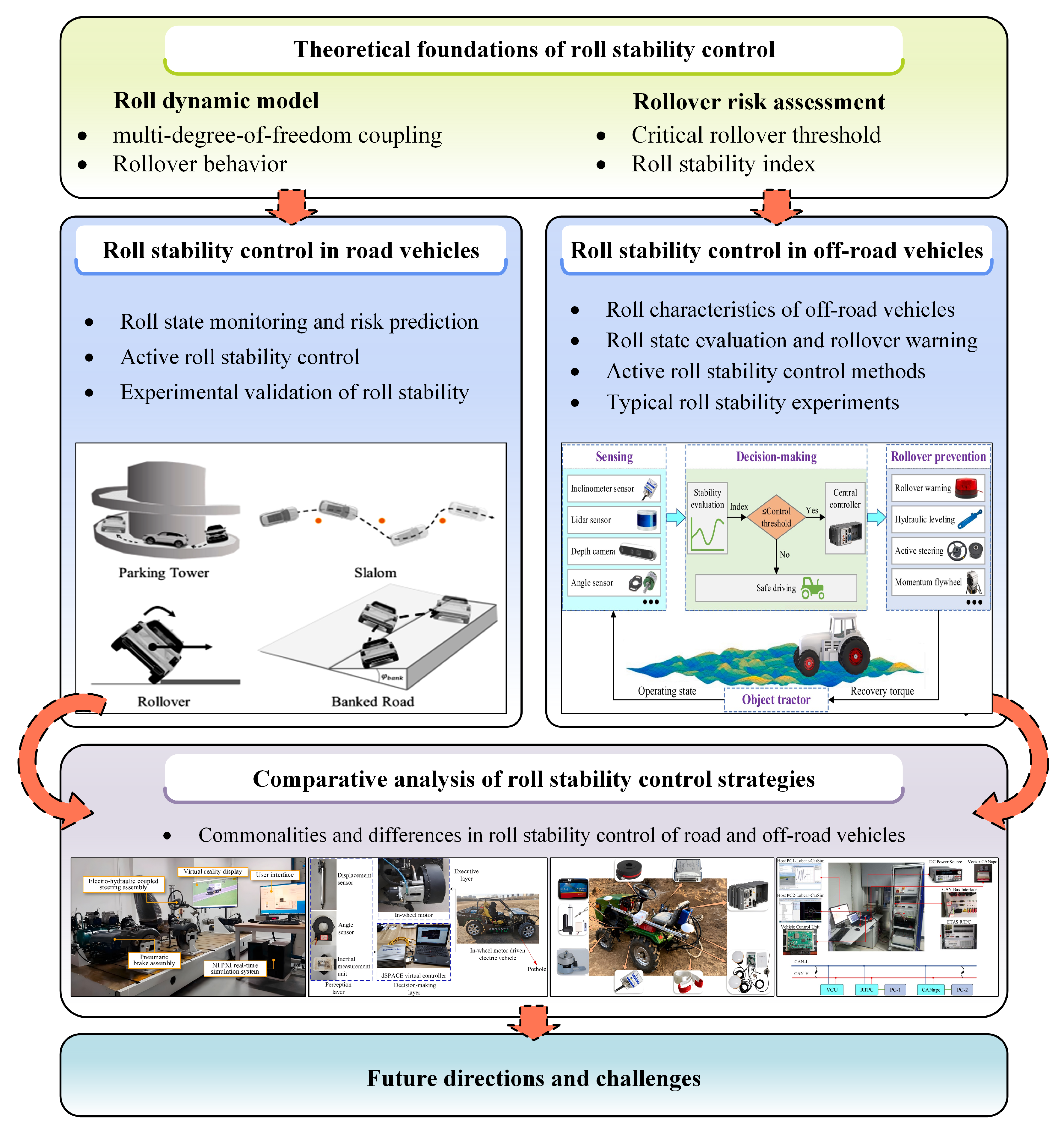

A Review of Recent Advances in Roll Stability Control in On-Road and Off-Road Vehicles

