Chloride-Induced Corrosion Effects on the Structural Performance of Concrete with Rebar and Fibres: A Review

Abstract

1. Introduction

2. FRC Under Chloride Ingress

2.1. Behaviour of FRC Under Tensile Stress

2.2. Impact of Fibres on Chloride Ingress in Concrete

| Paper | w/b | Duration [d] | Material | Vf [%] | NaCl [%] | w [mm] | Conclusion |

|---|---|---|---|---|---|---|---|

| [43] | 0.30 | 91 | MSFRC, SFRC, HyFRC 1 | SF: 0.25–1.00, PPF: 0.15–0.45 | 10.0 | 0.00 |

|

| [44] | 0.31 | - | PC, SFRC | SF: 0.76 | 10.0 | 0.00 |

|

| [45] | 0.32 | 91 | PC, MSFRC | PPF: 0.50–1.50 | 10.0 | 0.00 |

|

| [46] | 0.62 | - | PC, MSFRC | PPF: 0.05–0.15 | 3.0 | 0.00 |

|

| [47] | 0.60 | 120 | PC, MSFRC, SFRC | PPF: 0.40–0.80, S: 0.40–0.80 | 100.0 | 0.00 |

|

| [48] | 0.43 | 28 | PC, MSFRC, SFRC, HyFRC | PPF: 0.40–0.60, S: 0.65–0.85 | - | 0.00 |

|

| [49] | 0.32 | - | PC, MSFRC | PPF: 0.05–0.44 | - | 0.00 |

|

| [50] | 0.59 | 90 | PC, HyFRC | PPF: 0.12, S: 0.52 | 3.0, 3.5 and 10.0 | 0.00 |

|

| [51] | 0.41 | - | PC, MSFRC | PPF: 0.10–0.50 | 3.0 | 0.00 |

|

| [52] | 0.78, 0.48, 0.36 | 210 | SFRC | SF: 0.50 | 3.5 | 0.00 |

|

| [53] | 0.60 | - | PC, SFRC, MSFRC | SF: 0.50–1.25, PPF: 0.50–1.25 | - | 0.00 |

|

| [54] | 0.30 | 180 | PC, SFRC | SF: 1.50 | 3.5 | 0.00 |

|

| [55] | 0.60 | - | PC, MSFRC | PPF: 0.10–0.50 | - | 0.00 |

|

| [56] | 0.42 | - | PC, MSFRC | PPF: 0.06–0.09 | - | 0.00 |

|

| [57] | 0.48 | - | PC, MSFRC | PPF: 0.05–0.22 | - | 0.00 |

|

| [58] | 0.40 | 180 | PC, SFRC | SF: 0.50 | 3.5–7.0 | 0.00–0.30 |

|

| [59] | 0.50 | 238 | SFRC | SF: 0.32 | 5.0 | 0.50–0.60 |

|

| [60] | 0.43 | - | PC, MSFRC | PPF: 0.44–0.66 | - | 0.00–0.27 |

|

| [61] | 0.30 and 0.40 | 330 | PC, MSFRC | PPF: 0.75–1.00 | 10.0 | 0.02–0.28 |

|

| [62] | 0.43 | 90 | PC, SFRC | SF: 1.00 | 3.5 | 0.50 and 1.00 |

|

| [9] | 0.60 | 365 | SFRC | SF: 0.50 | 3.5 | 0.50 |

|

| [63] | 0.45 | - | PC, SFRC | SF: 0.50 and 1.00 | - | 0.00–0.50 |

|

| [64] | 0.43 | - | PC, SFRC, MSFRC, HyFRC | SF: 0.23, PP: 1.96 | 3.0 | 0.00 |

|

| [65] | 0.35 | 30 | PC, MSFRC | PVAF: 0.30–1.50 | 5.0 | 0.00 |

|

3. RR-FRC Under Chloride Ingress

3.1. Corrosion Initiation and Corrosion Propagation in RR-FRC

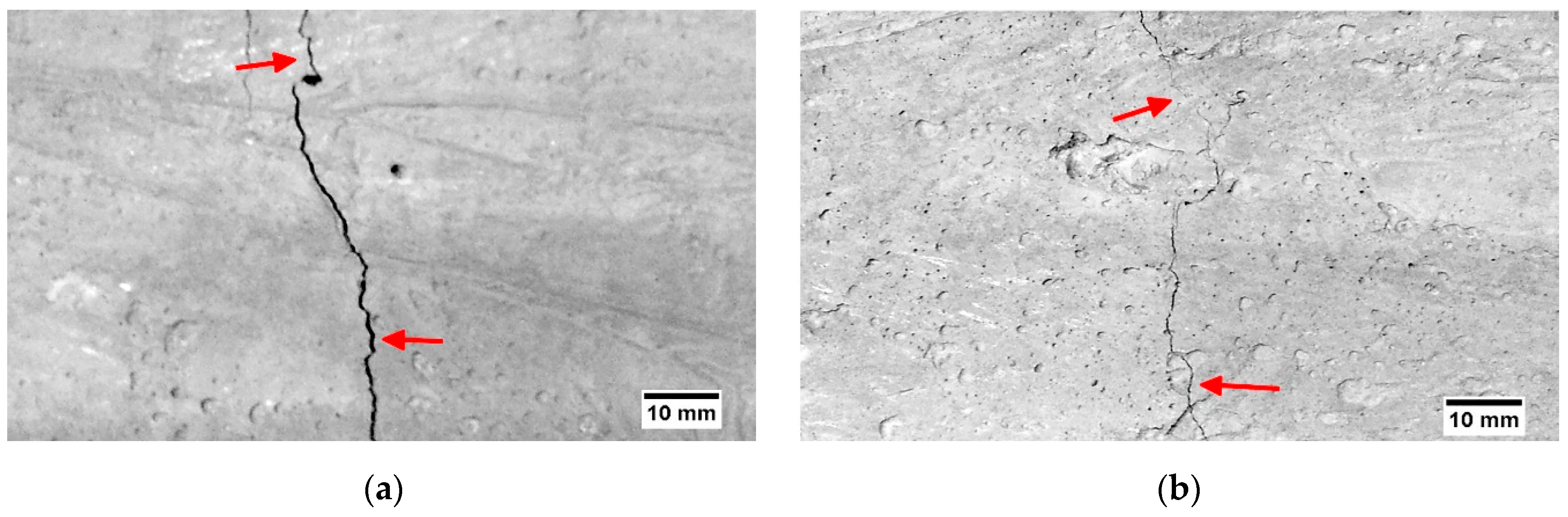

3.1.1. Effects of Cracks on Corrosion Initiation and Propagation

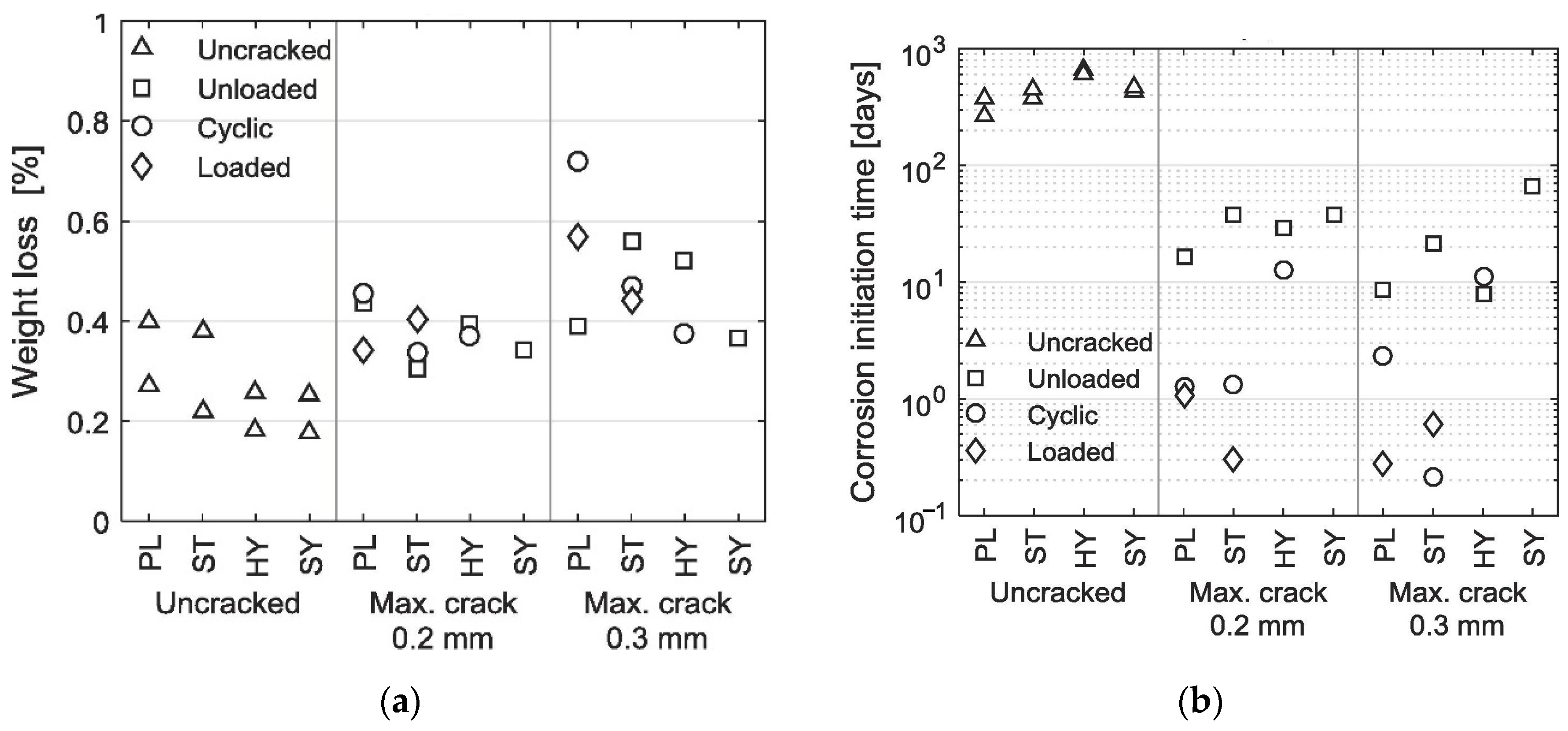

3.1.2. Effects of Loading Conditions on Corrosion Initiation and Propagation

3.1.3. Other Parameters Influencing Corrosion Initiation and Propagation

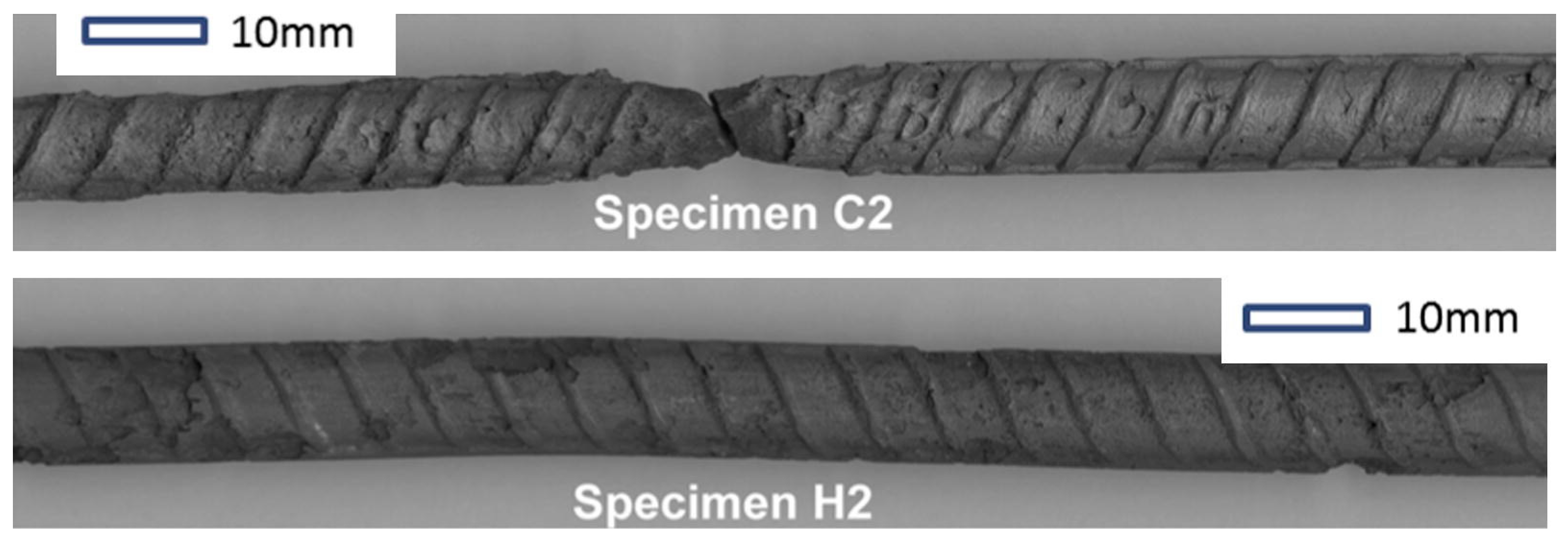

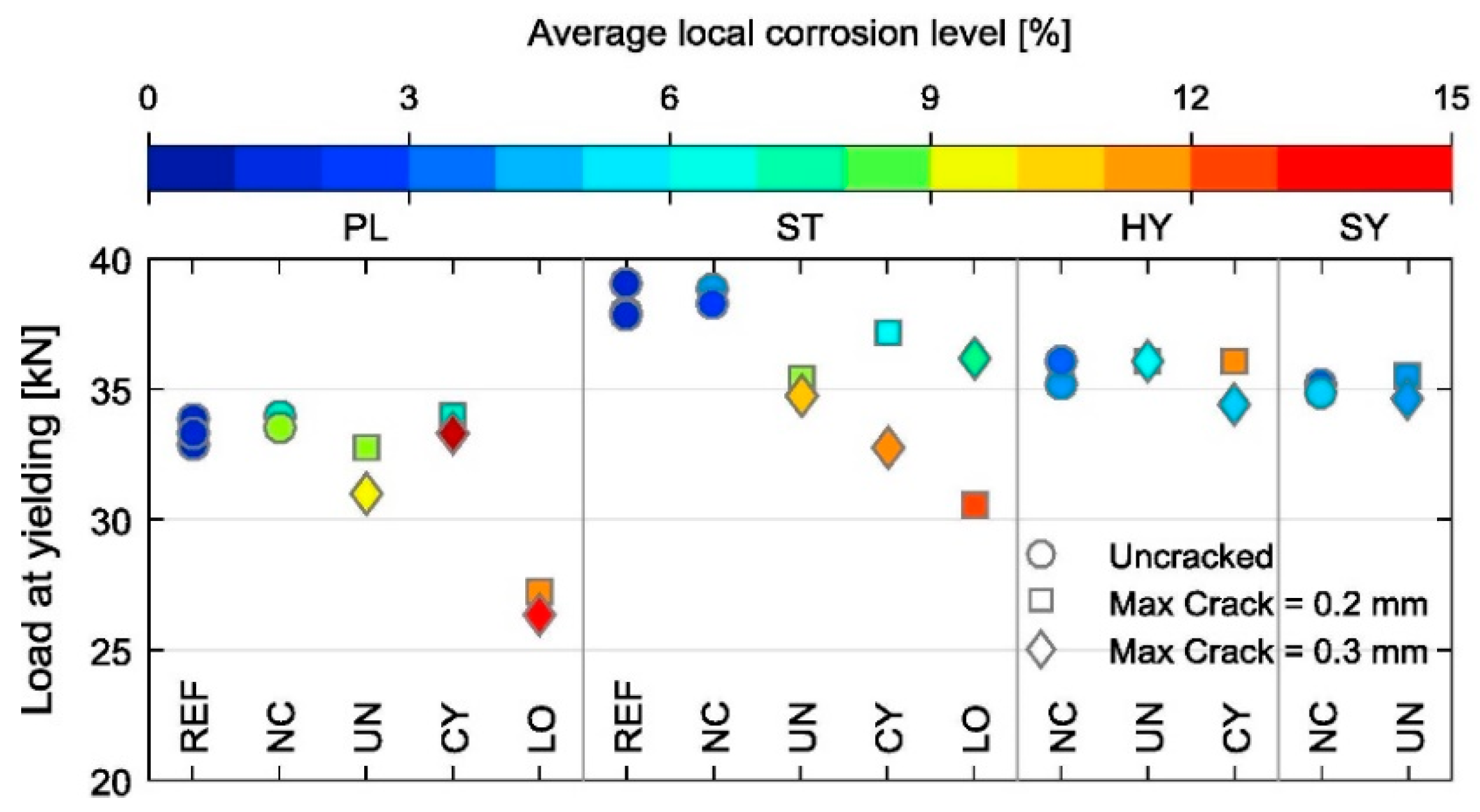

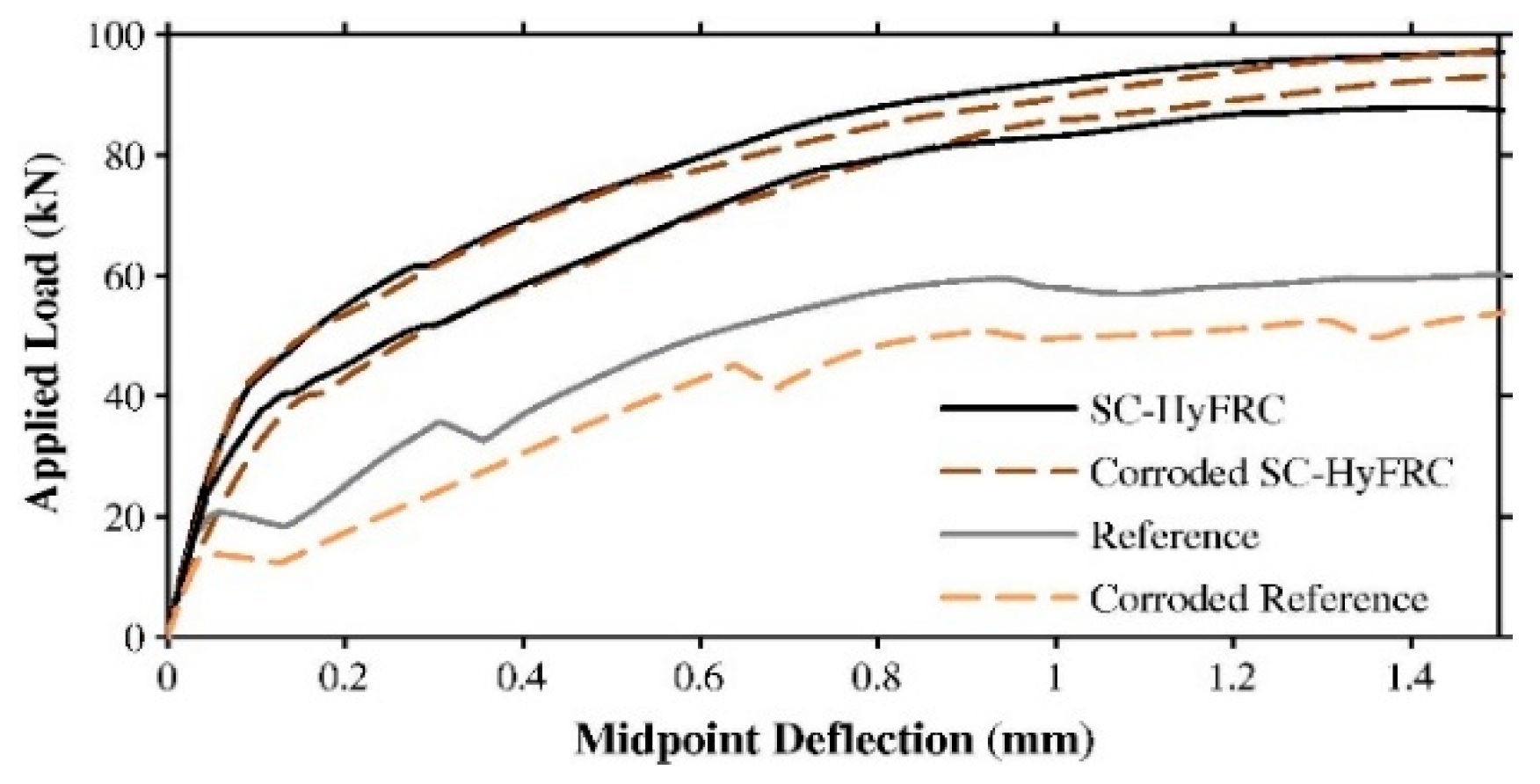

3.2. Effects on Load-Bearing Capacity of RR-FRC

4. Discussion

5. Conclusions and Future Research Needs

- Based on the electrochemical measurements of corrosion potential (Ecorr) or corrosion current density (icorr), corrosion initiation was prolonged in RR-FRC elements relative to RC ones. Furthermore, the evolution of Ecorr, icorr, over time and the gravimetric loss of rebar mass after exposure imply a better performance of RR-FRC in the propagation phase.

- Corrosion of RR-FRC elements is governed by the same mechanisms as corrosion in RC, and as such, similar strategies may be used to mitigate it (related to the mix design, porosity, impermeability, etc.).

