Research on Settlement and Section Optimization of Cemented Sand and Gravel (CSG) Dam Based on BP Neural Network

Abstract

1. Introduction

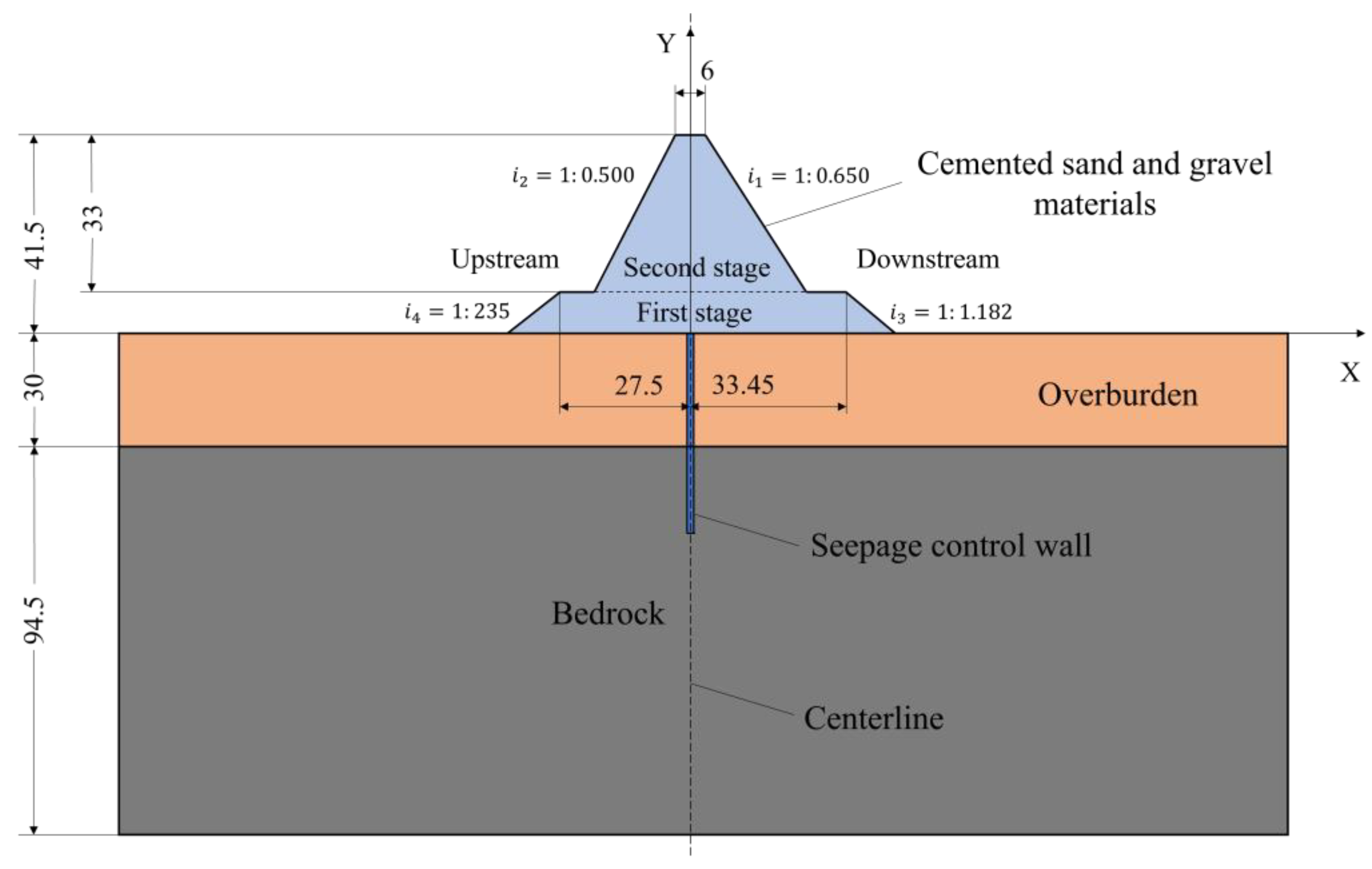

2. Numerical Simulation of CSG Dam upon Overburden

2.1. Project Overview and Establishment of Finite Element Model

2.1.1. Basic Assumptions

- (1)

- The model is simplified into four parts: dam body, cut-off wall, overburden, and bedrock.

