Investigation of the Applicability of Acoustic Emission Signals for Adaptive Control in CNC Wood Milling

Abstract

1. Introduction

- The investigation of AE signal characteristics during the CNC milling of wood-based materials under varying machining conditions;

- The evaluation of the feasibility of using AE signals for adaptive control by linking AE features to critical machining variables;

- The identification of challenges and limitations associated with AE-based monitoring, including signal variability due to material heterogeneity and environmental influences.

2. Materials and Methods

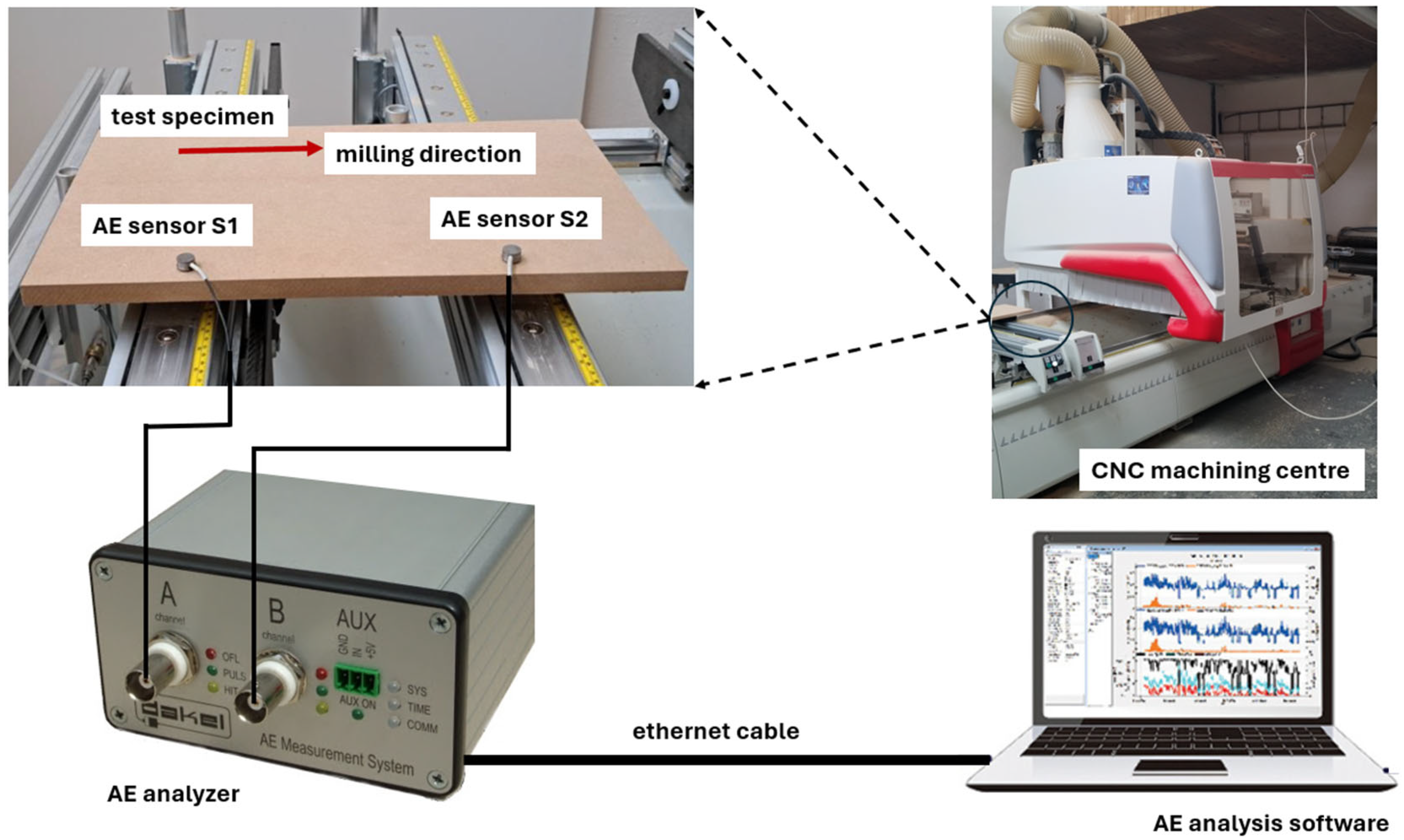

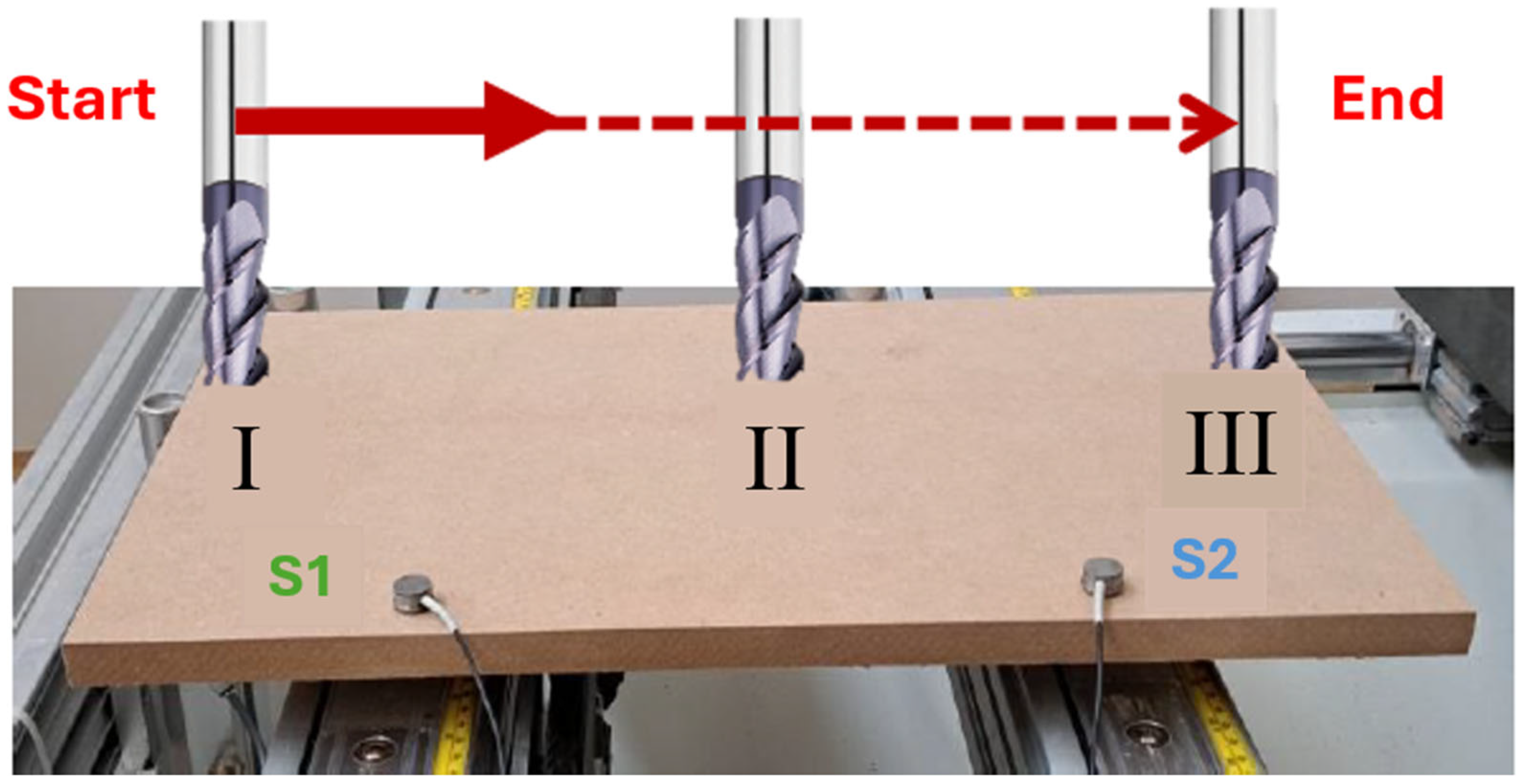

2.1. Experimental Setup

2.2. Test Specimens

2.3. Cutting Conditions

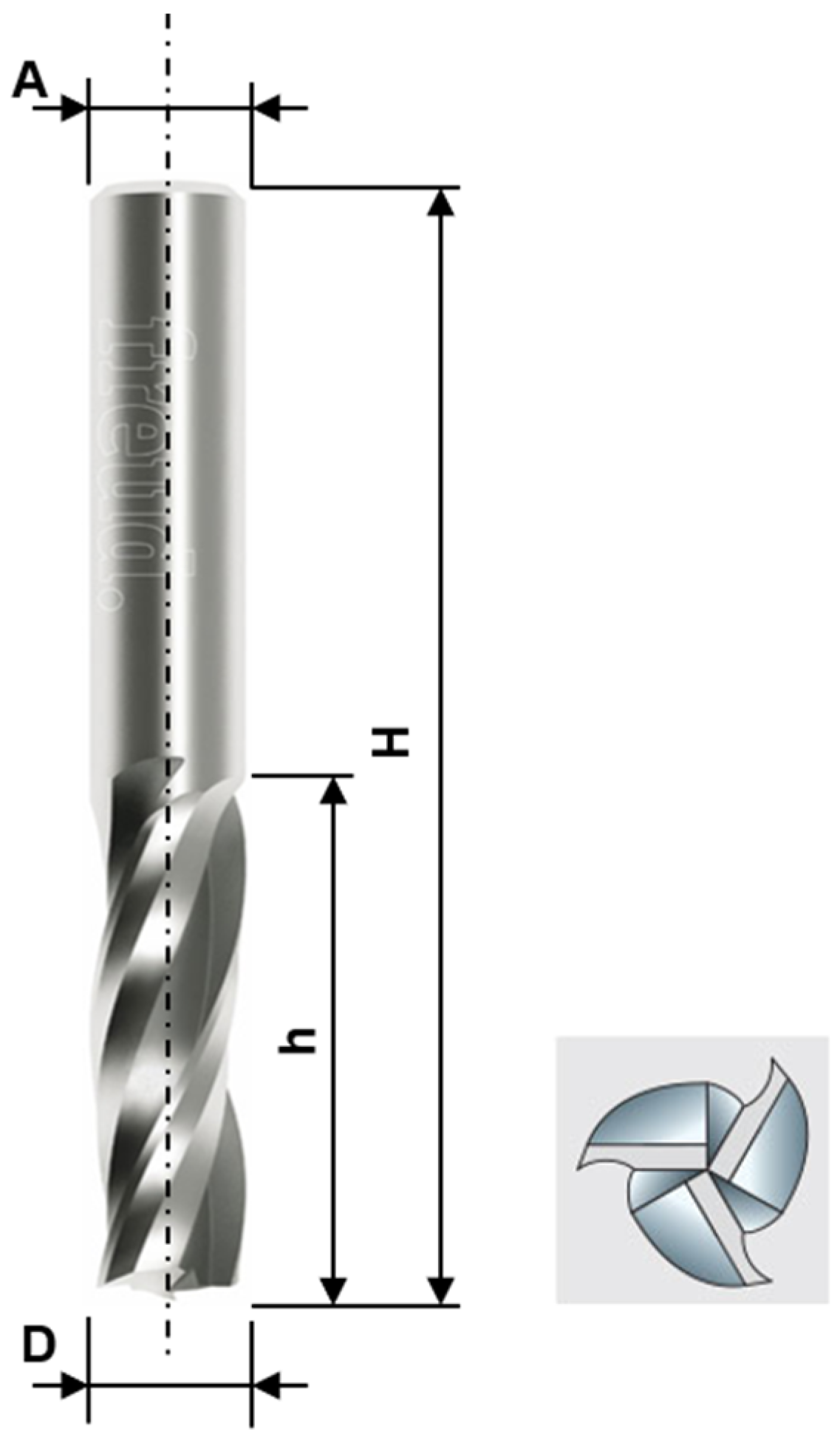

2.4. Cutting Tool

2.5. AE Sensors Calibration