Abstract

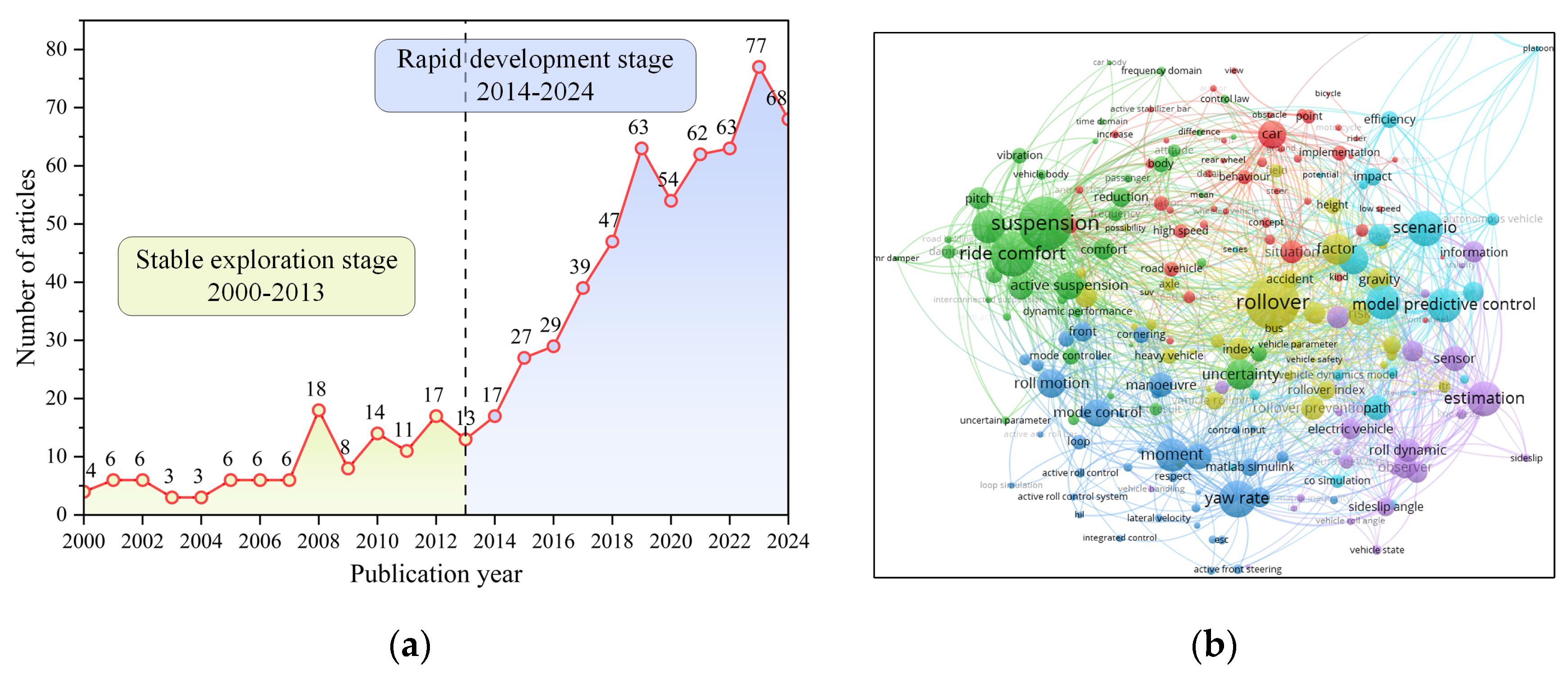

1. Introduction

2. Research Method

3. Theoretical Foundations of Roll Stability Control

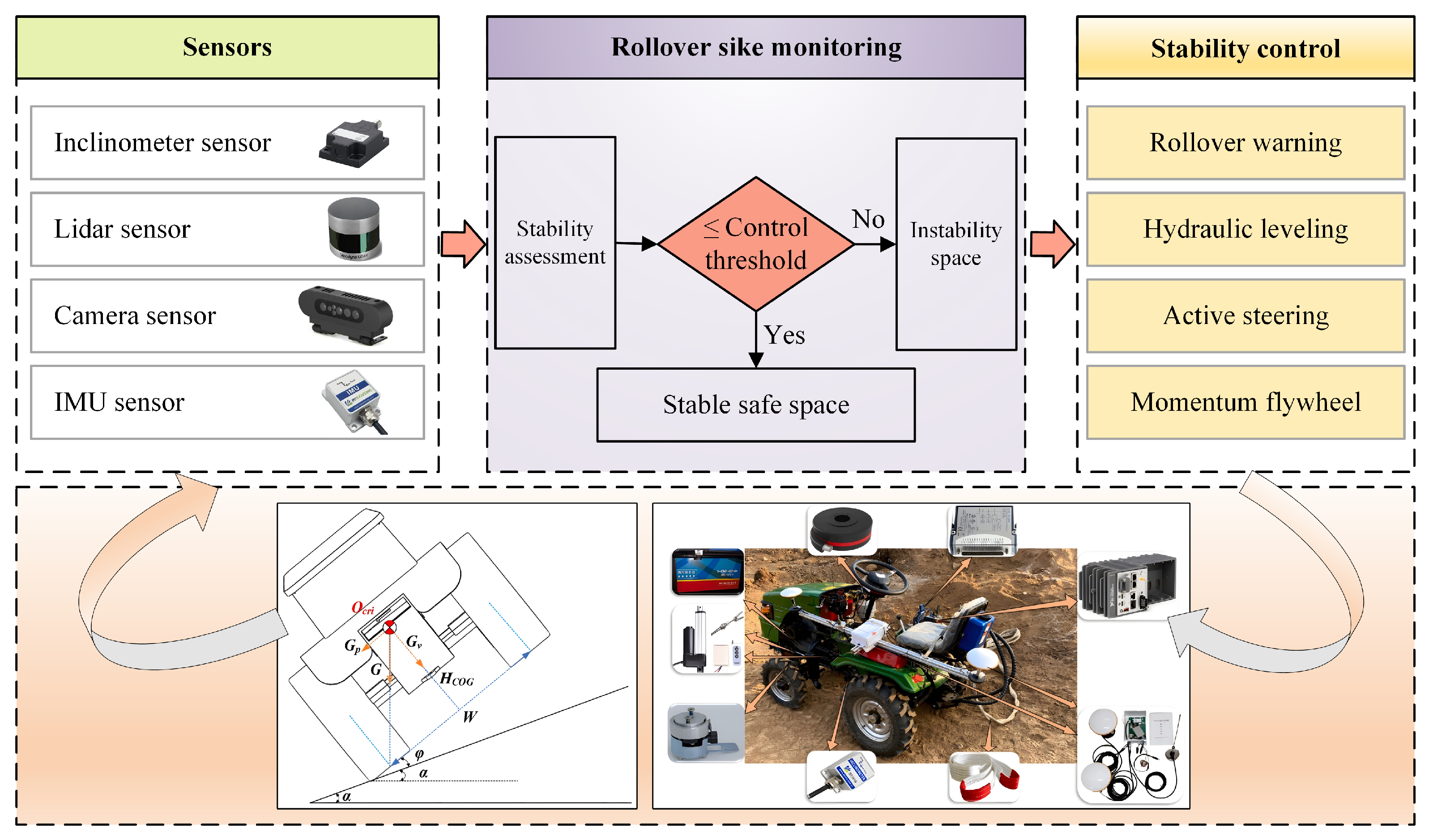

3.1. Roll Dynamic Model

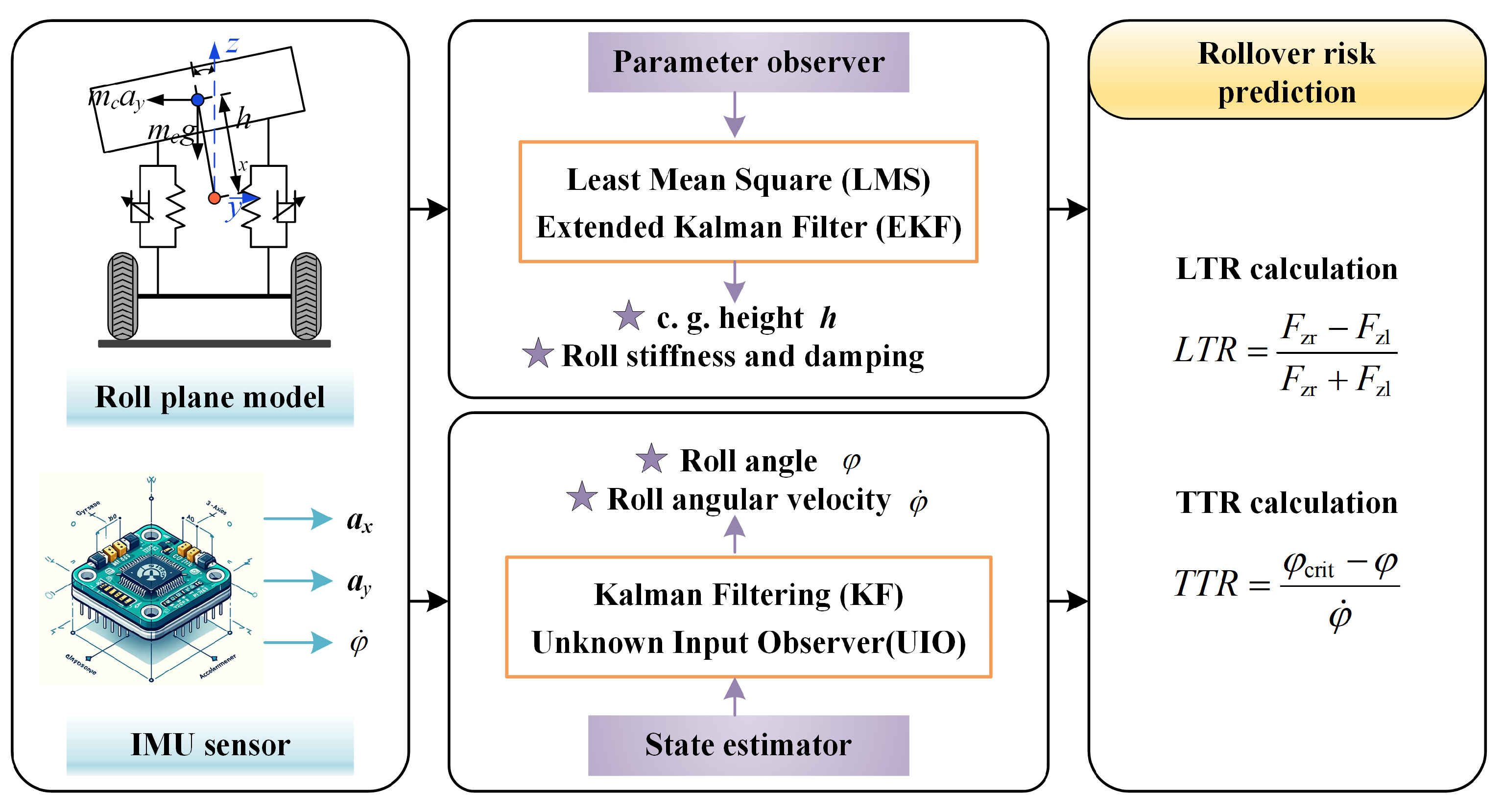

3.2. Rollover Prediction Index

3.3. Basic Principles of Roll Stability Control

4. Roll Stability Control in Road Vehicles

4.1. Roll State Monitoring and Risk Prediction

4.2. Active Roll Stability Control Technologies

4.2.1. Single-Actuator Control

4.2.2. Integrated Stability Control

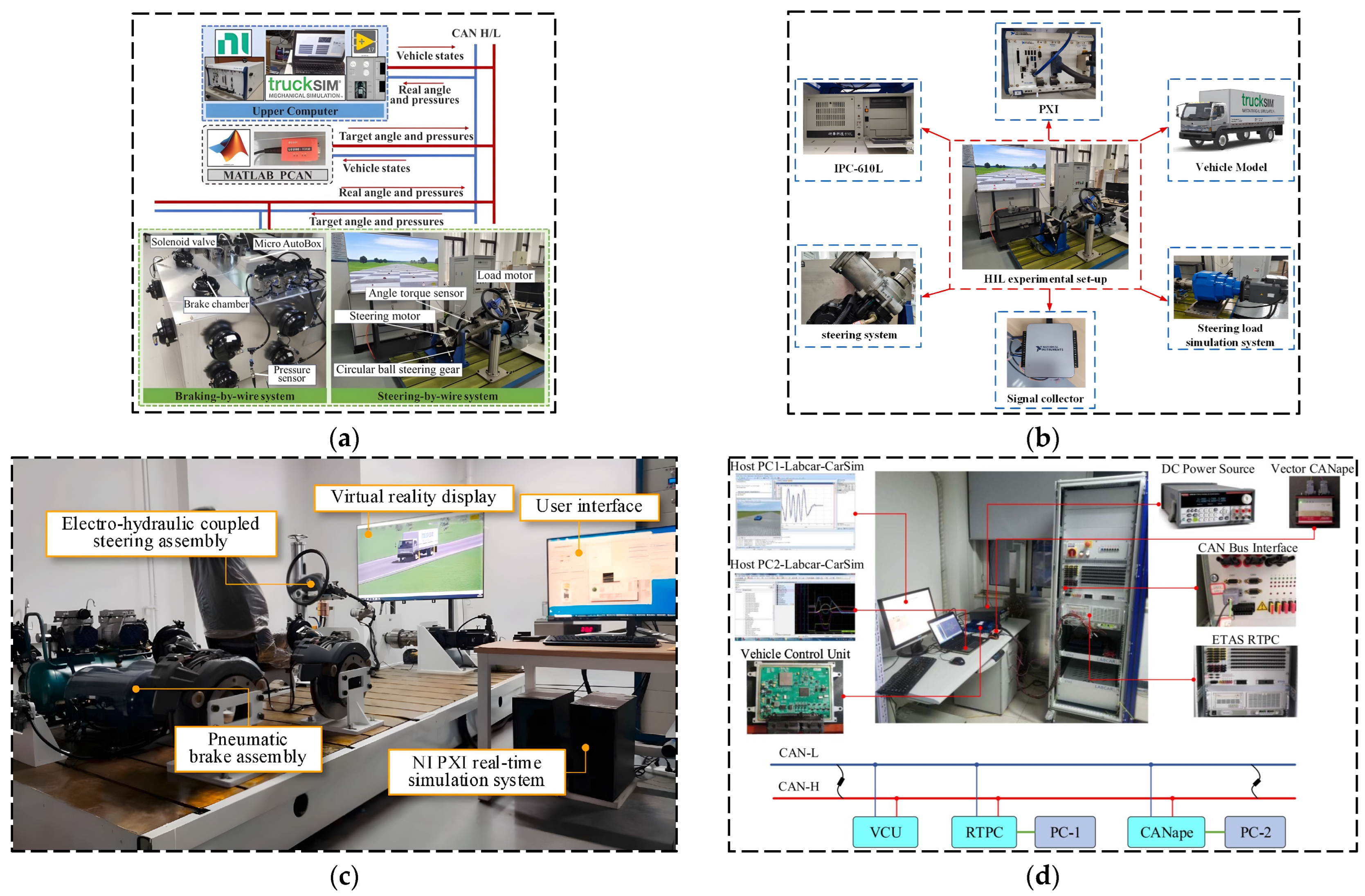

4.3. Experimental Validation of Roll Stability for Road Vehicles

4.3.1. HIL Experiment Tests

4.3.2. Real-Vehicle Tests

5. Roll Stability Control in Off-Road Vehicles

5.1. Roll Characteristics of Off-Road Vehicles

5.2. Roll State Evaluation and Rollover Warning

5.3. Active Roll Stability Control Methods

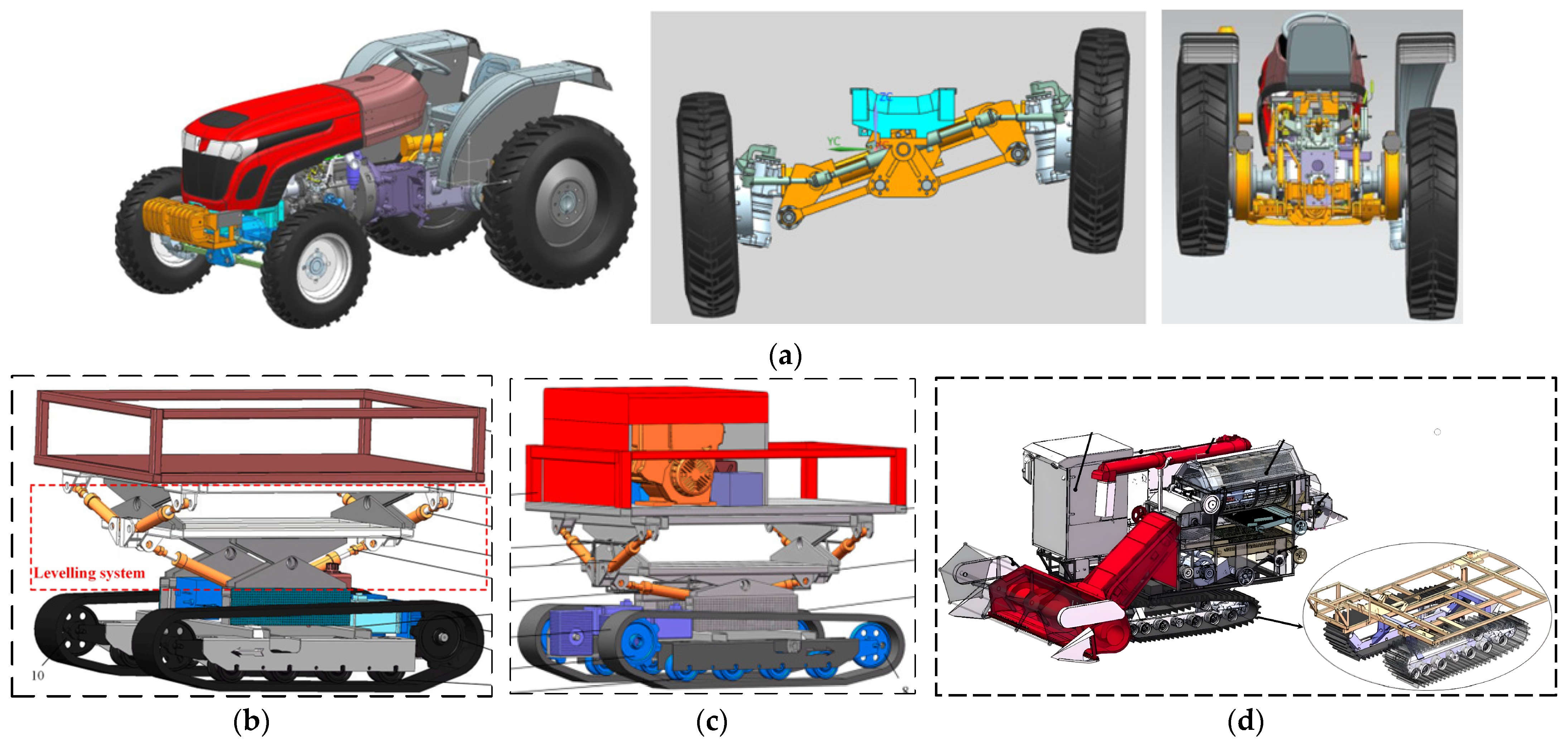

5.3.1. Active Leveling Control

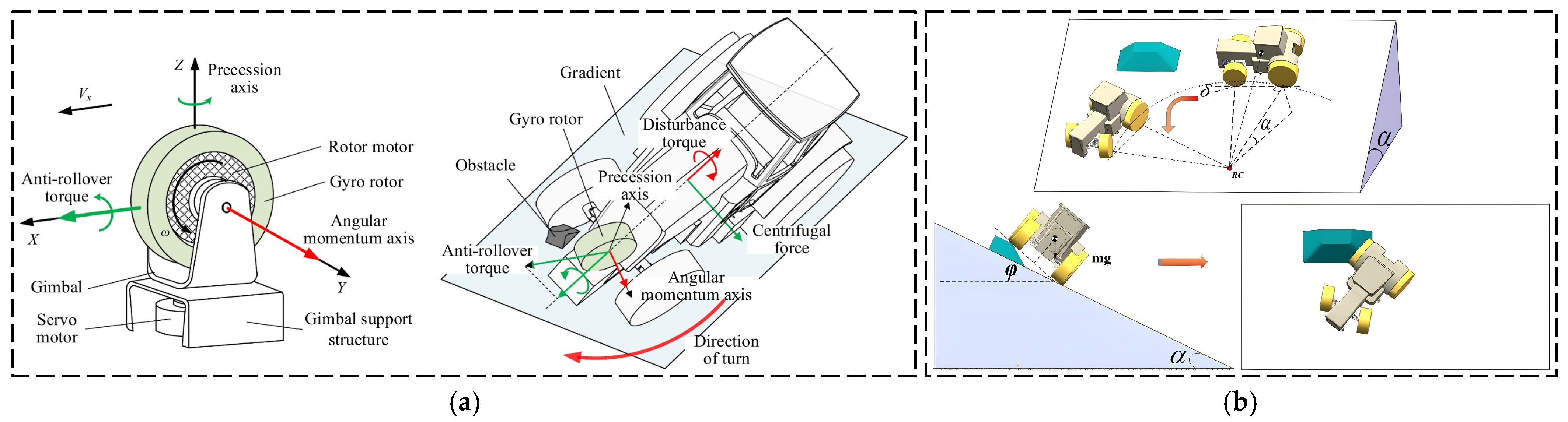

5.3.2. Direct Torque Control

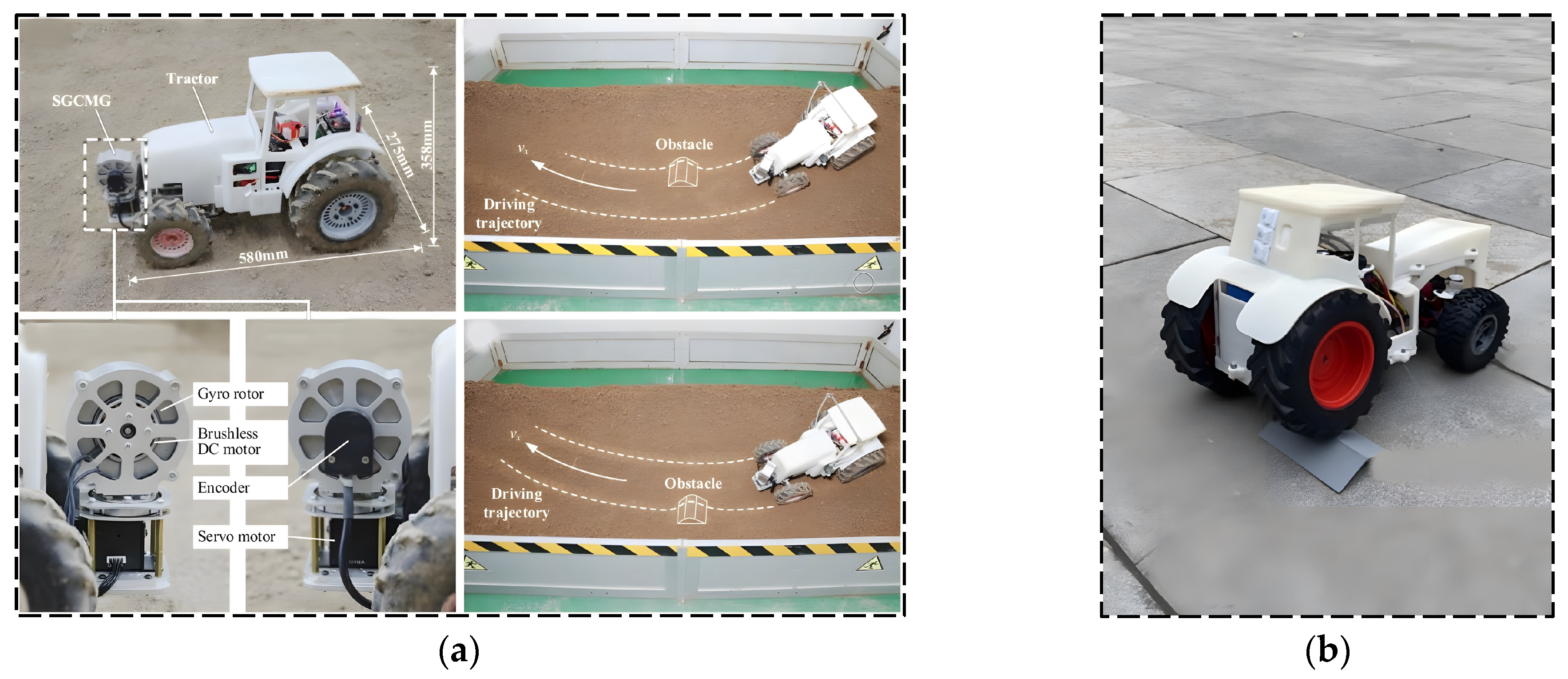

5.3.3. Active Steering

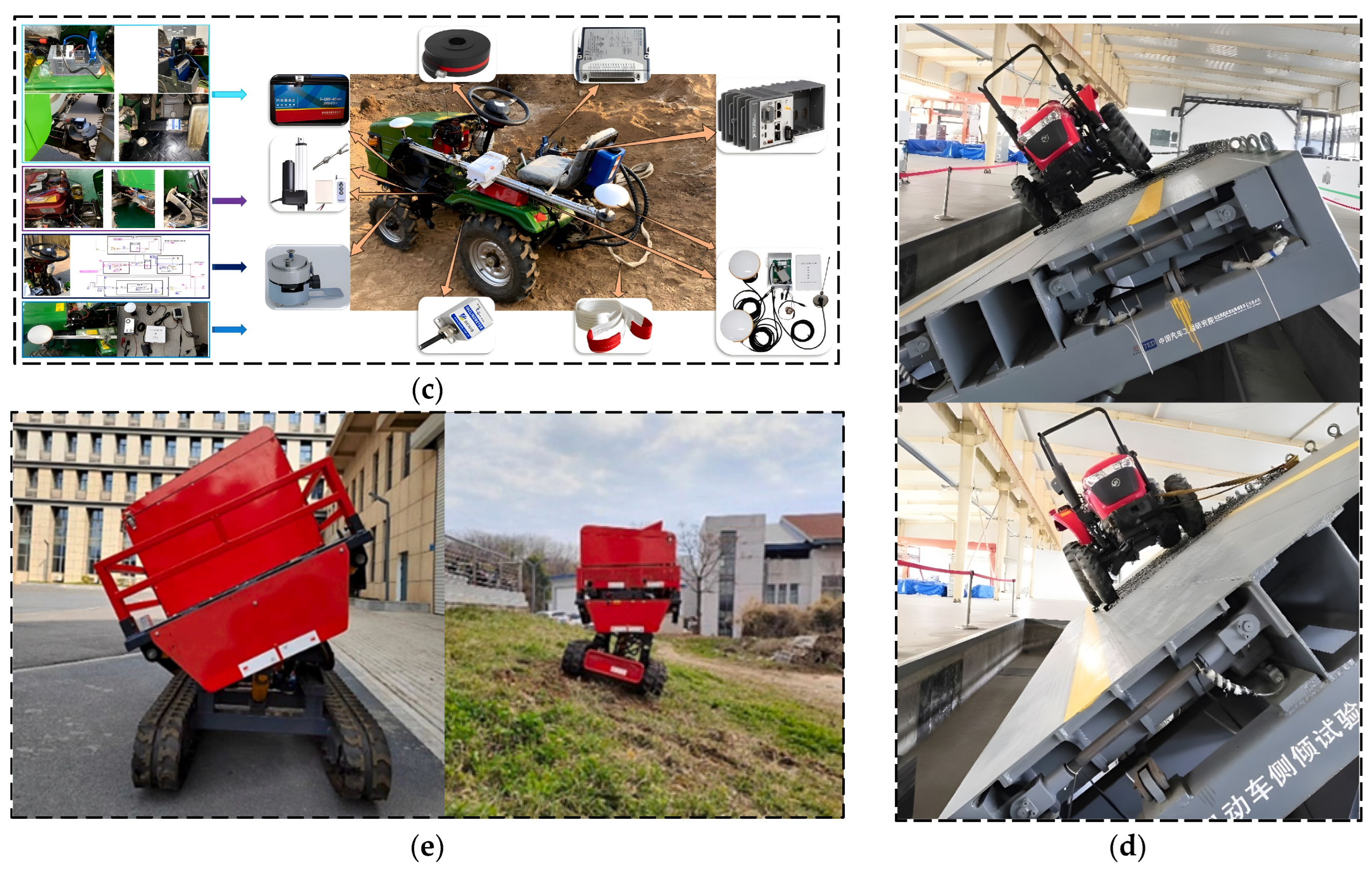

5.4. Typical Roll Stability Experiments for Off-Road Vehicles

6. Comparative Analysis and Future Directions

6.1. Comparisons of Roll Stability Control Between Road and Off-Road Vehicles

6.2. Future Directions

- Future roll state monitoring systems will prioritize real-time, robust roll state sensing through advanced multi-sensor fusion (e.g., IMU, LiDAR, GNSS, vision) and adaptive filtering or nonlinear observers to improve accuracy under dynamic and noisy conditions.

