Study of a Triaxial Testing System for Unsaturated Subgrade Fillers Using a High-Suction Tensiometer and Photogrammetry

Abstract

1. Introduction

2. Unsaturated Subgrade Filler Triaxial Testing System

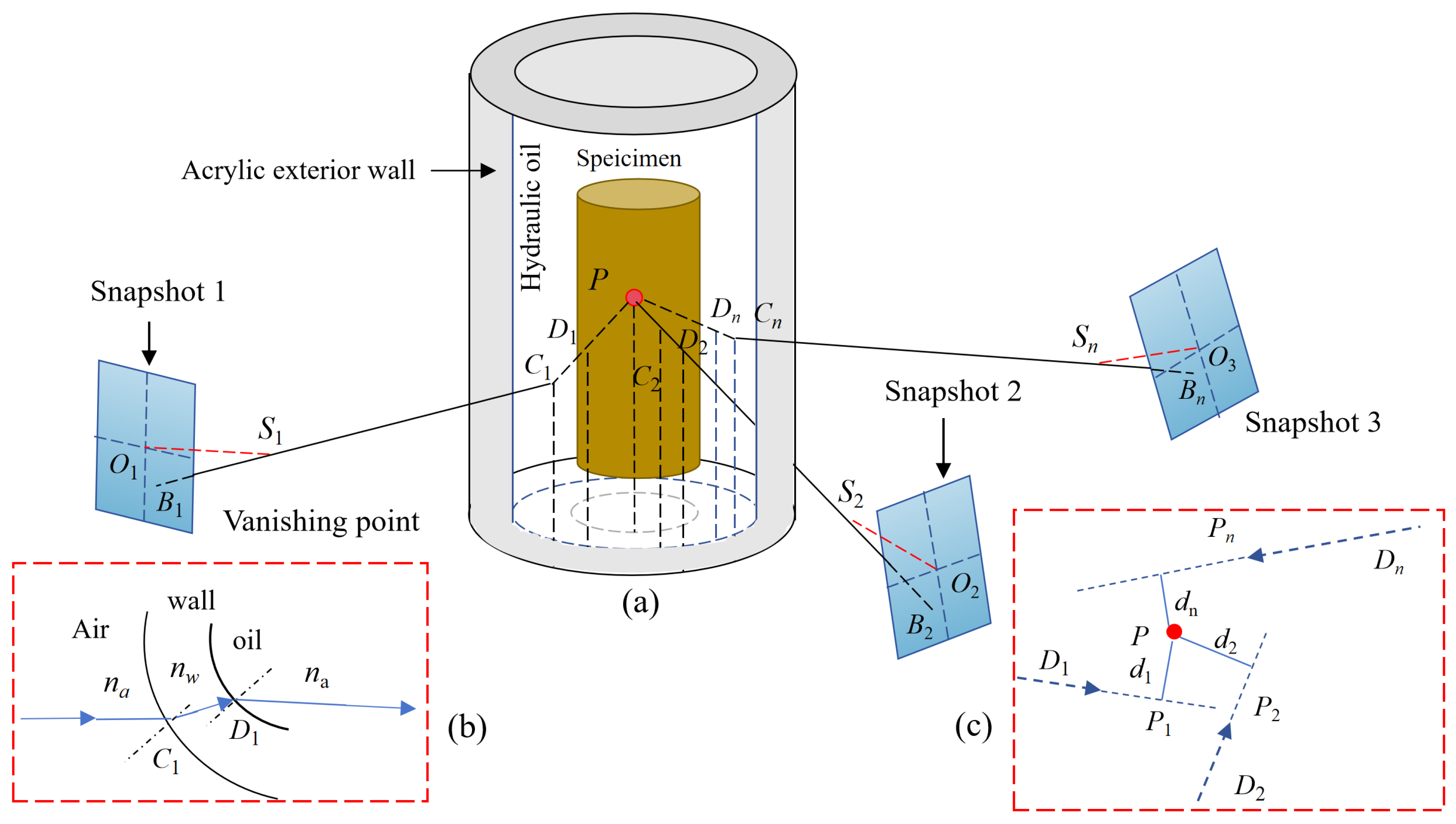

2.1. Three-Dimensional Volume Measurement of Samples Using Photogrammetry

2.2. Matric Suction Tensiometer

3. Reliability Evaluation of the 3D Settlement and Consolidation Testing System for Unsaturated Subgrade Fill

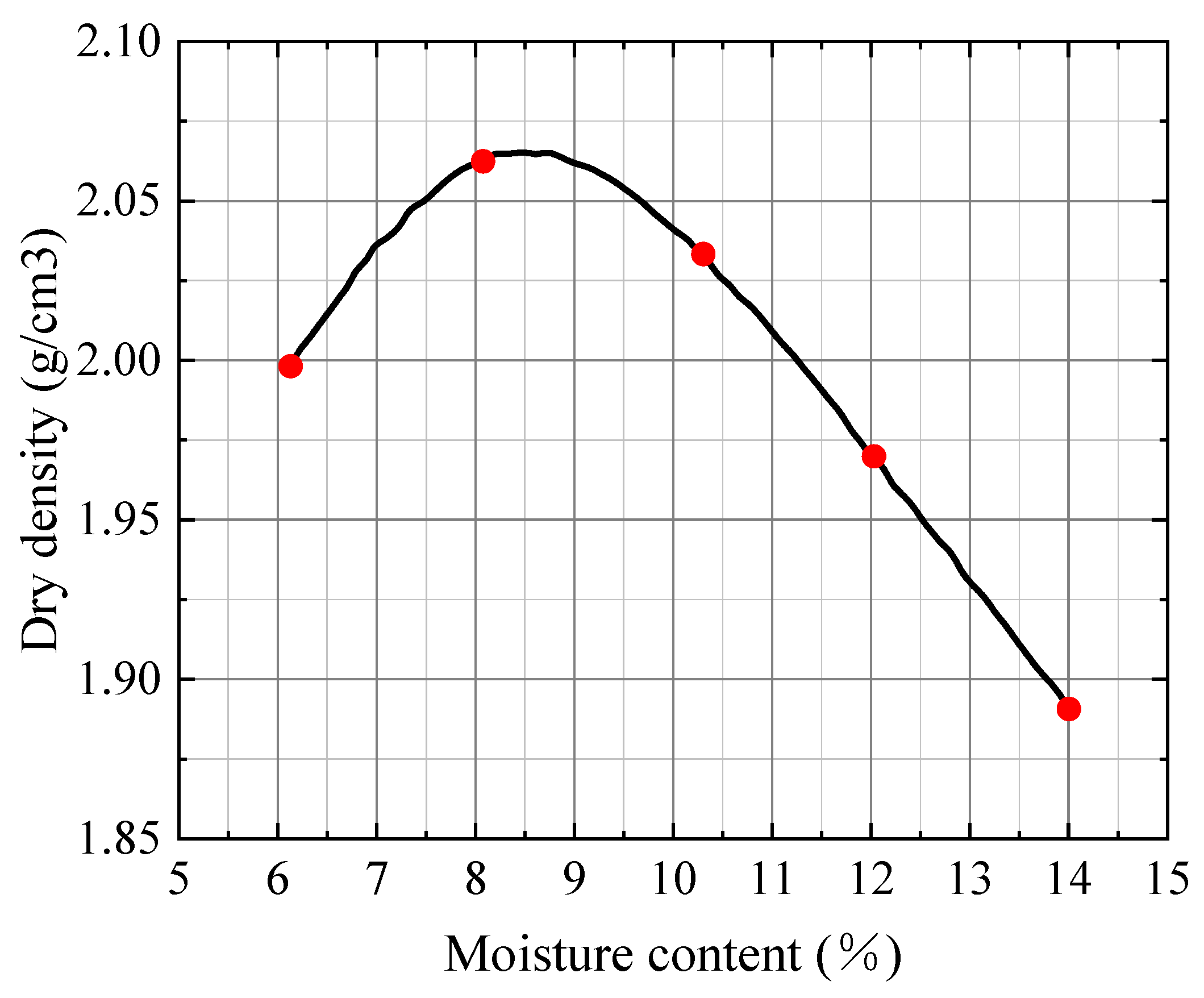

3.1. Sample Preparation

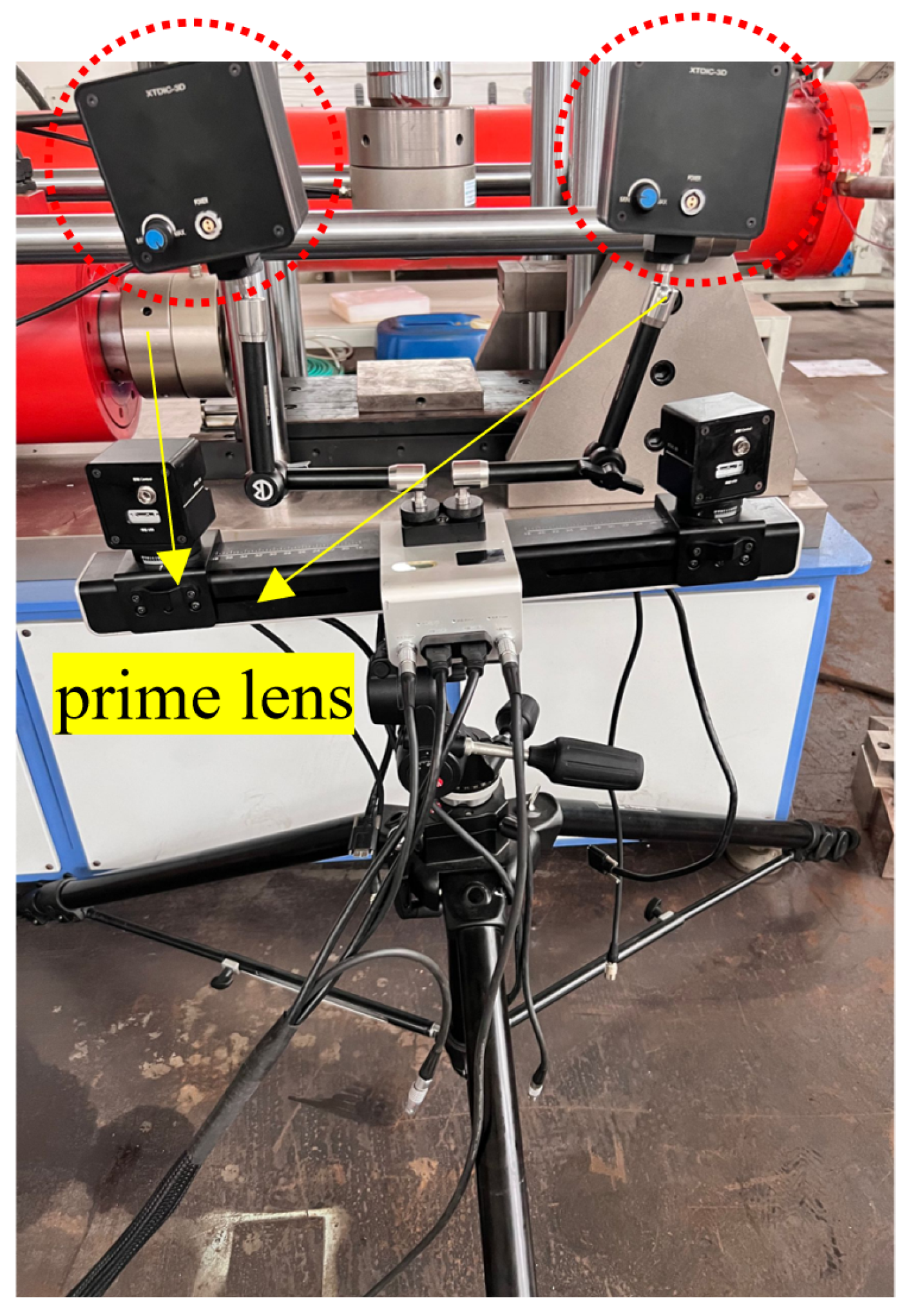

3.2. Photogrammetry System and Camera Calibration

3.3. Experimental Design

3.4. Analysis of Experimental Results

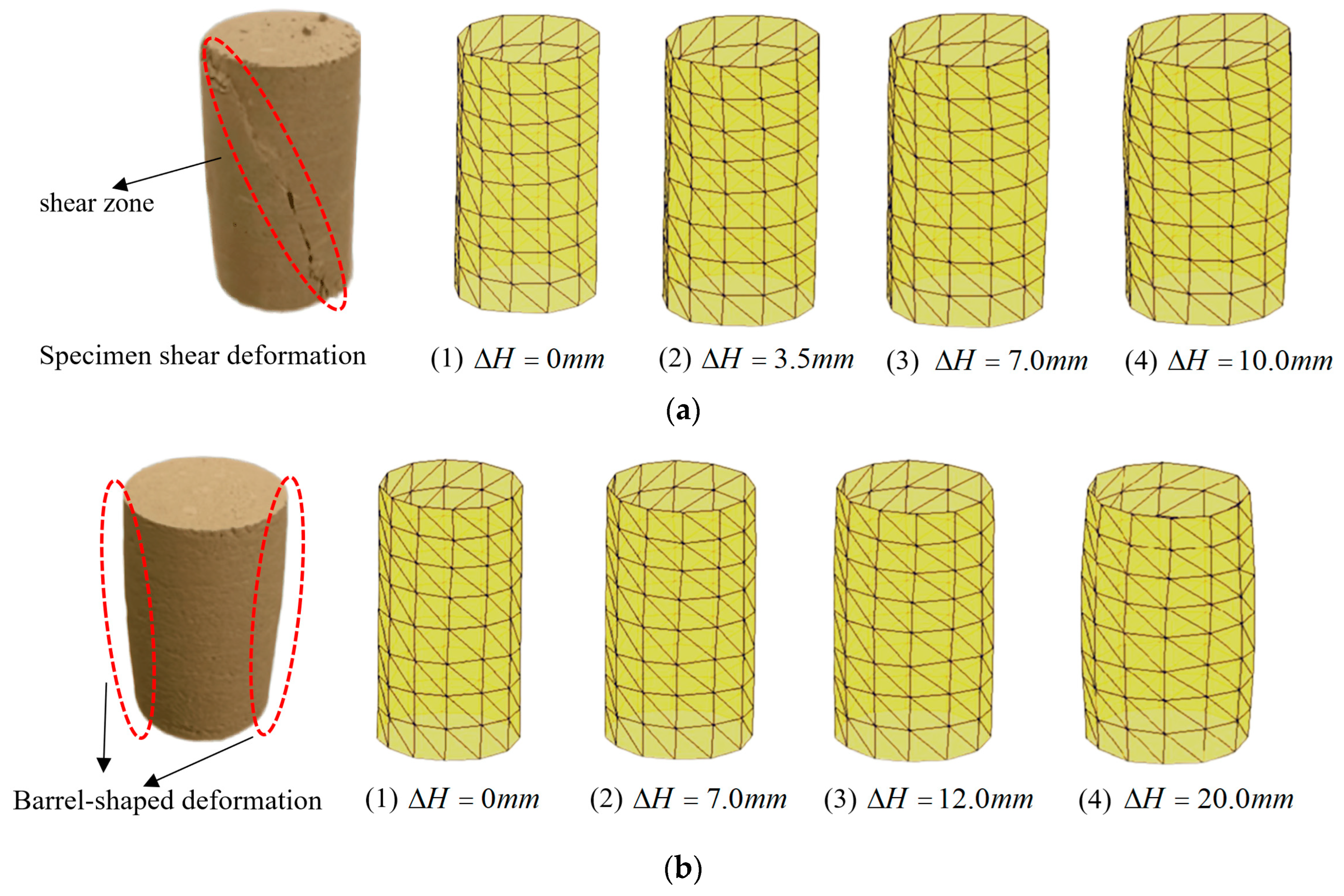

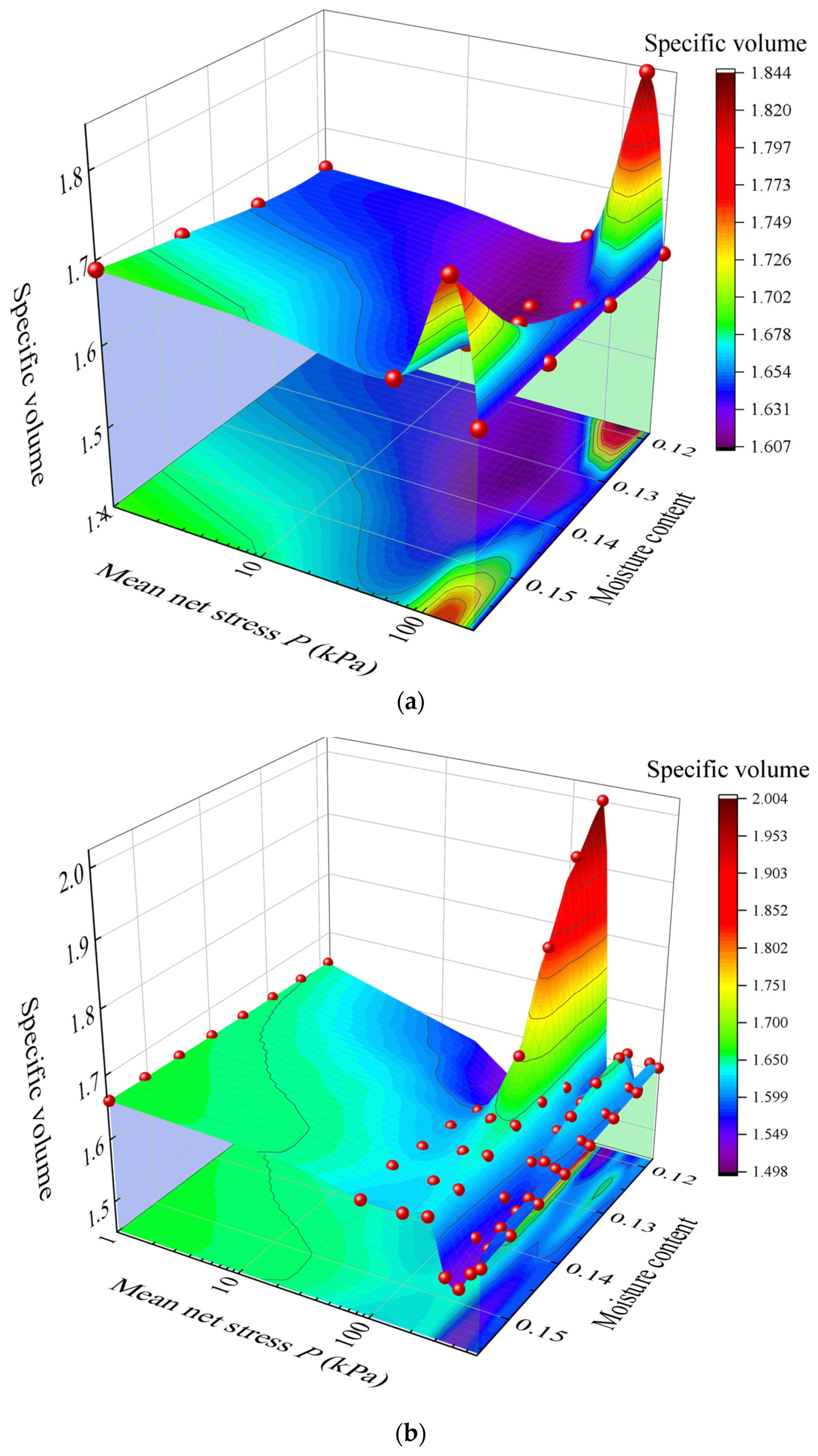

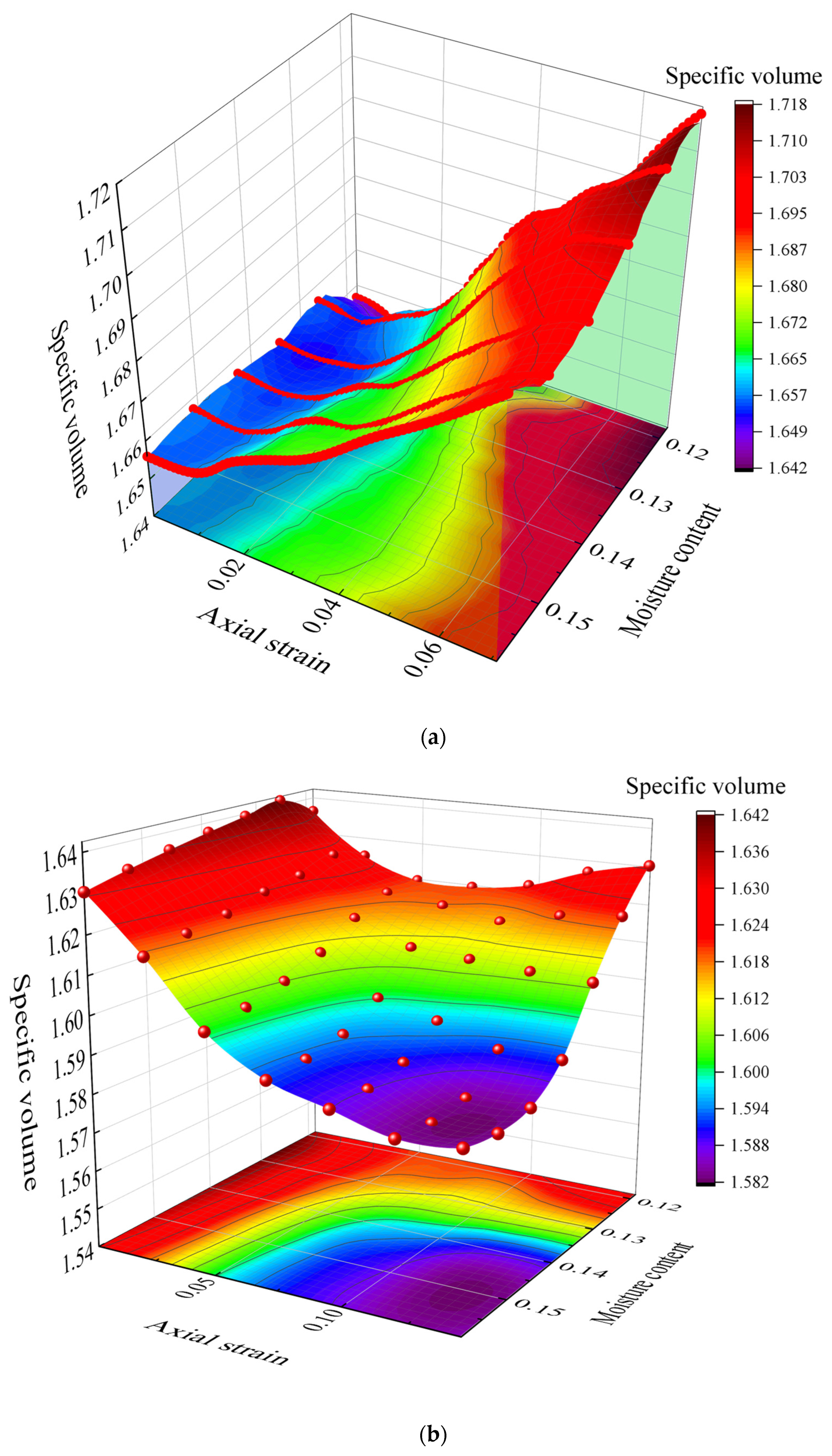

3.4.1. Sample Volume Change

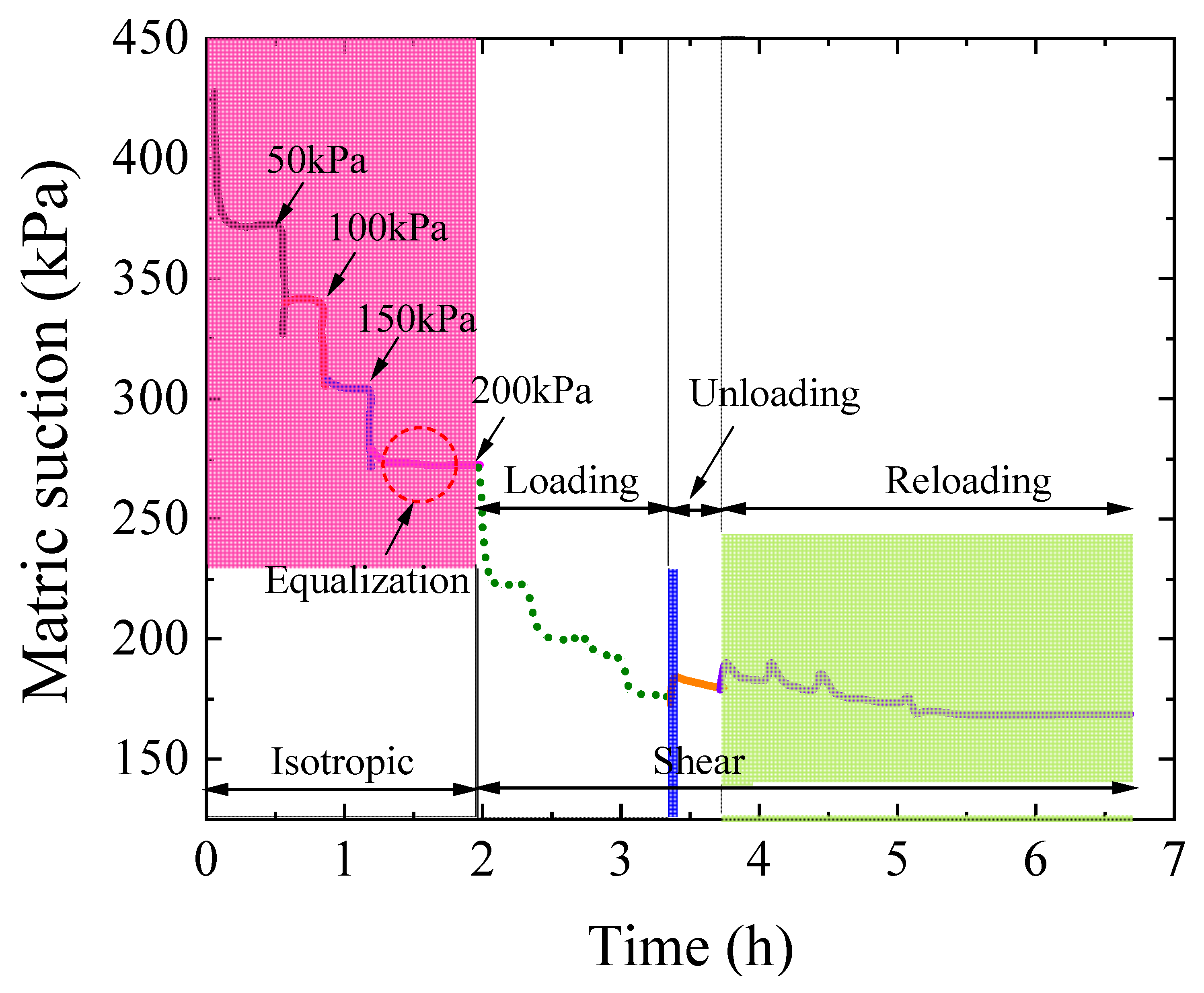

