Abstract

This research addresses the challenges faced in collecting and managing repair history information for architectural heritage due to its distribution among different institutions. To overcome this problem, this study proposes a building information modeling (BIM)-based repair history management framework that links non-formal repair details of architectural heritage to BIM. This framework was applied to the case study of the Great Hero Hall of Sudeoksa Temple in Yesan, South Korea. A repair history database in the form of structured data adhering to the historic building information modeling standard was utilized. The proposed framework effectively syncs the repair history database with BIM to preserve architectural heritage and streamline repair history information updates as well as management. Integrated heritage BIM is anticipated to furnish a thorough knowledge base for architectural heritage, comprising non-geometric details and formal information models, thus enhancing building maintenance planning. Ultimately, the benefits and limitations of the suggested framework and methodologies are deliberated for further implementation.

1. Introduction

Wooden architectural heritage, which is typically heavily influenced by climatic factors such as temperature and humidity, relies on information contained in records and reports, including past repairs and physical measurements, to analyze the cause of damage and determine potential repair and conservation measures. In particular, architectural heritage management and conservation plans that rely on records from the past that remain undigitized for long periods of time suffer from fragmentation and missing information over time [1]. This, in turn, makes it difficult to restore and preserve cultural heritage in its original form, and can lead to a decline in cultural value as well as subsequent economic losses [2].

The use of digital technologies, such as building information modeling (BIM) systems, can serve as a solution to this issue by replacing manual records and managing construction data throughout a building’s lifecycle. BIM systems can also function as integrated management systems, linking geometry and attribute information for efficient data processing [3]. Especially for wooden structures, the continuous accumulation of information and data-driven decision making are critical for maintenance and preservation. Recent incidents, such as the fires at South Korea’s Sungnyemun Gate and France’s Notre Dame Cathedral, underscore the global necessity for digitally integrated maintenance systems.

BIM has emerged as a new area of interest in the cultural heritage domain, and it is commonly known as historic or heritage building information modeling (HBIM). Since its introduction by Murphy et al. [4], HBIM has been extensively developed with innovative applications at various levels in the fields of archaeology and architectural heritage. Despite significant advances in the past decade, the integration of conservation-driven heritage data management remains incomplete [5]. To enable the sustainable archiving of architectural heritage data, an advanced management system that combines a geometrical model with preservation-related data is necessary to support the operation and maintenance phases effectively. Identifying and digitally documenting the current state and properties of heritage building components, along with all pertinent semantic information in a singular HBIM model, will establish a collaborative information management platform that optimizes the operation, preservation, and reconstruction stages [6]. This not only helps stakeholders make effective decisions throughout the lifecycle, but also furnishes a comprehensive overview.

This study introduces a BIM-based repair history management framework aimed at enhancing the connection between the BIM of cultural heritage and the corresponding repair history records. This is achieved by developing an add-in for data synchronization to preserve architectural heritage. The proposed framework is applied to a South Korean architectural heritage case study, validating its model efficacy and demonstrating its effectiveness in repair history management through data visualization. This integration of HBIM with synchronized repair history for building elements showcases its practical utility.

2. Literature Review

Heritage structures demand appropriate preservation and safeguarding measures to retain their intrinsic worth and significance. Notably, the utilization of conservation and restoration techniques grounded in original and traditional approaches, while respecting culturally significant values and evolving authenticity, is imperative. These viewpoints regarding cultural property conservation policy and practice are comprehensively outlined in the Venice Charter [7], the Burra Charter [8], and the Nara Document on Authenticity [9]. The principles of conservation are centered around safeguarding the cultural significance of a building, and guidelines are established to ensure the preservation and maintenance of the structural integrity of a building [10].

Preventive maintenance is a necessary set of routine tasks that extend the longevity and optimize the performance of historic structures, creating a sustainable legacy for future generations. These regular maintenance measures are crucial for preserving built heritage. Restoration techniques aim to efficiently restore the functional and cultural value of architectural heritage to its original state as closely as possible. For instance, when dealing with wooden architectural heritage, it is crucial to develop a restoration plan that preserves cultural heritage’s utmost originality. This may involve repairing or replacing certain wooden elements damaged by environmental factors and establishing an efficient process that minimizes resource, time, and cost usage; however, the issue arises that managing the as-built information necessary for performing maintenance and restoration activities, along with the accumulated repair information, is challenging to integrate [11].

Building information modeling is the process of creating and utilizing building data throughout the lifecycle of a construction project. The functional model of a typical BIM system encompasses the efficient digital documentation of a building’s physical and functional features within an integrated environment and the operational management of various facilities. The full-scale implementation of BIM in the architectural heritage sector is hindered by the complex geometry of heritage buildings and the non-standardization as well as diversity of part types, despite its potential benefits and uses. Unlike traditional construction projects, where BIM information is generated throughout the planning and construction processes, architectural heritage structures are already built and necessitate a precise post-modeling phase. Specifically, historical, environmental, and archaeological data must be collected independently and digitized to facilitate the operation and upkeep of the building. Therefore, it is essential to establish a framework for creating a precise 3D digital model along with merged maintenance data, encompassing damage, repair, and refurbishment.