- Future systems will apply deep learning and reinforcement learning to build data-driven rollover prediction models, reducing reliance on complex dynamics while improving adaptability to extreme conditions. V2X integration will enable real-time cooperative risk assessment using shared vehicle and road data.

- Control algorithms will increasingly utilize adaptive learning methods, such as deep reinforcement learning and neural networks, to dynamically adjust to diverse driving conditions. Hybrid modeling (physical + data-driven) will enhance robustness and applicability.

- Future systems will evolve toward coordinated control of suspension, braking, and steering, improving stability in high-risk scenarios. Technologies like steer-by-wire and active chassis systems will support real-time structural adjustments.

- To address computational challenges of high-precision controllers (e.g., MPC), research will focus on reduced-order modeling, control parameter tuning via reinforcement learning, and deployment via edge computing to ensure fast and efficient real-time performance.

- For off-road environments, future work will enhance terrain perception through LiDAR, IMU, and vision fusion. Control strategies will include adaptive suspension, variable track width, and real-time center-of-gravity adjustments to maintain stability on uneven terrain.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RSC | Roll stability control |

| MPC | Model predictive control |

| ESP | Electronic Stability Program |

| IMU | Inertial measurement unit |

| LTR | Load transfer rate |

| TTR | Time to rollover |

| HIL | Hardware-in-the-loop |

| SMC | Sliding mode control |

| LQR | Linear Quadratic Regulator |

References

