Development of a Hardware-in-the-Loop Platform for a Teleoperation Flexibility Robotic System

Abstract

1. Introduction

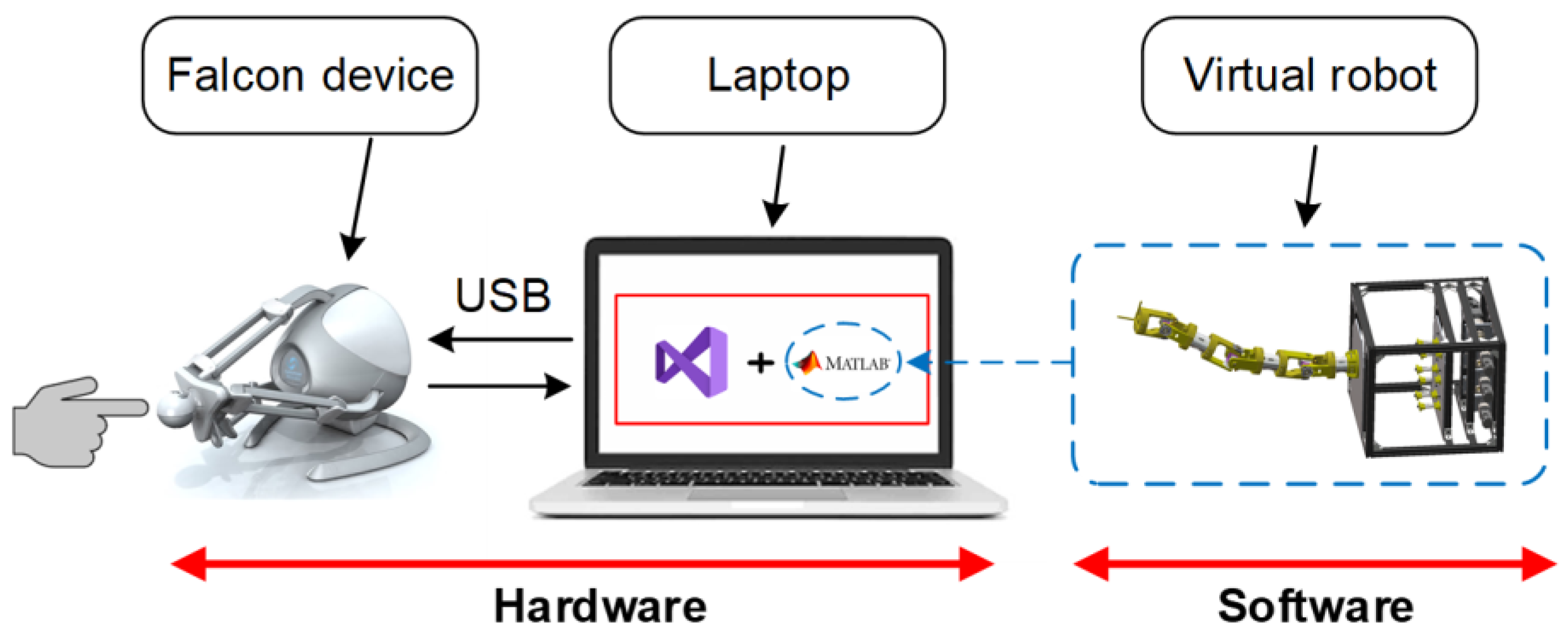

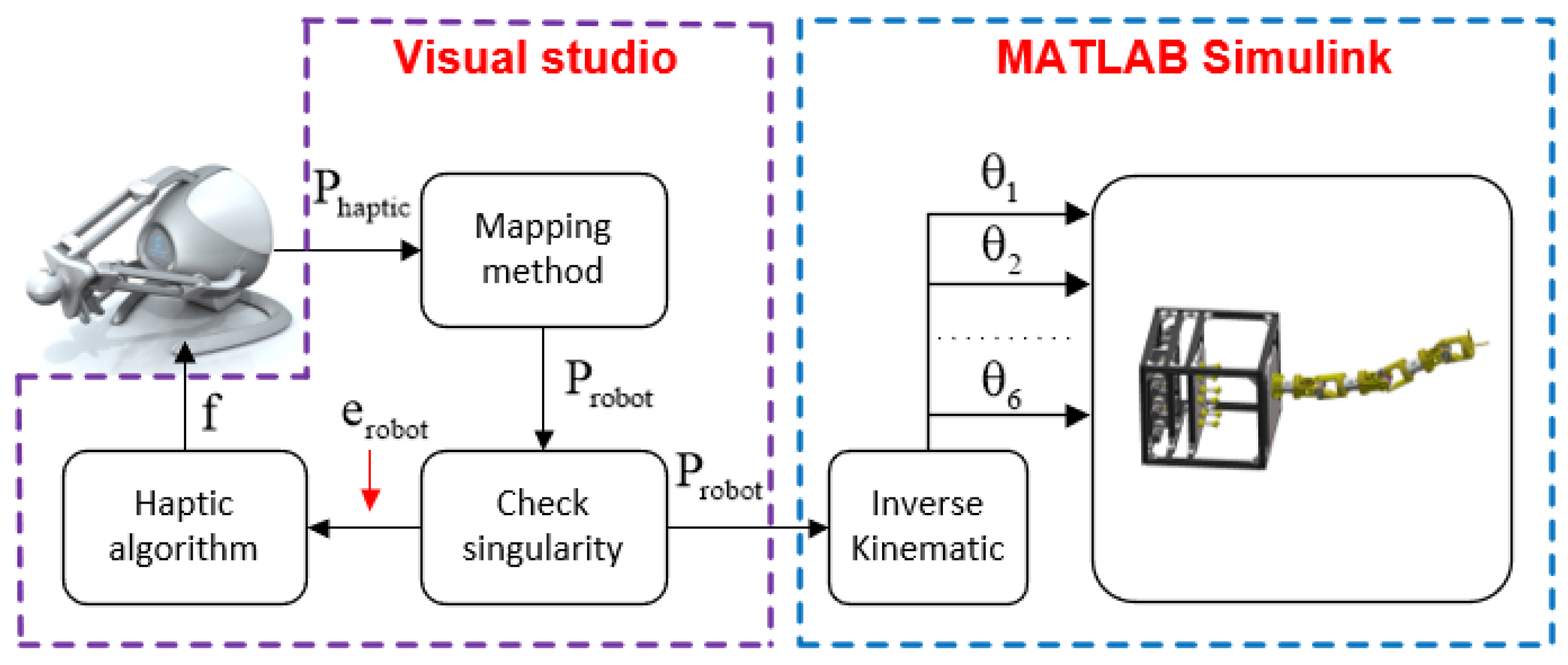

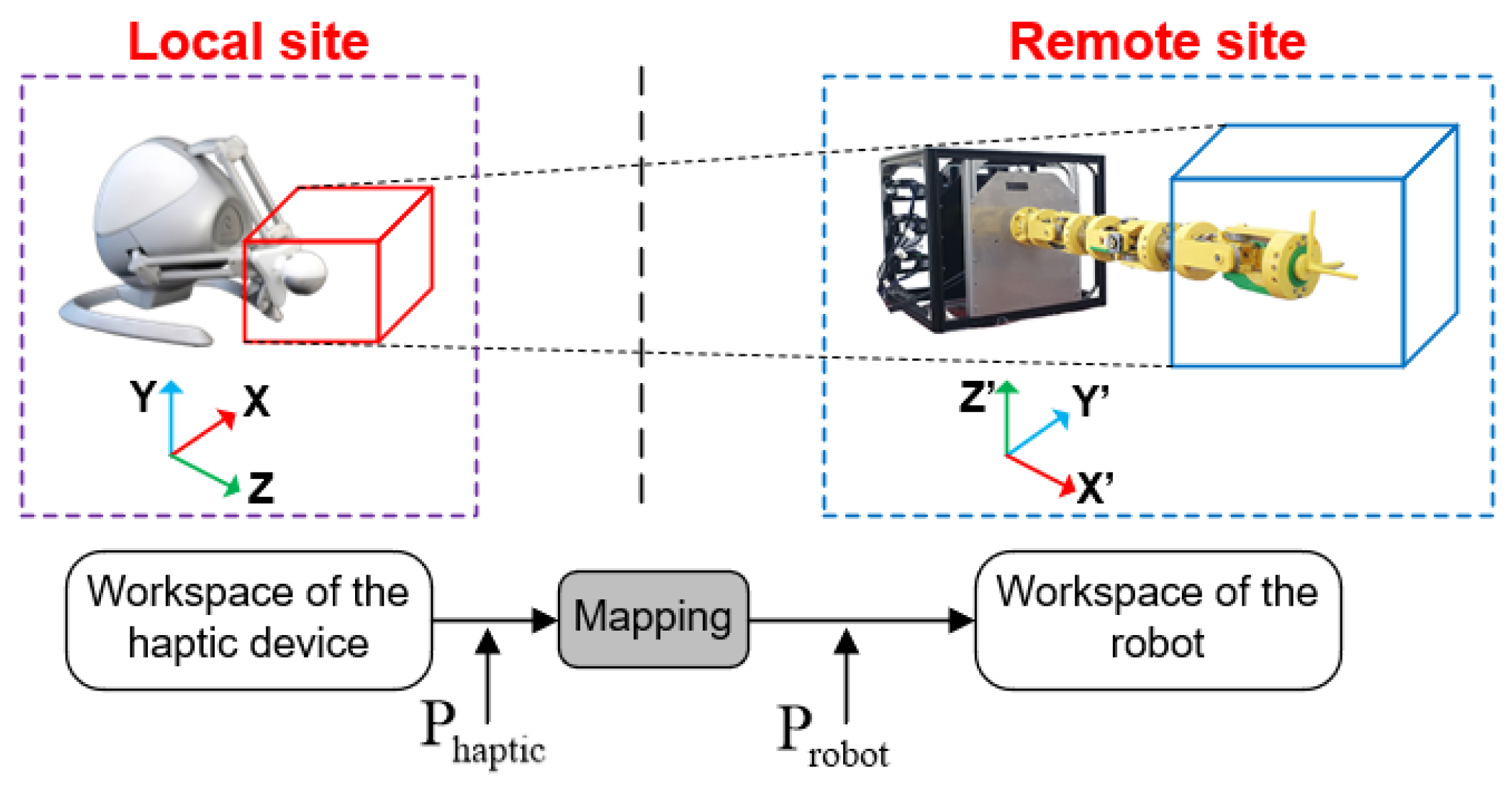

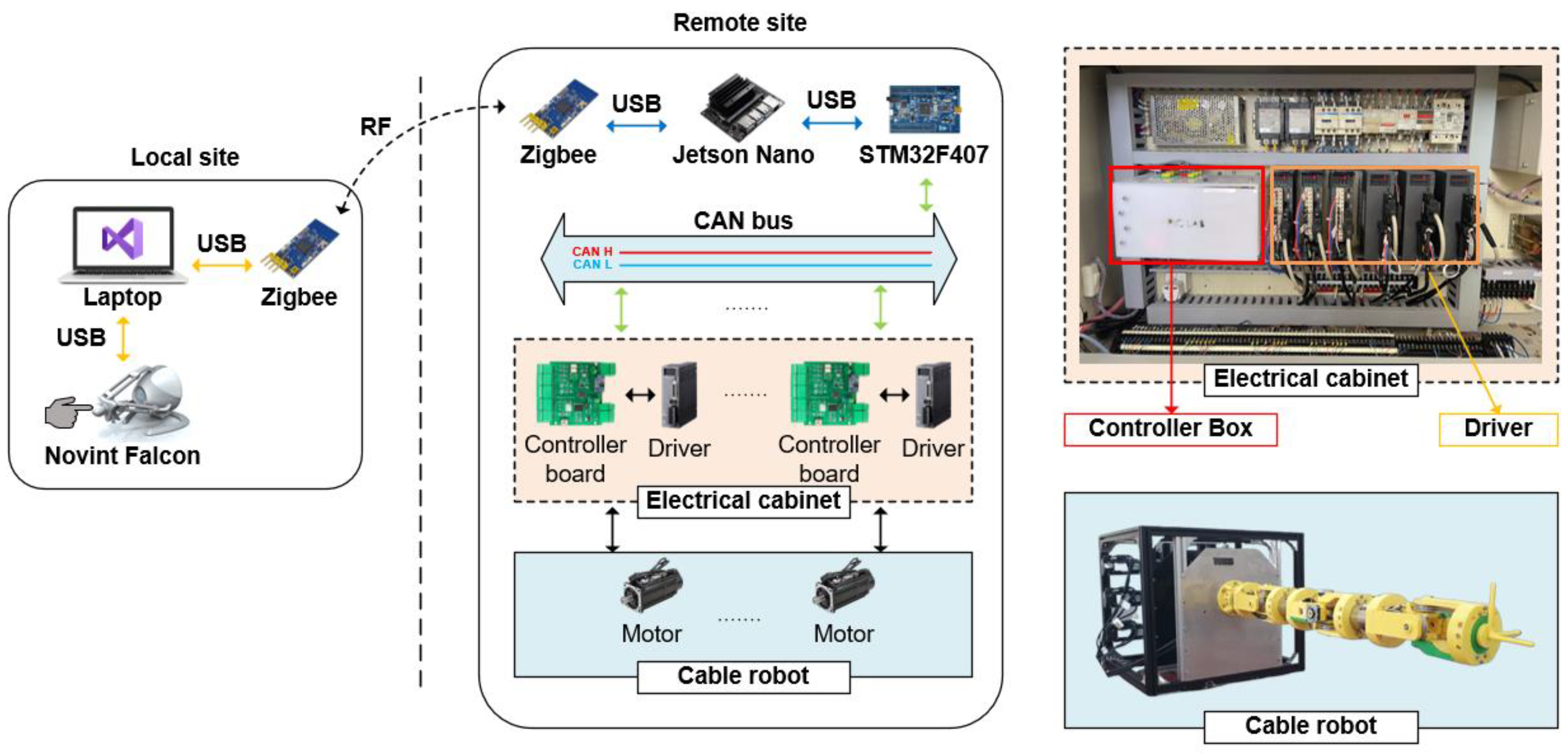

2. Description of HIL Simulation System

2.1. HIL Simulation System

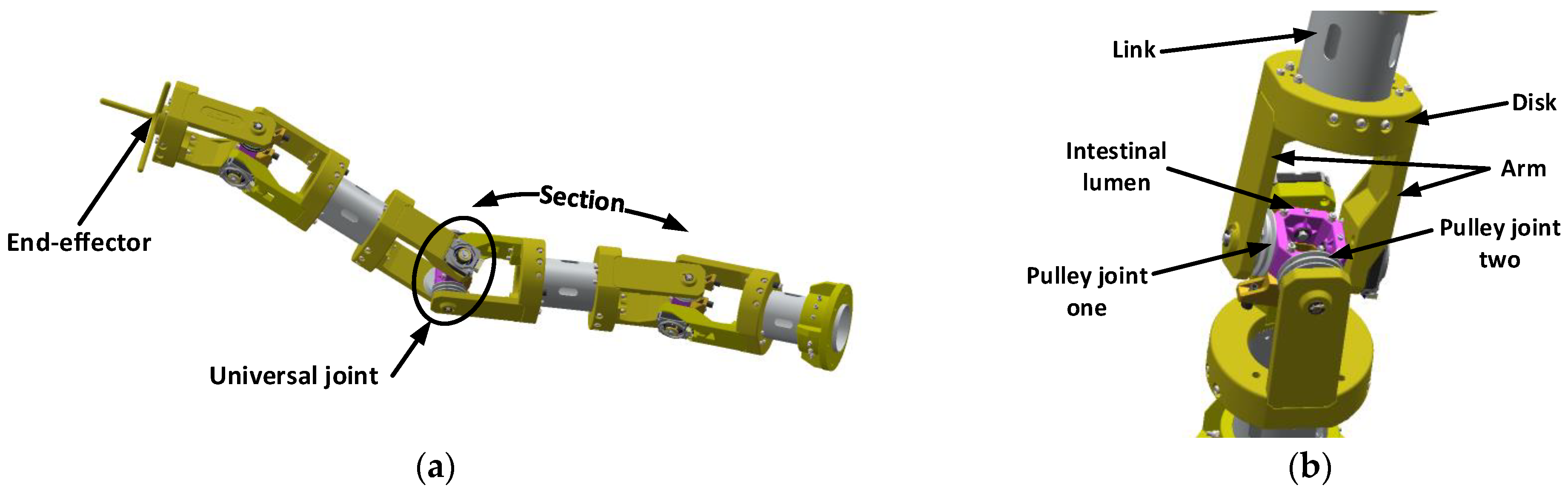

2.2. Mechanism Design of CDHR robot

2.3. Kinematics of Simulator

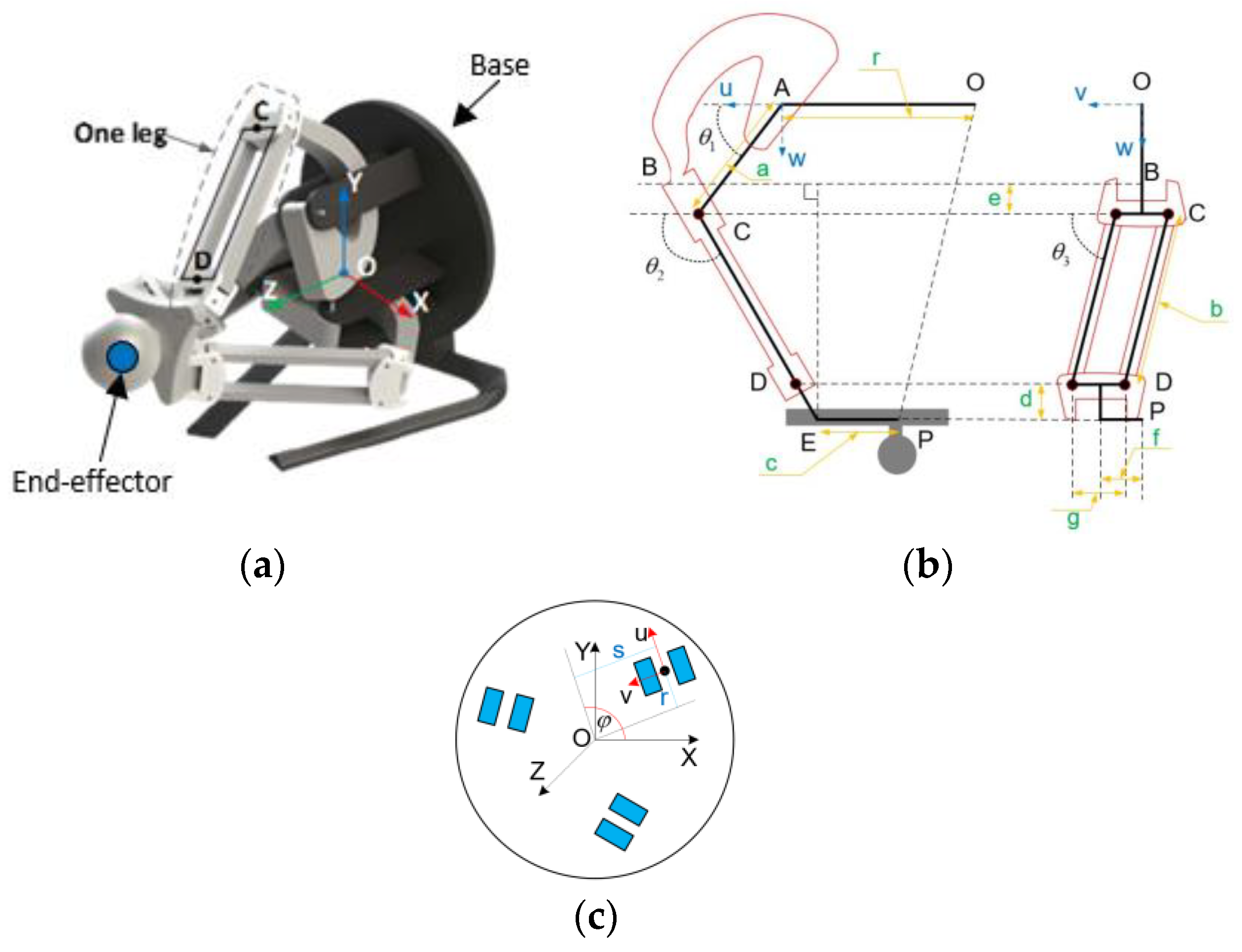

2.3.1. Slave Device

2.3.2. Master Device