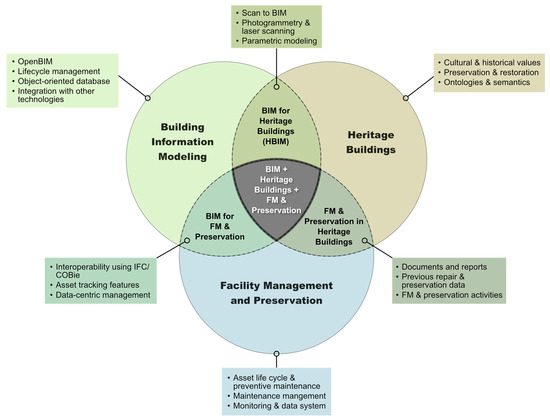

Figure 1 presents an overview of the existing and overlapping literature concerning BIM, heritage buildings, and facilities’ management as well as preservation. The circles depict research topics, and the bullet points within the rectangular boxes illustrate the research focus or overlap of each topic. Building information models utilize the OpenBIM standard to store a wide range of building properties as an information model, encompassing geometric data, non-shape attributes, project planning, and lifecycle management [12,13]. This method aligns with the fundamental concepts of object-oriented programming and modeling. In the context of heritage architecture, the HBIM concept has been used to model, document, and conserve historical structures. Several studies have investigated the implementation process and techniques of HBIM [14,15,16,17,18]. They have also examined its benefits and drawbacks in improving maintenance and operational efficiency. Furthermore, studies have investigated the incorporation of cutting-edge technologies and equipment, such as laser scanners, photogrammetry, and visual programming, into HBIM [19,20,21,22]. In the realm of the facility management of heritage buildings, there have been studies on data utilization methods to support decision making for building maintenance. These include structural [23,24] and condition analyses [25,26] of heritage buildings by integrating lifecycle data into HBIM. Methods to ensure data sharing and mutual compatibility for planning maintenance and restoration actions based on the integrated information of historic buildings for BIM have also been researched [27,28]. Furthermore, diverse web platforms were developed to promote cooperation and collaboration among the different stakeholders involved in the restoration and maintenance activities of built and cultural heritage sites, by integrating historical and geometric information and heritage documentation databases [29,30,31]. These HBIM case studies address issues related to modeling complex architecture, accurately documenting historic buildings, and creating data structures suitable for modern HBIM for an online platform. Although various technologies and applications have been explored in numerous studies, there is still a research gap in the application of BIM to preserve and manage heritage buildings. Most studies related to HBIM maintenance involve different technologies and application cases, but few focus on creating an organized BIM-based maintenance database, transferring non-shape data, or establishing maintenance procedures through attribute information, all of which are advantages of BIM. Furthermore, the discussion on the use of BIM for the preventive and repair maintenance of heritage buildings is limited. This study presents a framework for managing repair history based on BIM to address current practice gaps. To demonstrate practical implementation, the proposed framework and system modules are applied to heritage building cases.

Figure 1.

Literature analysis Venn diagram.

3. Research Methods

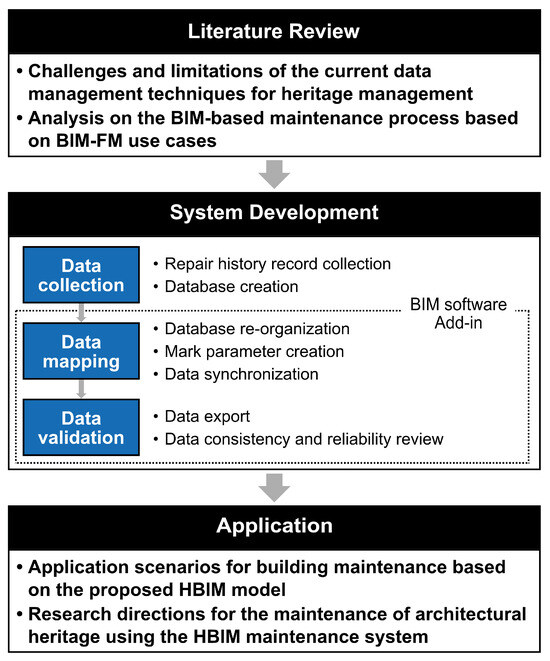

The aim of this study is to develop a management framework and approach for enhancing the data management of repair history records in architectural heritage through the creation of an add-in for BIM software (version 2022). This add-in is intended to integrate and manage the repair history data of architectural heritage in accordance with the HBIM standards [32], as defined by the Cultural Heritage Administration, by linking them to BIM through the use of pre-defined object classification codes for each part. The study begins with an analysis of business procedures related to the data management of BIM-based architectural heritage maintenance through the examination of existing BIM-based maintenance projects (Section 4). Based on this review, the study follows three phases to develop the proposed repair history data management system for architectural heritage: data collection, mapping, and validation. Each phase is explained as follows (Figure 2):

Figure 2.

Research workflow for the proposed BIM-based repair history management framework.

First, the study develops a BIM-based repair history synchronization system based on the results of the research trend analysis and case study of existing BIM-based maintenance projects. Repair history records are collected and stored in a database (DB) during the data collection phase (Section 5.1).

Second, the history record data stored in the database are re-organized into a structured format to be synchronized with BIM based on mark parameters (Section 5.2).

Third, integrated HBIM with the repair history records is reviewed to verify the data consistency and reliability, including possible missing and incorrect information (Section 5.3).

Finally, this study proposes application scenarios for the maintenance of architectural heritage using the repair history data entered into the BIM-based architectural heritage maintenance system (Section 6).

4. BIM-Based Maintenance Work Process Analysis

Maintaining a facility involves addressing problems related to deterioration through a contract with a maintenance and repair company [33]. The effective management of maintenance and support information requires systematic feedback from individual projects. BIM technology is increasingly used in facility maintenance, as BIM data generated during planning, design, construction, and operation provide source information for maintenance [34]. The real-time monitoring and evaluation of facility performance as well as safety status in a 3D space enables data-driven decision making for repair, rehabilitation, and maintenance. Data sharing among relevant parties enables efficient asset management [35]. Using BIM technology in facility maintenance increases the recyclability of the information generated during the facility lifecycle [36]. This supports consistent work performance and decision making among various project participants through the seamless sharing and exchanging of integrated BIM, in addition to creating and managing as-built as well as maintenance models to use BIM even after the construction stage. Business entities must make decisions through issue and information management, including facility operation management, based on each created model during the maintenance stage.

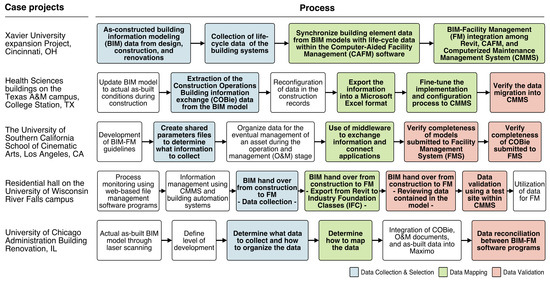

Figure 3, discussed in BIM for Facility Managers [37], examines the integration of BIM in facility management (FM). The case studies from Xavier University, Texas A&M Health Science Center (TAM HSC), the University of Southern California (USC) School of Cinematic Arts, and the University of Wisconsin River Falls Campus emphasize the importance of integrating building data and BIM through three stages for effective FM: data collection and selection, data mapping, and data validation.

Figure 3.

Analysis of the BIM-based maintenance process based on BIM-FM use cases from the International Facility Management Association [37].

During the data collection and selection stages, information is gathered on various aspects of a building, with a focus on identifying key data and securing necessary information for operations. In the subsequent data mapping stage, the collected information is transformed into appropriate formats and mapped to the structure of BIM. This provides a foundation for the comprehensive understanding and management of various aspects of a building. Thirdly, data validation involves verifying the accuracy and reliability of data to ensure their essential accuracy and consistency for building operations. This is achieved through necessary modifications and enhancements. While each project may vary in scope and objectives, they collectively highlight the importance of integrating building information and BIM through these three core stages.

Xavier University successfully streamlined space management and maintenance planning by integrating BIM with FM systems, resulting in a reduction in manual data entry efforts. Similarly, TAM HSC benefited from incorporating construction operations building information exchange (COBie) into their computerized maintenance management system (CMMS), which improved facility asset information precision and accessibility. USC’s development of BIM guidelines improved systematic data collection, while the University of Wisconsin River Falls Campus demonstrated effective BIM document linkage to CMMS.

