Numerical Simulation of Aerodynamic Pressure on Sound Barriers from High-Speed Trains with Different Nose Lengths

Abstract

1. Introduction

2. Numerical Simulation

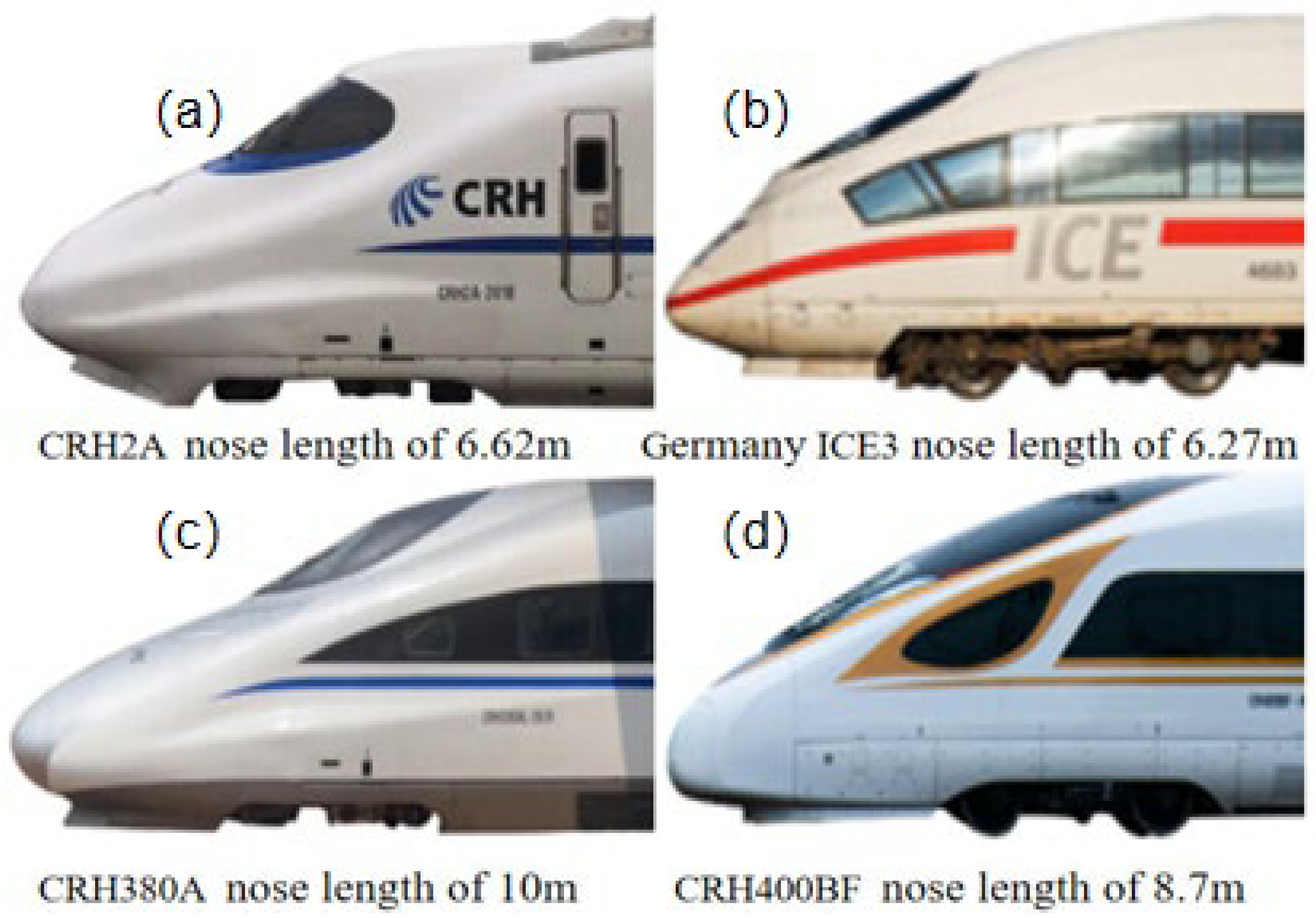

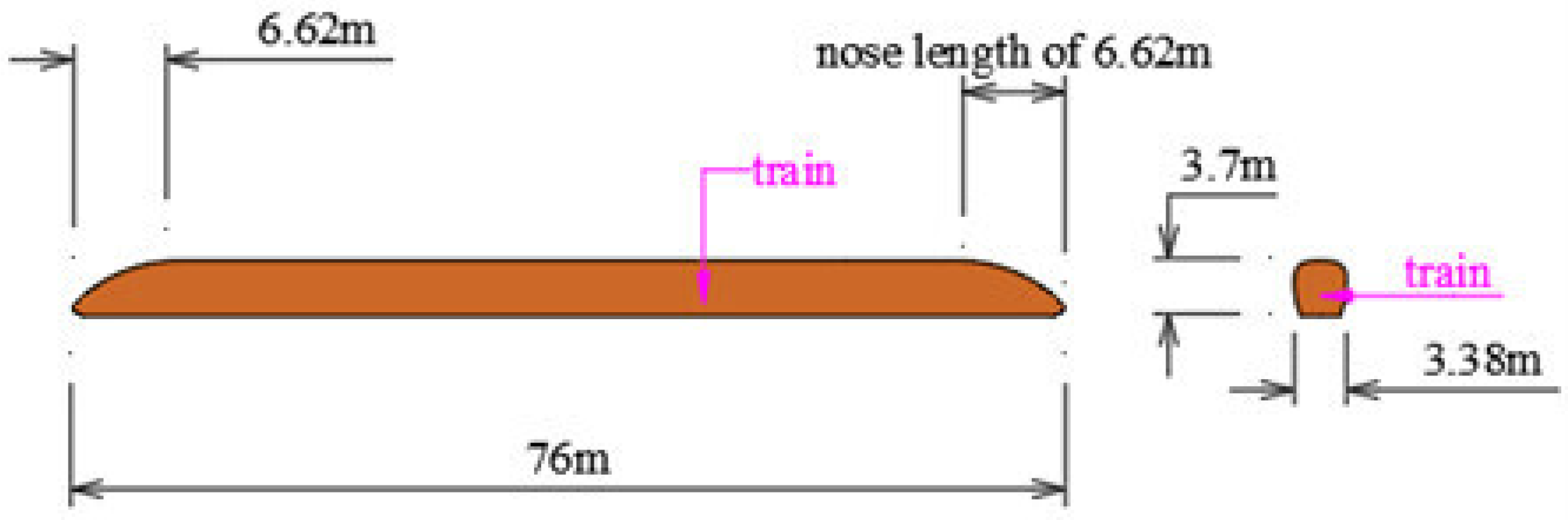

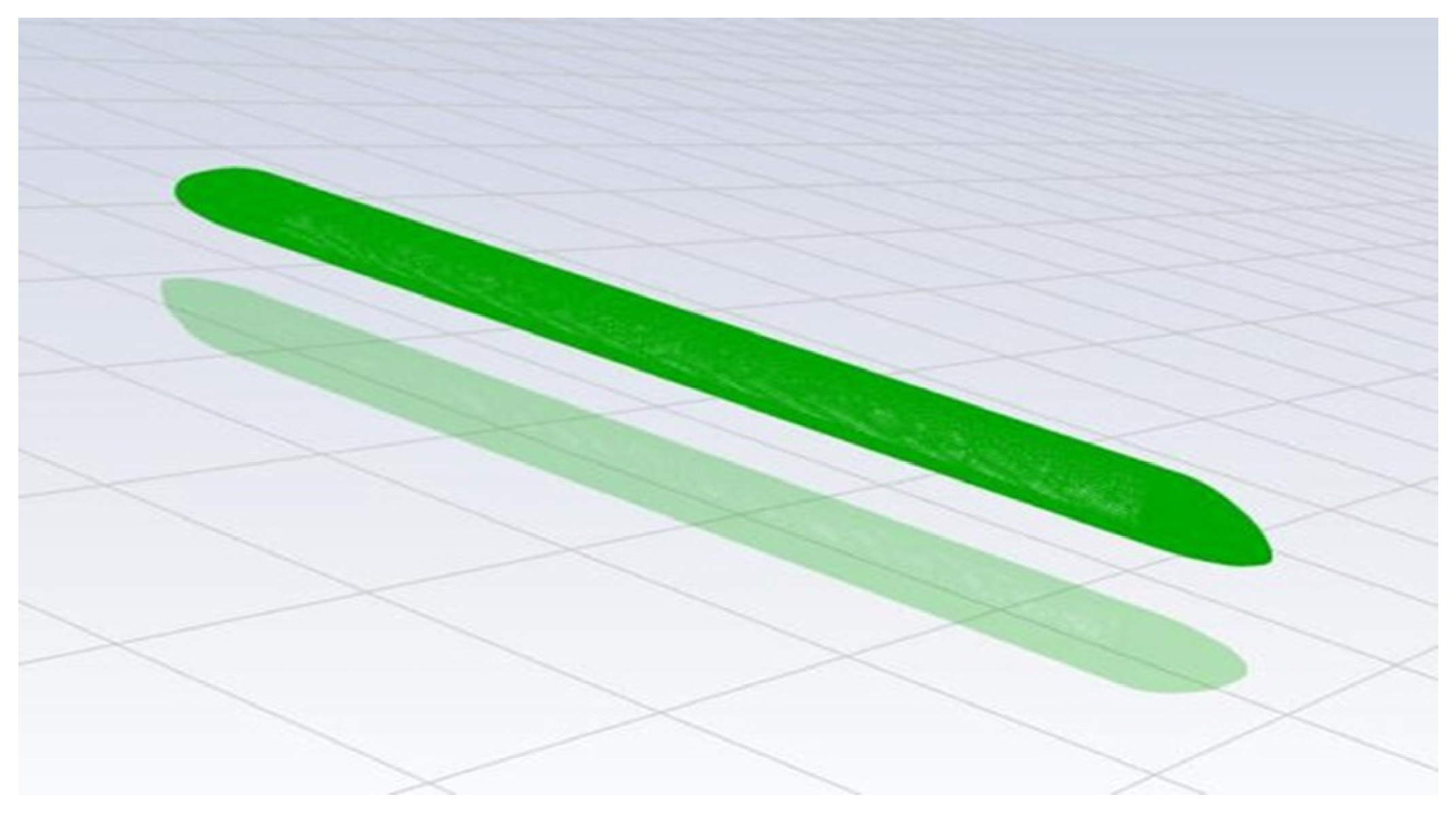

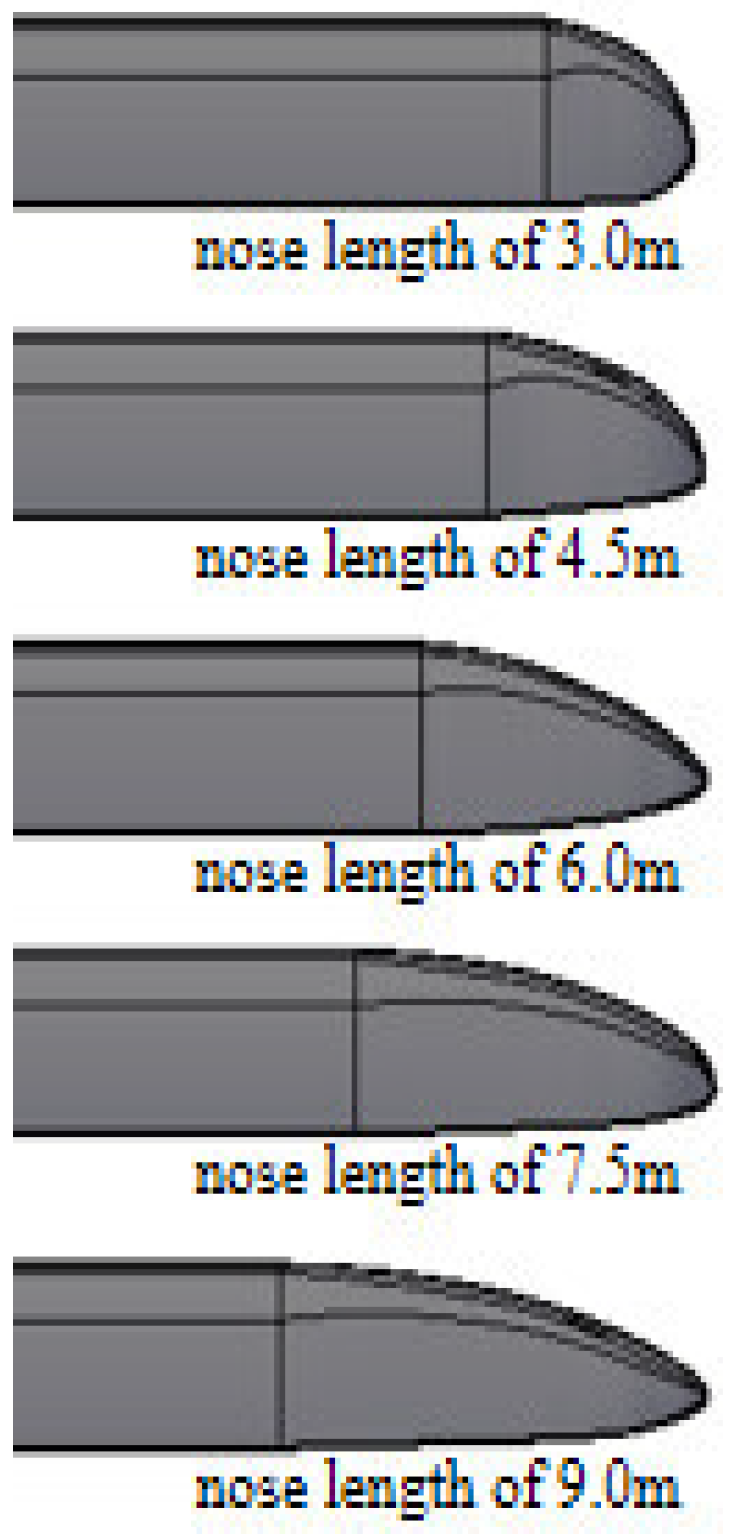

2.1. Train-Sound Barrier Modeling and Meshing

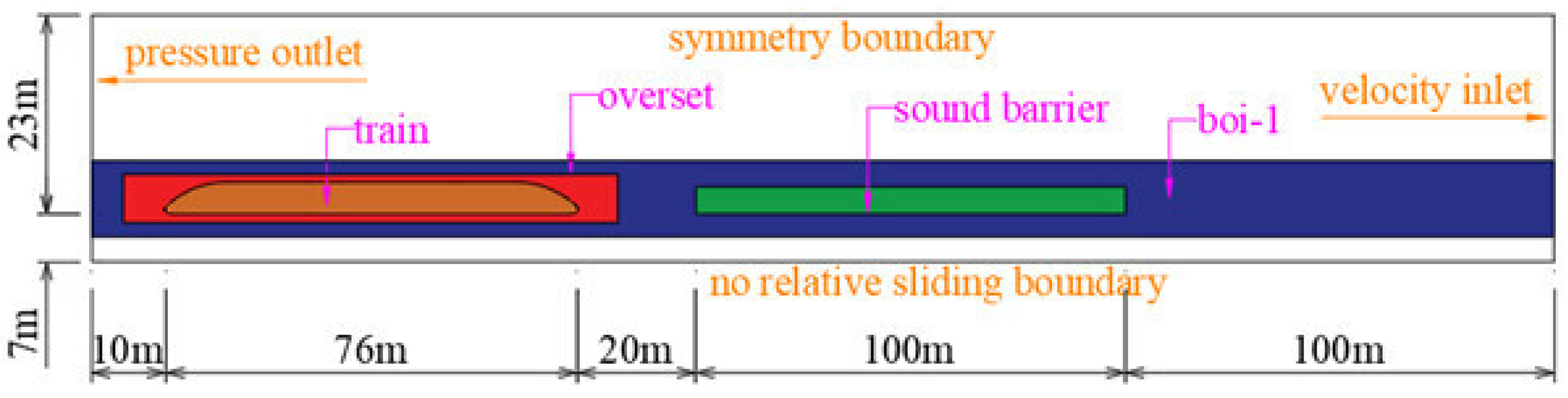

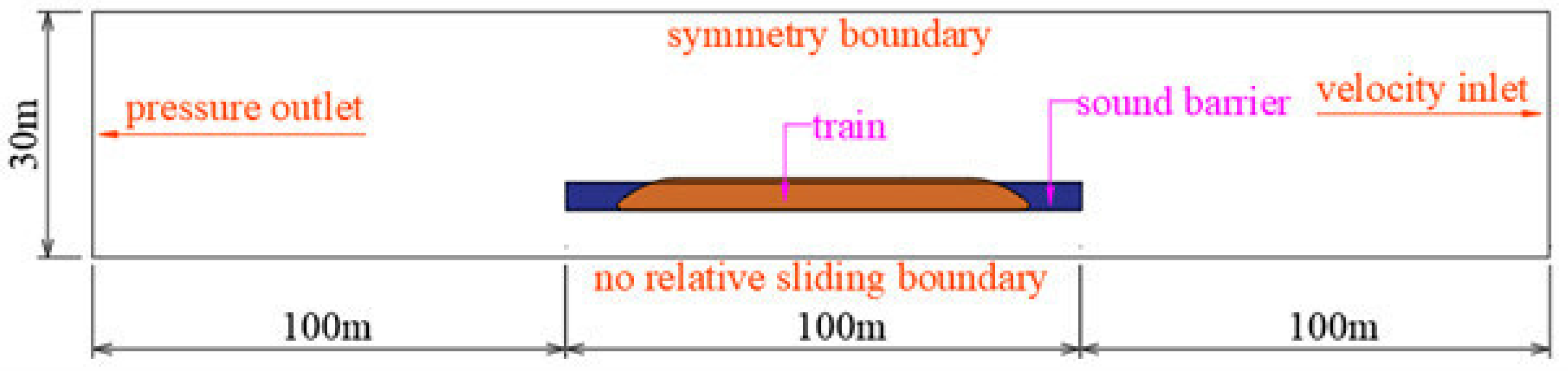

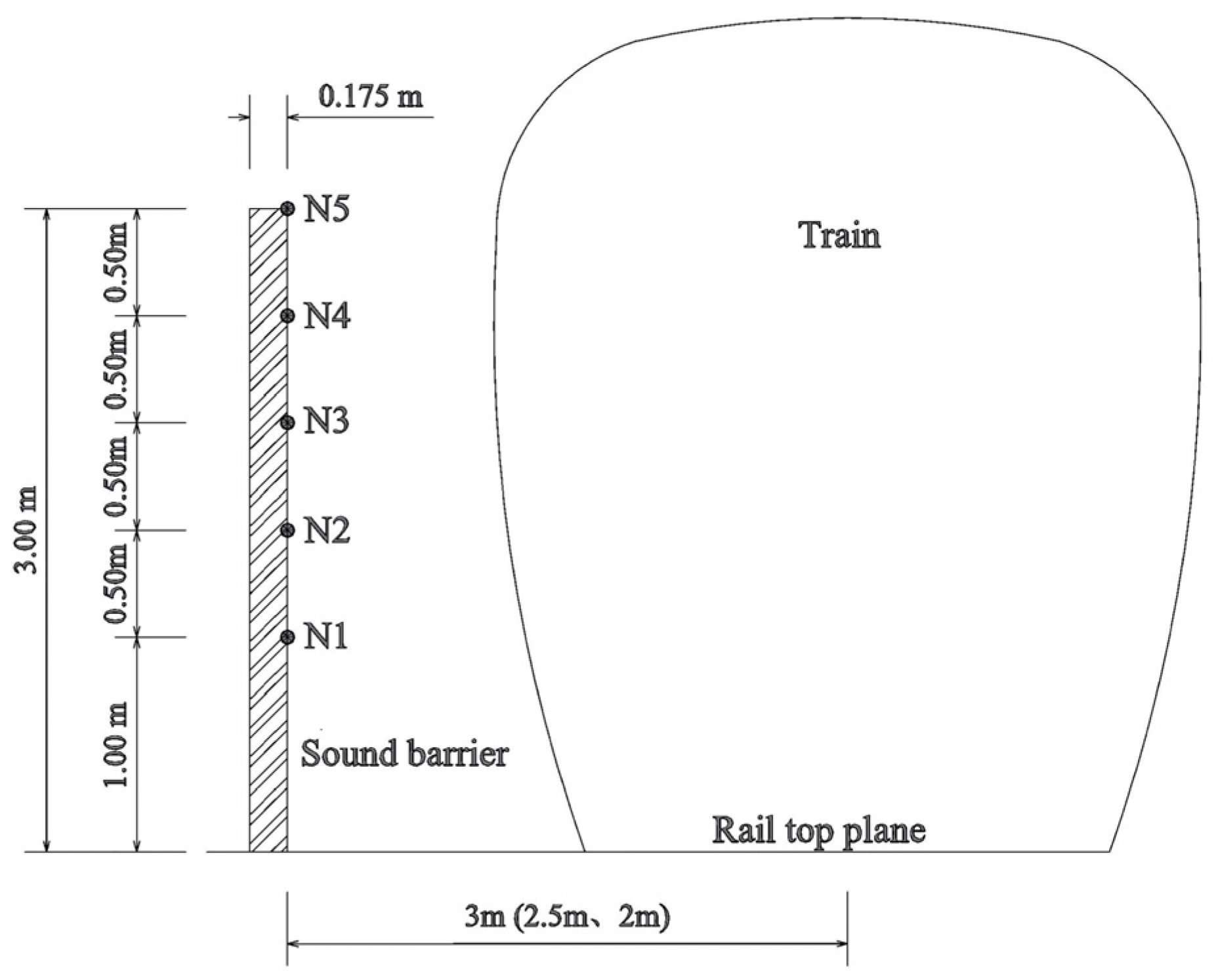

2.2. Train-Sound Barrier-Flow Field Transient Calculation Model

2.3. Train-Sound Barrier-Flow Field Steady Calculation Model

2.4. Parameter Analysis

