An Innovative Polypropylene/Waste Cork Composite Material for Spirit and Wine Stopper Caps

Abstract

1. Introduction

2. Materials and Methods

2.1. Equipment and Materials

2.2. Methodology

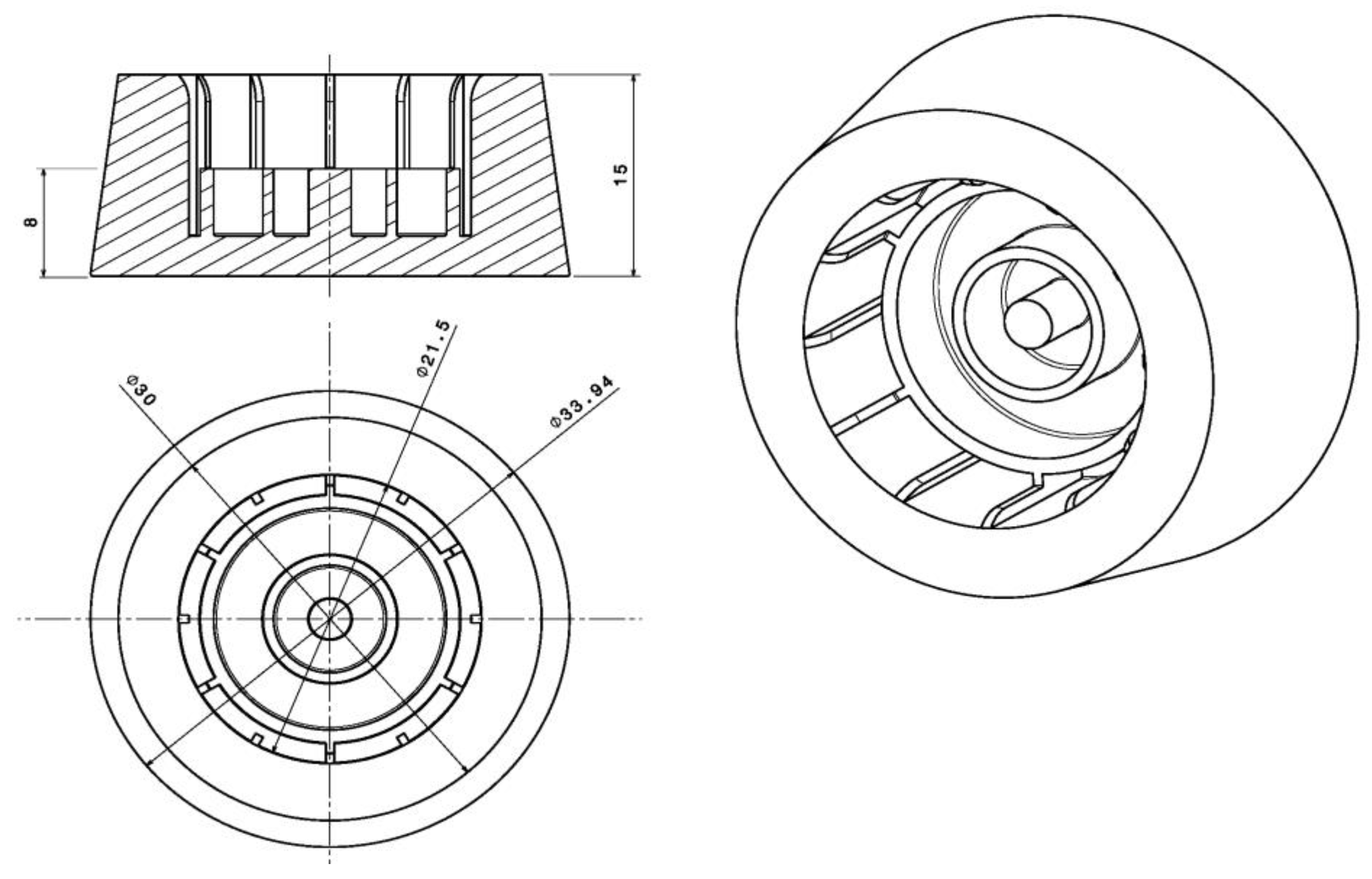

2.2.1. CAG Manufacturing Process

2.2.2. Description of Materials and Test Methods

- A.

- Structural and chemical characterization

- B.

