Dynamic Modeling and Altitude Control for Flying Cars Based on Active Disturbance Rejection Control

Abstract

1. Introduction

2. Dynamic Model

2.1. Structure of Flying Car

2.2. Motor Model

2.3. Propeller Model

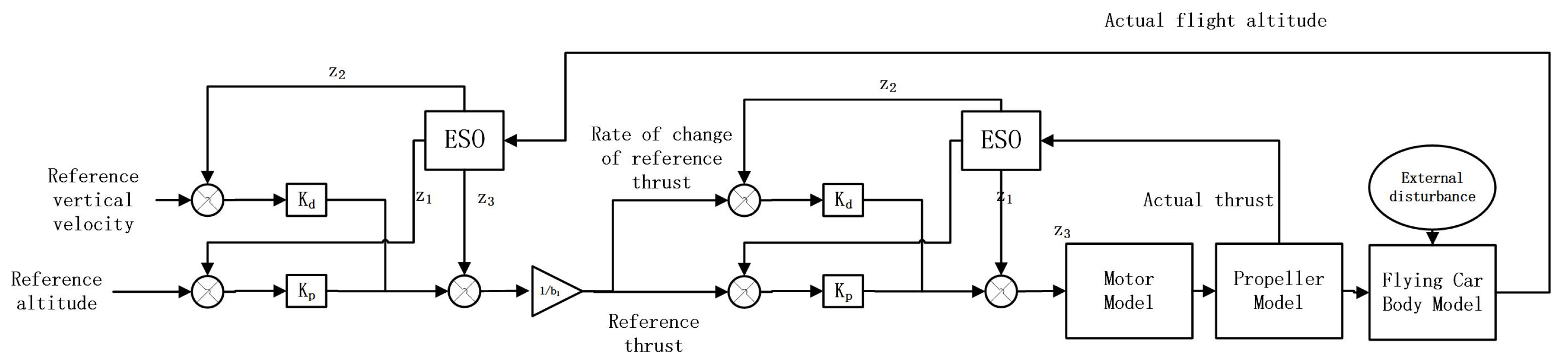

3. Active Disturbance Rejection Controller

4. Simulation Verification

4.1. Verification of the Propeller and Motor Models

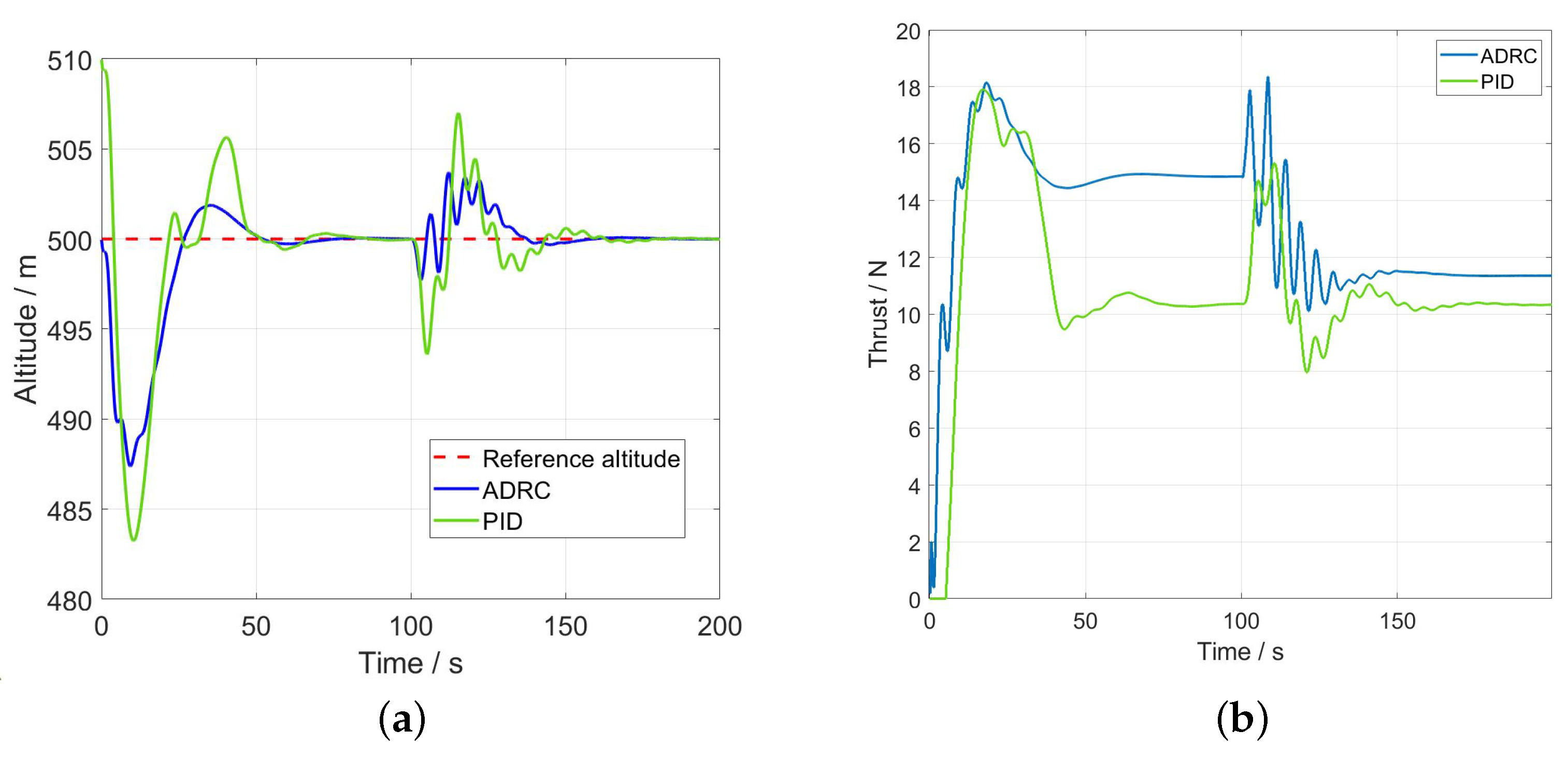

4.2. Altitude Control

5. Experimental Tests

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kasliwal, A.; Furbush, N.J.; Gawron, J.H.; McBride, J.R.; Wallington, T.J.; De Kleine, R.D.; Kim, H.C.; Keoleian, G.A. Role of flying cars in sustainable mobility. Nat. Commun. 2019, 10, 1555. [Google Scholar] [CrossRef] [PubMed]

- Pan, G.; Alouini, M.S. Flying car transportation system: Advances, techniques, and challenges. IEEE Access 2021, 9, 24586–24603. [Google Scholar] [CrossRef]

- Rajashekara, K.; Wang, Q.; Matsuse, K. Flying cars: Challenges and propulsion strategies. IEEE Electrif. Mag. 2016, 4, 46–57. [Google Scholar] [CrossRef]

- Postorino, M.N.; Sarné, G.M.L. Reinventing mobility paradigms: Flying car scenarios and challenges for urban mobility. Sustainability 2020, 12, 3581. [Google Scholar] [CrossRef]

- Swaminathan, N.; Reddy, S.R.P.; RajaShekara, K.; Haran, K.S. Flying cars and evtols—Technology advancements, powertrain architectures, and design. IEEE Trans. Transp. Electrif. 2022, 8, 4105–4117. [Google Scholar] [CrossRef]

