Preparation and Characterization of Polymer-Modified Sulphoaluminate-Cement-Based Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Materials’ Preparation

2.3. Orthogonal Experimental Design

2.4. Mechanical Performance Testing

2.5. Structural Characterization

3. Results and Discussion

3.1. Analysis of Orthogonal Experimental Results

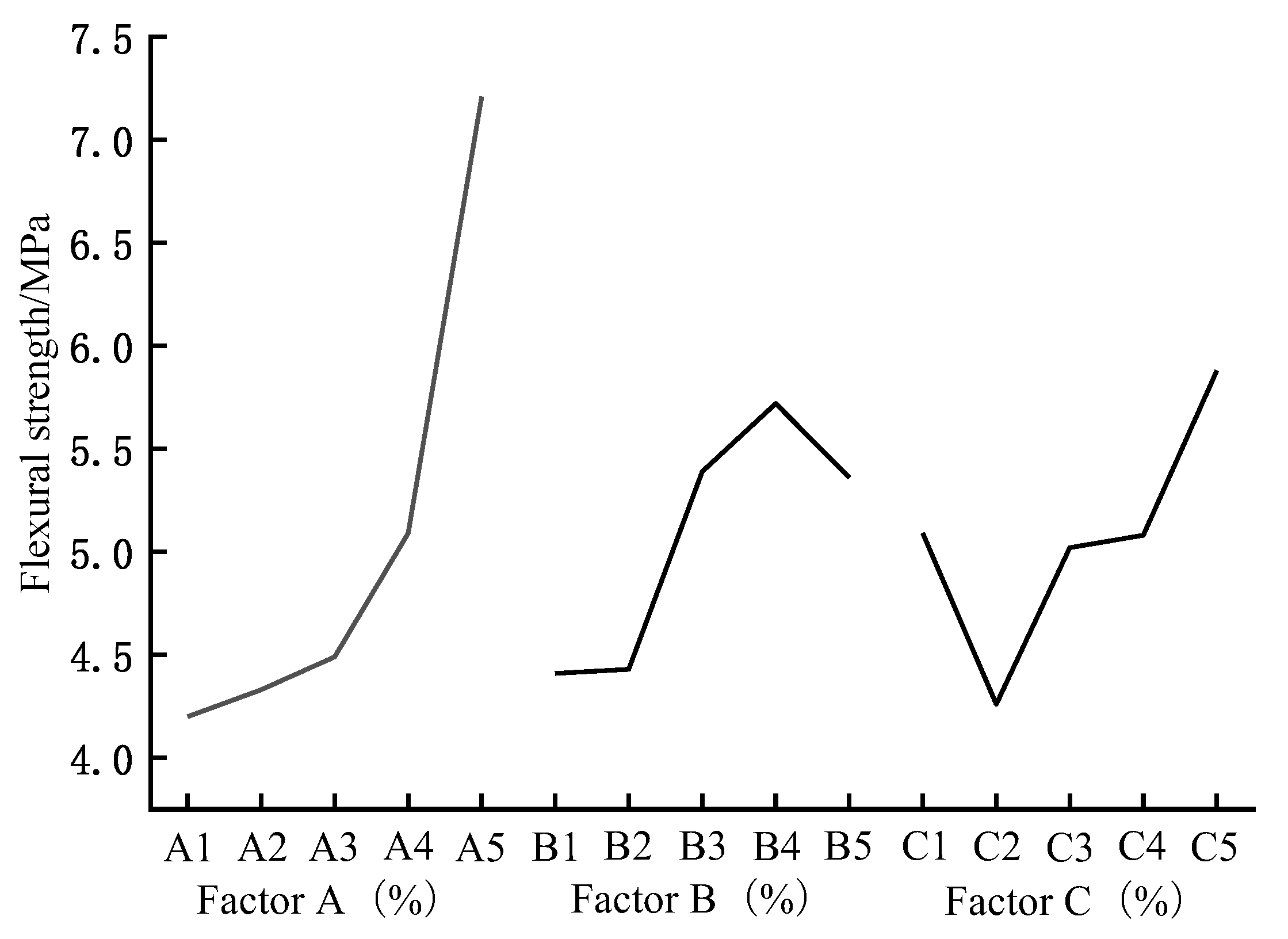

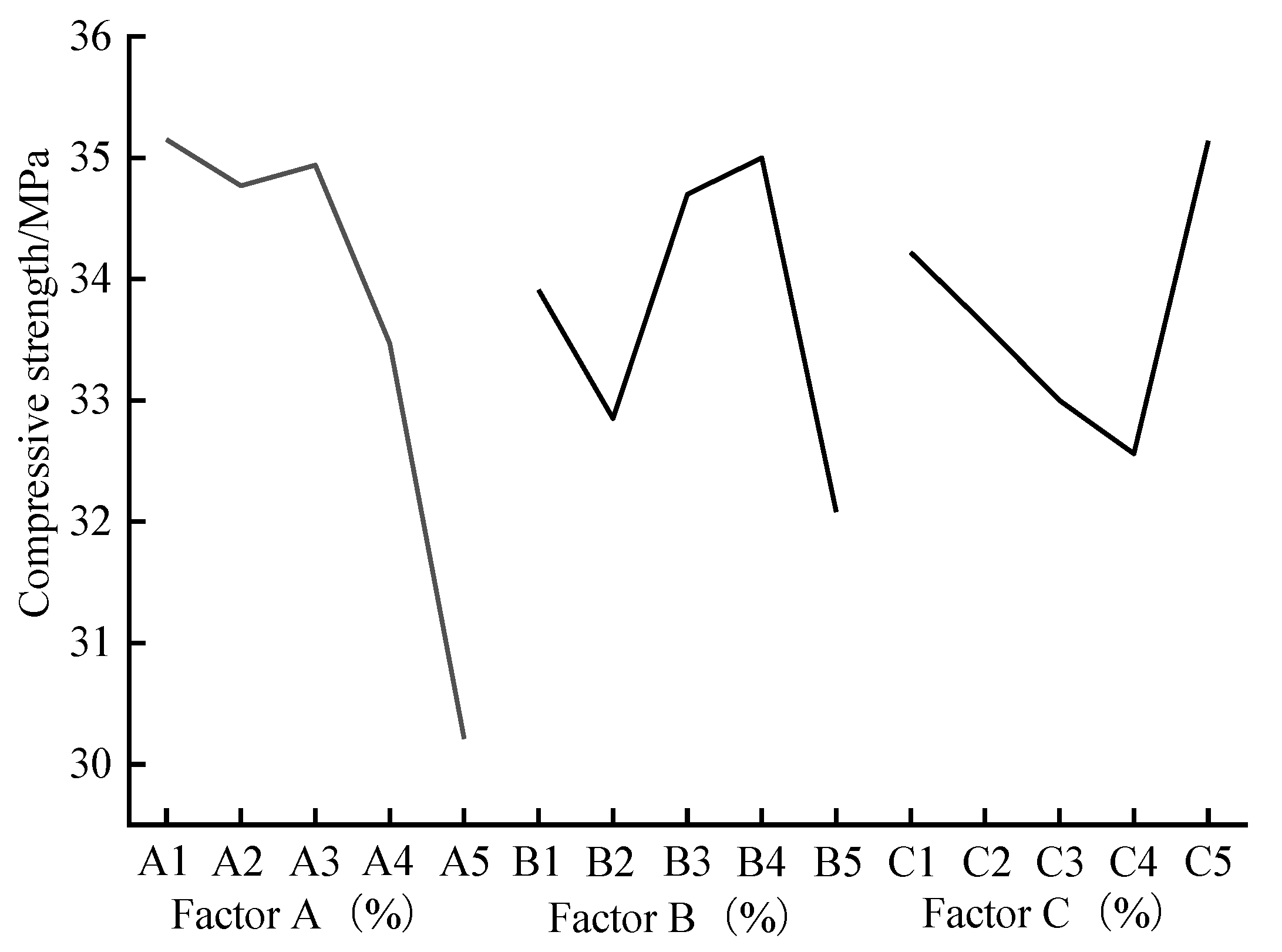

3.1.1. Range Analysis

3.1.2. Variance Analysis

3.2. Comprehensive Scoring Method for Selecting the Optimal Ratio

3.3. Characterization

