Temperature Effects on the Natural Frequencies of Composite Girders

Abstract

1. Introduction

2. Temperature Effects on a Composite Bridge

2.1. Thermal Properties and Elastic Moduli

- Eci(T) is the modulus of elasticity of concrete at temperature T;

- Eci is the elastic modulus of concrete at 20 °C (MPa);

- T is the temperature of concrete (°C).

- Ec(T) is the modulus of elasticity of steel at temperature T,

- Ec20°C is the elastic modulus of steel at 20 °C (MPa), and

- T is the temperature of steel (°C).

2.2. Impact of Temperature on the Size of Structures

- L1 is the beam length after temperature change,

- α is the linear expansion coefficient,

- ΔT is the temperature change, and

- L is the initial beam length.

3. Experiments on Temperature Effects

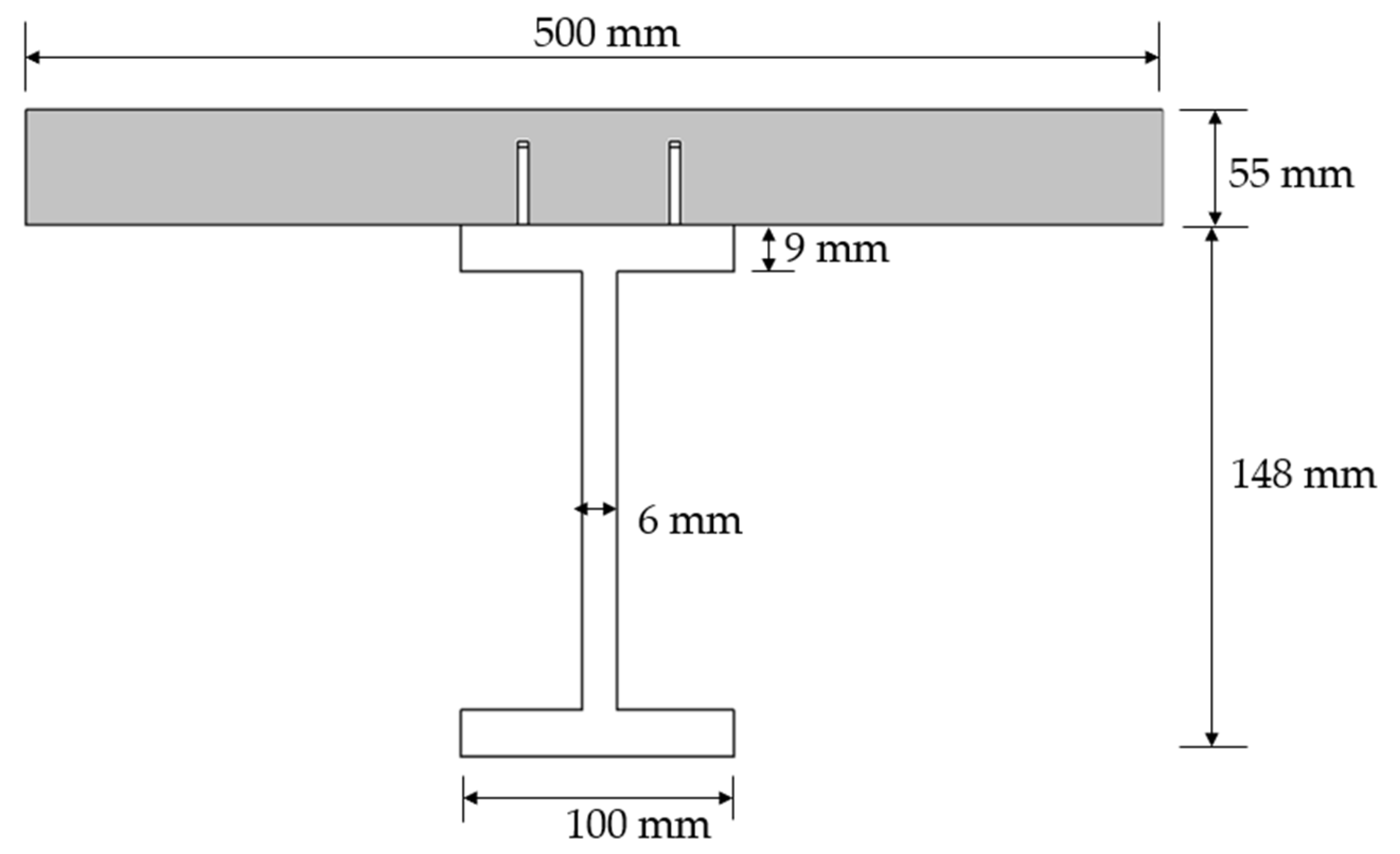

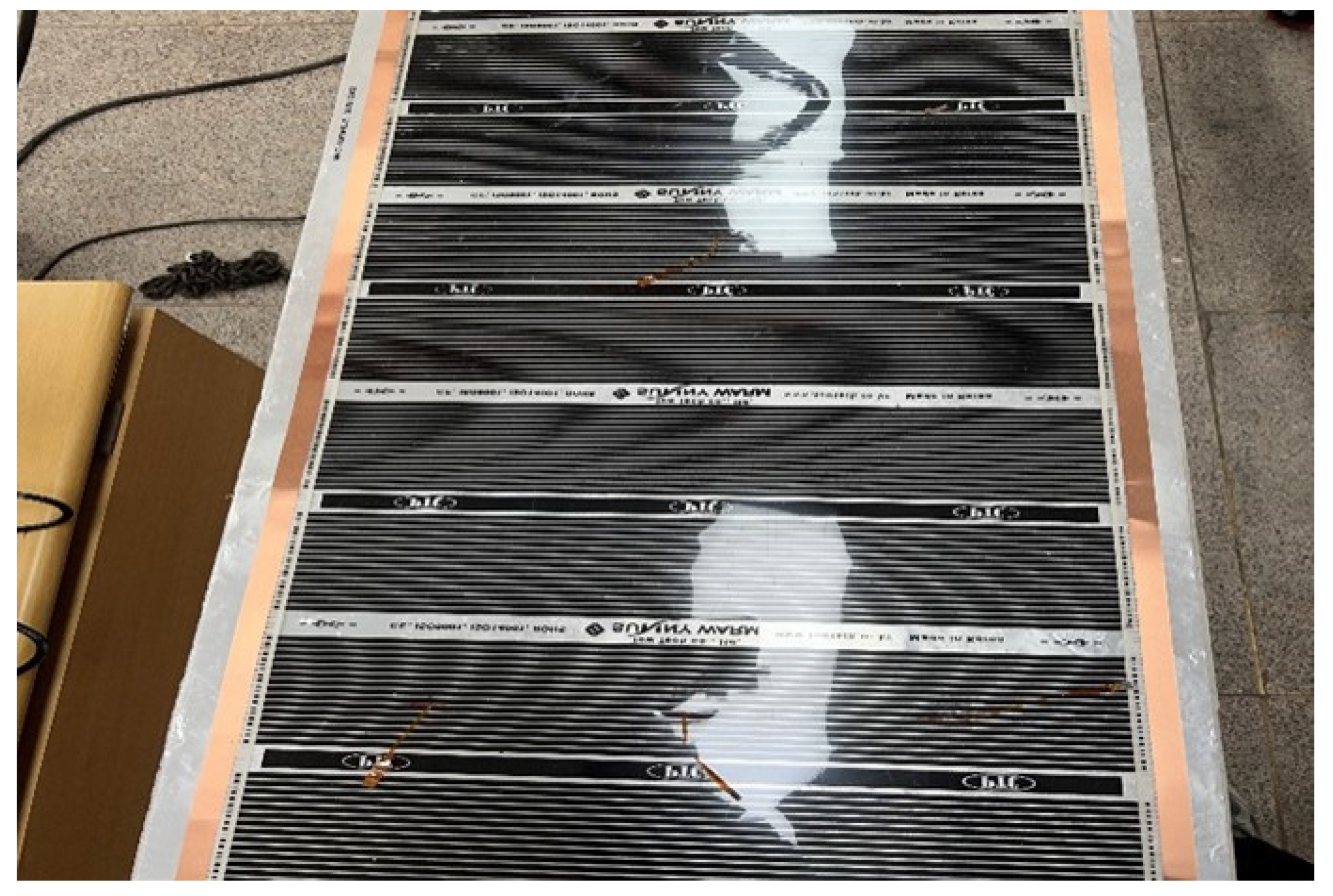

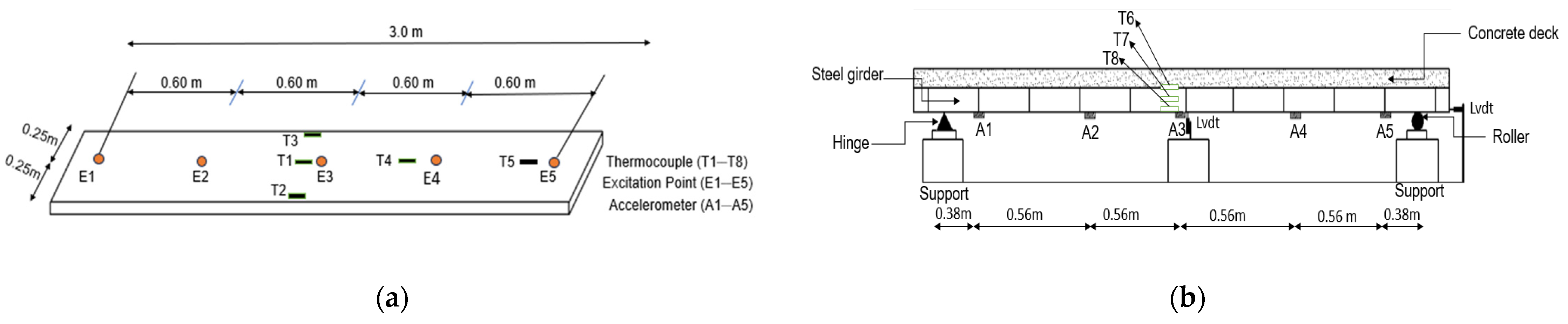

3.1. Test Specimen and Measurement Setup

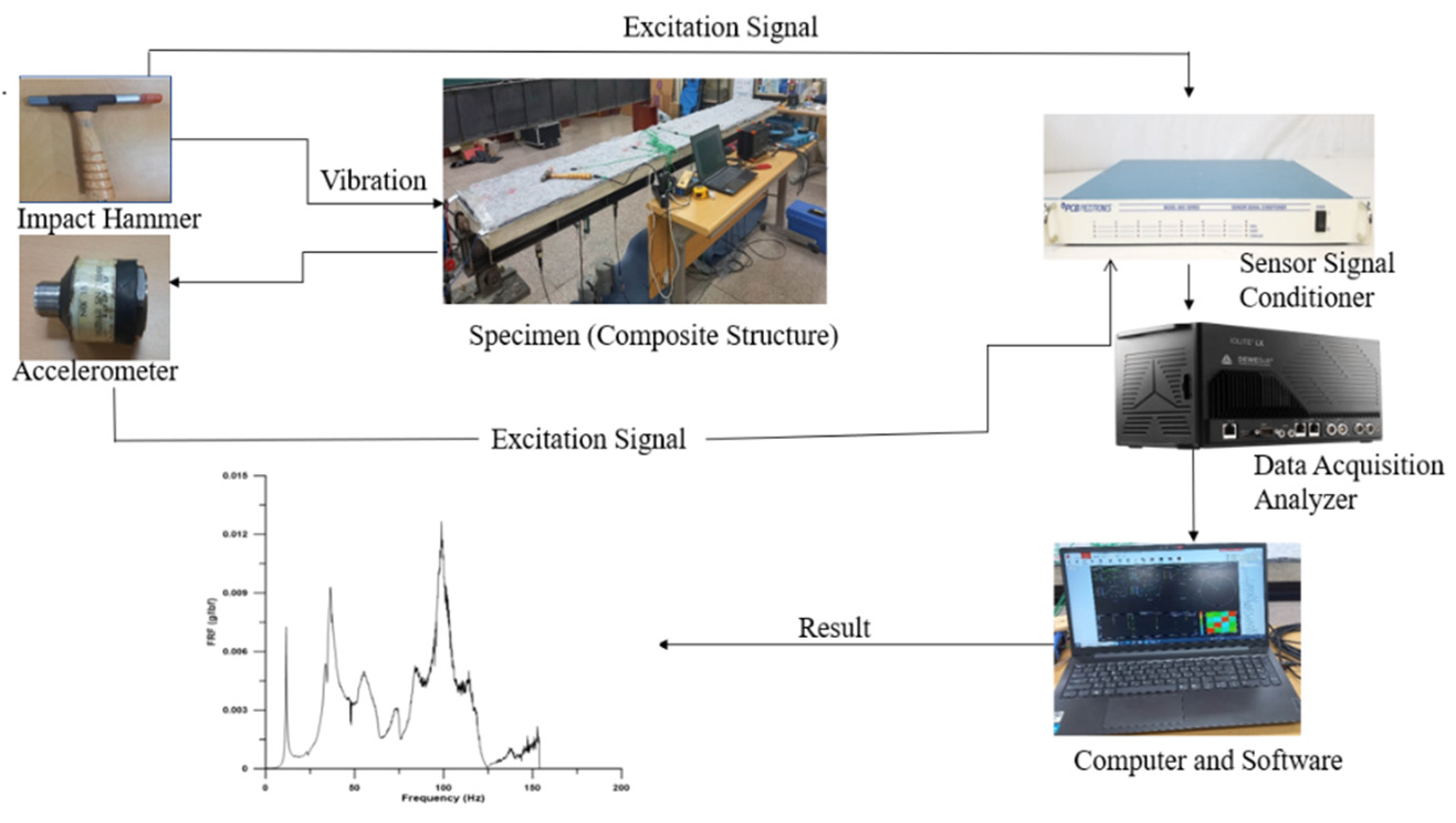

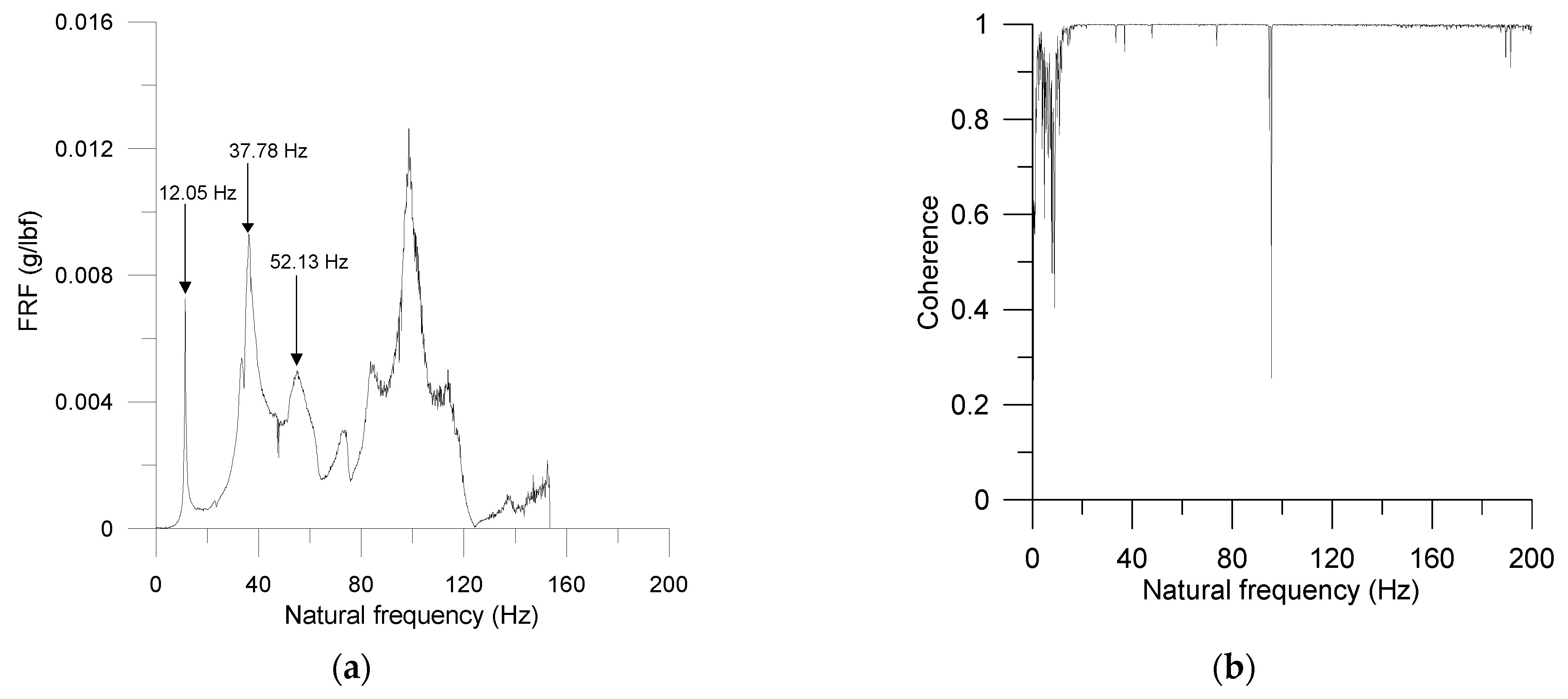

3.2. Modal Tests

4. Numerical Simulations for Modal Testing

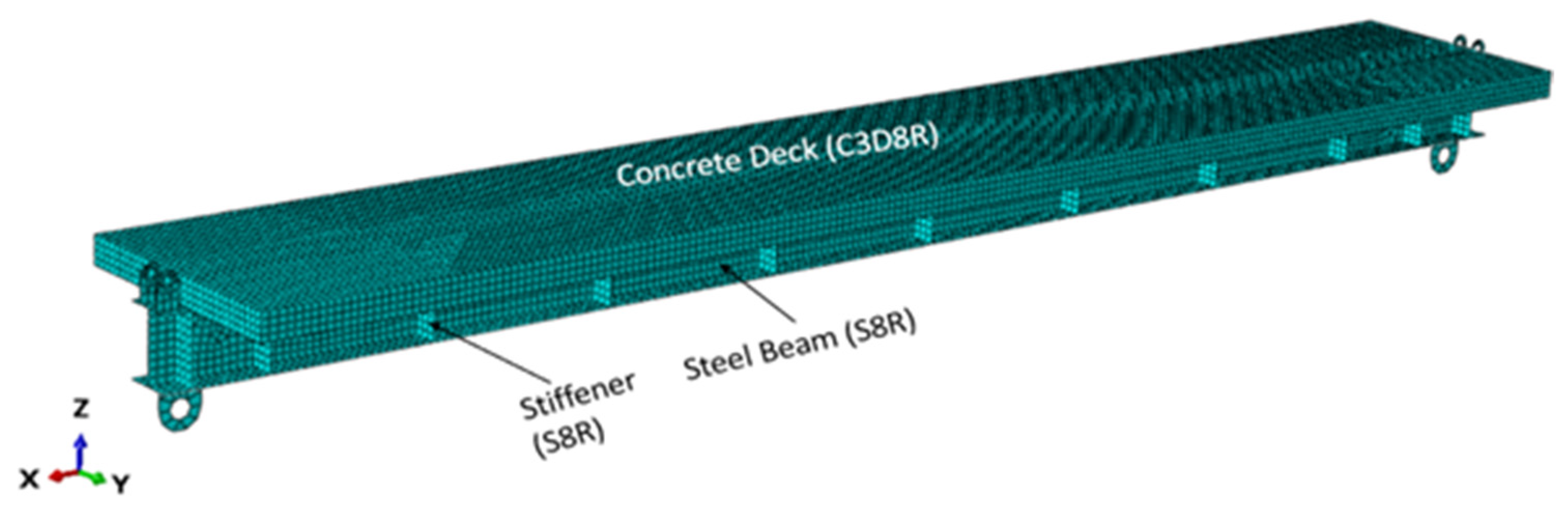

4.1. Numerical Model

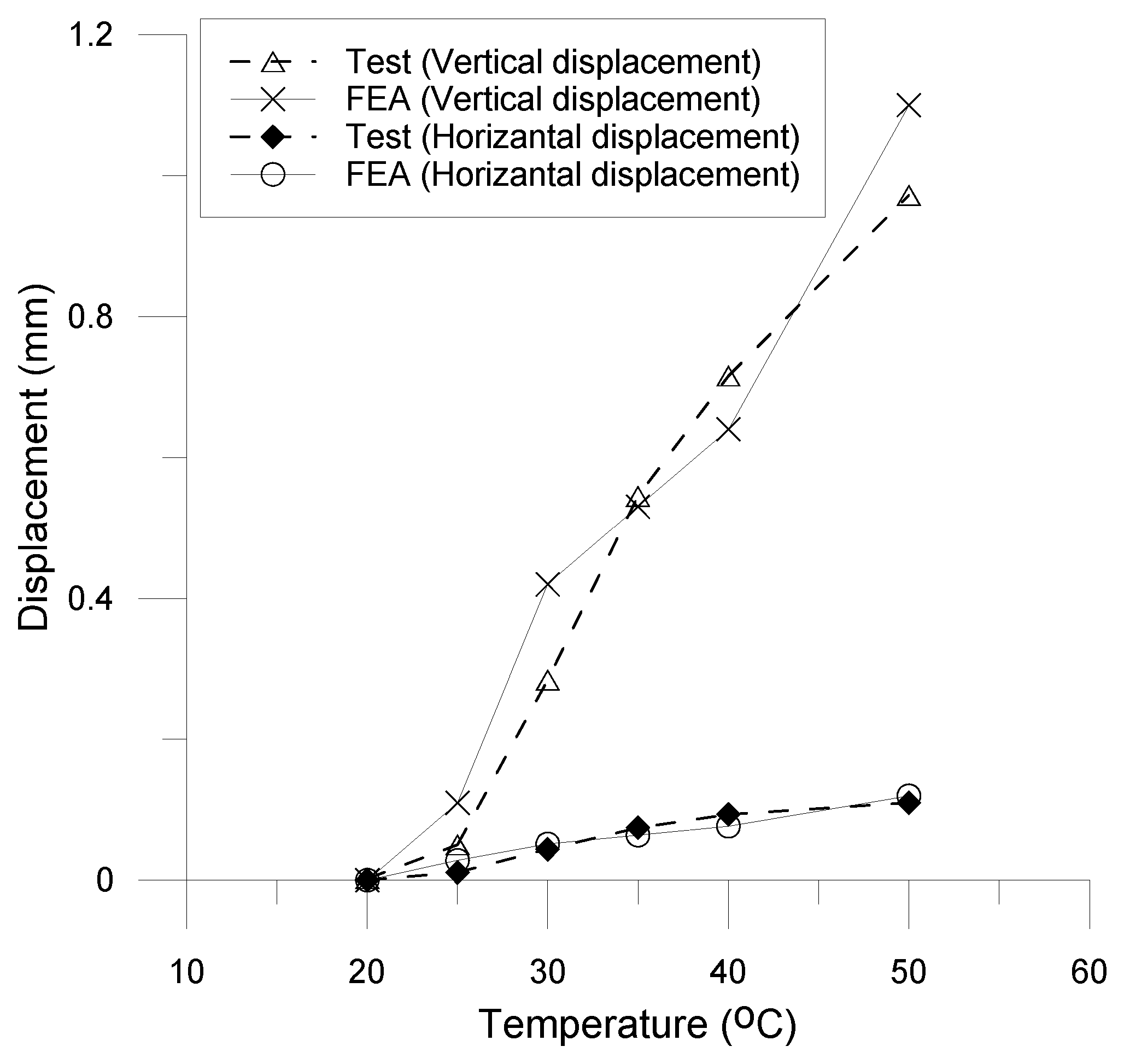

