Enhancing Dehumidification in the Cable Room of a Ring Main Unit through CFD-EMAG Coupling Simulation and Experimental Verification

Abstract

1. Introduction

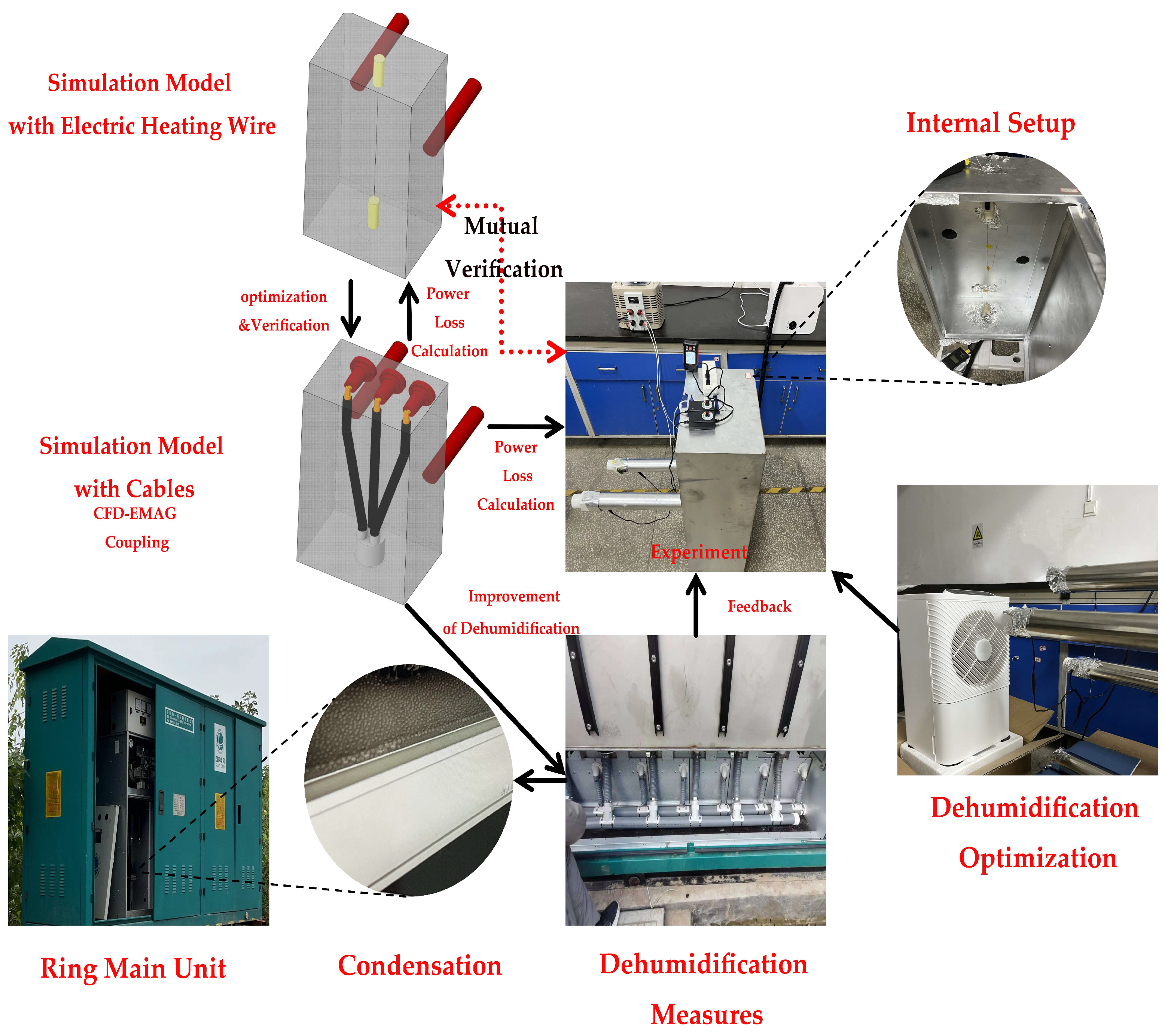

2. Materials and Methods

