Factors That Impact the Dynamics and Effectiveness of Work Teams during the Implementation of Continuous Improvement Tools in the Manufacturing Industry: A Systematic Literature Review

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Question and Objective

2.2. Eligibility Criteria

2.3. Types of Sources and Search Strategy

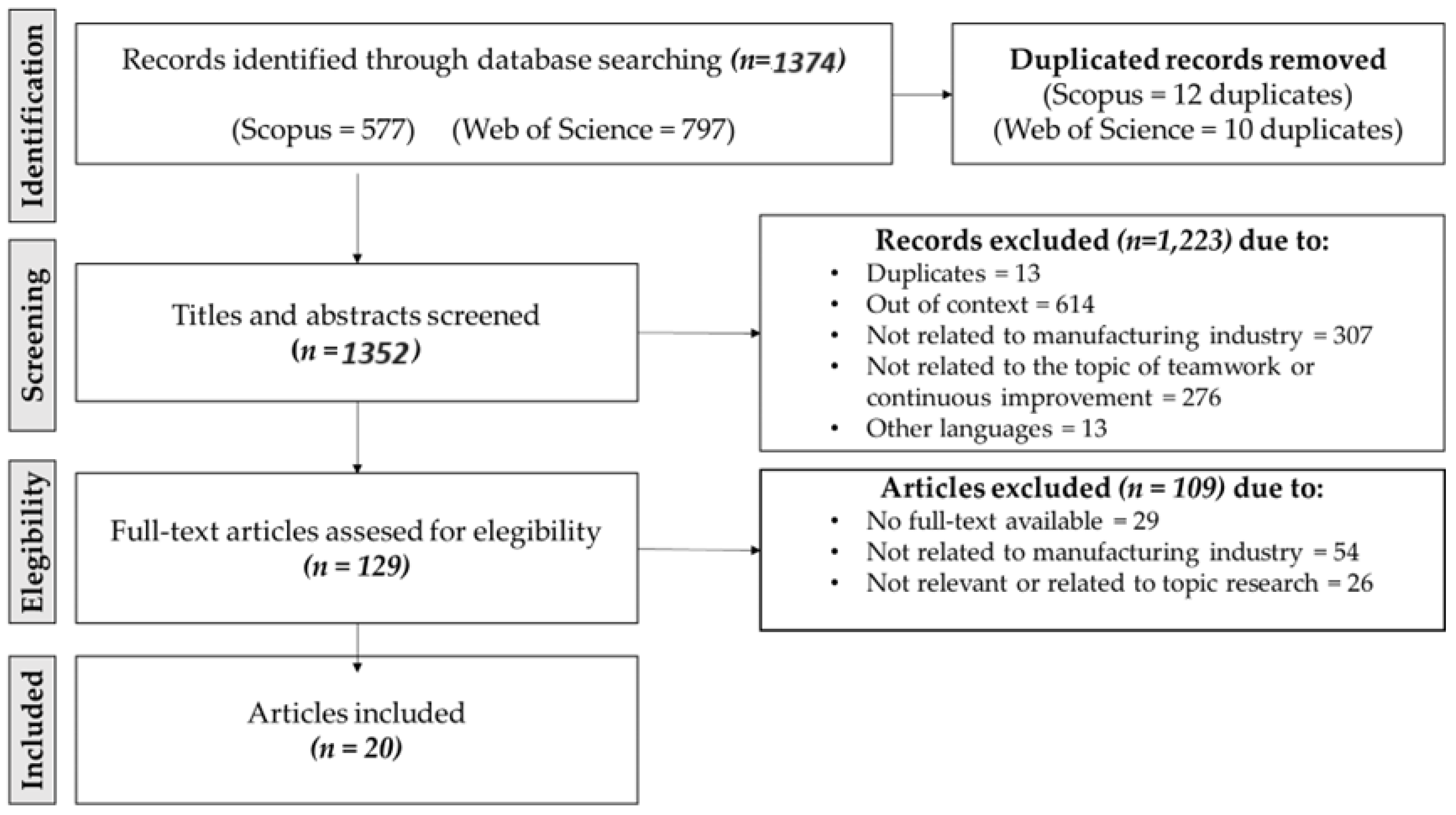

2.4. Study Selection

2.5. Data Extraction

3. Results

3.1. Encompassed Studies

3.2. Characteristics of the Studies

3.3. Data Analysis

3.3.1. Critical Success Factors (CSF) Found in the Literature

3.3.2. Pareto Analysis for CSF

3.3.3. Classification of CSF through Inductive Analysis

4. Discussion

5. Conclusions

- Thirty-two critical success factors (CSF) were identified for the effectiveness of work teams in continuous improvement projects;

