Fatigue of Bridge Steel Wire: A Corrosion Pit Evolution Model under the Effects of Wind and Vehicles

Abstract

1. Introduction

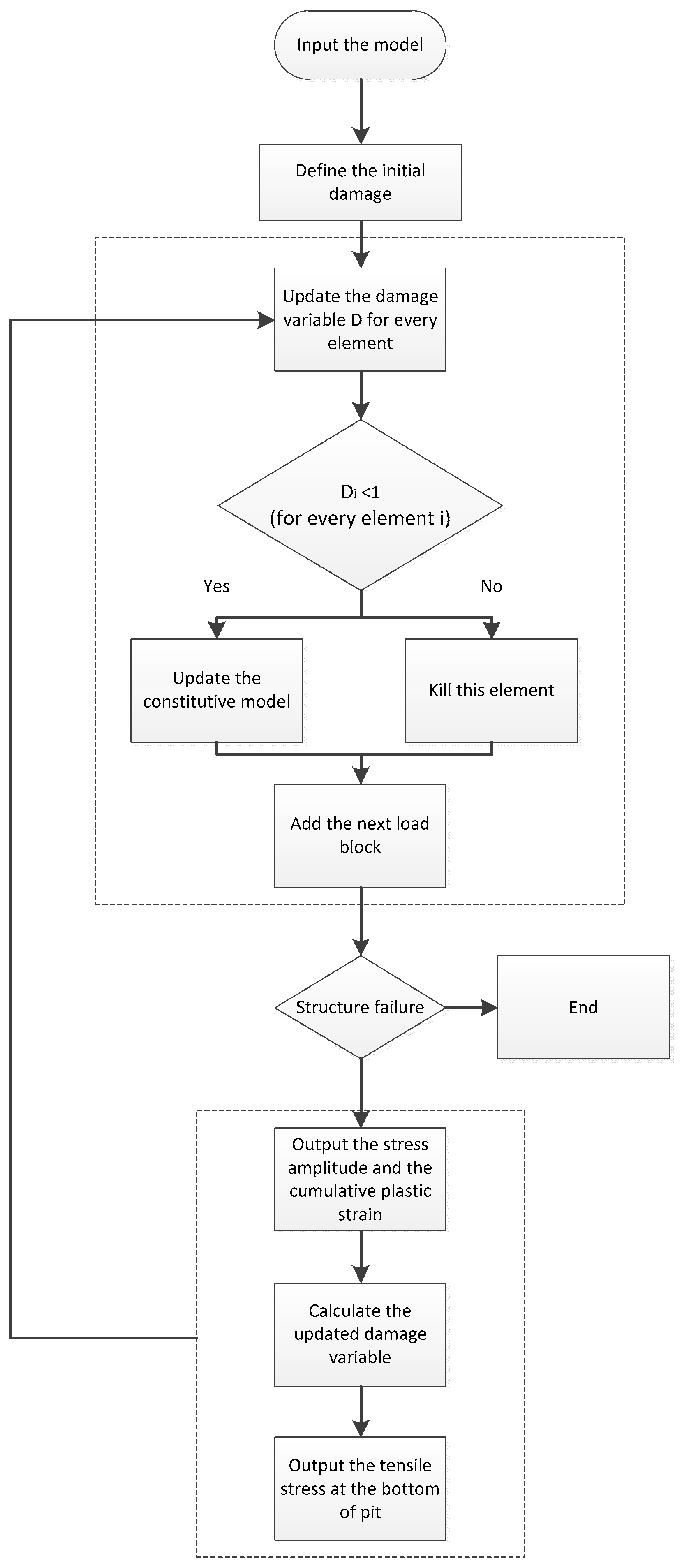

2. The Continuous Damage Mechanics Model

2.1. Elastic–Plastic Damage Model

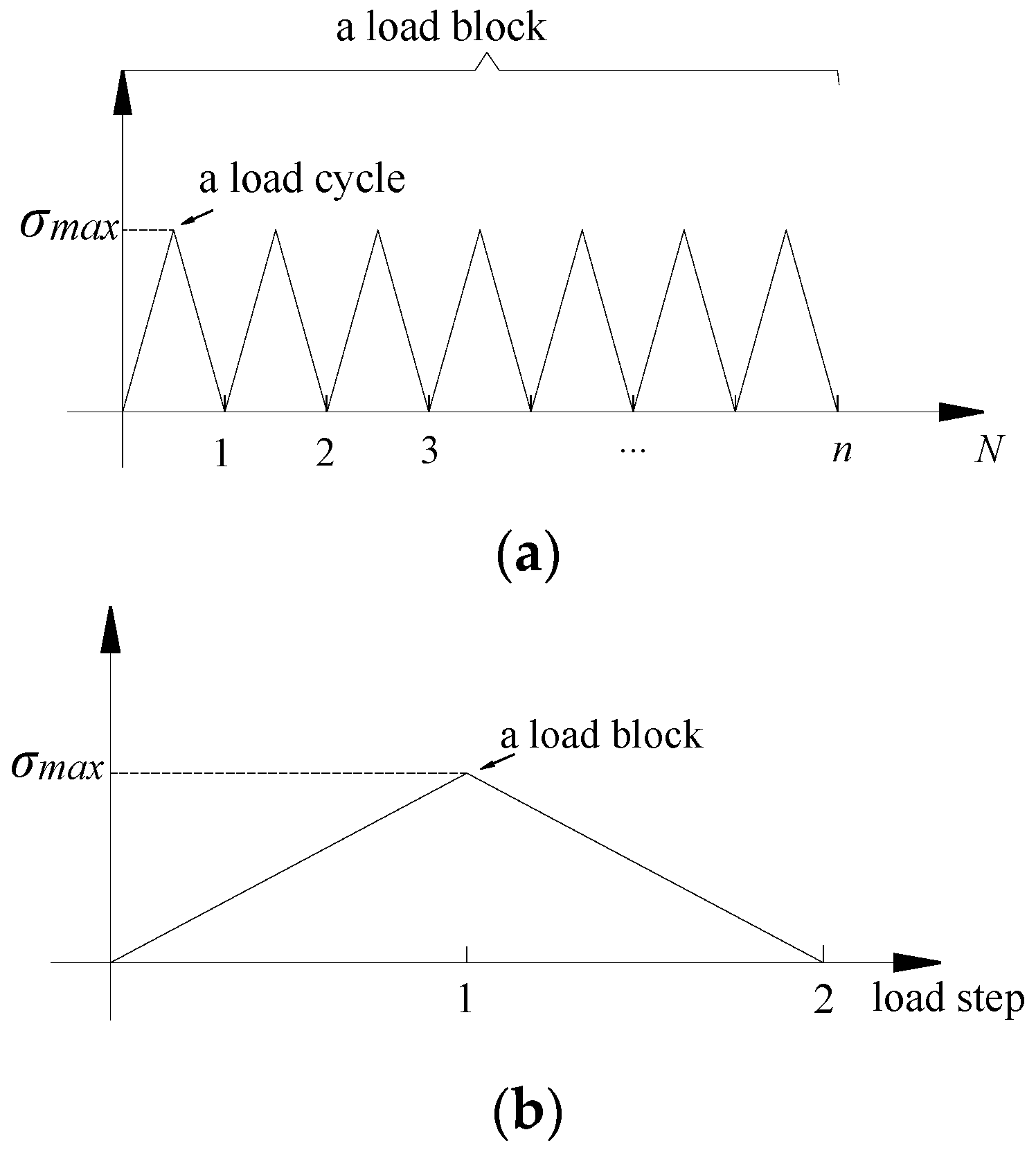

2.2. Load Block Method