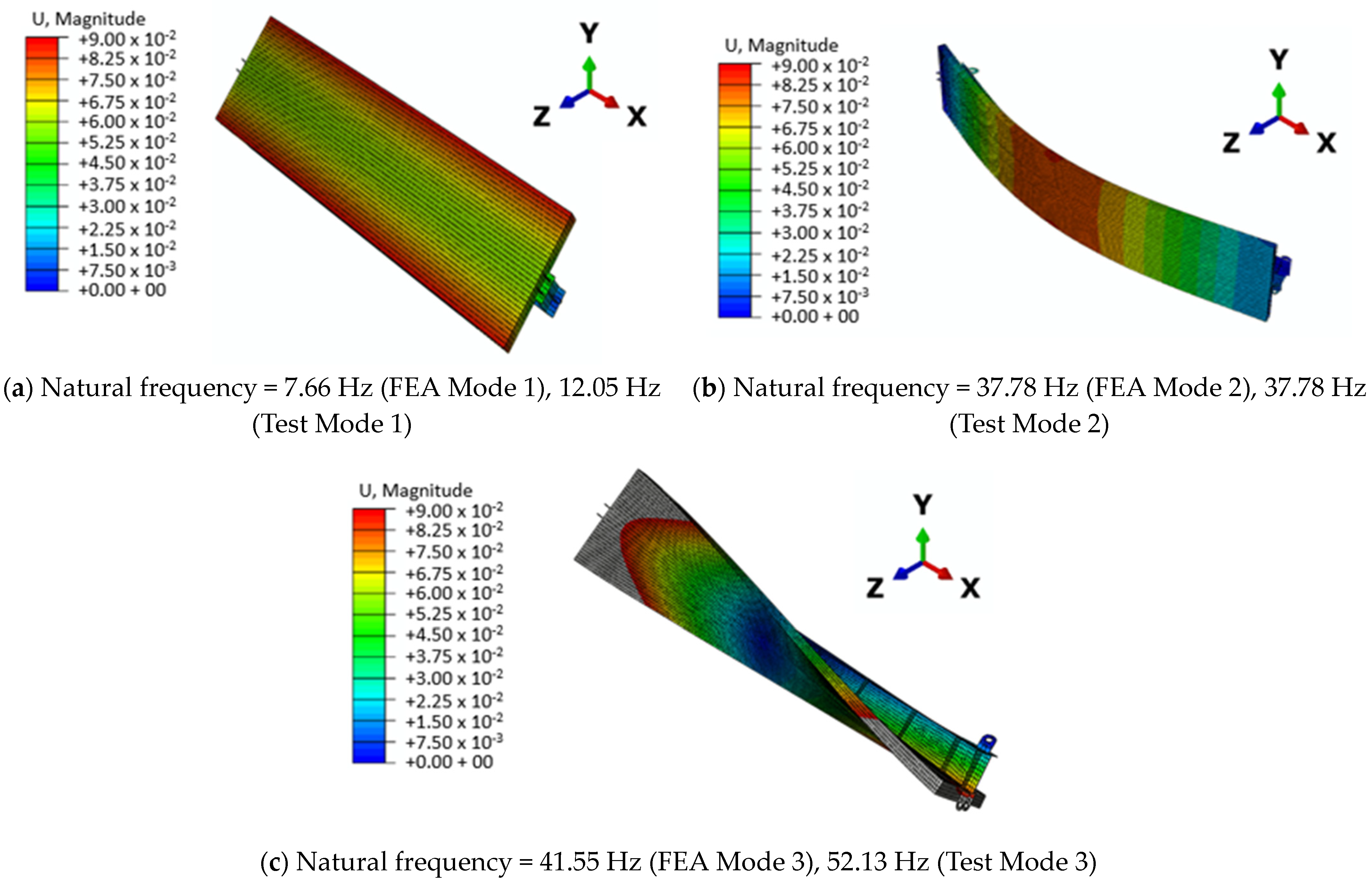

4.2. Simulation Procedure and Results

5. Summary and Conclusions

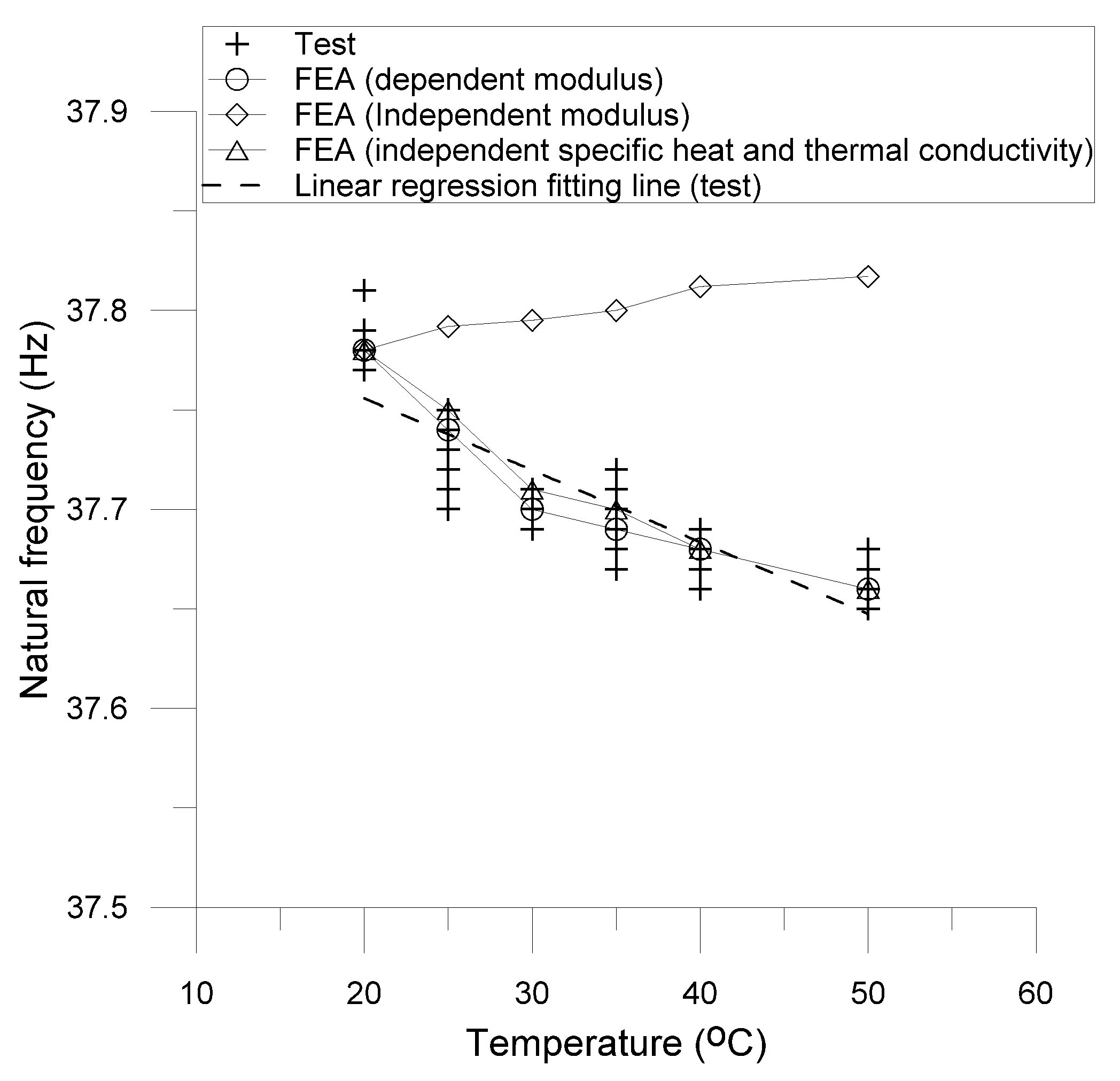

- The natural frequency of the composite girder tended to decrease, as the temperature of the top deck increased. The frequency decreased at a rate of 0.36% per degree according to the linear regression analysis of the test data in