These case studies demonstrate the fundamental importance of comprehensive data in facility management, including spatial configurations and material specifications. By utilizing high-quality information in BIM, facility managers were able to make informed decisions, optimize maintenance strategies, and improve building performance. The renovation of the University of Chicago’s administration building highlights the tangible benefits of utilizing customized COBie data collection methods for accurate facility management. Despite variations in project specifics, these studies shared a common approach to integrating BIM and FM. Teams used BIM authoring tools to develop as-constructed models based on specific levels of development (LODs) and established consistent data collection criteria, focusing on high-quality data over geometric accuracy. The integration of BIM with FM, using computer-aided facility management (CAFM), CMMS, or separate middleware, highlights the importance of high-quality data for FM. The importance of data-centric approaches in facility management is highlighted by the commitment to capturing and delivering accurate as well as complete BIM data.

5. Development of a BIM-Based Repair History Management Framework

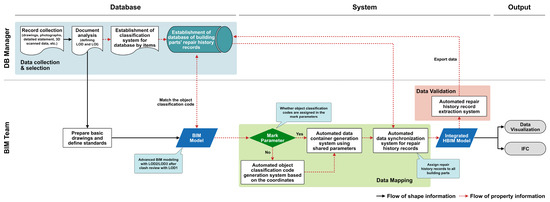

When designing a system for maintaining architectural cultural heritage based on BIM, it is crucial to include shape and property information, including the collection, processing, and management of repair history records for each part. Integrating the asset information generated during a building’s lifecycle into BIM and collecting, selecting, mapping, and validating the property information necessary for subsequent maintenance can enhance the quality control of buildings and facilitate the effective management of aging facilities, as demonstrated in Section 4. For wooden architectural heritage with numerous parts, developing a system that digitizes repair history records accumulated over time and inputting them into the established BIM model is essential. Figure 4 shows the BIM-based architectural cultural heritage maintenance system to which repair history records are applied, as proposed in this study. In the data collection and selection stage, the database manager collects, analyzes, and manages data on architectural heritage; in the data mapping stage, the BIM team integrates maintenance data to build integrated HBIM based on the data; in the managing sustainable repair records stage, maintenance is conducted through the validation stage of the produced integrated HBIM data. This maintenance database is built by analyzing shape information, such as drawings, photos, and 3D scans of architectural heritage, as well as the property information necessary for maintenance (Section 5.1). The HBIM standards, defined by the Cultural Heritage Administration, provide guidelines for defining the level of detail (LOD) and level of information (LOI) for each part. The LOD serves as a standard for building formal content and is intended to be an as-constructed asset information model, while the LOI serves as a standard for creating non-formal content such as a repair history DB.

Figure 4.

Process of the BIM-based architectural heritage management system.

The BIM team integrates the repair history for each part, which is stored in the repair history DB created by the DB manager, into the property information for each part in the BIM model. This process involves converting the part object name of each part into a standardized object classification code (Section 5.2.1), creating a data container to link the repair history record to each part of BIM (Section 5.2.2), and linking with the repair history DB (Section 5.2.3). The resulting updated attribute information of HBIM can be exported as a spreadsheet containing the repair history record and used to produce visualization information for maintenance. Furthermore, the effective interoperability of HBIM data through an IFC viewer can be achieved by exporting from BIM to IFC and conducting model-based consultations among project participants.

This study constructs integrated HBIM by mapping the information from the repair history DB built by the DB manager from the stages described above with the parts of BIM. The following sections provide a detailed description of the data flow and processing for system development at each stage of data collection and selection, mapping, and validation.

5.1. Data Collection and Selection

The DB manager collects repair history records for each part of HBIM during the data collection and selection stages. The collected information includes data related to repair work, such as design books, repair reports, and supervision reports. Architectural heritage comprises diverse materials, and a distinct approach must be adopted for each component based on its type, material, and current state to preserve its historical value and authenticity. Repair history data should include detailed information regarding cause and effect, phenomena, and countermeasures for each component and be structured according to standardized principles and regulations. Such data can be used as evidence in decision-making processes for restoring architectural heritage in the future. Consistent object classification and attribute information input are necessary for ensuring interoperability and compatibility with other systems.

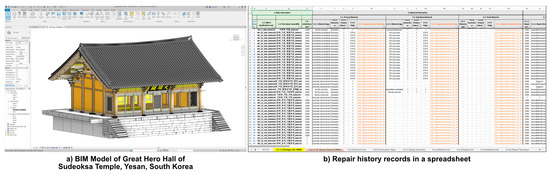

The data mapping automation system for the proposed integrated HBIM uses the repair history database of the Great Hero Hall of Sudeoksa Temple in Yesan, South Korea (Figure 5). The Great Hero Hall is the oldest wooden building in South Korea with a known foundation date, dating back to the Goryeo period (1308). It has a single-story gable roof design and features three front and four side compartments. In 1937, the building underwent a complete dismantling and subsequent repair, during which extensively damaged parts were replaced, and any elements that had been modified from their original style and shape at the time of construction were removed and restored to their original form wherever feasible [38]. The Great Hero Hall was designated as National Treasure No. 49 on 20 December 1962, in recognition of its well-preserved Goryeo wooden architectural form, which exudes aesthetic beauty.

Figure 5.

(a) BIM and (b) repair history records of the target heritage building.

The data mapping automation system for the proposed integrated HBIM in this study uses the repair history database of the Great Hero Hall of Sudeoksa Temple in Yesan, South Korea, which was constructed by the Far East Architectural History Lab (FAHL) at Hanyang University, South Korea, in accordance with HBIM Standard v1.1.3 of the Cultural Heritage Administration [32]. This database was created based on repair and maintenance data of archival materials, such as the compilation of repair history of the target building in 2020 by the National Research Institute of Cultural Heritage (Table 1). The database is classified into major, medium, small, and sub-classifications of the target architectural cultural heritage based on a classification system and comprises attribute information linking each part’s material and repair history information.

Table 1.

Detailed data entries in the repair history database according to the level of information (LOI).

The repair history database comprises fundamental information, material information, repair history, transformation and modification (T and M) history, and additional element information. Detailed data beyond the minimum expression level are input according to the level of information (LOI). The basic information includes the object classification code, part object name, and installation year, which represent the part’s information. The object classification code includes the part object name and index code according to the HBIM creation standards and serves as a reference parameter for mapping the HBIM configuration information and repair history record. Detailed explanations are provided in the subsequent section.

