Machine Learning-Supported Designing of Human–Machine Interfaces

Abstract

1. Introduction

2. Machine Learning-Supported HMI Optimisation

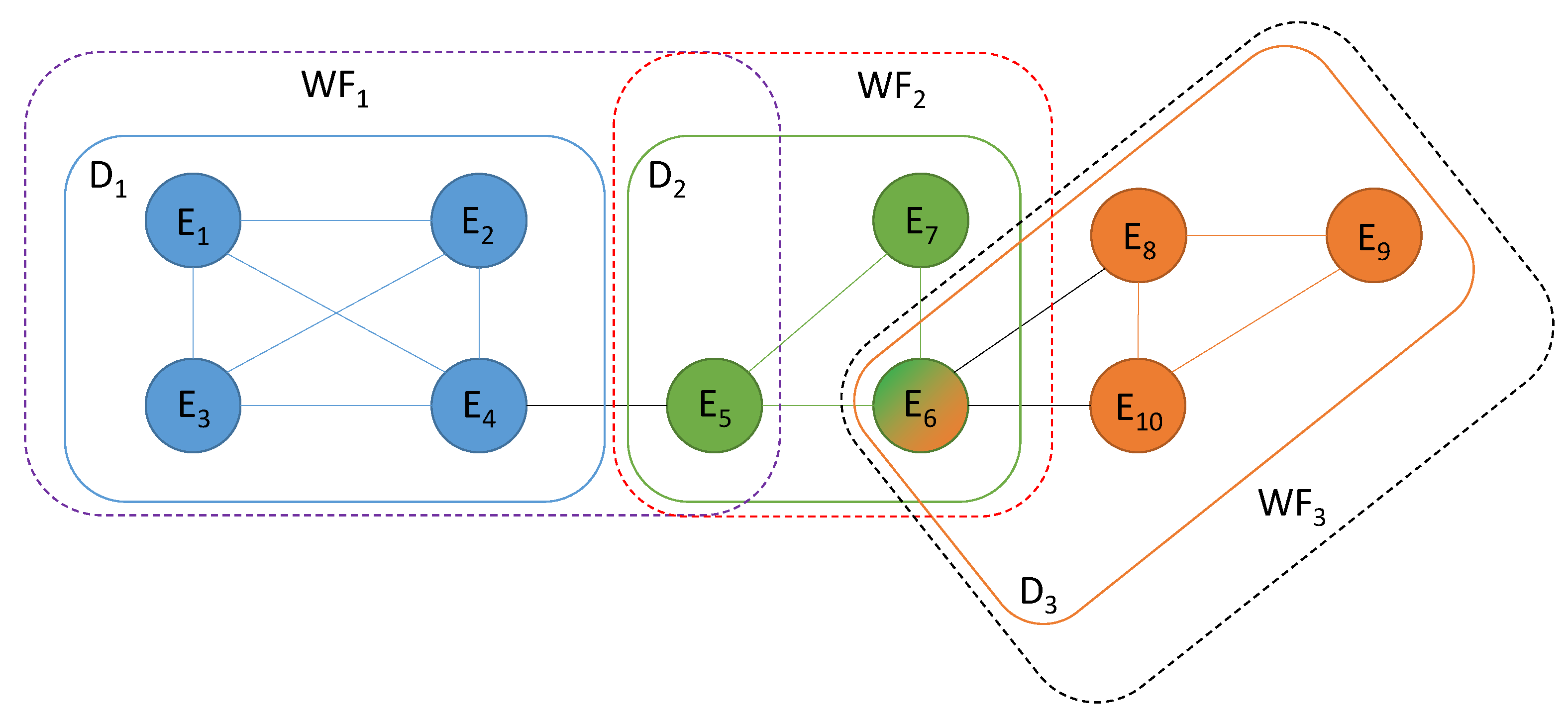

2.1. Identification of the Workflows as Frequent Event Patterns

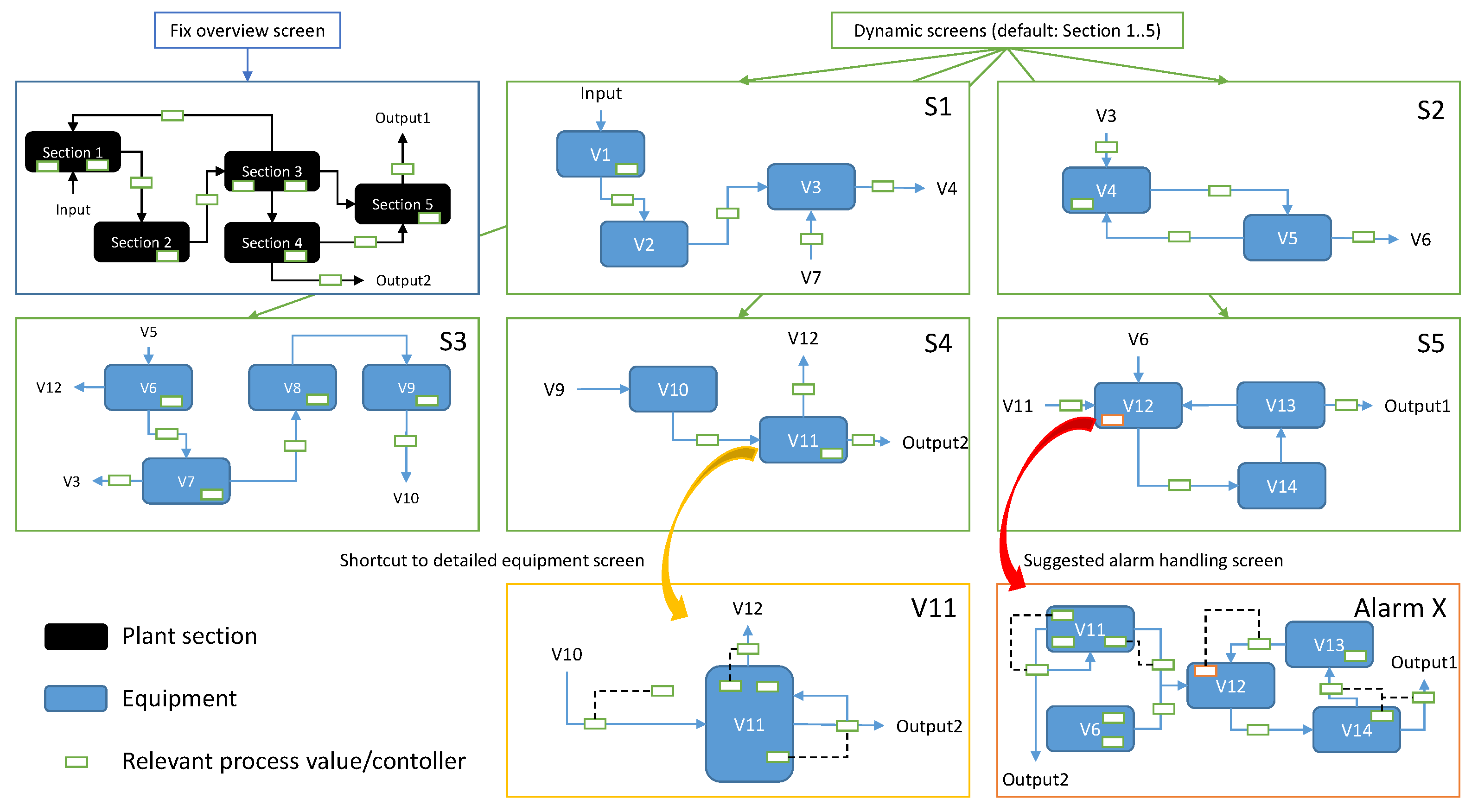

2.2. Connection between Workflows and Displays

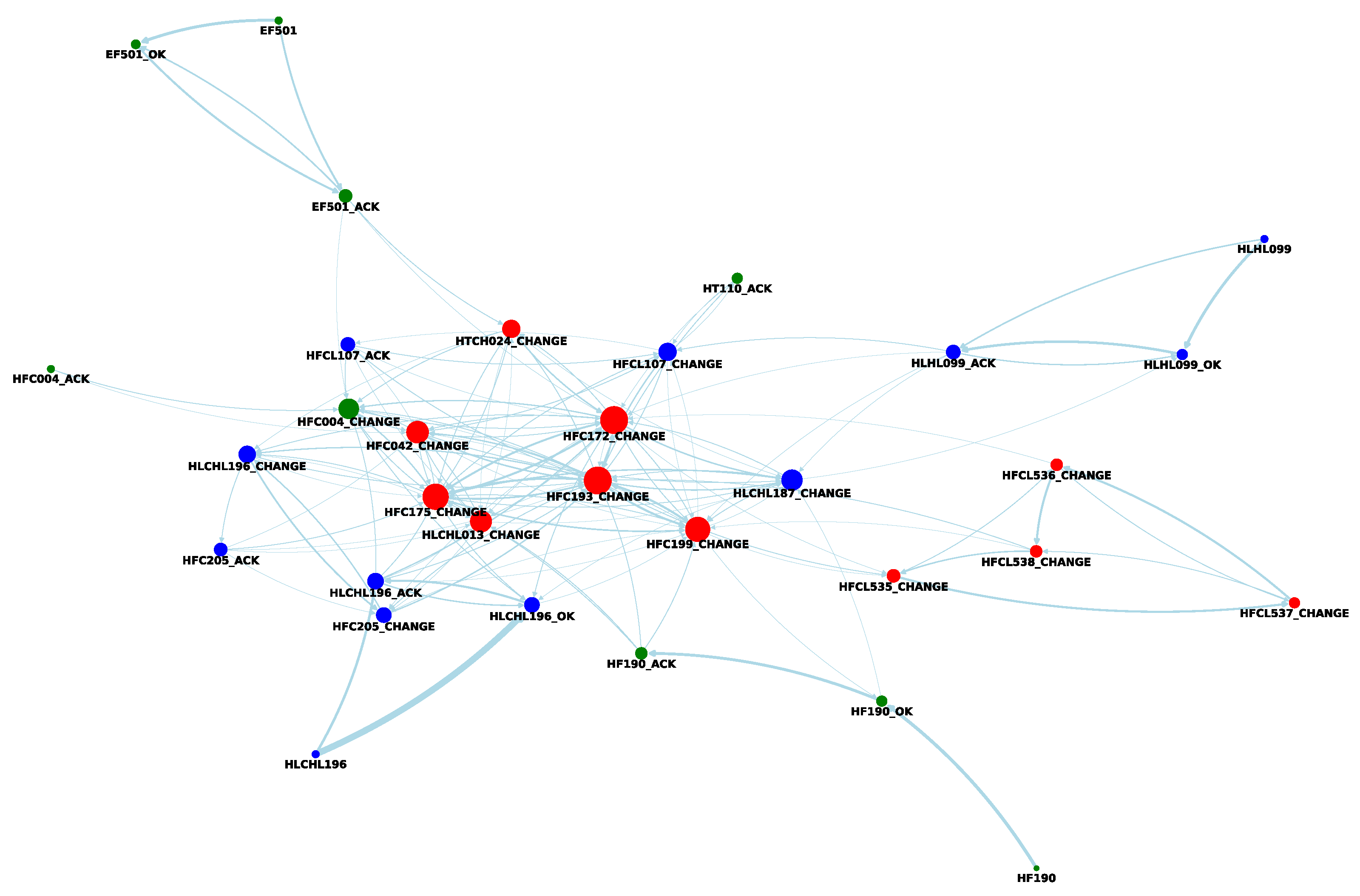

2.3. Workflows, Displays, and Their Elements as a Community

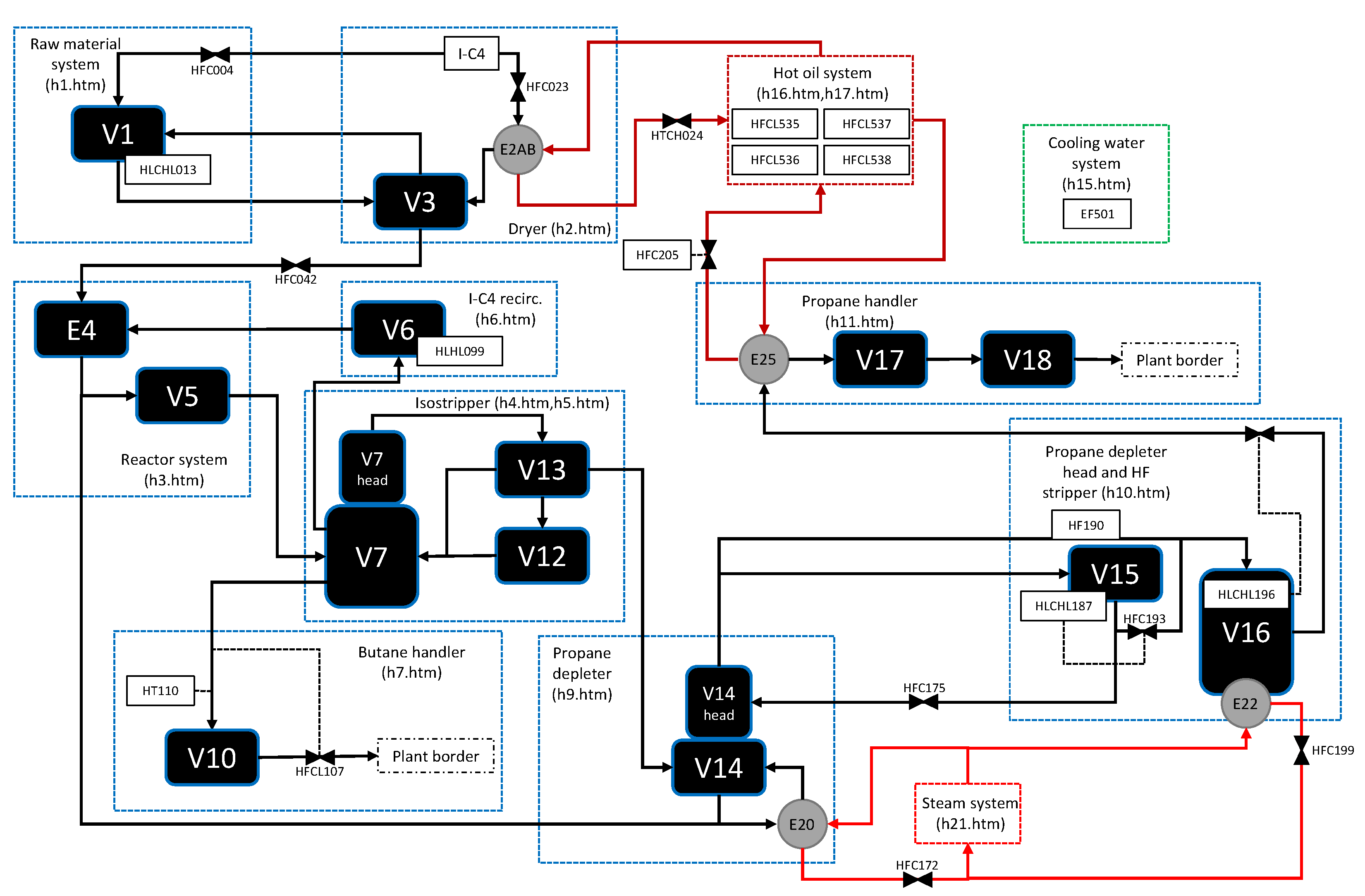