- Based on the recorded ultimate and yield loads (and their corresponding deflections), in general, the degradation of load-bearing capacity (relative to uncorroded elements) was lower in RR-FRC than in RC elements. In a smaller number of instances, where degradation of RC was lower than that of RR-FRC relative to their reference counterparts, corroded RR-FRC still outperformed corroded RC in absolute terms.

- Fibres prove effective in preserving the ductile failure mechanism in flexure in corroding RR-FRC elements, whereas corroded RC elements tend to fail abruptly, changing the failure mechanism from ductile to brittle. Furthermore, a comparison of ultimate deflection (or deformation) indicates that corroded RR-FRC elements exhibit greater overall ductility than RC.

- The negative effects of cracking on durability (corrosion initiation and propagation) persist for the RR-FRC elements, but their effects are mitigated by the presence of fibres. However, different campaigns reported vastly different corrosion initiation times, even for the same value of crack width.

- More than crack widths themselves, the loading conditions seem to have a more dominant effect on the performance of RR-FRC under chloride ingress, both on the corrosion initiation and propagation, and consequently, the level of degradation of load-bearing capacity. There is a strong correlation between damage at the steel–concrete interface and degradation of structural performance. Namely, cyclically loaded elements were found to exhibit the highest degradation of load-bearing capacity (even if they were left non-loaded afterwards), followed by elements under static sustained loads, and finally, by undamaged (non-loaded) elements. In this regard, the use of fibres may be especially important, as they mitigate the level of damage at the ITZ.

- There is no sufficient evidence to claim the superiority of one fibre type (or one RR-FRC type) over others.

- Due to the potential interference effects of DC usage to accelerate corrosion and fibres on the state of the ITZ, a direct comparison between RC and different types of RR-FRC might be complicated if a DC with high intensity is used.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC | Direct current |

| EU | European Union |

| FRC | Fibre-reinforced concrete |

| GDP | Gross domestic product |

| HPC | High-performance concrete |

| HyFRC | Hybrid-fibre-reinforced concrete |

| ITZ | Interfacial zone |

| MS | Macro-synthetic |

| MSFRC | Macro-synthetic-fibre-reinforced concrete |

| NACE | National Association of Corrosion Engineers |

| NaCl | Sodium chloride |

| PC | Plain concrete |

| PE | Polyethylene |

| PEF | Polyethylene fibres |

| PP | Polypropylene |

| PPF | Polypropylene fibres |

| PVA | Polyvinyl alcohol |

| PVAF | Polyvinyl alcohol fibre |

| RC | Reinforced concrete |

| RR-HyFRC | Rebar-reinforced–hybrid-fibre-reinforced concrete |

| RR-FRC | Rebar-reinforced–fibre-reinforced concrete |

| RR-PERC | Rebar-reinforced–polyethylene-fibre-reinforced concrete |

| RR-PPFRC | Rebar-reinforced–polypropylene-fibre-reinforced concrete |

| RR-PVAFRC | Rebar-reinforced–polyvinyl-alcohol fibre-reinforced concrete |

| RR-RTSFRC | Rebar-reinforced–recycled-tyre-steel-fibre-reinforced concrete |