3. Finite Element Simulation

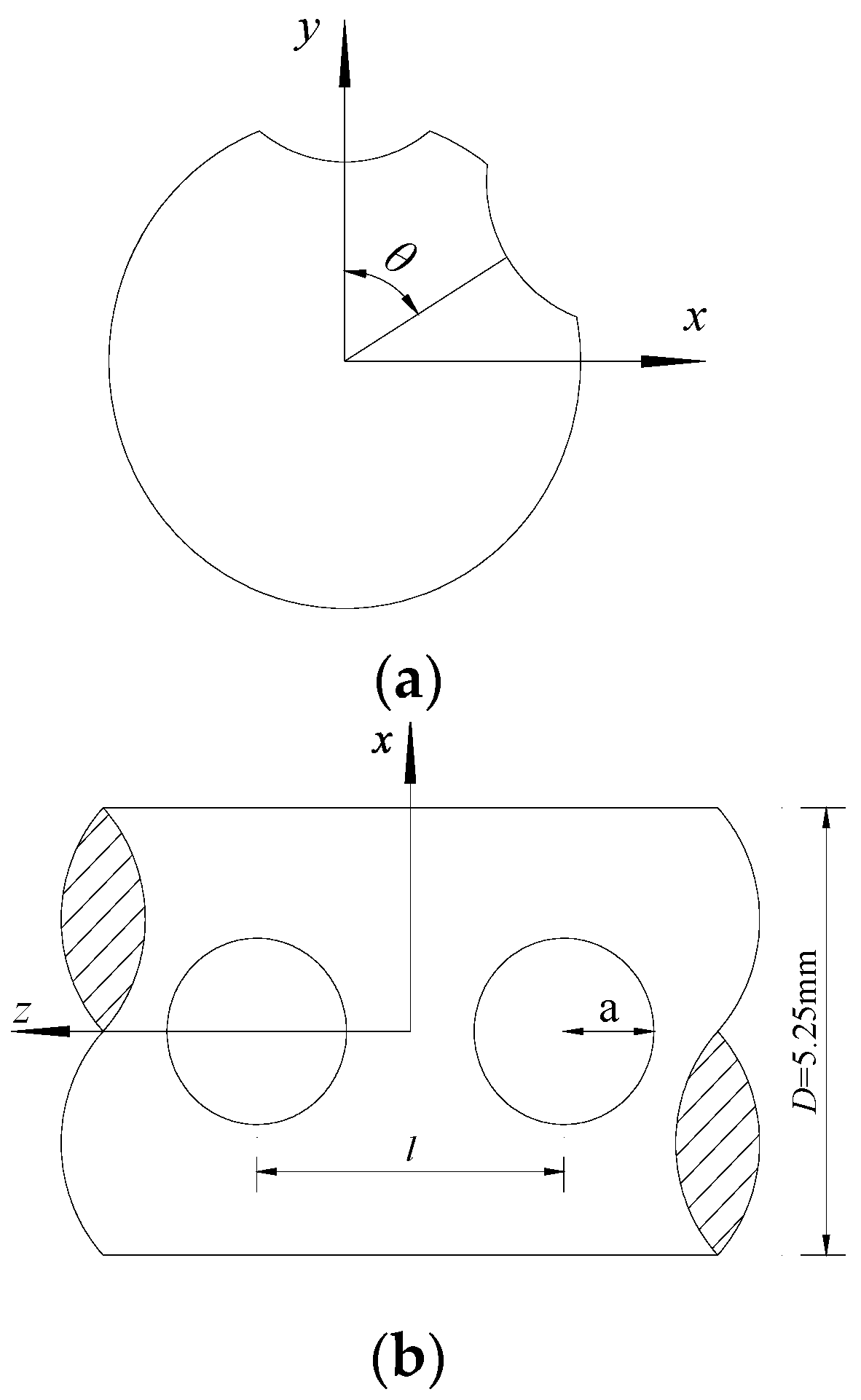

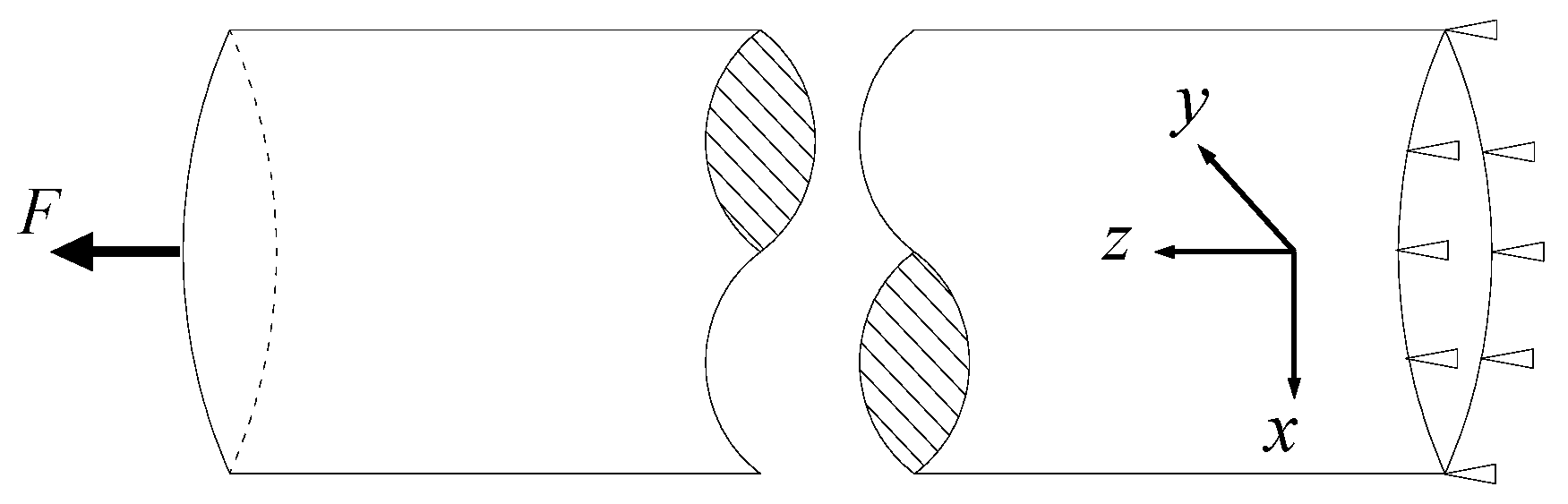

3.1. Finite Element Model

3.2. Boundary Conditions

4. Method Verification

5. Wind–Traffic–Bridge Coupled System

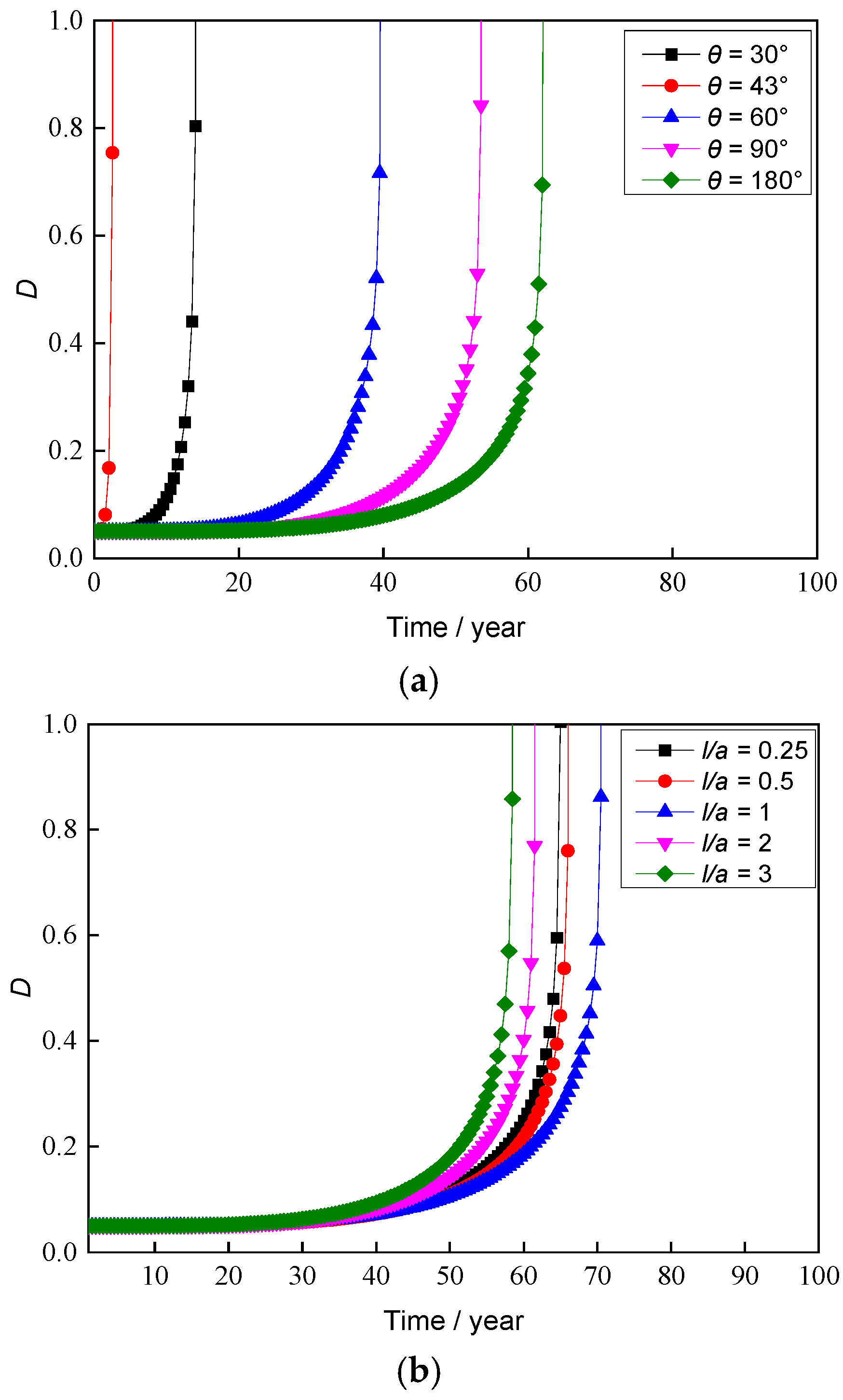