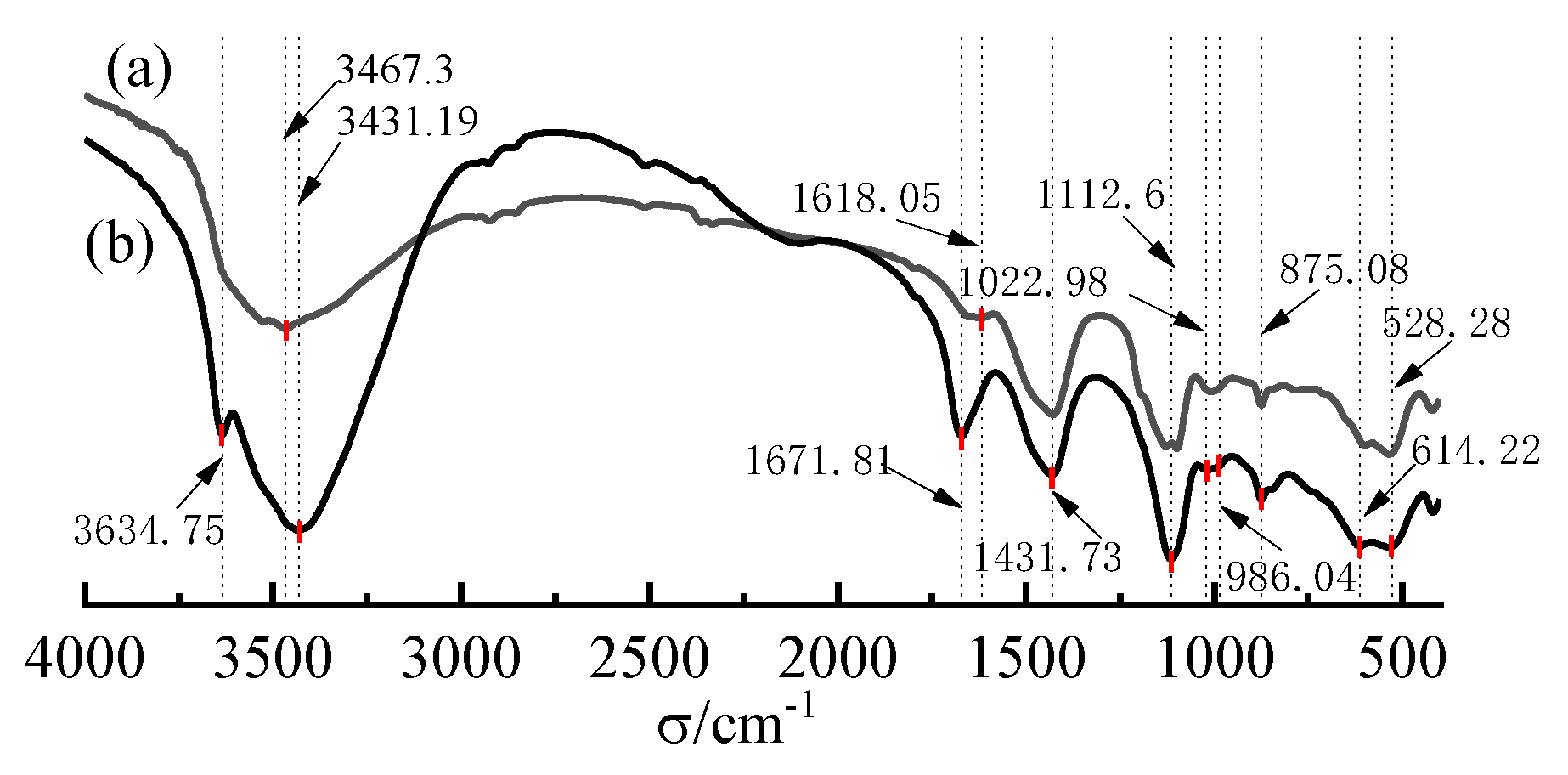

3.3.1. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

3.3.2. X-ray Diffraction (XRD) Analysis

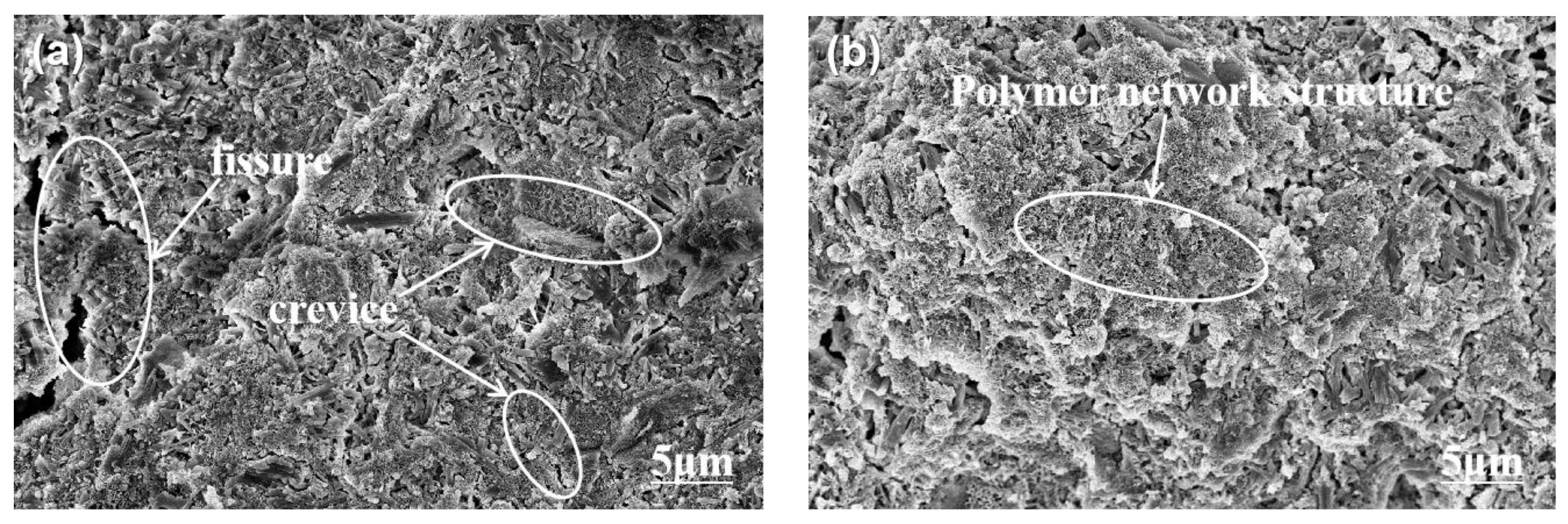

3.3.3. Field Emission Scanning Electron Microscopy (SEM) Analysis

4. Conclusions

- (1)

- According to the orthogonal experiment, the monomer was found to be a significant influencing factor for the performance of modified cement-based materials. The optimal preparation dosages of polymer-modified cement-based materials were as follows: monomer 5%, initiator 3%, and crosslinking agent 2.5%.