- Wang, F.; Bai, J.; Yang, L.; Rao, B.; Huang, L. An Overview on Development of Urban Air Traffic with a New Mode of Flying Car Commuting. Trans. Beijing Inst. Technol. 2023, 43, 665–675. [Google Scholar]

- Saeed, B.; Gratton, G.B. An evaluation of the historical issues associated with achieving non-helicopter V/STOL capability and the search for the flying car. Aeronaut. J. 2010, 114, 91–102. [Google Scholar] [CrossRef]

- Saeed, N.; Al-Naffouri, T.Y.; Alouini, M.S. Wireless communication for flying cars. Front. Commun. Netw. 2021, 2, 689881. [Google Scholar] [CrossRef]

- Yang, C.; Lu, Z.; Wang, W.; Wang, M.; Zhao, J. An efficient intelligent energy management strategy based on deep reinforcement learning for hybrid electric flying car. Energy 2023, 280, 128118. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, Y.; Ho, H.W. Aerodynamic design and evaluation of a ducted fan lift system for vertical takeoff and landing flying cars. Proc. Inst. Mech. Eng. Part J. Power Energy 2023, 237, 115–125. [Google Scholar] [CrossRef]

- Wang, Y.F.; Su, T.X. Autobody modelling analysis of the flying cars. Appl. Mech. Mater. 2014, 577, 1310–1313. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Y.; Wu, Z.; Li, Z.; Ran, S.; Tian, F. Preliminary Aerodynamic Simulation of a Flying Car Concept. In Proceedings of the 2023 International Conference on Unmanned Aircraft Systems (ICUAS), Warsaw, Poland, 6–9 June 2023; pp. 123–128. [Google Scholar]