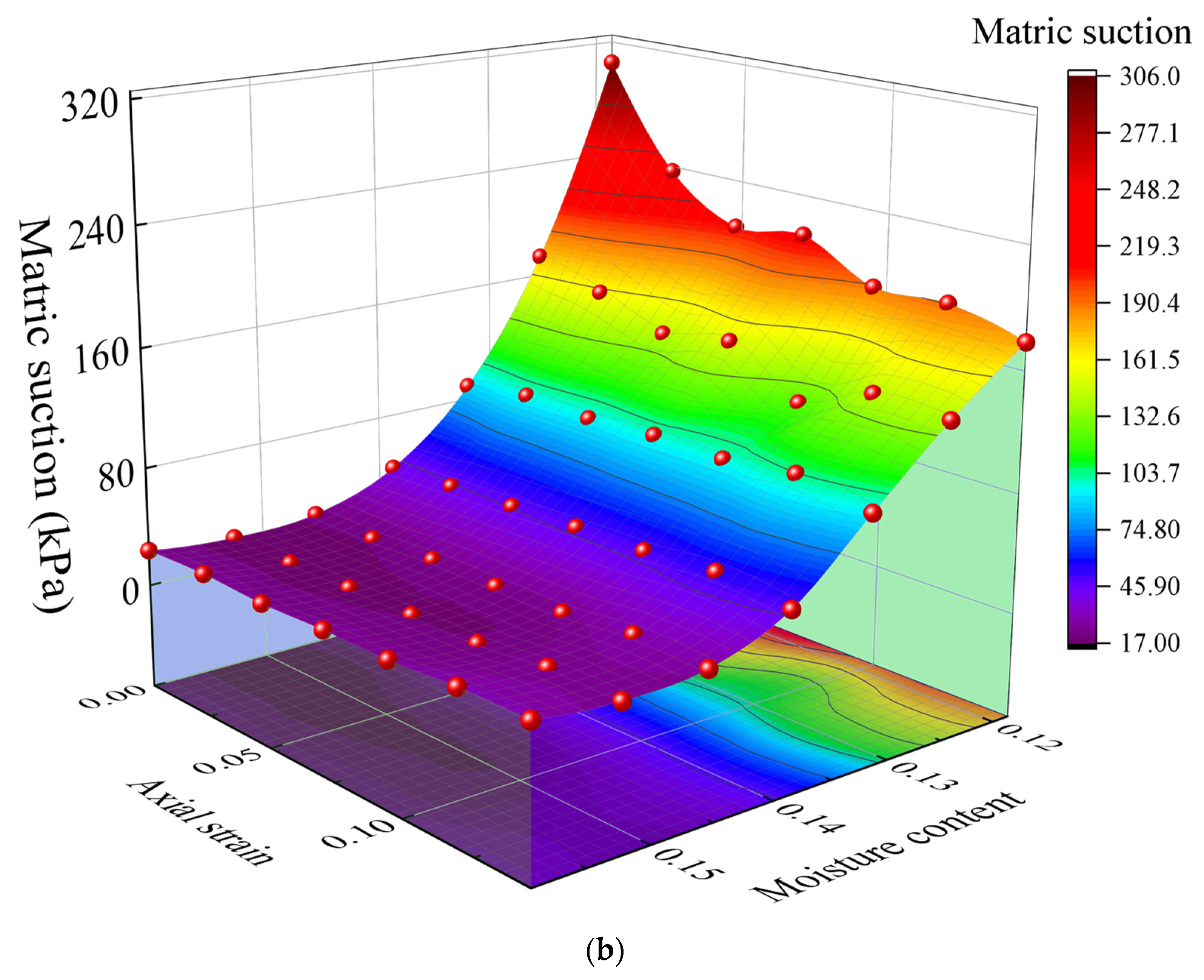

3.4.2. Analysis of Suction Variation

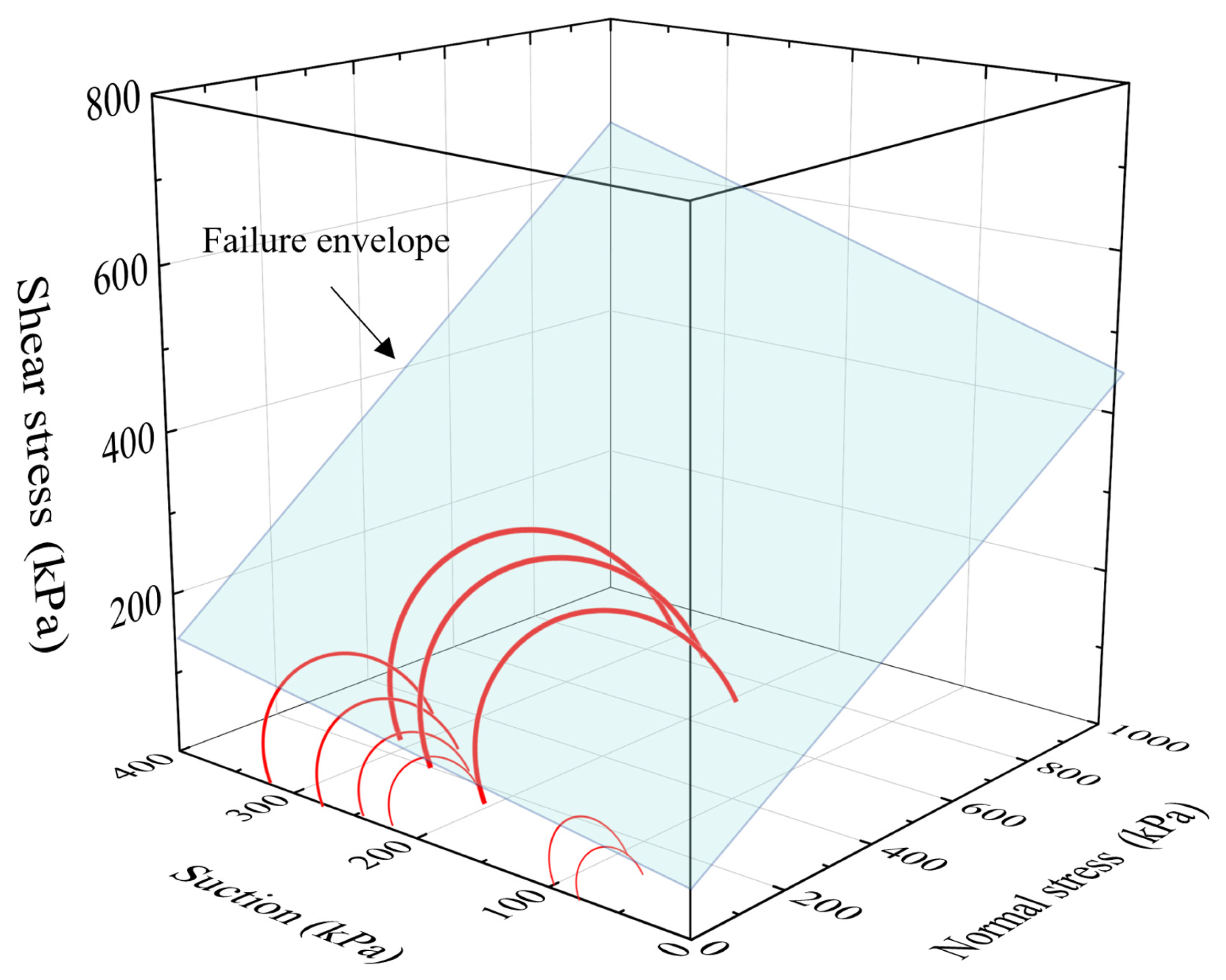

3.4.3. Analysis of Shear Strength

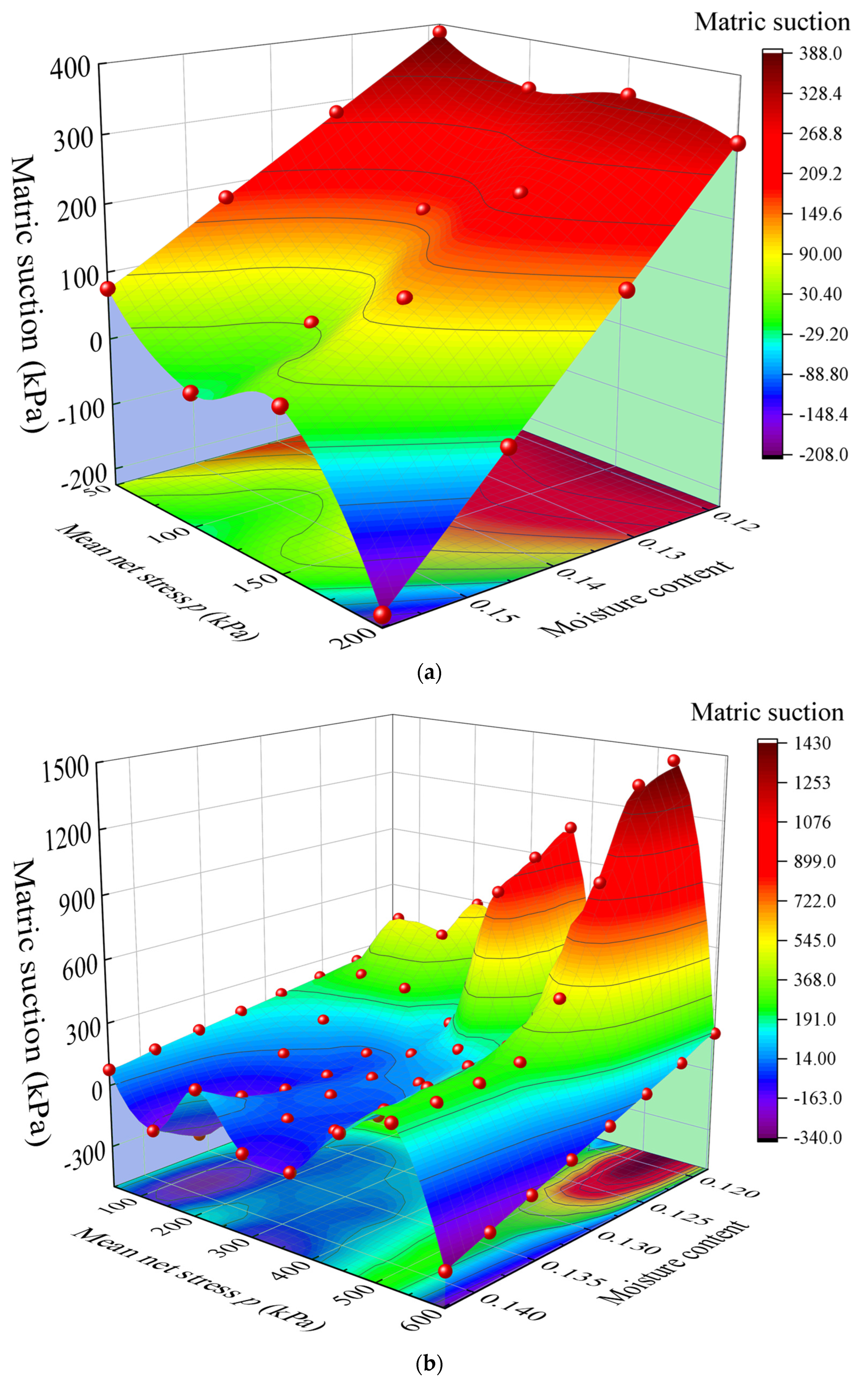

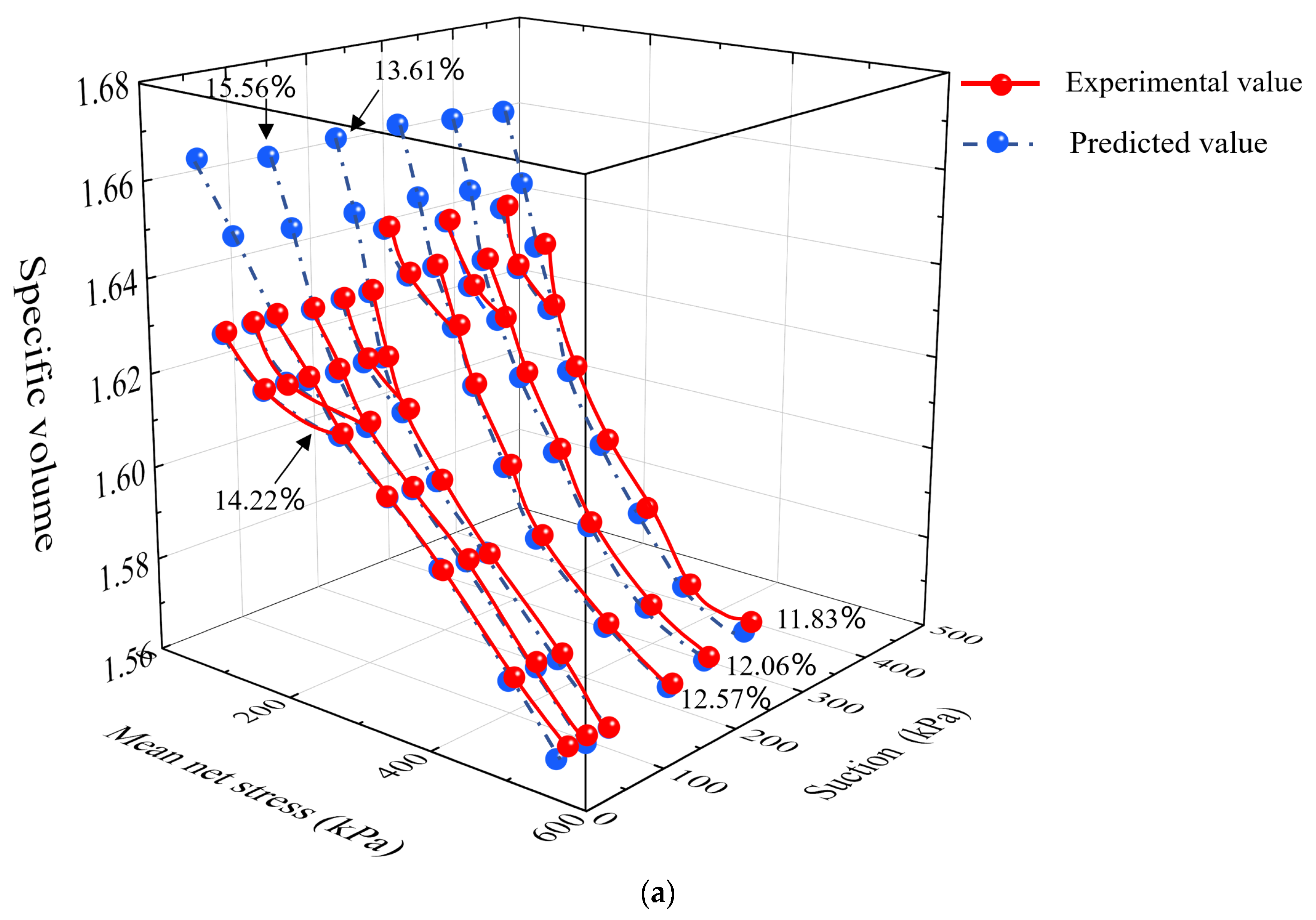

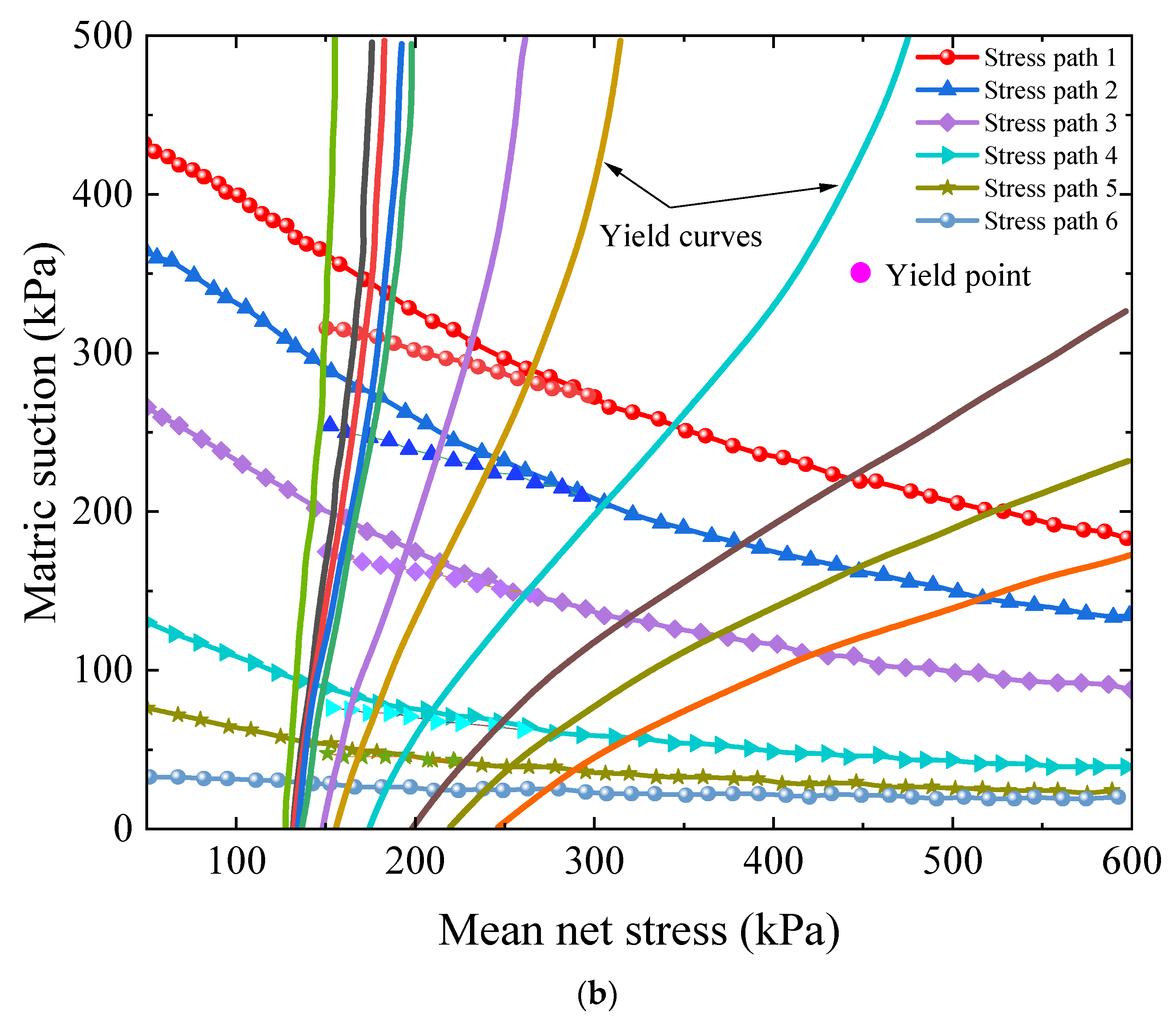

3.4.4. Analysis of Constitutive Behavior

4. Conclusions

- (1)

- The triaxial testing system developed in this study integrates high-suction tensiometer technology with digital image correlation (DIC), enabling the precise 3D reconstruction of sample models through non-contact photogrammetry. It effectively monitors the volume and suction changes of unsaturated subgrade fill samples. Compared with typical methods, which require several days to 24 h for the complete experiment, this system has reduced the experimental time by reducing the total test time to 6 