Recent Advances in the Application of Agricultural Waste in Construction

Abstract

1. Introduction

2. Agro-Wastes as Concrete Additives

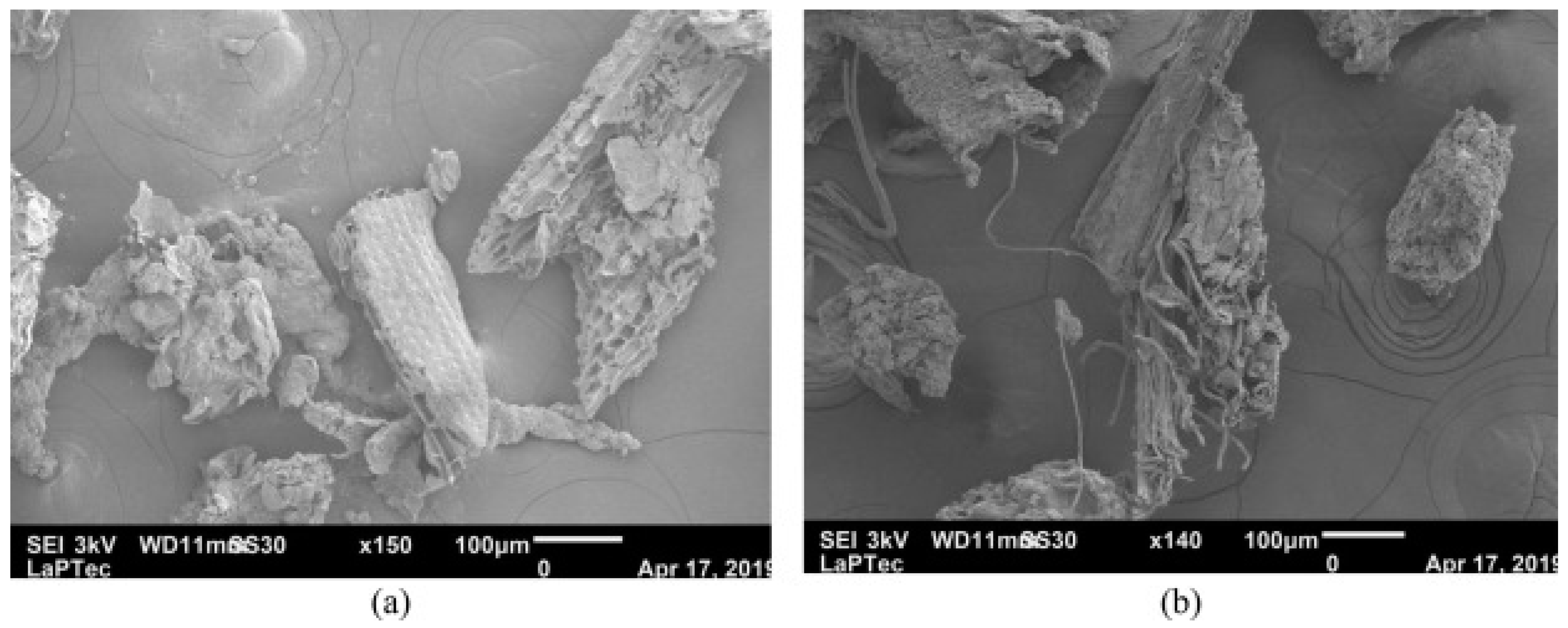

2.1. Waste from Pineapple

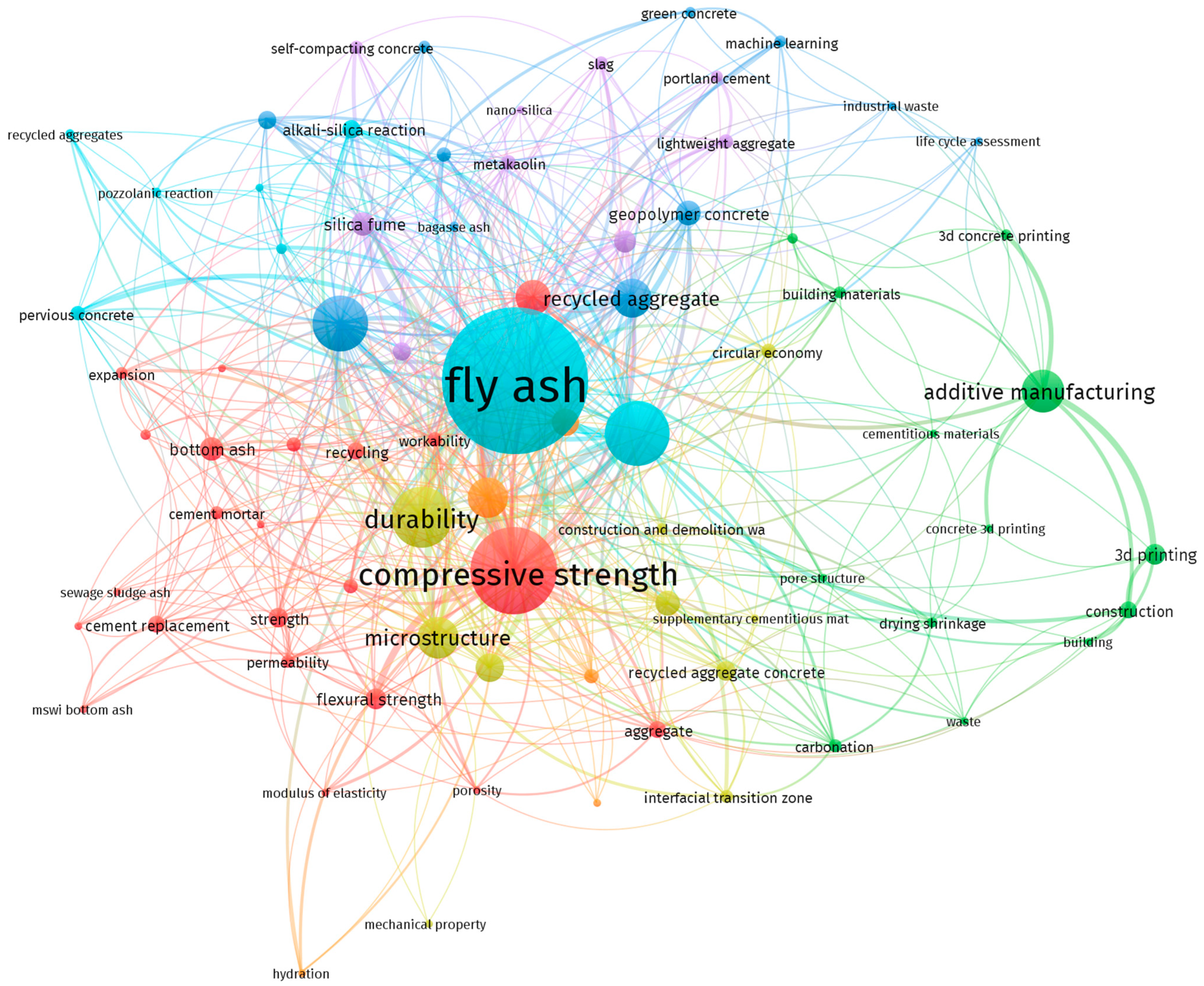

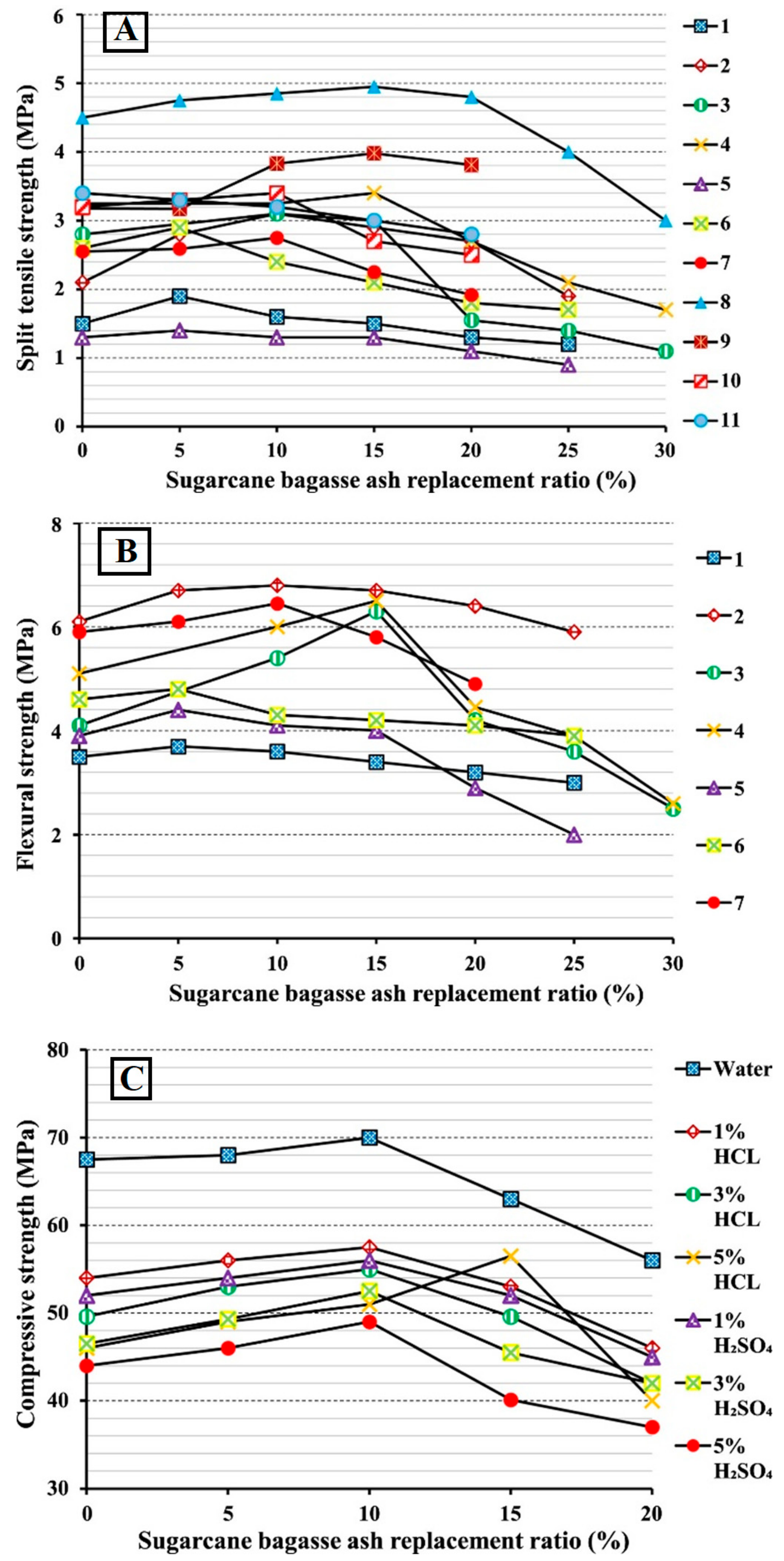

2.2. Waste from Sugarcane

2.3. Coconut Shell Waste

2.4. Waste from Rice Husk

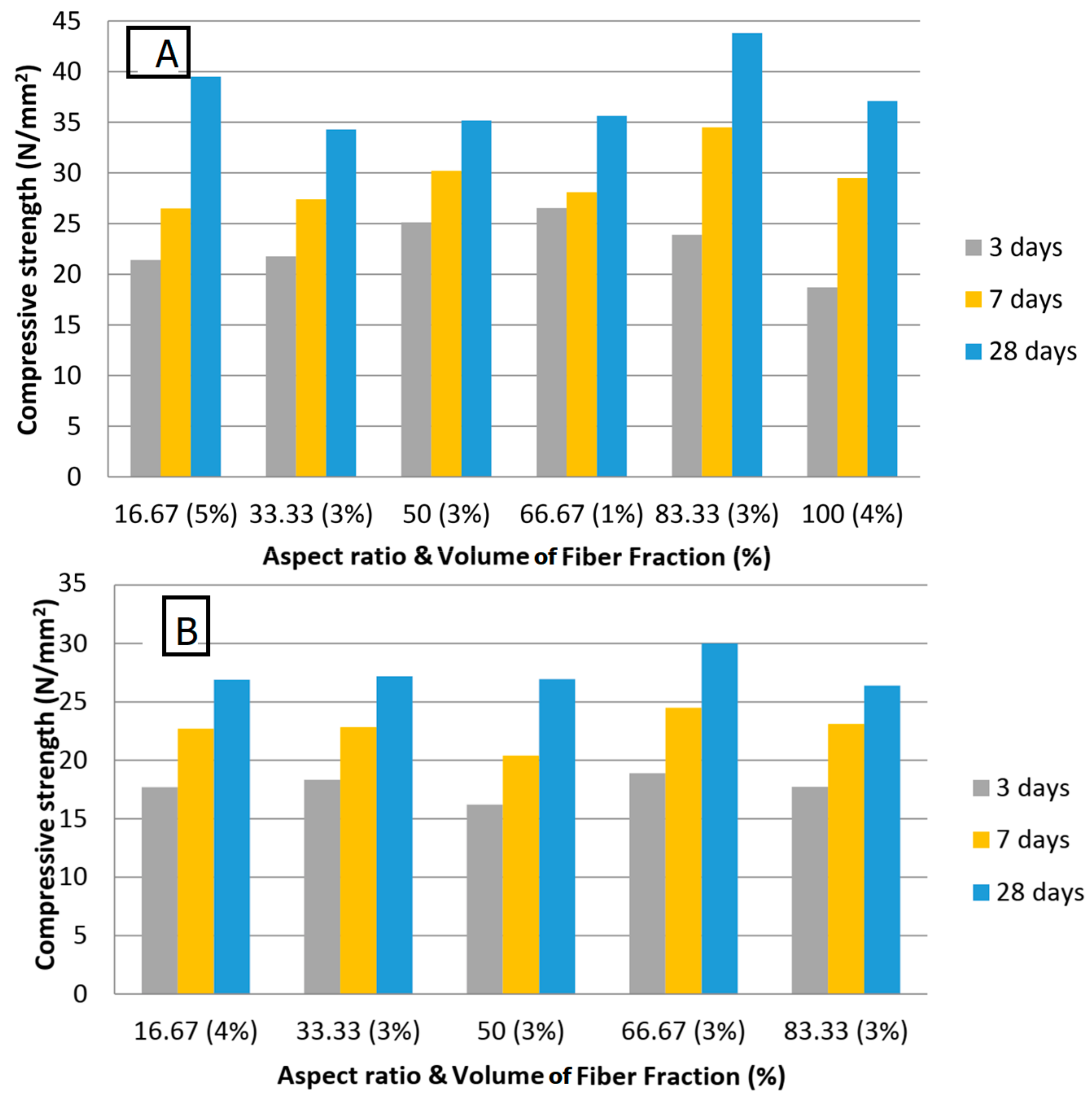

2.5. Nutshell Waste

3. Agro-Wastes as Building Insulation Materials

Advantages and Disadvantages of Agro-Materials as Insulation

4. Conclusions

5. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. Database. 2020. Available online: https://www.fao.org/faostat/en/#home (accessed on 10 October 2023).