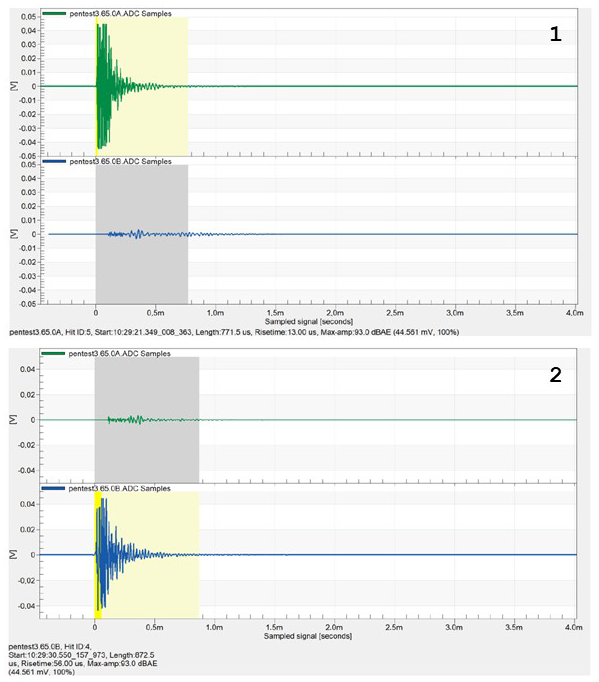

2.6. AE Signal Analysis

2.7. Data Analysis

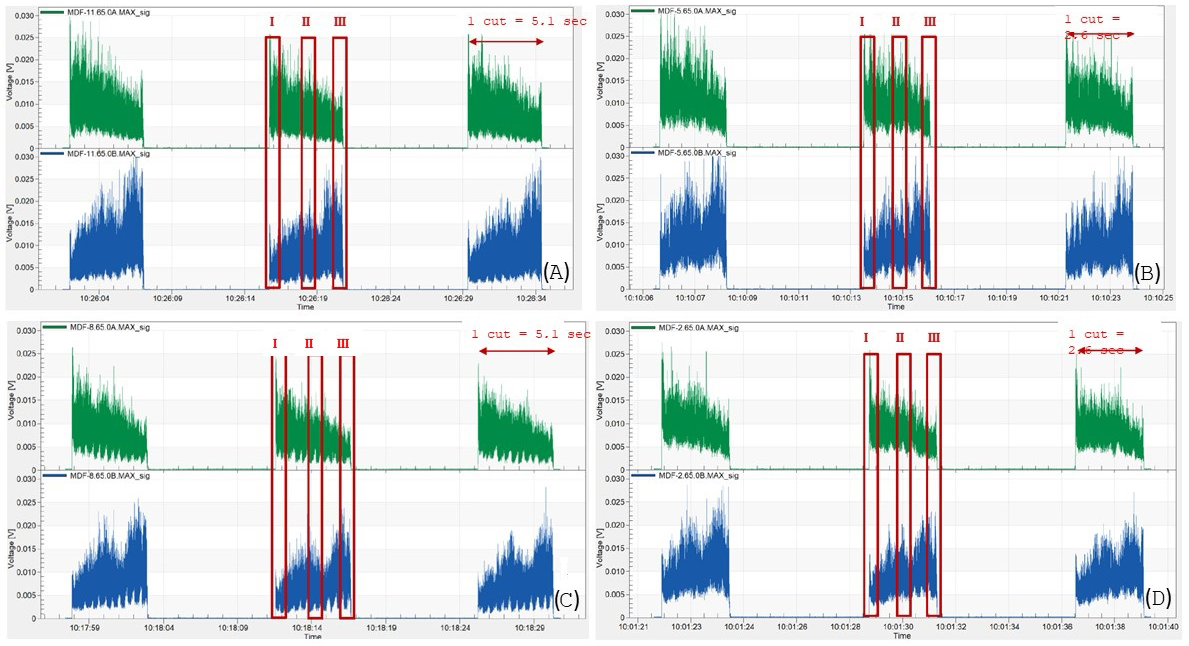

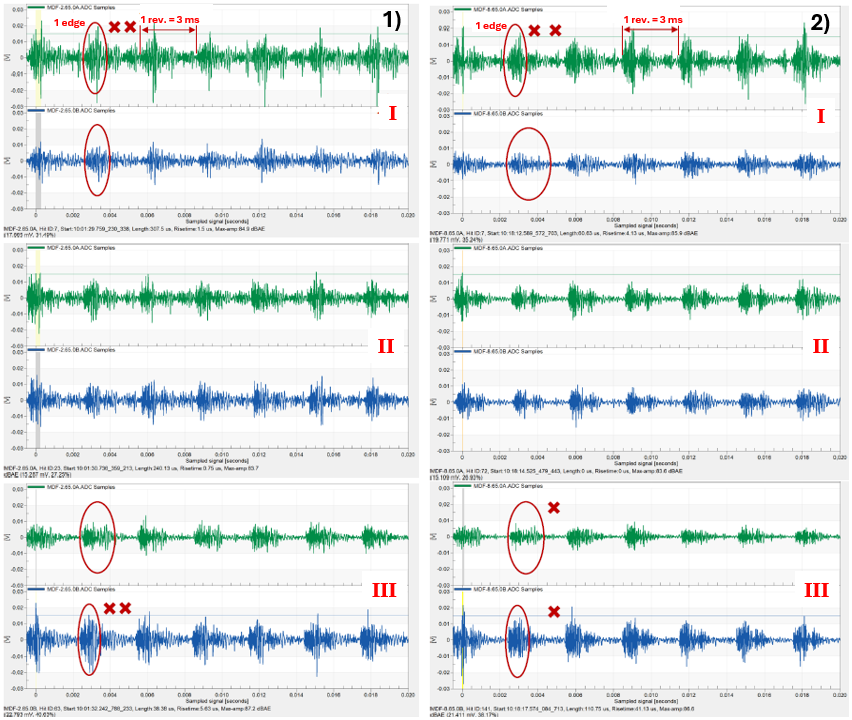

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ouyang, Z.; Wu, Y.; Shao, H.; Wang, X.; Tao, T.; Chen, X.; Peng, T. Method for Drill-Bit Arrangement in CNC Woodworking Drilling Machine for Mass Customization. J. Manuf. Syst. 2025, 78, 200–212. [Google Scholar] [CrossRef]

- Adamčík, L.; Kminiak, R.; Banski, A. Comparison of the Roughness of the CNC Milled Surface of Selected Wood Species. Acta Fac. Xylologiae Zvolen 2024, 66, 61–74. [Google Scholar]

- Chen, C. Application of Support Vector Machine–Based CNC Machining in Furniture Product Visual Design and Production Control Process. Int. J. Adv. Manuf. Technol 2024, 1–9. [Google Scholar] [CrossRef]