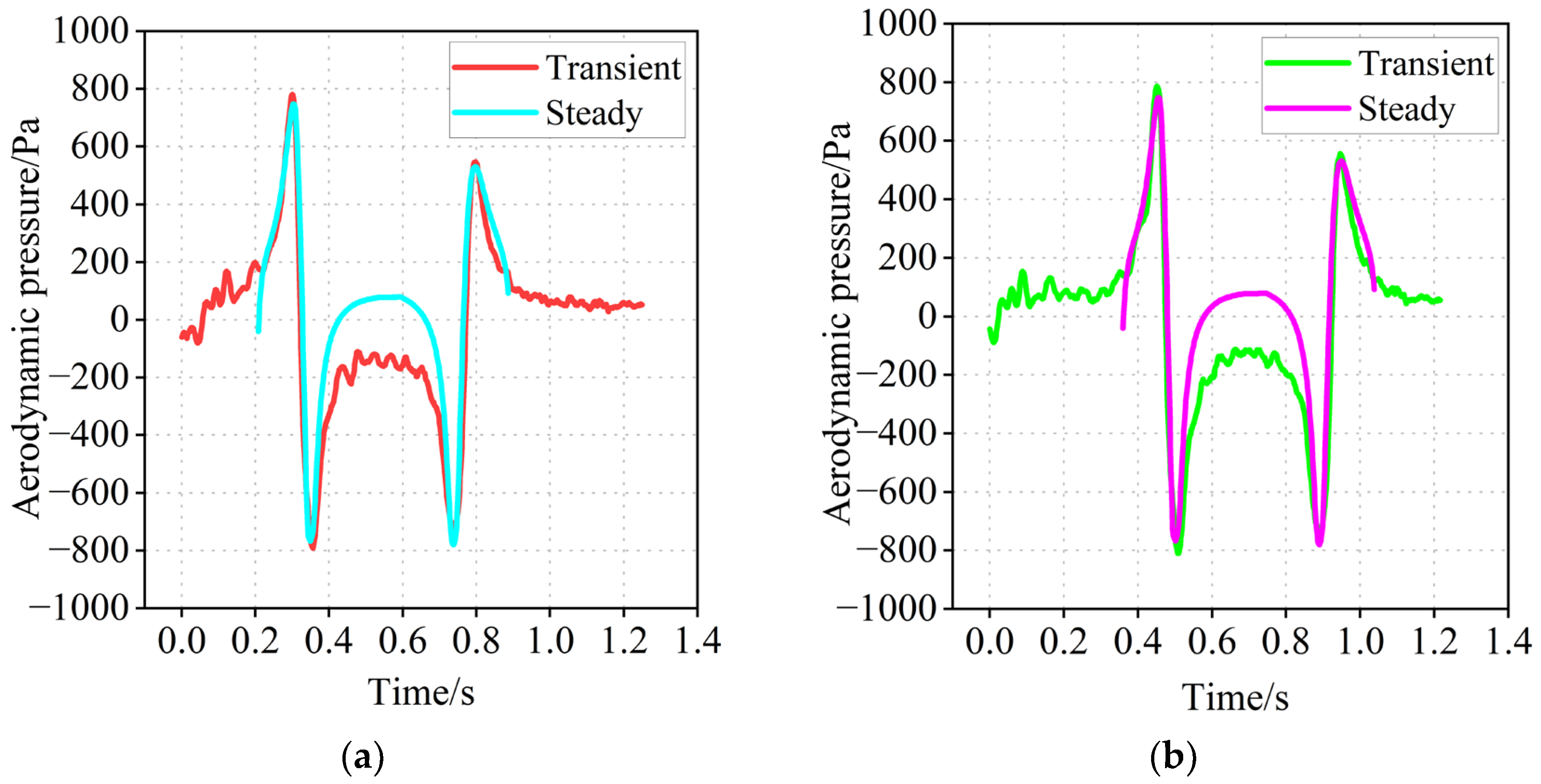

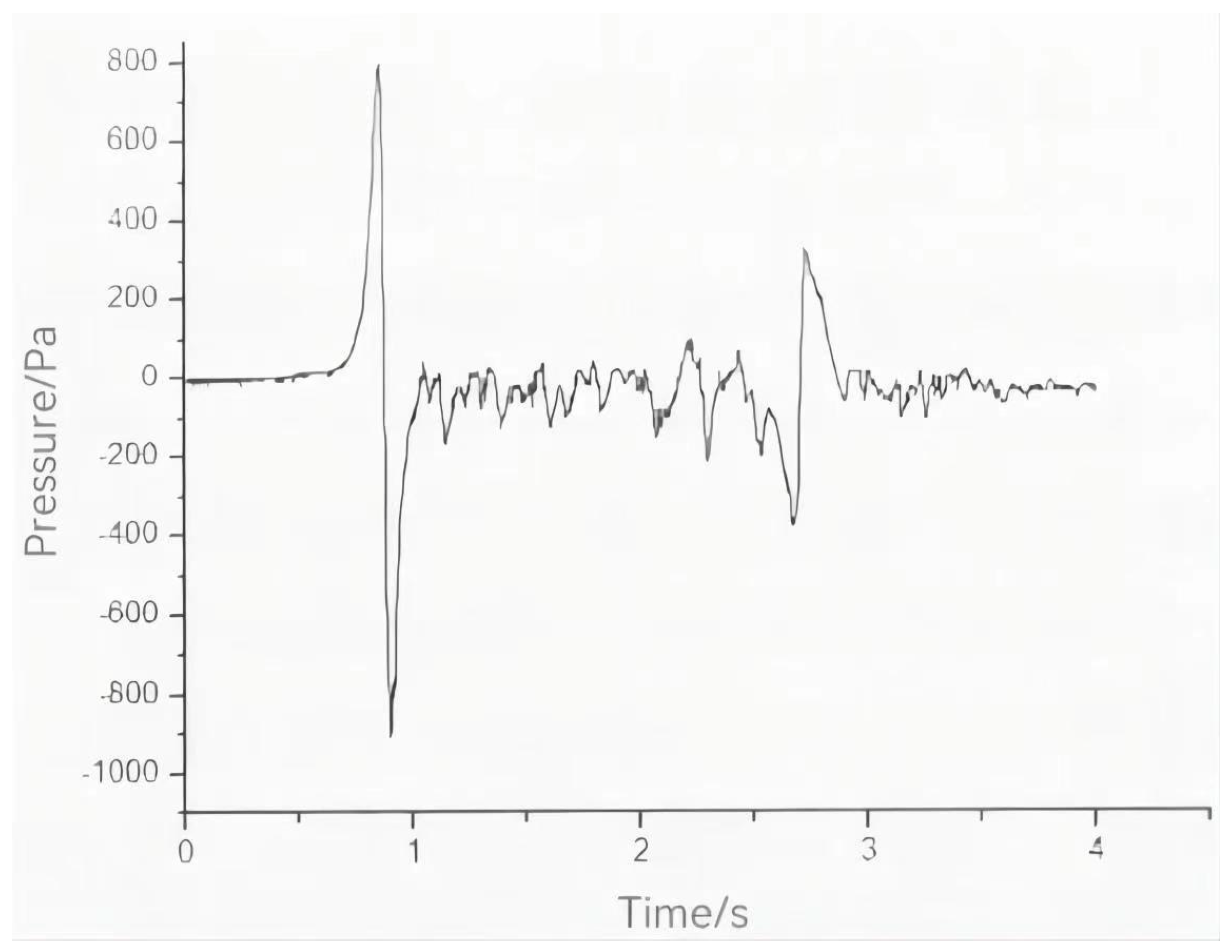

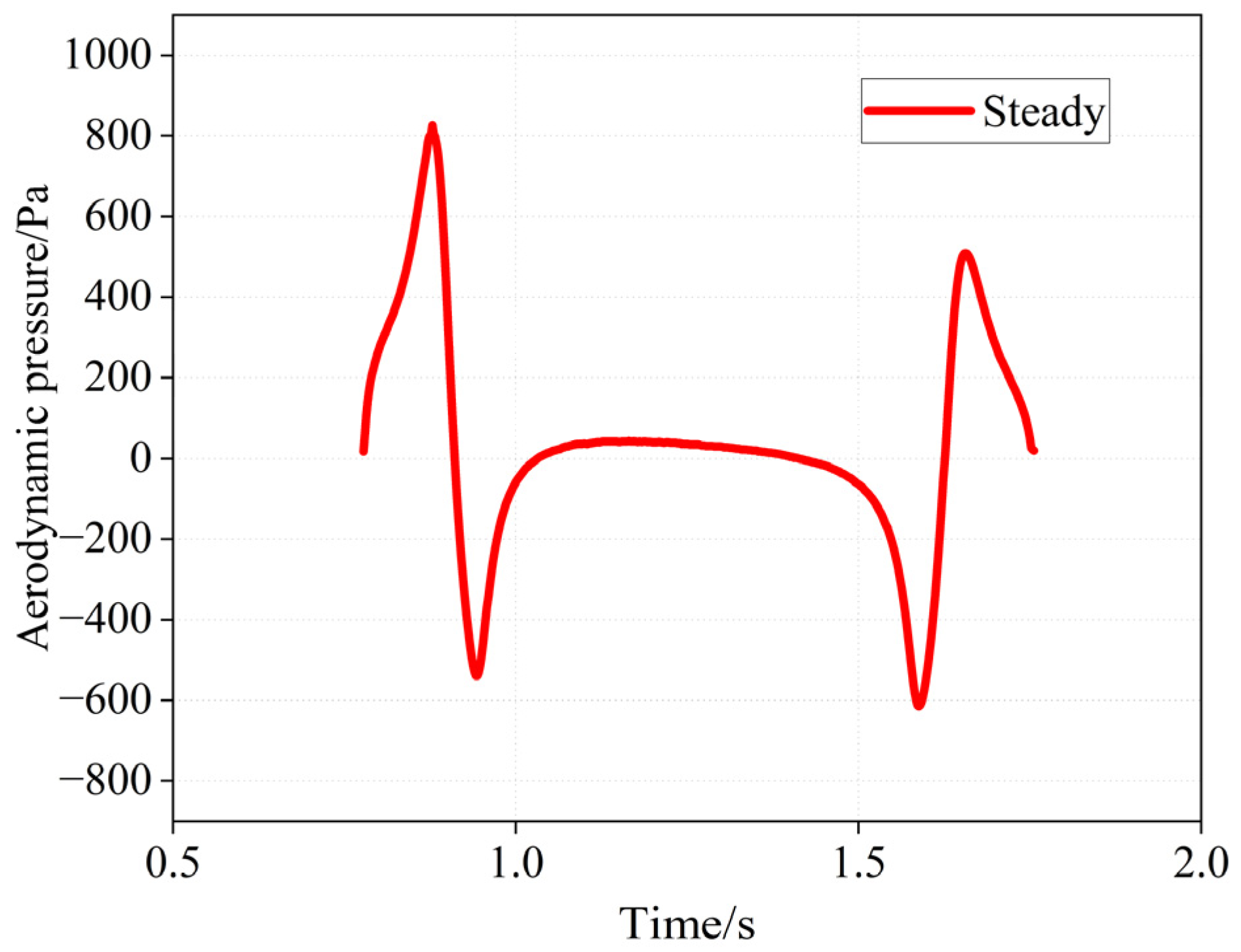

3. Model Validation

4. Results and Discussions

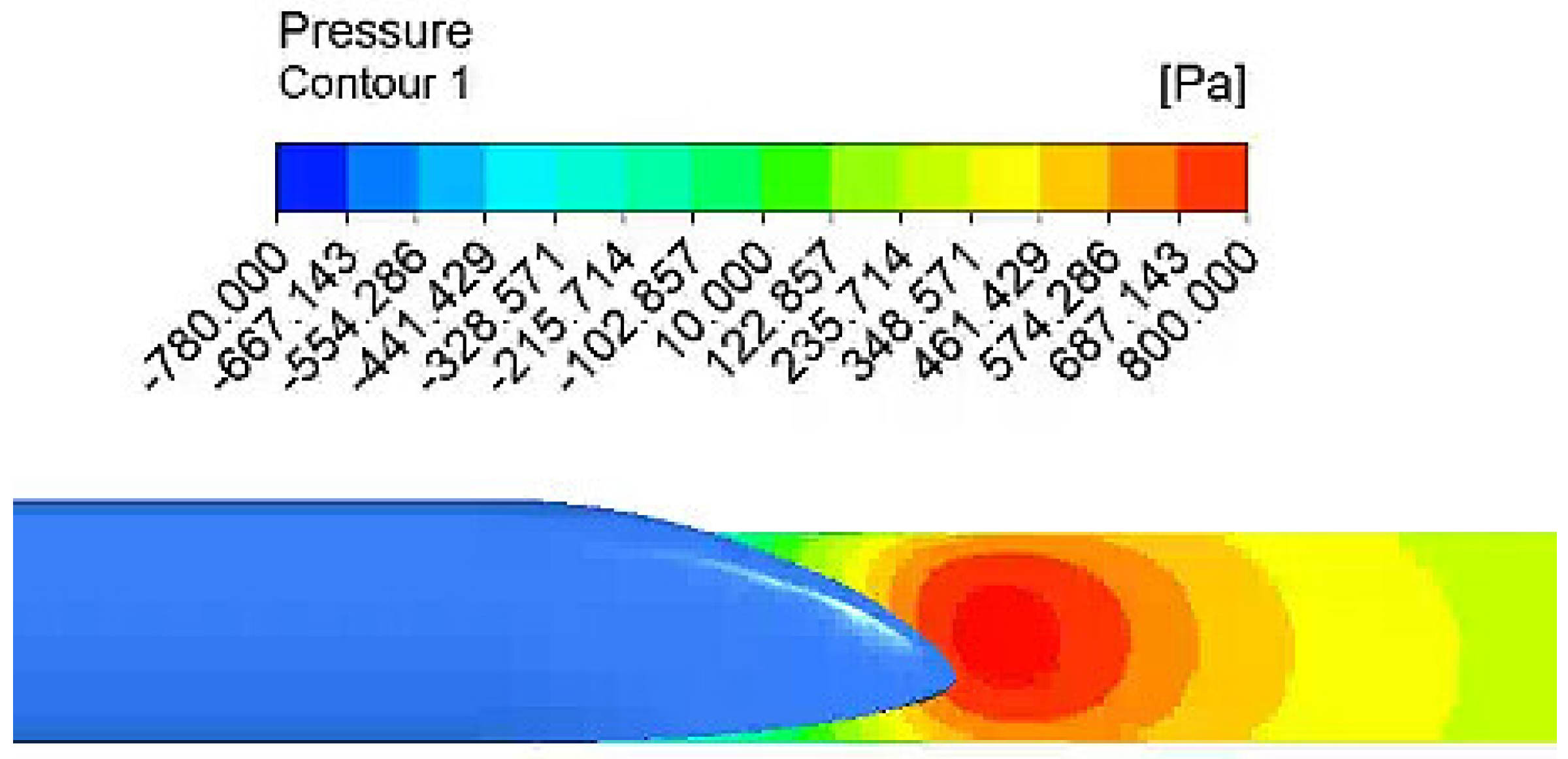

4.1. Basic Characteristics of Pressure Variation on Sound Barrier

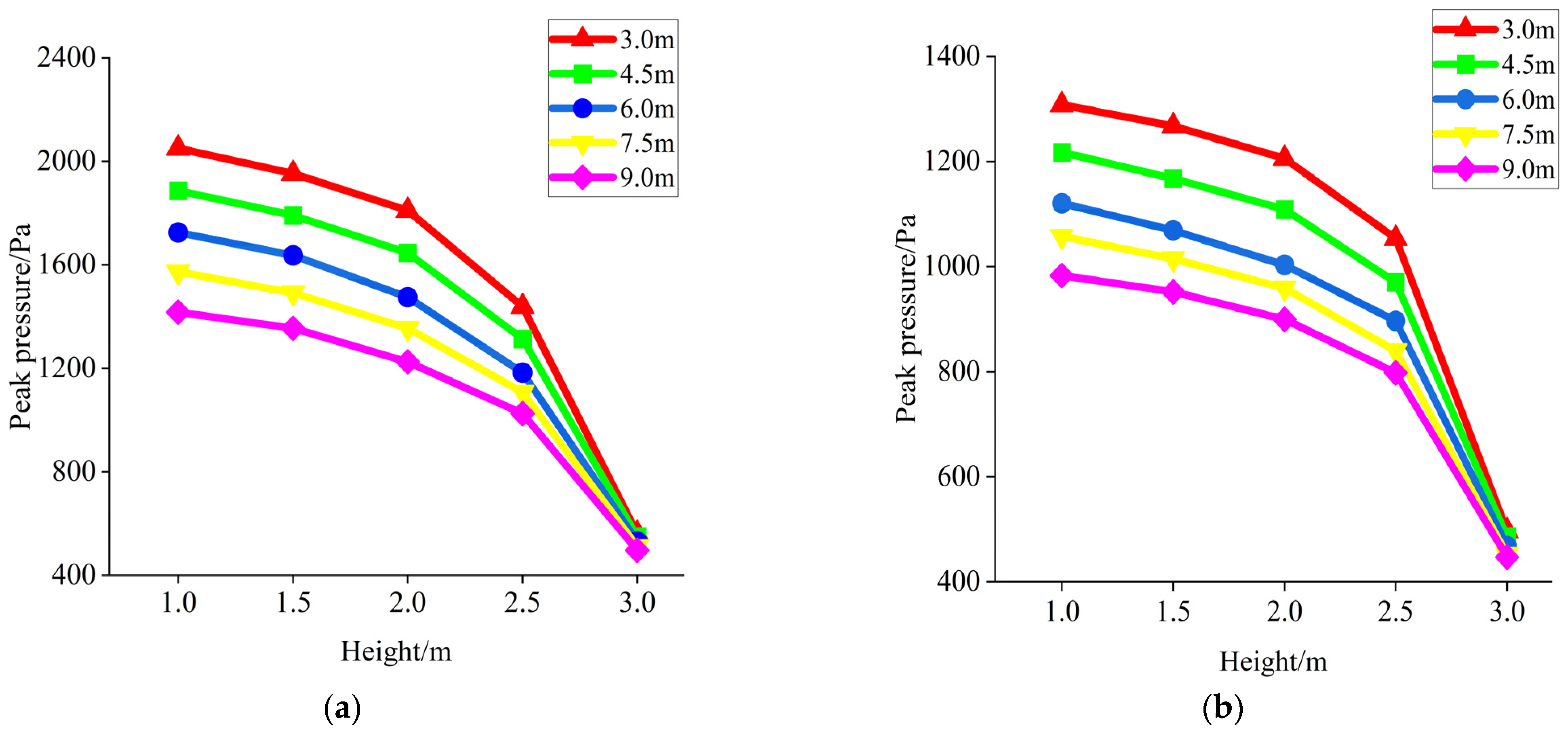

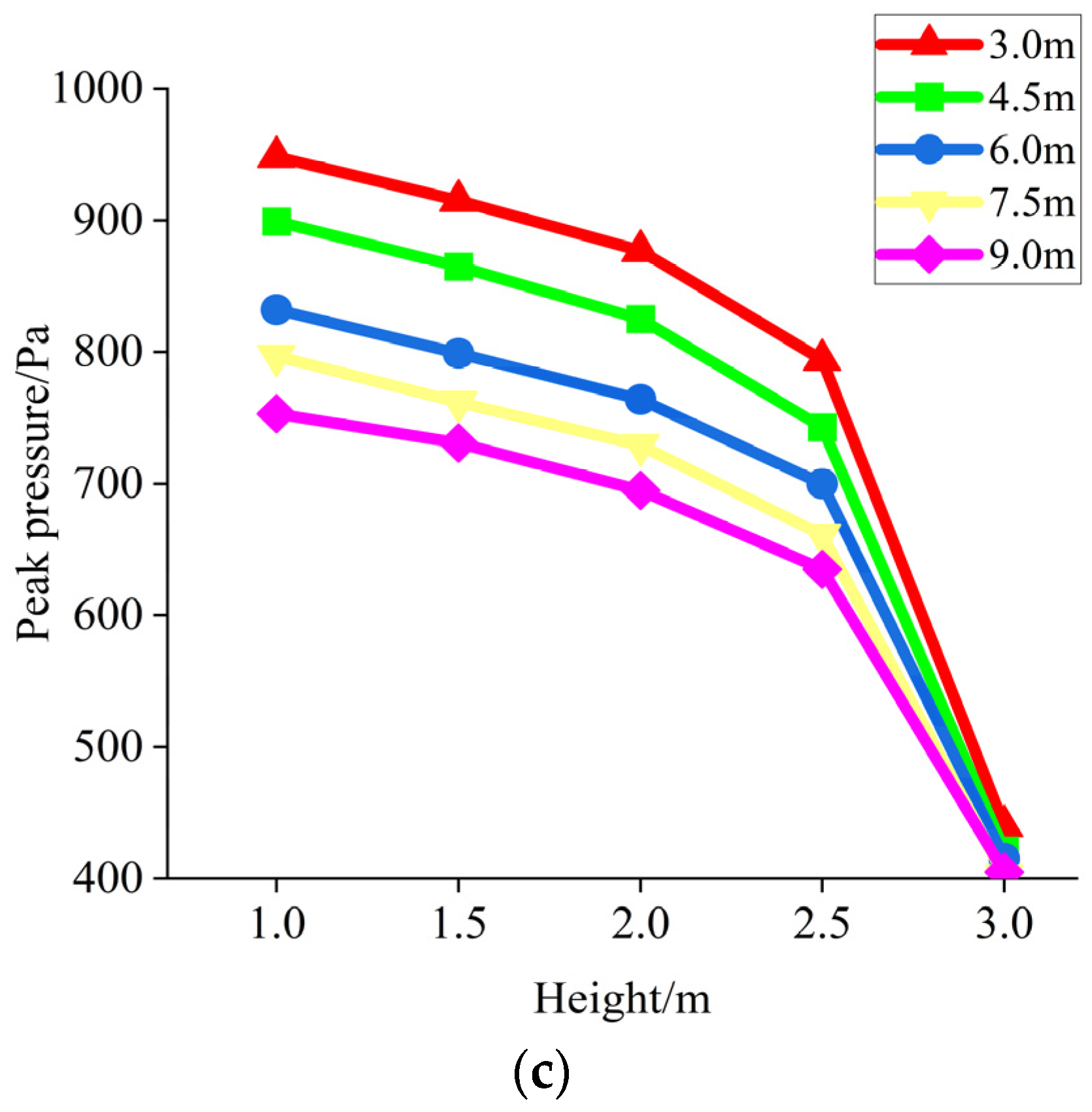

4.2. Distribution of Pressure on the Sound Barrier in the Vertical Direction

4.3. Influence of Distance to Track Center on Aerodynamic Pressure

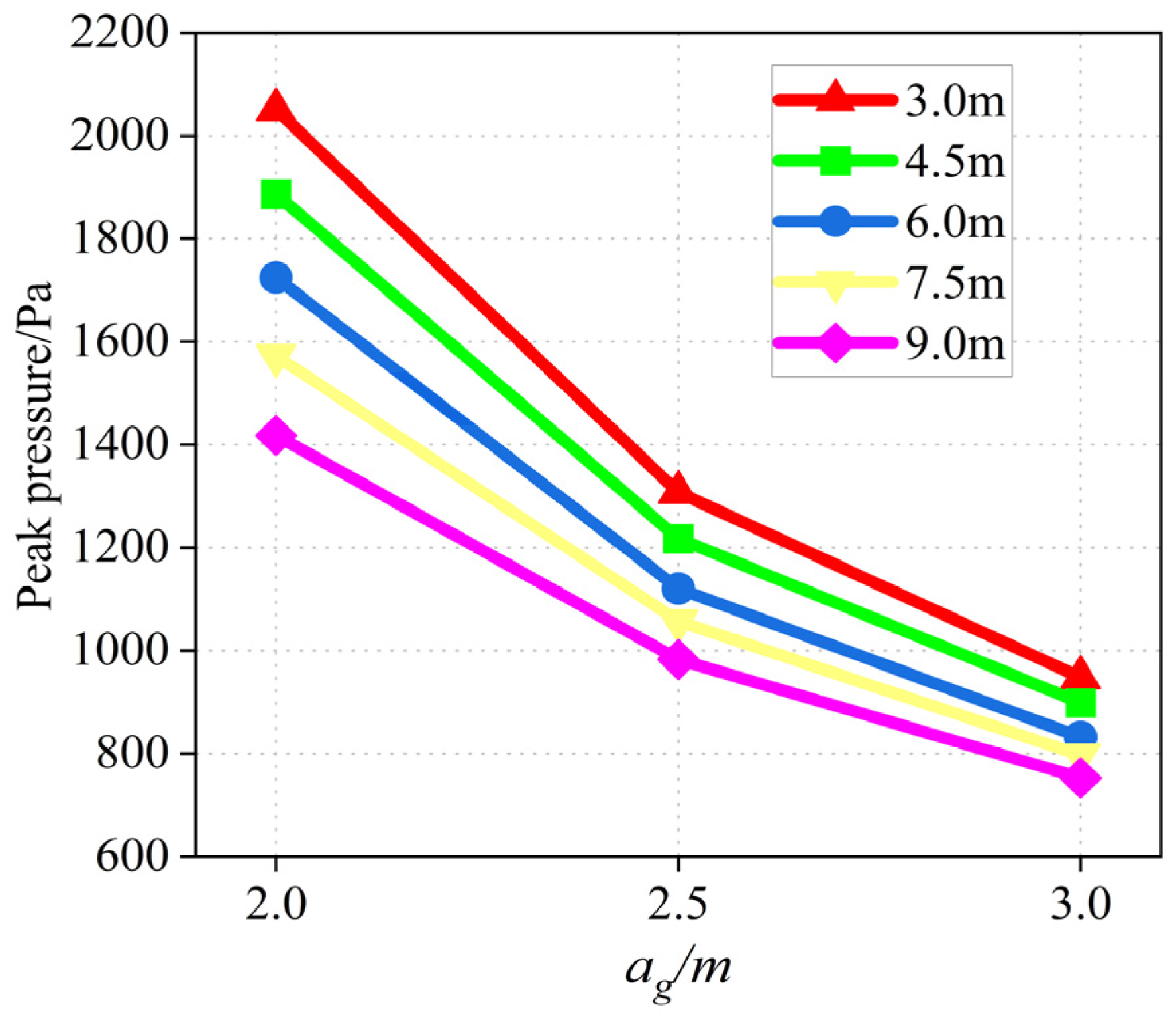

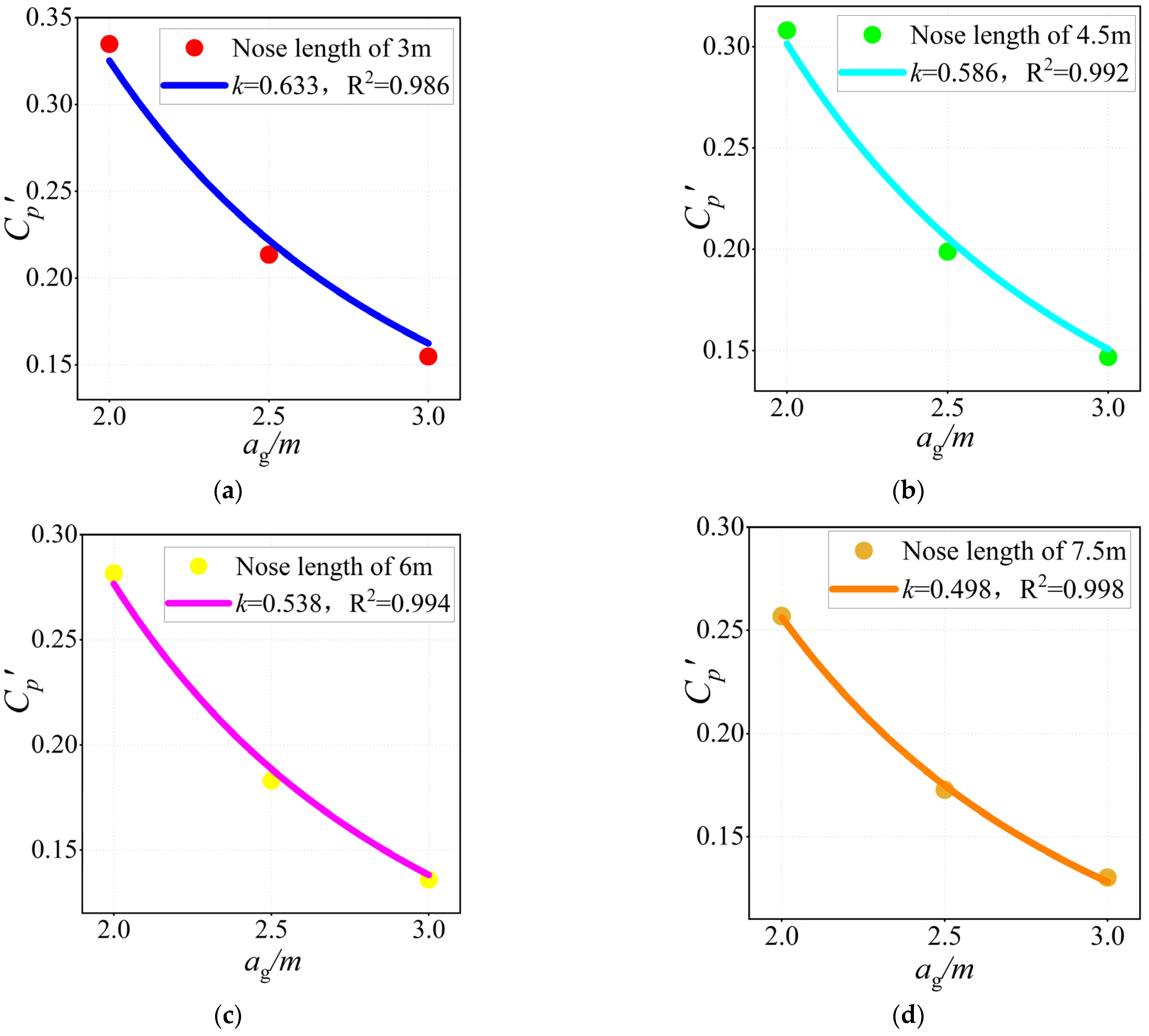

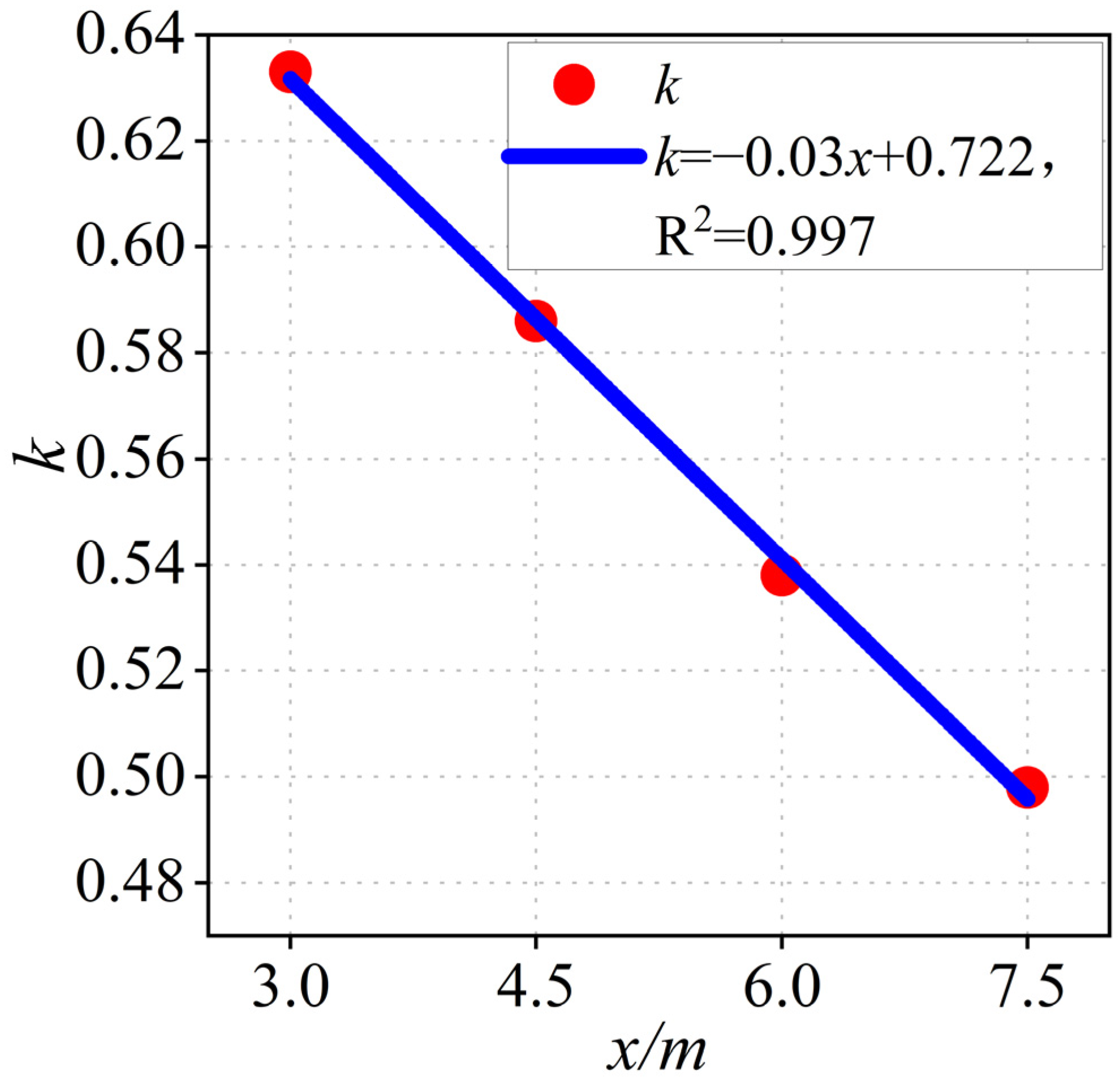

4.4. Effect of Train Nose Length on Aerodynamic Pressure