- Mechanical properties

- C.

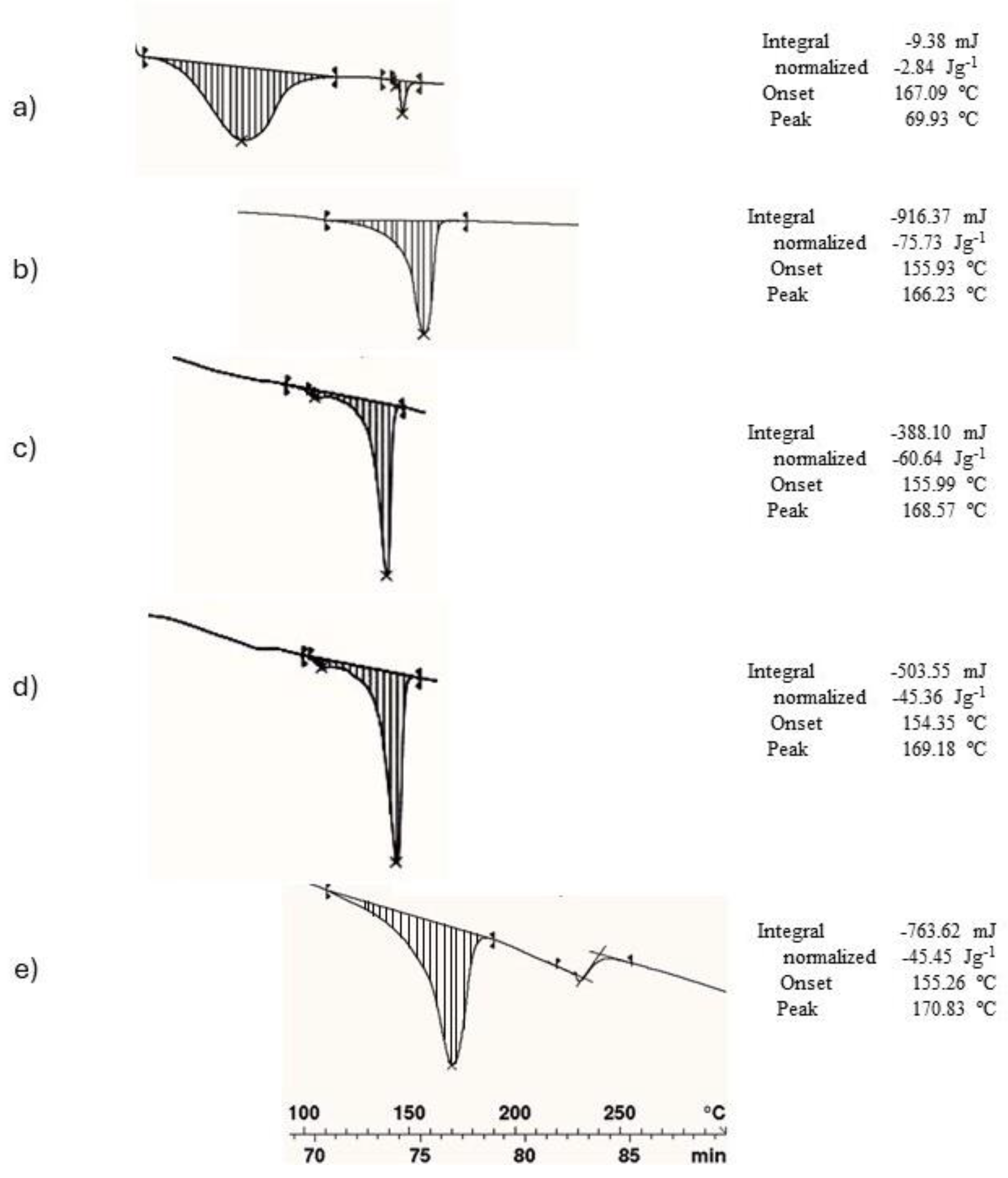

- Thermal and rheological properties

- Phase 1: (−37)–100 °C (10 °C/min);

- Phase 2: 100 °C (20 °C/min);

- Phase 3: 100–(−37) °C (10 °C/min);

- Phase 4: (−37) °C (20 °C/min);

- Phase 5: (−37)–200 °C (10 °C/min).