- Gaspar, P.; Szaszi, I.; Bokor, J. Reconfigurable control structure to prevent the rollover of heavy vehicles. Control Eng. Pract. 2005, 13, 699–711. [Google Scholar] [CrossRef]

- Artuñedo, A.; Moreno-Gonzalez, M.; Villagra, J. Lateral control for autonomous vehicles: A comparative evaluation. Annu. Rev. Control 2024, 57, 100910. [Google Scholar] [CrossRef]

- Gaspar, P.; Szaszi, I.; Bokor, J. Rollover Stability Control for Heavy Vehicles by Using LPV Model. IFAC Proc. Vol. 2004, 37, 673–678. [Google Scholar] [CrossRef]

- Jin, L.; Zhou, H.; Xie, X.; Guo, B.; Ma, X. A direct yaw moment control frame through model predictive control considering vehicle trajectory tracking performance and handling stability for autonomous driving. Control Eng. Pract. 2024, 148, 105947. [Google Scholar] [CrossRef]

- Dai, D.; Chen, D.; Wang, S.; Li, S.; Mao, X.; Zhang, B.; Wang, Z.; Ma, Z. Compilation and Extrapolation of Load Spectrum of Tractor Ground Vibration Load Based on CEEMDAN-POT Model. Agriculture 2023, 13, 125. [Google Scholar] [CrossRef]

- Chai, X.; Hu, J.; Ma, T.; Liu, P.; Shi, M.; Zhu, L.; Zhang, L.; Zhang, M.; Xu, L. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude-Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, H.; Li, H.; Li, Y.; Ding, Z.; Chen, J. Developments of crawler steering gearbox for combine harvester straight forward and steering in situ. Int. J. Agric. Biol. Eng. 2020, 13, 120–126. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, B.; Pan, S.; Ye, Y.; Wang, E.; Mao, H. Task Allocation of Multi-Machine Collaborative Operation for Agricultural Machinery Based on the Improved Fireworks Algorithm. Agronomy 2024, 14, 710. [Google Scholar] [CrossRef]