3. Methodology

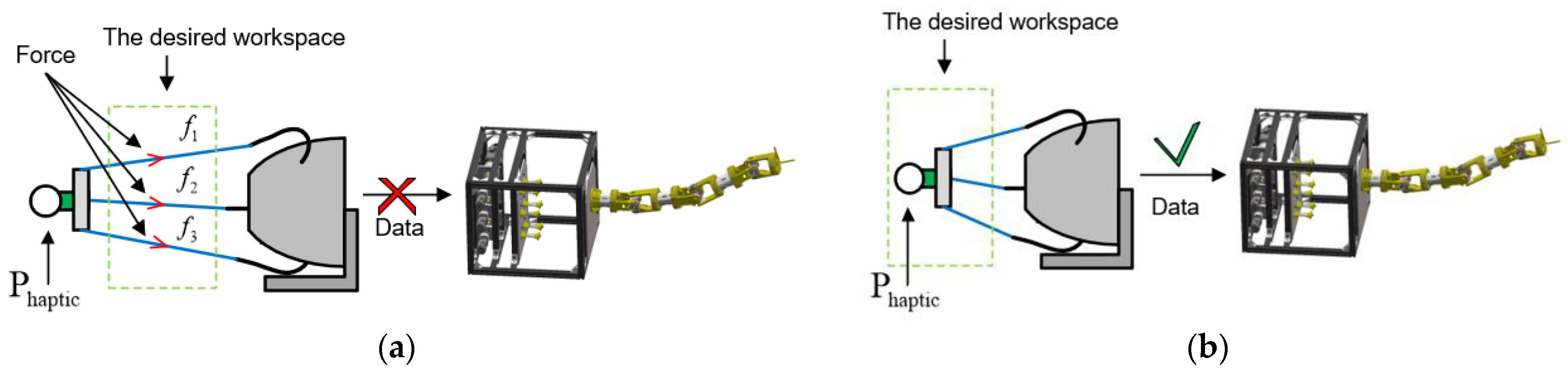

3.1. Position Mapping Method

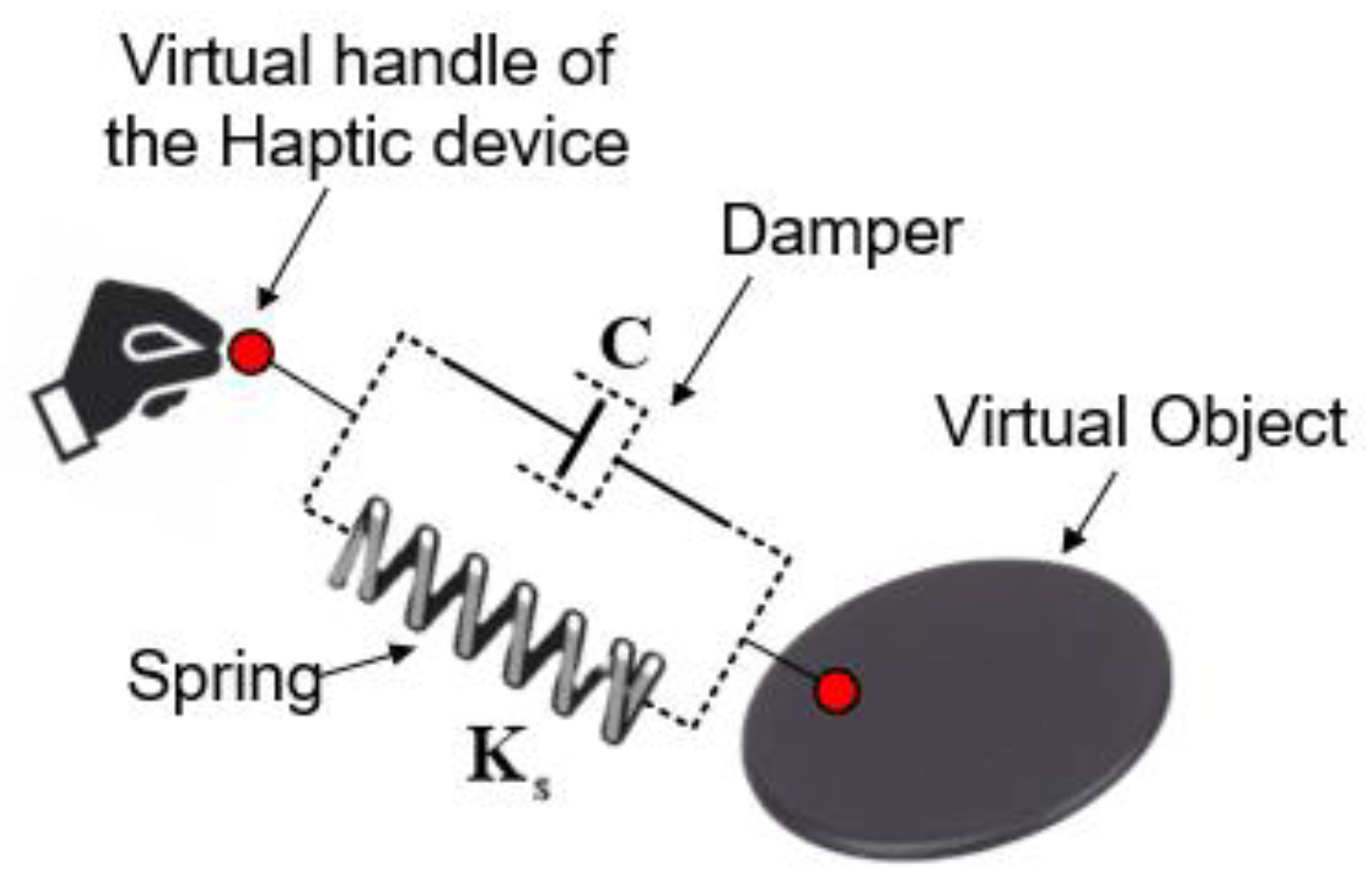

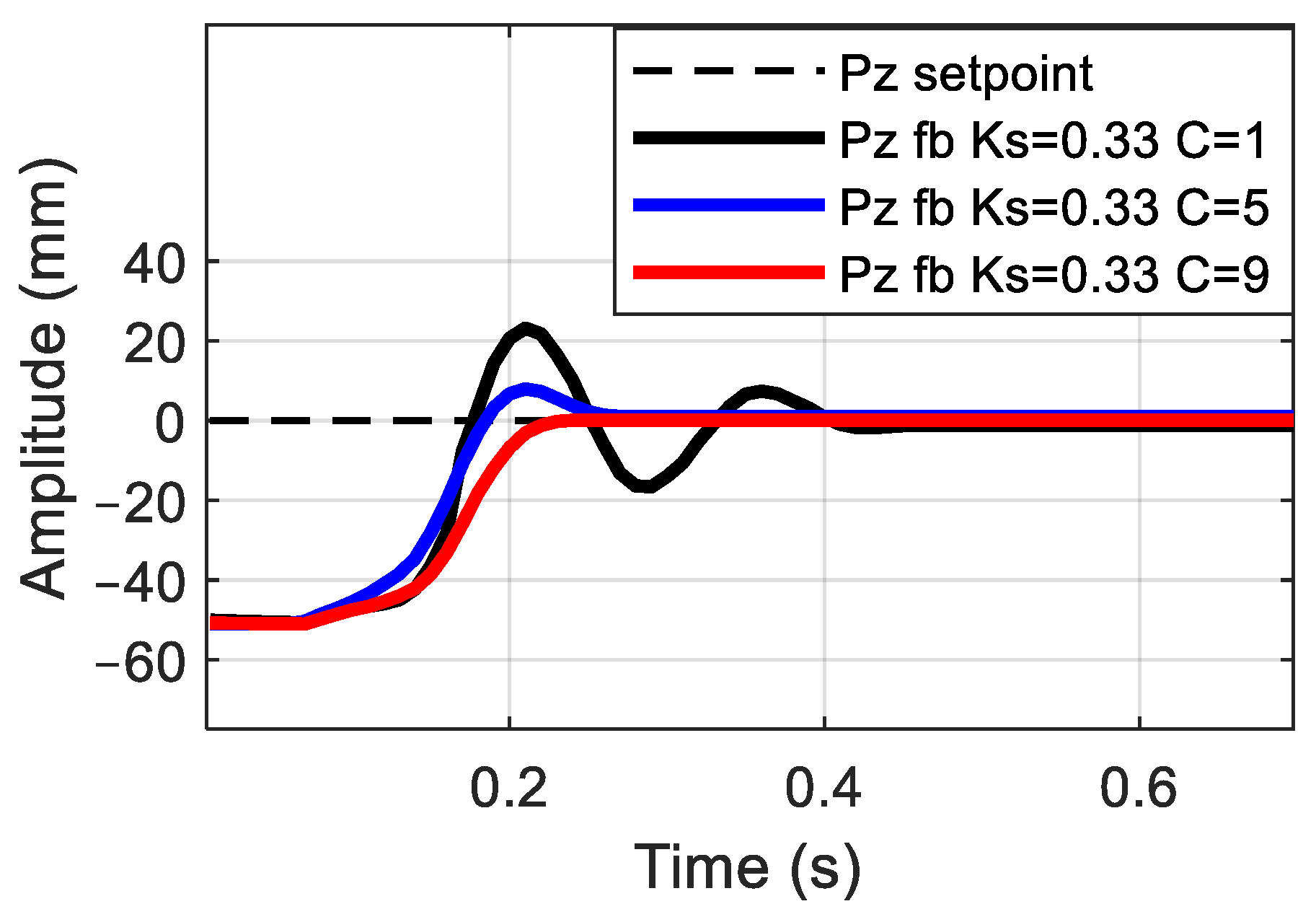

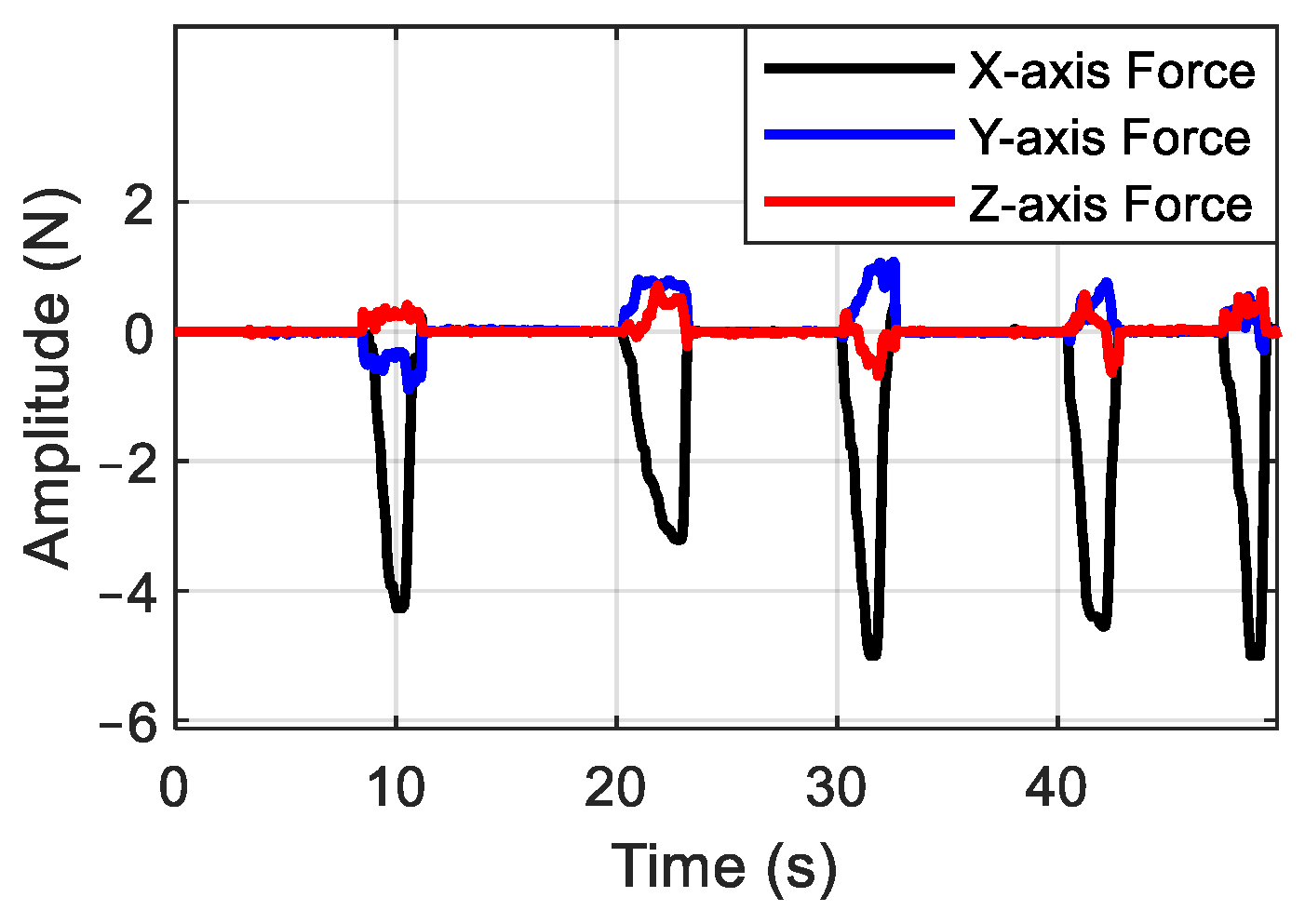

3.2. Haptic Algorithm

4. Simulations

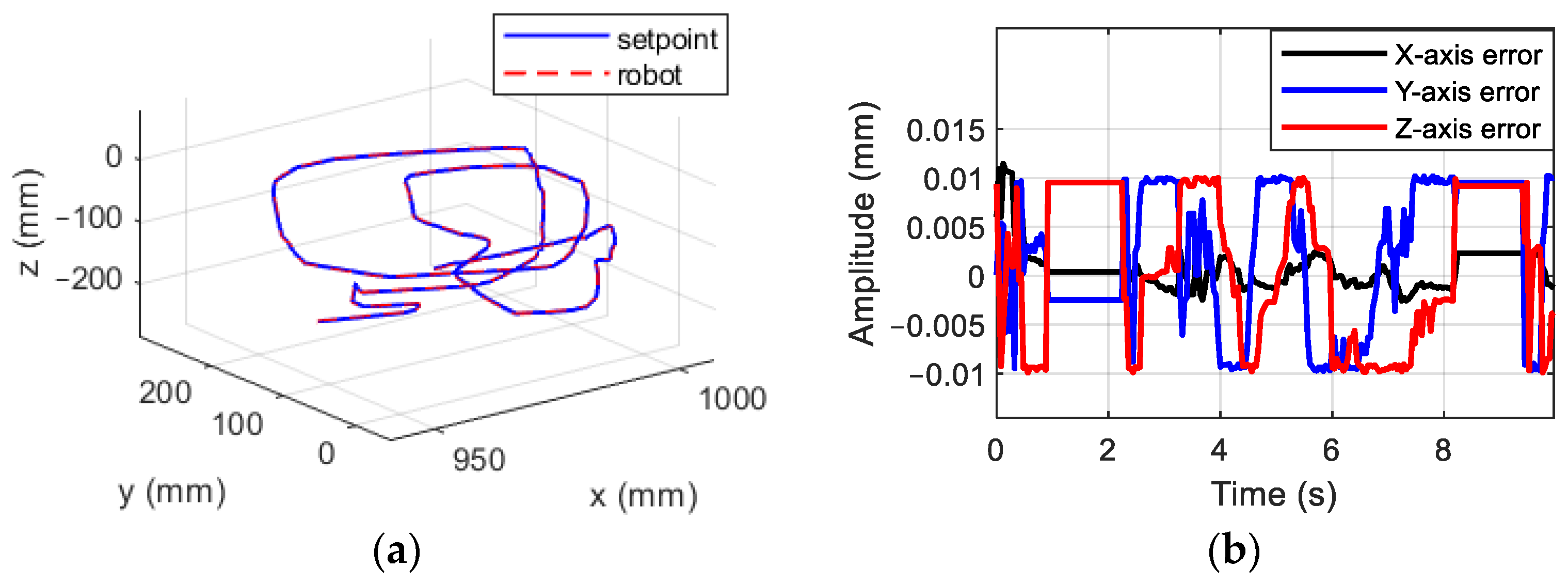

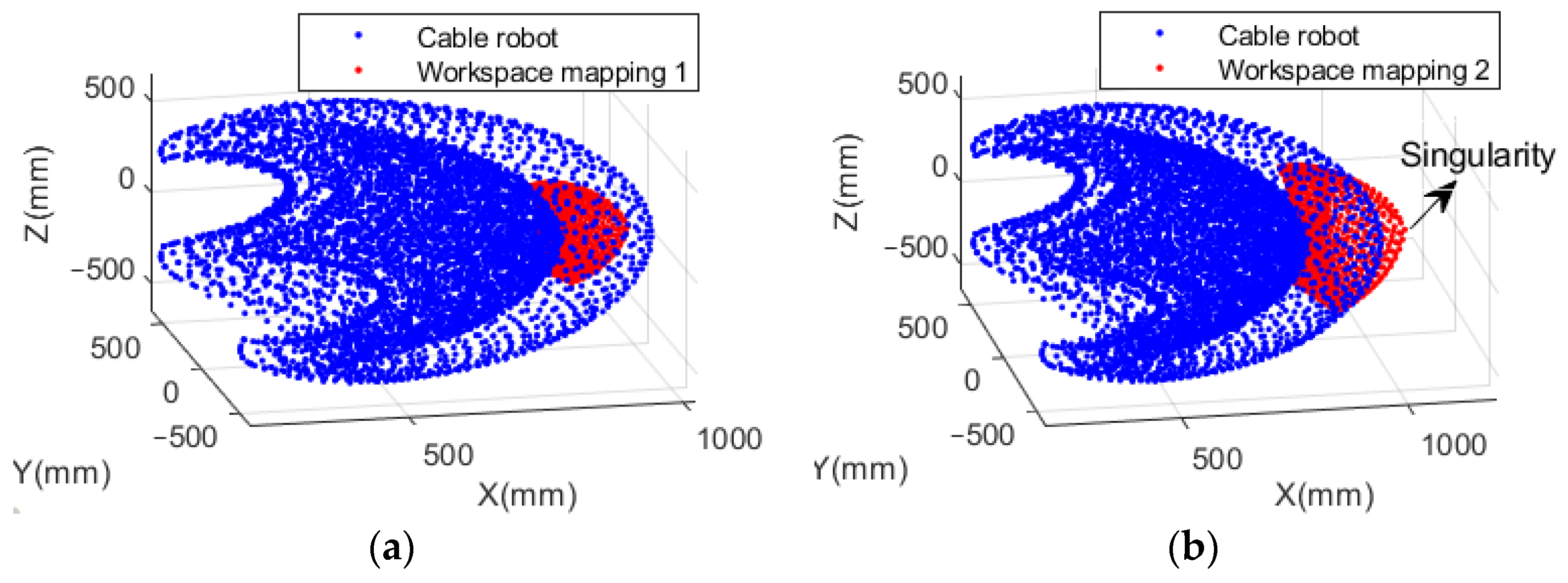

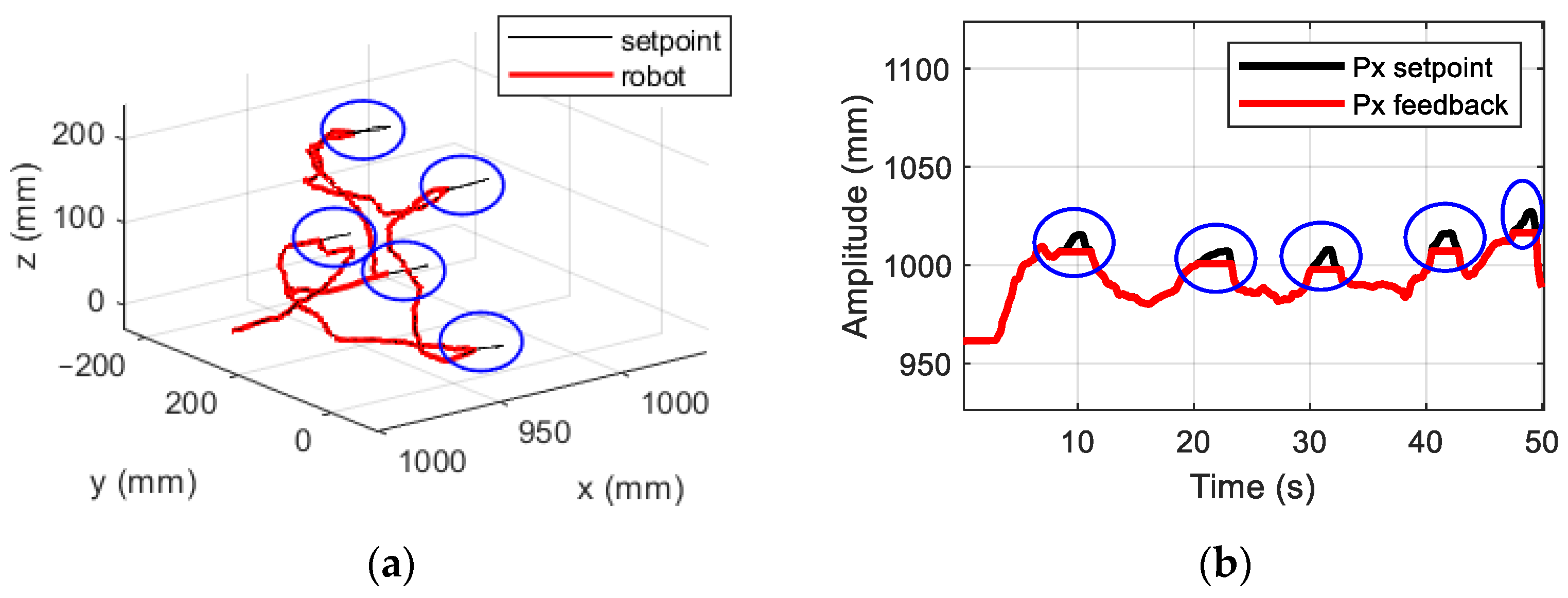

4.1. Verification Mapping Method

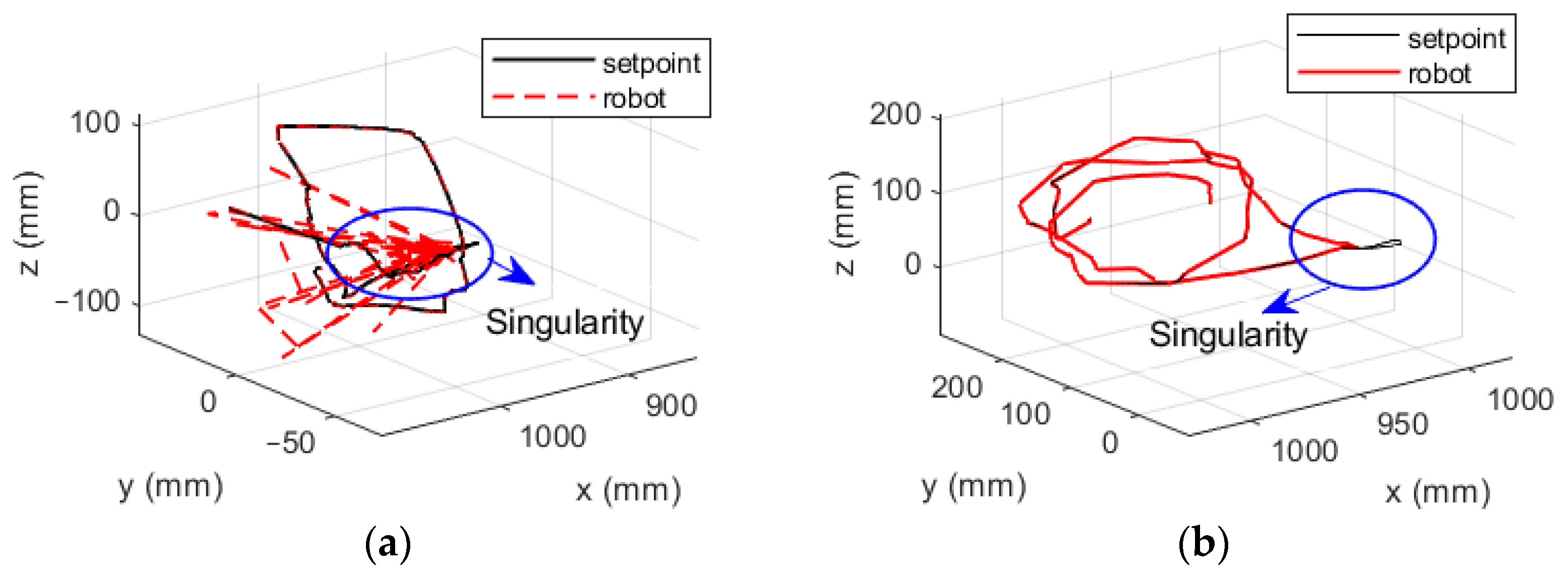

4.2. Teleoperation Simulation

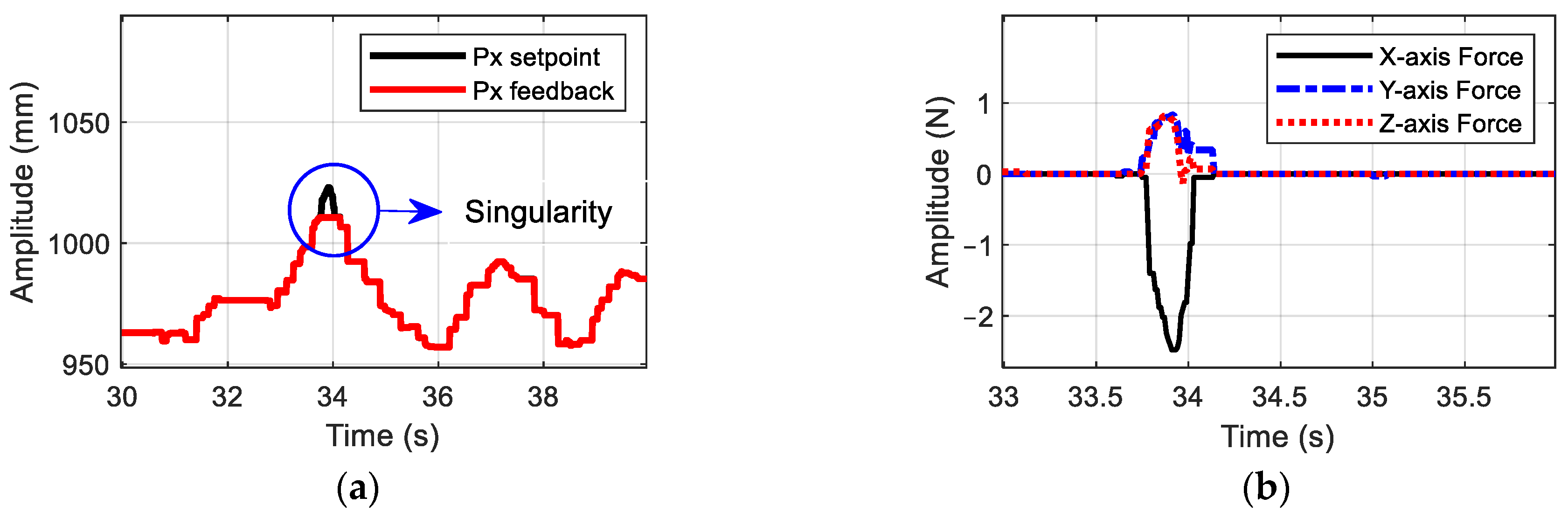