| RR-SFRC | Rebar-reinforced–steel fibre-reinforced concrete |

| RPEF | Recycled-polyethylene fibre |

| RTSF | Recycled-tyre-steel fibre |

| S | Steel |

| SF | Steel fibre |

| SFRC | Steel-fibre-reinforced concrete |

| SLS | Serviceability limit state |

| TEA | Triethanolamine |

| UHPC | Ultra-high-performance concrete |

| ULS | Ultimate limit state |

| US | United States |

| 3PBT | Three-point bending test |

| 4PBT | Four-point bending test |

References

- Landolfo, R.; Formisano, A.; Di Lorenzo, G.; Di Filippo, A. Classification of european building stock in technological and typological classes. J. Build. Eng. 2022, 45, 103482. [Google Scholar] [CrossRef]

- Callegher, C.Z.; Grazieschi, G.; Wilczynski, E.; Oberegger, U.F.; Pezzutto, S. Assessment of Building Materials in the European Residential Building Stock: An Analysis at EU27 Level. Sustainability 2023, 15, 8840. [Google Scholar] [CrossRef]

- Žnidarič, A.; Pakrashi, V.; O’Brien, E.; O’Connor, A. A review of road structure data in six European countries. Proc. Inst. Civ. Eng. Urban Des. Plan. 2011, 164, 225–232. [Google Scholar] [CrossRef]

- Koch, G.H.; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Costs and Preventive Strategies in the United States; United States Federal Highway Administration: Washington, DC, USA, 2001.

- Polder, R.; Pan, Y.; Courage, W.; Peelen, W.H.A. Preliminary study of life cycle cost of preventive measures and repair options for corrosion in concrete infrastructure. Heron 2016, 61, 1–13. [Google Scholar]

- Tilly, G.P.; Jacobs, J. Concrete Repairs: Observations on Performance in Service and Current Practice; BRE Electronic Publications: Watford, UK, 2007. [Google Scholar]

- Visser, J.H.M.; van Zon, Q. Performance and service life of repairs of concrete structures in The Netherlands. In Proceedings of the 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR, Cape Town, South Africa, 3–5 September 2012. [Google Scholar]

- Bowman, E.; Thompson, N.; Gl, D.; Moghissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application, and Economics of Corrosion Technologies Study; NACE Internationa: Houston, TX, USA, 2016. [Google Scholar]

- Granju, J.L.; Balouch, S.U. Corrosion of steel fibre reinforced concrete from the cracks. Cem. Concr. Res. 2005, 35, 572–577. [Google Scholar] [CrossRef]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete; Wiley-VCH: Weinheim, Germany, 2010. [Google Scholar]

- Khan, M.U.; Ahmad, S.; Al-Gahtani, H.J. Chloride-Induced Corrosion of Steel in Concrete: An Overview on Chloride Diffusion and Prediction of Corrosion Initiation Time. Int. J. Corros. 2017, 2017, 5819202. [Google Scholar] [CrossRef]

- Cosby, A.G.; Lebakula, V.; Smith, C.N.; Wanik, D.W.; Bergene, K.; Rose, A.N.; Swanson, D.; Bloom, D.E. Accelerating growth of human coastal populations at the global and continent levels: 2000–2018. Sci. Rep. 2024, 14, 22489. [Google Scholar] [CrossRef] [PubMed]

- Slamova, K.; Schill, C.; Wiesmeier, S.; Köhl, M.; Glaser, R. Mapping atmospheric corrosion in coastal regions: Methods and results. J. Photonics Energy 2012, 2, 022003. [Google Scholar] [CrossRef]

- EN 1992-1-1:2003; Eurocode 2—Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures. European Committee for Standardization: Brussels, Belgium, 2023.