3. Application of the Method on a Real-World Industrial System

3.1. Problem Description

3.2. Results

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HMI | Human–Machine Interface. |

| HP-HMI | High-Performance Human–Machine Interface. |

| ML | Machine Learning. |

| UX | User experience. |

| UI | User interface. |

| PLC | Programmable Logic Controller. |

| P&ID | Piping and Instrumentation Diagram. |

| DCS | Distributed Control System. |

| SCADA | Supervisory Control and Data Acquisition. |

| HAZOP | Hazard and Operability. |

| OTS | Operator Training System. |

References

- Kamizi, S.A. UI/UX of Human-Machine Interface for Industrial Application: Review and Preleminary Design. In Proceedings of the FCSIT UNIMAS FYP Symposium, Kota Samarahan, Malaysia, 28–30 January 2021; pp. 28–30. [Google Scholar]

- Kang, Z.; Catal, C.; Tekinerdogan, B. Machine learning applications in production lines: A systematic literature review. Comput. Ind. Eng. 2020, 149, 106773. [Google Scholar] [CrossRef]

- Kistan, T.; Gardi, A.; Sabatini, R. Machine learning and cognitive ergonomics in air traffic management: Recent developments and considerations for certification. Aerospace 2018, 5, 103. [Google Scholar] [CrossRef]

- Pérez-Reynoso, F.; Farrera-Vazquez, N.; Capetillo, C.; Méndez-Lozano, N.; González-Gutiérrez, C.; López-Neri, E. Pattern Recognition of EMG Signals by Machine Learning for the Control of a Manipulator Robot. Sensors 2022, 22, 3424. [Google Scholar] [CrossRef]