- HcPP is the enthalpy of crystallinity of the pure polymer at 100% crystallinity [31];

- HcAgro is the enthalpy of crystallinity of the CAG;

- wPP is the percentage of mass polymer in the CAG (1, 0.8, 0.7 and 0.65).

- D.

- Injection molded plastic

- E.

- Adhesion cap–cork test

3. Results and Discussion

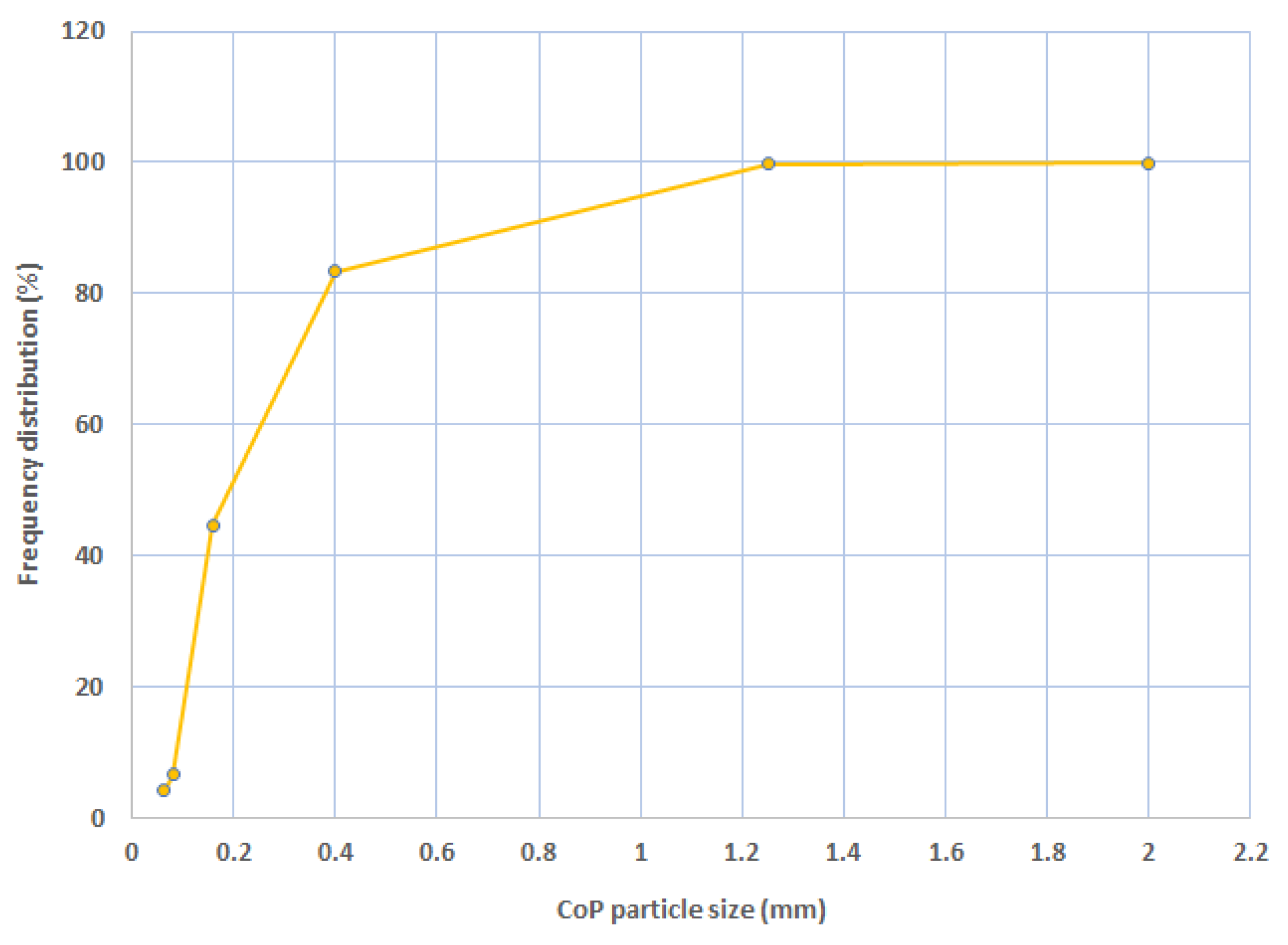

3.1. FTIR-ATR and Granulometry Analyses

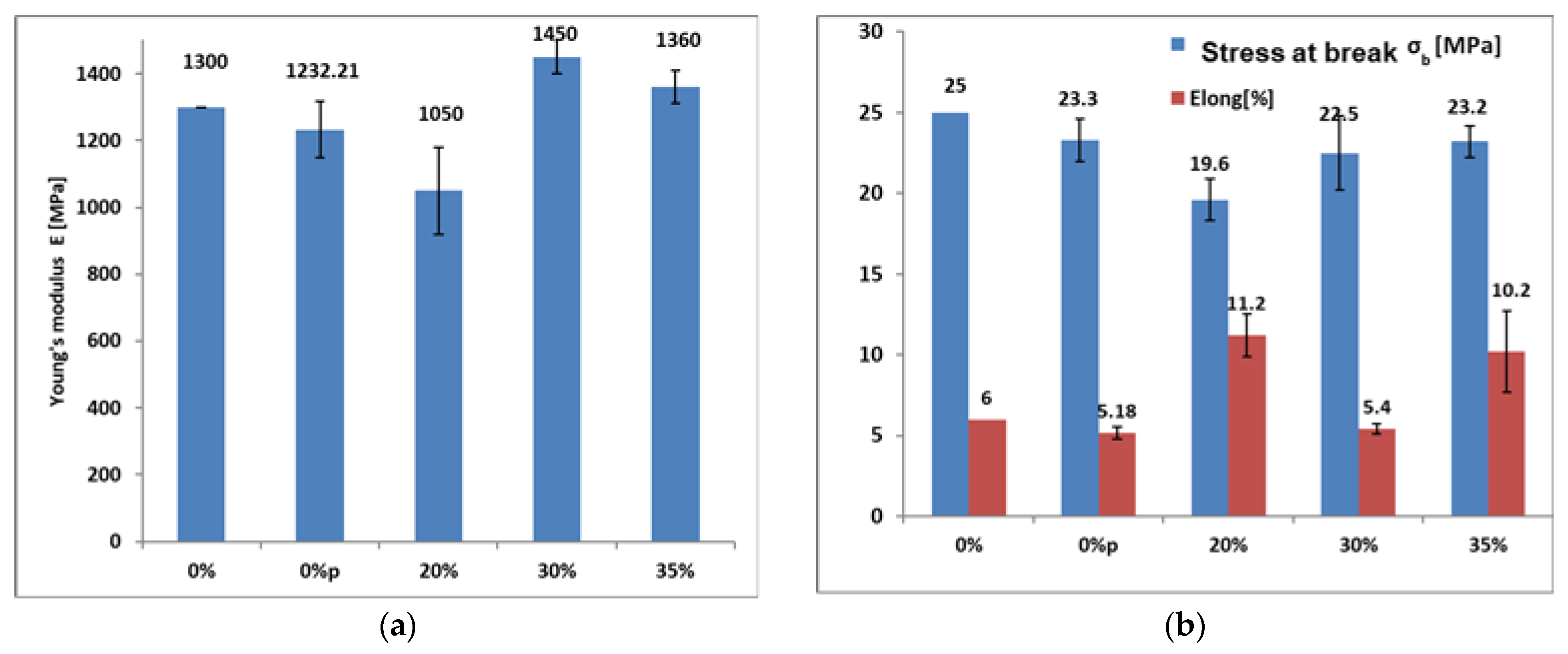

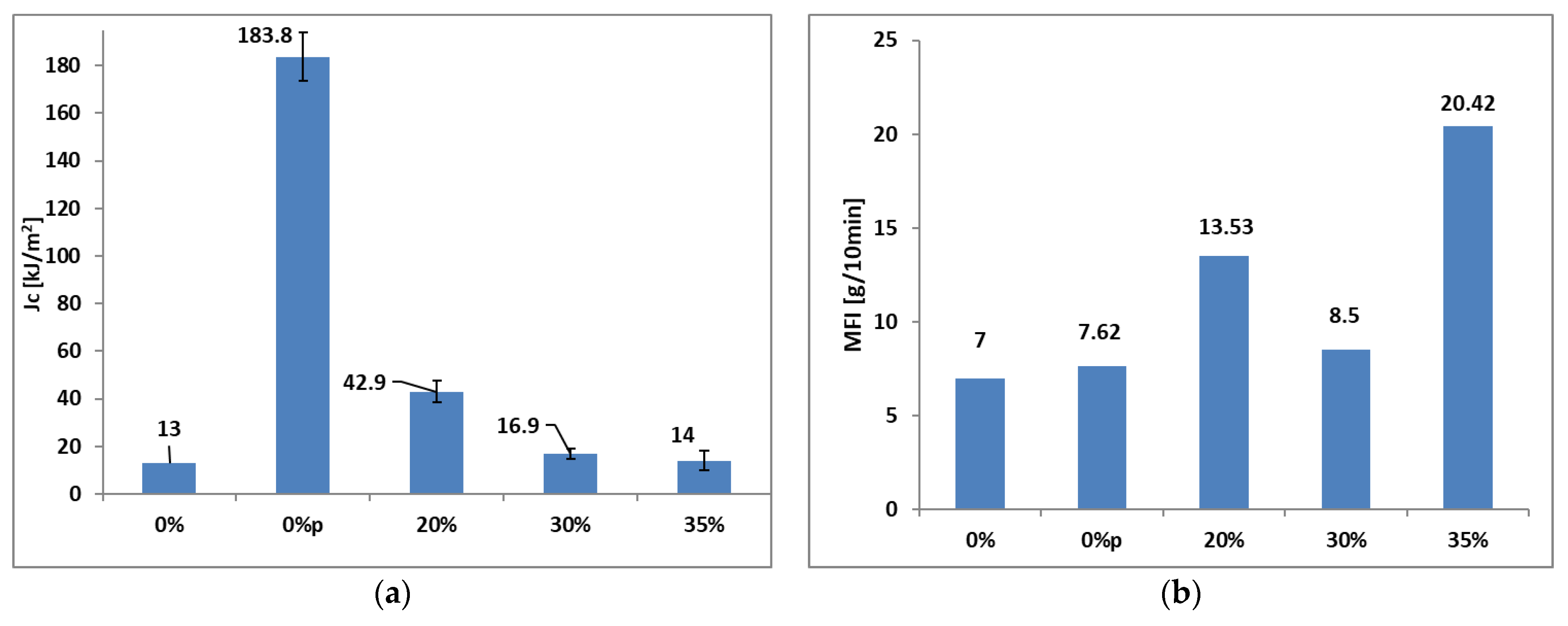

3.2. Thermomechanical Property Tests

3.3. Injection and Adhesion Cork Process

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Bycow | By-products/co-products/waste |

| CAG | Cork agrocomposite |

| CoP | Cork powder |