6. The Impact of Pitting Distribution on the Damage Evolution of Steel Wire

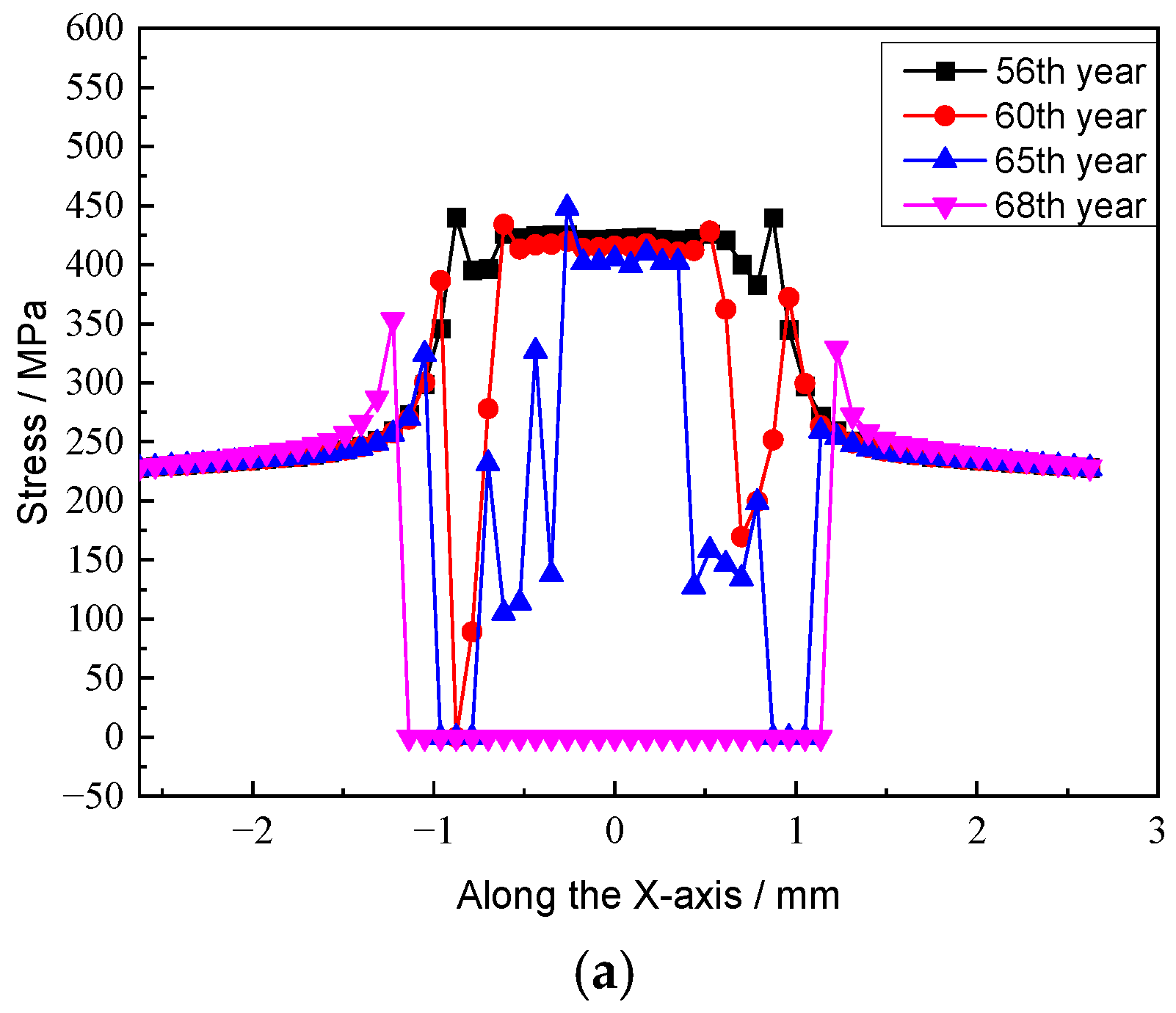

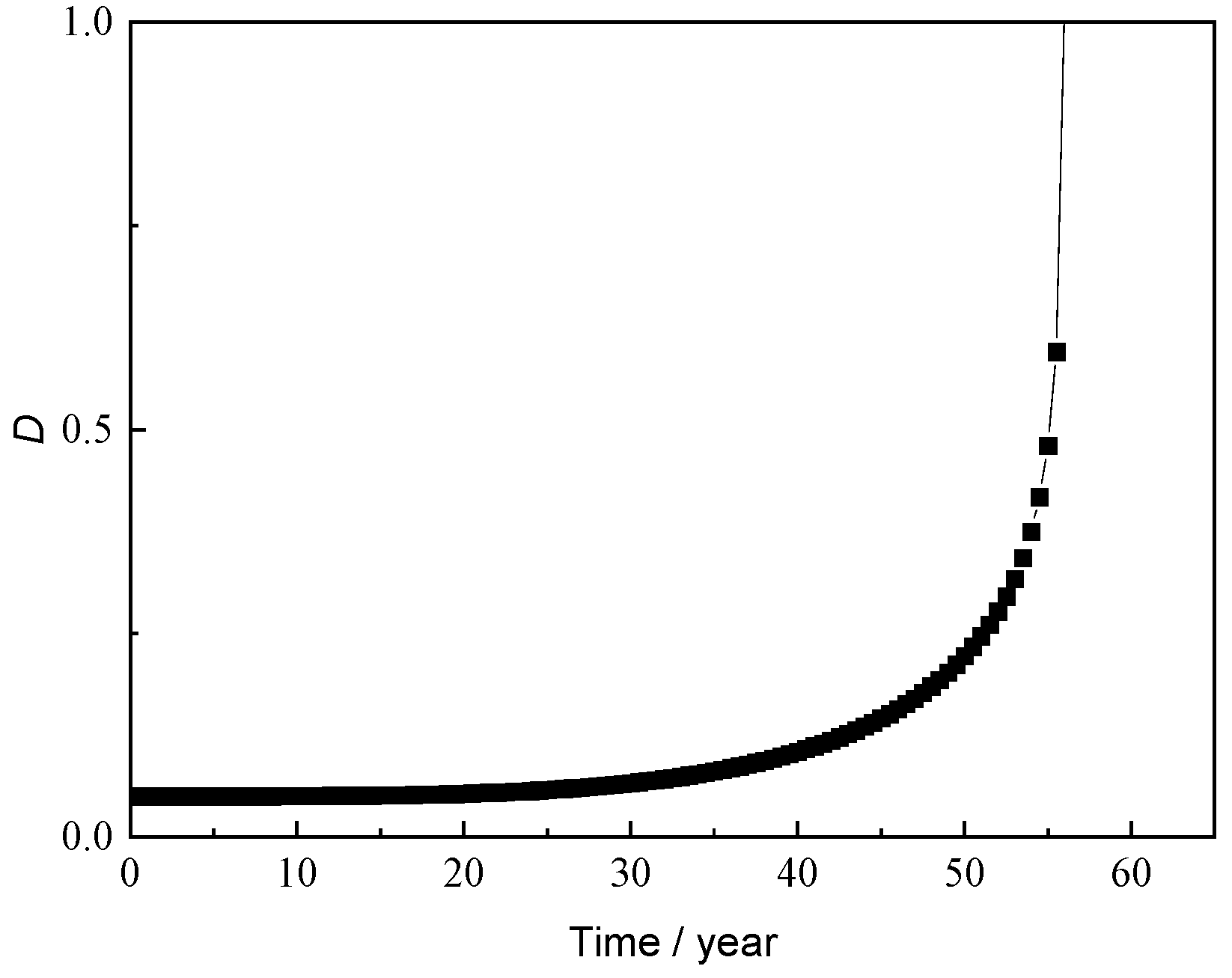

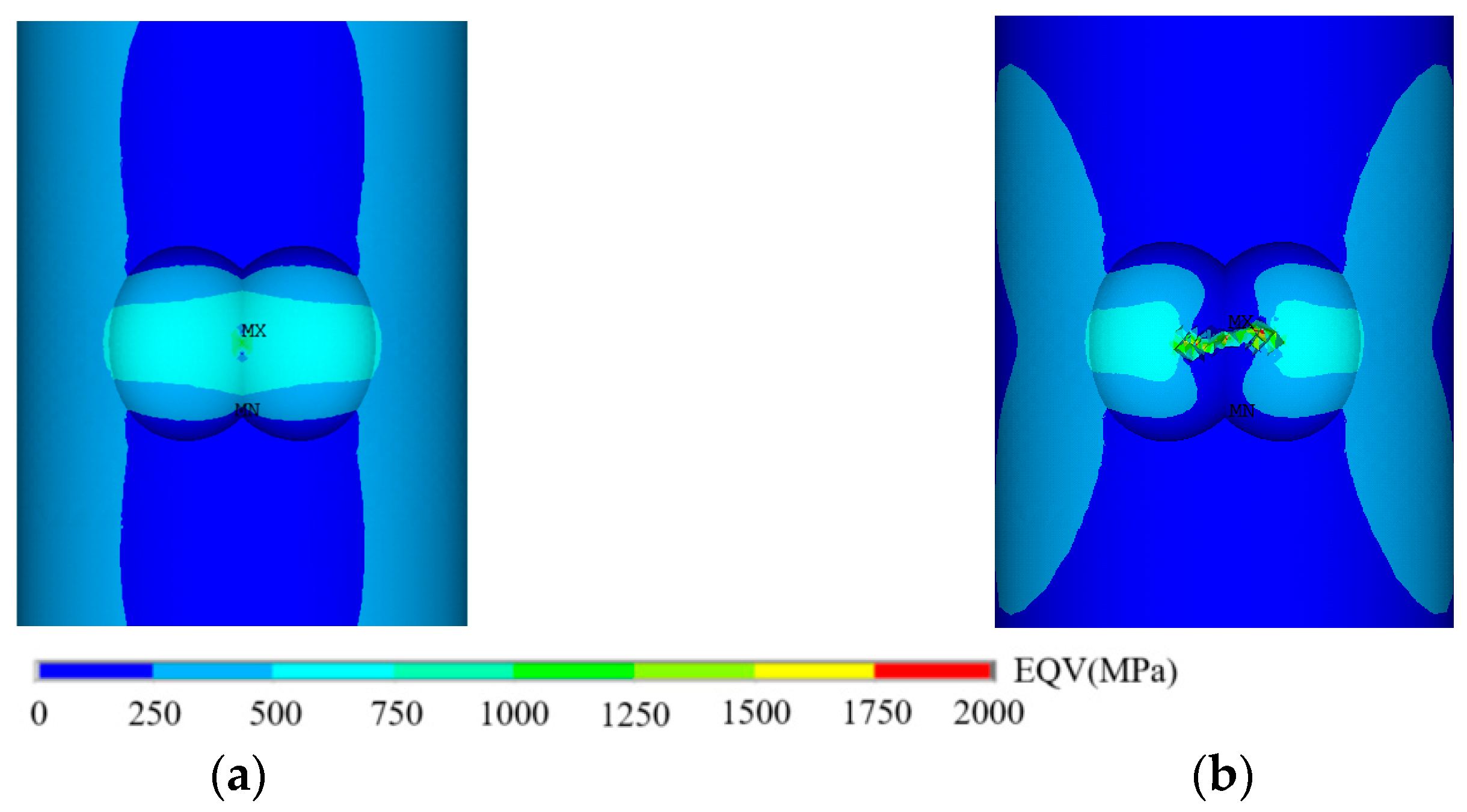

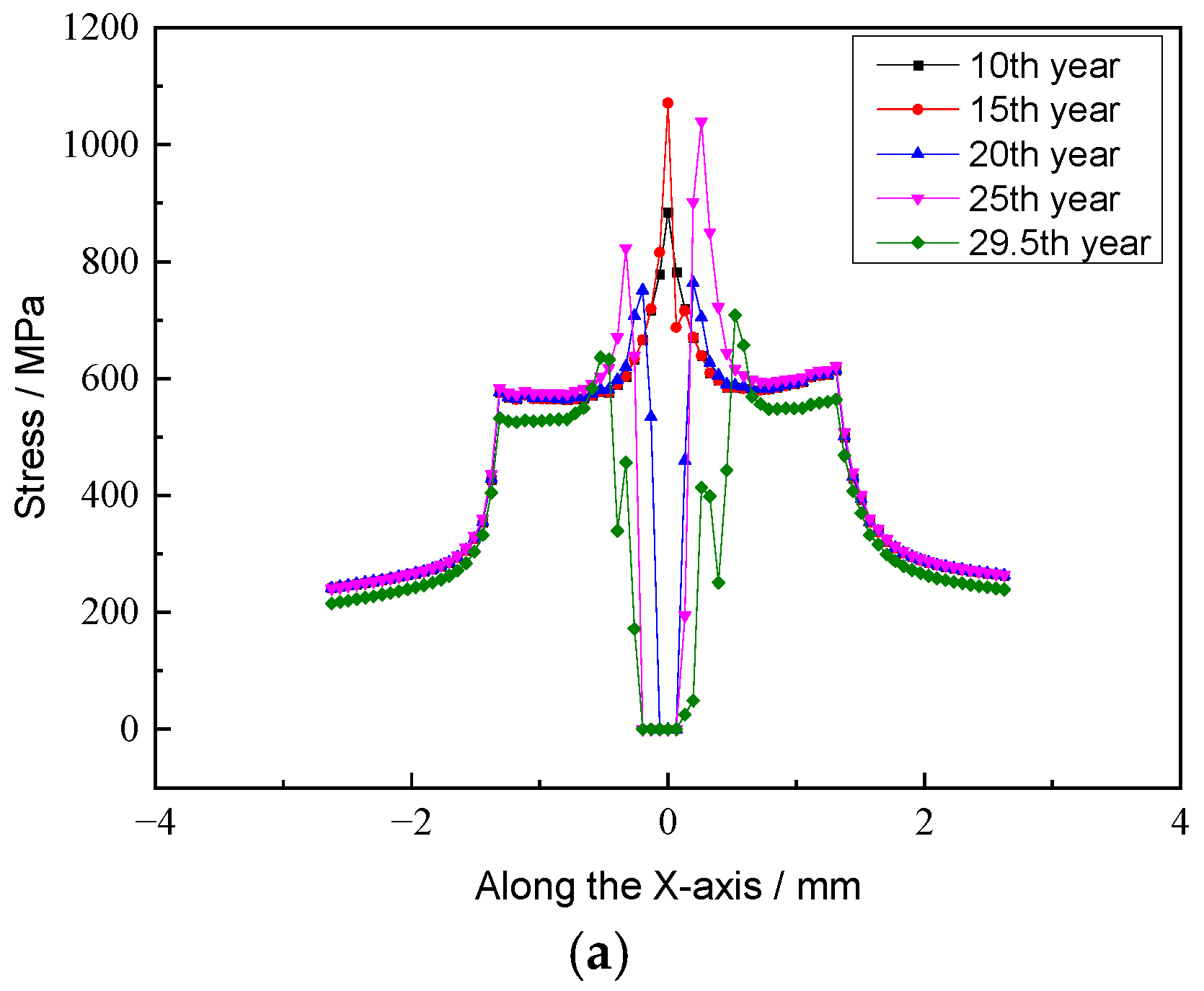

6.1. Damage Evolution Model for Single-Pit Steel Wire

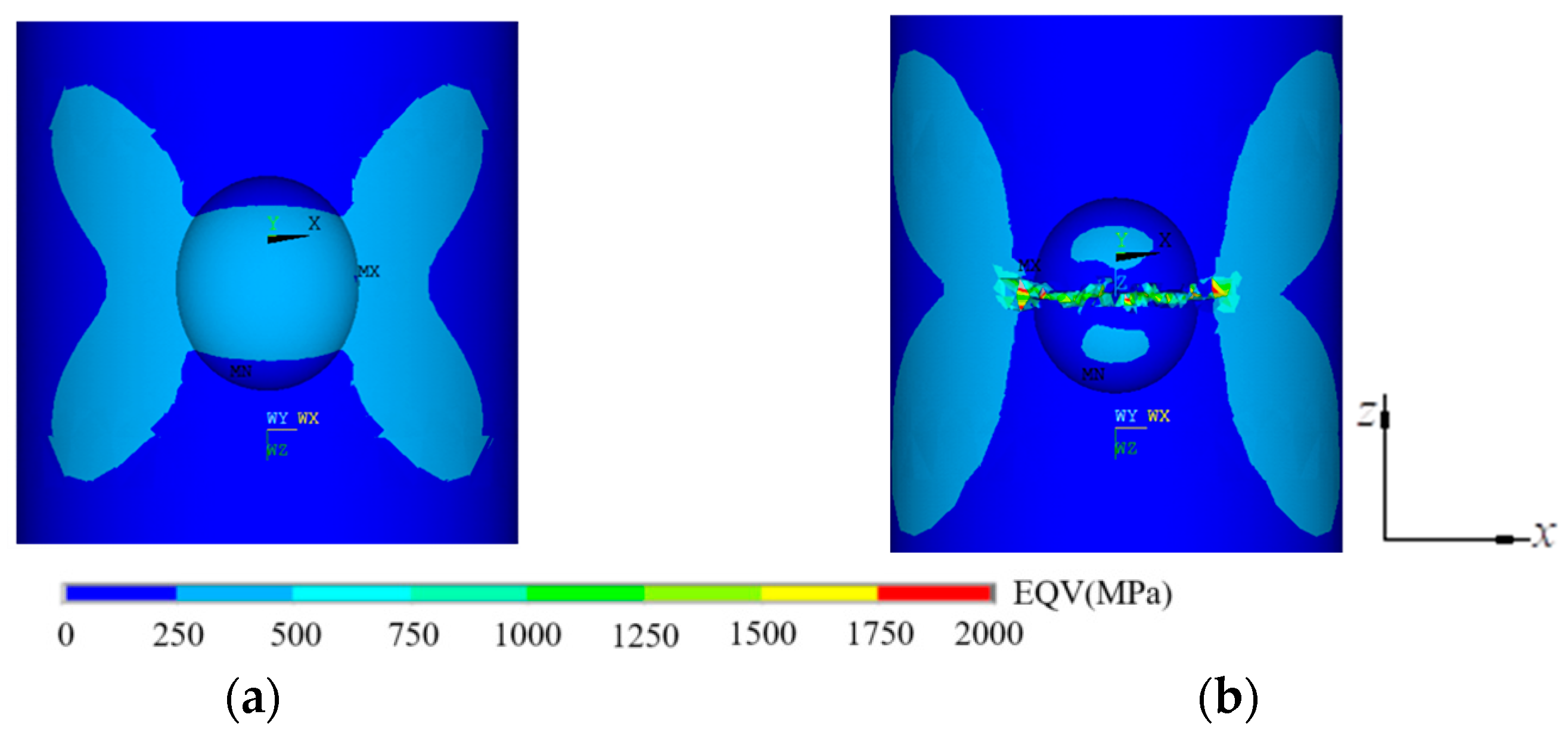