5. Experiments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nitendra Nath, T.; Darren, E.; Dawson, M. Teleoperation with Kinematically Redundant Robot Manipulators with Sub-Task Objectives. Robotica 2008, 27, 1027–1038. [Google Scholar] [CrossRef]

- Walker, M.E.; Hedayati, H.; Szafir, D. Robot Teleoperation with Augmented Reality Virtual Surrogates. In Proceedings of the 4th ACM/IEEE International Conference on Human-Robot Interaction (HRI), La Jolla, CA, USA, 9–13 March 2019. [Google Scholar] [CrossRef]

- Scibilia, A.; Pedrocchi, N.; Fortuna, L. Modeling Nonlinear Dynamics in Human–Machine Interaction. IEEE Access 2023, 11, 58664–58678. [Google Scholar] [CrossRef]

- Da Sun, F.N.; Du, H. Application of Wave-Variable Control to Bilateral Teleoperation Systems: A Survey; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Linping Chan, F.N.; Stirling, D. Application of adaptive controllers in teleoperation systems: A survey. IEEE Trans. Hum. Mach. Syst. 2014, 45, 1–12. [Google Scholar] [CrossRef]

- Fiorini, R.M.A.P. A Review of Bilateral Teleoperation Algorithms. Acta Polytech. Hung. 2016, 13, 191–208. [Google Scholar]