- (2)

- Structural characterization revealed that in situ polymerization of acrylamide formed a network polymer structure that intersected with and penetrated the rigid spatial skeleton structure formed by cement hydration products, leading to an organic–inorganic dual network structure. The polymer served as both filler and binder without altering the composition of cement hydration products. However, stable chemical bonds were established between these products and polymers. This improvement significantly enhanced the density and stability of polymer-modified cement-based materials, preparing them for subsequent marine performance research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Su, F.Y.; Wang, H.Y.; Ma, X.D. Review of the Influence of Acrylate Lotion on the Properties of Cement-Based Materials. Materials 2023, 16, 6597. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Chen, N. Preparation of Trilobal Poly Fiber and Its Reinforcement for Cement-based Composite Materials. Polym. Mater. Sci. Eng. 2020, 36, 275–279. [Google Scholar]

- Bahranifard, Z.; Tabrizi, F.F.; Vosoughi, R.A. An investigation on the effect of styrene-butyl acrylate copolymer latex to improve the properties of polymer modified concrete. Constr. Build. Mater. 2019, 20, 175–185. [Google Scholar] [CrossRef]

- Fan, L.D.; Xu, F.; Wang, S.R. A review on the modification mechanism of polymer on cement-based materials. J. Mater. Res. Technol. 2023, 26, 5816–5837. [Google Scholar] [CrossRef]

- Xu, Y.C.; Xing, G.H.; Hang, J.L. Effect of PVA Fiber and Carbon Nanotubes Modification on Mechanical Properties of Concrete. J. Build. Mater. 2023, 26, 809–815. [Google Scholar]

- Liu, F.; Wang, B.M.; Yuan, X.S. Experimental analysis on mechanical properties and durability of cement concrete modified by styrene-butadiene latex. J. Funct. Mater. 2019, 50, 6167–6173. [Google Scholar]

- Jin, H.S.; Li, F.H.; He, X. Research on Frost Resistance of Polypropylene Fiber Cement-based Composite Material. Mater. Rev. 2020, 34, 71–76. [Google Scholar]

- Li, L. Study on the Influence and Mechanism of Nano Organic and Inorganic Hybrid Materials on Cement Hydration. Ph.D. Thesis, Chongqing University, Chongqing, China, 2020. [Google Scholar]

- Abu, T.; Ala, S.; Ghassan, S.; Senouci, A. Using Aerosol OT in Hexane Solution to Synthesize Calcium Nitrate Self-Healing Refined Microcapsules for Construction Applications. Buildings 2022, 12, 751. [Google Scholar] [CrossRef]

- Yin, B.; Hau, X.L.; Qi, D.M. Multi-scale synergistic modification and mechanical properties of cement-based composites based on in-situ polymerization. Cem. Concr. Compos. 2023, 137, 104945. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Lin, Z.F.; Gao, X.J. Study on properties of Portland cement-sulfoaluminate cement-based grouting materials modified by in-situ polymerization of calcium acrylate. Constr. Build. Mater. 2023, 409, 175–185. [Google Scholar] [CrossRef]

- Wang, Z.M.; Cai, Y.Y.; Zhang, L. Study on properties and mechanism of interpenetrating network structure cementitious composites. Concrete 2021, 11, 70–74. [Google Scholar]

- Liu, Q.; Liu, W.; Li, Z.; Guo, S.; Sun, G. Ultra-lightweight cement composites with excellent flexural strength, thermal insulation and water resistance achieved by establishing interpenetrating network. Constr. Build. Mater. 2020, 250, 118923. [Google Scholar] [CrossRef]

- He, R.; Zheng, X.X.; Wang, Y. Research status of properties and modification technology of sulphoaluminate cement. Appl. Chem. Ind. 2022, 51, 1495–1501. [Google Scholar]

- Niu, M.; Li, G.; Wang, Y. Comparative study of immobilization and mechanical properties of sulfoaluminate cement and ordinary Portland cement with different heavy metals. Constr. Build. Mater. 2018, 19, 333–343. [Google Scholar] [CrossRef]

