1. Introduction

In response to the environmental impacts stemming from the linear produce–use–discard economic model, the construction industry is progressively transitioning toward a circular economic framework. This shift necessitates the closure of building material production loops, addressing the revision in using building materials like synthetic polymers and petroleum-based components, which are inherently non-biodegradable or necessitate extensive timeframes, often centuries, to decompose in landfills. Materials for acoustic insulation, specifically those made from synthetic mineral fibers such as glass wool, stone wool, and polystyrene, exemplify this [

1]. There has been a growing interest in the utilization of biomaterials as a pathway toward developing more sustainable materials. One such strategy is the development of composite biomaterials, composed of live organisms grown on biotic or abiotic substructures. Mycelium-based composites (MBCs) use fungal mycelium as a natural adhesive to turn waste into valuable resources [

2]. A living network of filamentous threads, fungal mycelium, prospers when fed lignocellulosic waste [

3]. Mycelial hyphae exhibit rapid growth within organic substrates, binding them into solid, lightweight foams with potential as alternatives to synthetic sound absorbers and insulators [

4,

5,

6]. Previous research shows that mycelium-based composites are also good acoustic and thermal insulators [

7,

8]. Mycelium’s filamentous network creates a dense 3D structure with interconnected pores, providing inherent insulating properties [

7,

9]. MBCs have been identified as an exceptional acoustic absorber of mid–low frequencies [

10]. Several studies have explored the use of MBCs as acoustic absorbers [

4,

8,

10]. These studies suggest that mycelium-based composites can present a biodegradable alternative to synthetic acoustic materials while still achieving optimal acoustic performance. At ForMat Lab, we have explored how the material composition, geometry, and surface shape affect the absorption properties of mycelium-based acoustic panels [

8]. We have additionally explored how the configuration, quantity, and location of the panels affect room acoustics [

11]. The mycelium strain, substrate type, and manufacturing methods, however, affect the insulation performance and scalability of mycelium-based sound absorbers [

2,

10]. A significant drawback in current research on mycelium-based acoustic absorbers is the reliance on molds for fabrication, and current fabrication methods for mycelium-based composites are limited when it comes to achieving large-scale fabrication and geometric complexity. Recently, material extrusion-based additive manufacturing (EAM) that implements mechanical or pneumatic extrusion to deposit layers of mycelium paste has been proposed as an alternative to molding of MBCs [

12,

13,

14,

15,

16,

17,

18,

19,

20], allowing for the manufacturing of unique shapes that can support the growth of mycelium, without the need for molds.

In this paper, we present a research project on robotic EAM of living mycelium mixtures to fabricate biodegradable acoustic wall panels. This research is structured into four main steps: (1) formulation of extrudable mycelium paste, (2) parametric optimization of robotic EAM processes, (3) establishment of an experimental framework for acoustic property assessment, and (4) implementation of hybrid slicing methods for robotic EAM to fabricate acoustic wall panels.

Previously, researchers have developed mycelium paste for mold-free composite fabrication [

12,

13,

14,

16]. The formulation of an extrudable paste plays an essential part in attaining optimal printability of the mycelium-based composites. According to Soh et al. [

14], developing an extrudable paste with form stabilization qualities and optimal workability and buildability involves the incorporation of additives, such as fibers and binders, and the adjustment of water content and viscosity modifiers. To expedite mycelium growth, lignocellulosic substrates or nutrient supplements are added to the paste as fibers. Hence, both a gelling agent and lignocellulosic substrate are combined for MBC additive manufacturing [

17]. Fiber size range and shape greatly influence the flow and packing behavior of dense pastes for EAM. These factors affect both the paste flow during EAM and the stability of the final structure [

21]. At ForMat Lab in collaboration with mycologists from the Plant Pathology department at Penn State, we have developed extrudable mixtures and workflows for EAM of living mycelium-based composites [

16]. The comprehensive workflow of EAM can be delineated into six steps, as outlined by [

12,

13]: mycelium inoculation, primary colonization, mixing, EAM, secondary colonization, and drying. It is important to mention that these steps have the potential to be combined or reordered depending on the application.

In this research, the workflow was streamlined by establishing a new workflow for preparing living, extrudable mycelium mixtures, involving alterations in the preparation sequence and adjustments in the admixture ratios. The resultant mycelium mixture was employed in a comprehensive series of experiments to optimize the parameters of robotic EAM. These parameters include layer height, extrusion speed, and robot arm velocity. An Artificial Neural Network (ANN) model was used, in which the resulting layer height and width data are used as inputs. This model was used to accurately determine the specific printing parameters required to achieve a predefined layer height and width, thereby ensuring precise control over the robotic EAM process. This approach allows for a more refined and data-driven method to fine-tune the EAM parameters. As the next step, a detailed experimental framework is established, utilizing the Taguchi method to generate nine varied acoustic samples [

22]. This design of experiments (DOE) focuses on altering key parameters, including infill patterns, the relative proportions of layers with distinct patterns, and the infill percentage. The objective is to systematically assess the impact of these variables on acoustic absorption. For the empirical evaluation, an impedance tube was used to measure the normal incidence sound absorption coefficients at various frequencies for each sample. This method provides a quantitative analysis of how the different robotic EAM parameters affect the acoustic absorption characteristics across a range of frequencies. Lastly, conformal toolpath generation and robotic EAM of biodegradable acoustic wall panels from living mycelium mixtures were explored based on previous research by the authors [

23]. While prior studies focused on paste formulation and extrusion feasibility of MBCs [

12,

13,

16], this study advances both the paste formulation and the EAM workflow. The paste is developed using ground Ecovative’s Dehydrated Grow-It-Yourself Mushroom

® Material (Ecovative Design LLC, Green Island, NY, USA), with inoculation initiated prior to EAM. This eliminates the need for a separate colonization step in growth bags, enabling direct EAM of the living material and significantly reducing the total fabrication timeline. Additionally, this study uses a data-driven strategy using an Artificial Neural Network (ANN) for optimizing the robotic EAM parameters for mycelium-based mixtures, which can be extended to future formulations for consistent and predictable extrusion. A hybrid slicing approach combining planar and non-planar slicing methods improves surface quality and enables fabrication of conformal geometries. Finally, this study uses robotic EAM for the fabrication of architectural-scale acoustic panels, demonstrating its potential for fabrication of performance-based building parts beyond conventional mold-based methods. This study underscores the transformative capacity of robotic EAM and conformal toolpath design utilizing mycelium-based biomaterials, presenting the development of sustainable biodegradable building materials and advanced acoustic solutions. The broader impacts of the research are to mitigate waste generated due to the manufacturing of building materials and the generation of new knowledge on the use of mycelium-based composites in architectural acoustics.