- American Concrete Institute. Guide for Specifying, Proportioning, Mixing, Placing, and Finishing Steel Fiber-Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- Mordor Intelligence. Fiber Reinforced Concrete Market Size & Share Analysis—Growth Trends & Forecasts up to 2030. Available online: https://www.mordorintelligence.com/industry-reports/fiber-reinforced-concrete-frc-market (accessed on 1 April 2025).

- Siemes, A.J.M.; Edvardsen, C. Duracrete Service Life Design For Concrete Structures. In Proceedings of the 8th International Conference on Durability of Building Materials and Components, Vancouver, BC, Canada, 30 May–3 June 1999. [Google Scholar]

- Morgese, M.; Ansari, F.; Domaneschi, M.; Cimellaro, G.P. Post-collapse analysis of Morandi’s Polcevera viaduct in Genoa Italy. J. Civ. Struct. Health Monit. 2020, 10, 69–85. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C.; Picazo, A. Recent advances in structural fibre-reinforced concrete focused on polyolefin-based macro-synthetic fibres. Mater. Constr. 2020, 70, e206. [Google Scholar] [CrossRef]

- Kanavaris, F.; Coelho, M.; Ferreira, N.; Azenha, M.; Andrade, C. A review on the effects of cracking and crack width on corrosion of reinforcement in concrete. Struct. Concr. 2023, 24, 7272–7294. [Google Scholar] [CrossRef]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cem. Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Ann, K.Y.; Song, H.W. Chloride threshold level for corrosion of steel in concrete. Corros. Sci. 2007, 49, 4113–4133. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318M-08) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Wang, K.; Jansen, D.C.; Shah, S.P.; Karr, A.F. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- fib. Fib Model Code for Concrete Structures 2010; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013. [Google Scholar] [CrossRef]

- Bischoff, P.H. Tension Stiffening and Cracking of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2003, 15, 174–182. [Google Scholar] [CrossRef]

- Tiberti, G.; Minelli, F.; Plizzari, G. Cracking behavior in reinforced concrete members with steel fibers: A comprehensive experimental study. Cem. Concr. Res. 2015, 68, 24–34. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Löfgren, I.; Lundgren, K.; Görander, N.; Halldén, C. Characterisation of bending cracks in R/FRC using image analysis. Cem. Concr. Res. 2016, 90, 104–116. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Lundgren, K.; Löfgren, I. Corrosion of steel bars embedded in fibre reinforced concrete under chloride attack: State of the art. Cem. Concr. Res. 2016, 80, 69–85. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Michel, A.; Solgaard, A.; Fischer, G.; Edvardsen, C.; Skovhus, T.L. Corrosion resistance of steel fibre reinforced concrete—A literature review. Cem. Concr. Res. 2018, 103, 1–20. [Google Scholar] [CrossRef]

- Gopu, G.N.; Joseph, S.A. Corrosion Behavior of Fiber-Reinforced Concrete—A Review. Fibers 2022, 10, 38. [Google Scholar] [CrossRef]

- Ma, J.; Yuan, H.; Zhang, J.; Zhang, P. Enhancing concrete performance: A comprehensive review of hybrid fiber reinforced concrete. Structures 2024, 64, 106560. [Google Scholar] [CrossRef]

- Hwang, J.P.; Jung, M.S.; Kim, M.; Ann, K.Y. Corrosion risk of steel fibre in concrete. Constr. Build. Mater. 2015, 101, 239–245. [Google Scholar] [CrossRef]

- Mangat, B.P.; Molloy, T. Size effect of reinforcement on corrosion initiation. In Proceedings of the Fifth International RILEM Symposium on Fibre-Reinforced Concrete (FRC), Lyon, France, 13–15 September 2000; pp. 691–701. [Google Scholar]

- Gao, D.; Tai, Y.; Yang, L.; Zhang, Z.; Liu, G.; You, P. Corrosion of Steel Fibers in Chloride-Contaminated Simulated Concrete Pore Solutions. J. Mater. Civ. Eng. 2023, 35, 04022429. [Google Scholar] [CrossRef]

- Masmoudi, A.M.; Bouaziz, J. Durability of Steel Fibres Reinforcement Concrete Beams in Chloride Environment Combined with Inhibitor. Adv. Mater. Sci. Eng. 2016, 2016, 1743952. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Liu, S. Effect of chloride-induced corrosion on bond performance of various steel fibers in cracked SFRC. Cem. Concr. Compos. 2023, 140, 105113. [Google Scholar] [CrossRef]

- Woishnis, W.; Ebnesajjad, S. Chemical Resistance of Thermoplastics; William Andrew: Norwich, NY, USA, 2012. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Monteiro, P.J.M. The effect of steel and polypropylene fibers on the chloride diffusivity and drying shrinkage of high-strength concrete. Compos. B Eng. 2018, 139, 84–96. [Google Scholar] [CrossRef]

- Frazão, C.; Camões, A.; Barros, J.; Gonçalves, D. Durability of steel fiber reinforced self-compacting concrete. Constr. Build. Mater. 2015, 80, 155–166. [Google Scholar] [CrossRef]

- Hassan, M.; Elahi, A.; Asad, M. Performance of Fibre Reinforced Self Compacting Concrete against Chloride Attack. Eng. Proc. 2022, 22, 5. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An experimental investigation on the integral waterproofing capacity of polypropylene fiber concrete with fly ash and slag powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Rashid, M.U. Experimental investigation on durability characteristics of steel and polypropylene fiber reinforced concrete exposed to natural weathering action. Constr. Build. Mater. 2020, 250, 118910. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.A.; Najafi, M.H. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Chloride ion penetration in reinforced concrete and steel fiber-Reinforced concrete precast tunnel lining segments. ACI Mater. J. 2014, 111, 613–622. [Google Scholar] [CrossRef]

- Toutanji, H.; McNeil, S.; Bayasi, Z. Chloride permeability and impact resistance of polypropylene-fiber-reinforced silica fume concrete. Cem. Concr. Res. 1998, 28, 961–968. [Google Scholar] [CrossRef]

- Balouch, S.U.; Forth, J.P.; Granju, J.-L. Surface corrosion of steel fibre reinforced concrete. Cem. Concr. Res. 2009, 40, 410–414. [Google Scholar] [CrossRef]

- Ghorpade, V.G.; Rao, H.S. Strength and permeability characteristics of Fibre reinforced recycled aggregate concrete with different fibres. Nat. Environ. Pollut. Technol. 2010, 9, 179–188. [Google Scholar]

- Anandan, S.; Manoharan, S.V.; Sengottian, T. Corrosion Effects on the Strength Properties of Steel Fibre Reinforced Concrete Containing Slag and Corrosion Inhibitor. Int. J. Corros. 2014, 2014, 595040. [Google Scholar] [CrossRef]

- Bhargava, A.; Banthia, N. Permeability of concrete with fiber reinforcement and service life predictions. Mater. Struct. 2008, 41, 363–372. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H. The resistance to chloride penetration of concrete containing nano-particles for pavement. In Testing, Reliability, and Application of Micro- and Nano-Material Systems IV; Geer, R.E., Meyendorf, N., Baaklini, G.Y., Vogel, D.W., Eds.; SPIE: Bellingham, DC, USA, 2006; p. 61750E. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Fischer, G.; Solgaard, A.; Edvardsen, C.; Michel, A. Mechanical performance of steel fibre reinforced concrete exposed to wet–dry cycles of chlorides and carbon dioxide. Materials 2021, 14, 2642. [Google Scholar] [CrossRef] [PubMed]

- Buratti, N.; Mazzotti, C.; Savoia, M. Long–Term Behavior of Cracked SFRC Elements Exposed to Chloride Solutions. ACI Symp. Publ. 2011, 280, 1–14. [Google Scholar] [CrossRef]

- Li, D.; Liu, S. Macro polypropylene fiber influences on crack geometry and water permeability of concrete. Constr. Build. Mater. 2020, 231, 117128. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Compos. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Bogas, J.A. Influence of the chloride attack on the post-cracking behavior of recycled steel fiber reinforced concrete. Materials 2021, 14, 1279. [Google Scholar] [CrossRef]

- Rapoport, J.; Aldea, C.-M.; Shah, S.P.; Ankenman, B.; Karr, A.F. Permeability of Cracked Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2002, 14, 355–358. [Google Scholar] [CrossRef]