- Chen, C.; Yang, S.; Chen, F. Simulation Analysis of Aerodynamic Characteristics of Flying Car Based on Bionic Seagull Wing. In Proceedings of the 2022 IEEE International Conference on Robotics and Biomimetics (ROBIO), Xishuangbanna, China, 5–9 December 2022; pp. 1301–1306. [Google Scholar]

- Ai, T.; Xu, B.; Xiang, C.; Fan, W.; Zhang, Y. Modeling and multimode analysis of electrically driven flying car. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 1565–1571. [Google Scholar]

- Yang, C.; Lu, Z.; Wang, W.; Li, Y.; Chen, Y.; Xu, B. Energy management of hybrid electric propulsion system: Recent progress and a flying car perspective under three-dimensional transportation networks. Green Energy Intell. Transp. 2023, 2, 100061. [Google Scholar] [CrossRef]

- Luo, Y.; Qian, Y.; Zeng, Z.; Zhang, Y. Simulation and analysis of operating characteristics of power battery for flying car utilization. eTransportation 2021, 8, 100111. [Google Scholar] [CrossRef]

- Gur, O.; Rosen, A. Optimization of propeller based propulsion system. J. Aircr. 2009, 46, 95–106. [Google Scholar] [CrossRef]

- Moelyadi, M.A. Development of Flying Car Model with Quad Rotors. J. Unmanned Syst. Technol. 2015, 3, 1–5. [Google Scholar]

- Wang, S.; Li, J.; Gao, X.; Yan, B.H. Conceptual Design of Four Rotors Flying Car Based on Bionics. In Proceedings of the 2017 5th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering (ICMMCCE 2017), Chongqing, China, 24–25 July 2017; Atlantis Press: Amsterdam, The Netherlands, 2018; pp. 928–933. [Google Scholar]

- Takii, A.; Gomi, R.; Yamakawa, M.; Tsubokura, M. Turning Flight Simulation with Fluid-Rigid Body Interaction for Flying Car with Contra-Rotating Propellers. In Proceedings of the International Conference on Computational Science, Prague, Czech Republic, 3–5 July 2023; Springer Nature: Cham, Switzerland, 2023; pp. 566–577. [Google Scholar]

- Mihara, Y.; Nakamura, T.; Nakamoto, A.; Nakano, M. Airframe design optimization and simulation of a flying car for medical emergencies. Int. J. Autom. Technol. 2022, 16, 183–196. [Google Scholar] [CrossRef]

- Kim, K.; Hwang, K.; Kim, H. Study of an adaptive fuzzy algorithm to control a rectangular-shaped unmanned surveillance flying car. J. Mech. Sci. Technol. 2013, 27, 2477–2486. [Google Scholar] [CrossRef]

- Pardede, W.M.; Adhitya, M. Take off and landing performance analysis for a flying car model using wind tunnel test method. In Proceedings of the AIP Conference Proceedings, Padang, India, 22–24 July 2020; AIP Publishing: Melville, NY, USA, 2020; p. 2227. [Google Scholar]

- Shi, X.; Kim, K.; Rahili, S.; Chung, S.J. Nonlinear control of autonomous flying cars with wings and distributed electric propulsion. In Proceedings of the 2018 IEEE Conference on Decision and Control (CDC), Miami Beach, FL, USA, 17–19 December 2018; pp. 5326–5333. [Google Scholar]

- Takahashi, N.; Gomi, R.; Takii, A.; Yamakawa, M.; Asao, S.; Takeuchi, S. Numerical Simulation of the Octorotor Flying Car in Sudden Rotor Stop. In Proceedings of the International Conference on Computational Science, Prague, Czech Republic, 3–5 July 2023; Springer Nature: Cham, Switzerland, 2023; pp. 33–46. [Google Scholar]

- Ruan, S.; Ma, Y.; Wei, Z.; Yang, N.; Zhang, C.; Xiang, C. Hierarchical Control Strategy for the Hybrid Electric Propulsion System of a Flying Car with Engine Start-Stop System and Dynamic Coordination. IEEE Trans. Transp. Electrif. 2023. [Google Scholar] [CrossRef]

- Trancossi, M.; Hussain, M.; Shivesh, S.; Pascoa, J. A new VTOL propelled wing for flying cars: Critical bibliographic analysis. SAE Tech. Pap. 2017, 1, 1–14. [Google Scholar]