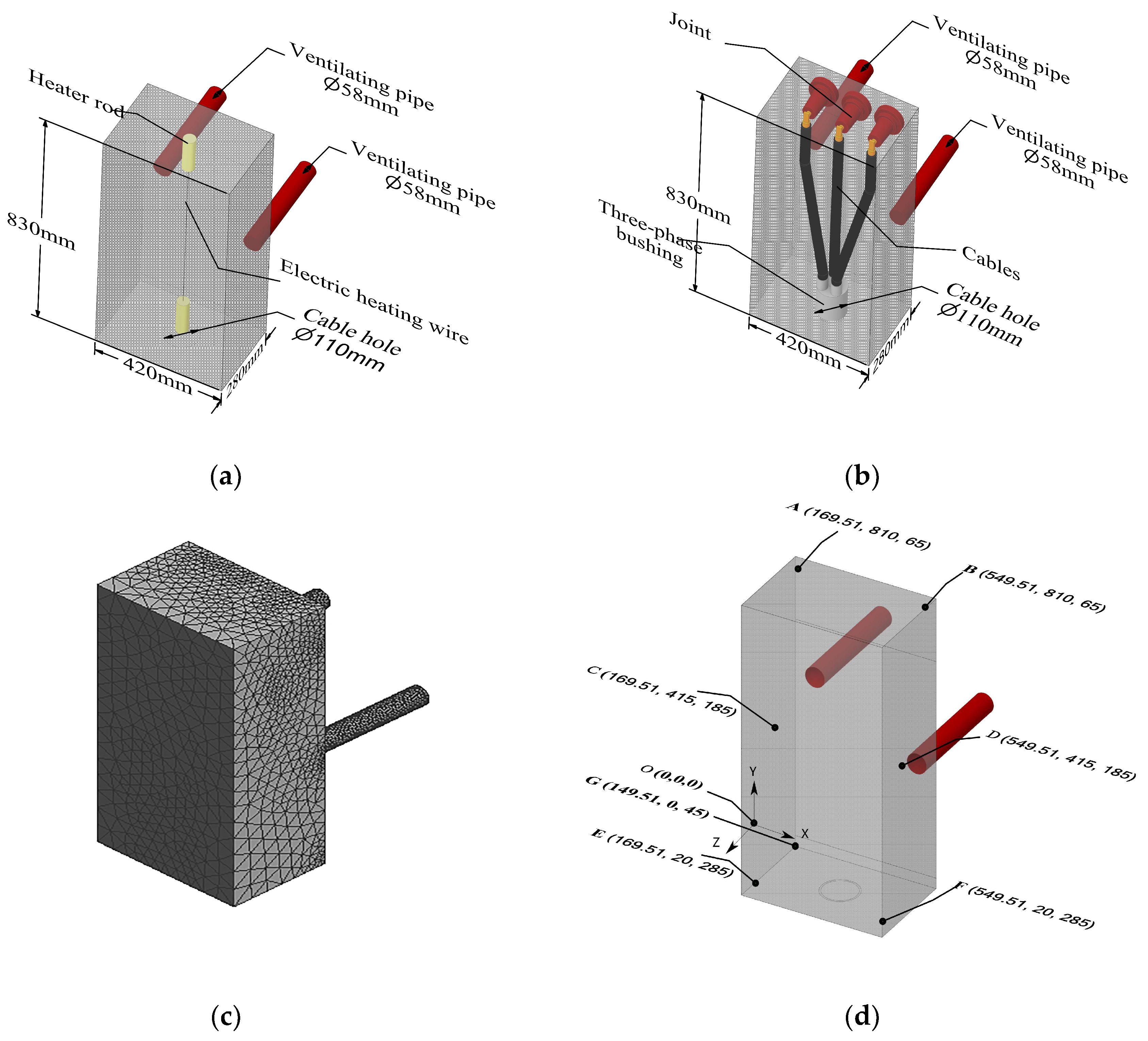

2.1. Structure and Modeling of the RMU

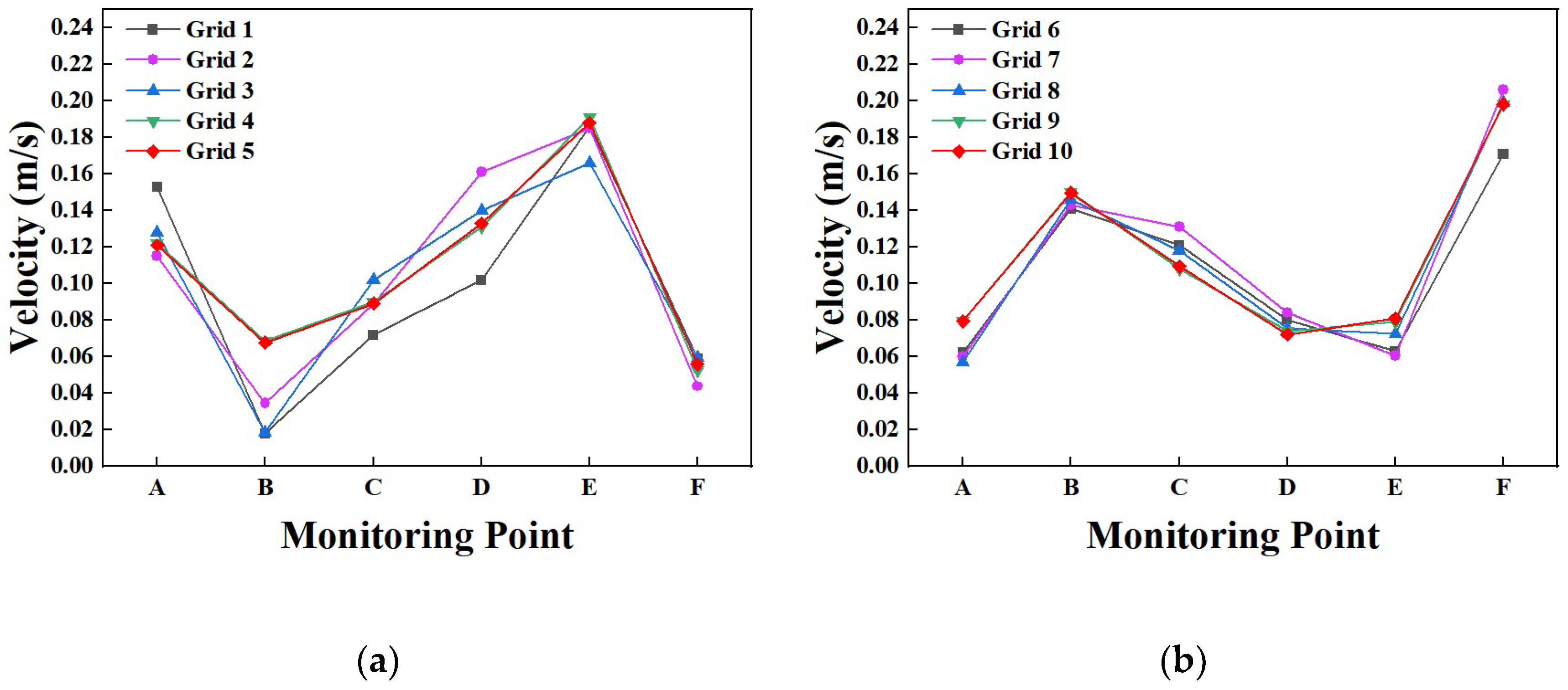

2.2. Simulation Grid

2.3. Governing Equations

2.3.1. Mathematical Model of Flow Field

2.3.2. Heat Conduction Model