2. Materials and Methods

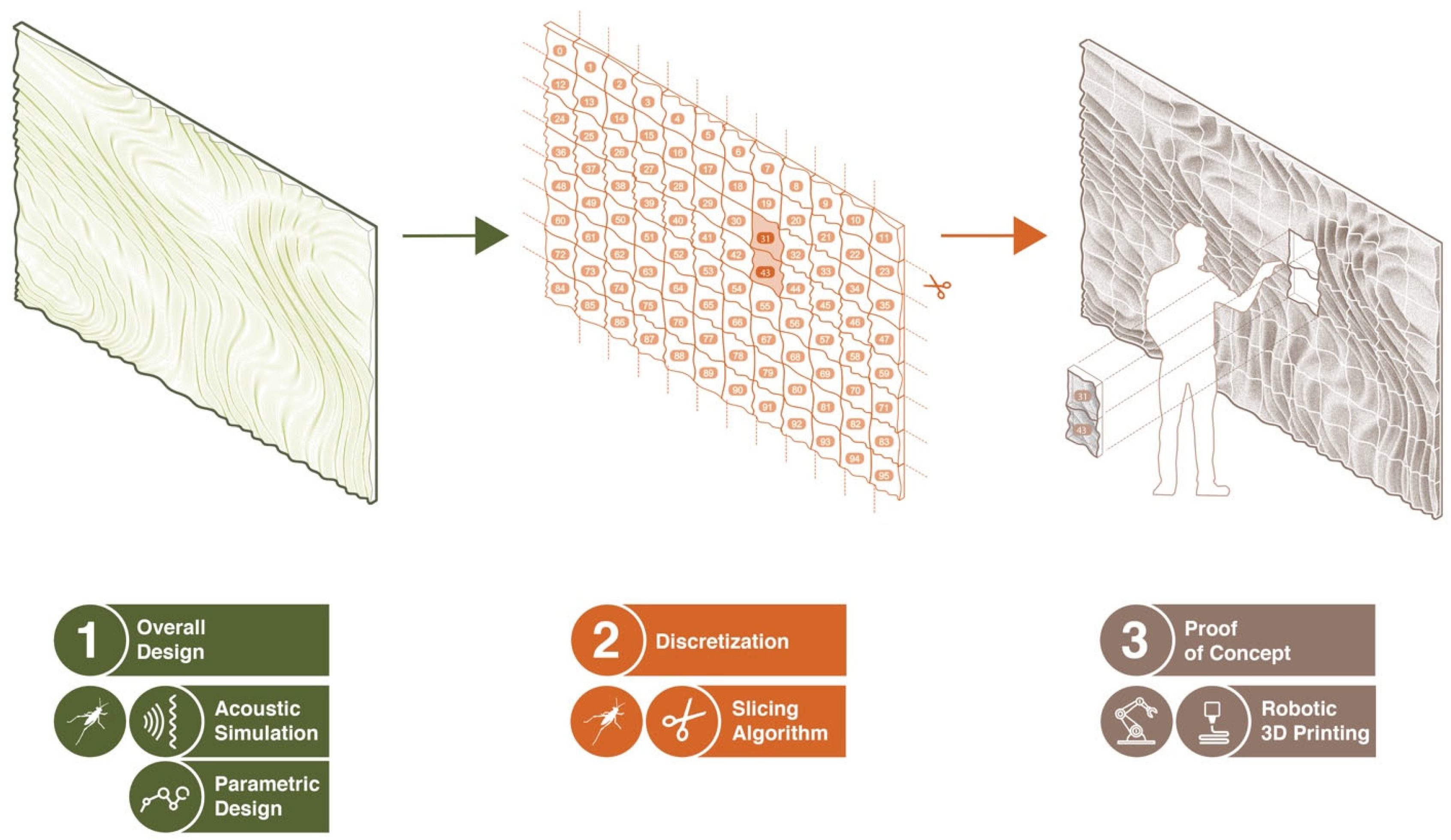

This study outlines a systematic workflow (

Figure 1), beginning with material formulation, where particle size distribution and different material mixture composition ratios are assessed. The prepared mycelium mixtures are then used to refine the robotic EAM parameters using an ANN model to have a consistent and precise bead deposition. In the next step, acoustic cylindrical samples with varied toolpath planning factors were fabricated, and their sound absorption coefficients were measured using an impedance tube. This study lastly explores conformal toolpath generation and robotic EAM of biodegradable acoustic panels informed by an experimental design space.

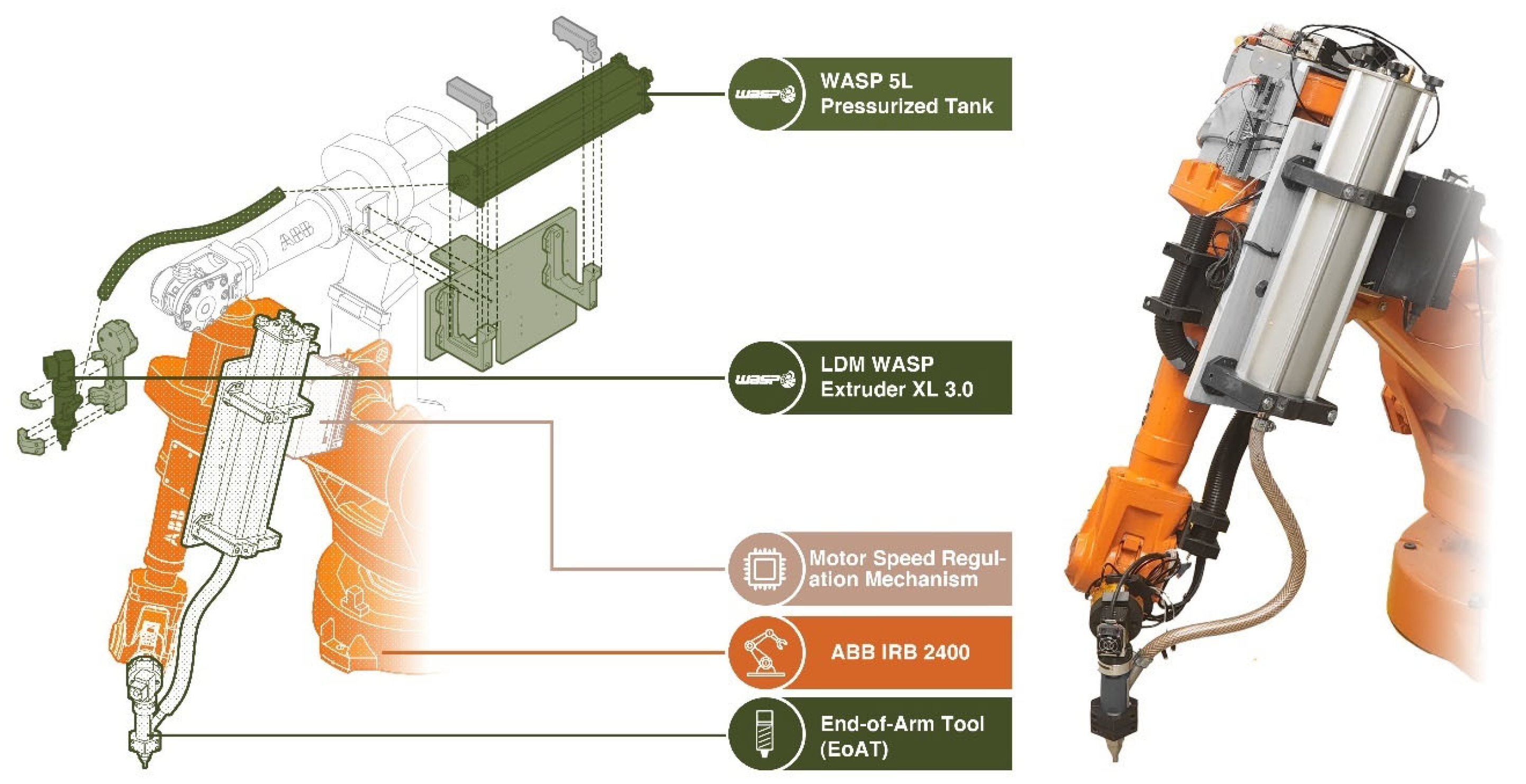

2.1. Robotic Fabrication System and Material Extrusion Tool

In this study, an ABB IRB 2400 industrial robotic arm (ABB Inc., Auburn Hills, MI, USA) located at the Stuckeman School DigiFab, was used for its six degrees of freedom, enabling precise and complex non-planar extrusion-based material deposition. The robotic toolpath generation for additive manufacturing was carried out using the Robots plugin (sourced from:

https://www.food4rhino.com/en/app/robots (accessed on 6 May 2025)) within Grasshopper for Rhinoceros 3D (Robert McNeel & Associates, Seattle, WA, USA).

Developed at ForMat Lab, the customized extruder system addresses the unique challenges of robotic EAM of mycelium-based composites with precision and sterility, as detailed in previous research by the authors [

23]. The extruder facilitates seamless disassembly and sterilization for contamination-free handling of living mycelium with a detachable end-of-arm tool (EoAT). The system combines an adapted LDM WASP Extruder XL 3.0 with a WASP 5L pressurized tank (sourced from Centro Sviluppo Progetti S.r.l.–WASP, Massa Lombarda, Italy) (

Figure 2, GitHub repository,

https://github.com/ForMat-Lab/WASP-XL-Extruder, accessed on 6 May 2025) [

24].

2.2. Formulation of Extrudable Mycelium Paste

The Ecovative Grow-It-Yourself Mushroom

® Material (Ecovative Design LLC, Green Island, NY, USA), a dehydrated blend of mycelium and hemp hurd, was used for this study [

25]. In the EAM workflow proposed by Bhardwaj et al. [

12,

13] using Dehydrated Grow-It-Yourself Mushroom

® Material, the entire process takes about 10–12 days. After a 5-day primary colonization in growth bags, psyllium husk (gelling agent) and water are added to the colonized mycelium mixture during the mixing stage, as a carrier liquid is necessary for the successful extrusion of binder-free pastes.

