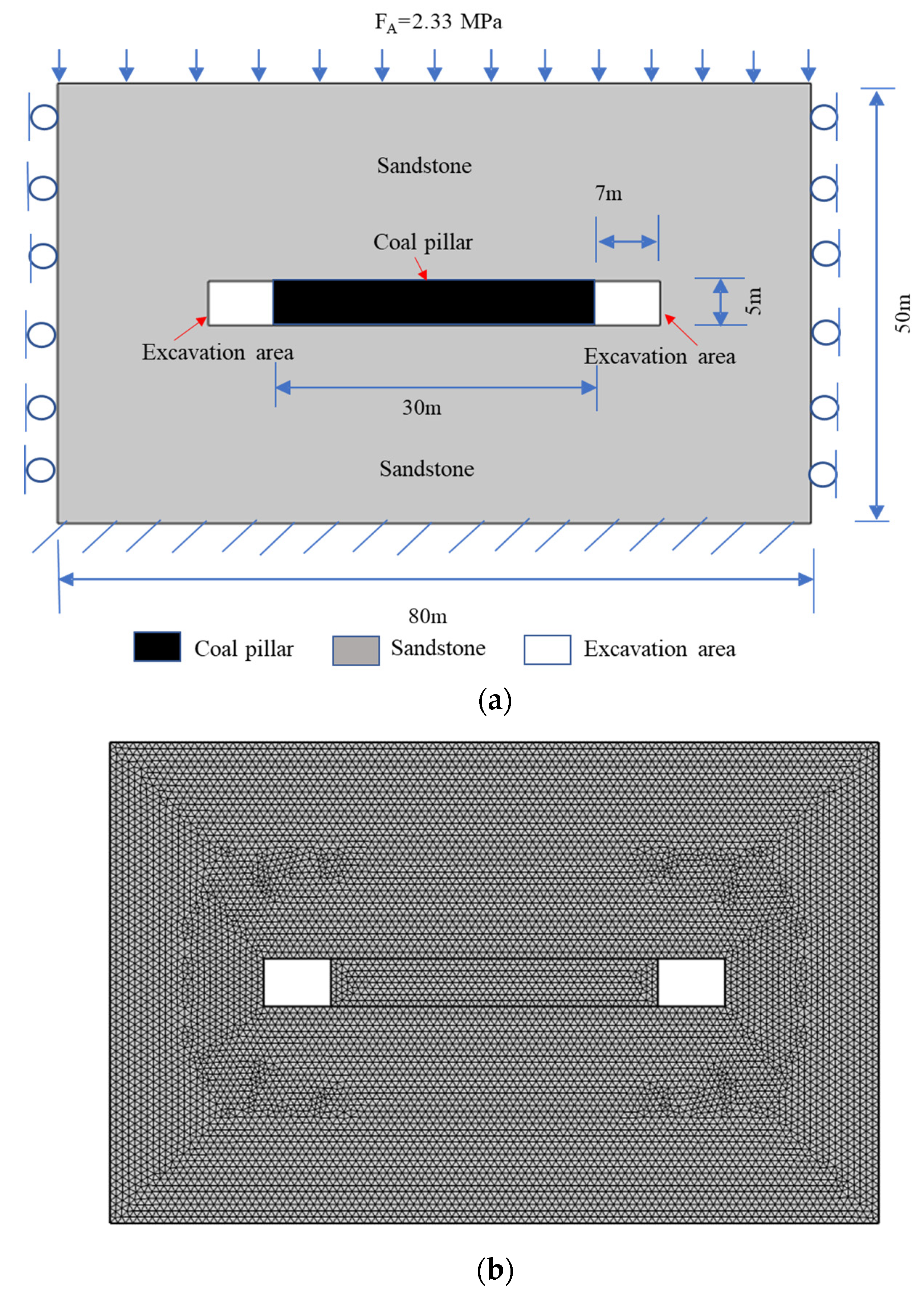

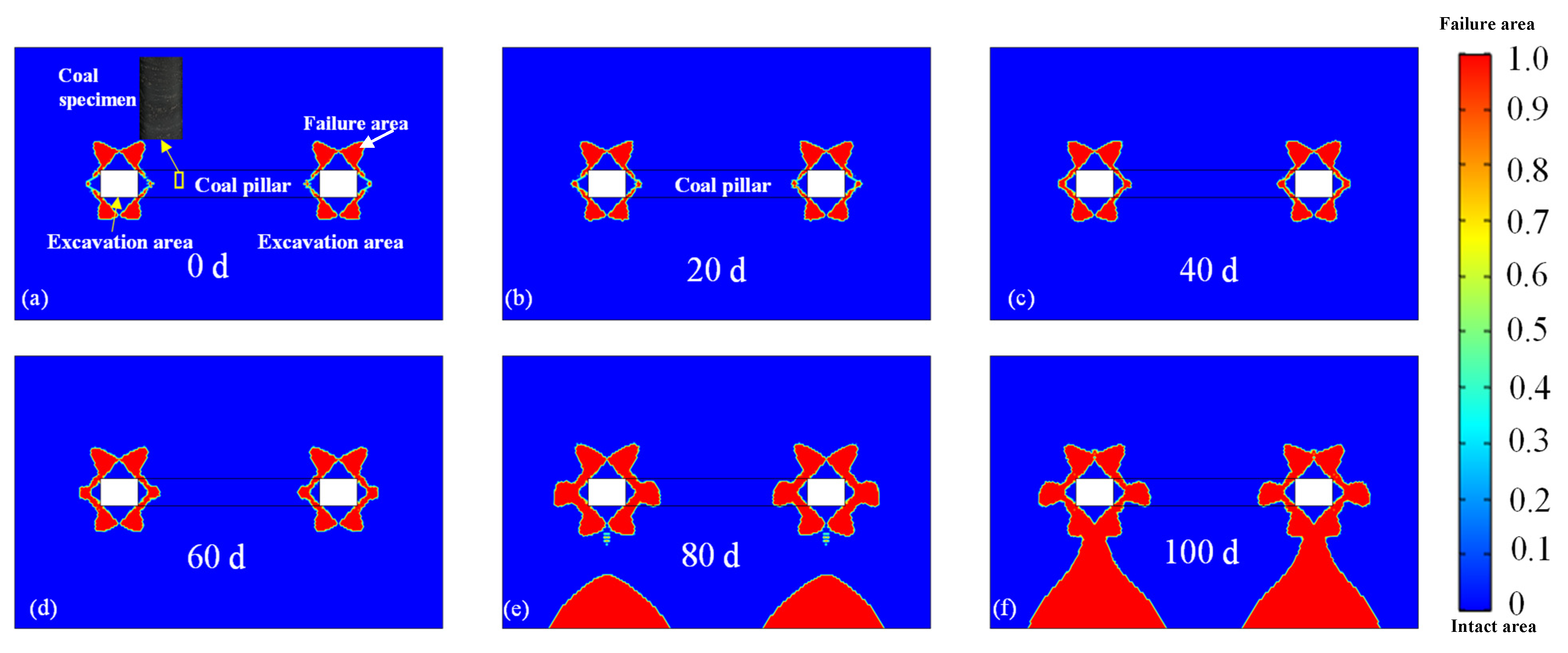

4.3. Application in Coal Pillar Failure

5. Conclusions

- (1)

- The natural water absorption rate of coal rock reaches its peak after being immersed in water for 1 day. As the immersion duration increases, the absorption rate gradually stabilizes at around 20 days, indicating the gradual saturation of the coal rock with water absorption. The saturated natural water absorption rate is 1.97%. The longitudinal wave velocity of the coal rock tends to increase after water immersion.

- (2)

- Short-term water immersion results in an improvement in the plasticity of the coal rock with only a minor softening effect, resulting in a relatively complete damage morphology and a low degree of fragmentation. Conversely, prolonged water immersion results in the significant softening of the coal rock, which causes a shift in the damage morphology from shear fracture to longitudinal fracture. A negative exponential function was used to establish the relationship between the compressive strength and peak strain of the coal rock during continuous immersion, revealing a linear correlation between the elastic modulus and immersion duration.