- Liu, Y.-C.; Chopra, N. Control of semi-autonomous teleoperation system with time delays. Automatica 2013, 49, 1553–1565. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, S.; Yu, X.; Kong, L.; Li, Q.; Li, G. Adaptive Neural Network Fixed-Time Control Design for Bilateral Teleoperation with Time Delay. IEEE Trans. Cybern. 2021, 52, 9756–9769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Song, A.; Shen, S. Adaptive Finite-Time Control Scheme for Teleoperation with Time-Varying Delay and Uncertainties. IEEE Trans. Syst. 2018, 6, 40940–40949. [Google Scholar] [CrossRef]

- Lu, S.; Ban, Y.; Zhang, X.; Yang, B.; Liu, S.; Yin, L.; Zheng, W. Adaptive control of time delay teleoperation system with uncertain dynamics. Percept. Recovery Augment. Med. Robot. 2022, 16, 928863. [Google Scholar] [CrossRef] [PubMed]

- Martín-Barrio, A.; Roldán, J.J.; Terrile, S.; Del Cerro, J.; Barrientos, A. Application of immersive technologies and natural language to hyper-redundant robot teleoperation. Virtual Real. 2019, 4, 541–555. [Google Scholar] [CrossRef]

- Tran, D.T.; Tran, T.L.; Duong, M.T.; Dao, H.V.; Ahn, K.K. The CCD-Algebraic Algorithm to solve the inverse kinematic and control the rotation of 6-DOF redundant manipulator in three spatial dimensions. In Proceedings of the 2022 25th International Conference on Mechatronics Technology (ICMT), Kaohsiung, Taiwan, 18–21 November 2022; pp. 1–6. [Google Scholar]

- Lv, H.; Pang, Z.; Bhimavarapu, K.; Yang, G. Impacts of Wireless on Robot Control: The Network Hardware-in-the-Loop Simulation Framework and Real-Life Comparisons. IEEE Trans. Ind. Inform. 2023, 19, 9255–9265. [Google Scholar] [CrossRef]