- Kim, S.G.; Heo, E.Y.; Lee, H.G.; Kim, D.W.; Yoo, N.H.; Kim, T.H. Advanced Adaptive Feed Control for CNC Machining. Robot. Comput. Integr. Manuf. 2024, 85, 102621. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Wang, K.; Qian, N.; Fu, Y.; Cao, S. Active-Passive Hybrid Feed Rate Control Systems in CNC Machining: Mitigating Force Fluctuations and Enhancing Tool Life. J. Manuf. Syst. 2024, 77, 184–195. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Fecheira, J.S.; Lopes, H.M.; Martinho, R.P.; Casais, R.B.; Ferreira, L.P. Cutting Forces Assessment in CNC Machining Processes: A Critical Review. Sensors 2020, 20, 4536. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, P.; Hu, P.; Yin, Y.; Zhou, H.; Chen, J.; Yang, J. Multi-Objective Feed Rate Optimization of Three-Axis Rough Milling Based on Artificial Neural Network. Int. J. Adv. Manuf. Technol. 2021, 114, 1323–1339. [Google Scholar] [CrossRef]

- Xu, G.; Chen, J.; Zhou, H.; Yang, J.; Hu, P.; Dai, W. Multi-Objective Feedrate Optimization Method of End Milling Using the Internal Data of the CNC System. Int. J. Adv. Manuf. Technol. 2019, 101, 715–731. [Google Scholar] [CrossRef]

- Petráček, P.; Vlk, B.; Švéda, J. Linear Programming Feedrate Optimization. Int. J. Adv. Manuf. Technol. 2022, 120, 3625–3646. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Gnanasekaran, S.; Thangamuthu, M.; Rakkiyannan, J. Machine-Learning- and Internet-of-Things-Driven Techniques for Monitoring Tool Wear in Machining Process: A Comprehensive Review. J. Sens. Actuator Netw. 2024, 13, 53. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool Condition Monitoring Techniques in Milling Process—A Review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- Lazar, E.; Bennett, K.S.; Hurtado Carreon, A.; Veldhuis, S.C. An Automated Feature-Based Image Registration Strategy for Tool Condition Monitoring in CNC Machine Applications. Sensors 2024, 24, 7458. [Google Scholar] [CrossRef]

- Kotha Amarnath, S.; Inturi, V.; Rajasekharan, S.G.; Priyadarshini, A. Combining Sensor Fusion and a Machine Learning Framework for Accurate Tool Wear Prediction During Machining. Machines 2025, 13, 132. [Google Scholar] [CrossRef]

- Khadka, S.; Rahman Rashid, R.A.; Stephens, G.; Papageorgiou, A.; Navarro-Devia, J.; Hägglund, S.; Palanisamy, S. Predicting Cutting Tool Life: Models, Modelling, and Monitoring. Int. J. Adv. Manuf. Technol. 2025, 136, 3037–3076. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Ercetin, A.; Der, O.; Mikolajczyk, T.; Giasin, K. State-of-the-Art Review of Applications of Image Processing Techniques for Tool Condition Monitoring on Conventional Machining Processes. Int. J. Adv. Manuf. Technol. 2024, 130, 57–85. [Google Scholar] [CrossRef]

- Przybyś-Małaczek, A.; Antoniuk, I.; Szymanowski, K.; Kruk, M.; Kurek, J. Application of Machine Learning Algorithms for Tool Condition Monitoring in Milling Chipboard Process. Sensors 2023, 23, 5850. [Google Scholar] [CrossRef]

- Guo, X.; Wang, J.; Buck, D.; Zhu, Z.; Ekevad, M. Cutting Forces and Cutting Quality in the Up-Milling of Solid Wood Using Ceramic Cutting Tools. Int. J. Adv. Manuf. Technol. 2021, 114, 1575–1584. [Google Scholar] [CrossRef]

- Sörnmo, O.; Olofsson, B.; Robertsson, A.; Johansson, R. Learning Approach to Cycle-Time-Minimization of Wood Milling Using Adaptive Force Control. J. Manuf. Sci. Eng. 2015, 138, 011013. [Google Scholar] [CrossRef]

- Cao, K.; Han, J.; Xu, L.; Shi, T.; Liao, G.; Liu, Z. Real-Time Tool Condition Monitoring Method Based on in Situ Temperature Measurement and Artificial Neural Network in Turning. Front. Mech. Eng. 2022, 17, 5. [Google Scholar] [CrossRef]

- Saloni, D.E.; Lemaster, R.L.; Jackson, S.D. Process Monitoring Evaluation and Implementation for the Wood Abrasive Machining Process. Sensors 2010, 10, 10401–10412. [Google Scholar] [CrossRef]

- Kminiak, R.; Němec, M.; Igaz, R.; Gejdoš, M. Advisability-Selected Parameters of Woodworking with a CNC Machine as a Tool for Adaptive Control of the Cutting Process. Forests 2023, 14, 173. [Google Scholar] [CrossRef]