- (3)

- The active periods of acoustic emission in coal rocks with different water immersion durations are comparable, with the most significant stress peaks occurring near the highest intensity. With increasing immersion durations, the cumulative number of acoustic events decreases, indicating the pronounced attenuation effect of water. Furthermore, the longer the immersion duration, the lower the extent of damage and the higher the level of integrity. The number of failure areas in the compressive fracture process of coal rock decreases after water immersion. The area of strain concentration forms a narrow strip in the direction of vertical lamination, and this is significantly influenced by the orientation of the primary joints within the coal.

- (4)

- The fitting curves of the compressive strength and elastic modulus under different immersion durations were obtained. The mechanical reduction relationship was applied to the failure patterns of coal pillars in underground reservoirs. The damage area of the coal pillar and the surrounding rock of the excavation area is expanded when increasing the duration of water immersion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, M.G.; Miu, X.X.; Xu, J.L. Green mining of coal resources harmonizing with environment. J. China Coal Soc. 2007, 32, 1–7. [Google Scholar]

- Qian, M.G. On sustainable coal mining in China. J. China Coal Soc. 2010, 35, 529–534. [Google Scholar]

- Gu, D.Z. Theory framework and technological system of coal mine underground reservoir. J. China Coal Soc. 2015, 40, 239–246. [Google Scholar]

- Liu, Q.; Sun, Y.J.; Li, J. Experimental study on seepage characteristics of Jurassic weakly cemented sandstone under water-rock interaction. Geofluids 2020, 3, 8543687. [Google Scholar] [CrossRef]

- Chen, T.; Yao, Q.L.; Du, M.; Zhu, C.G.; Zhang, B. Experimental research of effect of water intrusion times on crack propagation in coal. Chin. J. Rock Mech. Eng. 2016, 35, 3756–3762. [Google Scholar]

- Tang, C.J. Study on Damage Characteristics of Coal Under the Influence of Dryness-Saturation Cycles and Acid Water Environment. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Yao, Q.L.; Wang, W.N.; Li, X.H.; Tang, C.J.; Xu, Q.; Yu, L.Q. Study of mechanical properties and acoustic emission characteristics of coal measures under water-rock interaction. J. China Univ. Min. Technol. 2021, 50, 558–569. [Google Scholar]

- Chen, G.B.; Zhang, J.W.; Li, T.; Chen, S.J.; Zhang, G.H.; Lv, P.F.; Teng, P.C. Timeliness of damage and deterioration of mechanical properties of coal-rock combined body under water-rock interaction. J. China Coal Soc. 2021, 46, 701–712. [Google Scholar]

- Lu, J.; Xu, Q.Y.; Ning, Z.X. Analysis of structural characteristics of the coal with different water immersion time. J. Henan Polytech. Univ. (Nat. Sci.) 2019, 38, 28–36. [Google Scholar]

- Jiang, C.B.; Duan, M.K.; Yin, G.Z.; Wu, G.P.; Yu, H. Loading-unloading experiments of coal containing gas under the condition of different moisture contents. J. China Coal Soc. 2016, 41, 2230–2237. [Google Scholar]

- Yao, Q.L.; Chen, T.; Ju, M.H.; Ling, S.; Liu, Y.P.; Li, X.H. Effects of water intrusion on mechanical properties of and crack propagation in coal. Rock Mech. Rock Eng. 2016, 49, 4699–4709. [Google Scholar] [CrossRef]

- Ma, H.F.; Yin, D.W.; Chen, S.J.; Liu, X.Q.; Chen, B. Research on soaking effects on the tensile strength and failure characteristics of rock. Min. Res. Dev. 2018, 38, 56–60. [Google Scholar]

- Li, B.B.; Wang, Z.H.; Ren, C.H.; Zhang, Y.; Xu, J.; Li, J.H. Mechanical properties and damage constitutive model of coal under the coupled hydro-mechanical effect. Rock Soil Mech. 2021, 42, 315–323. [Google Scholar]