- Rashad, O.; Attallah, O.; Morsi, I. A smart PLC-SCADA framework for monitoring petroleum products terminals in industry 4.0 via machine learning. Meas. Control 2022, 55, 830–848. [Google Scholar] [CrossRef]

- Valette, E.; Bril El-Haouzi, H.; Demesure, G. Industry 5.0 and its technologies: A systematic literature review upon the human place into IoT- and CPS-based industrial systems. Comput. Ind. Eng. 2023, 184, 109426. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. The Future of the Human-Machine Interface (HMI) in Society 5.0. Future Internet 2023, 15, 162. [Google Scholar] [CrossRef]

- Hollifield, B. A High Performance HMI: Better Graphics for Operations Effectiveness. In Proceedings of the 2012 Water/Wastewater and Automation Controls Symposium, Orlando, FL, USA, 7–9 August 2012. [Google Scholar]

- Reguera-Bakhache, D.; Garitano, I.; Uribeetxeberria, R.; Cernuda, C.; Zurutuza, U. Data-driven industrial human-machine interface temporal adaptation for process optimization. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; IEEE: Piscataway, NJ, USA, 2020; Volume 1, pp. 518–525. [Google Scholar]

- Fortoul-Diaz, J.A.; Carrillo-Martinez, L.A.; Centeno-Tellez, A.; Cortes-Santacruz, F.; Olmos-Pineda, I.; Flores-Quintero, R.R. A Smart Factory Architecture Based on Industry 4.0 Technologies: Open-Source Software Implementation. IEEE Access 2023, 11, 101727–101749. [Google Scholar] [CrossRef]

- Sun, G.; Xu, P.; Guo, M.; Sun, H.; Du, Z.; Li, Y.; Zhou, B. OL-JCMSR: A Joint Coding Monitoring Strategy Recommendation Model Based on Operation Log. Mathematics 2022, 10, 2292. [Google Scholar] [CrossRef]

- Lin, C.H.; Wang, K.J.; Tadesse, A.A.; Woldegiorgis, B.H. Human-robot collaboration empowered by hidden semi-Markov model for operator behaviour prediction in a smart assembly system. J. Manuf. Syst. 2022, 62, 317–333. [Google Scholar] [CrossRef]

- Urbas, L.; Obst, M.; Stöss, M. Formal models for high performance HMI engineering. IFAC Proc. Vol. 2012, 45, 854–859. [Google Scholar] [CrossRef]

- Hägle, R.; Schlögel, S.; Klöpfer, K.; Bauernhansl, T. A Methodology for the Systematic Selection of Human-Machine Interface Device Types in Production Machinery Development. Procedia CIRP 2023, 119, 975–980. [Google Scholar] [CrossRef]

- Tran, T.A.; Ruppert, T.; Eigner, G.; Abonyi, J. Retrofitting-Based Development of Brownfield Industry 4.0 and Industry 5.0 Solutions. IEEE Access 2022, 10, 64348–64374. [Google Scholar] [CrossRef]

- Folgado, F.J.; González, I.; Calderón, A.J. Data acquisition and monitoring system framed in Industrial Internet of Things for PEM hydrogen generators. Internet Things 2023, 22, 100795. [Google Scholar] [CrossRef]

- ANSI-ISA-101.01-2015; Human Machine Interfaces for Process Automation Systems. American National Standards Institute: Washington, DC, USA, 2015.

- Bántay, L.; Abonyi, J. Frequent pattern mining-based log file partition for process mining. Eng. Appl. Artif. Intell. 2023, 123, 106221. [Google Scholar] [CrossRef]

- Fullen, M.; Schüller, P.; Niggemann, O. Semi-supervised Case-based Reasoning Approach to Alarm Flood Analysis. In Machine Learning for Cyber Physical Systems; Beyerer, J., Maier, A., Niggemann, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 53–61. [Google Scholar]

- Partovian, S.; Bucaioni, A.; Flammini, F.; Thornadtsson, J. Analysis of log files to enable smart-troubleshooting in Industry 4.0: A systematic mapping study. IEEE Access 2023. [Google Scholar] [CrossRef]

- van der Aalst, W. Data Science in Action. In Process Mining: Data Science in Action; Springer: Berlin/Heidelberg, Germany, 2016; pp. 3–23. [Google Scholar]