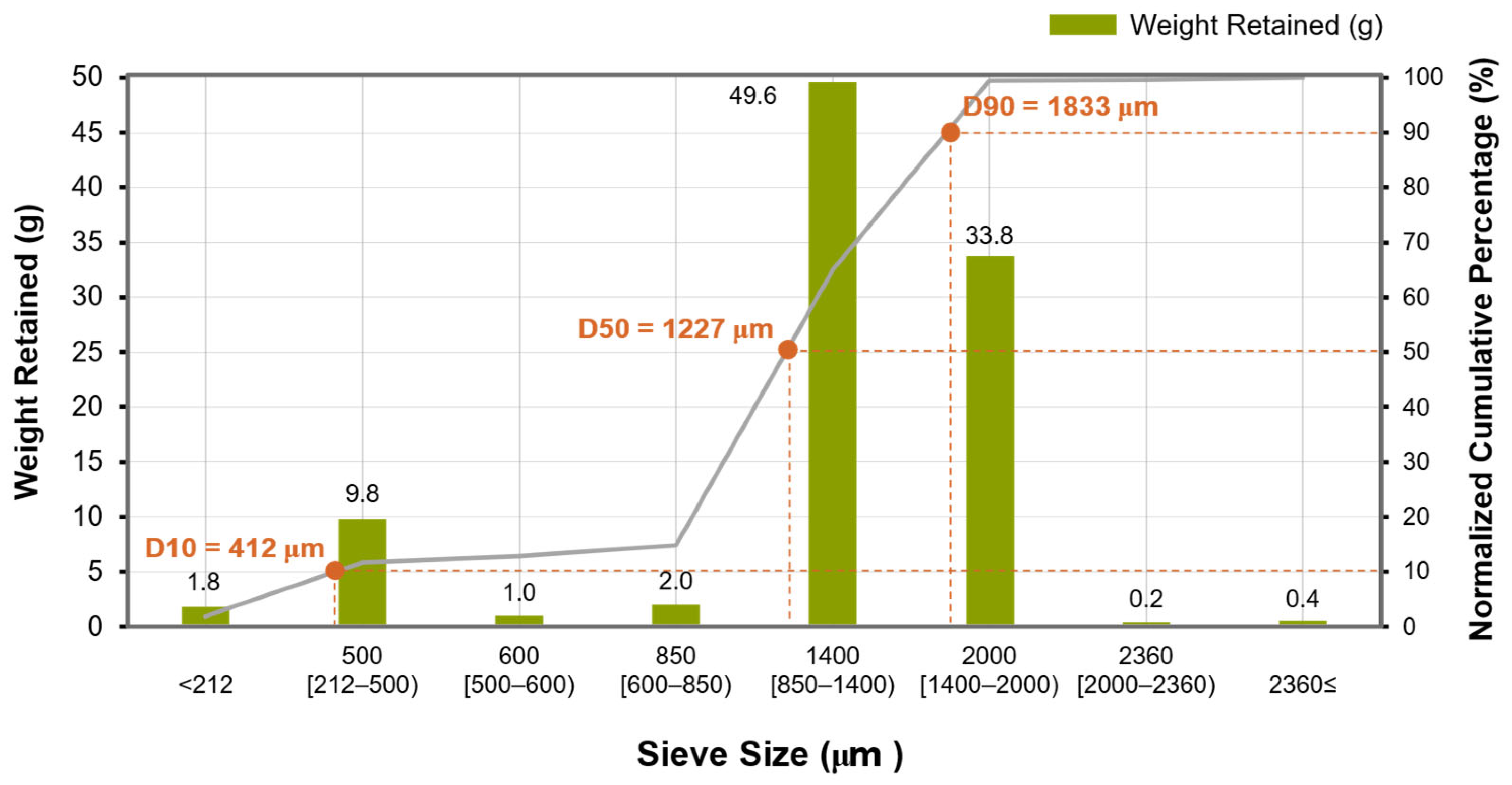

In this research, the process was streamlined by establishing a new workflow for preparing living, extrudable mycelium mixtures, involving alterations in the preparation sequence and adjustments in the admixture ratios. By strategically bypassing mycelium inoculation and first colonization steps, the overall timeline was reduced to 7 days from 12 days. The Ecovative Grow-It-Yourself bag was ground using a Homgeek 2000W Blender (Homgeek, Shenzhen, China) for 90 s to obtain a finer substrate. Particle size and distribution (PSD) are critical factors affecting the flowability, bulk density, and compressibility of densified materials [

26]. Given the diverse sizes and shapes of the ground Ecovative mixture in this study, it is important to determine and control the PSD. Sieve analysis, following ASTM C136, provides detailed particle size distribution data [

27]. In this study, an RX-86 Horizontal Vibrating Sieve Shaker (W.S. Tyler, Mentor, OH, USA) was used, and 100 g of ground Ecovative mixture was passed through a stack of sieves arranged by decreasing aperture sizes of 2.36 mm, 2.00 mm, 1.40 mm, 850 µm, 600 µm, 500 µm, and 212 µm. The ground Ecovative mixture was separated with mechanical shaking for 60 s into size fractions. After shaking, each sieve with captured material was weighted, and the weight of the sieves themselves was subtracted. After determining the PSD, the data were further analyzed to derive characteristic size parameters, like D10, D90, and D50, which are commonly used for specification purposes. Derived from the cumulative undersize curve, D10 signifies the particle size below which 10% of the sample lies, D50 represents the median particle size, and D90 marks the size below which 90% of the sample is distributed [

28]. For this study, these metrics help to develop an extrudable paste using the ground Ecovative mixture that has consistent rheological properties for EAM, avoiding nozzle blockage.

Following a previous study by the authors [

16], we based our calculation on the weight ratio of colonized mycelium, psyllium husk, and sterilized water as 5:2:30, where the psyllium husk is 10% of the weight ratio of water. This ratio is used as the foundation for preparing new mixtures for our experiments. To develop the paste directly from the ground Ecovative mixture, bypassing the initial colonization step of mycelium in growth bag, it is necessary to calculate the total water content added in two steps: (1) during the colonization step of the Ecovative Grow-It-Yourself Mushroom

® Material (Referred as W1 in this study) and (2) during the mixing step to prepare the paste (Referred as W2 in this study). According to the Ecovative

® website, the dry weight of the colonized material in each bag is 0.9 lb, which was approximated as 400 g for this study [

25]. The weight of the colonized material after five days of growth was 1132 g. Using these values, the total water added per 100 g of dry material during the colonization and mixing steps was calculated (

Table 1).

Following

Table 1, the total water content is determined as 1307 mL per 100 g of ground Ecovative mixture (GM). The water content was reduced in the new formulation compared to the previously developed mixtures [

12,

13,

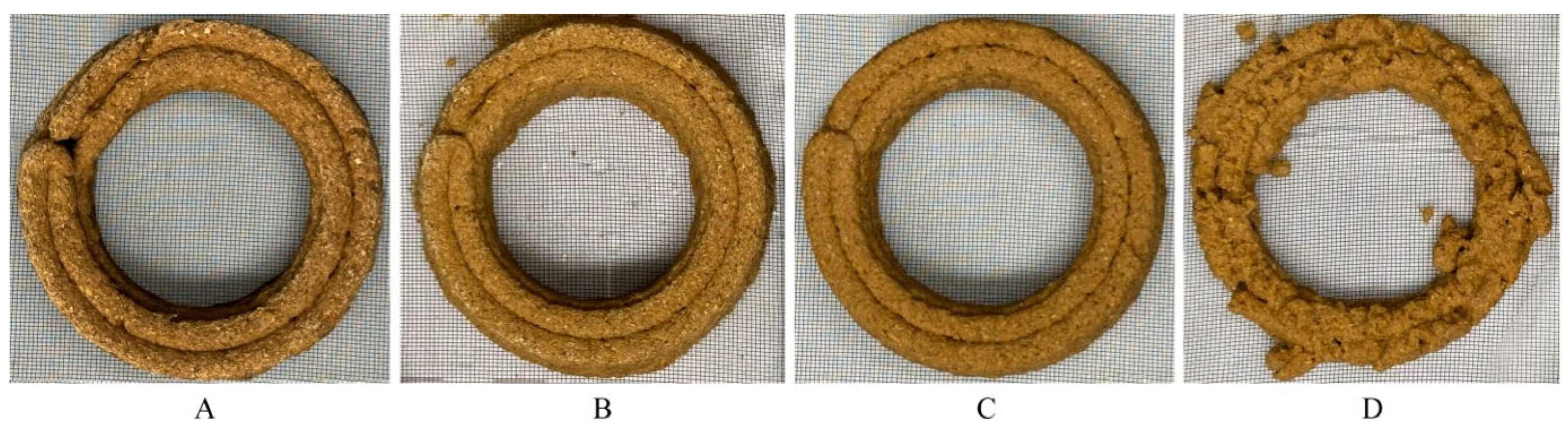

16] by 54% in this study, and 600 mL of water per 100 g of ground Ecovative mixture was added to formulate pastes with different amounts of psyllium husk (PH) for our experiments. Additionally, the flour content in the paste formulation is doubled to increase the nutritional support for the mycelium. The new ratio of GM:W:PH:F is 5:30:3:0.8 by weight. To assess the reduced growth duration using this new paste formulation, ring-shaped samples with a 6cm diameter were manually extruded and incubated at 25 °C and 65% relative humidity for 7 days. These samples were observed bi-daily to monitor mycelium colonization. Psyllium husk constitutes 10% of the water weight in the base mixture. To evaluate the effect of reducing psyllium husk content on the extrudability and buildability of different pastes, we prepared mixtures with psyllium husk constituting 8%, 6%, 4%, and 2% weight ratios of water (

Table 2). Cylindrical samples (10 cm diameter, 8 layers, 8 mm bead width) were robotically 3D printed to compare their extrudability and buildability.