- Hang, P.; Chen, X.; Wang, W. Cooperative Control Framework for Human Driver and Active Rear Steering System to Advance Active Safety. IEEE Trans. Intell. Veh. 2021, 6, 460–469. [Google Scholar] [CrossRef]

- Wu, J.; Yan, Y.; Liu, Y. Collaborative control of path tracking and roll stability in intelligent commercial vehicle: A minimax robust regulator based on Nash game. Eng. Appl. Artif. Intell. 2024, 133, 108321. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, Z.; Wang, R.; Ding, R.; Ye, Q. Design and control of a new omnidirectional levelling system for hilly crawler work machines. Comput. Electron. Agric. 2024, 218, 108661. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, W.; Luan, Z.; Wang, C.; Zhou, X.; Wu, H. An Antirollover Control Strategy Based on Time-Varying Nonlinear MPC for Three-Axle Steering/Braking-by-Wire Vehicle. IEEE Trans. Ind. Electron. 2024, 71, 11048–11060. [Google Scholar] [CrossRef]

- Yu, H.D.; Hu, M.M.; Liao, Z.W.; Fu, Z.C.; Gong, A.H. Anti-rollover control of heavy-duty dump truck with distributed model predictive control. Int. J. Heavy Veh. Syst. 2023, 30, 139–166. [Google Scholar] [CrossRef]

- Ding, C.; Wang, L.; Chen, X.; Yang, H.; Huang, L.; Song, X. A Blockchain-Based Wide-Area Agricultural Machinery Resource Scheduling System. Appl. Eng. Agric. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Song, Z.; Ni, Y.; He, Z.; Zhai, Z.; Zhu, Z.; Zhou, Z.; Song, Z.; Li, Z. Advances in tractor rollover and stability control: Implications for off-road driving safety. Comput. Electron. Agric. 2024, 226, 109483. [Google Scholar] [CrossRef]

- Yu, H.; Güvenc, L.; Özgüner, Ü. Heavy-Duty Vehicle Rollover Detection and Active Roll Control. IFAC Proc. Vol. 2005, 38, 128–133. [Google Scholar] [CrossRef]

- Yoon, J.; Cho, W.; Kang, J.; Koo, B.; Yi, K. Design and evaluation of a unified chassis control system for rollover prevention and vehicle stability improvement on a virtual test track. Control Eng. Pract. 2010, 18, 585–597. [Google Scholar] [CrossRef]

- Dahmani, H.; Chadli, M.; Rabhi, A.; El Hajjaji, A. Road bank angle considerations for detection of impending vehicle rollover. IFAC Proc. Vol. 2010, 43, 31–36. [Google Scholar] [CrossRef]

- Kidane, S.; Rajamani, R.; Alexander, L.; Starr, P.J.; Donath, M. Development and Experimental Evaluation of a Tilt Stability Control System for Narrow Commuter Vehicles. IEEE Trans. Control Syst. Technol. 2010, 18, 1266–1279. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Dong, Y.; Liu, S.; Zhang, L. Roll stability control of in-wheel motors drive electric vehicle on potholed roads. Control Eng. Pract. 2025, 157, 106247. [Google Scholar] [CrossRef]

- Zhao, D.; Gong, M.; Zhao, D.; Liu, W.; Chang, J.; Tang, J. Integrated control of anti-rollover for high-mobility emergency rescue vehicles. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2024, 239, 1455–1467. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, X.; Zhang, L. Chassis Coordinated Control for Full X-by-Wire Four-Wheel-Independent-Drive Electric Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 4394–4410. [Google Scholar] [CrossRef]

- Magalhaes Junior, Z.R.; Murilo, A.; Lopes, R.V. Vehicle Stability Upper-Level-Controller Based on Parameterized Model Predictive Control. IEEE Access 2022, 10, 21048–21065. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, S.; Zhao, W.; Wang, C.; Xu, K.; Liang, W. Coordinated control of yaw and roll stability in heavy vehicles considering dynamic safety requirements. Control Eng. Pract. 2024, 148, 105963. [Google Scholar] [CrossRef]

- Lu, E.; Ma, Z.; Li, Y.; Xu, L.; Tang, Z. Adaptive backstepping control of tracked robot running trajectory based on real-time slip parameter estimation. Int. J. Agric. Biol. Eng. 2020, 13, 178–187. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Franceschetti, B.; Lenain, R.; Rondelli, V. Comparison between a rollover tractor dynamic model and actual lateral tests. Biosyst. Eng. 2014, 127, 79–91. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V.; Capacci, E. Lateral Stability Performance of Articulated Narrow-Track Tractors. Agronomy 2021, 11, 2512. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zhang, Z. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2022, 13, 51. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, Y.; Wang, D.; Cai, Y.; Lai, L. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Jiangyi, H.; Fan, W. Design and Testing of a Small Orchard Tractor Driven by a Power Battery. Eng. Agrícola 2023, 43, e20220195. [Google Scholar] [CrossRef]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H. Evaluation of a Laser Scanning Sensor in Detection of Complex-Shaped Targets for Variable-Rate Sprayer Development. Trans. ASABE 2016, 59, 1181–1192. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic Measurement Method for Steering Wheel Angle of Autonomous Agricultural Vehicles. Agriculture 2024, 14, 1602. [Google Scholar] [CrossRef]

- Etezadi, H.; Eshkabilov, S. A Comprehensive Overview of Control Algorithms, Sensors, Actuators, and Communication Tools of Autonomous All-Terrain Vehicles in Agriculture. Agriculture 2024, 14, 163. [Google Scholar] [CrossRef]

- Denis, D.; Thuilot, B.; Lenain, R. Online adaptive observer for rollover avoidance of reconfigurable agricultural vehicles. Comput. Electron. Agric. 2016, 126, 32–43. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Son, J.; Kim, Y.; Kang, S.; Ha, Y. Enhancing Tractor Stability and Safety through Individual Actuators in Active Suspension. Inventions 2024, 9, 29. [Google Scholar] [CrossRef]

- Liu, F.; Chen, W.; Zhao, H. Adaptive Model Prediction of Unmanned Agricultural Machinery for Tracking Control in Mountain Environment. IEEE Access 2024, 12, 132175–132185. [Google Scholar] [CrossRef]

- Wang, R.; Wan, J.; Ye, Q.; Ding, R. Path Tracking and Anti-Roll Control of Unmanned Mining Trucks on Mine Site Roads. World Electr. Veh. J. 2024, 15, 167. [Google Scholar] [CrossRef]

- Chen, F.; Ding, J.; Luo, Z.; Zheng, E.; Lu, Y.; Shi, Y.; Zhang, Y.; Wang, X. A novel robust model predictive controller for improving the steering stability of electric drive mobile platform considering the effect of both yaw motion and rototiller lifting. Comput. Electron. Agric. 2025, 230, 109846. [Google Scholar] [CrossRef]

- Tang, L.; Wang, W.; Zhang, C.; Wang, Z.; Ge, Z.; Yuan, S. Linear Active Disturbance Rejection Control System for the Travel Speed of an Electric Reel Sprinkling Irrigation Machine. Agriculture 2024, 14, 1544. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Huang, C.; Lu, Y.; Wang, C. A dynamic tire model based on HPSO-SVM. Int. J. Agric. Biol. Eng. 2019, 12, 36–41. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, H.; Liu, S.; Lu, D.; Tang, Y. Development of Structure and Control System of Self-Propelled Small Green Vegetables Combine Harvester. J. Agric. Sci. Technol. 2023, 25, 1045–1058. [Google Scholar] [CrossRef]

- Wang, B.; Que, K.; Tang, Z.; Sun, M.; Lian, Y.; Wang, H. Multivariate Structural Vibration Coupling Response of the Self-Propelled Straw Pickup Baler Under Time-Varying Loads. Agriculture 2024, 14, 1960. [Google Scholar] [CrossRef]

- Cho, K.; Lee, H. Deep Learning-Based Hybrid Approach for Vehicle Roll Angle Estimation. IEEE Access 2024, 12, 157165–157178. [Google Scholar] [CrossRef]

- He, Z.; Song, Z.; Wang, L.; Zhou, X.; Gao, J.; Wang, K.; Yang, M.; Li, Z. Fasting the stabilization response for prevention of tractor rollover using active steering: Controller parameter optimization and real-vehicle dynamic tests. Comput. Electron. Agric. 2023, 204, 107525. [Google Scholar] [CrossRef]

- Liao, Y.; Ning, D.; Liu, P.; Du, H.; Li, W. A Versatile Semiactive Electrically Interconnected Suspension with Heave-Roll Vibration Decoupling Control. IEEE Trans. Ind. Electron. 2023, 70, 6159–6169. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, M.; Zhang, B.; Zhong, Z. Vehicle roll stability control with active roll-resistant electro-hydraulic suspension. Front. Mech. Eng. 2019, 15, 43–54. [Google Scholar] [CrossRef]

- Liu, W.; Wang, R.; Ding, R.; Meng, X.; Yang, L. On-line estimation of road profile in semi-active suspension based on unsprung mass acceleration. Mech. Syst. Sig Process 2020, 135, 106370. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Wang, R.; Yang, L.; Thiyagarajan, J. Trajectory control for tire burst vehicle using the standalone and roll interconnected active suspensions with safety-comfort control strategy. Mech. Syst. Sig Process 2020, 142, 106776. [Google Scholar] [CrossRef]