- (2)

- The material of the cut-off wall and the bedrock is uniform, isotropic, and linearly elastic.

- (3)

- The material of the overburden matches the Mohr Coulomb constitutive model.

- (4)

- The material of the dam body matches the Duncan Zhang constitutive model modified by rigid spring method.

- (5)

- The contact surface between the dam body and the covering layer is in complete contact.

- (6)

- Not considering the impact of groundwater.

- (7)

- Not considering changes in ambient temperature.

2.1.2. Model Size and Division of Finite Element Mesh

2.2. Project Overview and Establishment of Finite Element Model

2.2.1. Duncan–Chang Classical Model

2.2.2. Principle of Virtual Rigid Spring Method

2.3. Constitutive Model of Overburden and Foundation

2.4. Implementation of Nonlinear Computing

2.5. Stress–Strain Analysis

2.6. Analysis of Factors Affecting Characteristics

2.7. Grey Relational Grade Analysis

3. Neural Network Model

3.1. Data Normalization

3.2. BP Neural Network

3.3. Evaluation Indicators of Predictive Performance

3.4. Regression Analysis of BP Neural Network Model Data

4. Optimization Design

4.1. Process of Optimization

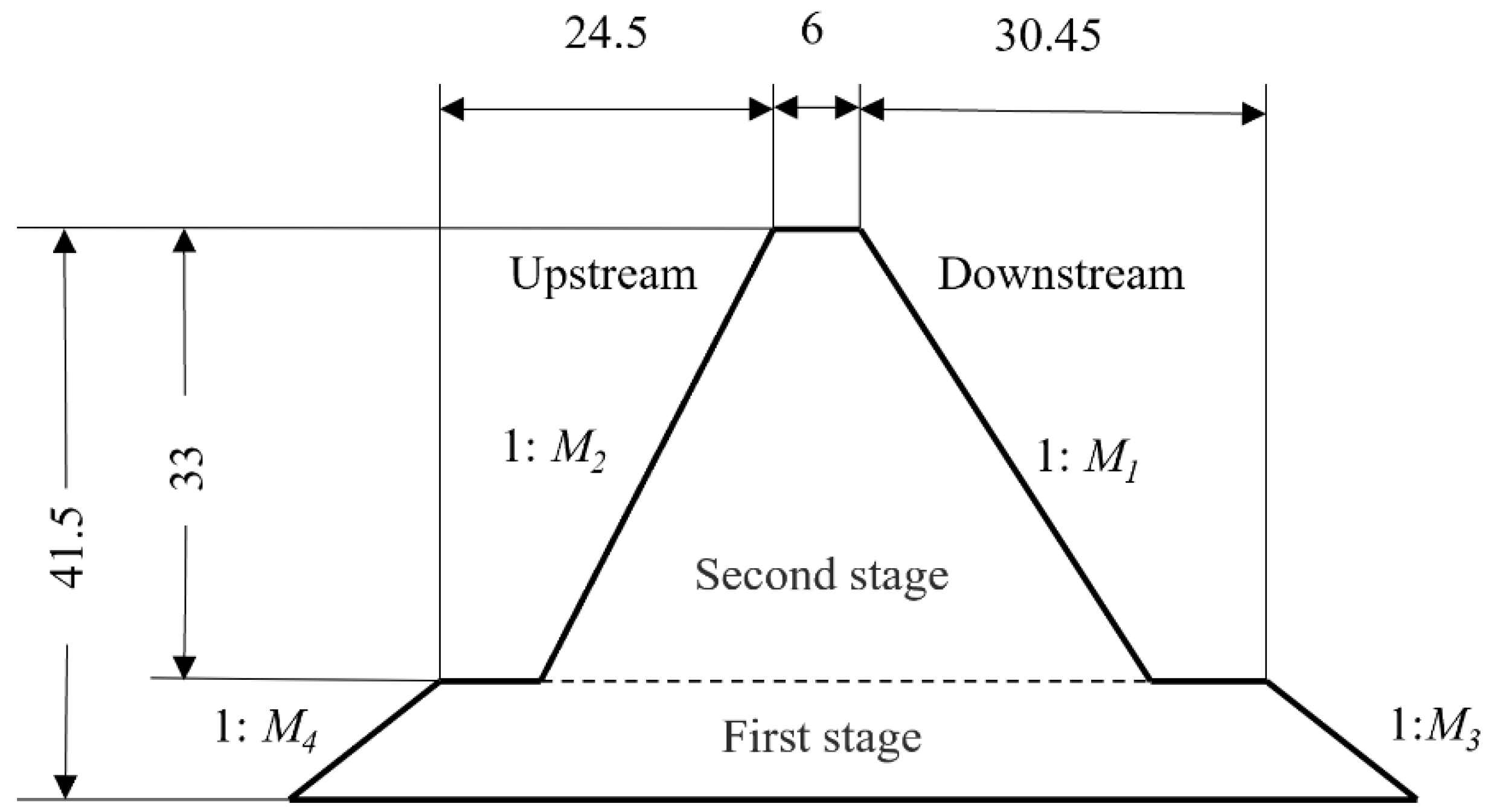

4.2. Objective Function and Constraints

4.3. Implementation and Comparison of Optimization

4.4. Analysis of Optimization Results

4.5. Evaluation of Optimization

5. Discussion

6. Conclusions

- (1)

- The upstream and downstream slope coefficients of the first and second stages of the CSG dam, as well as the elastic modulus and Poisson’s ratio of the overburden, all have a significant impact on the stress and deformation state of the dam body. In dimension parameters, the downstream slope coefficient of the second stage of the dam has the greatest impact on the maximum settlement, with a grey correlation degree of 0.7367. The influence of the elastic modulus of the overburden on the maximum settlement of the dam body is greater than its Poisson’s ratio.

- (2)

- The BP prediction model in this paper achieves an R2 of 0.9996 and an RMSE of 0.0109 cm when predicting maximum settlement, and achieves an R2 of 0.9871 and an RMSE of only 0.0335 MPa when predicting maximum compressive stress, which provides a prerequisite and accuracy guarantee for the optimization method based on a BP neural network. After inputting the slope parameters of the dam body and the material parameters of the overburden into the trained model, accurate maximum settlement and maximum compressive stress can be obtained.