2.3. Parameter Optimization of Robotic EAM Processes

The use of mycelium mixtures in EAM for fabricating biocomposites introduces unique challenges due to their material properties. Unlike more homogeneous materials such as clay, mycelium composites exhibit a degree of variability that complicates the consistency of extrusion rates. This variability is not solely due to the material’s heterogeneity but also a result of its tendency to de-gas, a process where air trapped within the composite is released during material deposition. This de-gassing effect can cause significant changes in the volume of the material as air is released, which in turn affects the stability of the extrusion rate—a factor critical to achieving accurate deposition of material.

Given the complexity of predicting the mycelium mixture’s behavior under extrusion, a data-driven approach utilizing machine learning offers a potential solution. By framing the task as a regression problem, we aim to establish a predictive model that can infer optimal extrusion speeds from a given set of robotic EAM parameters, thereby enhancing the precision and reliability of the robotic EAM process with mycelium-based materials.

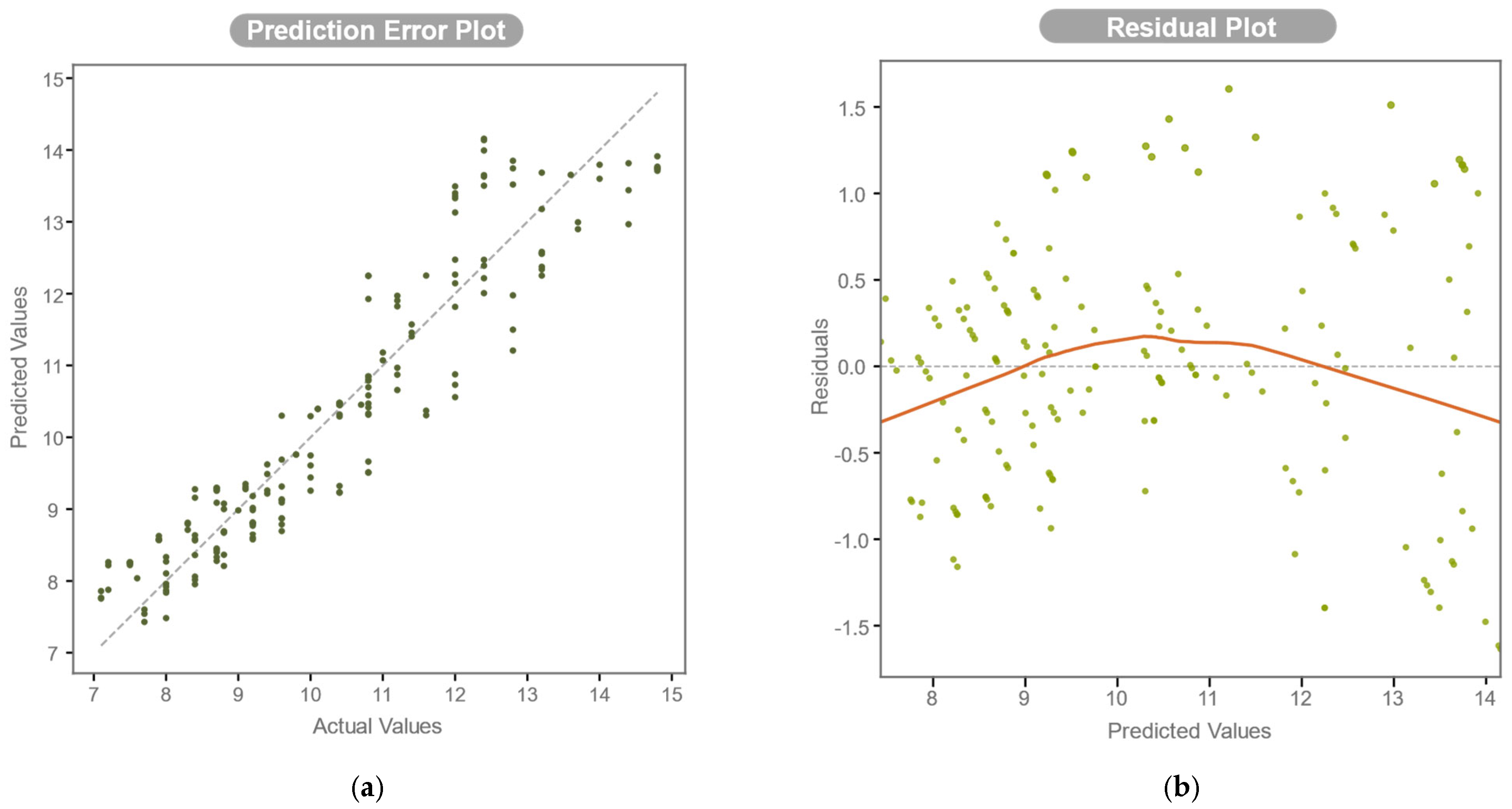

To achieve this goal, one of the key steps was collecting a comprehensive dataset that accurately reflected the behavior of mycelium mixtures during the robotic EAM process. Initially, heuristic approaches were employed to delineate an experimental space, setting baseline parameters for fabrication processes. This preliminary step was crucial to construct a foundational understanding of the relationship between robot speed and extrusion rate. From this, a preliminary Linear Regression model was developed to predict extrusion rates from robot speeds. This model guided the experimental design across a spectrum of robot speeds, facilitating the collection of empirical data. For each speed, the process was run at variations of ±50% around the predicted extrusion rate. During these runs, a single continuous bead of material was deposited, and the resulting layer height and width were meticulously measured with a caliper every 10 mm. This procedure was repeated across 42 experimental runs, each with 12 replicate measurements, yielding a comprehensive dataset reflective of the robotic EAM process’s nuances. The collected data were further processed into new features, namely difference in layer height (), and difference in layer width (), aiming to provide a clearer signal for the model to learn from as compared to raw measurements.

In our experimental observations, significant under- and over-extrusion at the extreme ends of the robot speed range indicated that the relationship between the robotic EAM parameters and extrusion speed was not strictly linear. To capture these interactions, we adopted an Artificial Neural Network (ANN) approach—well suited for modeling non-linear relationships and generalizing from data where traditional linear models fall short. Our ANN, implemented using the Keras API for TensorFlow, features a 3-32-32-1 architecture: three input features (robot speed, , and ) are processed through two hidden layers of 32 neurons each using the Exponential Linear Unit (ELU) activation function, and the network culminates in a single output neuron that predicts the extrusion speed. Prior to training, input features were standardized using a RobustScaler, which enhances resilience against outliers and ensures consistent scaling of the key parameters influencing extrusion quality.

The dataset was partitioned into training and test sets using an 80–20 split. Model training was first validated via 5-fold cross-validation conducted exclusively on the training data, with each fold undergoing independent scaling to prevent data leakage. Subsequently, the final model was trained on the complete training set and evaluated on the hold-out test set. During cross-validation, early stopping was employed to mitigate overfitting, and a learning rate reduction on the plateau ensured smooth convergence. The Adam optimizer was selected for its robustness and efficiency in handling the complexities of noisy, heterogeneous data. Our training objective was to minimize the mean squared error (MSE) between predicted and actual extrusion speeds, thereby fine-tuning the network to capture the intricate balance of factors inherent in the robotic EAM process.

2.4. Performance-Based Design and Conformal Toolpath Development for Robotic Extrusion-Based Additive Manufacturing of Acoustic Wall Panels

The design of the proof-of-concept acoustic wall is informed by simulations in Pachyderm, an open-source acoustic analysis plugin for Rhinoceros 3D (sourced from

https://www.food4rhino.com/en/app/pachyderm-acoustical-simulation (accessed on 6 May 2025)) [

29]. Pachyderm employs raytracing and image-source methods to predict room acoustics, using geometrical features and surface material data as inputs. The normal incidence absorption coefficients of the mycelium-based composites are included as inputs in these simulations. The primary objective is to validate mycelium-based composites as noise control materials and inform the design of the acoustic absorber wall before the robotic fabrication of panels.