2.3.3. EMAG Model

2.4. Physical Properties and Boundary Conditions

2.5. Grid Independence Verification

3. Experimental Results and Simulation Analysis

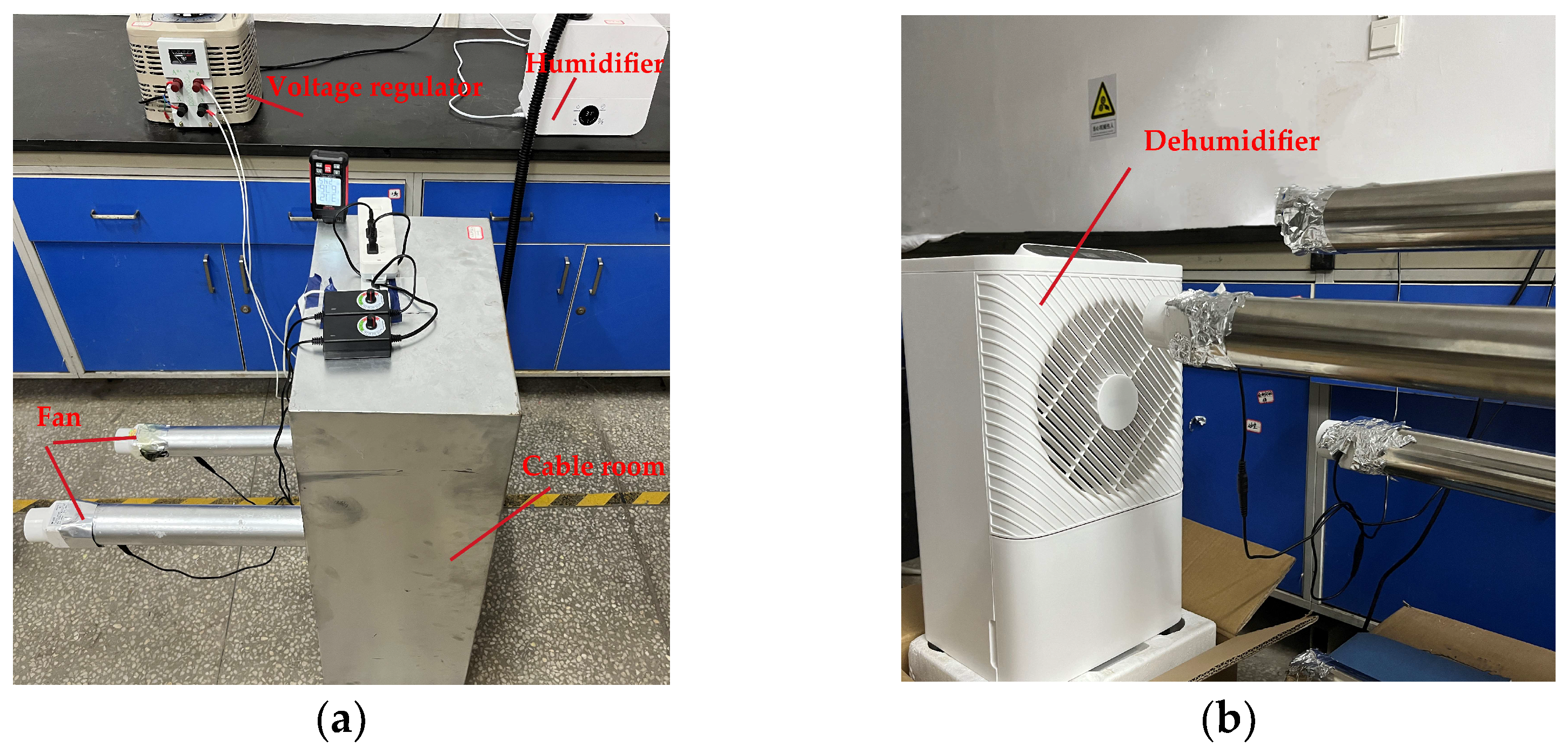

3.1. Experimental Conditions