- It allows organizations to identify areas of opportunity in the management of personnel and collaborative work teams in relation to the development and implementation of projects;

- It facilitates decision making in terms of prioritizing efforts and enhancing your human resources;

- The knowledge generated from this literature review can lead to statistical research that presents instruments and/or models;

- The methodology used is explained clearly, which allows it to be replicated to improve the literature on this topic.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Herrera, M.K.I.F.; Portillo, M.T.E.; López, R.R.; Gómez, J.A.H. Herramientas de manufactura esbelta que inciden en la productividad de una organización: Modelo conceptual propuesto. Rev Lasallista Investig 2019, 16, 115–133. [Google Scholar] [CrossRef]

- Jaca, C.; Viles, E.; Mateo, R.; Santos, J.; Tanco, M. Equipos de Mejora: Aplicación del modelo de efectividad en equipos de mejora de empresas de la Comunidad Autónoma Vasca. Mem. De Trab. De Difus. Cient. Y Tec. 2012, 10, 33–44. [Google Scholar]

- Bohórquez, J.A.B.; Cruz, O.H. El concepto de equipo en la investigación sobre efectividad en equipos de trabajo. Estud. Gerenciales 2012, 28, 121–132. [Google Scholar] [CrossRef]

- Argüelles, M.Á.; Noriega, S.; Hernández, J.A.; Industriales, T.P. Modelo predictor de la efectividad de los equipos de trabajo en proyectos Seis Sigma de la industria manufacturera: Resumen no. 2CP21-27. Mem. Cient. Y Tecnol. 2021, 1. Available online: https://erevistas.uacj.mx/ojs/index.php/memoriascyt/issue/view/727 (accessed on 27 September 2022).

- Marin-Garcia, J.A.; Bautista-Poveda, Y.; Garcia-Sabater, J.J. Etapas en la evolución de la mejora continua: Estudio multicaso. Intang. Cap. 2014, 10, 584–618. [Google Scholar] [CrossRef]

- Kaplan, H.C.; Brady, P.W.; Dritz, M.C.; Hooper, D.K.; Linam, W.M.; Froehle, C.M.; Margolis, P. The Influence of Context on Quality Improvement Success in Health Care: A Systematic Review of the Literature. Milbank Q. 2010, 88, 500–559. [Google Scholar] [CrossRef]

- Buljac-Samardzic, M.; Doorn, C.M.D.-V.; van Wijngaarden, J.D.; van Wijk, K.P. Interventions to improve team effectiveness: A systematic review. Health Policy 2010, 94, 183–195. [Google Scholar] [CrossRef]

- Brennan, S.E.; Bosch, M.; Buchan, H.; Green, S.E. Measuring team factors thought to influence the success of quality improvement in primary care: A systematic review of instruments. Implement. Sci. 2013, 8, 20. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, b2700. [Google Scholar] [CrossRef]

- Durán Asencio, A. Trabajo en Equipo; Editorial Elearning: Málaga, Spain, 2018. [Google Scholar]

- Ouzzani, M.; Hammady, H.; Fedorowicz, Z.; Elmagarmid, A. Rayyan—A web and mobile app for systematic reviews. Syst. Rev. 2016, 5, 210. [Google Scholar] [CrossRef]

- Jaca, C.; Viles, E.; Tanco, M.; Mateo, R.; Santos, J. Teamwork effectiveness factors in healthcare and manufacturing industries. Team Perform. Manag. Int. J. 2013, 19, 222–236. [Google Scholar] [CrossRef]

- Yang, C.; Yang, K. An Integrated Model of the Toyota Production System with Total Quality Management and People Factors. Hum. Factors Ergon. Manuf. 2013, 23, 450–461. [Google Scholar] [CrossRef]