The material information consists of primary, subsidiary, and finish materials, which include information on the materials, production, and usage of each component, such as wood, stone, metal, and paper. The repair history, which is core information for the maintenance of architectural heritage, is divided into repair information before and after the 1900s. The reason why the information is divided based on the year 1900 is that most of the data before the 1900s are old documents or map data, with no detailed repair history records; however, there are records of investigations and dismantling as well as repair work of entire heritage buildings during the Japanese colonial period in the 1900s, and relatively detailed repair records have been maintained under the management of related organizations afterwards [39]. Therefore, repair history before 1900 is classified as LOI 3 information. Repair history since the 1900s, which is included from LOI 2, consists of the year of repair, repair type, such as replacement, reinforcement treatment, and preservation treatment, and damage types, such as physical, chemical, and biological damage. T and M history includes information on changes in style, shape, structure, technique, and materials based on investigations and historical evidence. Finally, additional element information is appended for cases requiring additional information due to the characteristics of the target heritage building. In the repair history database, repair information of architectural heritage is entered as structured data according to the categories described above, and the characteristic information of each component of HBIM is entered with integers for quantitative data and strings or URLs for qualitative data, depending on the type.

5.2. Data Mapping

5.2.1. Object Classification Code Generation

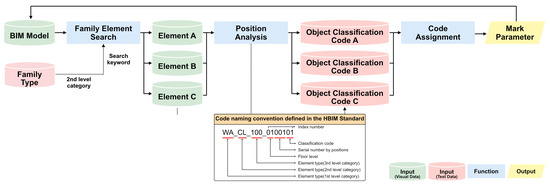

In order to link the shape information of architectural heritage constructed using BIM tools and information in the repair history database, a common rule parameter, referred to as the mark parameter, acts as a mediator between the two datasets. The repair history records of each corresponding part are retrieved from the database based on the value of the mark parameter input to each part of BIM following the same naming convention. An object classification code for each part, conforming to the definition of Historic BIM 1.1.3 [32], consisting of the element type constituting the building and a seven-digit index number, is then input into the mark parameter. Figure 6 depicts the process of mapping the object classification code to the mark parameter using the proposed automated data synchronization system.

Figure 6.

Automated code naming system generated with the Dynamo algorithm.

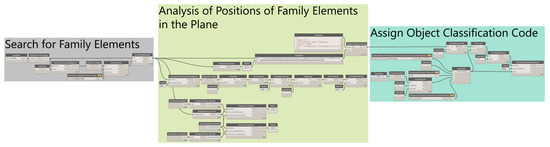

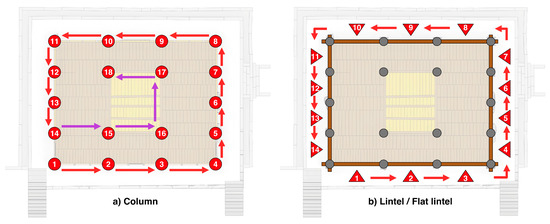

The algorithm is implemented using Dynamo, a visual scripting tool for Revit, as shown in Figure 7. Following the naming convention designated for each part family (a Revit family is a group of components used to build a BIM model with a common set of properties and a related graphical representation; for example, walls, doors, and fixtures) of the BIM model, the element type code from level 1 to 3 and the location information on the part plane are analyzed, and the index number is input. The index number consists of two digits for the floor-level information of the part, three digits for the serial number according to the location on the plane, and two digits for the classification number according to the aggregation type. The serial number is automatically assigned based on the X-, Y-, and Z-axis position information of each part and numbered per the HBIM preparation criteria, as shown in Figure 8, by assigning numbers in a counterclockwise direction based on the lowermost and outermost left of the target heritage building.

Figure 7.

Dynamo graph for generating object classification codes for the mark parameter.

Figure 8.

Example of the serial number assignment model for the (a) column and (b) lintel and flat lintel in accordance with the HBIM standard. Modified from the Cultural Heritage Administration [32].

5.2.2. Data Container Generation Using Shared Parameters

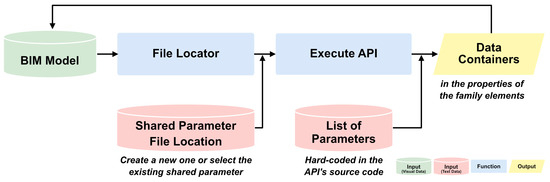

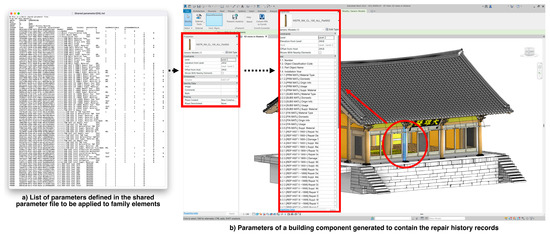

After assigning the object classification code for each part using Dynamo, a property information container is created to insert repair history records into BIM, organized in a spreadsheet format for each part. However, creating several identical parameters for all parts is a time-consuming task that can lead to spelling or ordering errors. To address this issue, the shared parameter function of Revit, which stores definitions in a text file, was used, reducing the likelihood of errors during repetitive tasks of parameter creation. To further streamline this process, an add-in was developed using the Revit API to quickly create the same parameter hierarchy for all parts using shared parameters (Figure 9).

Figure 9.

Pipeline for the API routine to generate parameters for the repair history record entries.

Autodesk Revit provides APIs based on the C# programming language that allow users to customize existing functions or add new ones, automating repetitive and time-consuming tasks in a BIM environment. This increases work efficiency, and standardized technology ensures fast execution speed as well as ease of use in any project after installation as if using a standard Revit function. With the proposed automated parameter creation system implemented as a Revit add-in, creating a set of parameters for entering repair history records for all parts of the project is as simple as clicking a command icon in the ribbon tab in the Revit program (Figure 10). Subsequent API operation is only necessary in the event of creating or adding a new family element to BIM.

Figure 10.

(a) Shared parameter file utilized by the developed add-in to generate (b) building element parameters.

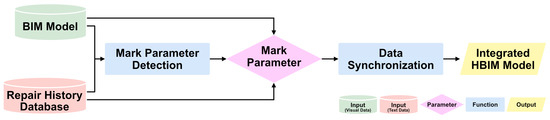

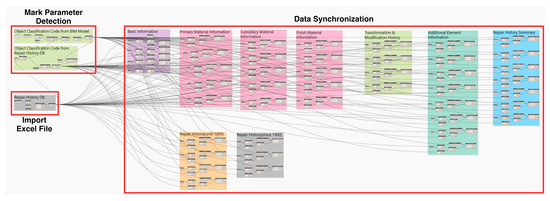

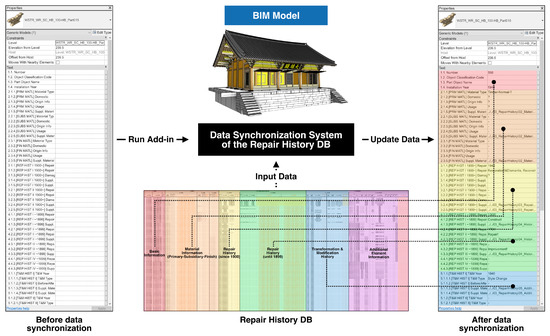

5.2.3. Data Synchronization for Repair History Records

An input automation algorithm utilizing Dynamo was developed to input repair history records organized in a spreadsheet into BIM (Figure 11 and Figure 12). The algorithm comprises two key functions for synchronizing the repair history records with BIM. The first function identifies the object classification code from both the mark parameter for each part in BIM and the repair history records stored in the Excel file. The second function synchronizes these two forms of data based on the common object classification code. These functions are implemented using a Python script node for reading the object classification codes and an import Excel node for incorporating textual data into BIM.