- Ananymous. WorldBank. 2021. Available online: https://ourworldindata.org/grapher/employment-in-agri-vs-urban-pop (accessed on 10 October 2023).

- Agamuthu, P. Challenges and opportunities in agro-waste management: An Asian perspective. In Inaugural Meeting of first regional 3R forum in Asia; University of Malasiya: Kuala Lumpur, Malasiya, 2009. [Google Scholar]

- Škrbić, S.; Ašonja, A.; Prodanović, R.; Ristić, V.; Stevanović, G.; Vulić, M.; Janković, Z.; Radosavac, A.; Igić, S. Analysis of Plant-Production-Obtained Biomass in Function of Sustainable Energy. Sustainability 2020, 12, 5486. [Google Scholar] [CrossRef]

- El-Sayed, T.A.; AErfan, M.; El-Naby, R. Flexural behavior of RC beams by using agricultural waste as a cement reinforcement materials. J. Eng. Res. Rep. 2019, 7, 1–12. [Google Scholar] [CrossRef]

- Gontard, N.; Sonesson, U.; Birkved, M.; Majone, M.; Bolzonella, D.; Celli, A.; Angellier-Coussy, H.; Jang, G.W.; Verniquet, A.; Broeze, J.; et al. A research challenge vision regarding management of agricultural waste in a circular bio-based economy. Crit. Rev. Environ. Sci. Technol. 2018, 48, 614–654. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853. [Google Scholar] [CrossRef]