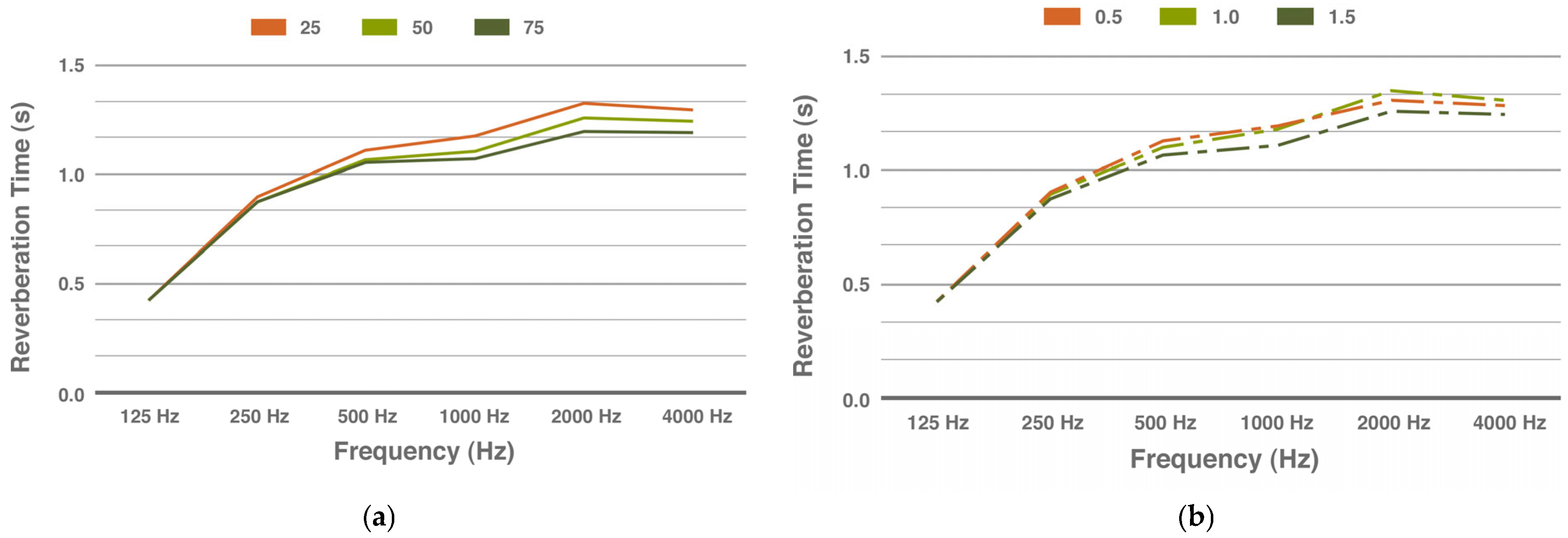

To compare the parametric design alternatives for the mycelium-based acoustic absorber wall, reverberation time is chosen as the comparative parameter in Pachyderm. Reverberation time refers to the amount of time it takes for the sound pressure level to reduce 60 dB after the sound source stops producing sound [

30]. For our purposes, shorter reverberation times are preferred, as longer reverberation times are associated with reduced speech intelligibility and quality [

31]. The simulation environment consists of an empty room, a geodesic sound source, a stationary receiver, and the proposed mycelium-based acoustic wall. Sound absorption coefficients are assigned to the interior surfaces of the 3D model using Pachyderm’s material editor. Each simulation traces 5000 rays to obtain the room’s reverberation time and is run four times. The results are averaged to reduce error.

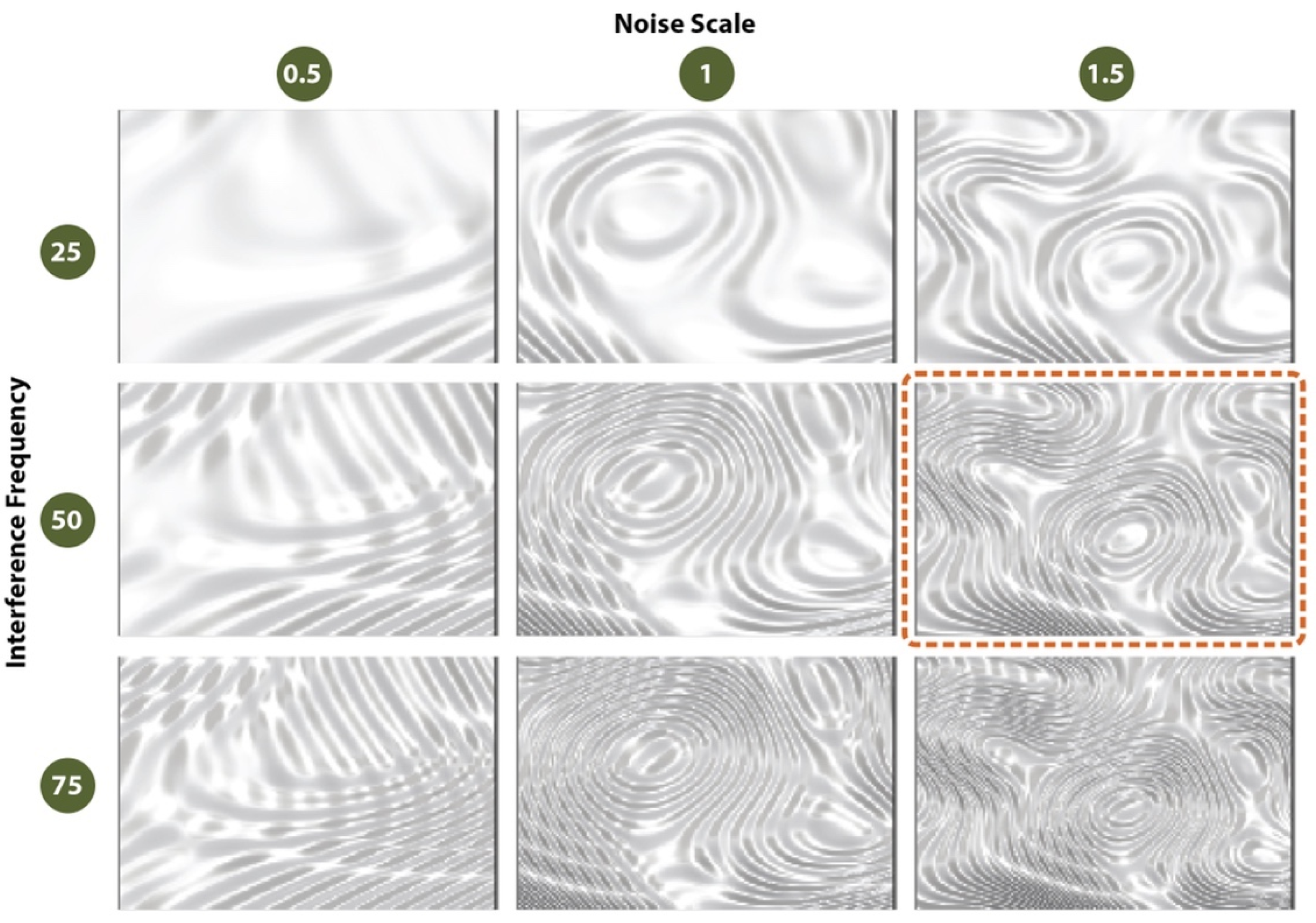

This study employs a geometric design space for methodically exploring the effects of surface complexity on acoustic performance, aiming to establish parametric control over the geometric feature frequency. This was achieved by deriving an interference pattern between a 2D simplex noise and a 1D sine wave across the proposed design. In our implementation, the parametric model was defined by three variables. The first was the scale of the 2D simplex noise, responsible for dictating the overall complexity of the design’s surface. The second variable was the frequency of the 1D sine wave, controlling the pattern periodicity within the design. Lastly, the amplitude of the resulting interference pattern was set, allowing us to adjust the depth and intricacy of the design. The effects of Noise Scale and Interference Frequency on geometric complexity can be seen in the design alternatives in

Figure 3.

To allow for a meaningful comparison of acoustic simulation results, we ensured that the average panel thickness across the whole design was consistently set at 38 mm. This choice of thickness is compatible with previous acoustic tests we conducted using an impedance tube, thus establishing a consistent baseline for performance evaluations. As shown in the graphs in

Figure 4, the more detailed and complex acoustic wall designs reduce reverberation time more than the less geometrically complex designs, achieved both by varying the Interference Frequency (

Figure 4a) and Noise Scale (

Figure 4b) parameters.

The design process of the acoustic absorber wall also involved a careful balance between achieving geometric complexity and ensuring fabricability by considering the constraints and affordances of the extruder end-of-arm tool. These lead to the development of the design option (highlighted in the red box in

Figure 3) with a Noise Scale of “1.5” and an Interference Frequency of “50.” The resulting geometry is discretized into individual wall panels with a footprint of 250 by 250 mm to ease the robotic fabrication process (