| CoPXPPY | Agrocomposite, X% cork powder weight in grams and Y% PP weight in grams |

| DSC | Differential Scanning Calorimetry |

| Et | Young’s modulus, MPa |

| EMI | Electromagnetic interference |

| Hc | Enthalpy of crystallinity, J/g |

| HDPE | High-density polyethylene |

| Jc | Fracture energy per unit area, kJ/m2 |

| MFI | Melt flow indicator, g/10 min |

| PE | Polyethylene |

| PET | Polyethylene terephthalate |

| PMCs | Polymer–matrix composites |

| PP | Polypropylene |

| SEM | Scanning electron microscopy |

| t | Time, min |

| T | Temperature, °C |

| Tm | Polymer melt temperature |

| V | Rotation speed, rpm |

| WPP | PP weight in grams |

| ΔH | Enthalpy rate, J/g |

| ε | Stress, % |

| εb | Stress at break, % |

| σb | Strain at break, % |

| χc | Degree of crystallinity, % |

References

- Gil, L. Cork composites: A review. Materials 2009, 2, 776–789. [Google Scholar] [CrossRef]

- Oliveira, F.R.; Silva, E.A.A.; do Carmo, S.N.; Steffens, F.; Souto, A.P.G.D.V. Functionalization of natural cork composite with microcapsules after plasma treatment. Adv. Mater. Sci. Eng. 2014, 2014, 685829. [Google Scholar] [CrossRef]

- Kunst, S.R.; Bianchin, A.C.V.; Mueller, L.T.; Santana, J.A.; Volkmer, T.M.; Morisso, F.D.P.; Carone, C.L.P.; Ferreira, J.Z.; Mueller, I.L.; Oliveira, C.T. Model of anodized layers formation in Zn-Al (Zamak) aiming to corrosion resistance. J. Mater. Res. Technol. 2021, 12, 831–847. [Google Scholar] [CrossRef]