- Teo, D.C.; Mannan, M.A.; Kurian, J.V. Flexural behaviour of reinforced lightweight concrete beams made with oil palm shell (OPS). J. Adv. Concr. Technol. 2006, 4, 459–468. [Google Scholar] [CrossRef]

- Ahmed, E.; Sobuz, H.R. Flexural and time-dependent performance of palm shell aggregate concrete beam. KSCE J. Civ. Eng. 2011, 15, 859–865. [Google Scholar] [CrossRef]

- Muda, Z.; Sharif, S.F.; Hong, N.J. Flexural behavior of lightweight oil palm shells concrete slab reinforced with geogrid. Int. J. Sci. Eng. Res. 2012, 3, 1–18. [Google Scholar]

- Mohammed, B.S.; Foo, W.L.; Hossain, K.M.A.; Abdullahi, M. Shear strength of palm oil clinker concrete beams. Mater. Des. 2013, 46, 270–276. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P. Study on reinforced lightweight coconut shell concrete beam behavior under shear. Mater. Des. 2013, 50, 293–301. [Google Scholar] [CrossRef]

- Rushforth, I.; Horoshenkov, K.V.; Miraftab, M.; Swift, M.J. Impact sound insulation and viscoelastic properties of underlay manufactured from recycled carpet waste. Appl. Acoust. 2005, 66, 731–749. [Google Scholar] [CrossRef]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s cob as a potential ecological thermal insulation material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Raut, S.; Ralegaonkar, R.; Mandavgane, S. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Ahmadi, R.; Souri, B.; Ebrahimi, M. Evaluation of wheat straw to insulate fired clay hollow bricks as a construction material. J. Clean. Prod. 2020, 254, 120043. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A.L.; D’Alessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and numerical characterization of innovative cardboard based panels: Thermal and acoustic performance analysis and life cycle assessment. Build. Environ. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- Ajayi, A.M.; Coker, A.I.; Oyebanjo, O.T.; Adebanjo, I.M.; Ademowo, O.G. Ananas comosus (L) Merrill (pineapple) fruit peel extract demonstrates antimalarial, anti-nociceptive and anti-inflammatory activities in experimental models. J. Ethnopharmacol. 2022, 282, 114576. [Google Scholar] [CrossRef]

- Chawalitsakunchai, W.; Dittanet, P.; Loykulnant, S.; Sae-oui, P.; Tanpichai, S.; Seubsai, A.; Prapainainar, P. Properties of natural rubber reinforced with nano cellulose from pineapple leaf agricultural waste. Mater. Today Commun. 2021, 28, 102594. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A. Possibilities for the application of agro-industrial wastes in cementitious materials: A brief review of the Brazilian perspective. Clean. Mater. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and review of physical and mechanical properties of raw and treated coconut fibers for their recycling in construction materials. Fibers 2020, 8, 37. [Google Scholar] [CrossRef]

- de Araujo Alves Lima, R.; Kawasaki Cavalcanti, D.; de Souza e Silva Neto, J.; Meneses da Costa, H.; Banea, M.D. Effect of surface treatments on interfacial properties of natural intralaminar hybrid composites. Polym. Compos. 2020, 41, 314–325. [Google Scholar] [CrossRef]

- Karolina, R.; Tandika, W.; Hasibuan, A.; Putra, M.A.; Fahreza, D. Pineapple leaf fiber (PALF) waste as an alternative fiber in making concrete. J. Phys. Conf. Series. 2022, 2193, 012061. [Google Scholar] [CrossRef]

- Che Osmi, S.K.; Zaınuddın, M.A.; Misnon, N.A.; Sojipto, S.; Husen, H. Effect of Pineapple Leaf Fibre as Additional Material in Concrete Mixture. In Proceedings of the 5th International Conference on Sustainable Civil Engineering Structures and Construction Materials; SCESCM 2020. Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 215. [Google Scholar]

- Chin, S.C.; Tang, M.L.; Bakar, N.; Che, J.L.; Doh, S.I. Effects of Pineapple Leaf Fibre as Reinforcement in Oil Palm Shell Lightweight Concrete. In Proceedings of the 2nd Energy Security and Chemical Engineering Congress; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Komal, U.K.; Lila, M.K.; Singh, I. Processing of PLA/pineapple fiber based next generation composites. Mater. Manuf. Process. 2021, 36, 1677–1692. [Google Scholar] [CrossRef]

- Ogunyewo, O.A.; Upadhyay, P.; Rajacharya, G.H.; Okereke, O.E.; Faas, L.; Gómez, L.D.; McQueen-Mason, S.J.; Yazdani, S.S. Accessory enzymes of hypercellulolytic Penicillium funiculosum facilitate complete saccharification of sugarcane bagasse. Biotechnol. Biofuels 2021, 14, 171. [Google Scholar] [CrossRef] [PubMed]

- Arpia, A.A.; Chen, W.H.; Ubando, A.T.; Tabatabaei, M.; Lam, S.S.; Culaba, A.B.; De Luna, M.D.G. Catalytic microwave-assisted torrefaction of sugarcane bagasse with calcium oxide optimized via Taguchi approach: Product characterization and energy analysis. Fuel 2021, 305, 121543. [Google Scholar] [CrossRef]

- Dharek, M.S.; Sreekeshava, K.S.; Vengala, J.; Pramod, K.; Sunagar, P.; Shivaprakash, M.V. Experimental investigations on utilization of bagasse ash in adobe bricks. In Sustainability Trends and Challenges in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2022; pp. 487–496. [Google Scholar]