h. This time reduction was achieved without compromising measurement accuracy, as demonstrated by side-by-side direct documentation using the same observation and validation methods as traditional studies. The time reduction represents a notable improvement in the testing process’s efficiency.

- (2)

- As the moisture content increases, the specific volume of the sample gradually increases. When the confining pressure is below 200 kPa, particularly at 50 kPa, the changes in specific volume are smaller, with limited deformation, and the changes remain relatively minor at medium and low moisture content. As the confining pressure approaches 100 kPa, the specific volume curve steepens, and the sample undergoes significant plastic deformation. Under a confining pressure of 600 kPa, the effect of moisture becomes more pronounced, and the specific volume increases substantially, especially under high moisture content conditions, with more noticeable deformation. At low moisture content, the sample exhibits shear compression, whereas under high moisture conditions, the lubricating effect of water reduces particle friction, leading to shear expansion.

- (3)

- During isotropic loading, an increase in confining pressure causes a rapid decrease in suction. When a confining pressure of 200 kPa is applied, the suction decreases to about 420 kPa and then slowly recovers to equilibrium, indicating an adjustment in soil structure and moisture distribution. During triaxial shear loading, the decrease in suction is more pronounced. After applying deviatoric stress, the suction rapidly decreases to 380 kPa and ultimately stabilizes at equilibrium. Compared to isotropic loading, suction changes during shear loading are more complex, particularly under high moisture conditions.