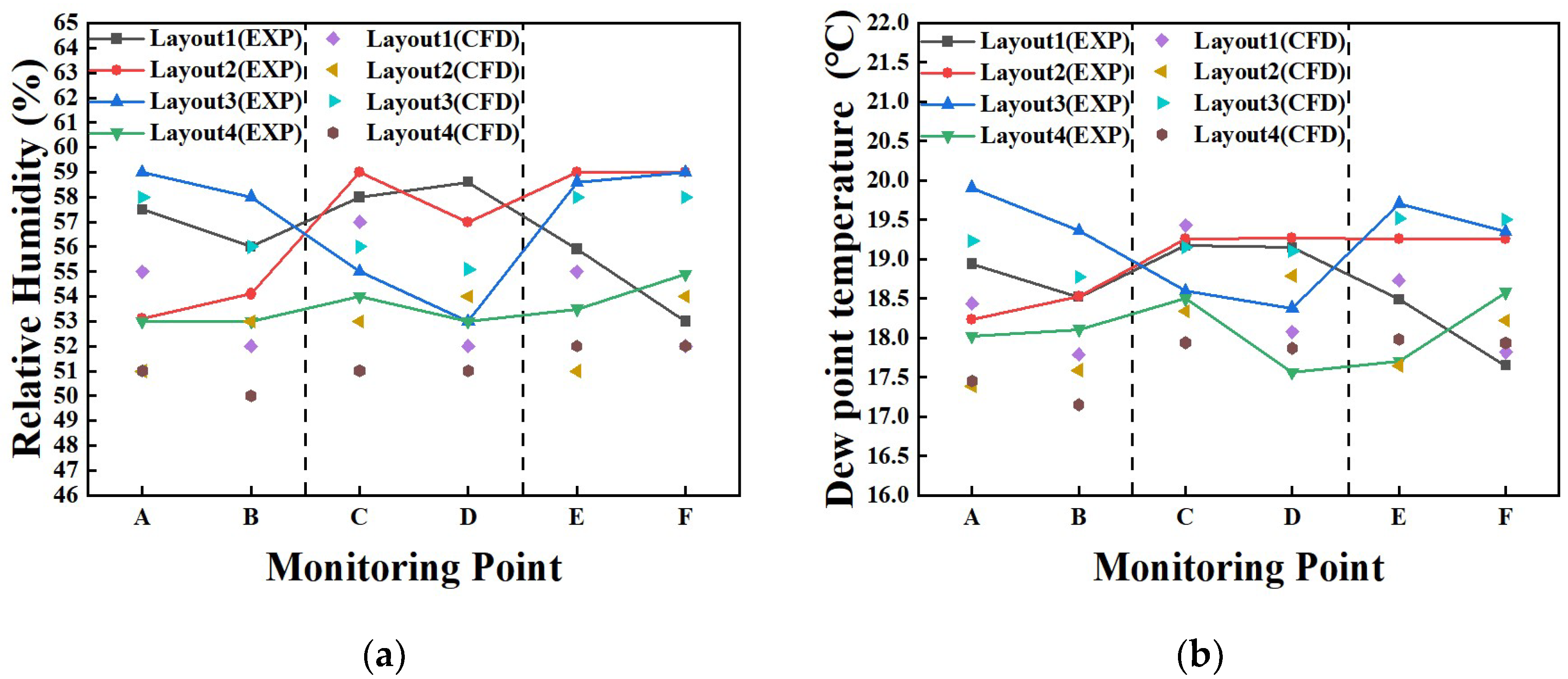

3.2. Experimental and Simulation Analysis

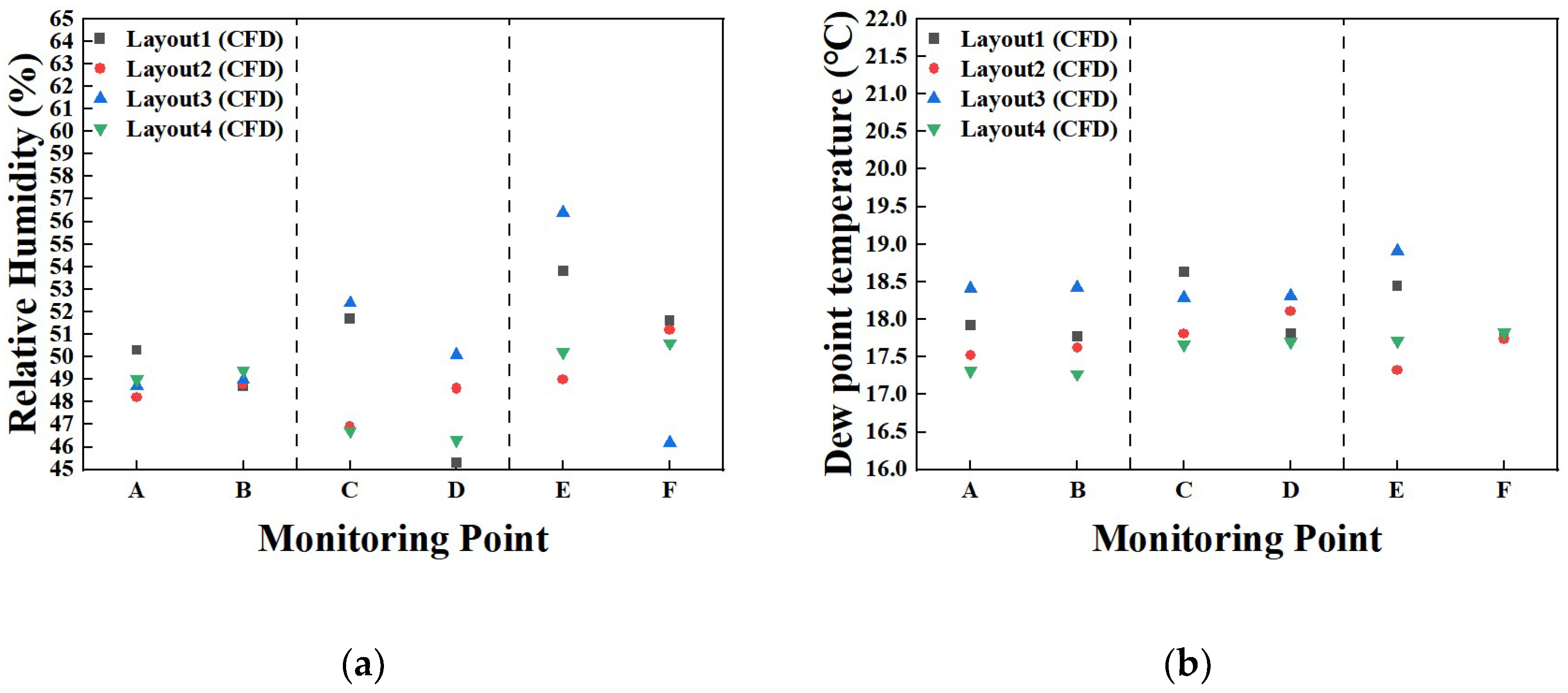

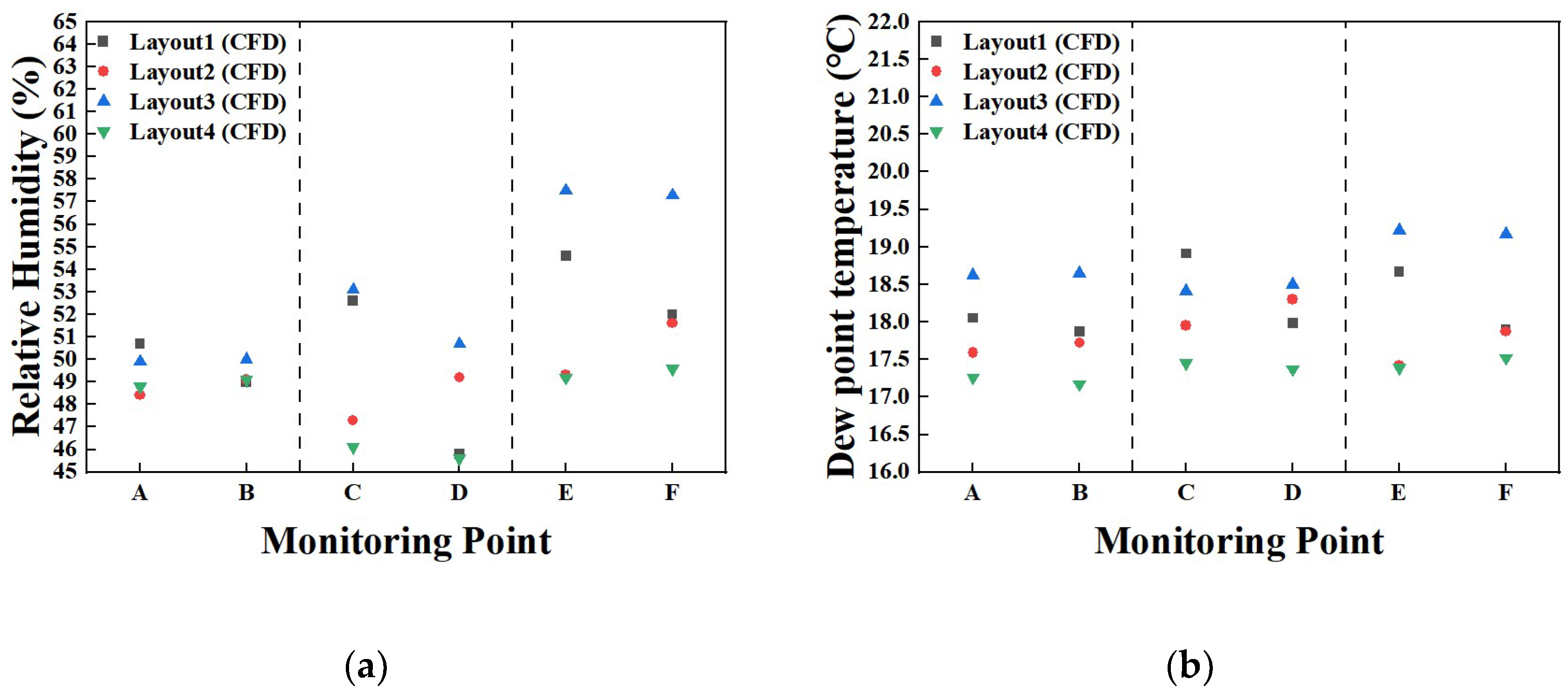

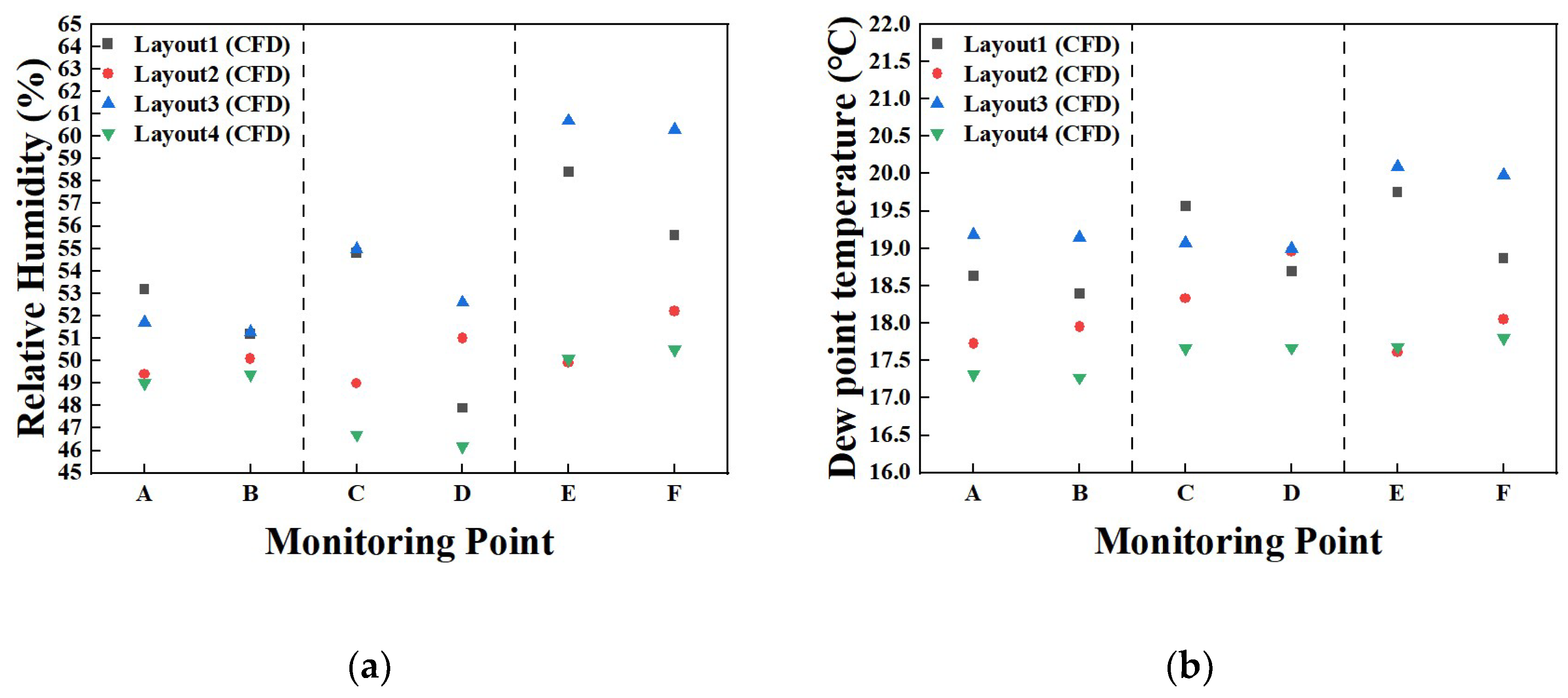

3.3. Simulation Optimization Analysis

3.3.1. Model Optimization

3.3.2. The Impact of Different Humidity Sources on Dehumidification Efficiency

3.3.3. The Impact of Pipeline Layout on the Flow Field of Cable Chambers

4. Conclusions

- (1)