- Ai, T.; Wu, S.Y.; Zhang, R.; Gao, M.Z. Changes in the structure and mechanical properties of a typical coal induced by water immersion. Int. J. Rock Mech. Min. Sci. 2021, 138, 104597. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock Mech. Min. Sci. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Chen, G.Q.; LI, T.B.; GUO, F.; Wang, Y.K. Brittle mechanical characteristics of hard rock exposed to moisture. Bull. Eng. Geol. Environ. 2017, 76, 219–230. [Google Scholar] [CrossRef]

- Chen, T.; Yao, Q.L.; Wei, F.; Zhong, Z.H.; Zhou, J.; Wang, C.B.; Li, J. Effects of water intrusion and loading rate on mechanical properties of and crack propagation in coal–rock combinations. J. Cent. S. Univ. 2017, 24, 423–431. [Google Scholar] [CrossRef]

- Jiang, L.J.; Zhao, H.J.; Zhao, Y.Q.; Fang, J.; Cao, Z.G. Study on mechanical properties of coal before and after flooding considering bedding direction. Coal Sci. Technol. 2023, 51, 97–108. [Google Scholar]

- Yao, Q.L.; Wang, W.N.; Yang, S.Y.; Fang, J.; Zhou, B.Q. Direct shear and acoustic emission characteristics of sandy mudstone under the effect of moisture content. J. China Coal Soc. 2021, 46, 2910–2922. [Google Scholar]

- Xia, D.; Yang, T.H.; Xu, T.; Wang, P.T.; Zhao, Y.C. Experimental study on AE properties during the damage process of water-saturated rock specimens based on time effect. J. China Coal Soc. 2015, 40, 337–345. [Google Scholar]

- Ma, S.W.; Liang, H.; Cao, C. Laboratory study of deformational characteristics and acoustic emission properties of coal with different strengths under uniaxial compression. Minerals 2021, 11, 1070. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, W.R.; Lu, W.; Hu, X.M.; Wu, H.; Wang, J.Q.; Kong, B. Study on the effects of temperature and immersion on the acoustic emission and electromagnetic radiation signals of coal rock damage under load. Eng. Geol. 2022, 297, 106503. [Google Scholar] [CrossRef]

- Yao, Q.L.; Wang, W.N.; Zhu, L.; Xia, Z.; Tang, C.J.; Wang, X.H. Effects of moisture conditions on mechanical properties and AE and IR characteristics in coal–rock combinations. Arab. J. Geosci. 2020, 13, 615–630. [Google Scholar] [CrossRef]

- Bai, J.W.; Du, X.J.; Feng, G.R.; Guo, J.; Li, Z.; Qi, T.Y.; Wang, P.F.; Wang, Z.H.; Yang, J. Dynamic mechanical behavior of dry and water saturated igneous rock with AE monitoring. Shock Vib. 2018, 4, 2348394. [Google Scholar]

- National Development and Reform Commission, National Energy Administration. Mine Water Utilization Development Planning; National Development and Reform Commission: Beijing, China, 2013; pp. 3–45.

- Wu, Q.; Shen, J.J.; Wang, Y. Mining techniques and engineering application for “Coal-Water” dual-resources mine. J. China Coal Soc. 2017, 42, 8–16. [Google Scholar]

- International Society for Rock Mechanics Commission on Standardization of Laboratory and Field Tests. Suggested methods for the quantitative description of discontinuities in rock masses. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 319–368. [Google Scholar]

- Galouei, M.; Fakhimi, A. Size effect material ductility and shape of fracture process zone in quasi-brittle materials. Comput. Geotech. 2015, 65, 126–135. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, J.; Liu, X.; Jiang, J.; Liu, B. The role of flaws on crack growth in rock-like material assessed by AE technique. Int. J. Fract. 2015, 193, 99–115. [Google Scholar] [CrossRef]

- Gu, D.Z.; Yan, Y.G.; Zhang, Y.; Wang, E.Z.; Cao, Z.G. Experimental study and numerical simulation for dynamic response of coal pillars in coal mine underground reservoir. J. China Coal Soc. 2016, 41, 1589–1597. [Google Scholar]