- Qi, C.; Ren, A.; Gao, F.; Zhao, X.; Wang, Q.; Sun, Q. Compensation of Velocity Divergence Caused by Dynamic Response for Hardware-in-the-Loop Docking Simulator. IEEE/ASME Trans. Mechatron. 2016, 22, 422–432. [Google Scholar] [CrossRef]

- He, J.; Shen, M. Hybrid Force/Velocity Control for Simulating Contact Dynamics of Satellite Robots on a Hardware-in-the-Loop Simulator. IEEE Access 2022, 10, 59277–59289. [Google Scholar] [CrossRef]

- He, J.; Shen, M.; Gao, F. A Passivity-Based Velocity Control Method of Hardware-in-the-Loop Simulation for Space Robotic Operations. Aerospace 2022, 9, 368. [Google Scholar] [CrossRef]

- Nabi, S.; Balike, M.; Allen, J.; Rzemien, K. An Overview of Hardware-In-the-Loop Testing Systems at Visteon. In Proceedings of the SAE 2004 World Congress & Exhibition, Sydney, Australia, 17–21 May 2004. [Google Scholar] [CrossRef]

- Barreras, J.V.; Fleischer, C.; Christensen, A.E.; Swierczynski, M.; Schaltz, E.; Andreasen, S.J.; Sauer, D.U. An Advanced HIL Simulation Battery Model for Battery Management System Testing. IEEE Trans. Ind. Appl. 2016, 52, 5086–5099. [Google Scholar] [CrossRef]

- Mihalič, F.; Truntič, M.; Hren, A. Hardware-in-the-Loop Simulations: A Historical Overview of Engineering Challenges. Electronics 2022, 11, 2462. [Google Scholar] [CrossRef]

- Herrmann, S.; Kluess, D.; Kaehler, M.; Grawe, R.; Rachholz, R.; Souffrant, R.; Zierath, J.; Bader, R.; Woernle, C. A Novel Approach for Dynamic Testing of Total Hip Dislocation under Physiological Conditions. PLoS ONE 2015, 10, e0145798. [Google Scholar] [CrossRef] [PubMed]

- Inés Tejado, J.S.; Pérez, E.; Torres, D.; Blas, M. Vinagre, Low-cost Hardware-in-the-loop Testbed of a Mobile Robot to Support Learning in Automatic Control and Robotics. ScienceDirect 2016, 49, 242–247. [Google Scholar]

- Fedak, V.; Durovsky, F.; Uveges, R.; Kyslan, K.; Lacko, M. HIL Simulator of Drives of an Industrial Robot with 6 DOF. Elektron. Elektrotech. 2015, 21, 14–19. [Google Scholar] [CrossRef]

- Mora-Soto, M.E.; Maldonado-Romo, J.; Rodríguez-Molina, A.; Aldape-Pérez, M. Building a Realistic Virtual Simulator for Unmanned Aerial Vehicle Teleoperation. Appl. Sci. 2021, 11, 12018. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Nguyen, T.N.T.; Tong, H.N.; Truong, H.V.A.; Tran, D.T. Dynamic Parameter Identification based on the Least Squares method for a 6-DOF Manipulator. In Proceedings of the 2023 International Conference on System Science and Engineering (ICSSE), Ho Chi Minh, Vietnam, 27–28 July 2023; pp. 301–305. [Google Scholar]

- Tran, D.T.; Nguyen, T.L.; Ha, T.T.; Hoang, H. Design Model and Synchronous Controllers for a Dual 3-DOF Manipulator based on CAN Network. In Proceedings of the 2023 International Conference on System Science and Engineering (ICSSE), Ho Chi Minh, Vietnam, 27–28 July 2023; pp. 287–291. [Google Scholar]

- Tran, M.P.; Ha, T.B.; Tong, H.N.; Duc, T.T. Nonlinear Controller with Dynamic Compensation for 6-DOF Manipulator in Practice. J. Tech. Educ. Sci. 2023, 75, 31–39. [Google Scholar] [CrossRef]

- Karbasizadeh, N.; Zarei, M.; Aflakian, A.; Masouleh, M.T.; Kalhor, A. Experimental dynamic identification and model feed-forward control of Novint Falcon haptic device. Mechatronics 2018, 51, 19–30. [Google Scholar] [CrossRef]

- Delta Robot Kinematics. Available online: https://hypertriangle.com/~alex/delta-robot-tutorial/ (accessed on 27 July 2009).

- Mokogwu, C.N.; Hashtrudi-Zaad, K. A hybrid position–rate teleoperation system. Robot. Auton. Syst. 2021, 141, 103781. [Google Scholar] [CrossRef]

- Ju, Z.; Yang, C.; Li, Z.; Cheng, L.; Ma, H. Teleoperation of humanoid baxter robot using haptic feedback. In Proceedings of the 2014 International Conference on Multisensor Fusion and Information Integration for Intelligent Systems (MFI), Beijing, China, 28–29 September 2014; pp. 1–6. [Google Scholar]

- Qin, L.; Huang, F.; Chen, Z.; Song, W.; Zhu, S. Teleoperation Control Design with Virtual Force Feedback for the Cable-Driven Hyper-Redundant Continuum Manipulator. Appl. Sci. 2020, 10, 8031. [Google Scholar] [CrossRef]

| (mm) | (Degrees) | (mm) | (Degrees) | Joint Limit (Degrees) | |

|---|---|---|---|---|---|

| 1 | 90 | 0 | −30 to 30 | ||

| 2 | 0 | −90 | 0 | −30 to 30 | |

| 3 | 90 | 0 | −45 to 45 | ||

| 4 | 0 | −90 | 0 | −45 to 45 | |

| 5 | 90 | 0 | −45 to 45 | ||

| 6 | 0 | −90 | 0 | −45 to 45 | |

| 7 | 0 | 0 | 0 | 0 |

| No. | B (mm) | (10−5 mm) | (10−5 mm) | (10−5 mm) |

|---|---|---|---|---|

| 1 | [900; 0; 0] | 0.9130 | 0.5629 | −0.7353 |

| 2 | [900; 10; −10] | 0.9136 | 0.5788 | −0.7519 |

| 3 | [900; −10; 10] | 0.9133 | 0.5474 | −0.7189 |

| 4 | [900; 20; 10] | 0.9170 | 0.6014 | −0.7176 |

| 5 | [900; 10; 40] | 0.9191 | 0.5911 | −0.6683 |

| The Parameter Set 1 | Value | The Parameter Set 2 | Value |

|---|---|---|---|

| Pw |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, D.T.; Nguyen, T.D.; Tran, M.K.; Ahn, K.K. Development of a Hardware-in-the-Loop Platform for a Teleoperation Flexibility Robotic System. Appl. Sci. 2024, 14, 2207. https://doi.org/10.3390/app14052207

Tran DT, Nguyen TD, Tran MK, Ahn KK. Development of a Hardware-in-the-Loop Platform for a Teleoperation Flexibility Robotic System. Applied Sciences. 2024; 14(5):2207. https://doi.org/10.3390/app14052207

Chicago/Turabian StyleTran, Duc Thien, Tien Dat Nguyen, Minh Khiem Tran, and Kyoung Kwan Ahn. 2024. "Development of a Hardware-in-the-Loop Platform for a Teleoperation Flexibility Robotic System" Applied Sciences 14, no. 5: 2207. https://doi.org/10.3390/app14052207

APA StyleTran, D. T., Nguyen, T. D., Tran, M. K., & Ahn, K. K. (2024). Development of a Hardware-in-the-Loop Platform for a Teleoperation Flexibility Robotic System. Applied Sciences, 14(5), 2207. https://doi.org/10.3390/app14052207