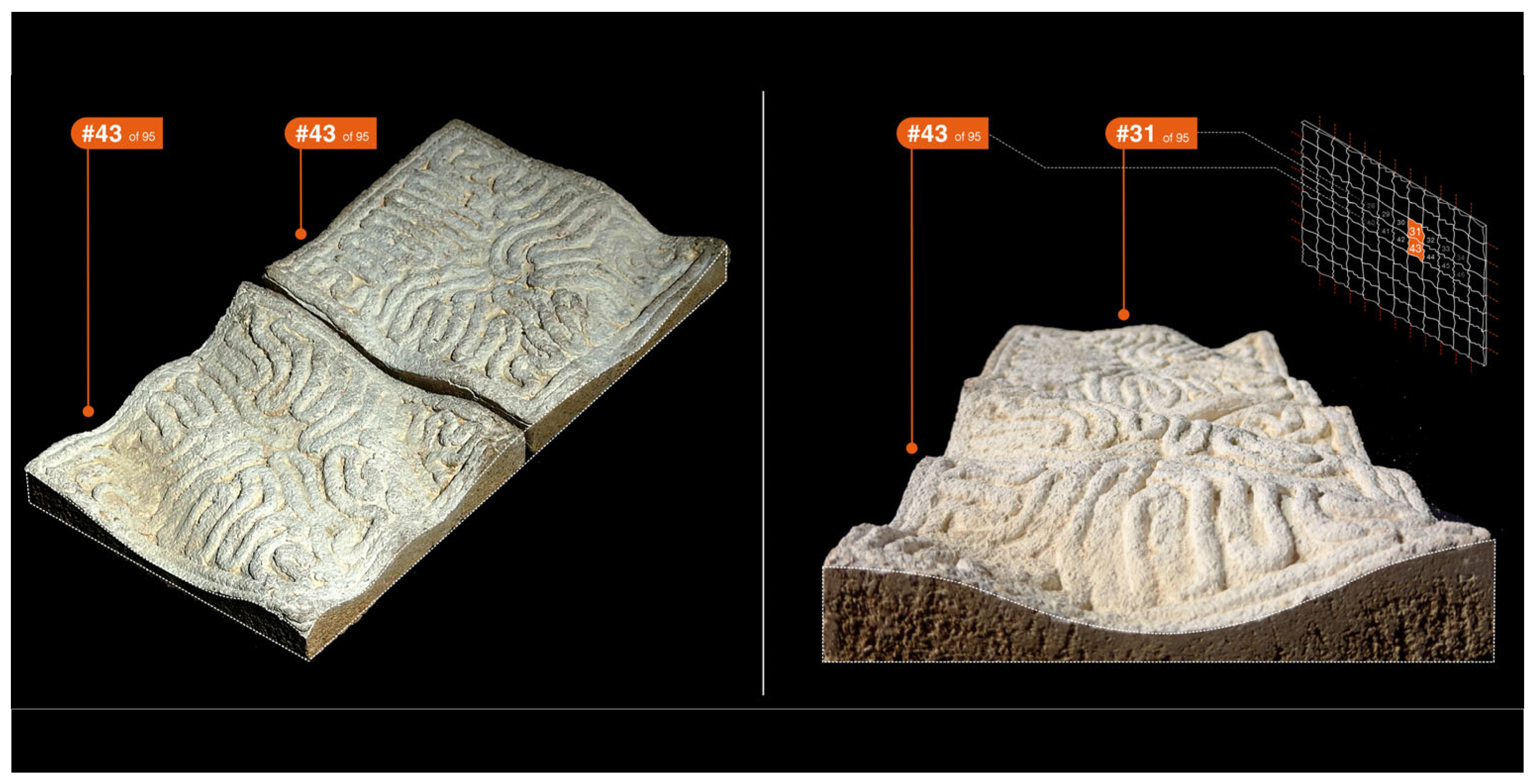

Figure 5).

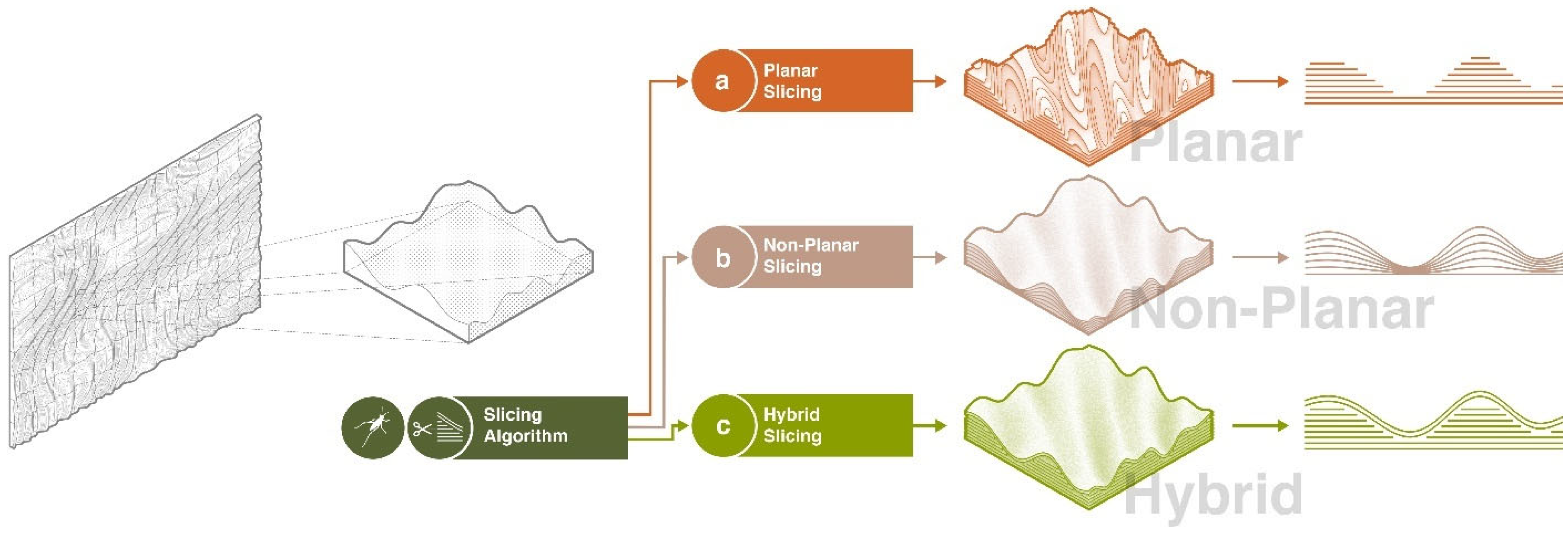

Building upon our previous research on conformal robotic EAM of mycelium-based composites, we selected two adjacent panels with more complex geometric feature frequency for fabrication (panels numbered 31 and 43). These panels were chosen to present a challenging test scenario where conventional planar slicing techniques are prone to significant stair-stepping phenomena, and non-planar slicing methods introduce irregularities in layer height. To address these limitations, highlighted in

Figure 6a,b, a hybrid slicing strategy was proposed by integrating both planar and non-planar slicing techniques (

Figure 6c). By combining planar and non-planar slicing methods, this hybrid strategy leverages the computational efficacy of planar slicing while enhancing geometric accuracy through the precision offered by non-planar slicing. The hybrid slicing strategy is built on a process of geometric discretization that divides the target volume into regions for planar and non-planar slicing. The process begins by identifying and offsetting the top surface of the target geometry to determine areas suitable for each slicing technique. The offset provides sufficient clearance above the base surface to prevent collisions during printing. The base volume is sliced using equidistant horizontal planes to generate planar layers, while the top volume is non-planarly sliced, following the contour of the offset surface.