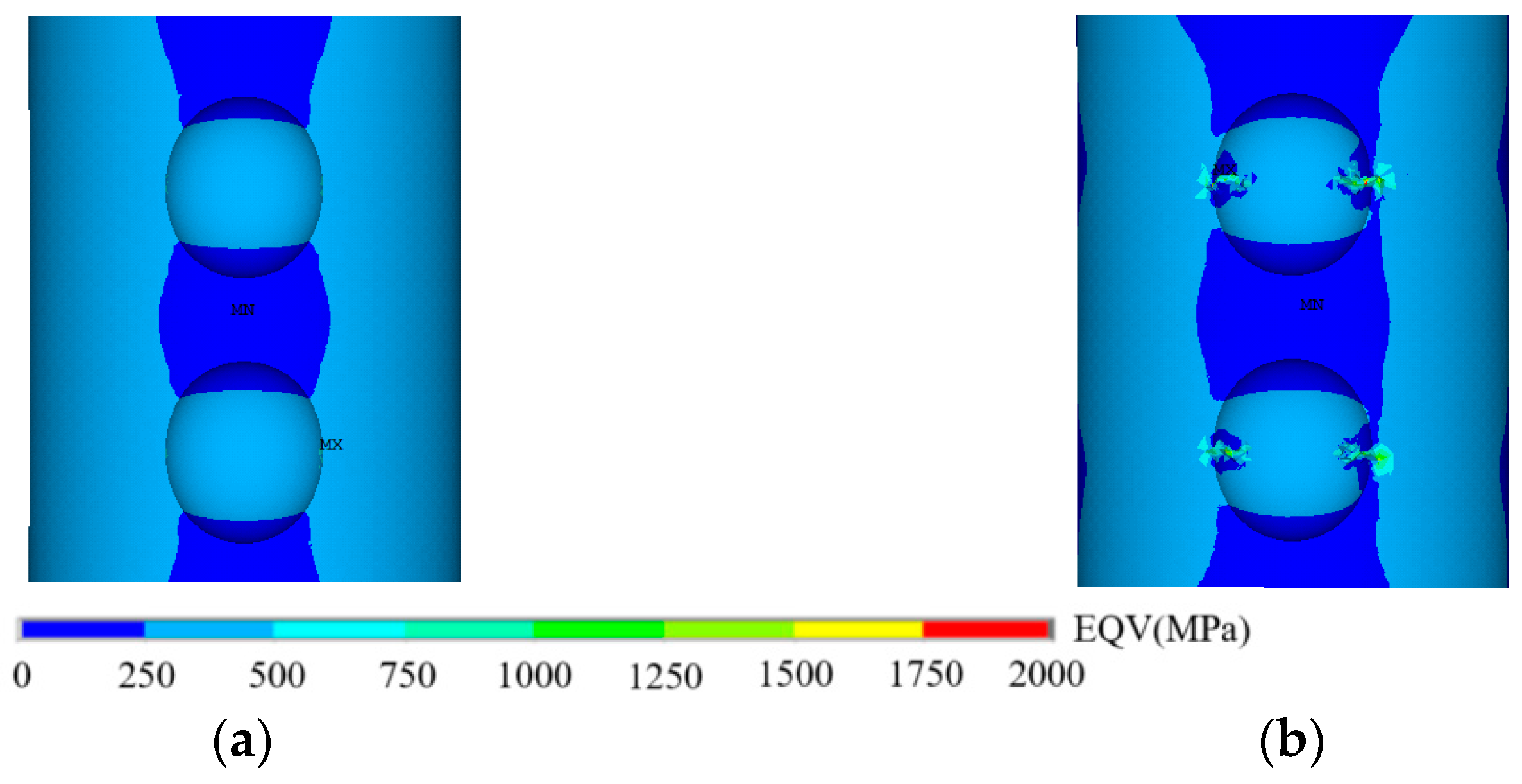

6.2. The Influence of Dual Pits on the Stress Distribution in Steel Wire

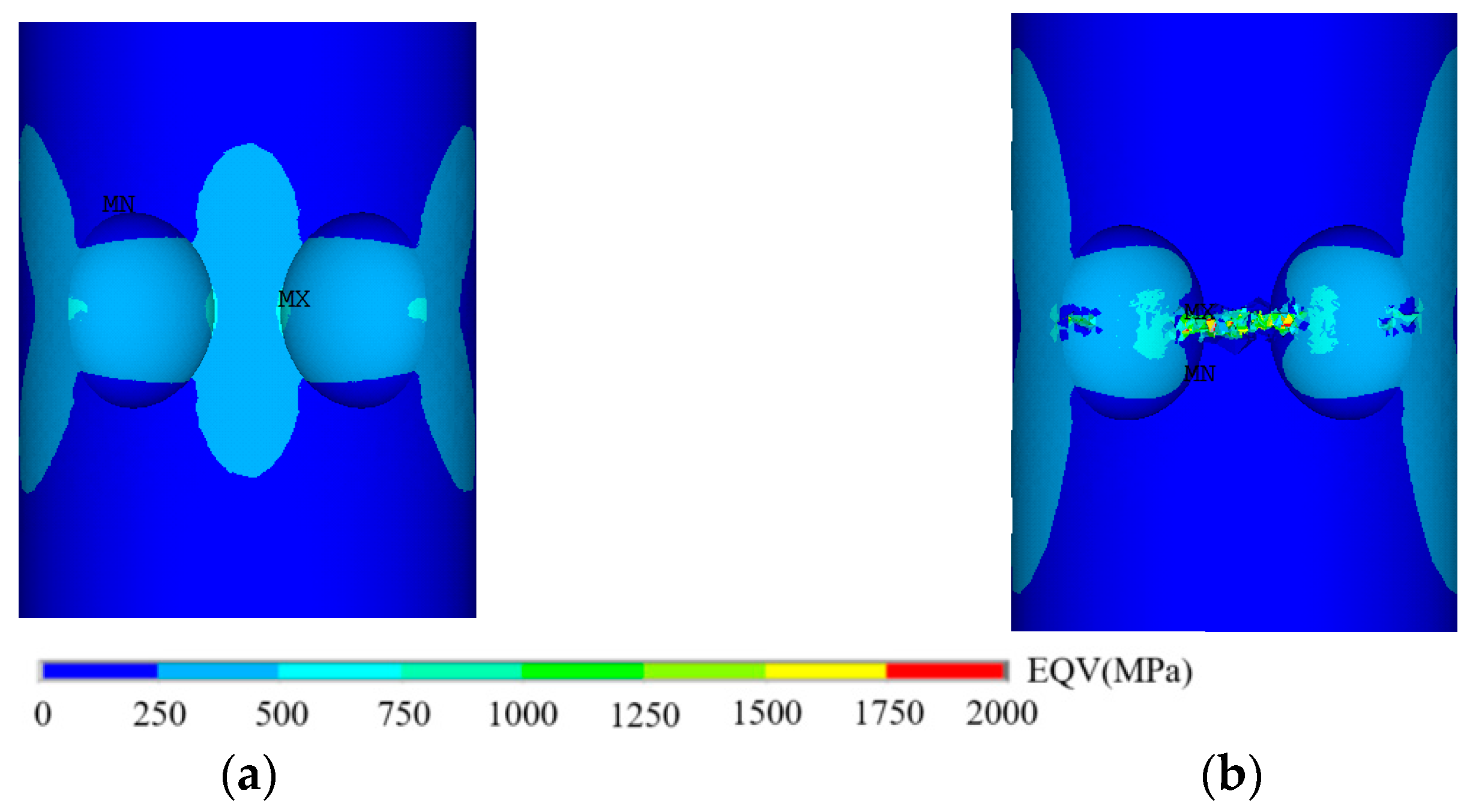

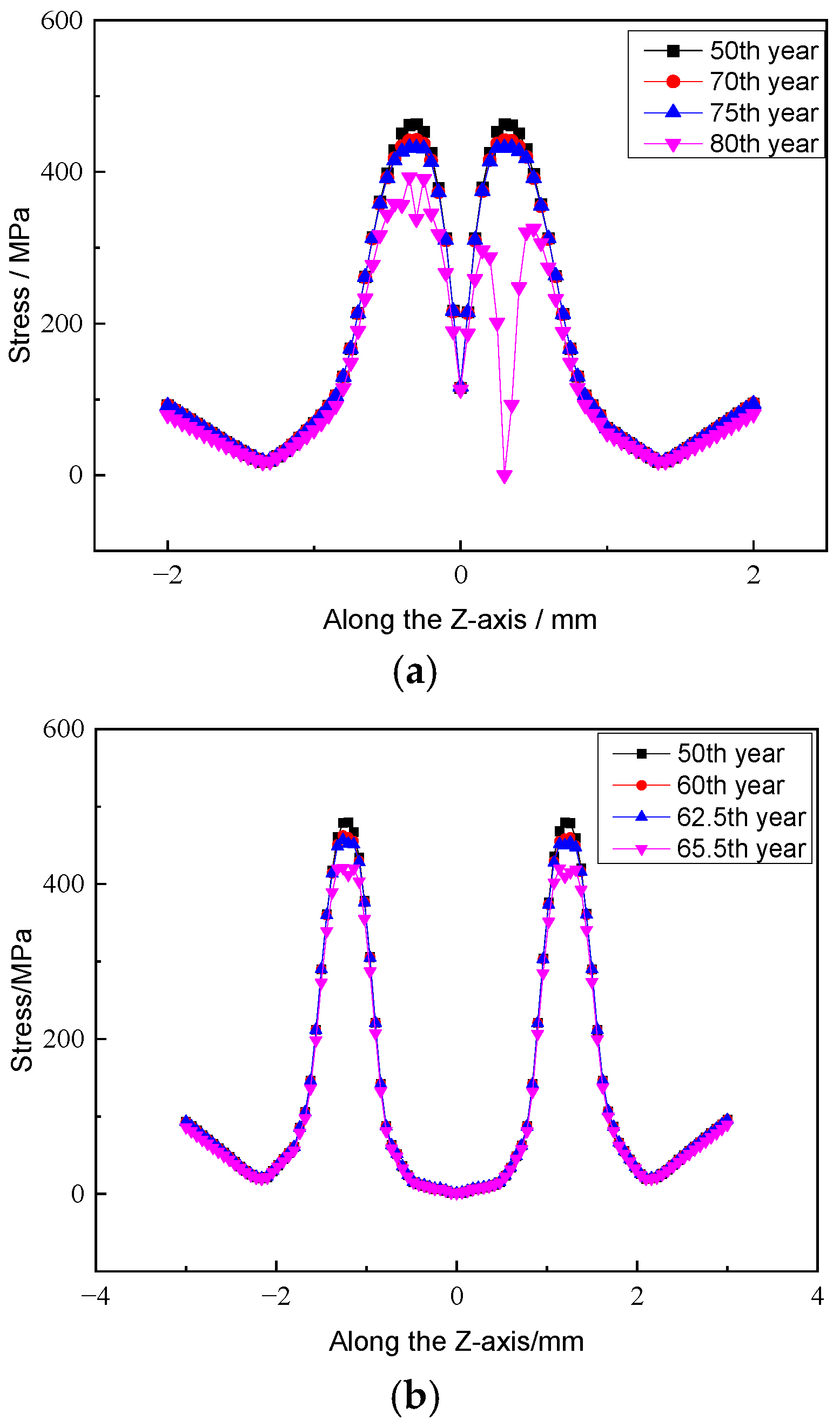

6.2.1. Dual Pits Distributed along the X-Axis on the Surface of Steel Wire