- Selvi, M.T.; Thandavamoorthy, T.S. Mechanical and durability properties of steel and polypropylene fibre reinforced concrete. Int. J. Earth Sci. Eng. 2014, 7, 696–703. [Google Scholar]

- Zhang, P.; Sun, X.; Wei, J.; Wang, J.; Gao, Z. Influence of PVA fibers on the durability of cementitious composites under the wet-heat-salt coupling environment. Rev. Adv. Mater. Sci. 2023, 62, 20230155. [Google Scholar] [CrossRef]

- Chen, E.; Berrocal, C.G.; Löfgren, I.; Lundgren, K. Comparison of the service life, life-cycle costs and assessment of hybrid and traditional reinforced concrete through a case study of bridge edge beams in Sweden. Struct. Infrastruct. Eng. 2023, 19, 39–57. [Google Scholar] [CrossRef]

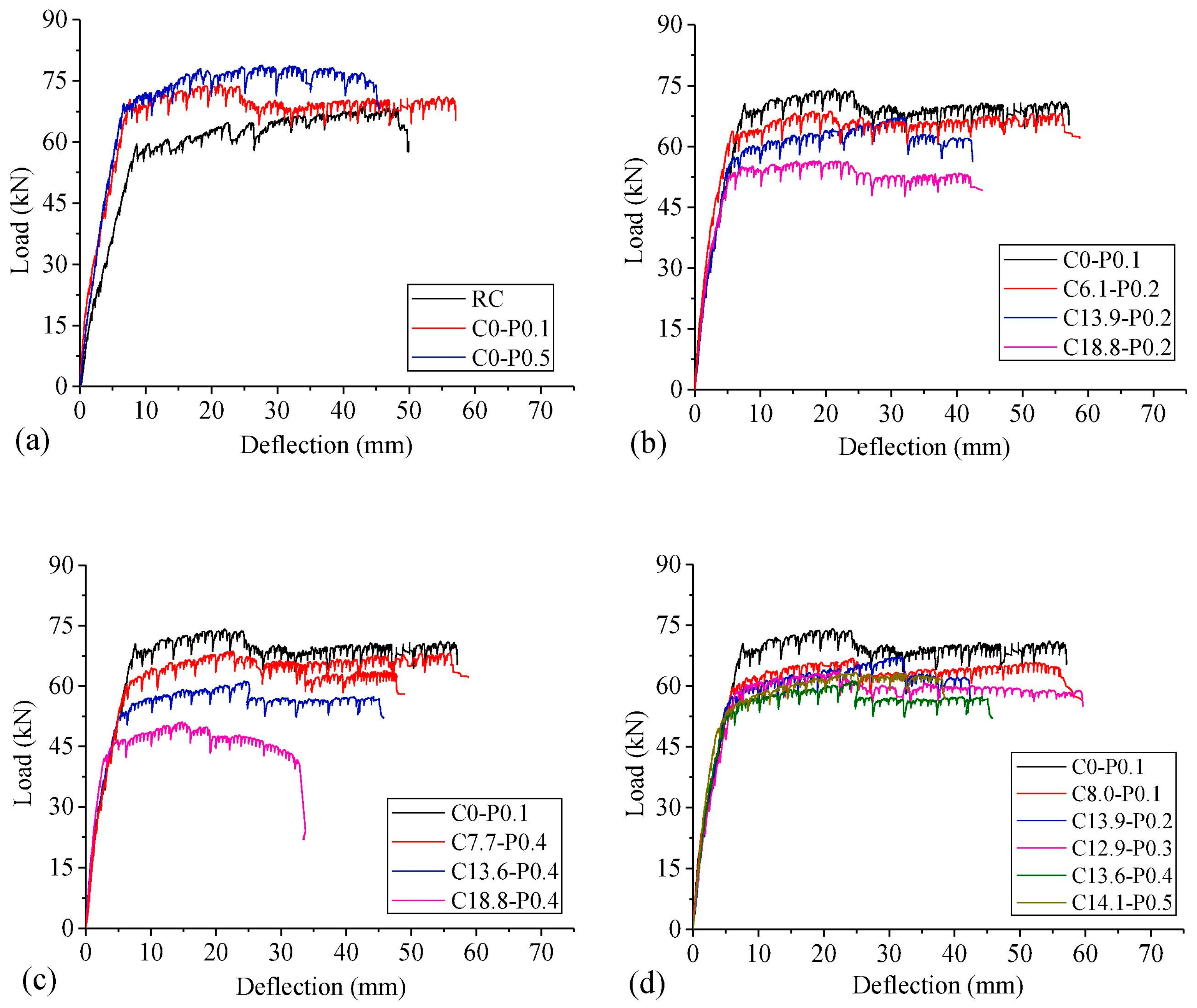

- Hou, L.; Peng, Y.; Xu, R.; Zhang, X.; Huang, T.; Chen, D. Corrosion behavior and flexural performance of reinforced SFRC beams under sustained loading and chloride attack. Eng. Struct. 2021, 242, 112553. [Google Scholar] [CrossRef]

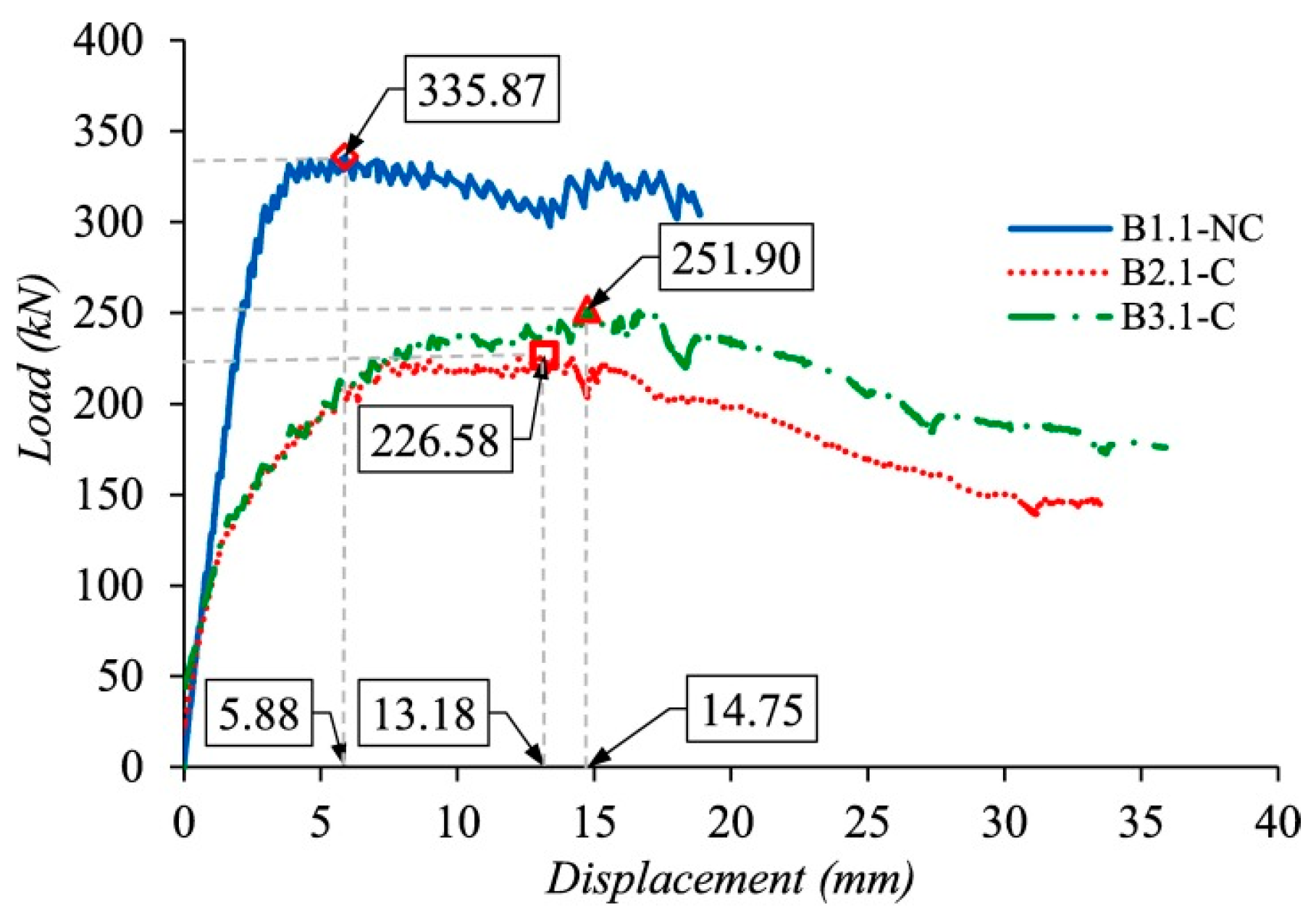

- Leporace-Guimil, B.; Conforti, A.; Zerbino, R.; Plizzari, G.A. Chloride-induced corrosion in reinforced concrete and fiber reinforced concrete elements under tensile service loads. Cem. Concr. Compos. 2021, 124, 104245. [Google Scholar] [CrossRef]