- Zhan, H.; Wang, G.; Shan, X.; Liu, Y. Risk-aware lane-change trajectory planning with rollover prevention for autonomous light trucks on curved roads. Mech. Syst. Sig Process 2024, 211, 111126. [Google Scholar] [CrossRef]

- Hajiloo, R.; Khajepour, A.; Kasaiezadeh, A.; Chen, S.-K.; Litkouhi, B. Integrated Lateral and Roll Stability Control of Multi-Actuated Vehicles Using Prioritization Model Predictive Control. IEEE Trans. Veh. Technol. 2022, 71, 8318–8329. [Google Scholar] [CrossRef]

- Li, L.; Lu, Y.; Wang, R.; Chen, J. A Three-Dimensional Dynamics Control Framework of Vehicle Lateral Stability and Rollover Prevention via Active Braking With MPC. IEEE Trans. Ind. Electron. 2017, 64, 3389–3401. [Google Scholar] [CrossRef]

- Li, H.Q.; Zhao, Y.Q.; Lin, F.; Zhu, M.M. Nonlinear dynamics modeling and rollover control of an off-road vehicle with mechanical elastic wheel. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 51. [Google Scholar] [CrossRef]

- Yun, S.; Lee, J.; Jang, W.; Kim, D.; Choi, M.; Chung, J. Dynamic Modeling and Analysis of a Driving Passenger Vehicle. Appl. Sci. 2023, 13, 5903. [Google Scholar] [CrossRef]

- Tan, X.; Li, Z.; Wang, X.; Liu, K.; Zhang, C.; Wu, G. Research on Vehicle Rollover Risk Prediction Based on CNN-LSTM and Unscented Kalman Filter Algorithm. IEEE Trans. Instrum. Meas. 2025, 74, 6503312. [Google Scholar] [CrossRef]

- Zheng, X.; Yu, L.; Ren, Y.; Li, X.; Liang, B.; Xi, J. Modeling of Tank Vehicle Rollover Risk Assessment on Curved–Slope Combination Sections for Sustainable Transportation Safety. Sustainability 2025, 17, 906. [Google Scholar] [CrossRef]

- Zhang, L.; Nguyen, T.A. Assessing the dependence of vehicle rollover on many factors based on new 4D graphs. PLoS ONE 2023, 18, e0284018. [Google Scholar] [CrossRef]

- Wang, J.; Wang, P.; Hu, Y.; Chen, H.; Xu, F. An MPC Strategy for Anti-Pitch/Roll in Electric Vehicle Active Suspension Systems with Wheelbase Preview Information on Uneven Roads. IEEE Trans. Transp. Electrif. 2025. [Google Scholar] [CrossRef]

- Ricco, M.; Alshawi, A.; Gruber, P.; Dhaens, M.; Sorniotti, A. Nonlinear model predictive control for yaw rate and body motion control through semi-active and active suspensions. Veh. Syst. Dyn. 2023, 62, 1587–1620. [Google Scholar] [CrossRef]

- Yang, K.; Liu, X.; Cao, B.; Chen, W.; Tan, P.; Cheng, X. Articulated vehicle rollover detection and active control based on center of gravity position metric. Proc. Inst. Mech. Eng. Part. I J. Syst. Control Eng. 2023, 238, 465–478. [Google Scholar] [CrossRef]

- Qin, Z.; Chen, L.; Hu, M.; Chen, X. A Lateral and Longitudinal Dynamics Control Framework of Autonomous Vehicles Based on Multi-Parameter Joint Estimation. IEEE Trans. Veh. Technol. 2022, 71, 5837–5852. [Google Scholar] [CrossRef]

- Yang, X.; Wu, C.; He, Y.; Lu, X.-Y.; Chen, T. A Dynamic Rollover Prediction Index of Heavy-Duty Vehicles with a Real-Time Parameter Estimation Algorithm Using NLMS Method. IEEE Trans. Veh. Technol. 2022, 71, 2734–2748. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L.; Liu, J. A Comprehensive Vehicle Stability Assessment System Based on Enabling Tire Force Estimation. IEEE Trans. Veh. Technol. 2022, 71, 11571–11588. [Google Scholar] [CrossRef]

- Qi, G.; Yue, M.; Shangguan, J.; Guo, L.; Zhao, J. Integrated control method for path tracking and lateral stability of distributed drive electric vehicles with extended Kalman filter–based tire cornering stiffness estimation. J. Vib. Control 2023, 30, 2582–2595. [Google Scholar] [CrossRef]

- Hung, T.T.; Khanh, D.N. A multi-body dynamic method to analysis of the rollover thresholds and roll safety thresholds of tractor semi-trailer vehicles based on roll safety factor and roll angle of vehicle bodies. Int. J. Interact. Des. Manuf. (IJIDeM) 2024. [Google Scholar] [CrossRef]

- Hung, T.T.; Khanh, D.N. Multibody System Dynamics Analysis Method Approach to Determine Dynamic Roll Early Warning and Control Thresholds of Tractor Semi-Trailer Vehicles. J. Vib. Eng. Technol. 2025, 13, 140. [Google Scholar] [CrossRef]

- Zheng, L.; Lu, Y.; Li, H.; Zhang, J. Anti-Rollover Control and HIL Verification for an Independently Driven Heavy Vehicle Based on Improved LTR. Machines 2023, 11, 117. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Y.; Zhou, G.; Liu, X.; Wu, M.; Dai, K. Vehicle Lateral Dynamics-Inspired Hybrid Model Using Neural Network for Parameter Identification and Error Characterization. IEEE Trans. Veh. Technol. 2024, 73, 16173–16186. [Google Scholar] [CrossRef]

- Hassan, A.; Ruiz-Moreno, S.; Frejo, J.R.D.; Maestre, J.M.; Camacho, E.F. Neural-Network Based MPC for Enhanced Lateral Stability in Electric Vehicles. IEEE Access 2024, 12, 23265–23278. [Google Scholar] [CrossRef]

- Xiao, F.; Hu, J.; Zhu, P.; Deng, C. A method of three-dimensional stability region and ideal roll angle to improve vehicle stability. Nonlinear Dyn. 2022, 111, 2353–2377. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, X.; Shi, J.; Gou, B.; Zhang, L.; Chen, H.; Hu, Y. Rollover Prevention Control of Electric Vehicles Based on Multi-Objective Optimization Coordination Under Extreme Conditions. IEEE Trans. Veh. Technol. 2023, 72, 12784–12798. [Google Scholar] [CrossRef]

- Zhu, B.; Piao, Q.; Zhao, J.; Guo, L.T. Integrated chassis control for vehicle rollover prevention with neural network time-to-rollover warning metrics. Adv. Mech. Eng. 2016, 8, 1687814016632679. [Google Scholar] [CrossRef]

- Tuan Hung, T. A Simulation Approach to Determine Dynamic Rollover Threshold of a Tractor Semi-Trailer Vehicle during Turning Maneuvers. J. Vib. Eng. Technol. 2024, 12, 63–78. [Google Scholar] [CrossRef]

- Mosconi, L.; Farroni, F.; Sakhnevych, A.; Timpone, F.; Gerbino, F.S. Adaptive vehicle dynamics state estimator for onboard automotive applications and performance analysis. Veh. Syst. Dyn. 2022, 61, 3244–3268. [Google Scholar] [CrossRef]

- Chao, P.-P.; Zhang, R.-Y.; Wang, Y.-D.; Tang, H.; Dai, H.-L. Warning model of new energy vehicle under improving time-to-rollover with neural network. Meas. Control 2022, 55, 1004–1015. [Google Scholar] [CrossRef]

- Lu, Y.; Han, Y.; Huang, W.; Wang, Y. Sliding mode control for overturning prevention and hardware-in-loop experiment of heavy-duty vehicles based on dynamical load transfer ratio prediction. Proc. Inst. Mech. Eng. Part. K J. Multi-Body Dyn. 2021, 236, 68–83. [Google Scholar] [CrossRef]

- Sukumaran, R.; Gaurkar, P.V.; Subramanian, S.C. Integrated Rollover Prevention and Antilock Brake System for Heavy Commercial Road Vehicles. IEEE Access 2023, 11, 124081–124097. [Google Scholar] [CrossRef]

- Rajamani, R.; Piyabongkarn, D.; Tsourapas, V.; Lew, J.Y. Parameter and State Estimation in Vehicle Roll Dynamics. IEEE Trans. Intell. Transp. Syst. 2011, 12, 1558–1567. [Google Scholar] [CrossRef]

- Tafner, R.; Reichhartinger, M.; Horn, M. Robust online roll dynamics identification of a vehicle using sliding mode concepts. Control Eng. Pract. 2014, 29, 235–246. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, T.; Zheng, M.; Luo, L.; Liu, P. Real-time identification of vehicle body motion-modes based on motion-mode energy method. Mech. Syst. Sig Process 2020, 143, 106843. [Google Scholar] [CrossRef]

- Phanomchoeng, G.; Treetipsounthorn, K.; Chantranuwathana, S.; Wuttisittikulkij, L. Untripped and Tripped Rollovers with a Neural Network. Int. J. Automot. Technol. 2023, 24, 811–828. [Google Scholar] [CrossRef]