- Yang, P. Study on Strength Damage Mechanism of Coal Pillar Dam in Coal Mine Groundwater Reservoir. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Wang, P.T.; Qi, Z.W.; Ma, C.; Cai, M.F. Anisotropic behavior of the seepage-stress coupling mechanical model of coal pillars of underground reservoirs. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 3. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stimpson, B.; Stead, D. Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures. Rock Mech. Rock Eng. 1999, 32, 81–99. [Google Scholar] [CrossRef]

| Time (d) | Size (mm × mm) | Mass Before Immersion (g) | Mass After Immersion (g) | Water Ratio (%) | Before Vp (km/s) | After Vp (km/s) |

|---|---|---|---|---|---|---|

| 0 | 50.06 × 100.10 | 323.90 | 323.90 | 0 | 2.12 | / |

| 1 | 50.02 × 100.00 | 325.70 | 329.10 | 0.89 | 2.34 | 2.45 |

| 3 | 50.06 × 100.00 | 323.60 | 327.60 | 1.61 | 2.24 | 2.48 |

| 5 | 50.00 × 100.04 | 321.40 | 326.30 | 1.31 | 2.19 | 2.50 |

| 7 | 50.02 × 100.04 | 325.40 | 330.80 | 1.66 | 2.18 | 2.41 |

| 10 | 50.11 × 10.10 | 321.5 | 326.6 | 1.59 | 2.22 | 2.43 |

| 15 | 50.10 × 100.30 | 317.4 | 322.9 | 1.73 | 2.19 | 2.45 |

| 20 | 50.00 × 100.34 | 325 | 331.2 | 1.91 | 2.17 | 2.38 |

| 25 | 50.21 × 100.18 | 327.4 | 333.8 | 1.95 | 2.27 | 2.45 |

| 30 | 50.00 × 100.28 | 325.1 | 331.5 | 1.97 | 2.27 | 2.32 |

| Rock Type | Thickness /m | Density /kg·m−3 | Elastic Modulus/GPa | Poisson’s Ratio | Cohesion /MPa | Friction/° | Tensile Strength/MPa | Compressive Strength/MPa |

|---|---|---|---|---|---|---|---|---|

| Aeolian sand | 20 | 1600 | 0.28 | 0.3 | 0.5 | 32 | 0.4 | 17.2 |

| Sandstone | 80 | 2330 | 15.1–29.50 | 0.2–0.34 | 6–13 | 23–35 | 1.4–4.75 | 36–48 |

| 5−2 coal seam | 3 | 1320 | 4.89–9.30 | 0.2–0.34 | 0.5–8.8 | 12–38 | 0.25–1.36 | 13–18 |

| Sandstone | 10~60 | 2380 | 15.1–29.50 | 0.2–0.34 | 6–13 | 23–35 | 1.4–4.75 | 36–48 |

| Floor sandstone | 20 | 2430 | 38.0 | 0.20 | 3.2 | 38 | 2.5 | 36.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Wang, P.; Zhang, K.; Gao, Y.; Qi, Z.; Cai, M. Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction. Appl. Sci. 2025, 15, 6700. https://doi.org/10.3390/app15126700

Zhu H, Wang P, Zhang K, Gao Y, Qi Z, Cai M. Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction. Applied Sciences. 2025; 15(12):6700. https://doi.org/10.3390/app15126700

Chicago/Turabian StyleZhu, Haihua, Peitao Wang, Kewei Zhang, Yijun Gao, Zhenwu Qi, and Meifeng Cai. 2025. "Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction" Applied Sciences 15, no. 12: 6700. https://doi.org/10.3390/app15126700

APA StyleZhu, H., Wang, P., Zhang, K., Gao, Y., Qi, Z., & Cai, M. (2025). Influence of Water Immersion on Coal Rocks and Failure Patterns of Underground Coal Pillars Considering Strength Reduction. Applied Sciences, 15(12), 6700. https://doi.org/10.3390/app15126700