- Bae, H.; Lee, J.; Lee, K. Marker-Based 3D Position-Prediction Algorithm of Mobile Vertiport for Cabin-Delivery Mechanism of Dual-Mode Flying Car. Electronics 2022, 11, 1837. [Google Scholar] [CrossRef]

- Tanjim, M.S.S.; Oishi, A.N.; Nandy, A.; Jannah, R.; Ahmed, S. A flight control system for a vehicle. In Proceedings of the 2019 International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 10–12 January 2019; pp. 313–318. [Google Scholar]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Feng, H.; Guo, B.Z. Active disturbance rejection control: Old and new results. Annu. Rev. Control. 2017, 44, 238–248. [Google Scholar] [CrossRef]

- Huang, Y.; Xue, W. Active disturbance rejection control: Methodology and theoretical analysis. ISA Trans. 2014, 53, 963–976. [Google Scholar] [CrossRef] [PubMed]

- Ahi, B.; Haeri, M. Linear active disturbance rejection control from the practical aspects. IEEE/Asme Trans. Mechatronics 2018, 23, 2909–2919. [Google Scholar] [CrossRef]

- Tan, W.; Fu, C. Linear active disturbance-rejection control: Analysis and tuning via IMC. IEEE Trans. Ind. Electron. 2015, 63, 2350–2359. [Google Scholar] [CrossRef]

- Ahmad, S.; Ali, A. On active disturbance rejection control in presence of measurement noise. IEEE Trans. Ind. Electron. 2021, 69, 11600–11610. [Google Scholar] [CrossRef]

- Gao, Z. Active disturbance rejection control: From an enduring idea to an emerging technology. In Proceedings of the 2015 10th International Workshop on Robot Motion and Control (RoMoCo), Poznan, Poland, 6–8 July 2015; pp. 269–282. [Google Scholar]

- Gupte, S.; Mohandas, P.I.T.; Conrad, J.M. A survey of quadrotor unmanned aerial vehicles. In Proceedings of the 2012 Proceedings of IEEE Southeastcon, Orlando, FL, USA, 15–18 March 2012; pp. 1–6. [Google Scholar]

- Alexis, K.; Nikolakopoulos, G.; Tzes, A. Model predictive quadrotor control: Attitude, altitude and position experimental studies. IET Control. Theory Appl. 2012, 6, 1812–1827. [Google Scholar] [CrossRef]

- Fernando, H.; De Silva, A.T.A.; De Zoysa, M.D.C.; Dilshan, K.D.C.; Munasinghe, S.R. Modelling, simulation and implementation of a quadrotor UAV. In Proceedings of the 2013 IEEE 8th International Conference on Industrial and Information Systems, Kandy, Sri Lanka, 17–20 December 2013; pp. 207–212. [Google Scholar]

- Chen, M.; Xiong, S.; Wu, Q. Tracking flight control of quadrotor based on disturbance observer. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 1414–1423. [Google Scholar] [CrossRef]

- Islam, S.; Liu, P.X.; El Saddik, A. Robust control of four-rotor unmanned aerial vehicle with disturbance uncertainty. IEEE Trans. Ind. Electron. 2014, 62, 1563–1571. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Lu, X.; Luo, W.; Sun, H.; Long, Z.; Xu, Y. Dynamic Modeling and Altitude Control for Flying Cars Based on Active Disturbance Rejection Control. Appl. Sci. 2024, 14, 2754. https://doi.org/10.3390/app14072754

Xu J, Lu X, Luo W, Sun H, Long Z, Xu Y. Dynamic Modeling and Altitude Control for Flying Cars Based on Active Disturbance Rejection Control. Applied Sciences. 2024; 14(7):2754. https://doi.org/10.3390/app14072754

Chicago/Turabian StyleXu, Jie, Xinjiang Lu, Wei Luo, Hao Sun, Zhenkun Long, and Yuteng Xu. 2024. "Dynamic Modeling and Altitude Control for Flying Cars Based on Active Disturbance Rejection Control" Applied Sciences 14, no. 7: 2754. https://doi.org/10.3390/app14072754

APA StyleXu, J., Lu, X., Luo, W., Sun, H., Long, Z., & Xu, Y. (2024). Dynamic Modeling and Altitude Control for Flying Cars Based on Active Disturbance Rejection Control. Applied Sciences, 14(7), 2754. https://doi.org/10.3390/app14072754