- Lyra, G.P.; Borrachero, M.V.; Soriano, L.; Paya, J.; Rossignolo, J.A. Comparison of original and washed pure sugar cane bagasse ashes as supplementary cementing materials. Constr. Build. Mater. 2021, 272, 122001. [Google Scholar] [CrossRef]

- Berenguer, R.; Lima, N.; Valdés, A.C.; Medeiros, M.H.F.; Lima, N.B.D.; Delgado, J.M.P.Q.; Silva, F.A.N.; Azevedo, A.C.; Guimarães, A.S.; Rangel, B. Durability of concrete structures with sugar cane bagasse ash. Adv. Mater. Sci. Eng. 2020, 2020, 6907834. [Google Scholar] [CrossRef]

- Zaheer, M.M.; Tabish, M. The Durability of Concrete Made Up of Sugar Cane Bagasse Ash (SCBA) as a Partial Replacement of Cement: A Review. Arab. J. Sci. Eng. 2023, 48, 4195–4225. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Sustainable approach of using sugarcane bagasse ash in cement-based composites: A systematic review. Case Stud. Constr. Mater. 2021, 15, e00698. [Google Scholar] [CrossRef]

- Arif, E.; Clark, M.W.; Lake, N. Sugar cane bagasse ash from a high efficiency co-generation boiler: Applications in cement and mortar production. Constr. Build. Mater. 2016, 128, 287–297. [Google Scholar] [CrossRef]

- Rambabu, P.; Rao, G.R. Study on sugarcane bagasse ash as a partial replacement of cement in M60 Grade concrete exposed to acidic environment. SSRG Int. J. Civil Eng. 2017, 4, 1–9. [Google Scholar]

- Joshaghani, A.; Moeini, M.A. Evaluating the effects of sugar cane bagasse ash (SCBA) and nanosilica on the mechanical and durability properties of mortar. Constr. Build. Mater. 2017, 152, 818–831. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hakamy, A.A.; Fattouh, M.S.; Mostafa, S.A. The effect of using nano agriculture wastes on microstructure and electrochemical performance of ultra-high-performance fiber reinforced self-compacting concrete under normal and acceleration conditions. Case Stud. Constr. Mater. 2023, 18, e01721. [Google Scholar] [CrossRef]

- Srinivasan, R.; Sathiya, K. Experimental study on bagasse ash in concrete. Int. J. Serv. Learn. Eng. Humanit. Eng. Soc. Entrep. 2010, 5, 60–66. [Google Scholar] [CrossRef]

- Priya, K.L.; Ragupathy, R. Effect of sugarcane bagasse ash on strength properties of concrete. Int. J. Res. Eng. Technol. 2016, 5, 159–164. [Google Scholar]

- Dhengare, S.W.; Raut, S.P.; Bandwal, N.V.; Khangan, A. Investigation into utilization of sugarcane bagasse ash as supplementary cementitious material in concrete. Int. J. Emerg. Eng. Res. Technol. 2015, 3, 109–116. [Google Scholar]

- Kiran, K.; Kishore, I.S. An experimental study on partial replacement of cement with bagasse ash in concrete mix. Int. J. Civ. Eng. Technol. 2017, 8, 452–455. [Google Scholar]

- Ranjith, A.; Sanjith, J.; Kiran, B.M. Experimental investigation on performance of sugarcane bagasse ash concrete in acidic environment. Int. J. Earth. Sci. Eng. 2015, 8, 471–476. [Google Scholar]

- Rao, M.; Prabath, N.V.N. Green concrete using agro industrial waste (sugarcane bagasse ASH. Int. J. Soft Comput. Eng. 2015, 5, 86–92. [Google Scholar]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of bagasse ash as supplementary cementitious material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Mamatha, P.; Narayana DS, M.V.; Naresh Kumar, T. To evaluate the mechanical & durability properties of nano sugarcane bagasse ash in cement concrete. Int. J. Sci. Res. Sci. Eng. Technol. 2017, 3, 425–430. [Google Scholar]

- Inbasekar DS, M.; Hariprasath, P.; Senthilkumar, D. International journal of engineering sciences & research technology study on potential utilization of sugarcane bagasse ash in steel fiber reinforced concrete. Int. J. Eng. Sci. Res. Technol. 2016, 5, 43–50. [Google Scholar]

- Kumari, A.; Kumar, P.S. Experimental study on partial replacement of cement by sugaracne bagasse ash. Int. J. Innov. Sci. Eng. Technol. 2015, 4, 2347–6710. [Google Scholar]

- Behera, G.C.; Behera, R.K. Effect of Coconut Shell Aggregate on Normal Strength Concrete. Int. J. Eng. Res. Technol. 2013, 2, 2405–2415. [Google Scholar]

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of coconut fiber in coconut shell concrete and its mechanical and bond properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef] [PubMed]

- Ranatunga, K.S.; del Rey Castillo, E.; Toma, C.L. Evaluation of the optimal concrete mix design with coconut shell ash as a partial cement replacement. Constr. Build. Mater. 2023, 401, 132978. [Google Scholar] [CrossRef]

- Hasan, N.M.; Sobuz, M.H.; Shaurdho, N.M.; Basit, M.A.; Paul, S.C.; Meraz, M.M.; Saha, A.; Miah, M.J. Investigation of lightweight and green concrete characteristics using coconut shell aggregate as a replacement for conventional aggregates. Int. J. Civ. Eng. 2023, 22, 37–53. [Google Scholar] [CrossRef]

- Bhoj, S.; Manoj, A.; Bhaskar, S. Usage potential and benefits of processed coconut shells in concrete as coarse aggregates. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Sagar, T.S.; Paluri, Y.; Krishna, Y.M.; Ravi, B.; Ravi, Y. Utilization of Fly Ash and Coconut Shell as Sustainable Alternatives in M30 Grade Concrete: A Feasibility Study. IOP Conf. Ser. Earth Environ. Sci. 2023, 1280, 012020. [Google Scholar] [CrossRef]