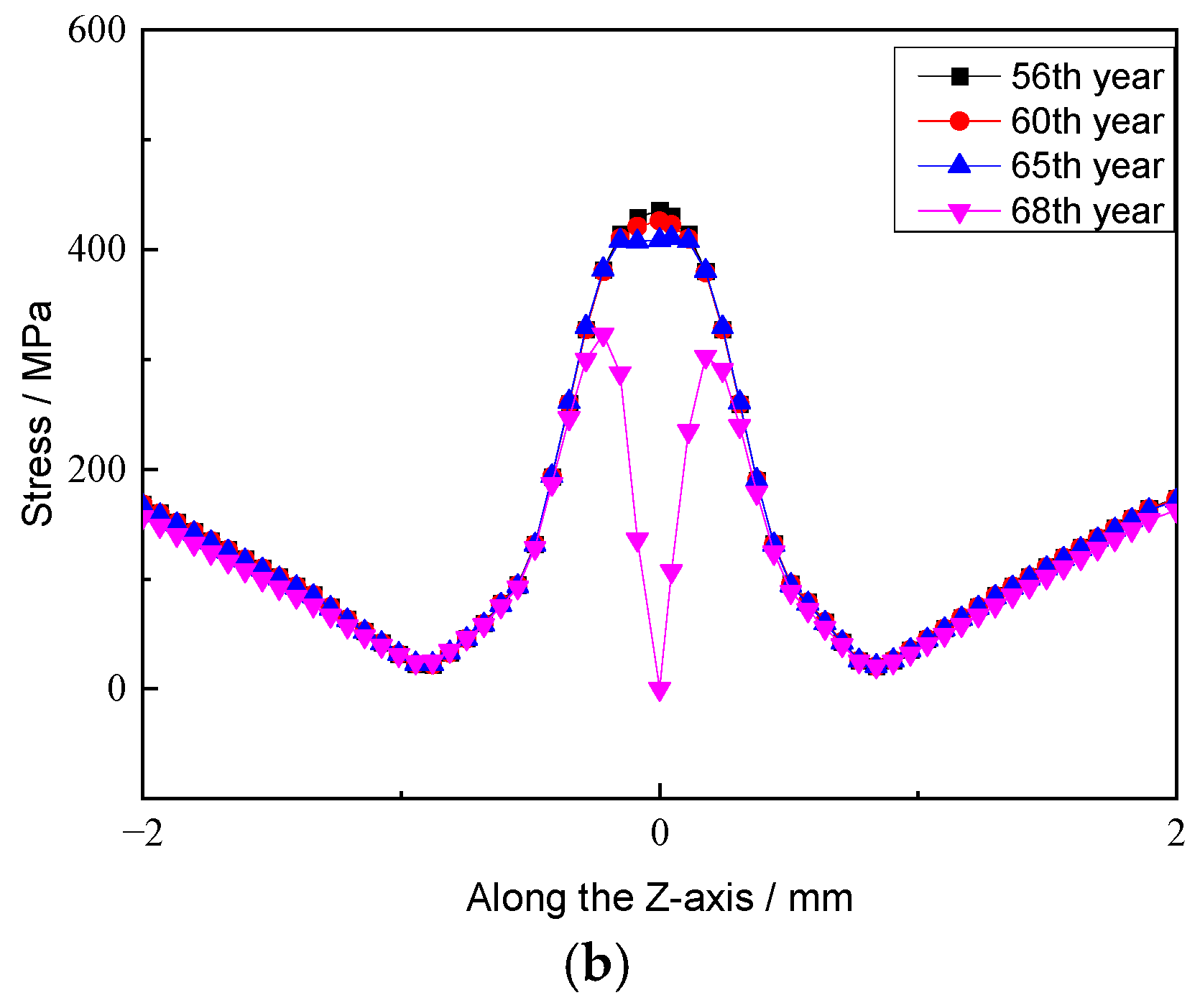

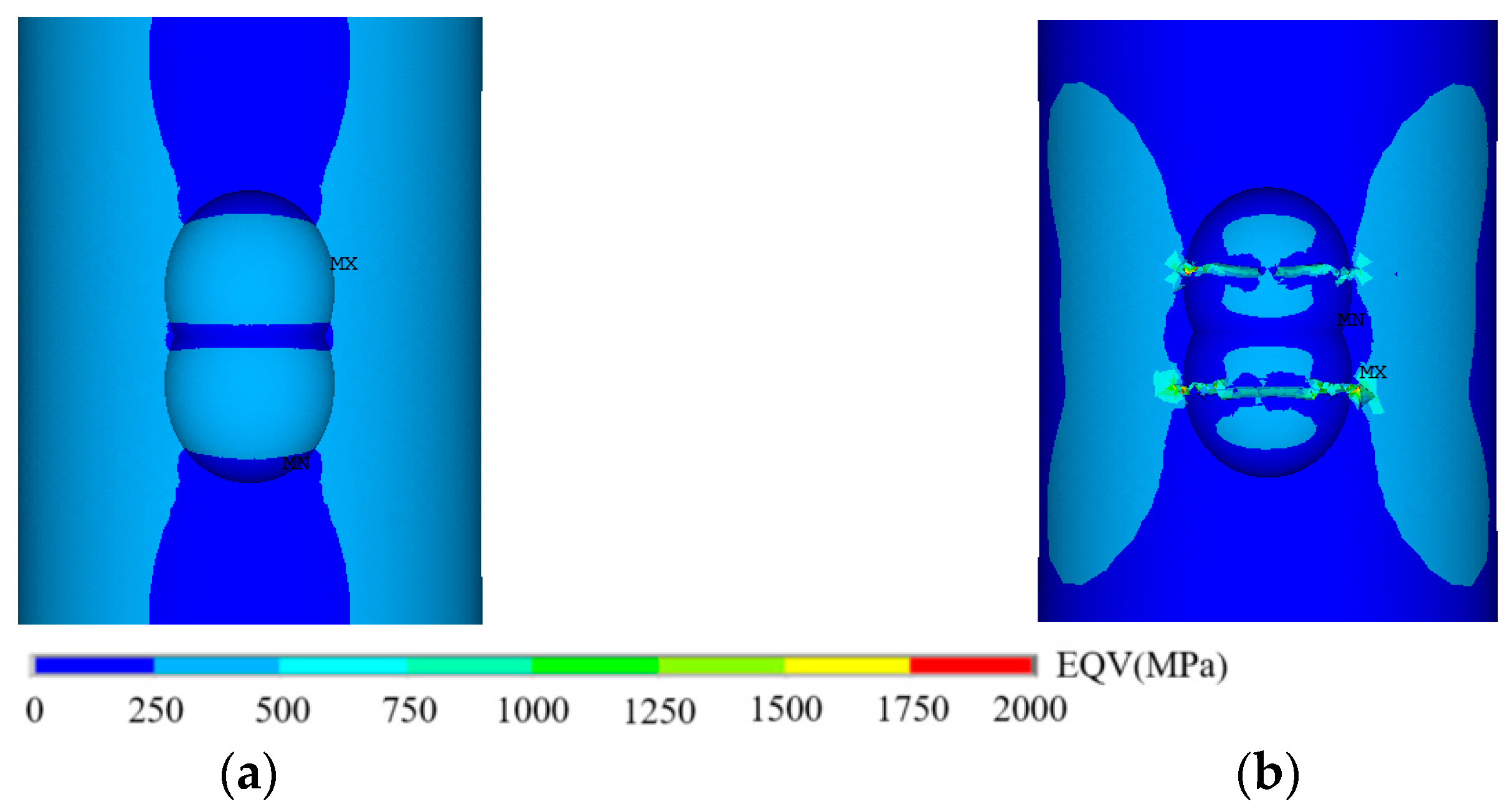

6.2.2. Dual Pits Distributed along the Z-axis on the Surface of Steel Wire

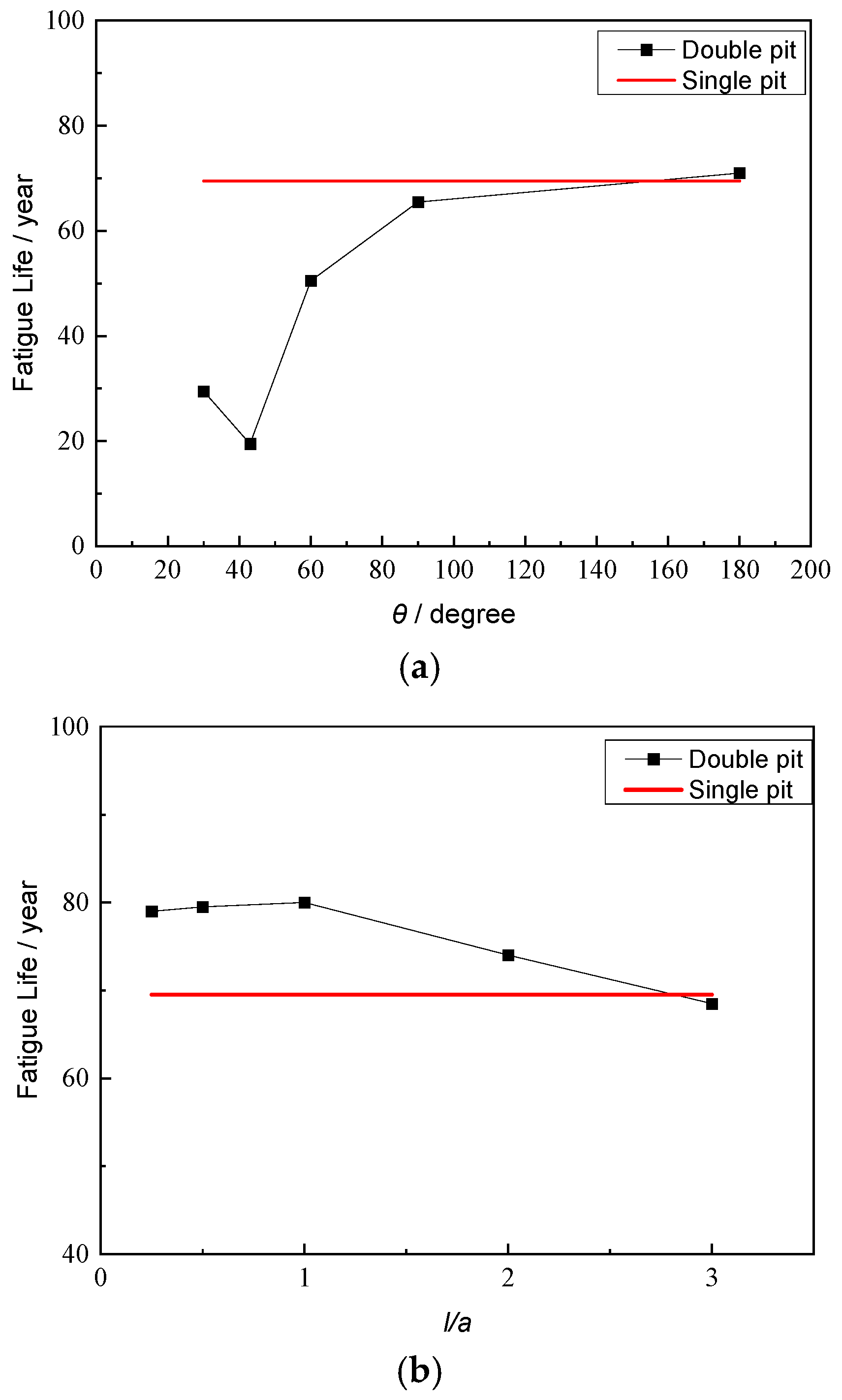

6.3. The Influence of Dual Pits on Fatigue Life

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.T.; Xia, R.C.; Zhang, H. Research and application of bridge internal steel structure disease detection. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2021, 40, 20–28. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, Y.; Xia, R.C.; Zhou, J.T.; Chen, Y. Research progress of stay cable disease detection robot. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2022, 41, 59–62. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, J.H.; Yang, Q.M. Corrosion mechanism and finite element analysis of single steel wire of stay-cable. Low Temp. Archit. Technol. 2016, 38, 69–72. (In Chinese) [Google Scholar] [CrossRef]