5. Conclusions

- (1)

- When a high-speed train passes through the sound barrier, it produces obvious “head wave” and “tail wave” effects, and the peak value of the “head wave” is obviously larger than the peak value of the “tail wave”; in the vertical direction of the sound barrier, the pressure reaches the peak value at the bottom, decreases gradually from the bottom to the top, and decreases rapidly when it is near the top of the sound barrier.

- (2)

- As the distance between the sound barrier and the center of the train gradually increases, the peak aerodynamic pressure on the surface of the sound barrier gradually decreases, showing a non-linear development trend.

- (3)

- The nose length has a great influence on the aerodynamic force of the sound barrier, the aerodynamic pressure generated by a train with a long nose length is smaller than that of a train with a short nose length, and the formula for calculating the aerodynamic pressure generated by a high-speed train on the sound barrier with respect to the nose length has been established.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mellet, C.; Letourneaux, F.; Poisson, F.; Talotte, C. High speed train noise emission: Latest investigation of the aerodynamic/rolling noise contribution. J. Sound Vib. 2006, 293, 535–546. [Google Scholar] [CrossRef]

- Kitagawa, T.; Nagakura, K. Aerodynamic noise generated by shinkasnsen cars. J. Sound Vib. 2000, 231, 913–924. [Google Scholar] [CrossRef]

- Jean, P. The effect of structural elasticity on the efficiency of noise barriers. J. Sound Vib. 2000, 237, 1–21. [Google Scholar] [CrossRef]

- Liu, W. Simulation Research of Aerodynamic Load on Sound Barrier of High-Speed Railway. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2014; pp. 3–12. [Google Scholar]

- Kikuchi, K.; Maeda, T.; Yanagizawa, M. Numerical simulation of the phenomena due to the passing-by of two bodies using the unsteady boundary element method. Int. J. Numer. Methods Fluids 1996, 23, 445–454. [Google Scholar] [CrossRef]