a range of 20–50 °C. The standard deviation of the linear model was 0.038 Hz.

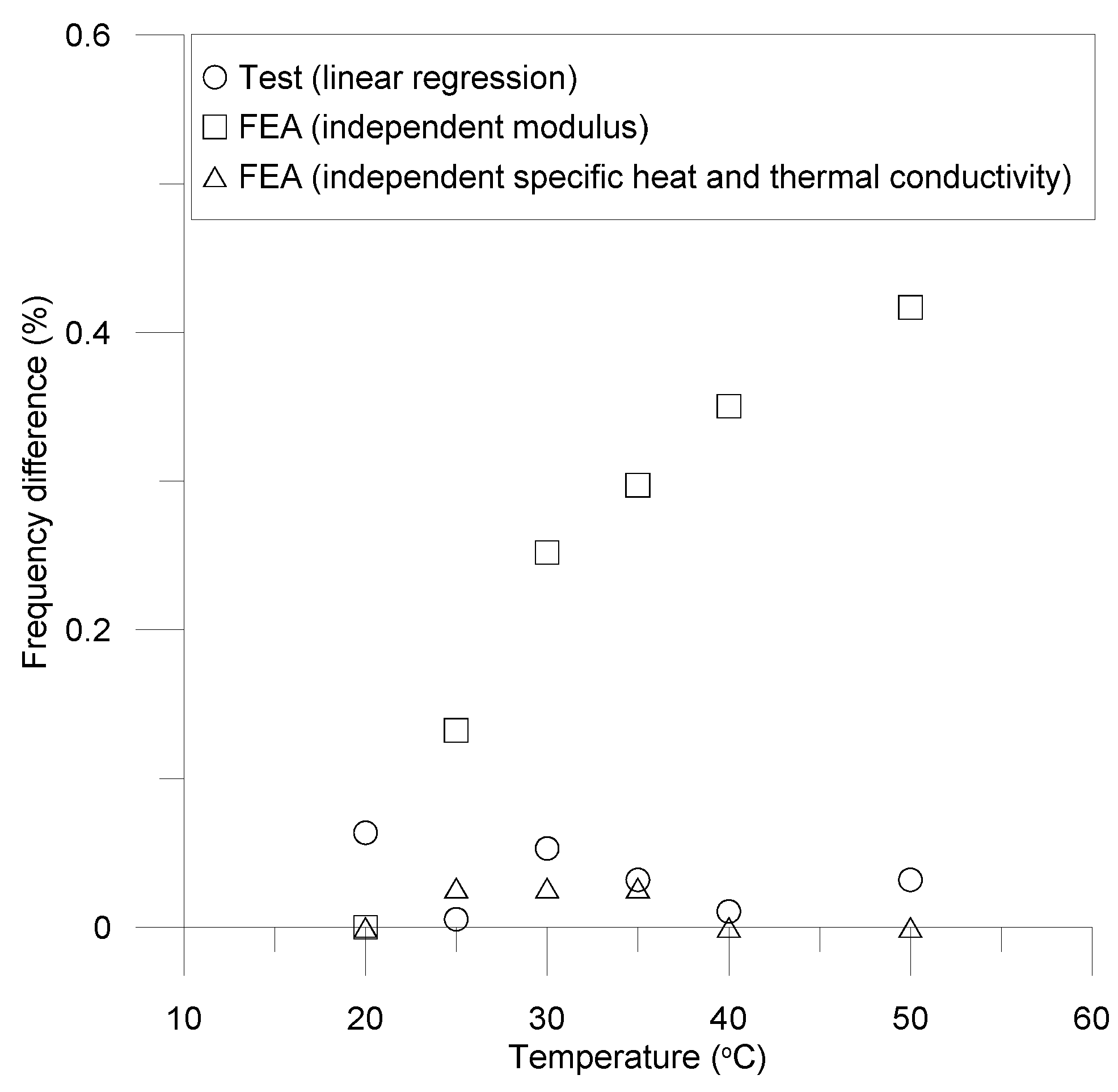

- The decreasing tendency of the frequency was primarily caused by the temperature dependency of the elastic modulus. Without this dependency, the frequency increases with temperature. It was presumed that the convex-shaped deformation induced by the temperature gradient increased the flexural stiffness of the composite girder such that the natural frequency increased. The frequency increased by up to 0.1%, as the temperature increased from 20 to 50 °C with a simply supported boundary condition. Considering the fact that the frequency decrease rate was 0.36% per degree, the effect of increased stiffness was negligible in the simply supported composite girder.