- Wu, Z.; Sandlöbes, S.; Wu, L.; Hu, W.; Gottstein, G.; Korte-Kerzel, S. Mechanical behaviour of Zn–Al–Cu–Mg alloys: Deformation mechanisms of as-cast microstructures. Mater. Sci. Eng. A 2016, 651, 675–687. [Google Scholar] [CrossRef]

- Ubeda, C.; Peña-Neira, Á.; Gil i Cortiella, M. Combined effects of the vessel type and bottle closure during Chilean Sauvignon Blanc wine storage over its volatile profile. Food Res. Int. 2022, 156, 111178. [Google Scholar] [CrossRef]

- Viguera, M.; Prieto, C.; Casas, J.; Casas, E.; Cabañas, A.; Calvo, L. The parameters that affect the supercritical extraction OF 2,4,6-trichloroanisol from cork. J. Supercrit. Fluids 2018, 141, 137–142. [Google Scholar] [CrossRef]

- Novais, R.M.; Senff, L.; Carvalheiras, J.; Seabra, M.P.; Pullar, R.C.; Labrincha, J.A. Sustainable and efficient cork—Inorganic polymer composites: An innovative and eco-friendly approach to produce ultra-lightweight and low thermal conductivity materials. Cem. Concr. Compos. 2019, 97, 107–117. [Google Scholar] [CrossRef]

- Kazemi Najafi, S. Use of recycled plastics in wood plastic composites–A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Chagas, J.A.M.; Mano, J.F.; Reis, R.L. Cork based composites using polyolefin’s as matrix: Morphology and mechanical performance. Compos. Sci. Technol. 2010, 70, 2310–2318. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Mano, J.F.; Reis, R.L. Cork-polymer biocomposites: Mechanical, structural and thermal properties. Mater. Des. 2014, 82, 282–289. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.F.; Franco, M.C.; Biscaia, S.; Mateus, A. The Use of Polypropylene and High-Density Polyethylene on Cork Plastic Composites for Large Scale 3D Printing. Appl. Mech. Mater. 2019, 890, 205–225. [Google Scholar] [CrossRef]

- Caban, R. FTIR-ATR spectroscopic, thermal and microstructural studies on polypropylene-glass fiber composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Suffo, M.; Sales, D.L.; Cortés-Triviño, E.; de la Mata, M.; Jiménez, E. Characterization and production of agglomerated cork stoppers for spirits based on a factor analysis method. Food Packag. Shelf Life 2022, 31, 100815. [Google Scholar] [CrossRef]

- Gil, L. Cork powder waste: An overview. Biomass Bioenergy 1997, 13, 59–61. [Google Scholar] [CrossRef]

- Vilela, C.; Sousa, A.F.; Freire, C.S.R.; Silvestre, A.J.D.; Pascoal Neto, C. Novel sustainable composites prepared from cork residues and biopolymers. Biomass Bioenergy 2013, 55, 148–155. [Google Scholar] [CrossRef]

- Magalhães da Silva, S.P.; Oliveira, J.M. Cork powders wettability by the Washburn capillary rise method. Powder Technol. 2021, 387, 16–21. [Google Scholar] [CrossRef]

- Pintor, A.M.A.; Ferreira, C.I.A.; Pereira, J.C.; Correia, P.; Silva, S.P.; Vilar, V.J.P.; Botelho, C.M.S.; Boaventura, R.A.R. Use of cork powder and granules for the adsorption of pollutants: A review. Water Res. 2012, 46, 3152–3166. [Google Scholar] [CrossRef] [PubMed]

- Tumwesigye, K.S.; Oliveira, J.C.; Sousa-Gallagher, M.J. New sustainable approach to reduce cassava borne environmental waste and develop biodegradable materials for food packaging applications. Food Packag. Shelf Life 2016, 7, 8–19. [Google Scholar] [CrossRef]

- Suffo, M.; de la Mata, M.; Molina, S.I. A sugar-beet waste based thermoplastic agro-composite as substitute for raw materials. J. Clean. Prod. 2020, 257, 120382. [Google Scholar] [CrossRef]