- Rong, X.; Chen, X. Aerodynamic characterization of high-speed trains and its development. J. China Railw. Soc. 1998, 20, 128–133. [Google Scholar]

- Li, H.; Xuan, Y.; Wang, L.; Li, Y.; Fang, X.; Shi, G. Research on numerical simulation of high-speed railway noise barrier aerodynamic pressure. Appl. Mech. Mater. 2013, 274, 45–48. [Google Scholar] [CrossRef]

- Luo, C.; Zhou, D.; Chen, G.; Krajnovic, S.; Sheridan, J. Aerodynamic effects as a maglev train passes through a noise barrier. Flow Turbul. Combust. 2020, 105, 6–7. [Google Scholar] [CrossRef]

- Bi, R.; Li, X.; Zheng, J.; Hu, Z.; Xu, H.; Li, S. Characteristics of aerodynamic pressure of vertical sound barriers on high speed railway bridge at 400 km/h. China Railw. Sci. 2021, 42, 68–77. [Google Scholar]

- Shi, Z.; Yang, S.; Pu, Q.; Deng, L. Study on the characteristic of aerodynamic load on sound barriers by 350-400km/h high-speed trains. China Railw. Sci. 2018, 39, 103–111. [Google Scholar]

- Kang, J.; Li, R. Fatigue performance analysis of sound barrier under aerodynamic pressure of high-speed train. Mech. Eng. Autom. 2016, 1, 23–25. [Google Scholar]

- Chen, X.; Li, S.; Wang, Z. Numerical simulation study on high-speed train induced impulsive pressure on railway noise barrier based on ALE. J. China Railw. Soc. 2011, 33, 21–26. [Google Scholar]