- Leporace-Guimil, B.; Russo, N.; Lollini, F.; Conforti, A. Morphological and mechanical characterization of reinforcement in cracked elements exposed to chloride-induced corrosion. Constr. Build. Mater. 2023, 364, 129822. [Google Scholar] [CrossRef]

- Özyurt, N.; Söylev, T.A.; Özturan, T.; Pehlivan, A.O.; Niş, A. Corrosion and chloride diffusivity of reinforced concrete cracked under sustained flexure. Tek. Dergi/Tech. J. Turk. Chamb. Civ. Eng. 2020, 31, 10315–10337. [Google Scholar] [CrossRef]

- Bafghi, M.A.B.; Amini, F.; Nikoo, H.S.; Sarkardeh, H. Effect of steel fiber and different environments on flexural behavior of reinforced concrete beams. Appl. Sci. 2017, 7, 1011. [Google Scholar] [CrossRef]

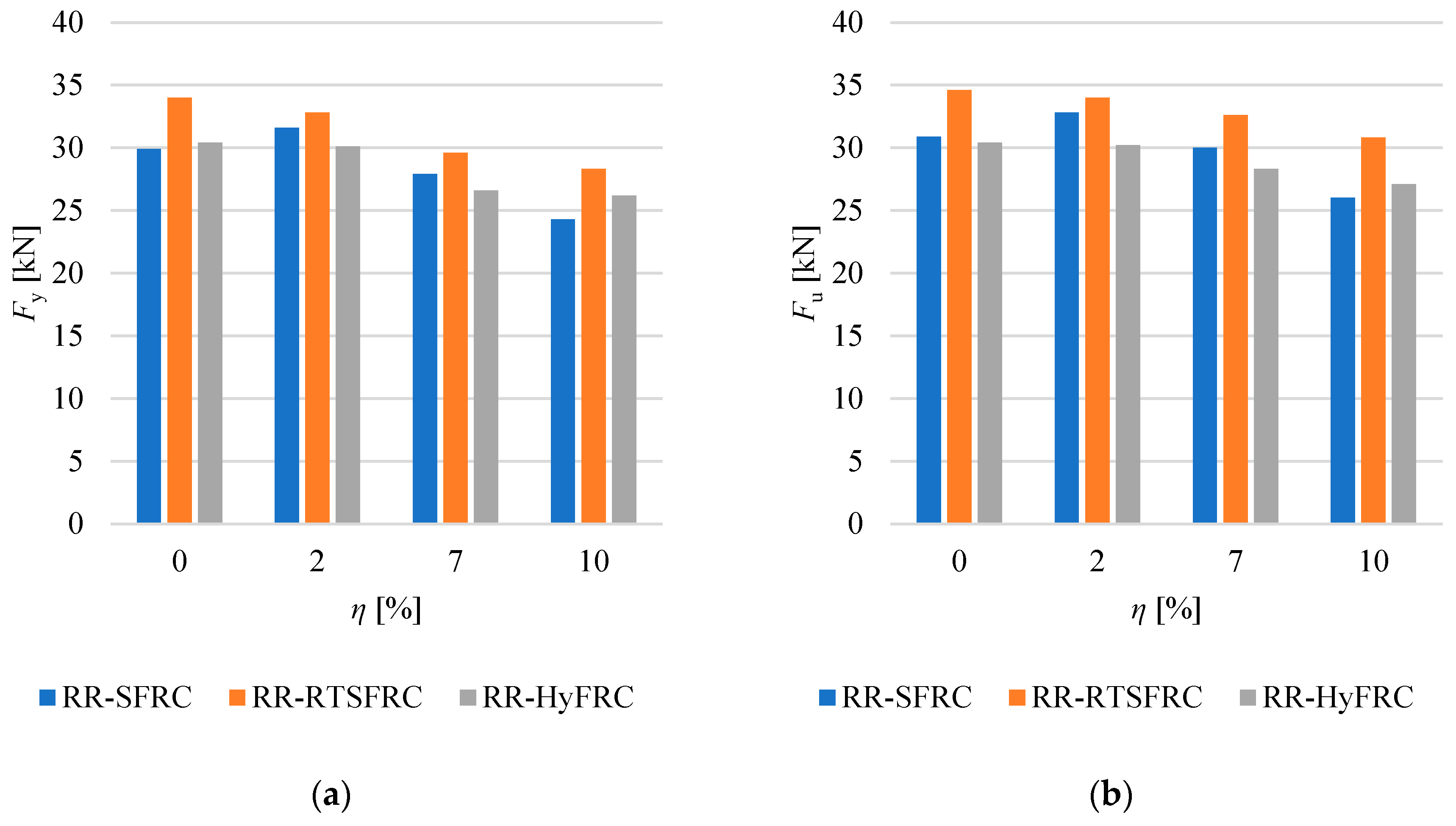

- Roshan, N.; Ghalehnovi, M. The effect of recycled-tire steel fiber and engineered steel fiber on rebar corrosion and shear behavior of corroded RC beam. Case Stud. Constr. Mater. 2023, 19, e02251. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Sultan, A. The effect of micro- Steel fiber on the corrosion steel reinforcement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 870, 012111. [Google Scholar] [CrossRef]

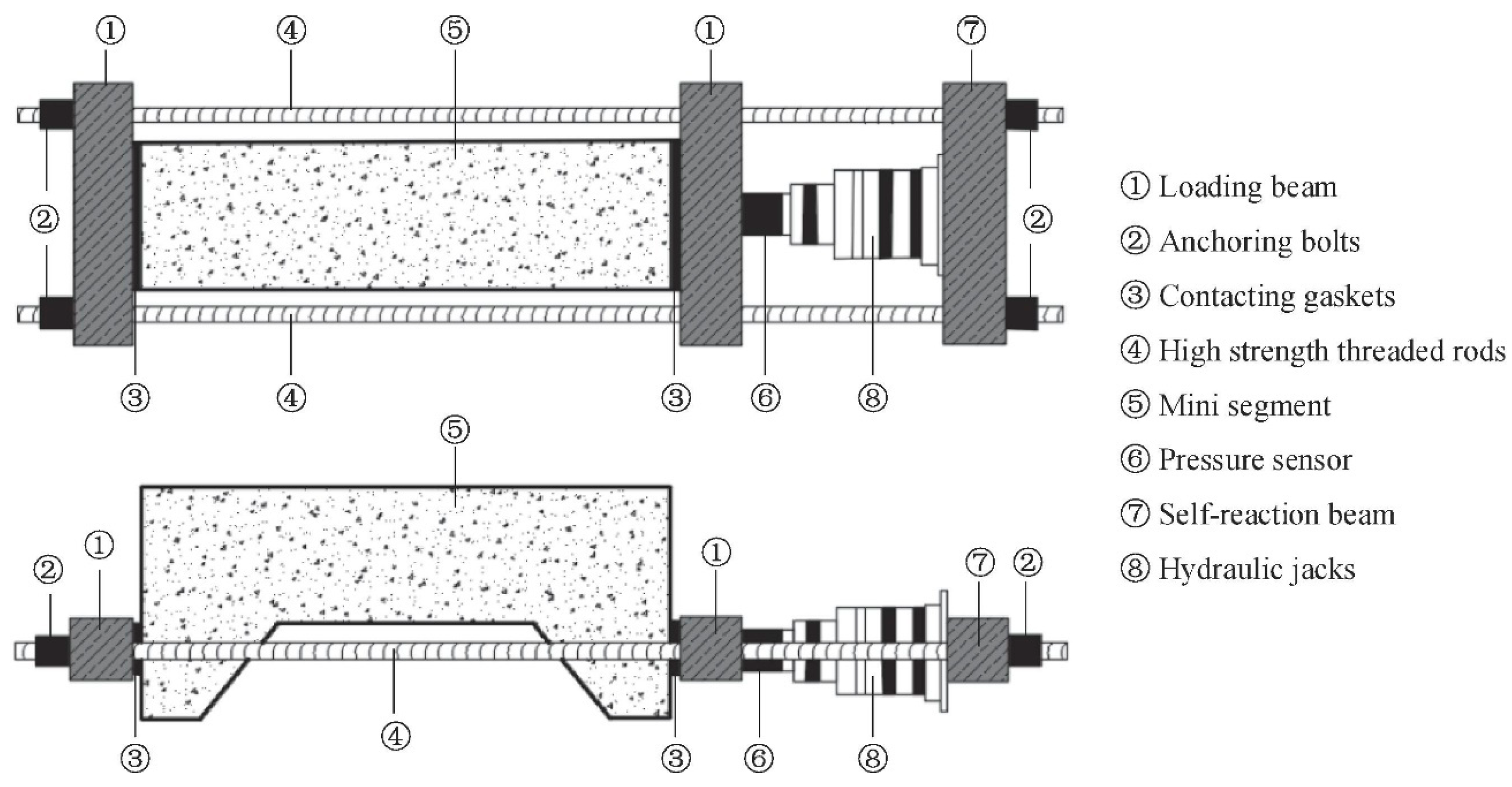

- Feng, K.; Yang, R.; Geng, J.; Cao, X.; He, C.; Yang, W.; Zhang, H. Experimental investigation of mechanical-performance deterioration of HFRC segment under combined effect of sustained loading and chloride-induced corrosion. Tunn. Undergr. Space Technol. 2021, 114, 104015. [Google Scholar] [CrossRef]