- Based on mutual verification between simulation and experiment, the maximum relative errors of temperature, relative humidity, and velocity at the six monitoring points set in all layout experiments and simulations are only 3.61%, 7.14%, and 7.14%. Meanwhile, the average temperature relative error between experiment and simulation is 2.7% in the electric heating wire, and the errors are both within an acceptable range.

- (2)

- Based on mutual verification of experimental and simulation results, after optimizing the model, the overall dehumidification has the same trend. Layout 2 and Layout 4 have better dehumidification compared to the original layout. Layout 4 is the optimal layout. After reaching a steady state, compared with other layouts, the relative humidity of the corresponding measurement points is reduced by up to 10.6% with a minimum relative humidity of 45.1%; the dew point temperature can be reduced by up to 2.61 °C, with a minimum dew point temperature of 17.2 °C.

- (3)

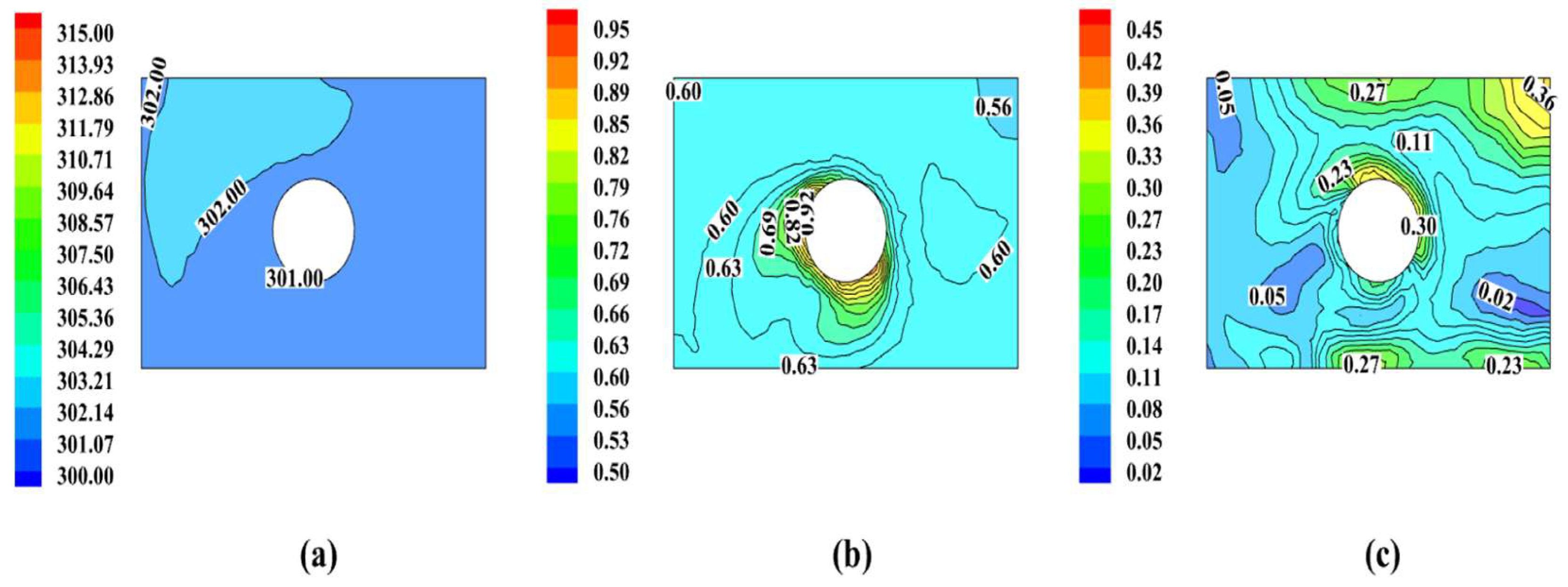

- The new layout has a more uniform flow distribution compared to the original layout, with an overall temperature of around 301 K and a relative humidity of 50% on typical cross-sections. The overall distribution of flow velocity is also more uniform, with a maximum of no more than 0.3 m/s. Based on the above experiments and simulations, optimized dehumidification methods and measures have been proposed, providing support for their safe operation. However, this study is mainly based on the experimental environment of 28 °C and 50% humidity, which has certain limitations, and the bidirectional coupling of electric-thermal needs to be further considered. In the future, further research will be conducted based on more environmental conditions, providing more references for the prevention of condensation in RMU.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, H.; Zhang, X.; Tang, J.; Xiao, S. The application of fluorescent optical fiber in partial discharge detection of Ring Main Unit. Measurement 2021, 174, 108979. [Google Scholar] [CrossRef]

- Bharat Heavy Electricals Limited. Handbook of Switchgears; McGraw-Hill: New Delphi, India, 2006. [Google Scholar]

- Jiang, T.; Sun, W. Analysis and solution of dewing problems for the looped-network switchgear. Rural. Electr. 2011, 19, 28. [Google Scholar]

- Xu, X.Y. 110–500 kV analysis of composite insulator flashover on transmission line and countermeasure of China. China Power 2000, 33, 54–56. [Google Scholar]

- Zeng, W. Study and practice of anti-condensation technology for high-voltage switchgear. Metall. Power 2016, 32, 49–50. [Google Scholar]

- Lin, F. Indoor dewing phenomenon and strategy in metal-enclosed switchgear. Premiere 2017, 28, 196. [Google Scholar]