Figure 11.

Pipeline for the Dynamo routine to synchronize the repair history records and BIM.

Figure 12.

Dynamo graph to synchronize BIM with the repair history database.

The developed input automation algorithm is executed through the Dynamo player provided by the Revit program. When the user designates the Excel file and corresponding worksheet for the repair history database, the repair history information of the record matching the object classification code in the database is inputted collectively to each part of BIM (Figure 13). The repair history records entered as attribute information of BIM can be modified inside the BIM tool, and the repair history database can be updated by re-exporting them in an Excel file format.

Figure 13.

The outcome of the repair history record synchronization routine using Revit Dynamo.

5.3. Data Validation and Repair History Database Update

After automatically creating object classification codes and a shared parameter-based data container, the data between the repair history DB and BIM are synchronized. The integer- and string-based repair history records are input to each part of BIM. In this study, for BIM of the Great Hero Hall of Sudeoksa Temple, the developed data synchronization system for repair history records allowed for the entry of details on 1592 parts, covering 18 repair and maintenance projects since its establishment in 1308; however, some parts have no repair history and some details, such as the exact cause or type of repair, are omitted for partial repair and maintenance work. Hence, discovering relevant data in the future will require adding missing information or correcting incorrect information by updating both the repair history DB and BIM.

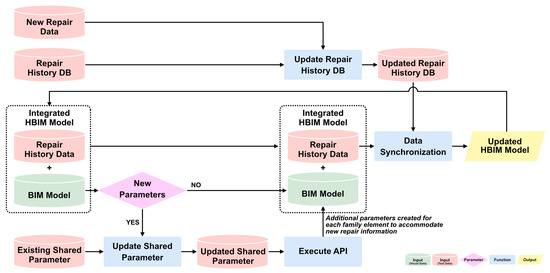

Wooden buildings have a high number of part types and volumes of data, making real-time interworking with the repair history database potentially hinder system performance. Therefore, in the proposed data synchronization system, the BIM data are updated based on the database only when the execute button is pressed. Conversely, the data updated in the BIM model can be exported to an Excel file through the export function to ensure data consistency and reliability of integrated HBIM.

When new maintenance and repair work is performed on architectural heritage, the first task is to verify whether new parameters are required to incorporate the new repair data into the family element of the existing integrated HBIM. If new parameters are needed, they should be appended to the pre-existing shared parameter file, followed by the operation of the developed API to update the data containers of HBIM. The parameter’s unique identifier (Global Unique Identifier, GUID: A unique identifier with a series of hexadecimal numbers assigned to every object in BIM. It serves as a unique reference to the object, which helps in the identification, tracking, and management of objects throughout the project lifecycle.) must remain unchanged by using the existing shared parameter file to avoid the risk of deletion due to overwriting the current parameter. Finally, new columns with the same parameter names should be added to the Excel spreadsheet to document the repair work’s contents. The proposed Dynamo should then be used to conduct data synchronization and update the integrated HBIM with the new repair history database (Figure 14).

Figure 14.

Proposed system’s pipeline for updating the repair history data of integrated HBIM with newly acquired repair information.

6. Results and Discussion

6.1. Application Case Scenarios for Building Maintenance Based on the Proposed HBIM

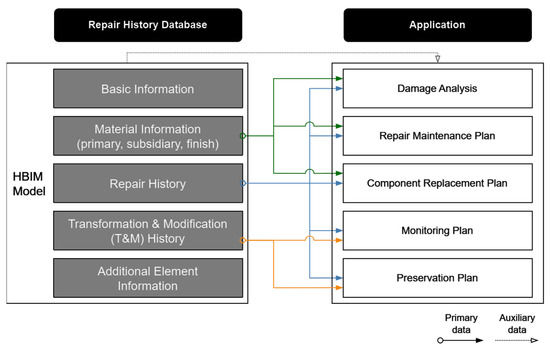

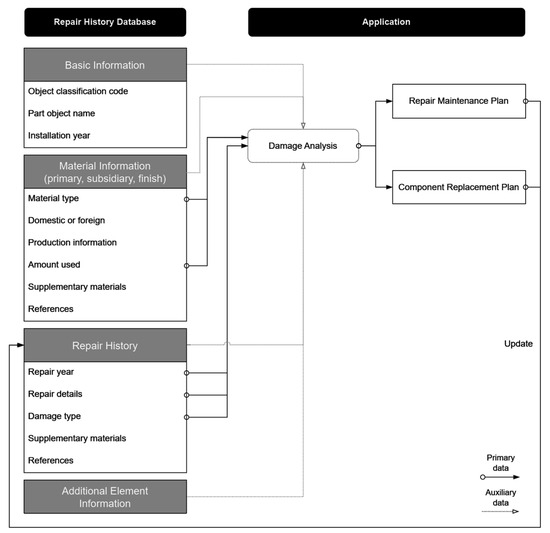

The proposed data synchronization system aims to enhance the preservation system and strengthen the value of architectural heritage. This is achieved through constructing a systematic data model by combining previously fragmented repair history records and integrating it with BIM. This can provide quantitative and qualitative evidence for the preservation and management master planning of architectural heritage assets [40]. Figure 15 shows the reconfiguration of the parameters of the repair history database (Table 1) for the repair and management planning of cultural heritage.

Figure 15.

Application scenario relationship diagram using the repair history database.