- Dong, W.; Xiong, X.; Ma, Y.; Yue, X. Woodworking Tool Wear Condition Monitoring during Milling Based on Power Signals and a Particle Swarm Optimization-Back Propagation Neural Network. Appl. Sci. 2021, 11, 9026. [Google Scholar] [CrossRef]

- Dong, W.; Guo, X.; Hu, Y.; Wang, J.; Tian, G. Discrete wavelet transformation and genetic algorithm—Back propagation neural network applied in monitoring woodworking tool wear conditions in the milling operation spindle power signals. BioResources 2021, 16, 2369–2384. [Google Scholar] [CrossRef]

- Zhu, Z.; Buck, D.; Guo, X.; Xiong, X.; Xu, W.; Cao, P. Energy Efficiency Optimization for Machining of Wood Plastic Composite. Machines 2022, 10, 104. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. Intelligent Wood Machining Monitoring Using Vibration Signals Combined with Self-Organizing Maps for Automatic Feature Selection. Int. J. Adv. Manuf. Technol. 2020, 108, 1811–1825. [Google Scholar] [CrossRef]

- Apostolou, G.; Ntemi, M.; Paraschos, S.; Gialampoukidis, I.; Rizzi, A.; Vrochidis, S.; Kompatsiaris, I. Novel Framework for Quality Control in Vibration Monitoring of CNC Machining. Sensors 2024, 24, 307. [Google Scholar] [CrossRef] [PubMed]

- Hortobágyi, Á.; Koleda, P.; Koleda, P.; Kminiak, R. Effect of Milling Parameters on Amplitude Spectrum of Vibrations during Milling Materials Based on Wood. Appl. Sci. 2023, 13, 5061. [Google Scholar] [CrossRef]

- Li, G.; Shang, X.; Sun, L.; Fu, B.; Yang, L.; Zhou, H. Application of audible sound signals in tool wear monitoring: A review. J. Adv. Manuf. Sci. Technol. 2025, 5, 2025003. [Google Scholar] [CrossRef]

- Ahmed, M.; Kamal, K.; Ratlamwala, T.A.H.; Hussain, G.; Alqahtani, M.; Alkahtani, M.; Alatefi, M.; Alzabidi, A. Tool Health Monitoring of a Milling Process Using Acoustic Emissions and a ResNet Deep Learning Model. Sensors 2023, 23, 3084. [Google Scholar] [CrossRef]

- Derbas, M.; Frömel-Frybort, S.; Möhring, H.-C.; Riegler, M. Accelerated Singular Spectrum Analysis and Machine Learning to Investigate Wood Machining Acoustics. Mech. Syst. Signal Process. 2025, 223, 111879. [Google Scholar] [CrossRef]

- Wilkowski, J.; Górski, J. Vibro-acoustic signals as a source of information about tool wear during laminated chipboard milling. Wood Res. 2011, 56, 57–66. [Google Scholar]

- Górski, J.; Szymanowski, K.; Podziewski, P.; Śmietańska, K.; Czarniak, P.; Cyrankowski, M. Use of cutting force and vibro-acoustic signals in tool wear monitoring based on multiple regression technique for compreg milling. Bioresources 2019, 14, 3379–3388. [Google Scholar] [CrossRef]

- Aguilera, A.; Vega, M.; Méausoone, P.-J. Effects of Grain Angle on the Amplitudes of Acoustic Emission and Surface Roughness in Wood Machining. Wood Sci. Technol. 2007, 41, 373–381. [Google Scholar] [CrossRef]

- Iskra, P.; Hernández, R.E. Toward a Process Monitoring and Control of a CNC Wood Router: Development of an Adaptive Control System for Routing White Birch. Wood Fiber Sci. 2010, 46, 523–535. [Google Scholar]

- Chen, Y.; Tian, J.; Guo, X.; Na, B. Tool Condition Monitoring Strategies from Metal Cutting: Insights for Optimizing Wood-Based Material Processing. Eur. J. Wood Prod. 2025, 83, 46. [Google Scholar] [CrossRef]

- Aguilera, A.; Méausoone, P.J.; Rolleri, A.; Barros, J.L.; Burgos, F.; Aguilar, C. Advances on Indirect Methods to Evaluate Tool Wear for Radiata Pine Solid Wood Molding. Wear 2016, 350–351, 27–34. [Google Scholar] [CrossRef]

- Nasir, V.; Dibaji, S.; Alaswad, K.; Cool, J. Tool Wear Monitoring by Ensemble Learning and Sensor Fusion Using Power, Sound, Vibration, and AE Signals. Manuf. Lett. 2021, 30, 32–38. [Google Scholar] [CrossRef]

- Derbas, M.; Jaquemod, A.; Frömel-Frybort, S.; Güzel, K.; Moehring, H.-C.; Riegler, M. A Machine Learning Approach to Predict Properties of Wood Products During Milling. For. Prod. J. 2024, 74, 1–8. [Google Scholar] [CrossRef]

- ISO 12716:2001; Non-Destructive Testing—Acoustic Emission Inspection. ISO: Geneva, Switzerland, 2001. Available online: http://www.iso.org/standard/34090.html (accessed on 9 May 2025).