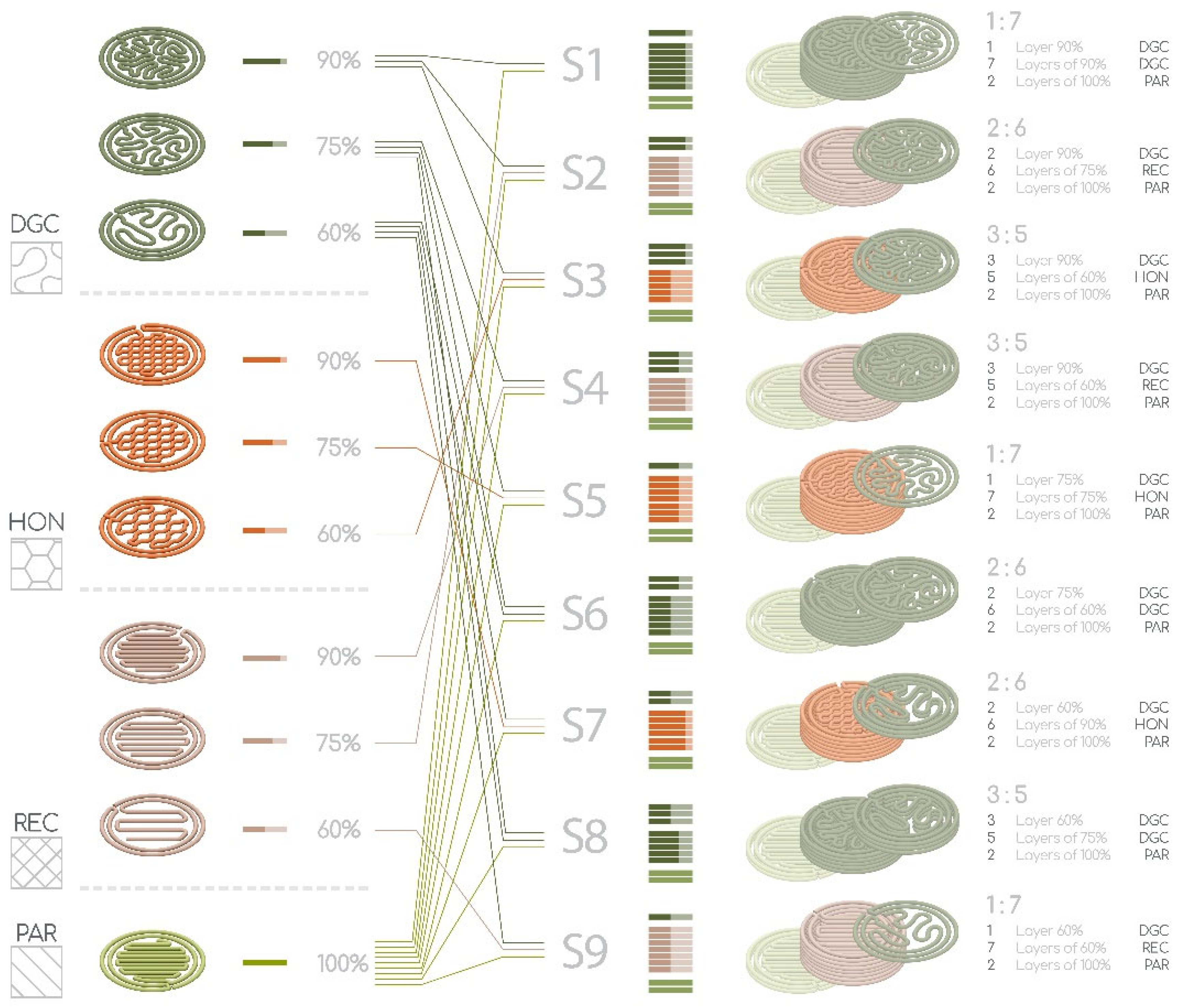

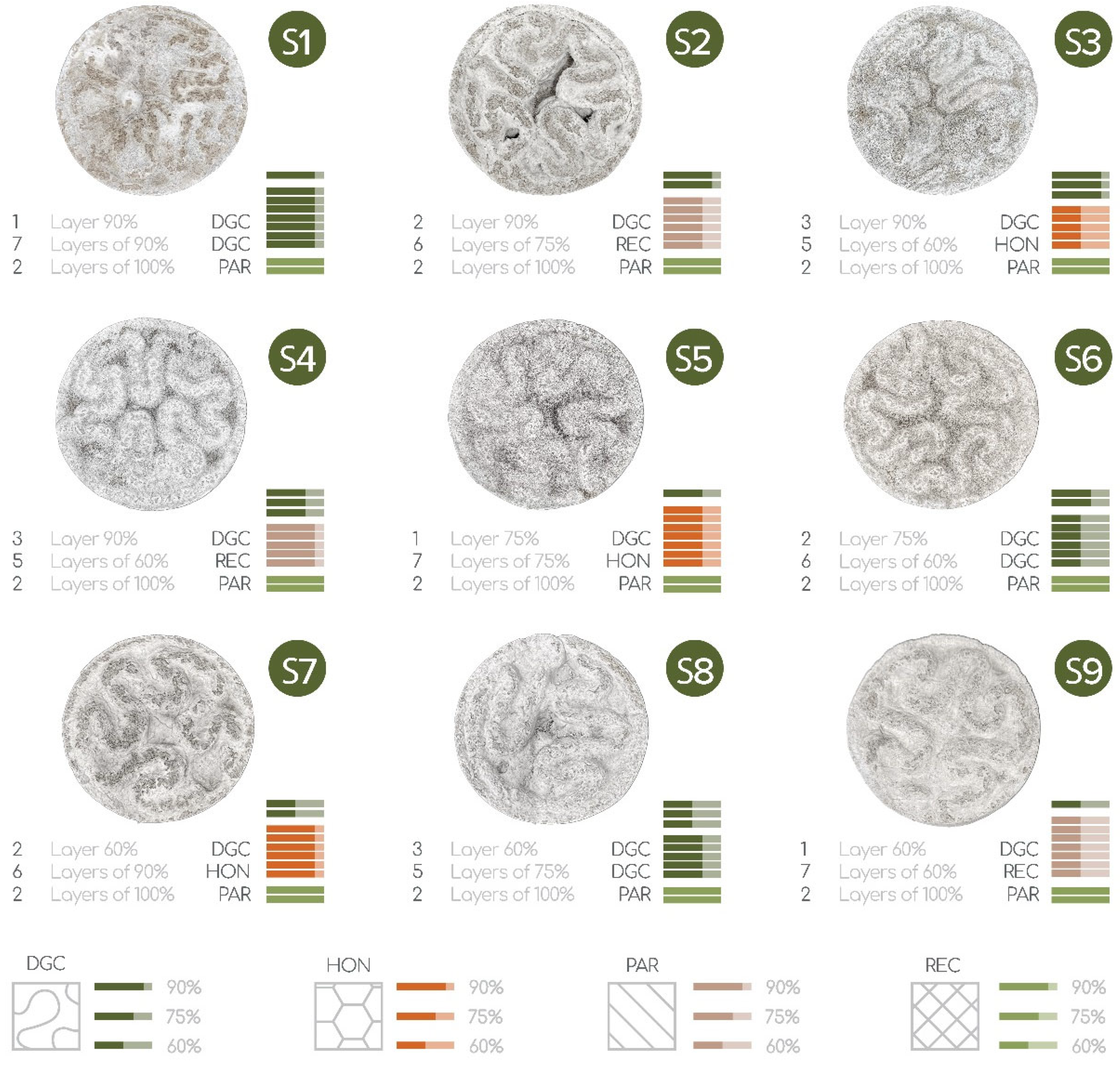

2.5. Experimental Framework for Acoustic Properties Assessment

To assess the influence of robotic EAM toolpath planning factors on the acoustic properties of the designed acoustic panels, a rigorous experimental framework has been developed. This framework adopts the Taguchi method for the design of experiments (DOE), a statistical approach that utilizes a set of orthogonal arrays to examine numerous factors with as few experiments as possible. The goal of this framework is to identify how three key toolpath planning factors, including the infill percentage of the toolpath referring to the spacing between adjacent beads of material, the toolpath design pattern, which defines the geometric arrangement of deposition toolpath, and the ratio of geometric discretization of the panels, which determines the division of the panels into planar and non-planar slicing regions.

The L9 Taguchi orthogonal array is being used in this study (

Table 3), which accommodates four factors, each tested at three levels. This configuration provides a comprehensive evaluation of the toolpath planning factors while reducing the total number of experiments to nine different configurations. Four factors being assessed in this experiment include the following:

The infill percentage of the non-planar layers, referring to the density of the deposited material in the region that is being sliced non-planarly;

The infill percentage of the planar layers, referring to the density of the deposited material in the region that is being sliced planarly;

The infill pattern used in the planar layers, including Differential Growth Curve (DGC), Parallel, and 3D Honeycomb. Planar layers here represent the region in the panels that will be sliced planar;

The ratio between the number of layers in planar and non-planar regions of the panel.

The Differential Growth Curve (DGC) is being used as an infill pattern for all non-planar layers to maintain the geodesic distance between adjacent material beads.

Table 3 shows the different levels of each factor being used in this experimental framework, and

Table 4 outlines the experimental matrix, where each row represents a specific combination of factor levels corresponding to the design of experiments.

The ASTM E1050-19 standard outlines a method for measuring the sound absorption coefficient and acoustic impedance of the material using an impedance tube [

32]. In this study, the two-microphone transfer-function method is used as defined in ASTM E1050-19. This study uses two tube sizes, 100 mm and 29 mm in diameter, to assess low- and high-frequency ranges, respectively. The 100 mm tube is calibrated for frequencies between 50 Hz and 1600 Hz, while the 29 mm tube covers a range from 505 Hz to 6400 Hz. Cylindrical acoustic samples are fabricated to match the inner dimensions of the impedance tubes for proper sealing and accurate measurements, and each sample is 38 mm in thickness. For statistical reliability, three replicates are fabricated for each of the samples defined in

Table 4. Each replicate was measured three times for the repeatability and reliability of the measurement. The measurement process includes both a 100 mm diameter and a 29 mm diameter impedance tube to collect data across the full standard acoustic frequency range (125 Hz to 4000 Hz). Low-frequency absorption data (125–1000 Hz) were collected using the 100 mm tube, whereas high-frequency data (2000–4000 Hz) were collected from the 29 mm tube measurement. This results in a total of 27 samples per tube size and 54 samples overall. Each sample is composed of 10 layers in total, with the bottom two layers uniformly printed in all of the samples using a parallel toolpath design pattern and 100% infill density. These base layers are implemented to prevent the formation of open vertical channels, which could potentially invalidate the impedance tube tests.

Figure 7 illustrates the configuration of each sample, with each color representing a specific infill pattern applied to the layers.