- Ghosh, A. Performance modifying techniques for recycled thermoplastics. Resour. Conserv. Recycl. 2021, 175, 105887. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ada, E.; Ozbiltekin-Pala, M.; Aşkın Uzel, R. In the nexus of sustainability, circular economy and food industry: Circular food package design. J. Clean. Prod. 2023, 415, 137778. [Google Scholar] [CrossRef]

- McNally, T.; McShane, P.; Nally, G.M.; Murphy, W.R.; Cook, M.; Miller, A. Rheology, phase morphology, mechanical, impact and thermal properties of polypropylene/metallocene catalysed ethylene 1-octene copolymer blends. Polymer 2002, 43, 3785–3793. [Google Scholar] [CrossRef]

- Totalenergies. Available online: https://polymers.totalenergies.com/ppc-5660 (accessed on 29 July 2023).

- Luyt, A.S.; Molefi, J.A.; Krump, H. Thermal, mechanical and electrical properties of copper powder filled low-density and linear low-density polyethylene composites. Polym. Degrad. Stab. 2006, 91, 1629–1636. [Google Scholar] [CrossRef]

- Jurado-Contreras, S.; Navas-Martos, F.J.; Rodríguez-Liébana, J.A.; la Rubia, M.D. Effect of Olive Pit Reinforcement in Polylactic Acid Biocomposites on Environmental Degradation. Materials 2023, 16, 5816. [Google Scholar] [CrossRef]

- UNE-EN ISO 527-2 UNE-EN ISO 527-2:2012 Plastics; Determination of Tensile Properties. Part 2: Test Conditions for Moulding and Extrusions Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- UNE-EN ISO179-2 UNE-EN ISO 179-2:2000 Plastics; Determination of Charpy Impact Properties. Part 2: Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2000.

- UNE-EN ISO 527-2 UNE-EN ISO 527-1:2012 Plastics; Determination of Tensile Properties. Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2012.

- UNE-EN ISO 1133-1 UNE-EN ISO 1133-1:2012; Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- Marcovich, N.E.; Villar, M.A. Thermal and mechanical characterization of linear low-density polyethylene/wood flour composites. J. Appl. Polym. Sci. 2003, 90, 2775–2784. [Google Scholar] [CrossRef]

- Spadetti, C.; da Silva Filho, E.A.; de Sena, G.L.; de Melo, C.V.P. Propriedades térmicas e mecânicas dos compósitos de Polipropileno pós-consumo reforçados com fibras de cellulose. Polimeros 2017, 27, 84–90. [Google Scholar] [CrossRef]

- Martins, I.; Hartmann, D.O.; Alves, P.C.; Martins, C.; Garcia, H.; Leclercq, C.C.; Ferreira, R.; He, J.; Renaut, J.; Becker, J.D.; et al. Elucidating how the saprophytic fungus Aspergillus nidulans uses the plant polyester suberin as carbon source. BMC Genomics 2014, 15, 613. [Google Scholar] [CrossRef] [PubMed]

- Paiva, D.; Magalhães, F.D. Dynamic mechanical analysis and creep-recovery behavior of agglomerated cork. Eur. J. Wood Wood Prod. 2018, 76, 133–141. [Google Scholar] [CrossRef]

- Greco, A.; Romano, G.; Maffezzoli, A. Selective reinforcement of LLDPE components produced by rotational molding with thermoplastic matrix pultruded profiles. Compos. Part B Eng. 2014, 56, 157–162. [Google Scholar] [CrossRef]

- Yan, W.; Lin, R.J.T.; Bhattacharyya, D. Particulate reinforced rotationally moulded polyethylene composites—Mixing methods and mechanical properties. Compos. Sci. Technol. 2006, 66, 2080–2088. [Google Scholar] [CrossRef]

- Soccalingame, L.; Perrin, D.; Bénézet, J.C.; Mani, S.; Coiffier, F.; Richaud, E.; Bergeret, A. Reprocessing of artificial UV-weathered wood flour reinforced polypropylene composites. Polym. Degrad. Stab. 2015, 120, 313–327. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, K.J.; Kim, H.; Kundu, P.P.; Kim, T.J.; Lee, Y.K.; Lee, B.H.; Choe, S. Tensile property and interfacial dewetting in the calcite filled HDPE, LDPE, and LLDPE composites. Polymer 2002, 43, 6901–6909. [Google Scholar] [CrossRef]