- (3)

- Combining a BP neural network with the optimization algorithm can achieve efficient section optimization of the CSG dam. Through optimization, the material consumption of the dam body is saved by 11.83%, the maximum settlement of the dam body is reduced by 2.60%, and the maximum compressive stress of the dam body is reduced by 37.35% compared to the initial size. By using an optimization method based on a BP neural network, the time consumption is reduced by 40.92% compared to the traditional optimization method. The economic benefits of the dam are improved, the state of stress and deformation is improved, computational efficiency is improved, and computational resources are saved. The application of different prediction models and optimization algorithms in engineering optimization problems deserves more in-depth research in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Downstream slope coefficient of the second stage of dam | |

| Upstream slope coefficient of the second stage of dam | |

| Downstream slope coefficient of the first stage of dam | |

| Upstream slope coefficient of the first stage of dam | |

| Elastic modulus of overburden | |

| Poisson’s ratio of overburden | |

| Maximum settlement of dam body | |

| Maximum compressive stress of dam body | |

| BP | Backpropagation |

| RMSE | Root mean square error |

| MAPE | Mean square error |

| Coefficient of determination which can reflect the degree of regression of data |

References

- Sun, M.; Yang, S.; Tian, Q. Review on Mechanical Properties, Durability and Dam Type of CSG Material. Yellow River 2016, 38, 83–85. [Google Scholar] [CrossRef]

- Wang, C.; Xu, S. Adaptability Analysis of Subgrade Condition of Cement Sand Gravel Dam Based on the Mechanical Properties. Water Conserv. Sci. Technol. 2018, 24, 43–46. [Google Scholar]

- Kim, S.; Choi, W.; Kim, Y.; Shin, J.; Kim, B. Investigation of Compressive Strength Characteristics of Hardfill Material and Seismic Stability of Hardfill Dams. Appl. Sci. 2023, 13, 2492. [Google Scholar] [CrossRef]