- The specific heat and the thermal conductivity of steel are also dependent on temperature. They affect the natural frequency with temperature changes; however, the maximum difference in the case considering these temperature dependencies was only 0.03%. Therefore, they are not comparable to the elastic modulus effect.

- The linear regression model exhibited a maximum frequency difference of 0.06% compared to the detailed FE simulation results at 20 °C, which decreased as the temperature increased. The difference fluctuated with temperature, which can be attributed to the nonlinear nature of the changes in specific heat with temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Hababi, T.; Alkayem, N.F.; Cui, L.; Zhang, S.; Liu, C.; Cao, M. The Coupled Effect of Temperature Changes and Damage Depth on Natural Frequencies in Beam-Like Structures. SDHM Struct. Durab. Health Monit. 2022, 16, 15–35. [Google Scholar] [CrossRef]

- Luo, J.; Huang, M.; Lei, Y. Temperature Effect on Vibration Properties and Vibration-Based Damage Identification of Bridge Structures: A Literature Review. Buildings 2022, 12, 1209. [Google Scholar] [CrossRef]

- Review, L.; Studies, C. This Is the Pre-Published Version. Temperature Effect on Vibration Properties of Civil Structures: A Literature Review and Case Studies. J. Civ. Struct. Health Monit. 2012, 2, 29–46. [Google Scholar]

- Zhou, H.F.; Ni, Y.Q.; Ko, J.M.; Wong, K.Y. Modeling of Wind and Temperature Effects on Modal Frequencies and Analysis of Relative Strength of Effect. Wind Struct. An Int. J. 2008, 11, 35–50. [Google Scholar] [CrossRef]

- Cai, Y.; Zhang, K.; Ye, Z.; Liu, C.; Lu, K.; Wang, L. Influence of Temperature on the Natural Vibration Characteristics of Simply Supported Reinforced Concrete Beam. Sensors 2021, 21, 4242. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y. Effect of Temperature Variation on Modal Frequency of Reinforced Concrete Slab and Beam in Cold Regions. Shock Vib. 2016, 2016, 4792786. [Google Scholar] [CrossRef]

- Cho, K.; Cho, J.R. Effect of Temperature on the Modal Variability in Short-Span Concrete Bridges. Appl. Sci. 2022, 12, 9757. [Google Scholar] [CrossRef]

- Zhou, G.D.; Yi, T.H. A Summary Review of Correlations between Temperatures and Vibration Properties of Long-Span Bridges. Math. Probl. Eng. 2014, 2014, 638209. [Google Scholar] [CrossRef]

- Ding, Y.L.; Li, A.Q. Temperature-Induced Variations of Measured Modal Frequencies of Steel Box Girder for a Long-Span Suspension Bridge. Int. J. Steel Struct. 2011, 11, 145–155. [Google Scholar] [CrossRef]

- Sun, L.; Zhou, Y.; Min, Z. Experimental Study on the Effect of Temperature on Modal Frequencies of Bridges. Int. J. Struct. Stab. Dyn. 2018, 18, 1850155. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Shi, Y.P.; Tan, G.J. The Natural Frequency Calculation Method of Simply-Supported Beam in the Sunshine Temperature Field. Appl. Mech. Mater. 2013, 394, 364–367. [Google Scholar] [CrossRef]

- Peeters, B.; Roeck, G.D. One-Year Monitoring of the Z24-Bridge: Environmental Effects versus Damage Events. Earthq. Eng. Struct. Dyn. 2015, 30, 149–171. [Google Scholar] [CrossRef]

- Beskhyroun, S.; Wegner, L.D.; Sparling, B.F. Integral Resonant Control Scheme for Cancelling Human-Induced Vibrations in Light-Weight Pedestrian Structures. Struct. Control Health Monit. 2011, 19, 55–69. [Google Scholar] [CrossRef]

- Tan, H.; Qian, D.; Xu, Y.; Yuan, M.; Zhao, H. Analysis of Vertical Temperature Gradients and Their Effects on Hybrid Girder Cable-Stayed Bridges. Sustainability 2023, 15, 1053. [Google Scholar] [CrossRef]

- Xiao, S.; Neti, S.; Suleiman, M.T.; Naito, C. A Modeling Approach of Heat Transfer of Bridges Considering Vehicle-Induced Thermal Effects. J. Appl. Meteorol. Climatol. 2018, 57, 2851–2869. [Google Scholar] [CrossRef]

- Peng, G.; Nakamura, S.; Zhu, X.; Wu, Q.; Wang, H. An Experimental and Numerical Study on Temperature Gradient and Thermal Stress of CFST Truss Girders under Solar Radiation. Comput. Concr. 2017, 20, 605–616. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Zhang, G. Experimental Analysis of Temperature Gradient Patterns of Concrete-Filled Steel Tubular Members. J. Bridg. Eng. 2019, 24, 04019109. [Google Scholar] [CrossRef]

- Hager, I.; Krzemień, M. An overview of concrete modulus of elasticity evolution with temperature and comments to European code provisions. In Proceedings of the IFireSS—International Fire Safety Symposium, Coimbra, Portugal, 20–22 April 2015. [Google Scholar]

- Shoukry, S.N.; William, G.W.; Downie, B.; Riad, M.Y. Effect of Moisture and Temperature on the Mechanical Properties of Concrete. Constr. Build. Mater. 2011, 25, 688–696. [Google Scholar] [CrossRef]

- Naus, D.J.; Graves, H.L. A Review of the Effects of Elevated Temperature on Concrete Materials and Structures. Int. Conf. Nucl. Eng. 2006, 42428, 615–624. [Google Scholar] [CrossRef]

- fib Bulletin 65: Model Code 2010—First Complete Draft; fib Bulletin: Lausanne, Switzerland, 2010; Volume 1, ISBN 9782883940956.