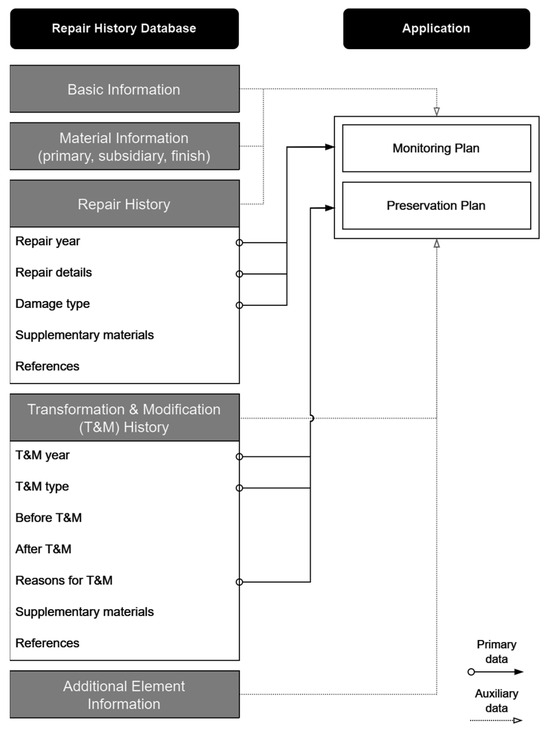

The HBIM repair history information can be used in two scenarios: developing a repair and replacement plan or developing a monitoring and preservation plan. Primary data for each application include material information, repair history, and T and M history. This information, along with basic information and additional element information, is also used as auxiliary data for each scenario to support the repair and preservation of cultural assets.

The initial scenario involves creating future conservation and monitoring plans based on past repair and replacement data (Figure 16). This includes repair history information, such as repair year, repair details, and damage type, as well as T and M data, such as T and M year, T and M type, and reasons for T and M, as primary data. Each piece of repair and T and M data can be used to determine the current state of each part, providing concrete evidence for the customized monitoring plans and preservation of similar parts.

Figure 16.

Application scenario for establishing a conservation and monitoring plan.

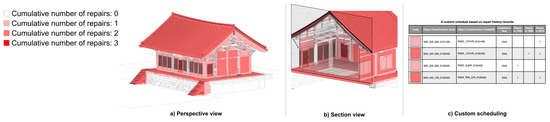

Quantitative and qualitative information can be conveyed through the use of shading colors based on their parameters. Figure 17 depicts a visual representation of the repair history records entered in the HBIM of the Great Hero Hall of Sudeoksa Temple. The data presented are based on repair history information after the 1900s, with the accumulated repair frequency data obtained through filtering the parameters corresponding to the repair year. This visualization of repair frequency data for each part of the architectural heritage, through the use of variables and data filtering functions in HBIM, can serve as basic data for the architectural heritage management entity in establishing an architectural heritage maintenance plan. Additionally, an architectural heritage repair company can utilize these data to determine the scope and repair method of heritage buildings by comparing HBIM with the on-site situation.

Figure 17.

Graphic visualizations based on the cumulative number of repairs of building components.

The second scenario is the most important application that utilizes information from the repair history database. It involves conducting a damage analysis based on past component-specific repair or T and M information to establish a repair or replacement plan for the component (Figure 18). This part emphasizes using the material information of the component to analyze the type and timing of damage, as well as detailed information about the damage. Integrating past repair and replacement information can expand the creation of an optimal repair and replacement suggestion system. The repair and replacement tasks conducted based on this information can be updated in the database to establish a sustainable repair and replacement system environment.

Figure 18.

Application scenario for establishing repair maintenance and component replacement plans based on a damage analysis.

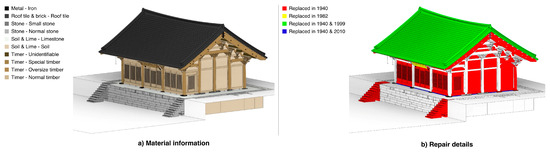

Figure 19 shows the causes of damage for different parts and their respective repair methods, using parameter filtering for damage types and main repair details. This integration of historical repair records into a unified information model helps architectural heritage managers identify whether new damage is part of a recurring issue, facilitating timely interventions.

Figure 19.

Graphic visualizations based on (a) the damage types and (b) repair details.

Figure 20 illustrates the correlation between the primary materials of parts and their replacement times, based on repair histories. This aids in the creation of a material replacement protocol and determining the lifespan of parts in accordance with heritage conservation guidelines. The information obtained serves as the foundation for quality standards in repairing heritage buildings, with a focus on material durability and strength. In the past, historical issue tracking was limited due to the absence of monitoring technologies; however, future advancements in repair technologies and continuous monitoring will enhance the accuracy of part replacement schedules and maintenance planning.

Figure 20.

Graphic visualizations based on (a) the material information and (b) corresponding repair details.

Table 2 represents the use of repair history records from a macro perspective to improve the architectural heritage maintenance system. It suggests setting repair standards and quality benchmarks for heritage components, using these as a basis for planning against natural and artificial degradation. This approach aims to build an advanced system tailored to various cultural heritage sites, covering diverse materials and forms beyond just wooden structures.

Table 2.

Potential applications of repair history records for enhancing the maintenance of architectural heritage.

The integration of cultural heritage data with information on humanities, society, and the natural environment offers an opportunity to create a collaborative digital twin-based system. This system facilitates cooperation among cultural heritage management entities, including administrations, agencies, and academics, to analyze repair histories and develop preventive strategies in a virtual space.

6.2. Results

Existing literature on BIM-based architectural heritage maintenance was reviewed, focusing on the use of maintenance data, and facility maintenance procedures were examined in accordance with BIM guidelines and case studies. Subsequently, a systematic development process for the management of architectural heritage facilities was formulated, spanning three stages: data collection and selection, mapping, and validation.

In the data collection and selection phase, standards and systems for the management of diverse data types in architectural heritage were established. These included the data composition system for the repair history database, object classification code generation standards, and BIM LOD and LOI standards. As a case study, structured repair history records of the Great Hero Hall of Sudeoksa Temple in Yesan, South Korea, were utilized, adhering to the Cultural Heritage Administration’s HBIM writing standards, with BIM following common family writing standards.

The data mapping stage, central to our repair history database linkage system, featured three core automation sub-systems using the Revit API and Dynamo. The first sub-system assigned object classification codes automatically to BIM elements through Dynamo, while the second sub-system generated a data container mirroring the repair history database using the Revit API. The third sub-system synchronized repair history database information in spreadsheets based on object classification codes through another Dynamo script. The system for creating data containers using the Revit API was originally planned to be developed on Dynamo in order to simplify the entire workflow; however, due to encoding errors, the development had to shift to the API. While both the Revit API and Dynamo have their advantages and disadvantages, using the Revit API made the system usage steps more complex but also improved usability by allowing the system to be operated through a simple click of a ribbon tab command icon; however, modifying the hardcoded shared parameter information in the API’s source code is difficult and poses a significant challenge to system maintenance. Therefore, it is necessary to simplify the entire process into a Dynamo-based automation system in the future, after correcting Revit’s inherent encoding bugs. In the data validation stage, repair history records entered into the integrated HBIM were re-exported to the database, concluding the core process of the BIM-based architectural heritage management system through data validation and modification by the database manager.