- Jia, J.; Ding, L.; Wu, Y.; Zhao, C.; Zhao, L. Research and Application of Key Technologies for the Construction of Cemented Material Dam with Soft Rock. Appl. Sci. 2023, 13, 4626. [Google Scholar] [CrossRef]

- Yang, H.; Jia, J.; Zheng, C.; Feng, W.; Lu, Y. Research on the anti-skid stability of the surface layer of Shoukoubao cementitious granular material dam. In Proceedings of the 2014 Academic Annual Conference of the China Dams Association; Jia, J., Ji, J., Eds.; The Yellow River Water Conservancy Press: Zhengzhou, China, 2014; pp. 567–574. [Google Scholar]

- Wu, M.; Du, B.; Yao, Y.; He, X. An experimental study on stress-strain behavior and constitutive model of hardfill material. Sci. China Phys. Mech. 2011, 54, 2015–2024. [Google Scholar] [CrossRef]

- Yang, S.; Chai, Q.; Sun, M. Nonlinear Finite Element Analysis of Stress and Displacement of CSG Dam. Yellow River 2016, 38, 89–91. [Google Scholar] [CrossRef]

- Guo, X.; Du, J.; Zhao, Q.; Cai, X. Creep Test of CSG and Long-Term Deformation Prediction of CSG Dams. Yellow River 2019, 41, 149–154. [Google Scholar] [CrossRef]

- Cao, S.; Pan, X.; Gao, Y. Neural network ensemble-based parameter sensitivity analysis in civil engineering systems. Neural Comput. Appl. 2017, 28, 1583–1590. [Google Scholar] [CrossRef]

- Sun, M.; Cheng, Y.; Ma, X.; Xia, Z.; Zhou, Q.; Zhu, Q.; Xue, X. Prediction of Critical Parameters of Reprocessing Non-uniform Conditions Based on Improved BP Neural-network. Nucl. Power Eng. 2023, 44, 16–22. [Google Scholar] [CrossRef]

- Yu, J.; Jin, A.; Pan, J.; Wang, J.; Zhang, C. GA-BP artificial neural networks for predicting the seismic response of arch dams. J Tsinghua Univ. Sci. Technol. 2022, 62, 1321–1329. [Google Scholar] [CrossRef]

- Zhang, M.; Huang, J.; Wang, Y. Finite element analysis and neural-network prediction of deformation of underground pipelines affected by excavation. Chin. J. Geotech. Eng. 2006, 28, 1350–1354. [Google Scholar] [CrossRef]

- Bai, F.; Shi, W.; Bao, Z.; Xing, C. Optimization design of flat steel gates based on BP neural network and genetic algorithm. Sichuan Water Resour. 2023, 44, 42–47. [Google Scholar]

- Chen, S.; Liu, Y.; Jing, G.; Chen, G.; Peng, Q. Optimization Design of the Interference Connection Structure for Turbocharger Turbine Rotors Based on Back Propagation. Chin. Intern. Combust. Engine Eng. 2024, 45, 10–17. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, J.; Lv, C.; Pan, K.; Li, Z. Optimization Design of Electromagnetic Drive Structure for Shaftless. Sci. Technol. Eng. 2024, 24, 3236–3242. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, L.; Wang, X. Design method of 100-meter cemented sand and gravel dams based on multivariate optimization. J. Hydroelectr. Eng. 2023, 42, 119–131. [Google Scholar]

- Sun, M.; Wu, P.; Yang, S.; Chai, Q. Experimental Study on Constitutive Model of CSG. Yellow River 2015, 37, 126–128+131. [Google Scholar] [CrossRef]

- Sun, M.; Yang, S.; Zhang, J. Study on constitutive model for over lean cemented material. Adv. Sci. Technol. Water Resour. 2007, 27, 35–37. [Google Scholar]

- Tian, Q.; Yang, S.; Chai, Q.; Sun, M. Finite Element Analysis of Shoukoubao Dam Based on the Virtual Rigid Spring Method. J. North China Univ. Water Resour. Electr. Power 2015, 36, 30–33. [Google Scholar] [CrossRef]

- Sun, M.; Yang, S.; Chai, Q. Basic Research of Cement-sand-gravel Dam. J. North China Univ. Water Resour. Electr. Power 2014, 35, 43–46. [Google Scholar] [CrossRef]