- Soccalingame, L.; Bourmaud, A.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. Reprocessing of wood flour reinforced polypropylene composites: Impact of particle size and coupling agent on composite and particle properties. Polym. Degrad. Stab. 2015, 113, 72–85. [Google Scholar] [CrossRef]

- Martins, M.H.; de Paoli, M.A. Polypropylene compounding with post-consumer material: II. Reprocessing. Polym. Degrad. Stab. 2002, 78, 491–495. [Google Scholar] [CrossRef]

- Luzuriaga, S.; Kovářová, J.; Fortelný, I. Degradation of pre-aged polymers exposed to simulated recycling: Properties and thermal stability. Polym. Degrad. Stab. 2006, 91, 1226–1232. [Google Scholar] [CrossRef]

- Jansson, A.; Möller, K.; Gevert, T. Degradation of post-consumer polypropylene materials exposed to simulated recycling—Mechanical properties. Polym. Degrad. Stab. 2003, 82, 37–46. [Google Scholar] [CrossRef]

- Bhagat, A.B.; Ghosh, A.K. Estimation of rheological percolation threshold and influence of fibre length on properties of polypropylene/sisal fibre composites having near critical fibre length. Polymer 2022, 258, 125304. [Google Scholar] [CrossRef]

- Fuad, M.Y.A.; Hanim, H.; Zarina, R.; Ishak, Z.A.M.; Hassan, A. Polypropylene/calcium carbonate nanocomposites—Effects of processing techniques and maleated polypropylene compatibiliser. Express Polym. Lett. 2010, 4, 611–620. [Google Scholar] [CrossRef]

- Lisperguer, J.; Bustos, X.; Saravia, Y.; Escobar, C.; Venegas, H. Efecto De Las Caracteristicas De Harina De Madera En Las Propiedades Físico-Mecánicas Y Térmicas De Polipropileno Reciclado. Maderas. Cienc. Tecnol. 2013, 15, 321–336. [Google Scholar] [CrossRef]

- Pluta, M.; Bartczak, Z.; Galeski, A. Changes in the morphology and orientation of bulk spherulitic polypropylene due to plane-strain compression. Polymer 2000, 41, 2271–2288. [Google Scholar] [CrossRef]

| Morphology | Powder |

|---|---|

| Genesis | Manufacturing process of cork stopper cap pins |

| Chemical composition | [13] |

| Humidity | 2.46% |

| Volume | 30% in incoming raw material [16,17] |

| Supplier | Melt Flow Indicator [g/10 min] | Density [kg/m3] | Stress at Yield [MPa] | Tensile Modulus [MPa] | Elongation at Yield [%] | Charpy Impact Notched at 23 °C [KJ/m2] | Vicat Softening Temperature at 10 N (VST/A) [°C] | |

|---|---|---|---|---|---|---|---|---|

| PP | TOTAL PPC 5660 | 7 * | 905 | 25 | 1300 | 6 | 13 | 145 |

| CoP [%] | PPC 5660 [%] | |

|---|---|---|

| CoP20PP80 | 20 | 80 |

| CoP30PP70 | 30 | 70 |

| CoP35PP65 | 35 | 65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suffo, M.; Pérez-Muñoz, C.; Alba, G.; Villar, M.P. An Innovative Polypropylene/Waste Cork Composite Material for Spirit and Wine Stopper Caps. Appl. Sci. 2024, 14, 3014. https://doi.org/10.3390/app14073014

Suffo M, Pérez-Muñoz C, Alba G, Villar MP. An Innovative Polypropylene/Waste Cork Composite Material for Spirit and Wine Stopper Caps. Applied Sciences. 2024; 14(7):3014. https://doi.org/10.3390/app14073014

Chicago/Turabian StyleSuffo, Miguel, Celia Pérez-Muñoz, Gonzalo Alba, and María Pilar Villar. 2024. "An Innovative Polypropylene/Waste Cork Composite Material for Spirit and Wine Stopper Caps" Applied Sciences 14, no. 7: 3014. https://doi.org/10.3390/app14073014

APA StyleSuffo, M., Pérez-Muñoz, C., Alba, G., & Villar, M. P. (2024). An Innovative Polypropylene/Waste Cork Composite Material for Spirit and Wine Stopper Caps. Applied Sciences, 14(7), 3014. https://doi.org/10.3390/app14073014