- Hassan, M.A.; Abdelkareem, M.A.A.; Moheyeldein, M.M.; Elagouz, A.; Tan, G. Advanced study of tire characteristics and their influence on vehicle lateral stability and untripped rollover threshold. Alex. Eng. J. 2020, 59, 1613–1628. [Google Scholar] [CrossRef]

- Jeong, D.; Kim, S.; Lee, J.; Choi, S.B.; Kim, M.; Lee, H. Estimation of Tire Load and Vehicle Parameters Using Intelligent Tires Combined with Vehicle Dynamics. IEEE Trans. Instrum. Meas. 2021, 70, 9502712. [Google Scholar] [CrossRef]

- Park, G.; Choi, S.B. An Integrated Observer for Real-Time Estimation of Vehicle Center of Gravity Height. IEEE Trans. Intell. Transp. Syst. 2021, 22, 5660–5671. [Google Scholar] [CrossRef]

- Wang, F.; Shi, Y.; Chen, Y. Hierarchical MIMO Decoupling Control for Vehicle Roll and Planar Motions With Control Allocation. IEEE Trans. Veh. Technol. 2024, 73, 494–503. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Zhang, L.; Cao, D.; Dorrell, D.G. A Vehicle Rollover Evaluation System Based on Enabling State and Parameter Estimation. IEEE Trans. Ind. Inf. 2021, 17, 4003–4013. [Google Scholar] [CrossRef]

- Wang, M.; Liu, J.; Zhang, H.; Gan, L.; Xu, X.; He, J.; Chen, S. Vehicle rollover warning system based on TTR method with inertial measurement. Meas. Sci. Technol. 2021, 33, 015108. [Google Scholar] [CrossRef]

- Her, H.; Koh, Y.; Joa, E.; Yi, K.; Kim, K. An Integrated Control of Differential Braking, Front/Rear Traction, and Active Roll Moment for Limit Handling Performance. IEEE Trans. Veh. Technol. 2016, 65, 4288–4300. [Google Scholar] [CrossRef]

- Yao, S.-J.; Yang, X.-H.; Bai, C.-X.; Lv, Y.; Zhao, D.-X.; Wang, Z.-H. Research on anti-rollover control of three-axle rescue vehicle based on active suspension and differential braking. Mech. Sci. 2024, 15, 501–514. [Google Scholar] [CrossRef]

- Zheng, L.; Lu, Y.; Wang, J.; Li, H. Braking failure anti-rollover control and hardware-in-the-loop verification of wire-controlled heavy vehicles. Sci. Rep. 2024, 14, 29802. [Google Scholar] [CrossRef]

- Botes, W.; Botha, T.R.; Els, P.S. Real-time lateral stability and steering characteristic control using non-linear model predictive control. Veh. Syst. Dyn. 2022, 61, 1063–1085. [Google Scholar] [CrossRef]

- van der Westhuizen, S.F.; Els, P.S. Slow active suspension control for rollover prevention. J. Terramech 2013, 50, 29–36. [Google Scholar] [CrossRef]

- Parida, N.C.; Raha, S.; Ramani, A. Rollover-Preventive Force Synthesis at Active Suspensions in a Vehicle Performing a Severe Maneuver With Wheels Lifted Off. IEEE Trans. Intell. Transp. Syst. 2014, 15, 2583–2594. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, Y.; Zhen, R.; Yue, Z.; Pazooki, A.; Soltani, A.; Sun, C.; Khajepour, A. Modelling and experimental validation of an adaptive interconnected suspension with adjustable roll stiffness (AIS-ARS). Veh. Syst. Dyn. 2024, 1–19. [Google Scholar] [CrossRef]

- Pang, L.; Yue, M.; Qi, G.; Zhao, X. Switched control strategy based on preview-based MPC for active suspension of heavy-duty vehicle to improve ride comfort and roll stability. Meas. Sci. Technol. 2025, 36, 036201. [Google Scholar] [CrossRef]

- Iben Ammar, I.; Doumiati, M.; Talj, R.; Chokor, A.; Machmoum, M. Analysis and Control of the Vehicle Roll Dynamics Using Sum of Squares Polynomial Approach. J. Syst. Sci. Complex. 2024, 37, 2318–2346. [Google Scholar] [CrossRef]

- Ataei, M.; Khajepour, A.; Jeon, S. Model Predictive Control for integrated lateral stability, traction/braking control, and rollover prevention of electric vehicles. Veh. Syst. Dyn. 2019, 58, 49–73. [Google Scholar] [CrossRef]

- Zhou, C.; Yu, L.; Li, Y.; Lu, Z.; Song, J. A layered roll stability control strategy for commercial vehicles based on adaptive model predictive control. Veh. Syst. Dyn. 2022, 61, 3067–3088. [Google Scholar] [CrossRef]

- Her, H.; Suh, J.; Yi, K. Integrated control of the differential braking, the suspension damping force and the active roll moment for improvement in the agility and the stability. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2014, 229, 1145–1157. [Google Scholar] [CrossRef]

- Termous, H.; Shraim, H.; Talj, R.; Francis, C.; Charara, A. Coordinated control strategies for active steering, differential braking and active suspension for vehicle stability, handling and safety improvement. Veh. Syst. Dyn. 2018, 57, 1494–1529. [Google Scholar] [CrossRef]

- Zhang, B.; Zong, C.; Chen, G.; Huang, Y.; Xu, T. A Novel Integrated Stability Control Based on Differential Braking and Active Steering for Four-axle Trucks. Chin. J. Mech. Eng. 2019, 32, 12. [Google Scholar] [CrossRef]

- German, R.; Kalogiannis, T.; Bouscayrol, A.; He, J.; Tournez, F.; Berecibar, M.; Husar, C.; Ciocan, M.; Costa, S.; Genic, A.; et al. A Flexible Cloud-Based HIL Testing of Batteries for Various Electrified Vehicles. IEEE Trans. Veh. Technol. 2024, 73, 4610–4620. [Google Scholar] [CrossRef]

- Pohren, D.H.; dos Santos Roque, A.; de Freitas, E.P.; Pereira, C.E. A HIL Test Approach for Data Generation on CAN Communication Under Disturbance Injections. IEEE Trans. Ind. Inf. 2025, 21, 2729–2737. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.; Liu, Y.; Zhang, T.; Yan, M.; Chen, J.; Zhou, C.; Hu, J.; Chen, X. An Ultrasonic Ridge-Tracking Method Based on Limiter Sliding Window Filter and Fuzzy Pure Pursuit Control for Ridge Transplanter. Agriculture 2024, 14, 1713. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Cheng, C. Development of multi-functional combine harvester with grain harvesting and straw baling. Span. J. Agric. Res. 2017, 15, e0202. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V.; Ciuffoli, A. Comparing the influence of Roll-Over Protective Structure type on tractor lateral stability. Saf. Sci. 2019, 115, 42–50. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar] [CrossRef]

- Zhu, Y.; Cui, B.; Yu, Z.; Gao, Y.; Wei, X. Tillage Depth Detection and Control Based on Attitude Estimation and Online Calibration of Model Parameters. Agriculture 2024, 14, 2130. [Google Scholar] [CrossRef]

- Han, J.; Yan, X.; Tang, H. Method of controlling tillage depth for agricultural tractors considering engine load characteristics. Biosyst. Eng. 2023, 227, 95–106. [Google Scholar] [CrossRef]

- Chen, T.; Xu, L.; Ahn, H.S.; Lu, E.; Liu, Y.; Xu, R. Evaluation of headland turning types of adjacent parallel paths for combine harvesters. Biosyst. Eng. 2023, 233, 93–113. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B.; Yu, X. Optimizing Contact Force on an Apple Picking Robot End-Effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Fu, S.; Feng, K.; Han, X.; Hu, Y.; Zhu, Q.; Wei, X. Analysis of Vibration Characteristics of Tractor–Rotary Cultivator Combination Based on Time Domain and Frequency Domain. Agriculture 2024, 14, 1139. [Google Scholar] [CrossRef]

- Petrović, D.V.; Cerović, V.B.; Radojević, R.L.; Mileusnić, Z.I. An approach to characterization of the agricultural self-propelled machines stability. J. Terramech 2021, 93, 51–63. [Google Scholar] [CrossRef]

- Song, Z.; Wang, L.; Liu, Y.; Wang, K.; He, Z.; Zhu, Z.; Qin, J.; Li, Z. Actively steering a wheeled tractor against potential rollover using a sliding-mode control algorithm: Scaled physical test. Biosyst. Eng. 2022, 213, 13–29. [Google Scholar] [CrossRef]

- Gao, J.; Yin, C.; Yuan, G. Warning and active steering rollover prevention control for agricultural wheeled tractor. PLoS ONE 2022, 17, e0280021. [Google Scholar] [CrossRef]

- Liu, B.; Koc, A.B. SafeDriving: A mobile application for tractor rollover detection and emergency reporting. Comput. Electron. Agric. 2013, 98, 117–120. [Google Scholar] [CrossRef]