- Shen, D.; Cai, X. Stress-strain characteristics and influencing factors of cemented sand and gravel (CSG) dam upon overburden. Water Resour. Hydropower Eng. 2019, 50, 80–86. [Google Scholar] [CrossRef]

- Kubota, S.; Kawai, Y.; Kadotani, R. Accuracy validation of point clouds of UAV photogrammetry and its application for river management. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 195–199. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, Y.; Xu, X. Application research of APDL secondary development in nonlinear analysis of earth rock dams. Disaster Control Eng. 2010, 1, 6–10. [Google Scholar]

- Liu, Z.; Miao, L. Finite element nonlinear analysis for rockfill dam with concrete lab based on APDL. J. Northwest Hydroelectr. Power 2004, 20, 17–20. [Google Scholar]

- Wang, T.; Xu, Q. Finite Element Analysis of Rock-filled Dams Based on Duncan-Chang Model. China Rural Water Hydropower 2016, 1, 151–155. [Google Scholar]

- Ni, X.; Wang, C.; Tang, D.; Lu, J.; Wang, X.; Chen, W. Early-warning and inducement analysis of super-large deformation of deep foundation pit on soft soil. J. Cent. South Univ. 2022, 53, 2245–2254. [Google Scholar] [CrossRef]

- Yuan, Z.; Gao, L.; Chen, H.; Song, S. Study on Settlement of Self-Compacting Solidified Soil in Foundation Pit Backfilling Based on GA-BP Neural Network Model. Buildings 2023, 13, 2014. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, N.; Dai, W.; Zhu, G.; Wen, J. Turbofan Engine Health Prediction Model Based on ESO-BP Neural Network. Appl. Sci. 2024, 14, 1996. [Google Scholar] [CrossRef]

- Cui, F.; Wang, H.; Shu, Z. Prediction of aerodynamic pressure amplitude in tunnel based on PSO-BP neural network. J. Cent. South Univ. 2023, 54, 3752–3761. [Google Scholar] [CrossRef]

- Pei, J.; Liu, L.; Wang, X.; Ling, Y. Derivation of Creep Parameters for Surrounding Rock through Creep Tests and Deformation Monitoring Data: Assessing Tunnel Lining Safety. Appl. Sci. 2024, 14, 2090. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.; Gong, X.; Wang, X. AirFlow Angle Estimation Method for Large Passenger Aircraft Based on GA-BP Neural Network. Comput. Simulation. 2024, 41, 53–57. [Google Scholar]

- Chai, H.; Xu, H.; Hu, J.; Geng, S.; Guan, P.; Ding, Y.; Zhao, Y.; Xu, M.; Chen, L. Application of a Variable Weight Time Function Combined Model in Surface Subsidence Prediction in Goaf Area: A Case Study in China. Appl. Sci. 2024, 14, 1748. [Google Scholar] [CrossRef]

- Harapin, A.; Jurišić, M.; Bebek, N.; Sunara, M. Long-Term Effects in Structures: Background and Recent Developments. Appl. Sci. 2024, 14, 2352. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X. Multi-Point Deformation Prediction Model for Concrete Dams Based on Spatial Feature Vector. Appl. Sci. 2023, 13, 11212. [Google Scholar] [CrossRef]

- SL678-2014; Technical Guideline for Cemented Granular Material Dams. China Water & Power Press: Beijing, China, 2014.

- SL319-2018; Design Specification for Concrete Gravity Dams. China Water & Power Press: Beijing, China, 2018.

- SL265-2016; Design Specifications for Sluices. China Water & Power Press: Beijing, China, 2016.

| Structure Name | (kPa) | (°) | ||||||

|---|---|---|---|---|---|---|---|---|

| CSG dam body | 1100 | 47 | 0.80 | 6400 | 0.35 | 0.30 | 0.01 | 0.30 |

| Structure Name | Density (kg·m−3) | Elastic Modulus (GPa) | Poisson’s Ratio | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| Overburden | 2200 | 1.2 | 0.4 | 5 | 36 |

| Bedrock | 2400 | 5.0 | 0.2 | - | - |

| Project | Maximum Displacement in the X Direction (cm) | Maximum Settlement in the Y Direction (cm) | Maximum Compressive Stress (MPa) | Maximum Tensile Stress (MPa) | |