- Odeyemi, S.O.; Durosinlorun, A.O.; Wilson, U.N. Determination of physical and mechanical properties of fibre reinforced coconut shell concrete. Civ. Eng. Infrastruct. J. 2023. [Google Scholar] [CrossRef]

- de Avila, L.A.; Noldin, J.A.; Mariot, C.H.; Massoni, P.F.; Fipke, M.V.; Gehrke, V.R.; Merotto, A.; Tomita, F.M.; Matos, A.B.; Facioni, G.; et al. Status of weedy rice (Oryza spp.) infestation and management practices in southern Brazil. Weed Sci. 2021, 69, 536–546. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Mohammadhosseini, H. State-of-the-art-review on rice husk ash: A supplementary cementitious material in concrete. J. King Saud Univ.-Eng. Sci. 2021, 33, 294–307. [Google Scholar] [CrossRef]

- Rithuparna, R.; Jittin, V.; Bahurudeen, A. Influence of different processing methods on the recycling potential of agro-waste ashes for sustainable cement production: A review. J. Clean. Prod. 2021, 316, 128242. [Google Scholar] [CrossRef]

- Silva, L.A.; dos Santos, I.F.S.; de Oliveira Machado, G.; Tiago Filho, G.L.; Barros, R.M. Rice husk energy production in Brazil: An economic and energy extensive analysis. J. Clean. Prod. 2021, 290, 125188. [Google Scholar] [CrossRef]

- Mboya, H.A.; King’ondu, C.K.; Njau, K.N.; Mrema, A.L. Measurement of pozzolanic activity index of scoria, pumice, and rice husk ash as potential supplementary cementitious materials for Portland cement. Adv. Civ. Eng. 2017, 2017, 6952645. [Google Scholar] [CrossRef]

- Hadipramana, J.; Samad, A.A.A.; Ahmad Mujahid, A.Z.; Mohamad, N.; Riza, F.V. Contribution of RHA granules as filler to improve the impact resistance of foamed concrete. Key Eng. Mater. 2014, 594, 93–97. [Google Scholar] [CrossRef]

- Makul, N.; Sua-iam, G. Characteristics and utilization of sugarcane filter cake waste in the production of lightweight foamed concrete. J. Clean. Prod. 2016, 126, 118–133. [Google Scholar] [CrossRef]

- Jayanthi, V.; Avudaiappan, S.; Amran, M.; Arunachalam, K.P.; Qader, D.N.; Delgado, M.C.; Flores, E.I.S.; Rashid, R.S. Innovative use of micronized biomass silica-GGBS as agro-industrial by-products for the production of a sustainable high-strength geopolymer concrete. Case Stud. Constr. Mater. 2022, 18, e01782. [Google Scholar] [CrossRef]

- Alyami, M.; Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of agricultural olive, rice husk and sugarcane leaf waste ashes on sustainable ultra-high-performance concrete. J. Build. Eng. 2023, 72, 106689. [Google Scholar] [CrossRef]