- (4)

- In this study, the BBM model parameters were calibrated using triaxial test data. The results demonstrate that the model performs well in the medium to low stress range, especially when the mean net stress is 200 kPa, with only a 0.61% difference in specific volume between experimental and predicted values. However, in the high stress or high suction region, the prediction error increases, particularly when the stress is 400 kPa, with a difference of approximately 12.57%. As the mean net stress increases, the yield suction also increases, and there are significant differences in the slope and shape of the yield curves under different stress paths. The yield points in the high suction region are more concentrated, further highlighting the significant role of the stress path in yield behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Houston, S.; Zhang, X. A unified two independent stress variable approach to moisture-change-induced unsaturated soil volume change. E3S Web Conf. 2023, 382, 01001. [Google Scholar] [CrossRef]

- Le Roux, P.F.; Jacobsz, S.W. Performance of the tensiometer method for the determination of soil-water retention curves in various soils. Geotech. Test. J. 2021, 44, 1079–1096. [Google Scholar] [CrossRef]

- Orazayeva, S.; Satyanaga, A.; Kim, Y.; Rahardjo, H.; Qian, Z.; Moon, S.-W.; Kim, J. Advanced scanning technology for volume change measurement of residual soil. Appl. Sci. 2024, 14, 10938. [Google Scholar] [CrossRef]

- Li, W.; Yang, Q.; Xue, Z.; Liu, W.; Hua, Y. Experimental study and constitutive modeling of volume change behavior in unsaturated soils. Bull. Eng. Geol. Environ. 2021, 80, 679–689. [Google Scholar] [CrossRef]