- Holford, K.M. Acoustic Emission–Basic Principles and Future Directions. Strain 2000, 36, 51–54. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Umer, U.; Mohany, A. Application of Acoustic Emissions in Machining Processes: Analysis and Critical Review. Int. J. Adv. Manuf. Technol. 2018, 98, 1391–1407. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. Characterization, Optimization, and Acoustic Emission Monitoring of Airborne Dust Emission during Wood Sawing. Int. J. Adv. Manuf. Technol. 2020, 109, 2365–2375. [Google Scholar] [CrossRef]

- Zhuo, R.; Deng, Z.; Chen, B.; Liu, G.; Bi, S. Overview on Development of Acoustic Emission Monitoring Technology in Sawing. Int. J. Adv. Manuf. Technol. 2021, 116, 1411–1427. [Google Scholar] [CrossRef]

- EN 316; Wood Fibre Boards. Definition, Classification and Symbols. CEN: Brussels, Belgium, 2009.

- EN 622-5; Fibreboards. Specifications. Part 5: Requirements for Dry Process Boards (MDF). CEN: Brussels, Belgium, 2009.

- EN ISO 12460-5; Wood-Based Panels. Determination of Formaldehyde Release. Part 5: Extraction Method (Called the Perforator Method). ISO: Geneva, Switzerland, 2015.

- EN 14584; Non-Destructive Testing. Acoustic Emission. Examination of Metallic Pressure Equipment During Proof Testing. Planar Location of AE Sources. CEN: Brussels, Belgium, 2013.

- Twardowski, P.; Tabaszewski, M.; Wiciak-Pikuła, M.; Felusiak-Czyryca, A. Identification of Tool Wear Using Acoustic Emission Signal and Machine Learning Methods. Precis. Eng. 2021, 72, 738–744. [Google Scholar] [CrossRef]

- Tien, D.H.; Thoa, P.T.T.; Duy, T.N. Application of Wavelet Ratio between Acoustic Emission and Cutting Force Signal Decomposing in Intelligent Monitoring of Cutting Tool Wear When Turning SKD 61. Int. J. Interact. Manuf. 2024, 18, 525–539. [Google Scholar] [CrossRef]

- Maia, L.H.A.; Abrão, A.M.; Vasconcelos, W.L.; Júnior, J.L.; Fernandes, G.H.N.; Machado, Á.R. Enhancing Machining Efficiency: Real-Time Monitoring of Tool Wear with Acoustic Emission and STFT Techniques. Lubricants 2024, 12, 380. [Google Scholar] [CrossRef]

- Uematsu, M.; Kato, K.; Watanabe, K.; Watanobe, T.; Natsu, W. Cutting Tool Monitoring Technology Using Wireless Acoustic Emission Sensor. Int. J. Autom. Technol. 2024, 18, 812–820. [Google Scholar] [CrossRef]

- Mathiyazhagan, V.; Meena, A. Predictive Modelling of Tool Wear in CFRP Drilling Using Acoustic Emission Sensors under Dry and Cryogenic Conditions. Wear 2025, 570, 205930. [Google Scholar] [CrossRef]

- Karabacak, Y.E. Intelligent Milling Tool Wear Estimation Based on Machine Learning Algorithms. J. Mech. Sci. Technol. 2024, 38, 835–850. [Google Scholar] [CrossRef]

- Mian, A.J.; Driver, N.; Mativenga, P.T. Estimation of Minimum Chip Thickness in Micro Milling Using Acoustic Emission. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1535–1551. [Google Scholar] [CrossRef]

| Technical Characteristic | Value |

|---|---|

| Density | 750 kg·m−3 ± 7% |

| Swelling in thickness after 24 h | ≤12% |

| Bending strength | ≥20 N·mm−2 |

| Modulus of elasticity in bending | ≥2200 N·mm−2 |

| Internal bond | ≥0.55 N·mm−2 |

| Moisture content | 4% ÷ 11% |

| Labeling | Tool Revolution (rev.min−1) | Feed Speed (m.min−1) |

|---|---|---|

| A | 10,000 | 6 |

| B | 10,000 | 12 |

| C | 20,000 | 6 |

| D | 20,000 | 12 |

| Parameter | Value |

|---|---|

| D (mm) | 20 |

| h (mm) | 92 |

| H (mm) | 170 |

| A (mm) | 20 |

| Number of cutting edges | 3 |

| Maximal revolution (rev.min−1) | 25,000 |

| Labeling | Tool Revolution (rev.min−1) | Feed Speed (m.min−1) | Number of Revolutions per One Cut | Number of Data |