- Pang, J.; Li, Y.; Ji, J.; Xu, L. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Hu, Y.; Han, X.; Feng, K.; Li, P.; Wei, X.; Zhai, C. Study on Operating Vibration Characteristics of Different No-Tillage Planter Row Units in Wheat Stubble Fields. Agriculture 2024, 14, 1878. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Jang, M.-K.; Hwang, S.-J.; Kim, J.-H.; Nam, J.-S. Overturning and rollover characteristics of a tractor through dynamic simulations: Effect of slope angle and obstacles on a hard surface. Biosyst. Eng. 2022, 219, 11–24. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, G.; Zeng, W.; Gao, F.; Tang, X. Design and Lateral Stability Analysis of an Attitude Adjustment Tractor for Moving on Side Slopes. Appl. Sci. 2024, 14, 2220. [Google Scholar] [CrossRef]

- Peng, H.; Ma, W.; Wang, Z.; Yuan, Z. Leveling Control of Hillside Tractor Body Based on Fuzzy Sliding Mode Variable Structure. Appl. Sci. 2023, 13, 6066. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Qin, J.; Wu, A.; Song, Z.; He, Z.; Suh, C.S.; Zhu, Z.; Suh, C.S.; Zhu, Z.; Li, Z. Recovering tractor stability from an intensive rollover with a momentum flywheel and active steering: System formulation and scale-model verification. Comput. Electron. Agric. 2021, 190, 106458. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, J.; Liu, F.; He, Z.; Lai, Q.; Zhu, Z.; Song, Z.; Li, Z. Algorithm and scale experiment of gyro-based tractor rollover control towards hilly farmland application. Comput. Electron. Agric. 2024, 220, 108925. [Google Scholar] [CrossRef]

- Ahn, D.V.; Kim, K.; Oh, J.; Seo, J.; Lee, J.W.; Park, Y.J. Optimal Control of Semi-Active Suspension for Agricultural Tractors Using Linear Quadratic Gaussian Control. Sensors 2023, 23, 6474. [Google Scholar] [CrossRef]

- Cui, L.; Xue, X.; Le, F.; Mao, H.; Ding, S. Design and experiment of electro hydraulic active suspension for controlling the rolling motion of spray boom. Int. J. Agric. Biol. Eng. 2019, 12, 72–81. [Google Scholar] [CrossRef]

- Cui, L.; Mao, H.; Xue, X.; Ding, S.; Qiao, B. Design optimization and test for a pendulum suspension of the crop sprayer boom in dynamic conditions based on a six DOF motion simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, J.; Xia, G.; Khajepour, A. Enhancing Roll Stability of Counterbalance Forklift Trucks with a Novel Rollover Index and Hierarchical Adaptive Model Predictive Control. IEEE Trans. Veh. Technol. 2024, 73, 7925–7938. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Kumi, F. Development of a riding-type fully automatic transplanter for vegetable plug seedlings. Span. J. Agric. Res. 2019, 17, e0205. [Google Scholar] [CrossRef]

- Xu, L.; Chai, X.; Gao, Z.; Li, Y.; Wang, Y. Experimental study on driver seat vibration characteristics of crawler-type combine harvester. Int. J. Agric. Biol. Eng. 2019, 12, 90–97. [Google Scholar] [CrossRef]

- Liu, J.; Xia, C.; Jiang, D.; Sun, Y. Development and Testing of the Power Transmission System of a Crawler Electric Tractor for Greenhouses. Appl. Eng. Agric. 2020, 36, 797–805. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tang, Z.; Cao, Y.; Zhao, Y. Structural Form and Field Operation Effect of Crawler Type Broccoli Harvester. Eng. Agrícola 2023, 43, e20230132. [Google Scholar] [CrossRef]

- Zhang, F.; Teng, S.; Wang, Y.; Guo, Z.; Wang, J.; Xu, R. Design of bionic goat quadruped robot mechanism and walking gait planning. Int. J. Agric. Biol. Eng. 2020, 13, 32–39. [Google Scholar] [CrossRef]

- Liu, H.; Ren, X.; Han, L.; Qin, Y.; Xie, J.; Liu, B. Enhancing high-speed steering stability of wheel-legged vehicles by active roll control. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2024, 239, 635–650. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, F.; Guan, Z.; Zhu, Y.; Shi, H.; Cheng, K. Development of a combined harvester navigation control system based on visual simultaneous localization and mapping-inertial guidance fusion. J. Agric. Eng. 2024, 55. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Liu, J.; Yue, R.; Zhang, T.; Yao, M.; Li, J. Method for the navigation line recognition of the ridge without crops via machine vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Shi, J.; Zhou, C.; Hu, J. SN-CNN: A Lightweight and Accurate Line Extraction Algorithm for Seedling Navigation in Ridge-Planted Vegetables. Agriculture 2024, 14, 1446. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Kong, C.-W.; Xin, H.; Ahmad, F.; Lin, J. A Data-Driven Dynamic Obstacle Avoidance Method for Liquid-Carrying Plant Protection UAVs. Agronomy 2022, 12, 873. [Google Scholar] [CrossRef]

- Bencatel, R.; Tian, R.; Girard, A.R.; Kolmanovsky, I. Reference Governor Strategies for Vehicle Rollover Avoidance. IEEE Trans. Control Syst. Technol. 2018, 26, 1954–1969. [Google Scholar] [CrossRef]

- Wei, W.; Yin, G.; He, T. Physics-Informed Data-Based LPV Modeling and Validations of Lateral Vehicle Dynamics. IEEE Trans. Intell. Veh. 2024, 9, 2459–2468. [Google Scholar] [CrossRef]

| References | Modeling Approach | Application | Analysis Perspective | Simulated Motion | Remarks |

|---|---|---|---|---|---|

| [64,65] | Nonlinear suspension model with MPC | Active roll stability control | Effects of different loads and steering conditions | Roll, lateral, yaw motion | Developed an MPC-based active anti-roll control strategy to adjust suspension stiffness and damping |

| [66,67] | Variable CG height model with lateral motion | Adaptive roll stability control | Impact of different loads and road conditions | Roll, lateral, vertical motion | Designed an adaptive roll stability controller based on variable CG height |

| [61,62,68] | Full-vehicle dynamic model with modified CRI | Rollover risk prediction | Influence of CG height and lateral acceleration | Roll, lateral acceleration | Proposed an improved Critical Roll Index (CRI) for rollover risk prediction |

| [69,70] | Vehicle stability analysis model with tire parameter estimation | Influence analysis of rollover factors | Effects of tire parameters | Roll, lateral, vertical motion | Verified the effects of tire parameters on rollover stability |

| [71,72,73] | Multi-body dynamic model | Heavy-duty vehicle rollover prevention | Structural deformation effects | Roll, yaw, lateral motion | Investigated rollover risk under high-speed cornering with multi-body dynamics |

| [74,75] | Integrated roll–yaw model with neural network | Intelligent roll stability control | Data-driven approach for active roll control | Roll, yaw, lateral motion | Utilized neural networks to enhance active roll stability control |

| Prediction Index | Evaluation Criteria | Equation | Rollover Threshold | Remarks | References |

|---|---|---|---|---|---|

| Roll rate () | Rate of change in roll angle, used to assess roll dynamics | No fixed threshold, usually combined with roll angle | Reflects roll tendency, but requires roll angle for rollover assessment | [84,85] | |

| Lateral acceleration (ay) | Lateral acceleration of vehicle, indicating rollover tendency | Typically, ay > 0.4 g indicates rollover risk | Suitable for steady-state rollover analysis, but requires suspension considerations | [68] | |

| Roll energy | Kinetic and potential energy of vehicle roll motion | Vehicle-dependent, no fixed threshold | Useful for predicting rollover trends, but complex to compute | [14,86] | |

| Dynamic stability index (DSI) | Considers multiple factors, such as roll angle, lateral acceleration, and speed | Computed based on multivariable functions | Depends on dynamic modeling, no fixed threshold | Suitable for intelligent vehicle rollover prediction, computationally complex | [80,87] |

| Tire lateral force ratio (TLFR) | Ratio of tire’s lateral force to its maximum available lateral force | TLFR > 1 indicates a limit condition, possibly leading to loss of control | Useful for analyzing tire adhesion limits, but sensitive to load variations | [88] | |

| CG height variation rate (CGVR) | Dynamic variation rate of vehicle’s center of gravity height | Vehicle-dependent, no fixed threshold | Suitable for uneven terrain analysis, computationally intensive | [89,90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, R.; Liu, W.; Sun, D.; Jiang, Y.; Ding, R. A Review of Recent Advances in Roll Stability Control in On-Road and Off-Road Vehicles. Appl. Sci. 2025, 15, 5491. https://doi.org/10.3390/app15105491

Chen J, Wang R, Liu W, Sun D, Jiang Y, Ding R. A Review of Recent Advances in Roll Stability Control in On-Road and Off-Road Vehicles. Applied Sciences. 2025; 15(10):5491. https://doi.org/10.3390/app15105491

Chicago/Turabian StyleChen, Jie, Ruochen Wang, Wei Liu, Dong Sun, Yu Jiang, and Renkai Ding. 2025. "A Review of Recent Advances in Roll Stability Control in On-Road and Off-Road Vehicles" Applied Sciences 15, no. 10: 5491. https://doi.org/10.3390/app15105491

APA StyleChen, J., Wang, R., Liu, W., Sun, D., Jiang, Y., & Ding, R. (2025). A Review of Recent Advances in Roll Stability Control in On-Road and Off-Road Vehicles. Applied Sciences, 15(10), 5491. https://doi.org/10.3390/app15105491