- Sterling, A.; Boxall, P. Lean production, employee learning and workplace outcomes: A case analysis through the ability-motivation-opportunity framework. Hum. Resour. Manag. J. 2013, 23, 227–240. [Google Scholar] [CrossRef]

- García, J.L.; Rivera, D.G.; Iniesta, A.A. Critical success factors for Kaizen implementation in manufacturing industries in Mexico. Int. J. Adv. Manuf. Technol. 2013, 68, 537–545. [Google Scholar] [CrossRef]

- García, J.L.; Maldonado, A.A.; Alvarado, A.; Rivera, D.G. Human critical success factors for kaizen and its impacts in industrial performance. Int. J. Adv. Manuf. Technol. 2014, 70, 2187–2198. [Google Scholar] [CrossRef]

- Lam, M.; O’Donnell, M.; Robertson, D. Achieving employee commitment for continuous improvement initiatives. Int. J. Oper. Prod. Manag. 2015, 35, 201–215. [Google Scholar] [CrossRef]

- Meneses, R.; Navarro, J. How to improve team effectiveness through group processes: An example in the automotive industry. Papeles del Psicol. 2015, 36, 224–229. [Google Scholar]

- Salas, E.; Shuffler, M.L.; Thayer, A.L.; Bedwell, W.L.; Lazzara, E.H. Understanding and Improving Teamwork in Organizations: A Scientifically Based Practical Guide. Hum. Resour. Manag. 2015, 54, 599–622. [Google Scholar] [CrossRef]

- Oropesa-Vento, M.; García-Alcaraz, J.L.; Rivera, L.; Manotas, D.F. Effects of management commitment and organization of work teams on the benefits of Kaizen: Planning stage. DYNA 2015, 82, 76–84. [Google Scholar] [CrossRef]

- van Dun, D.H.; Wilderom, C.P.M. Lean-team effectiveness through leader values and members’ informing. Int. J. Oper. Prod. Manag. 2016, 36, 1530–1550. [Google Scholar] [CrossRef]

- Alhuraish, I.; Robledo, C.; Kobi, A. A comparative exploration of lean manufacturing and six sigma in terms of their critical success factors. J. Clean. Prod. 2017, 164, 325–337. [Google Scholar] [CrossRef]

- NG, T.; Ghobakhloo, M. What derives lean manufacturing effectiveness: An interpretive structural mode. Int. J. Adv. Appl. Sci. 2017, 4, 104–111. [Google Scholar] [CrossRef][Green Version]

- Alvarado-Ramírez, K.M.; Pumisacho-Álvaro, V.H.; Miguel-Davila, J.; Barraza, M.F.S. Kaizen, a continuous improvement practice in organizations. TQM J. 2018, 30, 255–268. [Google Scholar] [CrossRef]

- Costa, F.; Lispi, L.; Staudacher, A.P.; Rossini, M.; Kundu, K.; Cifone, F.D. How to foster Sustainable Continuous Improvement: A cause-effect relations map of Lean soft practices. Oper. Res. Perspect. 2019, 6, 100091. [Google Scholar] [CrossRef]

- Yap, W.P.; Asokan, V.B. Factors Affecting Teamwork Effectiveness in Malaysian SMEs: Construction Industry. INTI J. 2020, 2020, 414–420. [Google Scholar]

- Yuik, C.J.; Perumal, P.A.; Feng, C.J. Exploring critical success factors for the implementation of lean manufacturing in machinery and equipment SMEs. Eng. Manag. Prod. Serv. 2020, 12, 77–91. [Google Scholar] [CrossRef]

- Paipa-Galeano, L.; Bernal-Torres, C.A.; Otálora, L.M.A.; Nezhad, Y.J.; González-Blanco, H.A. Key Lessons to Sustain Continuous Improvement: A Case Study of Four Companies. J. Ind. Eng. Manag. 2020, 13, 195–211. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fogliatto, F.S.; Vergara, A.M.C.; Quelhas, O.L.G.; Sawhney, R. Influence of team members’ characteristics on the sustainability of continuous improvement initiatives. Total. Qual. Manag. Bus. Excel. 2021, 32, 852–868. [Google Scholar] [CrossRef]