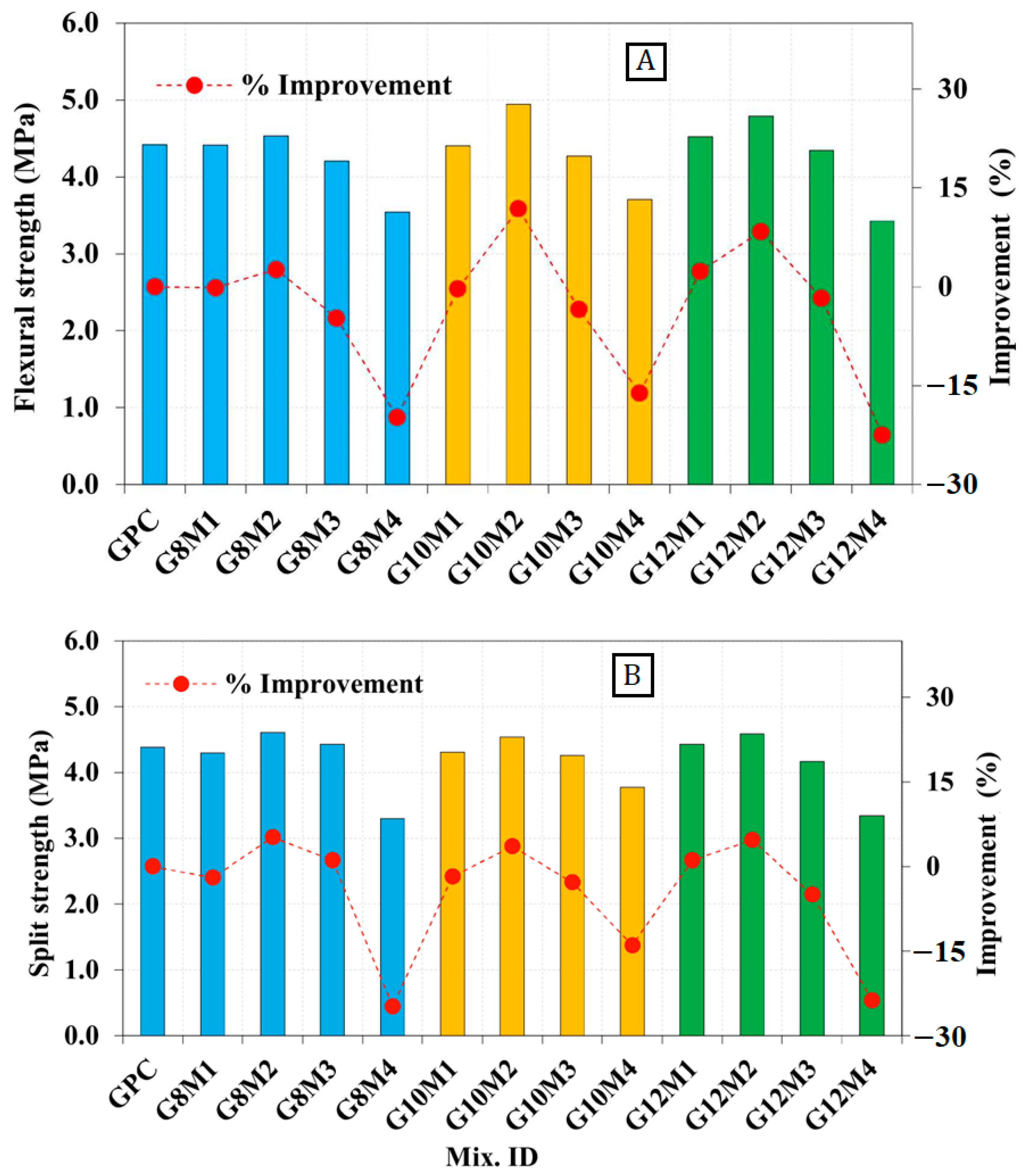

- Noaman, A.T.; Abed, M.S.; Al-Gebory, L.; Al-Zubaidi, A.B.; Al-Tabbakh, A.A. Production of Agro-waste cement Composites: Influence of nutshells on mechanical and hardened properties. Constr. Build. Mater. 2023, 394, 132137. [Google Scholar] [CrossRef]

- Baran, Y.; Gökçe, H.S.; Durmaz, M. Physical and mechanical properties of cement containing regional hazelnut shell ash wastes. J. Clean. Prod. 2020, 259, 120965. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee For Standardisation: London, UK, 2011.

- Jannat, N.; Al-Mufti, R.L.; Hussien, A.; Abdullah, B.; Cotgrave, A. Utilisation of nut shell wastes in brick, mortar and concrete: A review. Constr. Build. Mater. 2021, 293, 123546. [Google Scholar] [CrossRef]

- Türkmen, İ.; Ekinci, E.; Kantarcı, F.; Sarıcı, T. The mechanical and physical properties of unfired earth bricks stabilized with gypsum and Elazığ Ferrochrome slag. Int. J. Sustain. Built Environ. 2017, 6, 565–573. [Google Scholar] [CrossRef]

- Soni, A.; Kumar, D.P.; Yusuf, M.; Ridha, S. Experimental investigations on the workability of sustainable composite by recycling waste plastics and agro-waste. Zaštita Mater. 2022, 63, 493–501. [Google Scholar] [CrossRef]

- Soni, A.; Chakraborty, S.; Das, P.K.; Saha, A.K. Materials selection of reinforced sustainable composites by recycling waste plastics and agro-waste: An integrated multi-criteria decision making approach. Constr. Build. Mater. 2022, 348, 128608. [Google Scholar] [CrossRef]

- He, J.; Kawasaki, S.; Achal, V. The utilization of agricultural waste as agro-cement in concrete: A review. Sustainability 2020, 12, 6971. [Google Scholar] [CrossRef]

- Abdulrahman, U.; Ali, U.A. Characterization of groundnut shell ash as partial replacement of cement for cheaper construction in north-western Nigeria. CaJoST 2023, 5, 212–217. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Yusuf, M.; Ridha, S.; Kamyab, H.; Chelliapan, S.; Kirpichnikova, I.; Mussa, Z.H. Valorization of Post-Consumers Plastics and Agro-Waste in Sustainable Polymeric Composites for Tribological Applications. Waste Biomass Valorization 2023, 1–17. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O. Insulation material production from onion skin and peanut shell fibres, fly ash, pumice, perlite, barite, cement and gypsum. Mater. Today Commun. 2017, 10, 14–24. [Google Scholar] [CrossRef]

- Ozturk, S.; Sutcu, M.; Erdogmus, E.; Gencel, O. Influence of tea waste concentration in the physical, mechanical and thermal properties of brick clay mixtures. Constr. Build. Mater. 2019, 217, 592–599. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane bagasse waste fibers as novel thermal insulation and sound-absorbing materials for application in sustainable buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Onésippe, C.; Passe-Coutrin, N.; Toro, F.; Delvasto, S.; Bilba, K.; Arsène, M.A. Sugar cane bagasse fibres reinforced cement composites: Thermal considerations. Compos. Part A Appl. Sci. Manuf. 2010, 41, 549–556. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Binici, H.; Eken, M.; Kara, M.; Dolaz, M. An environment-friendly thermal insulation material from sunflower stalk, textile waste and stubble fibers. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013. [Google Scholar]

- Binici, H.; Aksogan, O.; Dıncer, A.; Luga, E.; Eken, M.; Isikaltun, O. The possibility of vermiculite, sunflower stalk and wheat stalk using for thermal insulation material production. Therm. Sci. Eng. Prog. 2020, 18, 100567. [Google Scholar] [CrossRef]

- Platt, S.L.; Maskell, D.; Shea, A.; Walker, P. Impact of fibre orientation on the hygrothermal properties of straw bale insulation. Constr. Build. Mater. 2022, 349, 128752. [Google Scholar] [CrossRef]

- Peng, H.; Walker, P.; Maskell, D.; Jones, B. Structural characteristics of load bearing straw bale walls. Constr. Build. Mater. 2021, 287, 122911. [Google Scholar] [CrossRef]