- Pan, Q.Z.; Yang, F.; Tang, X.L.; Yang, L.; Liu, S.L. Simulation environment design for the investigation of damping and dewing mechanisms in the 12 kV high-voltage switchgear. E3S Web Conf. 2018, 53, 03001. [Google Scholar] [CrossRef]

- Geng, J.H.; Guo, Q.; Xu, Z.; Liu, R. Research of outdoor equipment condensation development process based on improved morphology and optimization of condensation prevention measures. Sci. Technol. Eng. 2016, 22, 213–218. [Google Scholar]

- Yue, X.F. Discussion about the heating and dehumidification system in 12 kV switchgear. High Volt. Appar. 2002, 38, 57–58. [Google Scholar]

- Wang, Y.; Ding, Y.; Li, W. Humidity control of RMU based on COMSOL simulation analysis. Electr. Power 2020, 53, 206–213. [Google Scholar] [CrossRef]

- Bedkowski, M.; Smolka, J.; Banasiak, K.; Bulinski, Z.; Nowak, A.; Tomanek, T.; Adam, W. Coupled numerical modelling of power loss generation in busbar system of low-voltage switchgear. Int. J. Therm. Sci. 2014, 82, 122–129. [Google Scholar] [CrossRef]

- Chen, R.; Yan, X.; Yan, W.; Zhang, C.; Liu, W.; Yang, K. Numerical simulation on condensation phenomenon in the switch cabinet. Resour. Sav. Environ. Prot. 2015, 5, 21–23. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, Z.; Wang, Y. Anti-condensation method for outdoor RMU based on finite element analysis. High Volt. Appar. 2017, 53, 101–106, 113. [Google Scholar] [CrossRef]

- Wu, Y.; Ruan, J.; Li, P. Optimum simulation of thermal field for switchgear. Electr. Mach. Control. 2020, 24, 1. [Google Scholar] [CrossRef]

- Pan, Q.Z.; Yang, F.; Yang, Z. Discussion on mechanism of the dampness and dewing inside 12 kV high-voltage switchgear and its key control techniques. Power Syst. Prot. Control. 2019, 47, 160–172. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, F.; Wang, Y.; Zhang, H.; You, S.; Shi, R.; Shi, K. Optimization on airflow distribution for anti-condensation of high-voltage switchgear using CFD method. Case Stud. Therm. Eng. 2021, 28, 101479. [Google Scholar] [CrossRef]

- Pan, M.L. Research on Influence Law of Force on the Bushing Affected by Cable Bending in 10 kV RMU. Master’s Thesis, Three Gorges University, Yichang, China, 2018. [Google Scholar]

- Li, Z.W. Temperature Field Modeling and Thermal Analysis of Medium Voltage Switchgear Based on ANSYS. Master’s Thesis, Shanghai University of Engineering Science, Shanghai, China, 2020. [Google Scholar]

- Luo, W.Z.; Xiong, X.X.; Chen, C.; Lin, P. Research on Dehumidification Scheme of Cable Treanch in 35 kV Switchgear Room. Electr. Eng. 2022, 573, 145–147. [Google Scholar] [CrossRef]

| Boundary Condition | Type | Value |

|---|---|---|

| Solution domain | Fluent/Maxwell | / |

| Fluid | Air | / |

| Solid 1 | Copper | Thermal conductivity: 387.6 W/(m K); Bulk conductivity: 58,000,000 siemens/m; |

| Solid 2 | Ni-Cr | Thermal conductivity: 15 W/(m K); |

| Solid 3 | Epoxy resin | Thermal conductivity: 0.276 W/(m K); |

| Solid 4 | Steel | Thermal conductivity: 10.27 W/(m K); |

| Solid 5 | Cross-linked polyethylene | Thermal conductivity: 0.29 W/(m K); |

| Mixture | Water-vapor; Air | / |

| Wall | Convection | heat-transfer coefficient: 9.445 W/(m2K) |

| Inlet | Velocity-inlet 1; Velocity-inlet 2 | Velocity: 1.5 m/s, Temperature: 29 °C, Component mass fraction (H2O): 0.01204; Velocity: 0.4 m/s, Temperature: 28 °C, Component mass fraction (H2O):0.01791/0.01904/0.02038/2387 |

| Outlet | Pressure outer | −0.91 Pa, backflow temperature: 28 °C |

| Target residual | / | 10−4 |

| Equipment | Parameter | Measuring Accuracy |

|---|---|---|

| experimental cable room | 420 × 280 × 830 mm | / |

| electric heating wires | Length: 565 mm Radius: 0.5 mm | / |

| humidifier | Evaporation capacity: 200 mL/h, Power: 28 W, | / |

| single-phase voltage regulator | Voltage: 220 V Power: 5000 W | / |

| 12 L drying dehumidifier | Power: 230 W Dehumidification capacity: 0.29 kg/h Maximum air volume: 100 m3/h | / |

| pipeline axial flow fan | Power: 6 W, Maximum air volume: 36 m3/h | / |

| K-type thermocouple | Measuring range: −200 °C~+1372 °C | Temperature Accuracy: ±0.2% + 0.7 °C |

| anemometer | Use range: 0~0.99 m/s | Velocity accuracy: ±0.02 m/s |

| pressure gauge | Use range: 0~10 Pa | Pressure accuracy: ±0.1 Pa |

| hygrothermograph | Temperature range: −20~60 °C Humidity range: 0~100% Dew point temperature range: −50 °C~60 °C | Temperature accuracy: ±1.5 °C; Humidity accuracy: ±3.0%; Dew point temperature accuracy: ±1.5 °C |

| Points | Layout 1 | Layout 2 | Layout 3 | Layout 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | Temperature | Temperature | Temperature | |||||||||||||