- Scholz, M.; Buba, Z.; Boruttau, M. Consulting Report: Noise Barrier for High Speed Railway; Germany Planning Engineering Consulting+ Services Ltd.: Beijing, China, 2006. [Google Scholar]

- Schetz, J. Aerodynamics of high-speed trains. Annu. Rev. Fluid Mech. 2001, 53, 371–414. [Google Scholar] [CrossRef]

- Belloli, M.; Pizzigoni, B.; Ripamonti, F.; Rocchi, D. Fluid-structure interaction between trains and noise-reduction barriers numerical and experimental analysis. WIT Trans. Built Environ. 2009, 105, 49–60. [Google Scholar]

- Lv, M.; Li, Q.; Ning, Z.; Ji, Z. Study on the aerodynamic load characteristic of noise reduction barrier on high-speed railway. J. Wind. Eng. Ind. Aerod. 2018, 176, 254–262. [Google Scholar]

- Zou, Y.; Fu, Z.; He, X.; Cai, C.; Zhou, J.; Zhou, S. Wind load characteristics of wind barriers induced by high-speed trains based on field measurements. Appl. Sci. 2019, 9, 4865. [Google Scholar] [CrossRef]

- Rocchi, D.; Tomasini, G.; Schito, P.; Somaschini, C. Wind effects induced by high speed train pass-by in open air. J. Wind. Eng. Ind. Aerod. 2018, 173, 279–288. [Google Scholar] [CrossRef]

- MacNeill, R.A.; Holmes, S.; Lee, H.S. Measurement of the aerodynamic pressure produced by passing trains. In Proceedings of the IEEE/ASME Joint Railroad Conference, Washington, DC, USA, 4–6 April 2002; pp. 57–64. [Google Scholar]

- Paz, C.; Suárez, E.; Gil, C. Numerical methodology for evaluating the effect of sleepers in the underbody flow of a high-speed train. J. Wind. Eng. Ind. Aerod. 2017, 167, 140–147. [Google Scholar] [CrossRef]

- Dr. White CRH2A-2010 out of Nanjing Station toward Linchang. Available online: https://www.bilibili.com/video/av20644660/?redirectFrom=h5 (accessed on 11 March 2018).

- After Ulm—Going Global (Part II). Available online: https://www.puxiang.com/galleries/74d6ec9b558fa4bc8907510008088e81 (accessed on 25 November 2019).

- CRH380AL out of Shenzhen North Station. Available online: https://www.bilibili.com/video/BV1Ms4y1z7TT/ (accessed on 20 May 2023).

- CRH400BF. Available online: https://tuchong.com/2694859/ (accessed on 11 November 2017).

- Han, J.; Xiao, X.; He, B.; Zhou, X.; Jin, X. Study on dynamic characteristics of different forms of sound barriers. J. Mech. Eng. 2013, 49, 20–27. [Google Scholar] [CrossRef]

- Khier, W.; Breuer, M.; Durst, F. Flow structure around trains under side wind conditions: A numerical study. Comput. Fluids, 2000; 29, 179–195. [Google Scholar]

- Zhou, D.; Tian, H.; Lu, Z. Effects of high wind on the aerodynamic performance of passenger trains running on embankments. J. China Railw. Soc. 2007, 7, 6–9. [Google Scholar]

- Li, X.; Yang, Z.; Zhang, J.; Zhang, W. Aerodynamics properties of high-speed train in strong wind. J. Traffic Transp. Eng. 2009, 9, 66–73. [Google Scholar]

- Zhang, L.; Zhang, J.; Zhang, W. Fluid-solid coupling vibration response analysis of high-speed train passing through sound barrier. J. Dyn. Control 2014, 12, 153–159. [Google Scholar]

- TB/T 3503.4-2018; National Railway Administration of the People’s Republic of China: Aerodynamics for Railway Applications Part 4: Specification for Numerical Simulation of Train Aerodynamic Performance. China Railway Press: Beijing, China, 2018.

- Shi, M. Experimental Study on Aerodynamic Loading Characteristics of High-Speed Railroad Sound Barriers. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2015; pp. 61–67. [Google Scholar]

- Meng, S.; Zhou, D.; Xiong, X.; Chen, G. The effect of the nose length on the aerodynamics of a high-speed train passing through a noise barrier. Flow. Turbul. Combust. 2022, 108, 411–431. [Google Scholar] [CrossRef]

- Luo, W.; Li, H. Analysis of dynamic response of sound barrier under aerodynamic load. Noise Vib. Control. 2016, 36, 162–165. [Google Scholar]

- Wu, X.; Zhu, Y.; Xian, L.; Huang, Y.; Du, P. Numerical study on dynamic characteristics of Y-type sound barriers for high-speed railroads. J. Cen. South. Univ. 2022, 53, 737–746. [Google Scholar]

- Long, L.; Zhao, L.; Liu, L. Aerodynamic study of train-induced acoustic barrier structures. Eng. Mech. 2010, 27, 246–250. [Google Scholar]

- Lv, J. Research on High-Speed Railroad Plug-in Plate and Integral Sound Barrier Structure. Ph.D. Thesis, Southeast University, Nanjing, China, 2010; pp. 46–47. [Google Scholar]

- EN 14067-4; Railway Applications-Aerodynamics-Part 4: Requirements and Test Procedures for Aerodynamics on Open Track. European Committee for Standardization: Brussels, Belgium, 2005.

| Mesh Size of Nose Surface (m) | Peak Positive Pressure of Train Nose (Pa) | Peak Negative Pressure of Train Nose (Pa) |

|---|---|---|

| 0.02 | 826 | −614 |

| 0.05 | 827 | −615 |

| 0.08 | 823 | −613 |

| Working Conditions | Sound Barrier–Train Center Distance (m) | Nose Length (m) |

|---|---|---|

| 1 | 2.00 | 3.0, 4.5, 6.0, 7.5, 9.0 |

| 2 | 2.50 | 3.0, 4.5, 6.0, 7.5, 9.0 |

| 3 | 3.00 | 3.0, 4.5, 6.0, 7.5, 9.0 |

| Measuring Point | Measured Peak (Pa) | Steady-State Simulation | Transient Simulation | ||

|---|---|---|---|---|---|

| Peak Pressure (Pa) | Relative Error | Peak Pressure (Pa) | Relative Error | ||

| 219-2 | 759 | 737 | −2.9% | 780 | 2.8% |

| 230-5 | 767 | 742 | −3.3% | 786 | 2.5% |

| Working Conditions | Peak Head Wave Positive Pressure (Pa) | Peak Tail Wave Negative Pressure (Pa) | Relative Error |

|---|---|---|---|

| ag = 3.0 m, x = 6.0 m | 826 | −614 | 34% |

| ag = 2.5 m, x = 3.0 m | 1308 | −996 | 31% |

| ag (m) | Nose Length of 3.0 m | Nose Length of 4.5 m | Nose Length of 6.0 m | Nose Length of 7.5 m |

|---|---|---|---|---|

| 2.00 | 0.3281 | 0.3019 | 0.2760 | 0.2516 |

| 2.50 | 0.2092 | 0.1948 | 0.1793 | 0.1692 |

| 3.00 | 0.1516 | 0.1438 | 0.1331 | 0.1275 |

| Working Conditions | Simulated Value (Pa) | Calculated Value by Equation (5) (Pa) | Relative Error |

|---|---|---|---|

| ag = 2.0 m, x = 6.0 m | 1725 | 1706 | 1.1% |

| ag = 3.0 m, x = 7.5 m | 797 | 781 | 2.0% |

| ag = 2.5 m, x = 9.0 m | 983 | 971 | 1.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Liu, D.; Tu, Y. Numerical Simulation of Aerodynamic Pressure on Sound Barriers from High-Speed Trains with Different Nose Lengths. Appl. Sci. 2024, 14, 2898. https://doi.org/10.3390/app14072898

Jin J, Liu D, Tu Y. Numerical Simulation of Aerodynamic Pressure on Sound Barriers from High-Speed Trains with Different Nose Lengths. Applied Sciences. 2024; 14(7):2898. https://doi.org/10.3390/app14072898

Chicago/Turabian StyleJin, Jie, Dongyun Liu, and Yongming Tu. 2024. "Numerical Simulation of Aerodynamic Pressure on Sound Barriers from High-Speed Trains with Different Nose Lengths" Applied Sciences 14, no. 7: 2898. https://doi.org/10.3390/app14072898

APA StyleJin, J., Liu, D., & Tu, Y. (2024). Numerical Simulation of Aerodynamic Pressure on Sound Barriers from High-Speed Trains with Different Nose Lengths. Applied Sciences, 14(7), 2898. https://doi.org/10.3390/app14072898