- Petkova, A.P.; Domingo, M.A.; Lamm, E. Let’s be frank: Individual and team-level predictors of improvement in student teamwork effectiveness following peer-evaluation feedback. Int. J. Manag. Educ. 2021, 19, 100538. [Google Scholar] [CrossRef]

- Alvarez, M.; Valles, A.; Noriega, S. Six Sigma Projects Work Teams: A Literature Review of the Factors Influencing Their Effectiveness. In Proceedings of the 10th Annual World Conference of the Society for Industrial and Systems Engineering, Ciudad Juárez, México, 24 September 2021; Available online: http://cathi.uacj.mx/handle/20.500.11961/19947 (accessed on 28 September 2022).

- Sreedharan, R.V.; Sunder, V.M.; Raju, R. Critical success factors of TQM, Six Sigma, Lean and Lean Six Sigma: A literature review and key findings. Benchmarking 2018, 25, 3479–3504. [Google Scholar] [CrossRef]

- Azungah, T. Qualitative research: Deductive and inductive approaches to data analysis. Qual. Res. J. 2018, 18, 383–400. [Google Scholar] [CrossRef]

- Driskell, J.E.; Salas, E.; Driskell, T. Foundations of teamwork and collaboration. Am. Psychol. 2018, 73, 334–348. [Google Scholar] [CrossRef] [PubMed]

- Grobelny, J. Factors Driving the Workplace Well-Being of Individuals from Co-Located, Hybrid, and Virtual Teams: The Role of Team Type as an Environmental Factor in the Job Demand–Resources Model. Int. J. Environ. Res. Public Health 2023, 20, 3685. [Google Scholar] [CrossRef] [PubMed]

- Bouranta, N.; Psomas, E.; Suárez-Barraza, M.F.; Jaca, C. The key factors of total quality management in the service sector: A cross-cultural study. Benchmarking Int. J. 2019, 26, 893–921. [Google Scholar] [CrossRef]

- Bagherian, A.; Gershon, M.; Kumar, S. Unraveling the key determinants of successful six sigma implementation: An empirical investigation. Total. Qual. Manag. Bus. 2023, 1, 1–23. [Google Scholar] [CrossRef]

- Antony, J.; Snee, R.; Hoerl, R. Lean Six Sigma: Yesterday, today and tomorrow. Int. J. Qual. Reliab. Manag. 2017, 34, 1073–1093. [Google Scholar] [CrossRef]

- Ruiz-Torres, A.J.; Ayala-Cruz, J.; Alomoto, N.; Acero-Chavez, J.L. Literature review of quality management: The case of journals published in Latin-America and Spain. Estud. Gerenciales 2015, 31, 319–334. [Google Scholar] [CrossRef]

- Rojas Salazar, M.; Perez Olguin, I. Ciclo DMAIC en Latinoamérica: Análisis de aplicación y relación con el Producto Interno Bruto. Camino Hacia La Int. Logística Int. 2019, 1, 23–31. [Google Scholar]

- Chávez, J.; Osorio, F.; Altamirano, E.; Raymundo, C.; Dominguez, F. Lean Production Management Model for SME Waste Reduction in the Processed Food Sector in Peru. In Proceedings of the Advances in Manufacturing, Production Management and Process Control: Proceedings of the AHFE 2019 International Conference on Human Aspects of Advanced Manufacturing, and the AHFE International Conference on Advanced Production Management and Process Control, Washington, DC, USA, 24–28 July 2019; pp. 53–62. [Google Scholar] [CrossRef]

- Molina Rueda, J.A. Propuesta de Aplicación de Herramientas de Manufactura Esbelta en la MIPYME Láctea “PRODALSAN”. BS Thesis, Universidad Tecnica del Norte, Ibarra, Ecuador, 2020. Available online: http://repositorio.utn.edu.ec/handle/123456789/1028 (accessed on 12 February 2023).