- Liu, Z.X.; Wang, L.B. Experimental Design and Data Processing; Chemical Industry Press: Beijing, China, 2020; pp. 66–79. [Google Scholar]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Standards Press: Beijing, China, 2021; pp. 12–13.

| Level | Considerations | ||

|---|---|---|---|

| Monomer A | Initiator B | Crosslinker C | |

| 1 | 1% | 0.80% | 0.50% |

| 2 | 3% | 1.60% | 1% |

| 3 | 5% | 2.40% | 1.50% |

| 4 | 7% | 3.20% | 2% |

| 5 | 9% | 4.00% | 2.50% |

| Test No. | A | B | C | Amount of Test Material | Flexural Strength (MPa) | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water (g) | Cement (g) | Monomer (g) | Initiators (g) | Crosslinkers (g) | ||||||

| 1 | 1 | 1 | 1 | 630 | 1400 | 14 | 0.112 | 0.07 | 3.96 | 34.71 |

| 2 | 1 | 2 | 3 | 630 | 1400 | 14 | 0.224 | 0.21 | 3.54 | 35.23 |

| 3 | 1 | 3 | 5 | 630 | 1400 | 14 | 0.336 | 0.35 | 4.68 | 36.91 |

| 4 | 1 | 4 | 2 | 630 | 1400 | 14 | 0.448 | 0.14 | 4.61 | 36.87 |

| 5 | 1 | 5 | 4 | 630 | 1400 | 14 | 0.56 | 0.28 | 4.22 | 32.03 |

| 6 | 2 | 1 | 5 | 630 | 1400 | 42 | 0.336 | 1.05 | 4.74 | 36.53 |

| 7 | 2 | 2 | 2 | 630 | 1400 | 42 | 0.672 | 0.42 | 3.63 | 33.58 |

| 8 | 2 | 3 | 4 | 630 | 1400 | 42 | 1.008 | 0.84 | 5.34 | 36.03 |

| 9 | 2 | 4 | 1 | 630 | 1400 | 42 | 1.344 | 0.21 | 4.24 | 36.88 |

| 10 | 2 | 5 | 3 | 630 | 1400 | 42 | 1.68 | 0.63 | 3.67 | 30.83 |

| 11 | 3 | 1 | 4 | 630 | 1400 | 70 | 0.56 | 1.4 | 4.26 | 34.15 |

| 12 | 3 | 2 | 1 | 630 | 1400 | 70 | 1.12 | 0.35 | 4.49 | 34.71 |

| 13 | 3 | 3 | 3 | 630 | 1400 | 70 | 1.68 | 1.05 | 4.13 | 34.19 |

| 14 | 3 | 4 | 5 | 630 | 1400 | 70 | 2.24 | 1.75 | 5.40 | 38.05 |

| 15 | 3 | 5 | 2 | 630 | 1400 | 70 | 2.8 | 0.7 | 4.18 | 33.60 |

| 16 | 4 | 1 | 3 | 630 | 1400 | 98 | 0.784 | 1.47 | 5.18 | 34.42 |

| 17 | 4 | 2 | 5 | 630 | 1400 | 98 | 1.568 | 2.45 | 4.70 | 33.04 |

| 18 | 4 | 3 | 2 | 630 | 1400 | 98 | 2.352 | 0.98 | 4.94 | 34.29 |

| 19 | 4 | 4 | 4 | 630 | 1400 | 98 | 3.136 | 1.96 | 5.77 | 32.88 |

| 20 | 4 | 5 | 1 | 630 | 1400 | 98 | 3.92 | 0.49 | 4.87 | 32.74 |

| 21 | 5 | 1 | 2 | 630 | 1400 | 126 | 1.008 | 1.26 | 3.92 | 29.75 |

| 22 | 5 | 2 | 4 | 630 | 1400 | 126 | 2.016 | 2.52 | 5.80 | 27.70 |

| 23 | 5 | 3 | 1 | 630 | 1400 | 126 | 3.024 | 0.63 | 7.88 | 32.08 |

| 24 | 5 | 4 | 3 | 630 | 1400 | 126 | 4.032 | 1.89 | 8.59 | 30.31 |

| 25 | 5 | 5 | 5 | 630 | 1400 | 126 | 5.04 | 3.15 | 9.86 | 31.19 |

| Index | Monomer A | Initiators B | Crosslinkers C | |