7. Conclusions

Architectural heritage stands as a vital cultural asset, offering insights into historical spatial perceptions, lifestyles, and aesthetic values. To ensure its preservation and management, a systematic, long-term approach based on clear standards and rational methods is imperative. Nonetheless, the dispersed and fragmented nature of historical records poses challenges for systematic information management. This research established a spreadsheet-based repair history database compliant with government agency standards for architectural heritage management and developed a novel BIM add-in to automate the integration of repair history records into architectural heritage BIM, facilitating the easy updating and management of part repair history data.

Efficiently maintaining and managing cultural heritage requires comprehensive records of repair processes, which can substantially increase the size of accumulated repair history records for each architectural heritage element over time. Given the already-substantial data in BIM, integrating repair history records may burden integrated HBIM. Therefore, our proposed framework advocates managing HBIM and repair records as distinct raw databases, using data synchronization systems to maintain data integrity. The three-step approach utilized in this stage, which involved data collection, mapping, and validation, is a crucial methodology for establishing a solid foundation for data-based system development. In particular, as demonstrated in this study, a three-step approach can efficiently and systematically achieve building a database based on historical information and developing an information management system for generating and managing specific tasks like repair and maintenance on this data foundation by tailoring this three-step approach to the specific field.

This research presents several scenarios for maintaining cultural heritage buildings based on HBIM parameters; it offers additional opportunities to develop an interoperable system for maintaining architectural heritage using HBIM and refined data classification systems. Furthermore, introducing a data-oriented framework that merges non-geometric details and formal information models enables HBIM to connect with a comprehensive knowledge base, enhancing preliminary planning and conservation design phases for architectural heritage; however, the use of repair history information from an Excel-based database has limitations in systematically and efficiently recording and managing cultural heritage inspections or repair details in the future. Therefore, there is a need to develop a system that can effectively record and manage information on regular inspections and repairs of cultural heritage. To study the development of a comprehensive HBIM-based facility management system, it is necessary to conduct a comprehensive comparison and analysis of inspection and repair protocols for cultural heritage established according to the characteristics of architectural cultural heritage in various countries, such as Monumentenwacht Flanders in Belgium [41]. In addition, a revolutionary approach to heritage preservation is possible through the integration of historical repair information with digital twin models augmented by virtual reality technologies. Future efforts should focus on the creation of seamless interfaces for data exchange, the use of augmented reality for the enriched visualization of historical interventions, and the use of predictive analytics for informed maintenance planning. Furthermore, a collaborative virtual platform, supported by the proposed protocol for the management of a preventive database, could improve the interaction between the conservation entities. Achieving this vision requires a pragmatic roadmap from government and related agencies to organize scattered architectural heritage information and maintain high-quality datasets through vigilant monitoring. This integrated approach promises not only to safeguard historical integrity but also to advance the efficiency and effectiveness of cultural heritage management, embodying a dynamic synthesis of past, present, and future conservation strategies.

Author Contributions

Conceptualization, J.J.P., S.-Y.J. and H.J.J.; methodology, J.J.P. and S.-Y.J.; software, K.K.; validation, J.J.P. and K.K.; investigation, J.J.P. and K.K.; resources, J.J.P. and K.K.; data curation, K.K.; writing—original draft preparation, J.J.P. and K.K.; writing—review and editing, J.J.P. and H.J.J.; visualization, J.J.P. and K.K.; supervision, H.J.J.; project administration, H.J.J.; funding acquisition, H.J.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2021R1I1A4A01056401).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are openly available in Zenodo at https://doi.org/10.5281/zenodo.7751291, https://doi.org/10.5281/zenodo.8378823, and https://doi.org/10.5281/zenodo.8387780.

Acknowledgments

The authors would like to thank FAHL for providing the repair history records of the Great Hero Hall of Sudeoksa Temple in Yesan.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Shin, B.-U. A Study on the Analysis of the Types of Displacement Occurring in Wooden Architecture Cultural Assets. J. Reg. Assoc. Archit. Inst. Korea 2019, 21, 79–89. [Google Scholar]

- Shin, B.-U. A Study on the Utilization of Documentation using BIM on Wooden Architectural Cultural Assets. J. Korean Inst. Rural Archit. 2019, 21, 25–36. [Google Scholar] [CrossRef]

- Lee, J.-H.; Jun, H.-J. A Study on the Adaptability of BIM-based Integrated Building Design Process in Domestic Architectural Design Firms. Korean Inst. Inter. Des. J. 2007, 16, 19–27. [Google Scholar]

- Murphy, M.; McGovern, E.; Pavia, S. Historic building information modelling (HBIM). Struct. Surv. 2009, 27, 311–327. [Google Scholar] [CrossRef]

- Adegoriola, M.I.; Lai, J.H.K.; Chan, E.H.; Darko, A. Heritage building maintenance management (HBMM): A bibliometric-qualitative analysis of literature. J. Build. Eng. 2021, 42, 102416. [Google Scholar] [CrossRef]

- Khan, M.S.; Khan, M.; Bughio, M.; Talpur, B.D.; Kim, I.S.; Seo, J. An Integrated HBIM Framework for the Management of Heritage Buildings. Buildings 2022, 12, 964. [Google Scholar] [CrossRef]

- ICOMOS. The Venice Charter. Available online: https://www.icomos.org/en/participer/179-articles-en-francais/ressources/charters-and-standards/157-thevenice-charter (accessed on 12 September 2023).

- The Australian ICOMOS. The Burra Charter. Available online: https://australia.icomos.org/publications/burra-charter-practice-notes/ (accessed on 12 September 2023).

- ICOMOS. The NARA Document on Authenticity. Available online: https://www.icomos.org/en/charters-and-texts/179-articles-en-francais/ressources/charters-and-standards/386-the-nara-document-on-authenticity-1994 (accessed on 12 September 2023).

- Hou, H.; Wu, H. A case study of facilities management for heritage building revitalisation. Facilities 2019, 38, 201–217. [Google Scholar] [CrossRef]

- Akcay, C.; Şolt, A.; Korkmaz, N.M.; Sayin, B. A proposal for the reconstruction of a historical masonry building constructed in Ottoman Era (Istanbul). J. Build. Eng. 2020, 32, 101493. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-based life cycle assessment and life cycle costing of an office building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bastem, S.S.; Cekmis, A. Development of historic building information modelling: A systematic literature review. Build. Res. Inf. 2021, 50, 527–558. [Google Scholar] [CrossRef]

- Brumana, R.; Della Torre, S.; Previtali, M.; Barazzetti, L.; Cantini, L.; Oreni, D.; Banfi, F. Generative HBIM modelling to embody complexity (LOD, LOG, LOA, LOI): Surveying, preservation, site intervention—The Basilica di Collemaggio (L’Aquila). Appl. Geomat. 2018, 10, 545–567. [Google Scholar] [CrossRef]