- Müller, J. Análisis de la relación del modelo de recompensa total (salario, beneficios sociales y recompensas psicológicas) con la satisfacción, desempeño y el compromiso del trabajador. Master’s Thesis, Universidad de Granada, Granada, Spain, 2020. [Google Scholar] [CrossRef]

- Ander-Egg, E.; Aguilar, M.J. El Trabajo en Equipo. 2001. Available online: https://ayudacontextos.files.wordpress.com/2018/04/libro_el-trabajo-en-equipo.pdf (accessed on 22 December 2023).

- García Fernández, F.; Cordero Borjas, A.E. Los equipos de trabajo: Una práctica basada en la gestión del conocimiento. Visión Gerenc. 2008, 1, 45–58. Available online: https://www.redalyc.org/pdf/4655/465545878011.pdf (accessed on 22 December 2023).

- Cáceres García, A.I. Aplicación de la mejora continua y su efecto en la productividad de los procesos del almacén de una empresa comercializadora de productos electrónicos en Lima metropolitana. Master’s Thesis, Universidad Ricardo Palma, Santiago de Surco, Peru, 2017. [Google Scholar]

- Tuan, N.-T. The Other Side of Success Factors—A Systemic Methodology for Exploring Critical Success Factors. Syst. Pract. Action Res. 2022, 35, 441–452. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Kumar, S. Critical Success Factors of Industry 4.0 in Automotive Manufacturing Industry. IEEE Trans. Eng. Manag. 2022, 69, 2439–2453. Available online: https://search.ebscohost.com/login.aspx?direct=true&db=bth&AN=157687803&lang=es&site=ehost-live (accessed on 22 December 2023). [CrossRef]

- Sanchez-Lizarraga, M.A.; Limon-Romero, J.; Tlapa, D.; Baez-Lopez, Y.; Puente, C.; Puerta-Sierra, L.; Ontiveros, S. ISO 9001 Standard: Developing and Validating a Survey Instrument. IEEE Access 2020, 8, 190677–190688. [Google Scholar] [CrossRef]

- Rojas, M.; Jaimes, L.; Valencia, M. Efectividad, eficacia y eficiencia en equipos de trabajo. Espacios 2018, 39, 6. [Google Scholar]

- Strode, D.; Dingsøyr, T.; Lindsjorn, Y. A teamwork effectiveness model for agile software development. Empir. Softw. Eng. 2022, 27, 56. [Google Scholar] [CrossRef]

| Category | Inclusion | Exclusion |

|---|---|---|

| Participants | Work teams focused on collaboration within projects and the application of continuous improvement tools. | Workgroups (a set of individuals who share information and ideas having neither the same objective and/or common goals nor joint responsibility) [10]. |

| Context | Organizations and companies in the industrial sector (manufacturing and/or production). | Private and public companies related to the field of healthcare. |

| Dimension | Terms and Related Words |

|---|---|

| (1) Continuous improvement | Continuous improvement (CI), continuous improvement tools, CQI (continuous quality improvement), Kaizen, quality improvement. |

| (2) Teamwork | Teamwork, team functioning, work team, organizational behavior, team working, team management, group work, group behavior. |

| (3) Effectiveness | Effectiveness, effectiveness factors, critical success factors (CSF), performance. |

| No. | Author and Year | Publication | Reference | Country |

|---|---|---|---|---|

| 1 | (Jaca et al., 2013) | Teamwork effectiveness factors in healthcare and manufacturing industries | [12] | Spain |

| 2 | (Yang and Yang, 2013) | An Integrated Model of the Toyota Production System with Total Quality Management and People Factors | [13] | Taiwan |

| 3 | (Sterling and Boxall, 2013) | Lean production, employee learning and workplace outcomes: a case analysis through the ability-motivation-opportunity framework | [14] | New Zealand |

| 4 | (García et al., 2013) | Critical success factors for Kaizen implementation in manufacturing industries in Mexico | [15] | Mexico |

| 5 | (Garcia et al., 2014) | Human critical success factors for kaizen and its impacts in industrial performance | [16] | Mexico |

| 6 | (Lam et al., 2015) | Achieving employee commitment for continuous improvement initiatives | [17] | United States of America |

| 7 | (Meneses and Navarro, 2015) | How to improve team effectiveness through group processes: An example in the automotive industry | [18] | Spain |