- Pham, T.T.; Nguyen, N.T.; Nguyen, T.-T.T.; Nguyen, N.L. Numerical analysis of the shear behavior for steel fiber reinforced concrete beams with corroded reinforcing bars. Structures 2023, 57, 105081. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Bacharz, M.; Bacharz, K.; Teodorczyk, M. Reinforcement Corrosion Testing in Concrete and Fiber Reinforced Concrete Specimens Exposed to Aggressive External Factors. Materials 2023, 16, 1174. [Google Scholar] [CrossRef] [PubMed]

- Michel, A.; Solgaard, A.O.S.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Experimental investigation of the relation between damage at the concrete-steel interface and initiation of reinforcement corrosion in plain and fibre reinforced concrete. Corros. Sci. 2013, 77, 308–321. [Google Scholar] [CrossRef]

- Raczkiewicz, W. Use of polypropylene fibres to increase the resistance of reinforcement to chloride corrosion in concretes. Sci. Eng. Compos. Mater. 2021, 28, 555–567. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Löfgren, I.; Lundgren, K. The effect of fibres on steel bar corrosion and flexural behaviour of corroded RC beams. Eng. Struct. 2018, 163, 409–425. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Löfgren, I.; Lundgren, K.; Tang, L. Corrosion initiation in cracked fibre reinforced concrete: Influence of crack width, fibre type and loading conditions. Corros. Sci. 2015, 98, 128–139. [Google Scholar] [CrossRef]

- Nguyen, W.; Duncan, J.F.; Devine, T.M.; Ostertag, C.P. Electrochemical polarization and impedance of reinforced concrete and hybrid fiber-reinforced concrete under cracked matrix conditions. Electrochim. Acta 2018, 271, 319–336. [Google Scholar] [CrossRef]

- Mihashi, H.; Ahmed, S.F.U.; Kobayakawa, A. Corrosion of reinforcing steel in fiber reinforced cementitious composites. J. Adv. Concr. Technol. 2011, 9, 159–167. [Google Scholar] [CrossRef]

- Blunt, J.; Jen, G.; Ostertag, C.P. Enhancing corrosion resistance of reinforced concrete structures with hybrid fiber reinforced concrete. Corros. Sci. 2015, 92, 182–191. [Google Scholar] [CrossRef]

- Jen, G.; Ostertag, C.P. Experimental observations of self-consolidated hybrid fiber reinforced concrete (SC-HyFRC) on corrosion damage reduction. Constr. Build. Mater. 2016, 105, 262–268. [Google Scholar] [CrossRef]

- Sappakittipakorn, M.; Banthia, N. Corrosion of rebar and role of fiber reinforced concrete. J. Test. Evaluation 2012, 40, 127–136. [Google Scholar] [CrossRef]

- Maalej, M.; Ahmed, S.F.; Paramasivam, P. Corrosion Durability and Structural Response of Functionally-Graded Concrete Beams. J. Adv. Concr. Technol. 2003, 1, 307–316. [Google Scholar] [CrossRef]

- Roque, R.; Kim, N.; Kim, B.; Lopp, G. Durability of Fiber-Reinforced Concrete in Florida Environments; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2009. [Google Scholar]

- Nicolás, A.F.; Campos, E.C.M.; Nicolás, M.F.; González, J.J.M.; Noriega, O.A.G.; Chavarín, J.U. Influence of Recycled High-Density Polyethylene Fibers on the Mechanical and Electrochemical Properties of Reinforced Concrete. Fibers 2024, 12, 24. [Google Scholar] [CrossRef]

- Vo, K.M.; Pansuk, W.; Cao, T.N.; Nguyen, H.Y.T. Flexural Performance of Mill Cut Steel Fiber Reinforced Concrete Beam Degraded by Mild Corrosion. In Proceedings of The 17th East Asian-Pacific Conference on Structural Engineering and Construction, Singapore, 27–30 June 2022; Geng, G., Qian, X., Poh, L.H., Pang, S.D., Eds.; Springer: Singapore, 2023; pp. 1403–1412. [Google Scholar]

- ASTM International. Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Leung, C.K.Y.; Hou, D. Numerical Simulation of Chloride-Induced Corrosion Initiation in Reinforced Concrete Structures with Cracks. J. Mater. Civ. Eng. 2015, 27, 4014122. [Google Scholar] [CrossRef]

- DIANA Finite Element Analysis, DIANA Documentation, Release 10.3 (2019). Available online: https://manuals.dianafea.com/d103/Theory/Theory.html (accessed on 31 March 2025).

- Kumar, M.; Meena, B.; Subramanyam, P.; Suryakala, D.; Subrahmanyam, C. Recent trends in photoelectrochemical water splitting: The role of cocatalysts. NPG Asia Mater. 2022, 14, 88. [Google Scholar] [CrossRef]

- Dehghanian, R. Effect of Impressed Current on Bond Strength Between Steel Rebar and Concrete. Int. J. Eng. 1998, 11, 121–134. Available online: https://www.ije.ir/article_71205.html (accessed on 31 March 2025).

- Wong, H.S.; Angst, U.M.; Geiker, M.R.; Isgor, O.B.; Elsener, B.; Michel, A.; Alonso, M.C.; Correia, M.J.; Pacheco, J.; Gulikers, J.; et al. Methods for characterising the steel–concrete interface to enhance understanding of reinforcement corrosion: A critical review by RILEM TC 262-SCI. Mater. Struct. Mater. Constr. 2022, 55, 124. [Google Scholar] [CrossRef]

- Feng, W.; Tarakbay, A.; Memon, S.A.; Tang, W.; Cui, H. Methods of accelerating chloride-induced corrosion in steel-reinforced concrete: A comparative review. Constr. Build. Mater. 2021, 289, 123165. [Google Scholar] [CrossRef]

- Malumbela, G.; Moyo, P.; Alexander, M. A step towards standardising accelerated corrosion tests on laboratory reinforced concrete specimens. J. South Afr. Inst. Civ. Eng. = J. Van Die Suid-Afr. Inst. Van Siviele Ingenieurswese 2012, 54, 78–85. [Google Scholar] [CrossRef]

- Andrade, C.; Alonso, C. Test methods for on-site corrosion rate measurement of steel reinforcement in concrete by means of the polarization resistance method. Mater. Struct. 2004, 37, 623–643. [Google Scholar] [CrossRef]

- Poursaee, A.; Hansson, C.M. Potential pitfalls in assessing chloride-induced corrosion of steel in concrete. Cem. Concr. Res. 2009, 39, 391–400. [Google Scholar] [CrossRef]

| Paper | d [d] | NaCl [%] | Material | Dimensions [mm] | w/b [-] | Vf [%] | lf [mm] | df [mm] | c [mm] | fc [MPa] | w [mm] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [66] | - | - | RC | 450 × 450 × 15,000 | - | - | - | - | 45 | 40 | 0.21–0.58 |