- Pettersson, O. Structural Fire Protection. Fire Mater. 1980, 4, 1–16. [Google Scholar] [CrossRef]

- Khoylou, N. Modelling of Moisture Migration and Spalling Behaviour in Non-Uniformly Heated Concrete. Ph.D. Thesis, University of London, London, UK, 1997. [Google Scholar]

- Jansson, R. Measurement of Concrete Thermal Properties at High Temperature. In Proceedings of the Proceedings from the fib Task Group 4.3 Workshop “Fire Design of Concrete Structures: What Now? What Next?”, Milan, Italy, 2–3 December 2004. [Google Scholar]

- Mike, J.; Kodur, V.; Marrion, C. A Overview of Fire Protection in Buildings; FEMA 403, World Trade Center Building Performance Study; Federal Emergency Management Agency: Washington, DC, USA, 2013; pp. 1–28. [Google Scholar]

- Lucio-Martin, T.; Roig-Flores, M.; Izquierdo, M.; Alonso, M.C. Thermal Conductivity of Concrete at High Temperatures for Thermal Energy Storage Applications: Experimental Analysis. Sol. Energy 2021, 214, 430–442. [Google Scholar] [CrossRef]

- Chen, J.; Young, B. Design of High Strength Steel Columns at Elevated Temperatures. J. Constr. Steel Res. 2008, 64, 689–703. [Google Scholar] [CrossRef]

- Choi, I.R.; Chung, K.S.; Lee, H. Thermal and Mechanical Properties of Structural Steel SN400 at Elevated Temperatures. Int. J. Steel Struct. 2017, 17, 999–1007. [Google Scholar] [CrossRef]

- Chen, J.; Young, B.; Uy, B. Behavior of High Strength Structural Steel at Elevated Temperatures. J. Struct. Eng. 2006, 132, 1948–1954. [Google Scholar] [CrossRef]

- EN 1993-1-2; Eurocode 3: Design of Composite Steel Structure-Part 1-2: General Rules-Structural Fire Design. The European per Regulation: Ljubljana, Slovenia, 2011.

- Shan, W.; Wang, X.; Jiao, Y. Modeling of Temperature Effect on Modal Frequency of Concrete Beam Based on Field Monitoring Data. Shock Vib. 2018, 2018, 8072843. [Google Scholar] [CrossRef]

- Ruan, Z.; Chen, L.; Fang, Q. Numerical Investigation into Dynamic Responses of RC Columns Subjected for Fire and Blast. J. Loss Prev. Process Ind. 2015, 34, 10–21. [Google Scholar] [CrossRef]

- Teng, J.; Tang, D.H.; Hu, W.H.; Lu, W.; Feng, Z.W.; Ao, C.F.; Liao, M.H. Mechanism of the Effect of Temperature on Frequency Based on Long-Term Monitoring of an Arch Bridge. Struct. Health Monit. 2021, 20, 1716–1737. [Google Scholar] [CrossRef]

- Tan, G.; Kong, Q.; He, X.; Liu, H.; Wang, H. Effects of Temperature on Modal Characteristics of Non-Uniform Rigid-Frame Bridges. Adv. Struct. Eng. 2023, 26, 1011–1026. [Google Scholar] [CrossRef]

- Kim, J.T.; Park, J.H.; Lee, B.J. Vibration-Based Damage Monitoring in Model Plate-Girder Bridges under Uncertain Temperature Conditions. Eng. Struct. 2007, 29, 1354–1365. [Google Scholar] [CrossRef]

- Xia, Y.; Hao, H.; Zanardo, G.; Deeks, A. Long Term Vibration Monitoring of an RC Slab: Temperature and Humidity Effect. Eng. Struct. 2006, 28, 441–452. [Google Scholar] [CrossRef]

- ACI318-19; Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2019; ISBN 9781641950565.

| Temperature (°C) | Concrete (MPa) (Equation (1)) | Steel/rebar (MPa) (Equation (2)) |

|---|---|---|

| 20 | 19,188 | 205,420 |

| 25 | 18,900 | 204,370 |

| 30 | 18,612 | 203,320 |

| 35 | 18,324 | 202,280 |

| 40 | 18,037 | 201,230 |

| 50 | 17,461 | 199,130 |

| Material | Mass Density (kg/m3) | Poisson’s Ratio | Expansion Coefficient (/°C) | Specific Heat Capacity (J/kg·°C) | Thermal Conductivity |

|---|---|---|---|---|---|

| Concrete | 2400 | 0.18 | 1 × 10−5 | 880 | 1.5 |

| Steel and rebar | 7850 | 0.3 | 1 × 10−5 | Table 1 | Table 3 |

| Temperature (°C) | Specific Heat Capacity (J/kg·°C) (Equation (3)) | Thermal Conductivity (W/m·°C) (Equation (4)) |

|---|---|---|

| 20 | 439.8 | 53.33 |

| 25 | 443.3 | 53.16 |

| 30 | 446.7 | 53.00 |

| 35 | 450.1 | 52.83 |

| 40 | 453.4 | 52.66 |

| 50 | 459.7 | 52.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poudel, A.; Kim, S.; Cho, B.H.; Kim, J. Temperature Effects on the Natural Frequencies of Composite Girders. Appl. Sci. 2024, 14, 1175. https://doi.org/10.3390/app14031175

Poudel A, Kim S, Cho BH, Kim J. Temperature Effects on the Natural Frequencies of Composite Girders. Applied Sciences. 2024; 14(3):1175. https://doi.org/10.3390/app14031175

Chicago/Turabian StylePoudel, Arjun, Seungwon Kim, Byoung Hooi Cho, and Janghwan Kim. 2024. "Temperature Effects on the Natural Frequencies of Composite Girders" Applied Sciences 14, no. 3: 1175. https://doi.org/10.3390/app14031175

APA StylePoudel, A., Kim, S., Cho, B. H., & Kim, J. (2024). Temperature Effects on the Natural Frequencies of Composite Girders. Applied Sciences, 14(3), 1175. https://doi.org/10.3390/app14031175