| 8 | (Salas et al., 2015) | Understanding and Improving Teamwork in Organizations: A Scientifically Based Practical Guide | [19] | United States of America |

| 9 | (Oropesa-Vento et al., 2015) | Effects of management commitment and organization of work teams on the benefits of kaizen: Planning stage | [20] | Mexico |

| 10 | (H. van Dun and Wilderom, 2016) | Lean-team effectiveness through leader values and members’ informing | [21] | Netherlands |

| 11 | (Alhuraish et al., 2017) | A comparative exploration of lean manufacturing and six sigma in terms of their critical success factors | [22] | France |

| 12 | (NG and Ghobakhloo, 2017) | What derives lean manufacturing effectiveness: An interpretive structural mode | [23] | Malaysia |

| 13 | (Alvarado-Ramírez et al., 2018) | Kaizen, a continuous improvement practice in organizations | [24] | Mexico |

| 14 | (Costa et al., 2019) | How to foster Sustainable Continuous Improvement: A cause-effect relations map of Lean soft practices | [25] | Italy |

| 15 | (A. and B., 2020) | Factors Affecting Teamwork Effectiveness in Malaysian SMEs: Construction Industry. | [26] | Malaysia |

| 16 | (Yuik et al., 2020) | Exploring critical success factors for the implementation of lean manufacturing in machinery and equipment SMEs | [27] | Malaysia |

| 17 | (Paipa-Galeano et al., 2020) | Key Lessons to Sustain Continuous Improvement: A Case Study of Four Companies | [28] | Colombia |

| 18 | (Tortorella et al., 2021) | Influence of team members’ characteristics on the sustainability of continuous improvement initiatives | [29] | Brazil |

| 19 | (Petkova et al., 2021) | Let’s be frank: Individual and team-level predictors of improvement in student teamwork effectiveness following peer-evaluation feedback | [30] | United States of America |

| 20 | (Alvarez et al., 2021) | Six Sigma Projects Work Teams: A Literature Review of the Factors Influencing Their Effectiveness | [31] | Mexico |

| Critical Success Factors (CSF) | References | Total Citations | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [12] | [13] | [14] | [15] | [16] | [17] | [18] | [19] | [20] | [21] | [22] | [23] | [24] | [25] | [26] | [27] | [28] | [29] | [30] | [31] | |||

| 1 | Objectives and common goals | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 8 | ||||||||||||

| 2 | Shared values (respect, companionship, humility) | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 3 | Standards/Rules/Policies/Procedures | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 4 | Team size | ✓ | ✓ | 2 | ||||||||||||||||||

| 5 | Role assignment and assigned tasks | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 6 | Organizational structure | ✓ | ✓ | ✓ | ✓ | ✓ | 5 | |||||||||||||||

| 7 | Human and inter-multi-professional complementation/Cohesion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 8 | Communication | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 11 | |||||||||

| 9 | Sense of belonging to the team or organization | ✓ | 1 | |||||||||||||||||||

| 10 | Problem-solving | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 11 | Conflict management/ability to overcome (interpersonal) | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 12 | Knowledge, skills, and abilities (KSA) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 10 | ||||||||||

| 13 | Task design | ✓ | 1 | |||||||||||||||||||

| 14 | Team power | ✓ | 1 | |||||||||||||||||||

| 15 | Information (technology, systems, or information means) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 16 | Reward and recognition system | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 8 | ||||||||||||

| 17 | Training/Coaching | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 18 | Resources (time, technological, economic, etc.) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 9 | |||||||||||

| 19 | Planning/Strategies (Ability to establish and control action plans) | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 20 | Decision-making | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 21 | Leadership (Ability to direct and motivate) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 12 | ||||||||

| 22 | Safety (compliance with safety and protection standards) | ✓ | ✓ | 2 | ||||||||||||||||||

| 23 | Heterogeneity of members (individual characteristics aligned with team composition) | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 24 | Diversity (gender, age, culture, personality, tenure) | ✓ | ✓ | 2 | ||||||||||||||||||

| 25 | Commitment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 26 | Interdependence | ✓ | ✓ | 2 | ||||||||||||||||||