- Wang, G.; Ma, Y.; Guo, Z.; Bian, H.; Wang, L.; Zhang, J. Fatigue life assessment of high-strength steel wires: Beach marks test and numerical investigation. Constr. Build. Mater. 2022, 323, 126534. [Google Scholar] [CrossRef]

- Sankaran, K.K.; Perez, R.; Jata, K.V. Effects of pitting corrosion on the fatigue behavior of aluminum alloy 7075-T6: Modeling and experimental studies. Mater. Sci. Eng. 2001, 297, 223–229. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, Y.Q.; Zhang, W.H.; Lu, Q.R. Analysis on damage evolution and corrosion fatigue performance of high-strength steel wire for bridge cable: Experiments and numerical simulation. Theor. Appl. Fract. Mech. 2020, 107, 102571. [Google Scholar] [CrossRef]

- Amiri, M.; Arcari, A.; Airoldi, L.; Naderi, M.; Iyyer, N. A continuum damage mechanics model for pit-to-crack transition in AA2024-T3. Corros. Sci. 2015, 98, 678–687. [Google Scholar] [CrossRef]

- Hu, W.P.; Shen, Q.A.; Zhang, M.; Meng, Q.C.; Zhang, X. Corrosion–fatigue life prediction for 2024-T62 aluminum alloy using damage mechanics-based approach. Int. J. Damage Mech. 2012, 21, 1245–1266. [Google Scholar] [CrossRef]

- Zhao, Y.; Su, B.; Fan, X.; Yuan, Y.; Zhu, Y. Corrosion Fatigue Degradation Characteristics of Galvanized and Galfan High-Strength Steel Wire. Materials 2023, 16, 708. [Google Scholar] [CrossRef]

- Tang, S.; Xu, H.; Ao, N.; Liu, Y.; Zhang, J.; Guo, H.; Kan, Q.; Kang, G.; Wu, S. Experimental investigation on corrosion fatigue crack initiation and growth of heat-treated U75V rail steel. Int. J. Fatigue 2023, 178, 107973. [Google Scholar] [CrossRef]

- Khajeian, A.; Mahmoudi, A.H.; Seif, R. An approach to predicting corrosion fatigue for marine applications. Int. J. Fatigue 2023, 179, 108030. [Google Scholar] [CrossRef]

- Sun, B. A continuum model for damage evolution simulation of the high strength bridge wires due to corrosion fatigue. J. Constr. Steel Res. 2018, 146, 76–83. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L.; Maji, A.K. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1990; pp. 349–371. [Google Scholar]

- Cui, C.J.; Chen, A.R.; Ma, R.J. An improved continuum damage mechanics model for evaluating corrosion–fatigue life of high-strength steel wires in the real service environment. Int. J. Fatigue 2020, 135, 105540. [Google Scholar] [CrossRef]

- Hu, P.; Meng, Q.; Hu, W.; Shen, F.; Zhan, Z.; Sun, L. A continuum damage mechanics approach coupled with an improved pit evolution model for the corrosion fatigue of aluminum alloy. Corros. Sci. 2016, 113, 78–90. [Google Scholar] [CrossRef]

- Shen, F.; Hu, W.P.; Meng, Q.C. A damage mechanics approach to fretting fatigue life prediction with consideration of elastic-plastic damage model and wear. Tribol. Int. 2015, 82, 76–90. [Google Scholar] [CrossRef]

- Cerit, M.; Genel, K.; Eksi, S. Numerical investigation on stress concentration of corrosion pit. Eng. Fail. Anal. 2009, 16, 2467–2472. [Google Scholar] [CrossRef]

- Chang, K.H.; Choi, K.K. An error analysis and mesh adaptation method for shape design of structural components. Comput. Struct. 1992, 44, 1275–1289. [Google Scholar] [CrossRef]

- Wu, M.X.; Yin, L.; Tang, D.F. Influence of corrosion pit size on stress concentration of high strength steel wire. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2021, 43, 63–70. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, J.H.; Ma, A.B.; Weng, W.F.; Fu, G.H.; Zhang, Y.F.; Liu, G.G.; Lu, F.M. Corrosion Fatigue Performance of Pre-Split Steel Wires for High Strength Bridge Cables. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 769–779. [Google Scholar] [CrossRef]

- Zhang, F.; Jin, W.L.; Zhang, J.; Mao, H.Y.; Fan, W.J. Numerical Analysis of High Cycle Fatigue Damage and Life of Pitted Corroded Steel Bar Based on Continuum Damage Mechanics. J. Build. Mater. 2021, 24, 405–411. (In Chinese) [Google Scholar] [CrossRef]

- Wu, M.; Zhu, J.; Heng, J.; Kaewunruen, S. Fatigue assessment on suspenders under stochastic wind and traffic loads based on in-situ monitoring data. Appl. Sci. 2019, 9, 3405. [Google Scholar] [CrossRef]

| Cyclic Accuracy (Year) | Results (Year) |

|---|---|

| 0.3 | 66.0 |

| 0.4 | 67.6 |

| 0.5 | 68.0 |

| 0.6 | 69.0 |

| 0.7 | 70.0 |

| 0.8 | 68.0 |

| 0.9 | 72.0 |

| Mesh Accuracy (mm) | SE (MPa) | SN (MPa) | SE/SN (%) |

|---|---|---|---|

| 0.4 | 968.24 | 1055.12 | 91.77 |

| 0.2 | 996.95 | 1066.67 | 93.46 |

| 0.1 | 1019.91 | 1062.04 | 96.03 |

| 0.05 | 1041.12 | 1063.03 | 97.93 |

| Elastic Modulus (GPa) | Poisson’s Ratio | Element Type | Tensile Strength (MPa) | Density (kg·m−3) |

|---|---|---|---|---|

| 206 | 0.3 | SOLID95 | 1670 | 7850 |

| Ultimate Strength (MPa) | Yield Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|

| 1672 | 1473 | 206 |

| Code | Maximum Stress (MPa) | Stress Ratio | Frequency (Hz) | Fatigue Life in Tensile Testing (Times) | Numerical Simulation Fatigue Life (Times) | Error |

|---|---|---|---|---|---|---|

| F1 | 1200.5 | 0.167 | 30 | 128,564 | 115,000 | 10.6% |

| F2 | 960.4 | 199,723 | 160,000 | 19.9% | ||

| F3 | 720.3 | 425,827 | 375,000 | 11.9% |

| Suspender | Estimated Effective Stress Range | Estimated Daily Average Number of Cycles |

|---|---|---|

| S1 | 13.32 | 7278 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, L.; Wu, M. Fatigue of Bridge Steel Wire: A Corrosion Pit Evolution Model under the Effects of Wind and Vehicles. Appl. Sci. 2024, 14, 2015. https://doi.org/10.3390/app14052015

Yin L, Wu M. Fatigue of Bridge Steel Wire: A Corrosion Pit Evolution Model under the Effects of Wind and Vehicles. Applied Sciences. 2024; 14(5):2015. https://doi.org/10.3390/app14052015

Chicago/Turabian StyleYin, Li, and Mengxue Wu. 2024. "Fatigue of Bridge Steel Wire: A Corrosion Pit Evolution Model under the Effects of Wind and Vehicles" Applied Sciences 14, no. 5: 2015. https://doi.org/10.3390/app14052015

APA StyleYin, L., & Wu, M. (2024). Fatigue of Bridge Steel Wire: A Corrosion Pit Evolution Model under the Effects of Wind and Vehicles. Applied Sciences, 14(5), 2015. https://doi.org/10.3390/app14052015