|---|---|---|---|---|---|

| Completion period | Value | 0.132 (along the river direction) | 4.143 | 2.451 | 0.702 |

| Position | Toe of the first stage of the dam | Centerline of the dam crest | Junction of the first and second stages upstream of the dam | Upstream of the centerline of the dam bottom | |

| Impounding period | Value | 0.191 (along the river direction) | 4.190 | 2.412 | 0.671 |

| Position | Toe of the first stage of the dam | Upstream of the centerline of the dam crest | Junction of the first and second stages upstream of the dam | Upstream of the centerline of the dam bottom | |

| Working Condition | (MPa) | |||||

|---|---|---|---|---|---|---|

| 1 | 0.5 | 0.55 | 1.05 | 1.05 | 1200 | 0.4 |

| 2 | 0.65 | |||||

| 3 | 0.8 | |||||

| 4 | 0.65 | 0.4 | 1.05 | 1.05 | 1200 | 0.4 |

| 5 | 0.55 | |||||

| 6 | 0.7 | |||||

| 7 | 0.65 | 0.55 | 0.6 | 1.05 | 1200 | 0.4 |

| 8 | 1.05 | |||||

| 9 | 1.5 | |||||

| 10 | 0.65 | 0.55 | 1.05 | 0.6 | 1200 | 0.4 |

| 11 | 1.05 | |||||

| 12 | 1.5 | |||||

| 13 | 0.65 | 0.55 | 1.05 | 1.05 | 700 | 0.4 |

| 14 | 1200 | |||||

| 15 | 1700 | |||||

| 16 | 0.65 | 0.55 | 1.05 | 1.05 | 1200 | 0.35 |

| 17 | 0.4 | |||||

| 18 | 0.45 |

| Project | Training Set | Test Set | ||||

|---|---|---|---|---|---|---|

| RMSE | MAPE | R2 | RMSE | MAPE | R2 | |

| 0.0095 cm | 0.18% | 0.9997 | 0.0109 cm | 0.21% | 0.9996 | |

| 0.0239 MPa | 1.03% | 0.9931 | 0.0335 MPa | 1.43% | 0.9871 | |

(MPa) | (MPa) | (MPa) | (MPa) | (MPa) | ||

|---|---|---|---|---|---|---|

| Traditional method | −0.25 | −0.06 | 1.49 | 0.27 | 0.20 | 1.35 |

| Method based on BP | −0.26 | −0.11 | 1.51 | 0.39 | 0.35 | 1.11 |

| Requirement | <0 | <0 | <6 | - | - | <1.5 |

| Size | M1 | M2 | M3 | M4 | (cm) | (MPa) | (m3) | Time Consumption |

|---|---|---|---|---|---|---|---|---|

| Initial | 0.650 | 0.500 | 1.182 | 1.235 | 4.190 | 2.412 | 1429 | - |

| Optimization by traditional method | 0.517 | 0.403 | 0.651 | 0.647 | 4.083 | 1.492 | 1264 | 7 h 37 min |

| Optimization by method based on BP | 0.503 | 0.402 | 0.653 | 0.765 | 4.081 | 1.511 | 1260 | 4 h 30 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Yang, H.; Lin, Z. Research on Settlement and Section Optimization of Cemented Sand and Gravel (CSG) Dam Based on BP Neural Network. Appl. Sci. 2024, 14, 3431. https://doi.org/10.3390/app14083431

Wang S, Yang H, Lin Z. Research on Settlement and Section Optimization of Cemented Sand and Gravel (CSG) Dam Based on BP Neural Network. Applied Sciences. 2024; 14(8):3431. https://doi.org/10.3390/app14083431

Chicago/Turabian StyleWang, Shuyan, Haixia Yang, and Zhanghuan Lin. 2024. "Research on Settlement and Section Optimization of Cemented Sand and Gravel (CSG) Dam Based on BP Neural Network" Applied Sciences 14, no. 8: 3431. https://doi.org/10.3390/app14083431

APA StyleWang, S., Yang, H., & Lin, Z. (2024). Research on Settlement and Section Optimization of Cemented Sand and Gravel (CSG) Dam Based on BP Neural Network. Applied Sciences, 14(8), 3431. https://doi.org/10.3390/app14083431