| 27 | Autonomy | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 28 | Learning/development/training/continuous learning | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 29 | Openness or transparency environment/service climate | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 30 | External environment (customers, suppliers, external pressures) | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 31 | Member participation and empowerment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 9 | |||||||||||

| 32 | Collaboration/cooperation within the team | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 8 | ||||||||||||

| 33 | Coordination | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 34 | Feedback of results | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 35 | Trust among members | ✓ | ✓ | 2 | ||||||||||||||||||

| 36 | Motivation | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 37 | Common mental models/models of effectiveness | ✓ | 1 | |||||||||||||||||||

| 38 | Indicators and results reports | ✓ | ✓ | 2 | ||||||||||||||||||

| 39 | Methodology that supports continuous improvement | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 40 | Responsibility | ✓ | ✓ | 2 | ||||||||||||||||||

| 41 | Cognition | ✓ | 1 | |||||||||||||||||||

| 42 | Participation and commitment from senior management and/or management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 10 | ||||||||||

| 43 | Cultural Change/linking benefits to the organization | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 9 | |||||||||||

| 44 | Results-oriented/achievement of results | ✓ | ✓ | 2 | ||||||||||||||||||

| 45 | Employee evaluation system/performance management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 7 | |||||||||||||

| 46 | Documentation of success cases | ✓ | 1 | |||||||||||||||||||

| 47 | Uniform language and terminology | ✓ | 1 | |||||||||||||||||||

| 48 | Data analysis system and statistical methods | ✓ | 1 | |||||||||||||||||||

| 49 | Project management skills | ✓ | ✓ | ✓ | ✓ | 4 | ||||||||||||||||

| 50 | Innovation | ✓ | ✓ | 2 | ||||||||||||||||||

| 51 | Team organization | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6 | ||||||||||||||

| 52 | Customer-oriented | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 53 | Behavior and attitude of team members | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 54 | Support teams of consultants/facilitators | ✓ | ✓ | ✓ | ✓ | ✓ | 5 | |||||||||||||||

| 55 | Standardization and measurement of processes | ✓ | ✓ | ✓ | 3 | |||||||||||||||||

| 56 | Experience | ✓ | 1 | |||||||||||||||||||

| 57 | Authority | ✓ | 1 | |||||||||||||||||||

| 58 | Quality and culture system | ✓ | ✓ | 2 | ||||||||||||||||||

| 59 | Resistance to change | ✓ | 1 | |||||||||||||||||||

| 60 | Bottom-up vs. top-down approach | ✓ | 1 | |||||||||||||||||||

| TOTAL PER PUBLICATION | 29 | 4 | 2 | 10 | 7 | 15 | 29 | 5 | 5 | 14 | 12 | 19 | 12 | 10 | 9 | 13 | 10 | 7 | 17 | 19 | ||

| Critical Success Factors (CSF) | References | Total Citations | |

|---|---|---|---|

| 1 | Leadership | [12,14,17,18,21,23,24,25,28,29,30,31] | 12 |

| 2 | Communication | [12,14,17,18,21,22,23,25,26,30,31] | 11 |

| 3 | Knowledge, skills, and abilities | [12,16,17,21,23,26,28,29,30,31] | 10 |

| 4 | Senior-management participation and commitment | [18,20,21,23,24,26,28,29,30,31] | 10 |

| 5 | Resources (time, technological, and economic) | [12,18,21,23,24,25,28,29,31] | 9 |