- Jordan-Palomar, I.; Tzortzopoulos, P.; García-Valldecabres, J.; Pellicer, E. Protocol to Manage Heritage-Building Interventions Using Heritage Building Information Modelling (HBIM). Sustainability 2018, 10, 908. [Google Scholar] [CrossRef]

- Piselli, C.; Guastaveglia, A.; Romanelli, J.; Cotana, F.; Pisello, A.L. Facility Energy Management Application of HBIM for Historical Low-Carbon Communities: Design, Modelling and Operation Control of Geothermal Energy Retrofit in a Real Italian Case Study. Energies 2020, 13, 6338. [Google Scholar] [CrossRef]

- Yusoff, S.N.S.; Brahim, J. Implementation of Building Information Modeling (BIM) for Social Heritage Buildings in Kuala Lumpur. Int. J. Sustain. Constr. Eng. Technol. 2021, 12, 88–99. [Google Scholar] [CrossRef]

- Calvano, M.; Martinelli, L.; Calcerano, F.; Gigliarelli, E. Parametric Processes for the Implementation of HBIM—Visual Programming Language for the Digitisation of the Index of Masonry Quality. ISPRS Int. J. Geo Inf. 2022, 11, 93. [Google Scholar] [CrossRef]

- Machete, R.; Silva, J.R.; Bento, R.; Falcão, A.P.; Gonçalves, A.B.; de Carvalho, J.M.L.; Silva, D.V. Information transfer between two heritage BIMs for reconstruction support and facility management: The case study of the Chalet of the Countess of Edla, Sintra, Portugal. J. Cult. Herit. 2021, 49, 94–105. [Google Scholar] [CrossRef]

- Pereira, Á.; Cabaleiro, M.; Conde, B.; Sánchez-Rodríguez, A. Automatic Identification and Geometrical Modeling of Steel Rivets of Historical Structures from Lidar Data. Remote Sens. 2021, 13, 2108. [Google Scholar] [CrossRef]

- Reinoso-Gordo, J.F.; Rodríguez-Moreno, C.; Gómez-Blanco, A.J.; León-Robles, C. Cultural Heritage Conservation and Sustainability Based on Surveying and Modeling: The Case of the 14th Century Building Corral del Carbón (Granada, Spain). Sustainability 2018, 10, 1370. [Google Scholar] [CrossRef]

- Croce, P.; Landi, F.; Puccini, B.; Martino, M.; Maneo, A. Parametric HBIM Procedure for the Structural Evaluation of Heritage Masonry Buildings. Buildings 2022, 12, 194. [Google Scholar] [CrossRef]

- Nieto-Julián, J.E.; Antón, D.; Moyano, J.J. Implementation and Management of Structural Deformations into Historic Building Information Models. Int. J. Arch. Herit. 2020, 14, 1384–1397. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Nieto-Julián, J.E.; Moyano, J.J.; Macías-Bernal, J.M.; Castro, J. Implementing artificial intelligence in H-BIM using the J48 algorithm to manage historic buildings. Int. J. Archit. Herit. 2019, 14, 1148–1160. [Google Scholar] [CrossRef]

- Mol, A.; Cabaleiro, M.; Sousa, H.S.; Branco, J.M. HBIM for storing life-cycle data regarding decay and damage in existing timber structures. Autom. Constr. 2020, 117, 103262. [Google Scholar] [CrossRef]

- Bruno, N.; Roncella, R. HBIM for Conservation: A New Proposal for Information Modeling. Remote Sens. 2019, 11, 1751. [Google Scholar] [CrossRef]

- Cuperschmid, A.R.M.; Fabricio, M.M.; Franco, J.C. HBIM Development of A Brazilian Modern Architecture Icon: Glass House by Lina Bo Bardi. Heritage 2019, 2, 1927–1940. [Google Scholar] [CrossRef]

- Colucci, E.; Iacono, E.; Matrone, F.; Ventura, G.M. The development of a 2D/3D BIM-GIS web platform for planned maintenance of built and cultural heritage: The MAIN10ANCE project. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2023, 48, 433–439. [Google Scholar] [CrossRef]

- Diara, F.; Rinaudo, F. ARK-BIM: Open-Source Cloud-Based HBIM Platform for Archaeology. Appl. Sci. 2021, 11, 8870. [Google Scholar] [CrossRef]

- Palomar, I.J.; Valldecabres, J.L.G.; Tzortzopoulos, P.; Pellicer, E. An online platform to unify and synchronise heritage architecture information. Autom. Constr. 2020, 110, 103008. [Google Scholar] [CrossRef]

- Cultural Heritage Administration. Historic BIM (HBIM) Standard v.1.1.3 [Unpublished report]; Cultural Heritage Administration: Daejeon, Republic of Korea, 2022. [Google Scholar]

- Koo, K.-J.; Park, S.-H.; Cho, D.-H. COBie Document Prototype for supporting BIM based Smart Maintenance of Buildings. J. Korea Acad. Ind. Coop. Soc. 2019, 20, 60–68. [Google Scholar] [CrossRef]

- Kim, D.Y. Data analysis for facility maintenance based on BIM—Case studies of facility maintenance based on BIM and practical process. J. KIBIM 2020, 10, 1–11. [Google Scholar] [CrossRef]

- Ministry of Land Infrastructure and Transport. Construction Industry BIM Basic Guideline; Jinhan M&B: Seoul, Republic of Korea, 2021. [Google Scholar]

- Kim, B.-G.; Kim, J.-W.; Ji, S.-G.; Seo, J.-W. A study on BIM guidelines for model-based infrastructure management. J. KIBIM 2012, 2, 10–16. [Google Scholar]

- IFMA. BIM for Facility Managers; Teicholz, P., Ed.; John Wiley & Sons, Inc.: Honoken, NJ, USA, 2013. [Google Scholar]

- Angulo-Fornos, R.; Castellano-Román, M. HBIM as Support of Preventive Conservation Actions in Heritage Architecture. Experience of the Renaissance Quadrant Façade of the Cathedral of Seville. Appl. Sci. 2020, 10, 2428. [Google Scholar] [CrossRef]

- National Research Institute of Cultural Heritage. Repair History Data Collection of Wooden Architectural Heritage: Great Hero Hall of Sudeoksa Temple, Yesan; National Research Institute of Cultural Heritage: Daejeon, Republic of Korea, 2020. [Google Scholar]

- Cultural Heritage Administration. Basic Plan for Conservation, Management, and Utilization of Cultural Properties; Cultural Heritage Administration: Daejeon, Republic of Korea, 2022. [Google Scholar]

- Wu, M.; van Laar, B. The Monumentenwacht model for preventive conservation of built heritage: A case study of Monumentenwacht Vlaanderen in Belgium. Front. Archit. Res. 2021, 10, 92–107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).