- Alhaj, K.; Biscontin, G.; Elshafie, M.; Osman, A. Water retention and characteristic curves representing tropical clay soils from Africa. Geotech. Test. J. 2020, 195, 01019. [Google Scholar] [CrossRef]

- Saha, A.; Sekharan, S. Importance of volumetric shrinkage curve (VSC) for determination of soil–water retention curve (SWRC) for low plastic natural soils. J. Hydrol. 2021, 596, 126113. [Google Scholar] [CrossRef]

- Mishra, P.N.; Scheuermann, A.; Bhuyan, M.H. A unified approach for establishing soil water retention and volume change behavior of soft soils. Geotech. Test. J. 2021, 44, 1197–1216. [Google Scholar] [CrossRef]

- Zheng, F.; Shao, S.; Wang, Y.; Shao, S. A new suction-controlled true triaxial apparatus for unsaturated soil testing. Geotech. Test. J. 2021, 44, 833–850. [Google Scholar] [CrossRef]

- Haeri, S.M.; Borujerdi, S.S.; Garakani, A.A. A fully automated unsaturated triaxial device for testing of soils under complicated hydromechanical stress paths. E3S Web Conf. 2024, 544, 01014. [Google Scholar] [CrossRef]

- de Campos, T.M.; de CViana, A.C.; Silva, T.A.; Abrantes, L.G. Evaluation of the At-Rest Coefficient of Earth Pressure in Unsaturated Residual Soil with a New Suction-Controlled Device. Geotech. Test. J. 2021, 44, 373–391. [Google Scholar] [CrossRef]

- Xia, Y.; Mu, C.; Li, W.; Ye, K.; Wu, H. Study of dynamic evolution of the shear band in triaxial soil samples using photogrammetry technology. Sustainability 2022, 14, 14660. [Google Scholar] [CrossRef]

- Fayek, S.; Zhang, X.; Xia, P. Photogrammetry-Based Method for Measuring Volume Changes of Soil Specimens During Critical Phases of Triaxial Testing. Transp. Res. Rec. 2024, 2678, 1887–1901. [Google Scholar] [CrossRef]

- Zheng, G.; Shao, L.; Guo, X.; Zhang, J. Investigation of the mechanical behaviour of an unsaturated soil mixture using a digital image measurement system. Eur. J. Environ. Civ. Eng. 2020, 24, 1051–1067. [Google Scholar] [CrossRef]

- Li, L.; Li, P.; Cai, Y.; Lu, Y. Visualization of non-uniform soil deformation during triaxial testing. Acta Geotech. 2021, 16, 3439–3454. [Google Scholar] [CrossRef]

- Wang, P.; Guo, X.; Sang, Y.; Shao, L.; Yin, Z.; Wang, Y. Measurement of local and volumetric deformation in geotechnical triaxial testing using 3D-digital image correlation and a subpixel edge detection algorithm. Acta Geotech. 2020, 15, 2891–2904. [Google Scholar] [CrossRef]

- Macari, E.J.; Parken, J.; Costes, N.C. Measurement of volume changes in triaxial tests using digital imaging techniques. Geotech. Test. J. 1997, 20, 103–109. [Google Scholar] [CrossRef]

- Gachet, P.; Geiser, F.; Laloui, L.; Vulliet, L. Automated digital image processing for volume change measurement in triaxial cells. Geotech. Test. J. 2007, 30, 98–103. [Google Scholar] [CrossRef]

- Wu, M.; Wang, J.; Pan, B.; Yin, Z.-Y. Particle tracking-aided digital volume correlation for clay–sand soil mixtures. Géotechnique, 2024; ahead of print. [Google Scholar]

- Sharanya, A.G.; Mudavath, H.; Thyagaraj, T. Review of methods for predicting soil volume change induced by shrinkage. Innov. Infrastruct. Solut. 2021, 6, 116. [Google Scholar] [CrossRef]

- Mendes, J.; Najdi, A.; Encalada, D.; Prat, P.C.; Ledesma, A. Towards the development of new high-capacity tensiometers capable of measuring soil matric suction beyond 3 MPa. Can. Geotech. J. 2022, 59, 1539–1552. [Google Scholar] [CrossRef]

- Liu, H.; Rahardjo, H.; Satyanaga, A.; Du, H. Use of osmotic tensiometers in the determination of soil-water characteristic curves. Eng. Geol. 2023, 312, 106938. [Google Scholar] [CrossRef]

- Rahardjo, H.; Shen, Y.; Tsen-Tieng, D.L.; Ramos-Rivera, J.; Nong, X.-F.; Hamdany, A.H. New osmotic tensiometer development. Geotech. Test. J. 2021, 44, 722–740. [Google Scholar] [CrossRef]

- Hamdany, A.H.; Shen, Y.; Satyanaga, A.; Rahardjo, H.; Lee, T.-T.D.; Nong, X. Field instrumentation for real-time measurement of soil-water characteristic curve. Int. Soil Water Conserv. Res. 2022, 10, 586–596. [Google Scholar] [CrossRef]

- Guo, Y.; Lin, H.C.; Peng, J.B. Response characteristics of an insertion tensiometer investigated via the vacuum saturation method. Catena 2023, 224, 106966. [Google Scholar] [CrossRef]

- Tang, G.; Ma, X.; Zhang, H.; Liu, Z.; He, Y. Real-time determination of soil suction in unsaturated clay based on POF sensor. Measurement 2025, 245, 116569. [Google Scholar] [CrossRef]

- Najdi, A.; Encalada, D.; Mendes, J.; Prat, P.C.; Ledesma, A. Evaluating innovative direct and indirect soil suction and volumetric measurement techniques for the determination of soil water retention curves following drying and wetting paths. Eng. Geol. 2023, 322, 107179. [Google Scholar] [CrossRef]

- Liu, H.; Hamdany, A.H.; Rahardjo, H. Laboratory investigation of osmotic tensiometers filled with cross-linked polyacrylamide. Transp. Geotech. 2024, 44, 101173. [Google Scholar] [CrossRef]

- Kang, J.; Yu, Z.; Zhang, Y.; Zhang, T.; Yao, P.; Ye, X. Development of the thermophysical parameter tester for measuring the soil matrix suction and optimization of the calibration function. Comput. Electron. Agric. 2023, 211, 108018. [Google Scholar] [CrossRef]

- Thu, T.M.; Rahardjo, H.; Leong, E.C. Shear strength and pore-water pressure characteristics during constant water content triaxial tests. J. Geotech. Geoenviron. Eng. 2006, 132, 411–419. [Google Scholar] [CrossRef]

- Rasool, A.M.; Aziz, M. Advanced triaxial tests on partially saturated soils under unconfined conditions. Int. J. Civ. Eng. 2020, 18, 1139–1156. [Google Scholar] [CrossRef]

- Chen, B.; Gao, Y.; Sun, D.; Li, J. Simple testing method for measuring the triaxial stress-strain relations of unsaturated soils at high suctions. Geotech. Test. J. 2021, 44, 535–546. [Google Scholar] [CrossRef]

- Yoshikawa, T.; Noda, T. Triaxial test on water absorption compression of unsaturated soil and its soil-water-air-coupled elastoplastic finite deformation analysis. Soils Found. 2020, 60, 1151–1170. [Google Scholar] [CrossRef]

- Fang, J.; Feng, Y.; Li, Z. Compression and shear strength characteristics of unsaturated intact loess in true triaxial tests. Geotech. Test. J. 2020, 43, 1436–1462. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Chen, G.; Lytton, R. A photogrammetry-based method to measure total and local volume changes of unsaturated soils during triaxial testing. Acta Geotech. 2015, 10, 55–82. [Google Scholar] [CrossRef]

- TB10001-2016; Code for Design of Earthworks and Track Bed for Railway. China Railway Publishing: Beijing, China, 2016.

- TB10102-2010; The Code for Soil Test of Railway Engineering. China Railway Publishing: Beijing, China, 2010.

- Andrianatrehina, S.R.; Li, Z.-S.; Taibi, S.; Fleureau, J.-M.; Boutonnier, L. An improved unsaturated triaxial device to characterize the pore-water pressure and local volume change behavior of a compacted marl. Geotech. Test. J. 2020, 43, 339–350. [Google Scholar] [CrossRef]

- ASTM D2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils. ASTM International: West Conshohocken, PA, USA, 2011.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Housing and Urban-Rural Development of the People’s Republic of China; China Standards Press: Beijing, China, 2019.