- Platt, S.; Maskell, D.; Walker, P.; Laborel-Préneron, A. Manufacture and characterisation of prototype straw bale insulation products. Constr. Build. Mater. 2020, 262, 120035. [Google Scholar] [CrossRef]

- Bobet, O.; Nassio, S.; Seynou, M.; Remy, B.; Zerbo, L.; Sanou, I.; Sawadogo, M.; Millogo, Y.; Gilles, E. Characterization of peanut shells for their valorization in earth brick. J. Miner. Mater. Charact. Eng. 2020, 8, 301–315. [Google Scholar] [CrossRef]

- Damfeu, J.C.; Meukam, P.; Jannot, Y. Modeling and measuring of the thermal properties of insulating vegetable fibers by the asymmetrical hot plate method and the radial flux method: Kapok, coconut, groundnut shell fiber and rattan. Thermochimica Acta 2016, 630, 64–77. [Google Scholar] [CrossRef]

- Do, N.H.; Luu, T.P.; Thai, Q.B.; Le, D.K.; Chau, N.D.Q.; Nguyen, S.T.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Heat and sound insulation applications of pineapple aerogels from pineapple waste. Mater. Chem. Phys. 2020, 242, 122267. [Google Scholar] [CrossRef]

- Suphamitmongkol, W.; Khanoonkon, N.; Rungruangkitkrai, N.; Boonyarit, J.; Changniam, C.; Sampoompuang, C.; Chollakup, R. Potential of Pineapple Leaf Fibers as Sound and Thermal Insulation Materials in Thailand. Prog. Appl. Sci. Technol. 2023, 13, 26–32. [Google Scholar]

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-industrial wastes as building insulation materials: A review and challenges for Euro-Mediterranean countries. Ind. Crop. Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Bousshine, S.; Ouakarrouch, M.; Bybi, A.; Laaroussi, N.; Garoum, M.; Tilioua, A. Acoustical and thermal characterization of sustainable materials derived from vegetable, agricultural, and animal fibers. Appl. Acoust. 2022, 187, 108520. [Google Scholar] [CrossRef]

- Kouakou, A.C.; Agbodan, A.K.; Bakpo, A.; Koriko, M.; Fiaty, K.; Oudjaniyobi, S.; Jondo, K. Physico-Chemical Characterization of Nine Agricultural Biomasses of the Togolese Flora. Int. J. Geosci. 2023, 14, 19–35. [Google Scholar] [CrossRef]

- Kolak, M.N.; Oltulu, M. Investigation of mechanical and thermal properties of new type bio-composites containing camelina. Constr. Build. Mater. 2023, 362, 129779. [Google Scholar] [CrossRef]

- Li, Z.; Tian, Q.; Chen, Y.; Zhao, B.; Qiu, F.; Zhang, T. Superhydrophobic degradable cellulose-based film with radiation insulation performance for agricultural application. Cellulose 2023, 30, 5145–5156. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of particleboards made of agricultural by-products with a classical binder or self-bound. Ind. Crops Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Pavelek, M.; Adamová, T. Bio-waste thermal insulation panel for sustainable building construction in steady and unsteady-state conditions. Materials 2019, 12, 2004. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Lian, Z.; Wu, Y. Human physiological responses to wooden indoor environment. Physiol. Behav. 2017, 174, 27–34. [Google Scholar] [CrossRef] [PubMed]

| Rank | Country | Share of Agriculture GDP (2019) | Population (Millions) (2019) | Share of Population in Agriculture Sector (2019) |

|---|---|---|---|---|

| 1 | China | 7.6% | 1420 | 25% |

| 2 | India | 18% | 1380 | 42% |

| 3 | United States | 9% | 334 | 1.3% |

| 4 | Russia | 4% | 146 | 5.8% |

| 5 | I. R. of Iran | 12% | 86 | 17% |

| 6 | Brazil | 7.8% | 212 | 9% |

| 7 | Pakistan | 21% | 223 | 36% |

| 8 | Australia | 2.3% | 25 | 2.5% |

| 9 | Italy | 2% | 59 | 3.8% |

| 10 | Canada | 1.6% | 37 | 1.5% |

| Advantages (+) | Disadvantages (−) |

|---|---|

| Renewable, recyclable, and biodegradable properties Favorable LCA properties Cost-effective production Non-abrasive Insulation properties Comfortable for indoor environments Lightweight for construction Healthy for indoor environments Good acoustic properties High comfortability | Hydrophilic structures Breaking down at high temperatures High moisture content and water absorption potentiality Swelling and dimensional variation Short-lived durability Suitable environment for insects and mold growth Highly flammable Low thermal conductivity Fungal emissions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalife, E.; Sabouri, M.; Kaveh, M.; Szymanek, M. Recent Advances in the Application of Agricultural Waste in Construction. Appl. Sci. 2024, 14, 2355. https://doi.org/10.3390/app14062355

Khalife E, Sabouri M, Kaveh M, Szymanek M. Recent Advances in the Application of Agricultural Waste in Construction. Applied Sciences. 2024; 14(6):2355. https://doi.org/10.3390/app14062355

Chicago/Turabian StyleKhalife, Esmail, Maryam Sabouri, Mohammad Kaveh, and Mariusz Szymanek. 2024. "Recent Advances in the Application of Agricultural Waste in Construction" Applied Sciences 14, no. 6: 2355. https://doi.org/10.3390/app14062355

APA StyleKhalife, E., Sabouri, M., Kaveh, M., & Szymanek, M. (2024). Recent Advances in the Application of Agricultural Waste in Construction. Applied Sciences, 14(6), 2355. https://doi.org/10.3390/app14062355