| RR-SFRC | 0.50 | 35.0 | 0.550 | 0.21–0.27 | |||||||

| RR-SFRC | 1.00 | 0.13–0.15 | |||||||||

| [67] (15) | 72 (1) | 3.5 | RC | 120 × 180 × 1750 | 0.47 | - | - | - | - | 52.8 | 0.00–0.14 |

| RR-SFRC | 0.75 | 35.0 | 0.630 | 47.5 | |||||||

| [68,69] (13) | 280 | 5.0 | RC | 90 × 90 × 830 | 0.49 | - | - | - | 39 | 38 | 0.19–0.23 |

| RR-SFRC | 0.64 | 33.0 | 0.600 | 0.09–0.15 | |||||||

| [70] (13) | 560 | 3.5 | RC | 100 × 100 × 500 | 0.45 | - | - | - | 25 | 48 | 0.40 |

| RR-SFRC | 0.65 | 0.50 | 35.0 | 0.550 | 45 | 29 | |||||

| [71] | 28–180 | 2.7 (2) | PC, RC | 200 × 200 × 750 | 0.44 | - | - | - | 55 | 30 | 0.35 |

| RR-SFRC | 0.50 | 50.0 | 0.800 | ||||||||

| [72] (15) | 6–32 | 3.5 | RC | 100 × 120 × 1200 | 0.45 | - | - | - | - | 36 | - |

| RR-RTSFRC (3) | 0.50 | 10.0–60.0 | 0.250–0.350 | 50 | |||||||

| RR-SFRC | 0.50 | - | - | 47 | |||||||

| RR-HyFRC | 0.50 (4) | 44 | |||||||||

| [40] | 28 | 5.1 | RC | 150 × 200 × 2050 | 0.51 | - | - | - | 20 | 28 | - |

| RR-SFRC | - | - | - | ||||||||

| [73] (14) | - | 5.0 | RC | 100 × 150 × 1000 | 0.45 | - | - | - | - | 48 | - |

| RR-SFRC | 1.20 | 15.0 | 0.200 | 52 | |||||||

| [74] (15) | 20 | 20.0 | RC | 600 × 290 × 1360 | 0.39 | - | - | - | 50 | 70 | 0.01 |

| RR-SFRC | 0.50, 1.00 | 60.0 | 0.750 | 0.00 | |||||||

| [75] (15) | 24 | 3.5 | RR-SFRC | 150 × 200 × 1100 | 0.39 | 0.64 | 35.0 | 0.550 | 40 | 49 | - |

| [76] | 50 (5) | 3.0 | RC | 210 × 220 × 100 | 0.43 | - | - | - | 25 | 63 | 0.00 |

| RR-SFRC | 0.50 | 60.0 | 1.000 | 67 | |||||||

| RR-SFRC | 1.00 | 62 | |||||||||

| [77] | 24 | 3.0 | RC | 290 × 310 × 650 | - | - | - | 60 | - | 0.07 | |

| RR-SFRC | 0.50 | 35.0 | 0.550 | 0.14 | |||||||

| RR-SFRC | 1.00 | 0.07 | |||||||||

| [78] | 50 | 3.0 | RC | 210 × 228 × 100 | 0.43 | - | - | - | 25 | 62 | 0.00 |

| RR-PPFRC | 0.06 | 12.0 | 0.038 | 68 | |||||||

| [79,80] (13) | 1095 | 16.5 | RC | 100 × 180 × 1100 | 0.47 | - | - | - | 30 | 55 | 0.00–0.40 |

| RR-SFRC | 0.50 | 35.0 | 0.550 | 61 | |||||||

| RR-PVAFRC | 0.75 | 30.0 | 0.660 | 57 | |||||||

| RR-HyFRC | 0.50 (6) | - | - | 57 | |||||||

| [81] (13) | 910 | 3.5 | RC | 127 × 127 × 610 | 0.54 | - | - | - | 36 | 44 | 0.42 |

| RR-HyFRC | 1.50 (7) | - | - | 46 | 0.22 | ||||||

| [82] (14) | 365 | 3.0 | RC | 100 × 100 × 400 | 0.45 | - | - | - | 20 | - | 0.00 |

| RR-PEFRC | 1.50 | 6.0 | 0.012 | ||||||||

| RR-HyFRC | 1.50 (8) | - | - | ||||||||

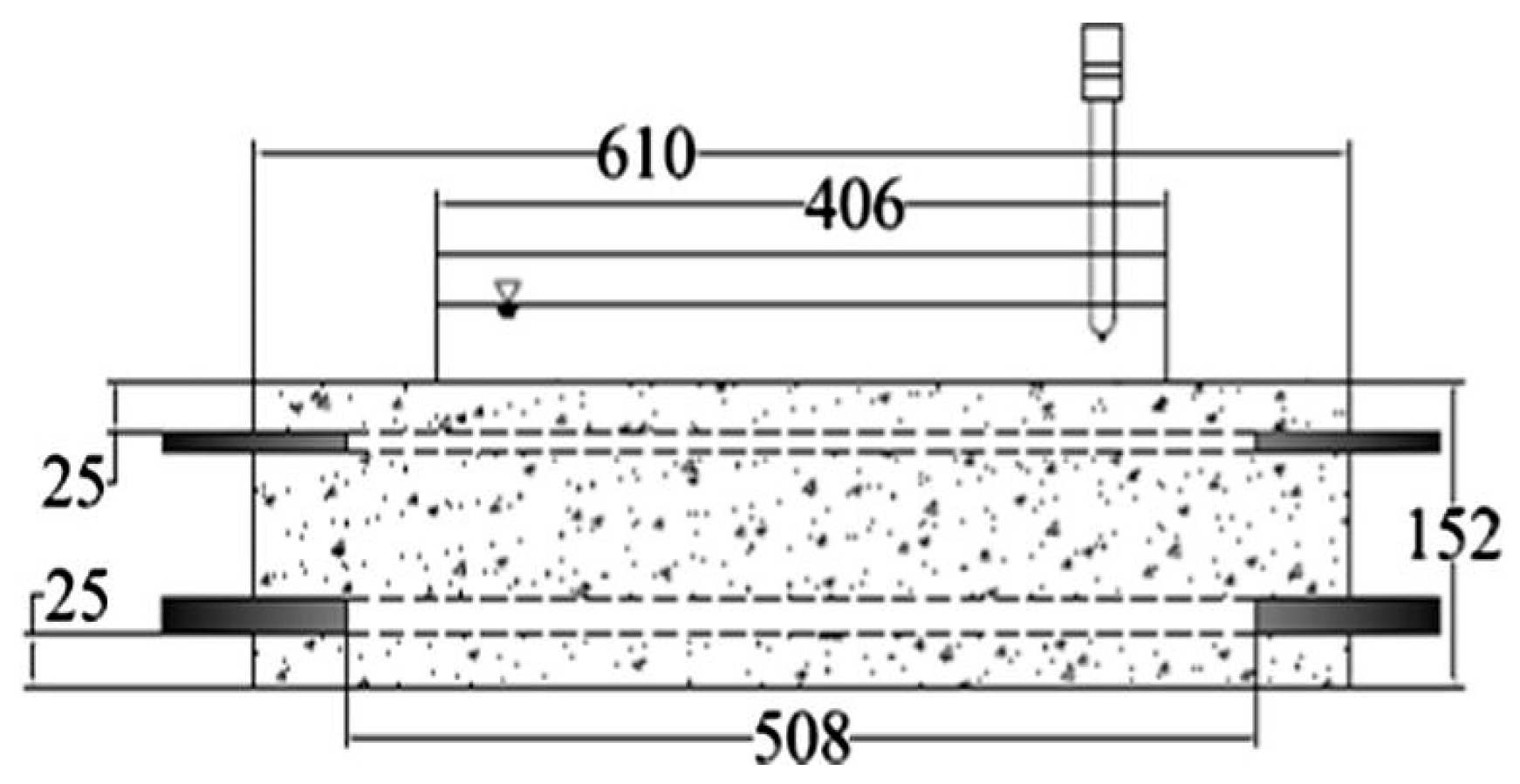

| [83] | 266 | - | RC | 152 × 152 × 608 | 0.54 | - | - | - | 25 | - | 0.30–0.40 |

| RR-HyFRC | 1.50 (9) | - | - | 0.00 | |||||||

| [84] | 730 | 3.5 | RC | 152 × 152 × 610 | 0.60 | - | - | - | 25 | - | 0.20–0.30 |

| RR-HyFRC | 1.80 (10) | - | - | 0.00 | |||||||

| [85] (13) | 392 | 3.5 | RC | 100 × 100 × 350 | 0.55 | - | - | - | 25 | - | 0.25–0.80 |

| RR-PPFRC | 0.10, 0.30 | 16.0 | 0.030 | ||||||||

| RR-HyFRC | 0.60, 1.10, 1.60 (11) | - | - | 52–68 | |||||||

| [86] (14) | - | 3.5 | RC | 300 × 210 × 2500 | 0.42 | - | - | - | 45 | 41 | 0.54 |

| RR-HyFRC | 0.45 | 2.50 (12) | - | - | 61 | 0.28–0.30 | |||||

| [87] | 810 | 5.0–16.5 | RC | 100 × 100 × 350, 115 × 150 × 280 | 0.37, 0.44 | - | - | - | - | 56–66 | - |

| RR-SFRC | 1.00 | 30.0 | 0.560 | 63–70 | |||||||

| RR-PPFRC | 0.50 | 39.0 | 0.430 | 56–68 | |||||||

| RR-PVAFRC | 0.75 | 30.0 | 0.660 | 57–71 | |||||||

| [88] | 365 | 3.0 | RC | 120 × 120 × 80 | 0.54 | - | - | - | 35 | 32 | 0.00 |

| RR-PEFRC | 0.2, 0.4 | 10.0, 30.0 | 0.050 | 28–34 | |||||||

| [89] (15) | 38 | 3.0 | RC | 150 × 200 × 1400 | 0.40 | - | - | - | - | 40 | 0.00 |

| RR-SFRC | 0.50, 1.00, 1.50 | 32.0 | 2.600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajić, P.; Leporace-Guimil, B.; Andrade, C.; Tošić, N.; de la Fuente, A. Chloride-Induced Corrosion Effects on the Structural Performance of Concrete with Rebar and Fibres: A Review. Appl. Sci. 2025, 15, 6457. https://doi.org/10.3390/app15126457

Bajić P, Leporace-Guimil B, Andrade C, Tošić N, de la Fuente A. Chloride-Induced Corrosion Effects on the Structural Performance of Concrete with Rebar and Fibres: A Review. Applied Sciences. 2025; 15(12):6457. https://doi.org/10.3390/app15126457

Chicago/Turabian StyleBajić, Petar, Bruno Leporace-Guimil, Carmen Andrade, Nikola Tošić, and Albert de la Fuente. 2025. "Chloride-Induced Corrosion Effects on the Structural Performance of Concrete with Rebar and Fibres: A Review" Applied Sciences 15, no. 12: 6457. https://doi.org/10.3390/app15126457

APA StyleBajić, P., Leporace-Guimil, B., Andrade, C., Tošić, N., & de la Fuente, A. (2025). Chloride-Induced Corrosion Effects on the Structural Performance of Concrete with Rebar and Fibres: A Review. Applied Sciences, 15(12), 6457. https://doi.org/10.3390/app15126457