|---|---|---|---|---|

| Flexural strength | k1 | 4.2 | 4.33 | 4.89 |

| k2 | 4.07 | 4.23 | 4.45 | |

| k3 | 4.54 | 4.93 | 5 | |

| k4 | 4.95 | 5.6 | 4.4 | |

| k5 | 6.85 | 5.51 | 5.88 | |

| R | 2.78 | 1.37 | 1.48 | |

| Compressive strength | k1 | 35.15 | 33.91 | 34.22 |

| k2 | 34.77 | 32.85 | 33.62 | |

| k3 | 34.94 | 34.7 | 33 | |

| k4 | 33.47 | 35 | 32.56 | |

| k5 | 30.21 | 32.08 | 35.14 | |

| R | 4.94 | 2.92 | 2.58 | |

| Index | Source of Variation | Deviation Squared and SS | Degree of Freedom (Df) | Mean Square Deviation (MS) | F | Significance | F0.05 | F0.01 |

|---|---|---|---|---|---|---|---|---|

| Compressive strength | Monomer A | 31.11 | 4 | 7.78 | 7.12 | Extremely significant | 3.26 | 5.41 |

| Initiator B | 7.28 | 4 | 1.82 | 1.67 | Not significant | |||

| Crosslinking agent C | 6.58 | 4 | 1.65 | 1.51 | Not significant | |||

| Error e | 13.12 | 12 | 1.09 | |||||

| Flexural strength | Monomer A | 85.20 | 4 | 21.30 | 14.92 | Extremely significant | 3.26 | 5.41 |

| Initiator B | 30.40 | 4 | 7.60 | 5.32 | Significant | |||

| Crosslinking agent C | 20.80 | 4 | 5.20 | 3.64 | Not significant | |||

| Error e | 17.13 | 12 | 1.43 |

| Test No. | A | B | C | Overall Scoring |

|---|---|---|---|---|

| k1 | 0.41 | 0.37 | 0.44 | 0.41 |

| k2 | 0.40 | 0.32 | 0.34 | |

| k3 | 0.43 | 0.49 | 0.37 | |

| k4 | 0.40 | 0.53 | 0.36 | |

| k5 | 0.41 | 0.36 | 0.54 | |

| Range R | 0.02 | 0.21 | 0.20 | - |

| Optimal Combination | Flexural Strength | Compressive Strength |

|---|---|---|

| A1B4C5 | 4.97 | 28.68 |

| A3B4C5 | 9.55 | 36.03 |

| A5B4C5 | 5.76 | 30.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Liu, B. Preparation and Characterization of Polymer-Modified Sulphoaluminate-Cement-Based Materials. Appl. Sci. 2024, 14, 3366. https://doi.org/10.3390/app14083366

Feng X, Liu B. Preparation and Characterization of Polymer-Modified Sulphoaluminate-Cement-Based Materials. Applied Sciences. 2024; 14(8):3366. https://doi.org/10.3390/app14083366

Chicago/Turabian StyleFeng, Xinrui, and Bei Liu. 2024. "Preparation and Characterization of Polymer-Modified Sulphoaluminate-Cement-Based Materials" Applied Sciences 14, no. 8: 3366. https://doi.org/10.3390/app14083366

APA StyleFeng, X., & Liu, B. (2024). Preparation and Characterization of Polymer-Modified Sulphoaluminate-Cement-Based Materials. Applied Sciences, 14(8), 3366. https://doi.org/10.3390/app14083366