After robotic EAM of the cylindrical samples, they were kept in an environmentally controlled room at 65% humidity and 24 °C at Mushroom Research Center (MRC, State College, PA, USA) for 7 days. The samples were air-dried for 24 h and then oven-dried at 90 °C for 48 h. Due to deformation and warping during growth and drying, as well as the precision required for impedance tube tests, additional post-processing was necessary. The samples were carefully sanded using a belt sander to achieve precise roundness for an exact fit within the impedance tubes for accurate acoustic measurements. An impedance tube was used to measure the normal incidence sound absorption coefficients at both high and low frequencies for each sample group, with three measurements taken per sample. This method provided a quantitative analysis of how different toolpath planning factors—namely infill percentage of planar and non-planar layers, infill patterns of the planar layers, and ratios of non-planar to planar layers—affect acoustic absorption coefficient across a range of frequencies. In the impedance tube test, a sound source sends broadband sound waves toward a sample, generating a pattern of forward and backward traveling waves inside the tube. Calculations of normal incidence absorption coefficients are then performed following standard ASTM E1050-19 to compare sound absorption in the 500 Hz to 6.4 kHz frequency range [

32].

Statistical analysis was performed using Minitab (Web-Based Version. Minitab LLC: State College, PA, USA.

https://app.minitab.com/ (accessed on 6 May 2025)) to study the impact of different levels of factors on mean performance (absorption coefficients) and variability in performance (signal-to-noise ratios, SN).

4. Discussion and Conclusions

This study underscores the potential of MBCs in sustainable construction, particularly for acoustic applications. By leveraging robotic EAM, we developed acoustic panels that exhibit promising sound absorption properties. The proposed material formulation and robotic EAM process demonstrated that MBCs could serve as viable alternatives to synthetic acoustic insulators.

The material formulation used in this study demonstrated significant improvements by reducing the EAM timeline presented in the literature [

12,

13,

16], from 12 days to 7 days. This was achieved by using ground Ecovative mixture directly, instead of colonized material, to prepare the paste. The resulting formulation, with a weight ratio of 5:30:1.2:0.8 for ground Ecovative mixture, water, psyllium husk, and flour, allowed for a substantial 54% reduction in water content compared to previously developed mixtures based on the literature [

12,

13,

16]. This reduction in the water content was critical to minimize the deformation and shrinkage of the samples after EAM and provide a better extrudability and extrusion through an 8 mm nozzle without clogging throughout the process. The formulation was further validated through sieve analysis, which revealed a particle size distribution (PSD) for consistent flow and material deposition across different test experiments. The majority of particles fell within the range of 850–1400 µm, with D10, D50, and D90 values measured at 412 µm, 1227 µm, and 1833 µm, respectively. These metrics are critical to achieving stable rheological properties and preventing the nozzle blockage during EAM, while establishing a repeatable and standardized metric for the particle size of the ground Ecovative mixture.

The evaluation of the Artificial Neural Network (ANN) model underscores its predictive accuracy and practical applicability in optimizing the robotic EAM parameters for mycelium-based mixtures, achieving an R2 of 0.912 with low error metrics (MSE = 0.301, RMSE = 0.548, MAE = 0.423). The ANN model demonstrated superior performance compared to Linear and Polynomial Regression, particularly in capturing the complex, non-linear relationships inherent to the EAM process. Residual analysis indicated minimal bias and uniform error distribution, validating its reliability across varying conditions. These results highlight the ANN’s effectiveness as a computational tool for enhancing precision and control in the robotic EAM of mycelium-based materials.

The acoustic assessment revealed that toolpath planning parameters significantly influenced the sound absorption characteristics of the fabricated samples. Key findings demonstrated that a 60% infill for non-planar layers, 90% infill for planar layers, the Differential Growth Curve (DGC) pattern, and a 2:6 non-planar-to-planar layer ratio provided better acoustic performance. However, the scope of this study was limited by selected factors and levels tested within the experimental framework. While the Taguchi L9 orthogonal array provided valuable outcomes, it limited the exploration of potential interactions between factors and the comprehensiveness of the analysis. Future work should aim to address these limitations by considering a broader range of factors and levels, as well as using more extensive experimental arrays, to capture the complexities of toolpath planning and material behavior.

Compared to packed Ecovative material (α = 0.28) [

8], the printed samples showed comparable sound absorption coefficient values across all of the frequency bands. Beyond absorption coefficient values, using the proposed fabrication method in this study provides the ability to produce lower-density acoustic panels with reduced material used, and the potential to fabricate complex, customized geometries. The fabricated acoustic panels have potential applications in interior architecture (e.g., wall panels, ceiling baffles, partitions), noise control in public spaces (e.g., libraries, offices, auditoriums, educational facilities), and bio-integrated urban design aiming for sustainable acoustic solutions. The acoustic performance in this study is measured using an impedance tube, which offers frequency-dependent sound absorption data. While this method is established for empirical assessment of the sample, it does not offer data about the microstructural characteristics that control the sound propagation within the material. Mycelium-based composites are porous materials with an interconnected hyphal network and interconnected voids formed during the fungal growth [

33], allowing for air permeability and visco-thermal dissipation of sound. Among the microstructural modeling approaches to characterize the acoustic behavior of porous materials, the Johnson–Champoux–Allard (JCA) model offers a physically grounded method for predicting acoustic properties of the material based on measurable microstructural parameters, including open porosity, air-flow resistivity, tortuosity, viscous characteristic length, and thermal characteristic length [

34,

35]. JCA is a model that estimates the bulk density and bulk modulus of porous materials by modeling them as a homogeneous fluid medium [

36]. While this model was not used in this study, future investigations could adopt the JCA framework to advance the empirical testing.

While this was not within the scope of this study, mechanical performance remains a critical consideration for the architectural application of mycelium-based composites. Future work should address key mechanical properties of the developed material, including compressive strength, dimensional stability, and flexural resistance. Previous studies have laid important groundwork on the mechanical characteristics of mycelium-based composites, though using different substrates or fungi strains than those used in this study. Research has shown that substrate composition, fiber characteristics, and post-processing of the material significantly influence mechanical strength and moisture sensitivity [

37,

38]. Reinforcement using bacterial cellulose has been reported to enhance tensile and compressive strength [

39], while functional grading with nanoclay improves stiffness and toughness [

40]. Other studies have examined the effects of incubation time, natural fiber additives, and substrate blends on compressive and flexural performance [

41,

42]. Cultivation factors such as substrate density and growth duration also play a significant role in determining compressive strength, with denser substrates and shorter cultivation periods yielding stronger materials [

43]. These findings establish a foundational for future investigations into the mechanical performance of the mycelium-based material developed in this study, particularly in the context of its potential integration into other architectural applications.

Contamination during the growth and fabrication process was minimized using sterile tools and a controlled environment. However, this study did not assess contamination risk following the drying phase. Similarly, the biodegradability rate and long-term material behavior under varying humidity and temperature conditions were not examined. A recent study explored the biodegradability of mycelium composites by adapting a soil burial test under controlled conditions, showing that material composition, fabrication method, and environmental factors influence the disintegration process. Mycelium acted as the primary degradable component, with weight loss of up to 43% observed in samples after sixteen weeks in potting soil [

44]. While this methodology was applied to a specific fungal strain and substrate, it presents a relevant approach that could be adapted to assess the degradation behavior of the material developed in this study.

The successful integration of the formulated paste optimized robotic EAM parameters, and toolpath planning parameters in this study provides a foundation for the designing and fabricating acoustic panels using living mycelium-based mixtures.

While prior studies focused on paste formulation and extrusion feasibility of MBCs [

12,

13,

16], this study advances both the paste formulation and the EAM workflow. The paste is developed using ground Ecovative’s Dehydrated Grow-It-Yourself Mushroom

® Material, with inoculation initiated prior to EAM. This eliminates the need for a separate colonization step in growth bags, enabling direct EAM of the living material and significantly reducing the total fabrication timeline. Additionally, this study uses a data-driven strategy using an Artificial Neural Network (ANN) for optimizing the robotic EAM parameters for mycelium-based mixtures, which can be extended to future formulations for consistent and predictable extrusion. A hybrid slicing approach combining planar and non-planar slicing methods improves surface quality and enables fabrication of conformal geometries. Finally, this study uses robotic EAM for the fabrication of architectural-scale acoustic panels, demonstrating its potential for fabrication of performance-based building parts beyond conventional mold-based methods.

While this study focused on panel-scale fabrication and acoustic performance, future work should address installation methods and mounting details. Studying boundary conditions of the panels, joinery, and support structures will be necessary to minimize acoustic bridging. Acoustic bridge refers to a structural sound transmission path that couples with the airborne sound pathway and reduces overall sound transmission loss [

45].

Beyond acoustic panel fabrication, this research addresses the growing need for precise and efficient fabrication solutions for biomaterials, ultimately contributing to more sustainable material development. Future studies could investigate the long-term durability and biodegradability of MBC-based acoustic panels to expand their use in architecture. Additionally, broadening the methodology to explore various paste formulations, geometries, and toolpath planning strategies would enable application-specific designs that meet an even wider range of performance requirements.