|---|---|---|---|---|

| A | 10,000 | 6 | 833 | n = 61,324 |

| B | 10,000 | 12 | 417 | n = 31,132 |

| C | 20,000 | 6 | 1667 | n = 61,326 |

| D | 20,000 | 12 | 833 | n = 31,156 |

| Cutting Conditions | Measurement | AE Signal Original Data (dB) | AE Signal Normalized Data (dB) | ||||

|---|---|---|---|---|---|---|---|

| Average | Sum | SD | Average | Sum | SD | ||

| A | 1 | 67.041 | 684,220.034 | 4.978 | 0.079 | 804.977 | 0.006 |

| 2 | 65.116 | 666,785.827 | 5.663 | 0.077 | 784.445 | 0.007 | |

| 3 | 65.225 | 666,469.970 | 5.429 | 0.077 | 784.030 | 0.006 | |

| 4 | 65.391 | 668,553.260 | 5.424 | 0.077 | 786.524 | 0.006 | |

| 5 | 65.314 | 667,901.824 | 5.602 | 0.077 | 785.744 | 0.007 | |

| 6 | 65.407 | 667,805.955 | 5.375 | 0.077 | 785.668 | 0.006 | |

| B | 1 | 69.621 | 361,330.751 | 4.606 | 0.080 | 416.771 | 0.005 |

| 2 | 67.891 | 351,810.091 | 4.630 | 0.078 | 405.792 | 0.005 | |

| 3 | 67.836 | 351,119.527 | 4.717 | 0.078 | 404.976 | 0.005 | |

| 4 | 69.549 | 361,097.696 | 4.727 | 0.080 | 416.511 | 0.005 | |

| 5 | 67.967 | 352,477.798 | 4.981 | 0.078 | 406.565 | 0.006 | |

| 6 | 67.965 | 353,824.205 | 4.933 | 0.078 | 408.081 | 0.006 | |

| C | 1 | 65.007 | 664,633.701 | 5.016 | 0.076 | 781.932 | 0.006 |

| 2 | 65.077 | 665,473.423 | 4.989 | 0.077 | 782.930 | 0.006 | |

| 3 | 65.210 | 666,571.525 | 4.885 | 0.077 | 784.169 | 0.006 | |

| 4 | 66.778 | 683,936.462 | 4.866 | 0.079 | 804.685 | 0.006 | |

| 5 | 65.342 | 667,274.433 | 4.859 | 0.077 | 785.019 | 0.006 | |

| 6 | 65.481 | 667,910.095 | 4.730 | 0.077 | 785.764 | 0.006 | |

| D | 1 | 69.661 | 361,540.940 | 3.916 | 0.080 | 417.013 | 0.005 |

| 2 | 68.258 | 354,669.920 | 4.413 | 0.079 | 409.070 | 0.005 | |

| 3 | 68.214 | 354,710.700 | 4.584 | 0.079 | 409.116 | 0.005 | |

| 4 | 69.675 | 362,586.659 | 4.352 | 0.080 | 418.184 | 0.005 | |

| 5 | 68.404 | 354,607.667 | 4.225 | 0.079 | 409.056 | 0.005 | |

| 6 | 68.390 | 354,399.495 | 4.093 | 0.079 | 408.767 | 0.005 | |

| Cutting Conditions Comparison | Z Statistic | p-Value | |

|---|---|---|---|

| Group 1 | Group 2 | ||

| A | B | 46.80 | <0.001 |

| A | C | 0.86 | 0.388 |

| A | D | 57.93 | <0.001 |

| B | C | 47.50 | <0.001 |

| B | D | 9.65 | <0.001 |

| C | D | 58,64 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dado, M.; Koleda, P.; Vlašic, F.; Salva, J. Investigation of the Applicability of Acoustic Emission Signals for Adaptive Control in CNC Wood Milling. Appl. Sci. 2025, 15, 6659. https://doi.org/10.3390/app15126659

Dado M, Koleda P, Vlašic F, Salva J. Investigation of the Applicability of Acoustic Emission Signals for Adaptive Control in CNC Wood Milling. Applied Sciences. 2025; 15(12):6659. https://doi.org/10.3390/app15126659

Chicago/Turabian StyleDado, Miroslav, Peter Koleda, František Vlašic, and Jozef Salva. 2025. "Investigation of the Applicability of Acoustic Emission Signals for Adaptive Control in CNC Wood Milling" Applied Sciences 15, no. 12: 6659. https://doi.org/10.3390/app15126659

APA StyleDado, M., Koleda, P., Vlašic, F., & Salva, J. (2025). Investigation of the Applicability of Acoustic Emission Signals for Adaptive Control in CNC Wood Milling. Applied Sciences, 15(12), 6659. https://doi.org/10.3390/app15126659