- GB/T 50123-1999; Standard for Soil Test Method. Ministry of Housing and Urban-Rural Development of the People’s Republic of China; China Standards Press: Beijing, China, 1999.

- Li, Y.Z.; Liu, E.L.; He, M. Mechanical properties of artificially structured soil and Binary-medium-based constitutive model under undrained conditions. PLoS ONE 2024, 19, e0296441. [Google Scholar] [CrossRef]

- Ning, Y.; Huang, Q.F.; Shi, C.; Meng, Q.X. Numerical simulation study on compression characteristics of gravelly soil mixture based on soft servo method. Geofluids 2021, 2021, 9946628. [Google Scholar] [CrossRef]

- Luo, T.; Chen, D.; Yao, Y.P.; Zhou, A.N. An advanced UH model for unsaturated soils. Acta Geotech. 2020, 15, 145–164. [Google Scholar] [CrossRef]

- Bardanis, M.; Grifiza, S.; Kokoviadis, D.; Feuillas, M. The combination of splitting tensile strength and unconfined compression tests on unsaturated soils to measure the evolution of unsaturated shear strength. E3S Web Conf. 2023, 382, 04001. [Google Scholar] [CrossRef]

- Rivera-Hernandez, X.A.; Vahedifard, F.; Ellithy, G.S. Effect of suction and confining pressure on shear strength and dilatancy of highly compacted silty sand: Single-stage versus multistage triaxial testing. Geotech. Test. J. 2021, 44, 407–421. [Google Scholar] [CrossRef]

- Mu, Q.Y.; Dai, B.L.; Zhou, C. A constitutive model for structured soils under saturated and unsaturated conditions. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 2562–2586. [Google Scholar] [CrossRef]

- Pande, P.; Giri, J.; Ali, M.S.; Mohammad, F.; Raut, J.; Raut, S.; Sathish, T.; Giri, P. Comparative analysis of saturated–unsaturated shear strength under undrained loading: Experimental validation and ANN prediction of clayey soils. AIP Adv. 2024, 14, 075118. [Google Scholar] [CrossRef]

- Rasool, A.M.; Kuwano, J. Effect of constant loading on unsaturated soil under water infiltration conditions. Geomech. Eng. 2020, 20, 221–232. [Google Scholar]

- Altamirano Muñiz, E.F. Modeling soils’ failure envelope with virtual displacements (LSVD). arXiv 2023, arXiv:2406.18594. [Google Scholar]

- Tian, D.; Zheng, H. The generalized Mohr-Coulomb failure criterion. Appl. Sci. 2023, 13, 5405. [Google Scholar] [CrossRef]

- Handspiker, W.; Liu, Z.; Ghafghazi, M. On stress ratio equations in three-dimensional stress space for modelling soil behaviour. Geotech. Res. 2024, 11, 243–255. [Google Scholar] [CrossRef]

- Rawat, A.; Lang, L.; Baille, W.; Dieudonne, A.C.; Collin, F. Coupled hydro-mechanical analysis of expansive soils: Parametric identification and calibration. J. Rock Mech. Geotech. Eng. 2020, 12, 620–629. [Google Scholar] [CrossRef]

- Zhang, X.; Riad, B.; Alonso, E.E. Calibration of BBM parameters using the modified state surface approach. J. Geotech. Eng. 2023, 382, 15001. [Google Scholar] [CrossRef]

- Ji, Z.; Yi, H.; Li, G.; Liu, B.; Wu, Z. Numerical Implementation of the Barcelona Basic Model Based on Return-Mapping Integration. Appl. Sci. 2022, 12, 11933. [Google Scholar] [CrossRef]

- Prajapati, V.; Das, A. Numerical implementation of BBM in FE package for solving unsaturated soil boundary value problems. E3S Web Conf. EDP Sci. 2023, 382, 15003. [Google Scholar] [CrossRef]

| Particle Size/mm | >10 | 10–5 | 2–5 | 1–2 | 0.5–1 | 0.25–0.5 | 0.074–0.25 | ≤0.074 |

|---|---|---|---|---|---|---|---|---|

| Percent content/% | 1.13 | 10.129 | 11.234 | 27.7 | 15.613 | 13.144 | 18.188 | 2.862 |

| Sample | Serial Number | Preliminary Condition | ||

|---|---|---|---|---|

| w (%) | e | s (kPa) | ||

| Set 1 | ① | 15.89 | 0.655 | 28.0 |

| ② | 14.56 | 0.655 | 57.2 | |

| ③ | 13.48 | 0.652 | 170.0 | |

| ④ | 13.05 | 0.654 | 241.4 | |

| ⑤ | 12.16 | 0.652 | 387.3 | |

| ⑥ | 11.76 | 0.647 | 501.7 | |

| Set 2 | ① | 15.90 | 0.656 | 73.1 |

| ② | 13.41 | 0.654 | 145.6 | |

| ③ | 12.92 | 0.652 | 253 | |

| ④ | 11.98 | 0.650 | 364.8 | |

| ⑤ | 11.84 | 0.647 | 417.2 | |

| Set 3 | ① | 15.56 | 0.658 | 34.0 |

| ② | 14.22 | 0.655 | 76.7 | |

| ③ | 13.61 | 0.653 | 130.3 | |

| ④ | 12.57 | 0.650 | 265.8 | |

| ⑤ | 12.04 | 0.649 | 364.6 | |

| ⑥ | 11.83 | 0.648 | 430.3 | |

| Coefficient | Prior to Idealization | Post-Idealization | Unit |

|---|---|---|---|

| Fx | 23.8975 | 24.3567 | (mm) |

| Fy | 15.8862 | 16.1234 | (mm) |

| M | 4936 | 4936 | (mm) |

| Px | 12.1289 | 12.4433 | (mm) |

| Py | 9.1389 | 9.2448 | (mm) |

| P1 | −3.8976 | 0 | (×10−6) |

| P2 | 1.6156 | 0 | (×10−6) |

| K1 | 5.998 | 0 | (×10−5) |

| K2 | −4.876 | 0 | (×10−9) |

| N | 3218 | 3218 | (mm) |

| f | 54.3985 | 54.3885 | (mm) |

| Sample | Serial Number | sd (kPa) | (kPa) | (kPa) |

|---|---|---|---|---|

| Set 1 | ① | 35.7 | 95.6 | 5 |

| ② | 63.9 | 127.3 | 5 | |

| ③ | 127.9 | 197.8 | 5 | |

| ④ | 164.9 | 249.4 | 5 | |

| ⑤ | 256.8 | 290.7 | 5 | |

| ⑥ | 322.9 | 336.3 | 5 | |

| Set 2 | ① | - | - | 200 |

| ② | - | - | 200 | |

| ③ | 121.7 | 748.9 | 200 | |

| ④ | 171.9 | 786.9 | 200 | |

| ⑤ | 196.9 | 830.9 | 200 | |

| Set 3 | ① | - | - | 200 |

| ② | - | - | 200 | |

| ③ | - | - | 200 | |

| ④ | - | - | 200 | |

| ⑤ | - | - | 200 | |

| ⑥ | - | - | 200 |

| Coefficient | Optimal Fit |

|---|---|

| pc (MPa) | 0.121 |

| 0.0077 | |

| β (MPa−1) | 7.999 |

| r | 0.377 |

| Q(0) | 0.667 |

| λ(0) | 0.054 |

| 0.0116 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Ling, X. Study of a Triaxial Testing System for Unsaturated Subgrade Fillers Using a High-Suction Tensiometer and Photogrammetry. Appl. Sci. 2025, 15, 5380. https://doi.org/10.3390/app15105380

Hu Y, Ling X. Study of a Triaxial Testing System for Unsaturated Subgrade Fillers Using a High-Suction Tensiometer and Photogrammetry. Applied Sciences. 2025; 15(10):5380. https://doi.org/10.3390/app15105380

Chicago/Turabian StyleHu, Yiru, and Xianzhang Ling. 2025. "Study of a Triaxial Testing System for Unsaturated Subgrade Fillers Using a High-Suction Tensiometer and Photogrammetry" Applied Sciences 15, no. 10: 5380. https://doi.org/10.3390/app15105380

APA StyleHu, Y., & Ling, X. (2025). Study of a Triaxial Testing System for Unsaturated Subgrade Fillers Using a High-Suction Tensiometer and Photogrammetry. Applied Sciences, 15(10), 5380. https://doi.org/10.3390/app15105380