| 6 | Participation and empowerment | [12,16,18,21,24,26,27,28,29] | 9 |

| 7 | Cultural change | [18,20,21,23,25,26,27,30,31] | 9 |

| 8 | Common objectives and goals | [12,14,17,18,19,23,24,31] | 8 |

| 9 | Reward and recognition system | [12,13,14,18,24,26,27,30] | 8 |

| 10 | Collaboration/Cooperation | [12,13,14,17,18,22,23,31] | 8 |

| 11 | Performance/Management evaluation system | [18,22,23,24,25,30,31] | 7 |

| 12 | Standards/Rules/Policies/Procedures | [12,17,23,24,25,31] | 6 |

| 13 | Role assignment and assigned tasks | [12,14,16,17,18,19] | 6 |

| 14 | Human complementarity and multifunctionality | [12,14,16,19,27,30] | 6 |

| 15 | Technology, systems, or information means | [12,13,18,22,29,30] | 6 |

| 16 | Decision making | [12,14,18,20,28,30] | 6 |

| 17 | Commitment | [12,18,23,25,30,31] | 6 |

| 18 | Learning/Development/Training | [12,18,21,24,26,30] | 6 |

| 19 | Motivation | [12,13,18,23,27,31] | 6 |

| 20 | Methodology that provides support to CI | [18,21,23,24,26,31] | 6 |

| 21 | Team organization | [20,24,25,28,29,30] | 6 |

| 22 | Organizational structure | [12,18,20,23,31] | 5 |

| 23 | Support Teams of Consultants/Facilitators | [21,23,25,30,31] | 5 |

| 24 | Shared values | [17,19,22,27] | 4 |

| 25 | Training/coaching | [17,23,27,31] | 4 |

| 26 | Planning/Strategies | [12,17,18,21] | 4 |

| 27 | Autonomy | [12,14,22,27] | 4 |

| 28 | Work environment | [12,17,27,30] | 4 |

| 29 | Project-management skills | [18,21,26,30] | 4 |

| 30 | Problem solving | [12,14,28] | 3 |

| 31 | Conflict management (interpersonal) | [12,16,17] | 3 |

| 32 | Heterogeneity of members | [23,25,31] | 3 |

| Category | Description | Variables/CSF |

|---|---|---|

| Psychosocial Factors | These represent the behavioral aspects of individuals within the organization, encompassing both plant-level employees and top-tier management and executives. These behavioral factors influence how individuals interact with other team members, as well as with the organization and the environment, particularly in evolving contexts that demand mental flexibility and commitment, as continuous improvement does. Similarly, this category also considers broader cultural aspects at the organizational level, pertaining to values, standards, and behaviors that characterize the actions of all individuals. | 1, 6, 7, 10, 17, 19, 24, 27, 31 |

| Technical Factors | These factors encompass the technical expertise in continuous improvement held by all members of the organization. | 3, 14, 15, 18, 20, 21, 23, 25, 29, 30, 32 |

| Administrative Factors | These factors involve external aspects that influence how the process of introducing continuous improvement and cultural change within the organization is implemented. These are variables easily controlled by management and senior leadership, including those related to organization and coordination. | 2, 4, 5, 8, 9, 11, 12, 13, 16, 22, 26, 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-Zavala, M.R.; López-Guerrero, A.; Olivares-Fong, L.d.C.; Velázquez-Victorica, K.I.; Montoya-Alcaraz, M. Factors That Impact the Dynamics and Effectiveness of Work Teams during the Implementation of Continuous Improvement Tools in the Manufacturing Industry: A Systematic Literature Review. Appl. Sci. 2024, 14, 1017. https://doi.org/10.3390/app14031017

Ramírez-Zavala MR, López-Guerrero A, Olivares-Fong LdC, Velázquez-Victorica KI, Montoya-Alcaraz M. Factors That Impact the Dynamics and Effectiveness of Work Teams during the Implementation of Continuous Improvement Tools in the Manufacturing Industry: A Systematic Literature Review. Applied Sciences. 2024; 14(3):1017. https://doi.org/10.3390/app14031017

Chicago/Turabian StyleRamírez-Zavala, Miriam Rubí, Aída López-Guerrero, Luz del Consuelo Olivares-Fong, Karla Isabel Velázquez-Victorica, and Marco Montoya-Alcaraz. 2024. "Factors That Impact the Dynamics and Effectiveness of Work Teams during the Implementation of Continuous Improvement Tools in the Manufacturing Industry: A Systematic Literature Review" Applied Sciences 14, no. 3: 1017. https://doi.org/10.3390/app14031017

APA StyleRamírez-Zavala, M. R., López-Guerrero, A., Olivares-Fong, L. d. C., Velázquez-Victorica, K. I., & Montoya-Alcaraz, M. (2024). Factors That Impact the Dynamics and Effectiveness of Work Teams during the Implementation of Continuous Improvement Tools in the Manufacturing Industry: A Systematic Literature Review. Applied Sciences, 14(3), 1017. https://doi.org/10.3390/app14031017