| EXP (°C) | CFD (°C) | RE (%) | MAPE | EXP (°C) | CFD (°C) | RE (%) | MAPE | EXP (°C) | CFD (°C) | RE (%) | MAPE | EXP (°C) | CFD (°C) | RE (%) | MAPE | |

| A | 28.10 | 28.32 | 0.78 | 1.92% | 28.70 | 28.48 | 0.77 | 1.76% | 28.70 | 28.26 | 1.53 | 0.78% | 28.50 | 28.55 | −0.18 | 1.49% |

| B | 28.10 | 28.58 | 1.71 | 28.70 | 28.37 | 1.15 | 28.40 | 28.37 | 0.11 | 28.60 | 28.56 | 0.14 | ||||

| C | 28.20 | 28.78 | 2.10 | 28.00 | 28.85 | −3.04 | 28.50 | 28.78 | −0.98 | 28.70 | 29.08 | −1.32 | ||||

| D | 28.00 | 28.90 | 3.21 | 28.60 | 29.02 | −1.47 | 28.90 | 29.00 | −0.35 | 28.00 | 29.01 | −3.61 | ||||

| E | 28.10 | 28.64 | 1.92 | 28.00 | 28.76 | −2.71 | 28.60 | 28.57 | 0.10 | 28.00 | 28.79 | −2.82 | ||||

| F | 28.10 | 28.61 | 1.81 | 28.00 | 28.40 | −1.43 | 28.10 | 28.55 | −1.60 | 28.50 | 28.74 | −0.84 | ||||

| Points | Layout 1 | Layout 2 | Layout 3 | Layout 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH | RH | RH | RH | |||||||||||||

| EXP (%) | CFD (%) | RE (%) | MAPE | EXP (%) | CFD (%) | RE (%) | MAPE | EXP (%) | CFD (%) | RE (%) | MAPE | EXP (%) | CFD (%) | RE (%) | MAPE | |

| A | 57.5 | 55.0 | −4.35 | 3.95% | 53.1 | 51.0 | 3.95 | 5.87% | 59.0 | 58.0 | 1.69 | 2.27% | 53.0 | 51.0 | 3.77 | 4.47% |

| B | 56.0 | 52.0 | −7.14 | 54.1 | 53.0 | 2.03 | 58.0 | 56.0 | 3.45 | 53.0 | 50.0 | 5.66 | ||||

| C | 58.0 | 57.0 | −1.72 | 58.0 | 54.0 | 6.90 | 55.0 | 56.0 | −1.82 | 54.0 | 51.0 | 5.56 | ||||

| D | 57.0 | 53.0 | −7.02 | 57.0 | 54.0 | 5.26 | 53.0 | 55.1 | −3.96 | 53.0 | 51.0 | 3.77 | ||||

| E | 55.9 | 55.0 | −1.61 | 58.0 | 53.0 | 8.62 | 58.6 | 58.0 | 1.02 | 53.5 | 52.0 | 2.80 | ||||

| F | 53.0 | 52.0 | −1.89 | 59.0 | 54.0 | 8.47 | 59.0 | 58.0 | 1.69 | 54.9 | 52.0 | 5.28 | ||||

| Points | Layout 1 | Layout 2 | Layout 3 | Layout 4 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Velocity | Velocity | Velocity | Velocity | |||||||||||||

| EXP (m/s) | CFD (m/s) | RE (%) | MAPE | EXP (m/s) | CFD (m/s) | RE (%) | MAPE | EXP (m/s) | CFD (m/s) | RE (%) | MAPE | EXP (m/s) | CFD (m/s) | RE (%) | MAPE | |

| A | 0.02 | 0.02 | 0.00 | 0.67% | 0.13 | 0.12 | 7.69 | 3.31% | 0.02 | 0.02 | 0.00 | 2.86% | 0.09 | 0.09 | 0.00 | 1.49% |

| B | 0.13 | 0.12 | −7.14 | 0.01 | 0.01 | 0.00 | 0.02 | 0.02 | 0.00 | 0.08 | 0.08 | 0.00 | ||||

| C | 0.15 | 0.14 | −6.66 | 0.09 | 0.09 | 0.00 | 0.18 | 0.17 | 5.56 | 0.21 | 0.20 | 4.76 | ||||

| D | 0.09 | 0.09 | 0.00 | 0.14 | 0.13 | 7.14 | 0.24 | 0.23 | 4.17 | 0.24 | 0.23 | 4.17 | ||||

| E | 0.14 | 0.15 | −7.14 | 0.20 | 0.19 | 5.00 | 0.29 | 0.28 | 3.45 | 0.10 | 0.10 | 0.00 | ||||

| F | 0.25 | 0.26 | 4.00 | 0.05 | 0.05 | 0.00 | 0.25 | 0.24 | 4.00 | 0.09 | 0.09 | 0.00 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Xing, F.; Gao, H.; Mei, D. Enhancing Dehumidification in the Cable Room of a Ring Main Unit through CFD-EMAG Coupling Simulation and Experimental Verification. Appl. Sci. 2024, 14, 1602. https://doi.org/10.3390/app14041602

Yan Y, Xing F, Gao H, Mei D. Enhancing Dehumidification in the Cable Room of a Ring Main Unit through CFD-EMAG Coupling Simulation and Experimental Verification. Applied Sciences. 2024; 14(4):1602. https://doi.org/10.3390/app14041602

Chicago/Turabian StyleYan, Yaoyu, Futang Xing, Haonan Gao, and Dan Mei. 2024. "Enhancing Dehumidification in the Cable Room of a Ring Main Unit through CFD-EMAG Coupling Simulation and Experimental Verification" Applied Sciences 14, no. 4: 1602. https://doi.org/10.3390/app14041602

APA StyleYan, Y., Xing, F., Gao, H., & Mei, D. (2024). Enhancing Dehumidification in the Cable Room of a Ring Main Unit through CFD-EMAG Coupling Simulation and Experimental Verification. Applied Sciences, 14(4), 1602. https://doi.org/10.3390/app14041602