- Bántay, L.; Sas, N.; Dörgő, G.; Abonyi, J. Sequence Compression and Alignment-Based Process Alarm Prediction. Ind. Eng. Chem. Res. 2023, 62, 10577–10586. [Google Scholar] [CrossRef]

- Villani, V.; Sabattini, L.; Loch, F.; Vogel-Heuser, B.; Fantuzzi, C. A general methodology for adapting industrial HMIs to human operators. IEEE Trans. Autom. Sci. Eng. 2019, 18, 164–175. [Google Scholar] [CrossRef]

- Barabási, A.L. Network science. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2013, 371, 20120375. [Google Scholar] [CrossRef] [PubMed]

- Shchur, O.; Günnemann, S. Overlapping community detection with graph neural networks. arXiv 2019, arXiv:1909.12201. [Google Scholar]

- Teng, X.; Liu, J.; Li, M. Overlapping Community Detection in Directed and Undirected Attributed Networks Using a Multiobjective Evolutionary Algorithm. IEEE Trans. Cybern. 2021, 51, 138–150. [Google Scholar] [CrossRef]

- Fournier-Viger, P.; Lin, C.; Gomariz, A.; Gueniche, T.; Soltani, A.; Deng, Z.; Lam, H.T. The SPMF Open-Source Data Mining Library Version 2. In Machine Learning and Knowledge Discovery in Databases, Proceedings of the 19th European Conference on Principles of Data Mining and Knowledge Discovery (PKDD 2016), Riva del Garda, Italy, 19–23 September 2016; Springer: Cham, Switzerland, 2016; pp. 36–40. [Google Scholar]

- Fournier-Viger, P.; Gomariz, A.; Campos, M.; Thomas, R. Fast vertical mining of sequential patterns using co-occurrence information. In Advances in Knowledge Discovery and Data Mining, Proceedings of the 18th Pacific-Asia Conference, PAKDD 2014, Tainan, Taiwan, 13–16 May 2014; Springer: Cham, Switzerland, 2014; pp. 40–52. [Google Scholar]

- Van Der Aalst, W.M.; Reijers, H.A.; Song, M. Discovering social networks from event logs. Comput. Support. Coop. Work. (CSCW) 2005, 14, 549–593. [Google Scholar] [CrossRef]

- Nielsen, J. Usability inspection methods. In Proceedings of the Conference Companion on Human Factors in Computing Systems, Boston, MA, USA, 24–28 April 1994; pp. 413–414. [Google Scholar]

- Gadár, L.; Abonyi, J. Frequent pattern mining in multidimensional organizational networks. Sci. Rep. 2019, 9, 3322. [Google Scholar] [CrossRef]

| Minimum Support | Found Sequential Patterns | Elapsed Time [ms] | Performance Factor |

|---|---|---|---|

| 0.2 | 6,777,245 | 312,271 | 21.7 |

| 0.3 | 65,601 | 4278 | 15.3 |

| 0.4 | 3058 | 322 | 9.5 |

| 0.5 | 405 | 101 | 4.0 |

| 0.6 | 99 | 72 | 1.4 |

| Number of Traces | Number of Events | Found Sequential Patterns | Elapsed Time [ms] | Performance Factor |

|---|---|---|---|---|

| 495 | 21,277 | 99 | 72 | 1.4 |

| 982 | 50,870 | 31 | 83 | 0.4 |

| 1474 | 62,496 | 27 | 88 | 0.4 |

| 1970 | 70,404 | 26 | 113 | 0.2 |

| 2464 | 84,824 | 25 | 112 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bántay, L.; Abonyi, J. Machine Learning-Supported Designing of Human–Machine Interfaces. Appl. Sci. 2024, 14, 1564. https://doi.org/10.3390/app14041564

Bántay L, Abonyi J. Machine Learning-Supported Designing of Human–Machine Interfaces. Applied Sciences. 2024; 14(4):1564. https://doi.org/10.3390/app14041564

Chicago/Turabian StyleBántay, László, and János Abonyi. 2024. "Machine Learning-Supported Designing of Human–Machine Interfaces" Applied Sciences 14, no. 4: 1564. https://doi.org/10.3390/app14041564

APA StyleBántay, L., & Abonyi, J. (2024). Machine Learning-Supported Designing of Human–Machine Interfaces. Applied Sciences, 14(4), 1564. https://doi.org/10.3390/app14041564